Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Motoring interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Motoring Interview

Q 1. Explain the operation of an internal combustion engine.

The internal combustion engine (ICE) is the powerhouse of most vehicles. It converts chemical energy stored in fuel into mechanical energy to propel the vehicle. This happens through a series of precisely timed events within the engine’s cylinders.

The four-stroke cycle, the most common type, involves:

- Intake Stroke: The piston moves downward, drawing a mixture of air and fuel into the cylinder.

- Compression Stroke: The piston moves upward, compressing the air-fuel mixture, increasing its temperature and pressure.

- Power Stroke: The compressed mixture ignites (spark plug in gasoline engines, compression in diesel), forcing the piston downward with tremendous force. This is where the power is generated.

- Exhaust Stroke: The piston moves upward, pushing the spent gases out of the cylinder through the exhaust valve.

Imagine it like a tiny controlled explosion happening repeatedly in each cylinder. The crankshaft converts the linear motion of the pistons into rotational motion, which drives the wheels via the transmission. Different engine designs (V6, V8, inline-4, etc.) vary the cylinder arrangement for different power and efficiency characteristics. For example, a V8 generally offers more power than an inline-4, but might be less fuel-efficient.

Q 2. Describe the different types of transmissions and their applications.

Transmissions are crucial for adapting the engine’s output to the vehicle’s needs. They allow for smooth starts, efficient cruising at various speeds, and the ability to move in reverse. Several types exist:

- Manual Transmission: The driver manually selects gears, providing direct control and potentially better fuel efficiency. Think of it as a system of levers that change the gear ratio between the engine and the wheels.

- Automatic Transmission: A computer-controlled system automatically selects gears based on driving conditions, offering convenience and smoother shifts. It uses a complex system of hydraulics or electronics to change gear ratios.

- Continuously Variable Transmission (CVT): This type uses a belt and pulleys to provide an infinite number of gear ratios, offering smooth acceleration and potentially better fuel economy. Think of it like a continuously adjustable gear ratio, optimizing for efficiency at all speeds.

- Automated Manual Transmission (AMT): This system combines the efficiency of a manual transmission with the convenience of automatic shifting, utilizing computer-controlled actuators to shift gears.

The application depends on the vehicle and driver preference. Manual transmissions are often preferred for their control and efficiency, particularly in smaller, sportier vehicles. Automatic transmissions are favored for their ease of use and smooth operation in larger vehicles, family cars, and those used in stop-and-go traffic.

Q 3. What are the common causes of engine overheating?

Engine overheating is a serious issue that can cause significant damage. Several factors contribute:

- Low Coolant Levels: Insufficient coolant reduces the engine’s ability to dissipate heat.

- Faulty Thermostat: A malfunctioning thermostat can prevent the coolant from circulating properly.

- Clogged Radiator: A dirty radiator restricts airflow and heat dissipation.

- Water Pump Failure: A broken water pump stops the coolant circulation.

- Faulty Fan: The cooling fan is essential for drawing air through the radiator; if it’s malfunctioning, the engine won’t cool down adequately.

- Head Gasket Failure: In severe cases, a blown head gasket can allow coolant to leak into the combustion chamber, resulting in overheating and potentially engine damage.

Think of the cooling system as the engine’s circulatory system; any blockage or malfunction will prevent efficient heat removal.

Q 4. How do you diagnose a misfire in an engine?

A misfire occurs when one or more cylinders fail to ignite properly, causing rough running, loss of power, and potentially damage. Diagnosis involves a systematic approach:

- Check Engine Light: A lit check engine light often indicates a misfire, and an OBD-II scanner can provide diagnostic trouble codes (DTCs).

- Visual Inspection: Inspect spark plug wires, spark plugs, and ignition coils for visible damage.

- Listen to the Engine: A misfire often produces a rough idling sound or a noticeable sputtering.

- Use a Misfire Diagnostic Tool: Specialized tools can detect individual cylinder misfires by monitoring crank sensor signals.

- Compression Test: Low compression in a cylinder indicates a possible problem with valves, piston rings, or head gasket.

For example, a cracked spark plug or a faulty ignition coil can lead to misfires. The systematic approach ensures you pinpoint the faulty component efficiently.

Q 5. Explain the function of different automotive sensors.

Automotive sensors are crucial for monitoring various engine and vehicle parameters. Some key examples include:

- Mass Airflow Sensor (MAF): Measures the amount of air entering the engine, essential for fuel injection control.

- Throttle Position Sensor (TPS): Monitors the throttle plate position, informing the engine control unit (ECU) about the driver’s throttle input.

- Oxygen Sensor (O2): Measures the oxygen content in the exhaust gases to optimize fuel mixture and emissions.

- Crankshaft Position Sensor (CKP): Monitors the crankshaft’s rotational position, crucial for precise ignition timing.

- Cam Position Sensor (CMP): Monitors the camshaft’s position, ensuring proper valve timing.

- Temperature Sensors: Monitor coolant temperature, intake air temperature, and other crucial temperatures.

Think of them as the nervous system of the car, constantly monitoring vital functions and sending information to the ECU, which adjusts the engine’s operation accordingly.

Q 6. Describe the braking system components and their interactions.

The braking system is critical for vehicle safety. It involves several interacting components:

- Brake Pedal: The driver’s input initiates the braking process.

