Unlock your full potential by mastering the most common Moldings interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Moldings Interview

Q 1. Explain the difference between injection molding and blow molding.

Injection molding and blow molding are both plastic forming processes, but they differ significantly in how they create the final product. Imagine making a water bottle: injection molding is like injecting molten plastic into a precisely shaped mold, filling it completely and letting it solidify. Blow molding is more like inflating a plastic balloon inside a mold.

Injection Molding: Molten plastic is injected under high pressure into a closed mold cavity. The plastic fills the cavity completely, cools, and then the mold opens to release the finished part. This is excellent for creating complex, intricate shapes with high precision and repeatability. Think of things like bottle caps, electronic components, or even car dashboards.

Blow Molding: A heated plastic tube (parison) is clamped within a mold. Then, compressed air is forced into the parison, expanding and shaping the plastic against the mold walls. This is ideal for hollow items with a relatively uniform wall thickness, such as bottles, containers, and toys.

In short: Injection molding is for solid parts, blow molding is for hollow parts. The choice depends entirely on the desired part geometry and production volume.

Q 2. Describe the various types of molding resins used in the industry.

The choice of molding resin depends heavily on the application’s requirements for strength, flexibility, heat resistance, chemical resistance, and cost. Here are some common types:

- Polyethylene (PE): A versatile, inexpensive plastic known for its flexibility and chemical resistance. Used extensively in blow molding for containers.

- Polypropylene (PP): Stronger and more heat-resistant than PE, often used in injection molding for containers, automotive parts, and appliances.

- Polyethylene Terephthalate (PET): Known for its clarity, strength, and barrier properties, making it ideal for food and beverage containers (think soda bottles).

- Polyvinyl Chloride (PVC): Rigid, durable, and inexpensive; frequently used in piping and window frames. It’s worth noting that PVC requires special handling due to its potential environmental impact.

- Acrylonitrile Butadiene Styrene (ABS): Tough, impact-resistant, and easily molded, ABS is used in many applications, from toys to automotive parts.

- Polycarbonate (PC): Extremely strong and impact-resistant, often used in high-performance applications requiring durability and transparency (think safety glasses or phone cases).

The selection process considers factors like chemical compatibility, desired mechanical properties, cost-effectiveness, and environmental concerns.

Q 3. What are the common causes of molding defects and how are they resolved?

Molding defects can significantly impact product quality and efficiency. Common causes include:

- Short Shots: Insufficient plastic filling the mold cavity, often caused by insufficient injection pressure or speed. Solution: Increase injection pressure or speed, or check for mold leaks.

- Flashing: Excess material escaping between mold halves, usually due to improper mold closure or excessive injection pressure. Solution: Adjust mold clamping force or reduce injection pressure, ensure proper mold alignment and maintenance.

- Sink Marks: Surface depressions caused by internal shrinkage during cooling. Solution: Thicker wall design, optimize cooling, use different resin with improved flow properties.

- Warping: Distortion of the part after molding, often caused by uneven cooling or internal stresses. Solution: Adjust cooling conditions, consider design changes to improve part balance, post-mold annealing may be necessary.

- Burn Marks: Discoloration or degradation of the plastic due to excessive heat. Solution: Check melt temperature, optimize processing parameters, ensure proper mold venting.

Addressing these issues requires careful observation, thorough analysis, and often adjustments to the molding machine parameters, mold design, or material selection.

Q 4. How do you perform a mold setup and ensure proper clamping force?

Mold setup is crucial for consistent and high-quality parts. It involves several key steps:

- Mold Preparation: Clean and inspect the mold for any damage or debris. Lubricate the mold surfaces as needed.

- Mold Installation: Carefully mount the mold onto the molding machine, ensuring proper alignment and secure fastening.

- Clamping Force Adjustment: This is critical for preventing mold leakage or misalignment. The clamping force should be sufficient to withstand the pressure generated during injection, yet not so high as to damage the mold. The appropriate clamping force is usually specified by the mold manufacturer. It’s often adjusted through the machine’s control panel. For example, a typical setting might be

Clamping Force: 200 tons. Always refer to the machine’s operating manual and the mold’s specifications. - Parameter Setting: Configure the molding machine’s parameters, including injection pressure, injection speed, holding pressure, and cooling time based on material properties and part design.

- Trial Run and Adjustment: Perform a test run to assess the quality of the molded parts. Make adjustments to the parameters as needed to optimize the process.

Incorrect clamping force can lead to flashing, part distortion, or even mold damage, emphasizing the importance of precise setup.

Q 5. Explain the importance of maintaining proper mold temperature control.

Maintaining proper mold temperature control is essential for consistent part quality and efficient production. The mold temperature affects several key aspects of the molding process:

- Part Quality: Consistent mold temperature ensures uniform cooling and reduces the risk of warping, sink marks, or residual stresses. Too low a temperature can lead to slower cycle times and increased viscosity issues.

- Cycle Time: Optimizing mold temperature can significantly reduce cycle time. Faster cooling allows for quicker mold opening and part ejection.