- Master Cylinder: This hydraulic component converts pedal pressure into hydraulic pressure.

- Brake Lines: These carry the hydraulic pressure to the wheels.

- Wheel Cylinders (drum brakes) or Calipers (disc brakes): These components convert hydraulic pressure into mechanical force on the brake shoes or pads.

- Brake Pads or Shoes: These friction materials create the braking force by clamping against the brake rotor or drum.

- Brake Rotors or Drums: These components rotate with the wheels and are slowed by the pads or shoes.

- Anti-lock Braking System (ABS): This system prevents wheel lockup during hard braking, enhancing control and stability.

When the brake pedal is pressed, hydraulic pressure builds in the master cylinder, forcing the brake fluid through the lines to the calipers or wheel cylinders. This pressure then acts on the brake pads or shoes, creating friction and slowing the wheels. ABS actively modulates brake pressure to each wheel to prevent lock-up.

Q 7. How do you perform a tire rotation and balancing?

Tire rotation and balancing are essential for even tire wear and optimal handling. Tire rotation involves moving tires from one position to another on the vehicle, according to a specific pattern (e.g., front-to-rear cross, or X pattern). This ensures even wear across all four tires. Balancing involves adding small weights to the wheel rims to compensate for any imbalances that could cause vibrations.

Tire Rotation: The specific pattern chosen depends on the vehicle’s manufacturer’s recommendations. Consult your owner’s manual for guidance.

Balancing: A tire balancing machine is used to precisely measure the imbalance, and weights are carefully added to the wheel rim to correct it. The goal is to make the wheel spin smoothly without vibration.

Performing these procedures correctly helps to extend the life of your tires and improve vehicle handling and safety. An unbalanced tire can lead to premature wear and vibrations which negatively affect handling, comfort, and even fuel economy.

Q 8. What are the safety procedures for working on a vehicle’s electrical system?

Working on a vehicle’s electrical system can be dangerous if safety procedures aren’t followed meticulously. Before you even touch a wire, the first step is disconnecting the battery’s negative terminal. This prevents accidental shorts and protects you from electrical shocks. Think of it like turning off the main power switch in your house before doing any electrical work.

- Always wear safety glasses: Protecting your eyes from flying debris or sparks is crucial.

- Use insulated tools: These prevent electrical shocks by providing a barrier between you and the vehicle’s electrical components. Never use metal tools unless absolutely necessary and you’re certain the system is completely de-energized.

- Consult a wiring diagram: Before working on any circuit, understand its components and how they’re interconnected. This helps prevent accidental damage or short circuits.

- Be aware of high-voltage systems: Modern vehicles often incorporate high-voltage components, especially in hybrid and electric vehicles. These systems require specialized training and safety equipment.

- Work in a well-ventilated area: Battery fumes are hazardous. Ensure proper ventilation to avoid inhaling them.

Failing to follow these simple steps can lead to serious injury or damage to the vehicle’s electrical system. Remember, safety should always be your top priority.

Q 9. Explain the principles of vehicle suspension and its impact on handling.

A vehicle’s suspension system is the bridge between the chassis and the wheels, crucial for comfort, handling, and safety. It absorbs shocks and vibrations from the road, keeping the tires in contact with the surface for optimal traction. Think of it as a sophisticated shock absorber for your car.

The principles revolve around springs (coils, leaf springs, torsion bars, air springs) that store energy from bumps and dampers (shock absorbers) that control the release of that energy, preventing excessive bouncing. The interplay between these two components dictates ride quality and handling.

A well-designed suspension system improves handling by:

- Maintaining tire contact: By absorbing bumps, it keeps the tires firmly planted on the road, enhancing grip and control, especially during cornering.

- Reducing body roll: Anti-roll bars and sophisticated suspension geometries help minimize the vehicle’s lean during turns, improving stability.

- Enhancing steering response: A responsive suspension allows for precise steering input and feedback, leading to better maneuverability.

Different suspension types, such as MacPherson struts, double wishbones, and multi-link systems, offer varying degrees of comfort and handling characteristics. The choice depends on the vehicle’s intended use and target market.

Q 10. Describe different types of fuel injection systems.

Fuel injection systems meter and deliver fuel to the engine’s cylinders, replacing the older carburetor systems. They offer better fuel efficiency, reduced emissions, and improved performance.

There are several types:

- Single-Point (Throttle Body) Injection: Fuel is injected into the throttle body, which mixes it with air before entering the intake manifold. It’s a simpler system, often found in older vehicles.

- Multi-Point (Port) Injection: Fuel injectors are located in the intake manifold, injecting fuel directly into each intake port. This provides more precise fuel metering and better performance.

- Direct Injection: Fuel is injected directly into the combustion chamber, improving combustion efficiency and reducing emissions. This system is commonly found in modern gasoline and diesel engines.

- Common Rail Direct Injection (Diesel): A high-pressure fuel rail supplies fuel to multiple injectors simultaneously, enabling precise fuel delivery and better control over engine operation. This is a hallmark of modern diesel engines.

The choice of fuel injection system depends on factors like engine design, performance goals, and emission regulations. Modern vehicles increasingly utilize direct injection for its efficiency and power benefits.

Q 11. How do you troubleshoot a faulty alternator?