- Material Properties: Temperature affects the fluidity of the molten plastic. Precise control allows for better filling of complex mold geometries and reduces defects.

- Mold Life: Consistent temperature prevents thermal stress on the mold, extending its lifespan and reducing maintenance needs. Excessive temperature fluctuations can lead to warping or cracking of the mold material.

Mold temperature control is often achieved through circulating temperature-controlled water or oil through channels within the mold. This requires careful monitoring and adjustment using temperature sensors and controllers.

Q 6. Describe the process of troubleshooting a molding machine malfunction.

Troubleshooting a molding machine malfunction requires a systematic approach:

- Safety First: Always disconnect power and follow safety protocols before attempting any repairs.

- Identify the Problem: Observe the machine’s behavior, noting any error messages, unusual sounds, or visible issues. This may involve reviewing machine logs or alarm history.

- Check Basic Issues: Verify power supply, hydraulic fluid levels, and air pressure. Simple problems like low fluid levels can easily be overlooked.

- Systematic Inspection: Inspect sensors, valves, pumps, and other components for damage or malfunction. This often involves checking for leaks, blockages, or electrical faults.

- Consult Documentation: Refer to the machine’s operating manuals, schematics, and troubleshooting guides. These resources contain valuable information about identifying and resolving common problems.

- Call for Support: If you cannot resolve the issue, seek assistance from qualified technicians or the machine manufacturer. Improper repairs can lead to further damage or safety hazards.

A systematic approach, along with careful observation and documentation, is crucial for efficient and safe troubleshooting of molding machine malfunctions.

Q 7. What are the key quality control checks performed during the molding process?

Quality control checks are critical for ensuring consistent product quality. These checks are performed at various stages of the molding process:

- Visual Inspection: Checking for defects such as flashing, short shots, sink marks, and warping. This is often the first line of defense, and a trained eye can identify many defects quickly.

- Dimensional Measurement: Using calibrated tools such as calipers or CMM (Coordinate Measuring Machine) to verify that the molded parts meet the required dimensions and tolerances. This is especially important for parts with tight tolerances.

- Weight Measurement: Measuring the weight of the molded parts to ensure consistency and detect any deviations. Significant variations may indicate problems with injection parameters or material consistency.

- Material Testing: Testing the mechanical properties of the molded parts, such as tensile strength, impact resistance, and flexural modulus to ensure the parts meet required specifications. This often involves destructive testing of samples.

- Statistical Process Control (SPC): Employing statistical methods to monitor the molding process and identify trends. This helps to prevent future defects and improve process efficiency. Control charts can help to track key parameters, such as cycle time, temperature, and part dimensions.

Implementing rigorous quality control checks throughout the molding process helps to guarantee consistent product quality and customer satisfaction.

Q 8. How do you interpret a molding process flow chart?

Interpreting a molding process flowchart is like following a recipe for creating a plastic part. Each step represents a crucial stage in the process, from material preparation to final ejection. A well-structured flowchart clearly illustrates the sequence of operations, highlighting key decision points and potential bottlenecks. I look for things like material loading, injection, clamping, cooling, and ejection stages clearly defined. The use of symbols like diamonds for decision points and rectangles for processes is essential for clarity. For example, a diamond might represent a quality check after injection, leading to either acceptance or rejection and a subsequent rework loop.

A good flowchart shows the flow of materials and information, allowing me to quickly assess the efficiency and identify potential areas for improvement. For instance, a long cooling time might indicate a need for mold redesign or changes in the molding parameters. It’s a visual roadmap of the entire process, critical for troubleshooting and process optimization.

Q 9. Explain the concept of cycle time optimization in molding.

Cycle time optimization in molding is all about minimizing the time it takes to complete one molding cycle, from injection to ejection. It’s like trying to bake the perfect cake in the shortest time possible without compromising quality. This is achieved through a systematic analysis of each stage. Every second shaved off the cycle time directly translates to increased productivity and lower manufacturing costs.

We employ several strategies for optimization, including improving mold design for faster cooling (e.g., using thinner sections or incorporating cooling channels), adjusting machine parameters (injection pressure, speed, temperature), and streamlining auxiliary operations (robotic handling of parts). For example, in one project, we reduced cycle time by 15% by implementing a more efficient cooling system and optimizing the injection parameters based on Finite Element Analysis (FEA) data. The result was a significant boost in production without sacrificing quality.

Q 10. What are the safety procedures involved in operating molding machinery?

Safety is paramount in molding operations. We follow strict protocols to prevent accidents and injuries. Before operating any molding machinery, operators must complete thorough safety training and understand the specific hazards associated with the equipment. This includes lockout/tagout procedures, proper handling of hot materials and molten plastics, and the correct use of personal protective equipment (PPE), such as safety glasses, hearing protection, and heat-resistant gloves. Regular machine inspections are critical to identify and address any potential mechanical failures.

- Lockout/Tagout: Ensuring the machine is completely shut down and secured before maintenance or cleaning.