Troubleshooting a faulty alternator involves a systematic approach. The alternator charges the battery, so a malfunction can lead to a dead battery and electrical system failure.

Here’s a step-by-step guide:

- Visual Inspection: Check the alternator’s belt for wear or damage. A slipping or broken belt can prevent the alternator from charging.

- Voltage Test: With the engine running, measure the voltage at the battery terminals using a voltmeter. A reading below 13.5 volts indicates a charging problem. A reading above 15 volts suggests overcharging.

- Load Test: A load test applies a simulated load to the alternator to assess its ability to provide sufficient current under stress. This requires specialized equipment.

- Check the Wiring and Connections: Inspect the alternator’s wiring harness and connectors for damage or corrosion. Loose or corroded connections can disrupt the charging circuit.

- Battery Test: A faulty battery can mask an alternator problem. A battery load test will determine if the battery itself is capable of holding a charge.

If the problem persists after checking these points, the alternator may need replacement. It’s best to take the vehicle to a qualified mechanic for diagnosis and repair if you lack the necessary tools or experience.

Q 12. Explain the importance of regular vehicle maintenance.

Regular vehicle maintenance is vital for safety, reliability, and longevity. Think of it as preventative healthcare for your car. Neglecting maintenance can lead to costly repairs and potential breakdowns. Regular maintenance helps extend the life of the vehicle significantly and reduces unforeseen problems.

The importance of regular vehicle maintenance lies in:

- Safety: Regular checks of brakes, tires, lights, and steering ensure the vehicle is safe to operate.

- Reliability: Preventative maintenance, such as oil changes and fluid top-ups, helps prevent unexpected breakdowns.

- Fuel Efficiency: Properly maintained systems like the air filter and spark plugs contribute to better fuel economy.

- Resale Value: A well-maintained vehicle commands a higher resale value.

- Environmental Impact: Regular maintenance helps reduce harmful emissions.

A regular maintenance schedule should include checks and services like oil changes, tire rotations, fluid top-ups, and inspections of crucial components. Always refer to the vehicle’s owner’s manual for specific recommendations.

Q 13. What are the common causes of brake failure?

Brake failure is a serious safety concern, and understanding its causes is vital. Brake systems are complex, and failure can stem from multiple sources.

Common causes include:

- Worn brake pads or shoes: These are consumable components and need regular replacement. Driving with worn brakes significantly reduces stopping power.

- Low brake fluid: Leaking brake lines or a damaged master cylinder can lead to low brake fluid levels, resulting in spongy brakes or complete failure.

- Faulty master cylinder: The master cylinder converts pedal pressure into hydraulic pressure to actuate the brakes. A faulty master cylinder can lead to inconsistent braking or complete brake failure.

- Faulty calipers or wheel cylinders: These components apply pressure to the brake pads or shoes. A seized or leaking caliper can prevent a wheel from braking effectively.

- Brake line leaks: Leaks in the brake lines can lead to a loss of hydraulic pressure and brake failure.

- ABS (Anti-lock Braking System) malfunction: While the ABS shouldn’t cause complete brake failure, a malfunction can affect its operation, potentially lengthening stopping distances.

Regular brake inspections and maintenance are crucial to prevent brake failure. Any signs of reduced braking performance should be addressed immediately by a qualified mechanic.

Q 14. Describe the different types of steering systems.

Steering systems are responsible for directing the vehicle’s wheels, ensuring safe and controlled movement. Different types exist, each with its advantages and disadvantages.

Common types include:

- Recirculating Ball Steering: This is a robust and relatively simple system using a recirculating ball mechanism to reduce friction and provide smooth steering. It’s been widely used but is less precise than newer systems.

- Rack and Pinion Steering: This system uses a rack and pinion gear to translate rotary motion from the steering wheel into linear motion for the wheels. It’s more precise and efficient than recirculating ball, commonly found in modern vehicles.

- Power Steering: A hydraulic or electric system that assists the driver in turning the steering wheel, reducing effort and improving maneuverability, especially at low speeds.

The choice of steering system depends on factors like vehicle size, performance requirements, and cost. Modern vehicles primarily use rack and pinion steering with power assistance for optimal performance and driver comfort.

Q 15. How do you diagnose and repair a faulty wheel bearing?

Diagnosing a faulty wheel bearing involves a multi-step process combining visual inspection, listening for sounds, and sometimes using specialized tools. A failing wheel bearing often produces a humming, grinding, or rumbling noise, especially at higher speeds or when turning. The noise will typically increase with speed.

Diagnosis:

- Visual Inspection: Check for any obvious damage, such as cracks or leaks in the bearing seal. Look for play in the wheel by grabbing the wheel at the top and bottom and attempting to move it. Excessive movement indicates a worn bearing.

- Sound Check: Carefully listen for unusual noises while someone slowly rotates the wheel. A rough or grating sound is a strong indicator of a failing bearing. Jacking up the vehicle and spinning the wheel by hand can also help isolate the noise.

- Play Check (Advanced): Use a pry bar to check for play in the wheel hub. If significant movement is detected, the bearing is likely faulty.

Repair: Replacing a wheel bearing is a more involved task requiring specialized tools. It usually involves removing the wheel, brake caliper, and often the hub assembly. The old bearing is then pressed out and a new one is pressed in, ensuring proper seating and alignment. It is crucial to use the correct tools and follow the manufacturer’s specifications to avoid damage.