- Emergency Stop Procedures: Knowing the location and operation of emergency stop buttons.

- Hot Surface Awareness: Using proper tools and protective equipment to handle hot molds and components.

- Material Handling: Safe storage and handling of raw materials to prevent spills and accidents.

We maintain a clean and organized workspace to minimize tripping hazards. Regular safety audits ensure compliance and identify any potential issues before they lead to accidents. A culture of safety is ingrained throughout the operation.

Q 11. Describe your experience with different types of molding machines.

My experience encompasses a wide range of molding machines, including hydraulic, electric, and hybrid systems. Hydraulic machines, known for their high clamping forces, are well-suited for large parts and thick-walled molds. Electric machines offer precise control and energy efficiency, often preferred for intricate parts and demanding tolerances. Hybrid machines combine the strengths of both, providing both high clamping force and precise control.

I’ve worked extensively with injection molding machines from various manufacturers, such as Arburg, Engel, and Nissei. Each machine has its unique features and capabilities. My experience extends beyond simple operation; I can troubleshoot malfunctions, optimize machine settings for specific applications, and understand the intricacies of their control systems. For instance, I once resolved a recurring issue with an electric molding machine by identifying a minor misalignment in the injection unit, which was causing premature wear and inconsistent injection pressure. This highlights the importance of understanding the mechanics of different machine types for effective troubleshooting and maintenance.

Q 12. How do you handle material variations during the molding process?

Material variations can significantly impact the molding process, leading to defects and inconsistencies. We address these variations through careful material selection and rigorous quality control. This begins with thorough incoming inspection of materials— verifying that the resin’s properties, such as melt flow index (MFI) and moisture content, fall within specified limits. Beyond this initial stage, process monitoring tools provide ongoing oversight.

We use sensors to monitor parameters such as melt temperature, pressure, and flow rate, providing real-time feedback that helps us adjust machine settings to compensate for material variations. For example, if the MFI is higher than expected, we might need to adjust the injection pressure or melt temperature. Statistical Process Control (SPC) charts are essential for tracking trends and identifying any systematic issues. Careful documentation and analysis of these processes are crucial for maintaining consistent product quality despite material variability.

Q 13. Explain the importance of preventative maintenance on molding equipment.

Preventative maintenance (PM) is crucial for maintaining the efficiency and longevity of molding equipment. It’s like regular servicing of a car – it prevents major breakdowns and extends the lifespan of the machine. Ignoring PM can lead to unexpected downtime, costly repairs, and compromised product quality.

Our PM program includes regular inspections, lubrication, and cleaning of critical components. We adhere to a strict schedule, with tasks like mold cleaning and lubrication performed daily, while more extensive maintenance, such as hydraulic system checks, occurs at set intervals. Preventive maintenance also includes calibrating sensors and controllers to ensure accurate readings and optimal machine performance. This approach minimizes unexpected failures, allowing for a more stable and predictable production environment. A well-maintained machine produces higher-quality parts and experiences less downtime, resulting in significant cost savings in the long run.

Q 14. Describe your experience with mold design software (e.g., CAD).

I have extensive experience using CAD software for mold design, primarily SolidWorks and Autodesk Inventor. My skills extend beyond basic modeling; I’m proficient in creating complex 3D models, conducting FEA simulations to predict part behavior and optimize mold design for manufacturability. I understand the importance of designing for moldability— incorporating features like draft angles, ejection systems, and cooling channels to prevent part defects and facilitate efficient mold operation.

For example, I once used FEA simulations to identify areas of high stress in a complex mold design. By adjusting the cooling channels based on simulation results, we successfully reduced warpage and improved part quality. Proficient use of CAD software is fundamental to creating efficient and cost-effective molds, leading to improved product quality and reduced manufacturing costs.

Q 15. What are the different types of mold materials and their applications?

Mold materials are chosen based on the properties required for the final product and the molding process. The selection impacts factors like durability, appearance, and cost. Common types include:

- Steel: The workhorse of mold making, offering high strength, durability, and excellent heat transfer properties. Different grades of steel are used depending on the application; for example, hardened tool steels for high-volume production and pre-hardened steels for smaller runs. Steel molds are suitable for a wide range of plastics and are particularly well-suited for high-precision parts.

- Aluminum: Lighter and less expensive than steel, aluminum molds are commonly used for prototypes, shorter production runs, and applications where rapid cooling is desired. They are generally less durable than steel and are better suited for lower-volume, less demanding applications.

- BeCu (Beryllium Copper): Used for its high strength, excellent electrical conductivity (important for certain applications), and good wear resistance. BeCu is ideal for molds producing intricate details, especially in electronic components.

- Thermoplastic polymers (e.g., PEEK, PPS): These are used for making molds for less demanding applications or when the part count is low. These materials are less expensive but have lower heat resistance and wear resistance than metals. This makes them unsuitable for high-temperature or high-volume applications.

The choice of material is a complex decision, involving factors like part geometry, production volume, required surface finish, material cost, and cycle time.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate injection pressure for a given mold?

Determining the appropriate injection pressure is crucial for successful molding. Too low, and the plastic won’t fully fill the mold cavity, leading to incomplete parts. Too high, and you risk damaging the mold or producing parts with internal stress and warping. The optimal pressure depends on several interconnected factors:

- Melt Viscosity: Higher viscosity requires higher injection pressure to fill the mold. Viscosity is affected by the plastic type and its temperature.

- Mold Design: Complex mold geometries with thin sections or long flow paths require higher injection pressures to compensate for pressure loss during flow.

- Mold Temperature: Colder molds will increase the viscosity of the molten plastic and require higher injection pressures. Warmer molds generally require less.

- Part Size and Wall Thickness: Larger parts and parts with thicker walls generally necessitate higher injection pressures.

- Gate Design: The size and location of the gate(s) in the mold affect pressure drop.

In practice, we use a combination of experience, simulation software, and trial runs to find the optimal injection pressure. We start with estimated pressures based on similar past projects, and then fine-tune it during testing, carefully monitoring for any defects like short shots or weld lines. Pressure transducers in the mold provide real-time data, which helps to optimize the process.

Q 17. Explain the importance of proper venting in a mold.

Proper venting in a mold is essential for preventing trapped air from creating defects like voids, sink marks, and surface blemishes in the molded parts. Think of it like letting air escape from a balloon as you fill it. If the air can’t escape, it will impede the filling process and result in inferior parts.

Vents are small channels that are strategically placed in the mold cavity. They allow air to escape as the molten plastic enters, preventing air entrapment. Insufficient venting leads to cosmetic defects and compromised part strength. Over-venting, on the other hand, can cause flashing—plastic leaking out from the mold cavity due to excessive pressure release.

The design and placement of vents involve considerations like the mold geometry, the plastic material used, and the injection pressure. Proper venting is a critical element in ensuring both the quality and efficiency of the molding process.

Q 18. What are the common problems related to mold cooling systems?

Mold cooling systems are crucial for maintaining a consistent cycle time and ensuring that the molded parts are properly solidified before ejection. Problems with mold cooling can significantly impact productivity and part quality. Common issues include:

- Insufficient Cooling: Leads to longer cycle times, warping, and insufficiently solidified parts. This can be caused by insufficient coolant flow, clogged cooling lines, or inadequate cooling capacity.

- Uneven Cooling: Results in unevenly cooled parts, leading to warping, stress cracking, and dimensional inconsistencies. This often stems from poorly designed cooling channels or blockages in the system.

- Coolant Leaks: Can cause corrosion, contamination, and downtime for repairs. Regular inspections and maintenance are critical to prevent leaks.

- Scaling and Corrosion: Buildup of scale and corrosion in the cooling lines can reduce coolant flow and heat transfer efficiency, leading to problems similar to insufficient cooling.

- Temperature Control Issues: Inaccurate temperature control can lead to inconsistent part quality. Malfunctioning temperature sensors or controllers can be the culprit.

Regular maintenance, including flushing cooling lines and checking for leaks, is critical to preventing these problems. Monitoring coolant temperature and flow rates also helps to identify potential issues early on.

Q 19. How do you manage scrap and waste reduction in molding operations?

Scrap reduction is a critical aspect of cost-effective molding. Strategies involve a multi-pronged approach focusing on both preventative and reactive measures:

- Process Optimization: Fine-tuning molding parameters like injection pressure, temperature, and cycle time through experiments and data analysis. Statistical Process Control (SPC) is invaluable here.

- Preventive Maintenance: Regular maintenance reduces downtime and prevents unexpected failures that can lead to scrap generation.

- Mold Design Improvements: Well-designed molds with efficient filling patterns reduce the chances of defects. Simulation software can play a significant role here.

- Operator Training: Proper training ensures that operators follow established procedures and promptly identify potential issues.

- Material Selection: Using high-quality materials reduces the likelihood of defects and rework.

- Scrap Recycling: Implementing a robust recycling program for usable scrap materials can minimize waste.

We track scrap rates meticulously and use data-driven approaches to identify the root causes of defects and implement corrective actions. A continuous improvement mindset is essential for effective scrap reduction.

Q 20. Explain your experience with statistical process control (SPC) in molding.

Statistical Process Control (SPC) is an integral part of our molding operations. We use control charts to monitor key process parameters like injection pressure, melt temperature, cycle time, and part dimensions. By tracking these parameters over time, we can identify trends and deviations from established targets, allowing us to take proactive corrective actions before defects become widespread.

For example, we use control charts for part dimensions like thickness and length to ensure that they remain within specified tolerances. If a control chart shows a trend indicating that parts are becoming thinner, we would investigate the potential root causes, such as mold wear, changes in material properties, or adjustments in molding parameters. This data-driven approach helps us maintain consistent part quality and prevent costly scrap.