Example: I once diagnosed a faulty wheel bearing on a customer’s car that was making a low humming sound. A visual inspection revealed no obvious damage, but a thorough sound check while rotating the wheel confirmed the issue. Replacing the bearing completely resolved the noise.

Career Expert Tips:

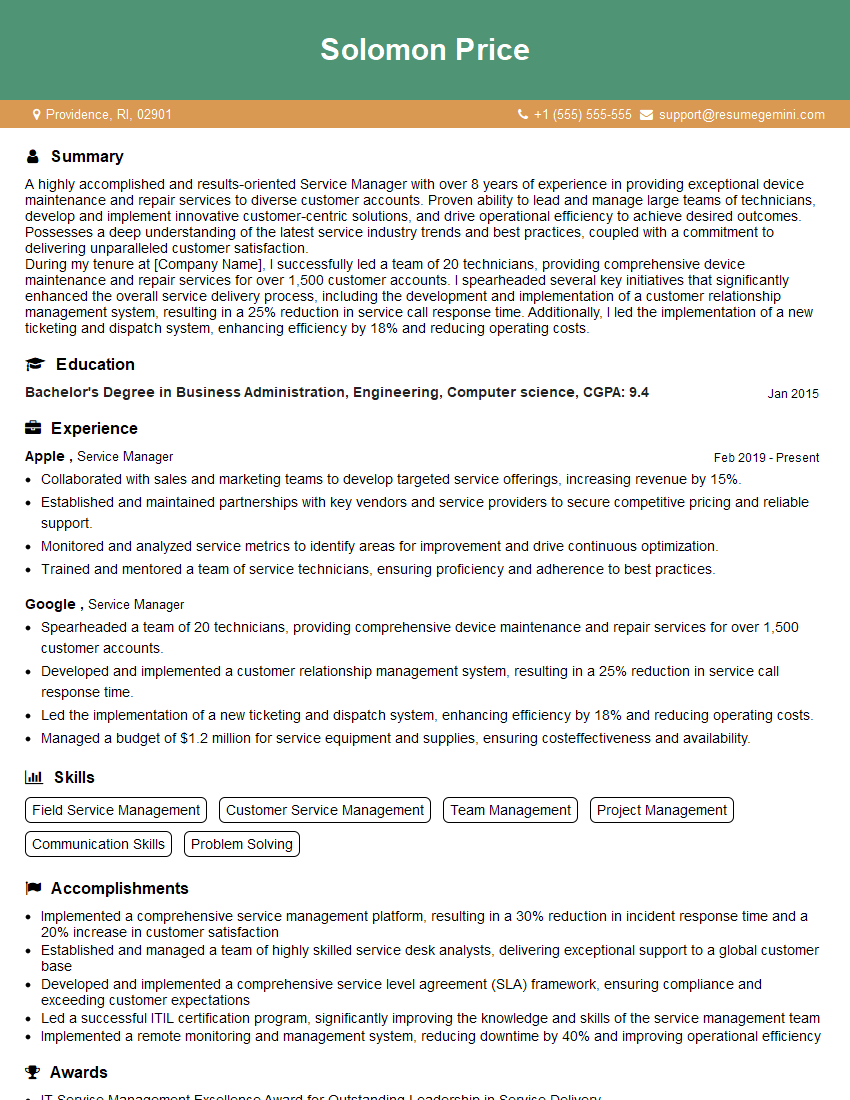

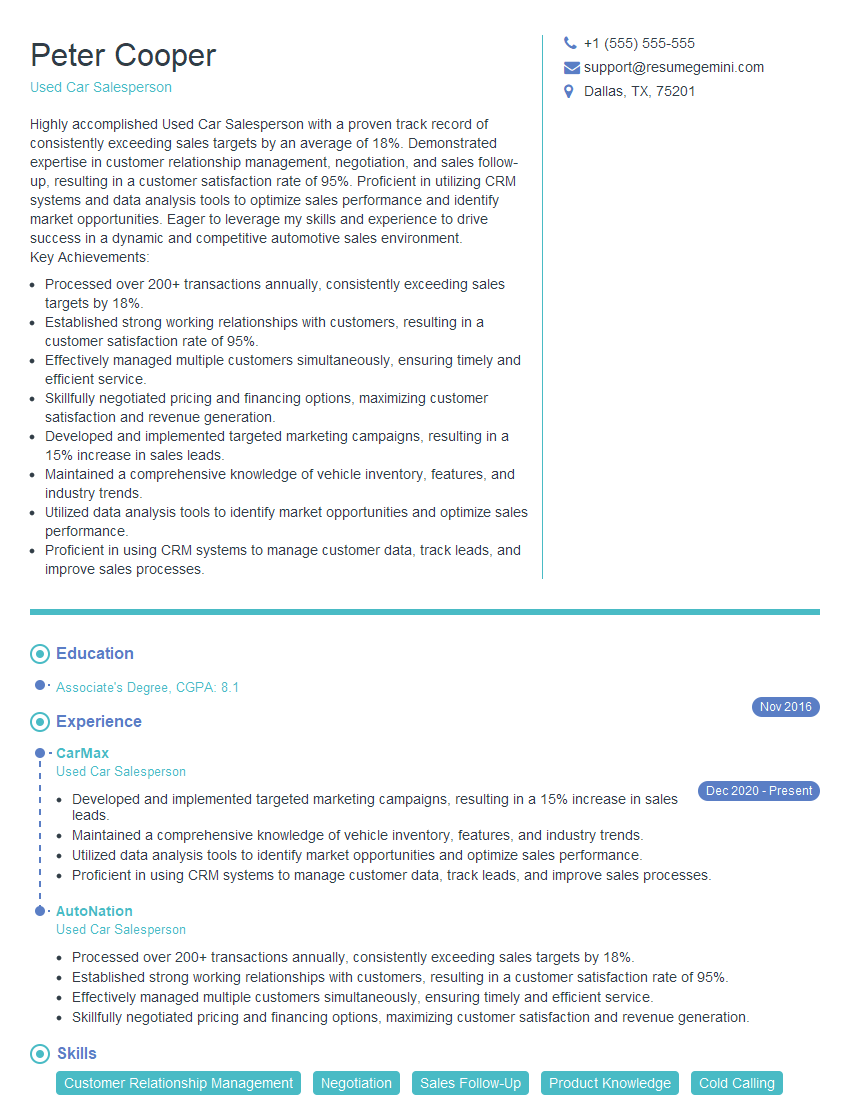

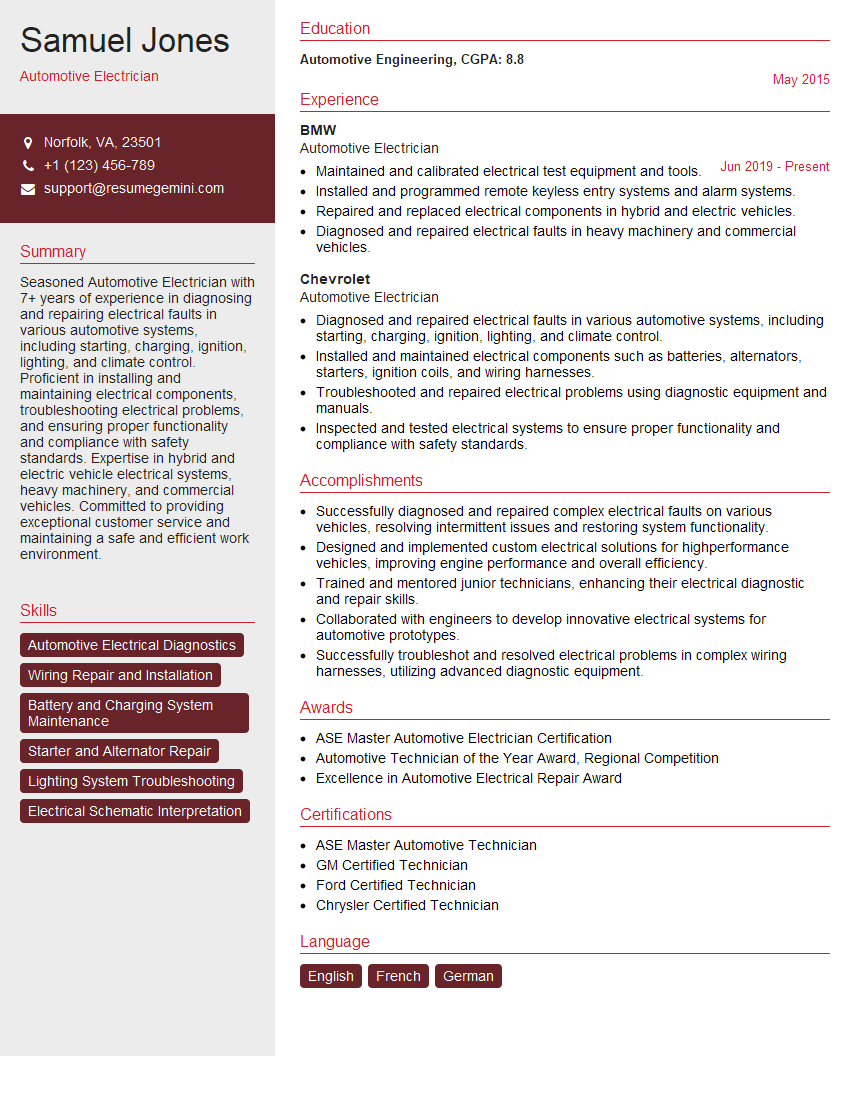

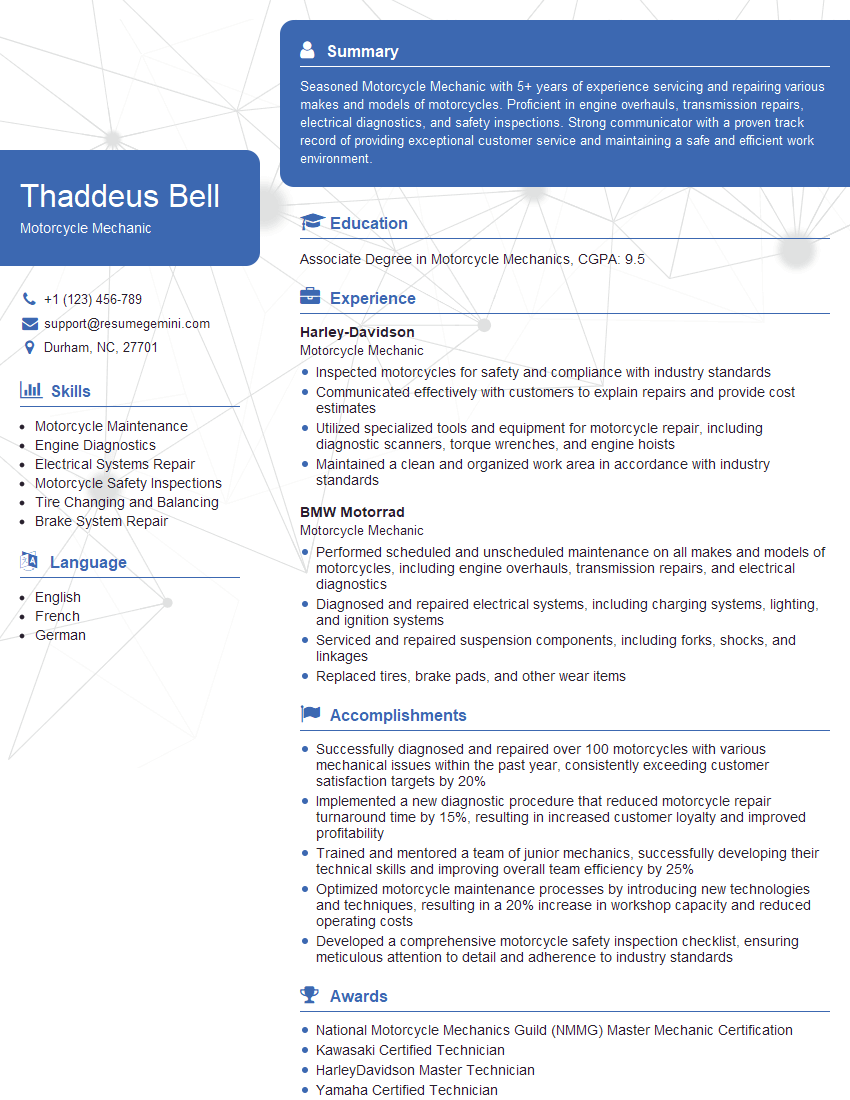

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the principles of vehicle aerodynamics.

Vehicle aerodynamics is the study of how air flows around a vehicle. Its primary goal is to minimize aerodynamic drag, which reduces fuel consumption and improves stability at high speeds. Other factors considered include lift, downforce, and yaw.

Principles:

- Drag: The force that opposes the movement of a vehicle through the air. Minimizing drag is key to improving fuel efficiency. This is achieved through streamlining the vehicle’s shape, reducing its frontal area, and managing airflow around various components.

- Lift: The upward force acting on a vehicle, particularly at high speeds. This is undesirable as it reduces traction. Aerodynamic design aims to minimize lift by managing air pressure distribution.