We also use capability analysis to assess the ability of our processes to meet customer specifications. This helps us identify areas for improvement and ensure that our processes are capable of producing parts within the required tolerances.

Q 21. Describe your experience with root cause analysis in molding process failures.

Root cause analysis is critical for resolving molding process failures effectively and preventing recurrence. We utilize a structured approach like the 5 Whys technique or a Fishbone diagram (Ishikawa diagram) to delve into the underlying reasons for defects or malfunctions.

For instance, if we experience recurring short shots (incomplete filling of the mold cavity), we wouldn’t simply increase the injection pressure. We’d systematically investigate: Why were the short shots occurring? (Insufficient pressure) Why was the pressure insufficient? (Clogged runner system) Why was the runner system clogged? (Material degradation) Why did the material degrade? (Contamination). By repeatedly asking “why,” we uncover the root cause – in this case, perhaps material contamination.

This systematic approach allows us to address the fundamental problem rather than just treating the symptoms, resulting in more sustainable solutions and preventing future occurrences of the same issue. Thorough documentation of the root cause analysis is essential for continuous improvement and knowledge sharing within the team.

Q 22. How do you maintain accurate records and documentation for molding processes?

Maintaining accurate records in molding is crucial for traceability, quality control, and continuous improvement. We utilize a combination of digital and physical methods. Digitally, we employ a Manufacturing Execution System (MES) to track every aspect of the molding process, from raw material intake and machine parameters (temperature, pressure, cycle time) to finished product inspection results and quality certifications. This system generates detailed reports and allows for real-time monitoring. Physically, we maintain detailed batch records, including material certifications, operator logs documenting any deviations or adjustments, and inspection reports with photographic evidence. This dual approach ensures redundancy and allows for easy data retrieval and analysis should discrepancies arise. For example, if a batch shows defects, we can quickly trace back to the specific material lot, machine settings, and operator to pinpoint the root cause and implement corrective actions.

Q 23. What are your preferred methods for communicating technical information related to molding?

Effective communication is paramount in molding. My preferred methods depend on the audience and the complexity of the information. For simple updates, I utilize clear and concise email communication. For complex technical discussions or troubleshooting, I prefer face-to-face meetings or video conferences, allowing for immediate clarification and visual aids like process flow diagrams or images from the shop floor. For large-scale projects or changes in processes, I utilize detailed technical reports, often incorporating visuals such as CAD drawings and process flowcharts. We also maintain a comprehensive digital library of technical documentation, including standard operating procedures (SOPs) and troubleshooting guides, easily accessible to all relevant personnel. I always prioritize clarity and avoid jargon whenever possible, ensuring everyone understands the information.

Q 24. How do you ensure compliance with relevant safety and environmental regulations in molding?

Ensuring compliance with safety and environmental regulations is non-negotiable. We adhere strictly to OSHA guidelines for workplace safety, implementing procedures like lock-out/tag-out protocols for machine maintenance, providing mandatory safety training for all personnel, and ensuring the use of appropriate personal protective equipment (PPE). Environmentally, we comply with all local and national regulations regarding waste disposal and emissions. This includes proper handling and recycling of plastics, utilizing energy-efficient equipment, and regularly monitoring emissions to ensure they stay within permitted limits. We maintain detailed records of all safety inspections, training sessions, and environmental monitoring data. For example, we have a rigorous system for tracking and managing hazardous waste, ensuring its proper disposal through licensed contractors. Regular audits are conducted to verify our compliance and identify potential areas for improvement.

Q 25. Describe your experience working with different types of mold cavities and inserts.

My experience encompasses a wide range of mold cavities and inserts, from simple single-cavity molds for basic parts to complex multi-cavity molds with intricate inserts for high-precision components. I’ve worked with various materials including steel, aluminum, and beryllium copper, each requiring different machining and maintenance techniques. For example, I’ve worked with molds featuring complex cooling channels to optimize part cooling rates and prevent warping, and molds incorporating specialized inserts for overmolding or creating unique surface textures. I understand the importance of proper design and material selection for optimal performance and part quality. The selection process considers factors like material compatibility, thermal properties, wear resistance, and ease of maintenance. I’ve been involved in the design review process, ensuring the chosen materials and mold configurations are appropriate for the application and that they meet the required tolerances and surface finish.

Q 26. How do you handle a production line bottleneck or disruption in the molding process?

Handling production line bottlenecks requires a systematic approach. My first step is to identify the root cause of the disruption using data from our MES and operator feedback. This could range from a malfunctioning machine component to a shortage of raw materials or even a problem with the mold itself. Once the cause is identified, we implement immediate corrective actions. This could involve repairing the faulty equipment, expediting the delivery of materials, or switching to a backup mold. Simultaneously, we initiate a root cause analysis to prevent future occurrences. This involves analyzing historical data, investigating potential contributing factors, and implementing preventive maintenance schedules. For instance, if a recurring bottleneck is due to a specific machine constantly failing, we might invest in upgrading the equipment or improving its maintenance procedures. Effective communication throughout this process is crucial to ensure everyone is informed and collaborating towards a timely resolution.