- Downforce: The downward force acting on a vehicle, generated using aerodynamic devices like spoilers and diffusers. This increases traction and improves handling, especially during cornering.

- Yaw: The rotation of a vehicle around its vertical axis. Effective aerodynamic design helps minimize yaw by managing air flow around the vehicle’s rear, improving stability.

Practical Application: Modern cars incorporate various aerodynamic features, such as spoilers, diffusers, underbody panels, and carefully sculpted body shapes, to optimize airflow and reduce drag. Formula 1 cars are a prime example, showcasing highly advanced aerodynamic solutions to maximize downforce and stability.

Q 17. What are the environmental regulations related to automotive emissions?

Environmental regulations concerning automotive emissions aim to reduce harmful pollutants released into the atmosphere. These regulations vary by country and region but generally focus on limiting emissions of greenhouse gases (GHGs) and pollutants like nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and hydrocarbons (HC).

Examples of Regulations:

- Euro Standards (Europe): A series of progressively stricter emission limits for vehicles sold in Europe.

- OBD-II (On-Board Diagnostics): A system mandated in many countries that monitors vehicle emissions and stores diagnostic trouble codes (DTCs) that indicate problems.

- California Air Resources Board (CARB) Standards (USA): Stringent emission regulations in California often influencing national standards.

- Corporate Average Fuel Economy (CAFE) Standards (USA): Regulations aimed at improving the average fuel economy of vehicles sold by manufacturers.

Impact: These regulations drive technological advancements in vehicle emission control systems, such as catalytic converters, selective catalytic reduction (SCR) systems, and particulate filters. They also encourage the development and adoption of alternative fuel vehicles (AFVs) and electric vehicles (EVs) to further reduce emissions.

Q 18. Describe the different types of vehicle body construction.

Vehicle body construction varies based on factors such as cost, safety, and desired performance. Common types include:

- Unibody Construction (Monocoque): The body shell and chassis are a single unit, providing high stiffness-to-weight ratio. Most modern passenger cars use this method.

- Body-on-Frame Construction: A separate chassis (frame) is used, with the body mounted on top. This provides more ruggedness and is commonly found in trucks, SUVs, and off-road vehicles.

- Space Frame Construction: Uses a framework of interconnected tubes or beams to form the structure, offering excellent strength and rigidity with relatively low weight. Often used in high-performance vehicles.

Materials: Modern vehicle bodies incorporate a variety of materials to optimize strength, weight, and cost. These include:

- Steel: Common and cost-effective, offering good strength but relatively heavy.

- Aluminum: Lighter than steel, offering improved fuel efficiency but more expensive.

- Carbon Fiber Reinforced Polymer (CFRP): Extremely strong and lightweight, used in high-performance and luxury vehicles.

Example: A typical family sedan will utilize unibody construction with a combination of high-strength steel alloys for optimal strength and safety at an affordable cost. In contrast, a high-end sports car might employ a space frame construction with carbon fiber components to maximize performance and reduce weight.

Q 19. How do you use diagnostic tools to identify vehicle problems?

Diagnostic tools are essential for identifying vehicle problems efficiently. These range from simple handheld scanners to sophisticated computer-based systems capable of accessing vast amounts of vehicle data.

Types of Diagnostic Tools:

- OBD-II Scanners: These connect to the vehicle’s On-Board Diagnostics port (usually located under the dashboard) and retrieve diagnostic trouble codes (DTCs). DTCs provide clues about potential issues within the vehicle’s systems.

- Advanced Scanners: More comprehensive tools that offer deeper access to vehicle data, allowing technicians to monitor various sensors, actuators, and modules in real time.

- Scope Meters/Oscilloscope: These measure electrical signals, helping to analyze sensor outputs and identify intermittent problems.

Using Diagnostic Tools:

- Connect the scanner: Plug the scanner into the OBD-II port.

- Retrieve DTCs: The scanner will retrieve a list of DTCs stored in the vehicle’s computer.

- Interpret DTCs: Use a DTC lookup table or the scanner’s database to understand the meaning of each code.

- Monitor Live Data: Many scanners allow monitoring real-time data from various sensors, helping pinpoint the cause of the problem.

- Perform Tests: Some scanners allow performing specific tests, such as actuator tests, to verify component function.

Example: Using an advanced scanner, I once diagnosed an intermittent misfire in a vehicle. By monitoring live data, I observed erratic sensor readings from a particular cylinder’s oxygen sensor, pinpointing the faulty component and leading to a quick and effective repair.

Q 20. Explain the importance of proper torque specifications.

Proper torque specifications are crucial for ensuring the correct tightness of fasteners in a vehicle. Using incorrect torque can lead to loose components that can cause damage, poor performance, or even safety hazards. Over-tightening can strip threads, causing permanent damage, or even break the bolt itself. Under-tightening can result in loose components, leading to potential failures.

Importance:

- Safety: Ensuring critical components, such as wheel nuts, are tightened to the correct torque is paramount for safe operation. Loose wheel nuts can cause the wheel to come off, while over-tightening can damage the wheel studs.

- Reliability: Proper torque ensures that components are correctly secured, preventing leaks, vibrations, and premature wear.

- Performance: In some cases, correct torque is essential for proper engine performance or the operation of specific systems.

Application: Torque specifications are usually found in repair manuals or online databases specific to the make and model of the vehicle. A torque wrench is a specialized tool used to apply the precise amount of torque required. It’s important to use the correct torque wrench and ensure it is properly calibrated.

Example: When changing a wheel, using the incorrect torque on the lug nuts can lead to the wheel becoming loose during driving, potentially causing a serious accident. Using a torque wrench and the manufacturer’s specifications is essential to ensure safety.

Q 21. What are the safety precautions when working with automotive chemicals?

Working with automotive chemicals requires strict adherence to safety precautions to prevent injury or harm. These chemicals can be corrosive, flammable, toxic, or even carcinogenic.

Safety Precautions:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, and respiratory protection, depending on the chemical being handled.

- Ventilation: Work in a well-ventilated area to minimize inhalation of fumes. Use respirators when necessary.

- Proper Handling: Follow instructions carefully when handling chemicals. Avoid spills and leaks.

- Storage: Store chemicals in designated areas away from ignition sources, and ensure proper labeling.

- Disposal: Dispose of chemicals properly according to local regulations. Never pour chemicals down the drain.

- First Aid: Be aware of the first aid procedures for potential chemical exposures and have appropriate materials readily available.

- SDS (Safety Data Sheets): Consult the SDS for each chemical to understand potential hazards and appropriate handling procedures.

Example: When working with brake fluid, which is corrosive, always wear gloves and eye protection to prevent skin irritation or eye damage. Improper disposal of used brake fluid can contaminate the environment. Always consult the SDS for detailed information on safe handling and disposal.

Q 22. Describe your experience with different types of engine repair.

My experience spans a wide range of engine repair, encompassing both gasoline and diesel powertrains. I’m proficient in diagnosing and rectifying issues related to internal combustion engines, including problems with the fuel system (fuel injectors, fuel pumps, fuel pressure regulators), ignition system (spark plugs, ignition coils, distributor), cooling system (radiator, water pump, thermostat), and lubrication system (oil pump, oil filter). I’ve also worked extensively on engine rebuilds, replacing worn components like pistons, rings, bearings, and cylinder heads. For instance, I once successfully rebuilt a heavily worn V6 engine in a minivan, restoring it to peak performance. This involved meticulous inspection, precise measurements, and the careful assembly of all components. I am also experienced with newer technologies like direct injection systems and variable valve timing, and can troubleshoot issues related to their unique complexities.