Q 27. Explain your experience with automation and robotics in molding operations.

I have extensive experience with automation and robotics in molding operations. We utilize robotic arms for tasks such as part removal, placing parts into secondary operations, and loading and unloading molds, improving efficiency and reducing labor costs. The integration of robotics requires careful planning and programming, ensuring the robots operate safely and effectively within the production environment. We also leverage automated inspection systems, utilizing vision systems and other sensors to detect defects in real-time. This allows for immediate corrective actions, minimizing waste and improving product quality. Furthermore, we are exploring the use of AI-powered predictive maintenance systems to anticipate potential equipment failures before they occur. This proactive approach minimizes downtime and optimizes production efficiency. For example, the implementation of a robotic arm for part removal increased our production rate by 15% and reduced labor costs by 10%.

Key Topics to Learn for Moldings Interview

- Molding Materials: Understanding the properties and applications of various molding materials (e.g., plastics, metals, composites) is crucial. Explore their strengths, weaknesses, and suitability for different applications.

- Mold Design and Engineering: Learn about the principles of mold design, including gate locations, cooling systems, and ejection mechanisms. Consider how design choices impact product quality and manufacturing efficiency.

- Molding Processes: Become familiar with different molding techniques such as injection molding, blow molding, and rotational molding. Understand the advantages and disadvantages of each process and their respective applications.

- Quality Control and Inspection: Master the methods used to ensure the quality of molded parts, including dimensional inspection, visual inspection, and material testing. Understand common defects and their root causes.

- Manufacturing Processes and Equipment: Familiarize yourself with the machinery and processes involved in molding production, from raw material handling to finished product packaging. This includes understanding automation and optimization techniques.

- Troubleshooting and Problem Solving: Develop your ability to identify and solve common molding problems, such as short shots, flash, and sink marks. Practice analyzing process parameters and making adjustments to optimize production.

- Safety Procedures and Regulations: Understand and adhere to all relevant safety regulations and procedures within a molding environment. This is crucial for a safe and productive workplace.