Furthermore, I have experience diagnosing and repairing various engine management system (EMS) problems. I can utilize diagnostic tools like OBD-II scanners to read fault codes, analyze sensor data, and identify the root cause of engine malfunctions. This diagnostic approach is crucial for modern vehicles, where many engine parameters are electronically controlled.

Q 23. How do you manage your time effectively when working on multiple vehicles?

Effective time management in a busy automotive workshop is crucial. My approach involves several key strategies. Firstly, I prioritize tasks based on urgency and the customer’s needs. Emergency repairs always take precedence. Secondly, I meticulously plan my workflow for each vehicle, creating a checklist of necessary steps. This avoids unnecessary backtracking and ensures efficiency. Thirdly, I utilize digital tools to manage appointments and track progress on each vehicle, keeping a clear overview of my workload. Think of it like conducting an orchestra – each instrument (task) needs to be played (completed) at the right time to create a harmonious whole (successful repair). Finally, I constantly reassess my schedule and adapt my approach as needed, adjusting to unexpected delays or complications.

Q 24. Explain your experience with customer service in an automotive setting.

Customer service is paramount in the automotive industry. I believe in providing clear, transparent communication throughout the entire repair process. I always explain the problem to the customer in simple, understandable terms, avoiding technical jargon. I provide accurate estimates and keep customers updated on the progress of their repairs. I actively listen to their concerns and answer their questions thoroughly. One memorable instance involved a frustrated customer whose vehicle was experiencing intermittent starting problems. After patiently listening to their concerns, I used my diagnostic expertise to identify a faulty crankshaft position sensor and explain the repair in detail. The customer appreciated my honesty and transparency, which resulted in a positive outcome and strengthened their trust in my abilities. Building trust and open communication fosters positive relationships.

Q 25. Describe your problem-solving skills in a challenging automotive repair scenario.

A challenging scenario I encountered involved a vehicle with a seemingly intermittent misfire. Standard diagnostic procedures initially yielded inconclusive results. My problem-solving strategy involved a systematic approach: I started with the basics, carefully inspecting spark plugs, wires, and ignition coils. I then moved on to more advanced diagnostics, checking fuel pressure, air intake system, and utilizing an oscilloscope to analyze the ignition signals. After several hours of methodical troubleshooting, I pinpointed the problem to a faulty camshaft position sensor, causing intermittent timing issues and leading to the misfire. Replacing the sensor resolved the problem completely. This experience highlighted the importance of a structured approach, combined with patience and the ability to utilize various diagnostic techniques in complex situations.

Q 26. What are your strengths and weaknesses as an automotive technician?

My strengths include a strong diagnostic aptitude, meticulous attention to detail, and a commitment to providing excellent customer service. I am also a quick learner and thrive in challenging situations. My ability to remain calm and organized under pressure is crucial in this demanding field.

A weakness I’m actively working to improve is delegation. While I pride myself on my thoroughness, I sometimes find it difficult to delegate tasks when I feel I can do them faster myself. However, I’m learning to trust my colleagues and delegate effectively to improve overall team efficiency. It’s about balancing quality with team workflow.

Q 27. How do you stay up-to-date with the latest automotive technology?

Staying current with automotive technology is essential in this rapidly evolving industry. I actively participate in manufacturer training programs, attend industry conferences and workshops, and subscribe to professional automotive journals and online resources. I also leverage online platforms and manufacturer websites to access the latest technical service bulletins and repair information. Keeping my skills updated enables me to work effectively on the latest vehicle models and utilize the most advanced diagnostic tools and techniques. Continuous learning is an investment in my professional growth and ensures I remain a valuable asset in this rapidly changing field.

Q 28. Describe your experience working with advanced driver-assistance systems (ADAS).

My experience with Advanced Driver-Assistance Systems (ADAS) is growing, and I’m currently undergoing specialized training to expand my knowledge in this area. I understand the complexities of these systems, including features like adaptive cruise control, lane departure warning, automatic emergency braking, and parking assist. I am aware of the safety precautions required when working on ADAS components, such as calibration procedures and the use of specialized diagnostic tools. Currently, my work involves assisting in the diagnosis and repair of some ADAS components, while fully understanding the need for proper training to handle these systems effectively and safely. The field is highly technical, requiring precise calibration to avoid safety concerns.

Key Topics to Learn for a Motoring Interview

- Vehicle Mechanics & Technology: Understanding engine operation, transmission systems, braking systems, electronic control units (ECUs), and emerging technologies like hybrid and electric powertrains. Consider practical applications like diagnosing common engine problems or explaining the benefits of different fuel injection systems.

- Vehicle Safety & Regulations: Knowledge of safety standards, regulations, and compliance procedures within the automotive industry. Think about how you would explain the importance of specific safety features or the impact of new emission regulations.

- Automotive Diagnostics & Troubleshooting: Proficiency in using diagnostic tools and software to identify and resolve vehicle malfunctions. Explore case studies where you successfully diagnosed and repaired a complex vehicle issue.

- Manufacturing & Supply Chain: Familiarity with automotive manufacturing processes, supply chain management, and quality control. Consider the challenges of managing