Next Steps

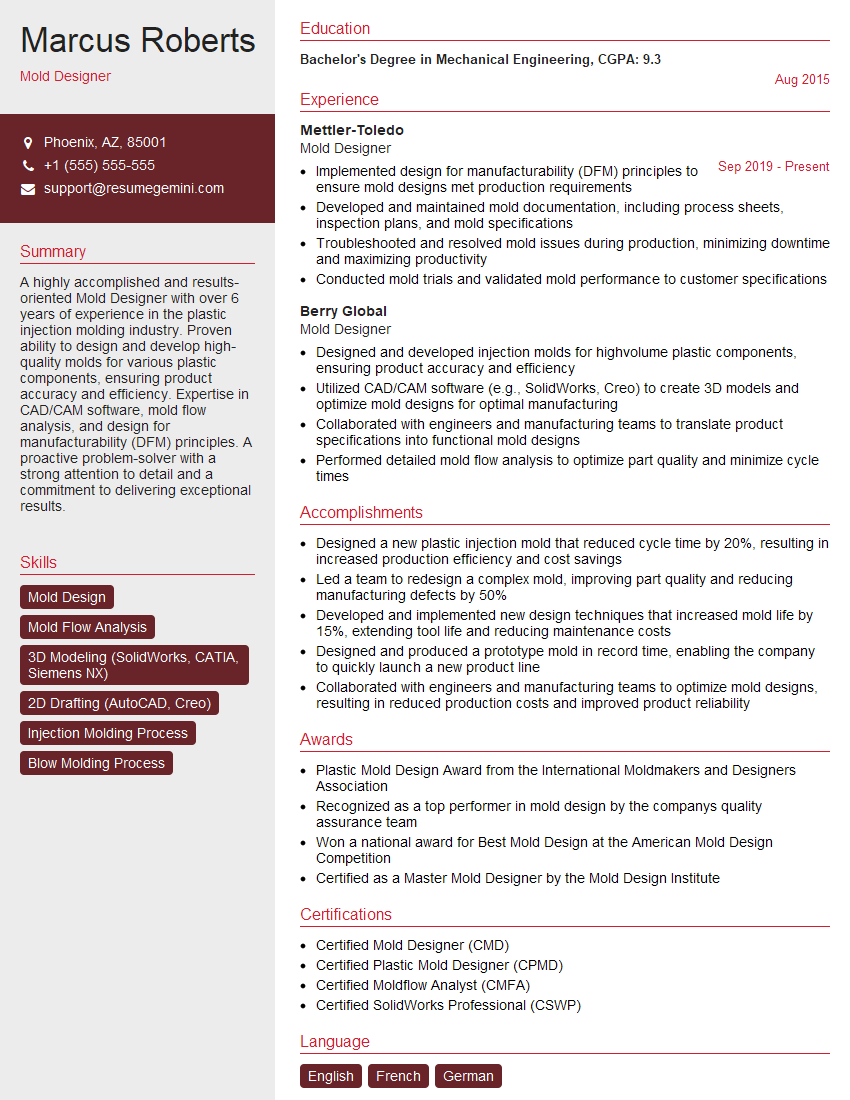

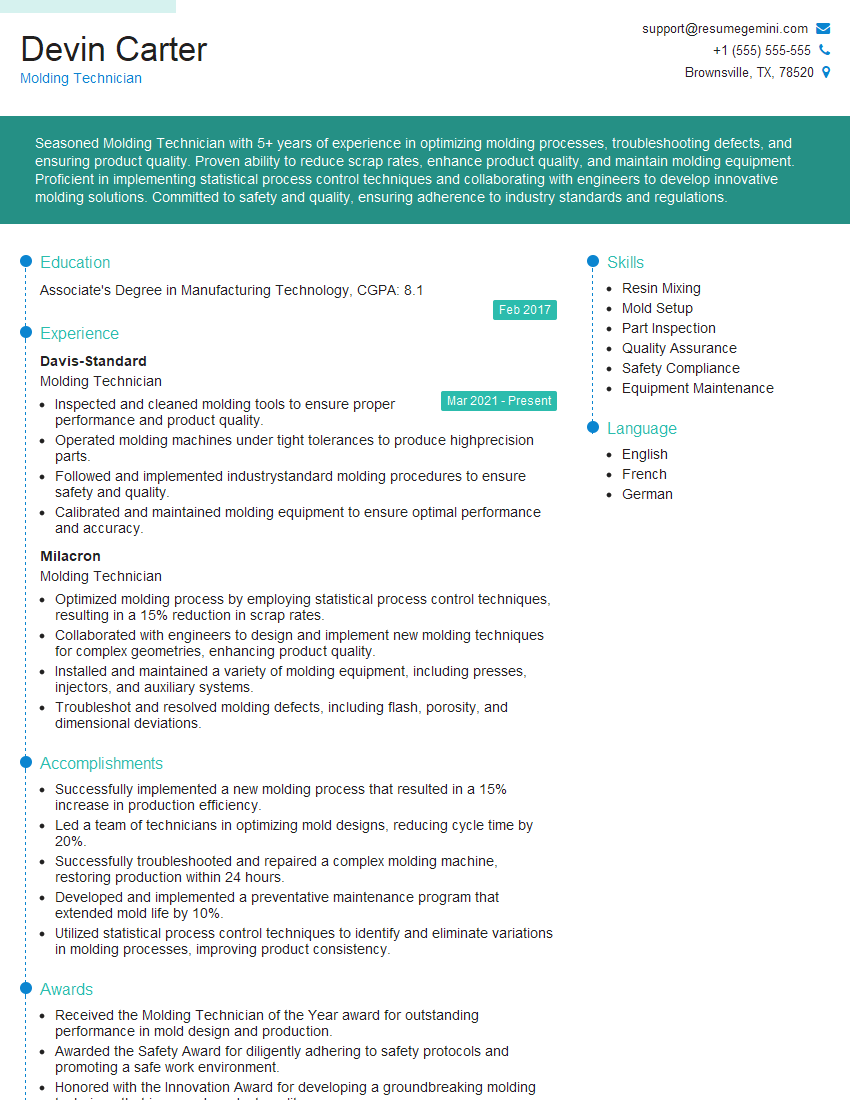

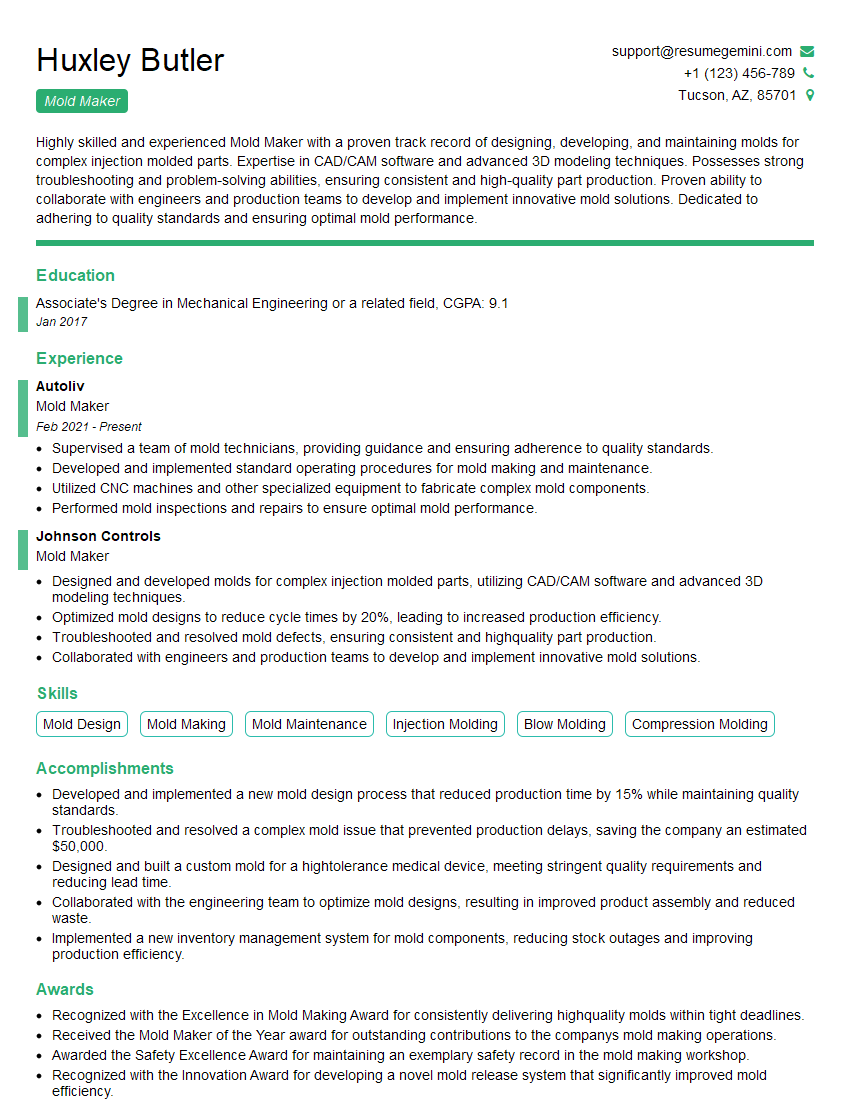

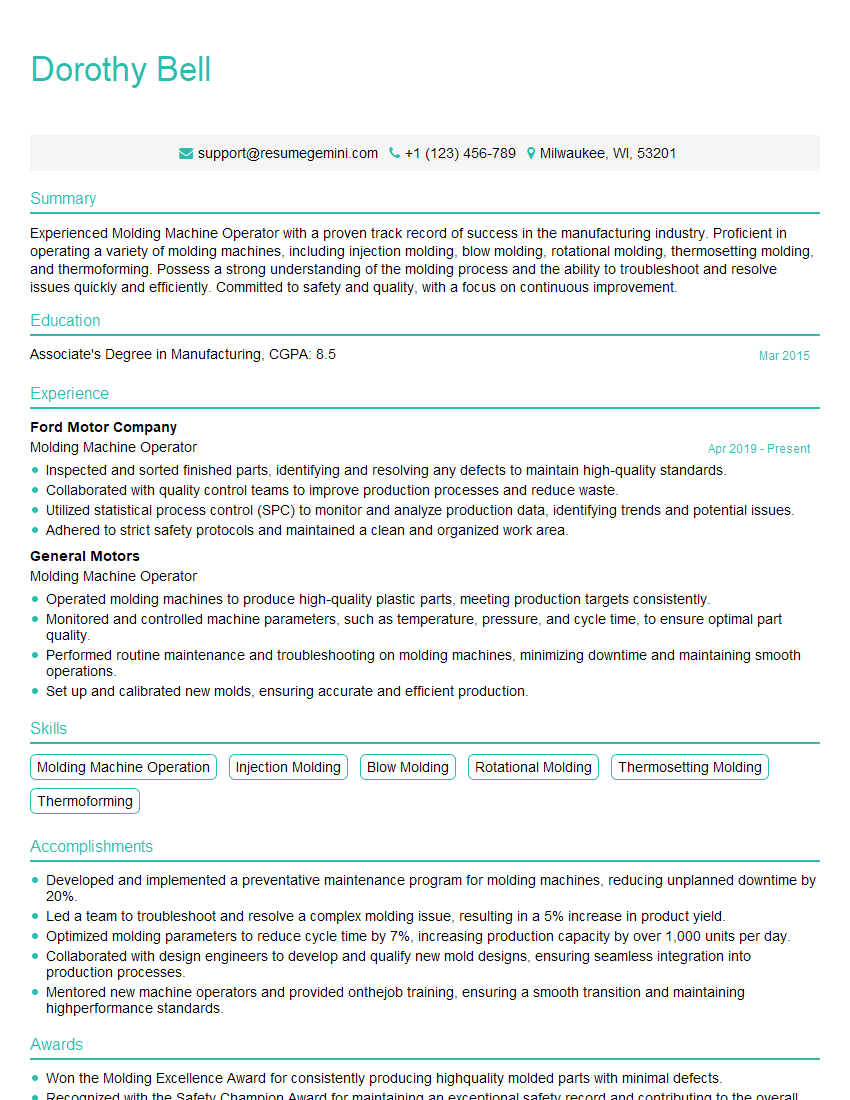

Mastering the intricacies of moldings opens doors to exciting career opportunities in manufacturing, engineering, and design. A strong understanding of molding processes and techniques is highly sought after, making you a valuable asset to any company. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out from the competition. Examples of resumes tailored specifically for Moldings professionals are available to guide you. Take the next step in your career journey – craft a winning resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO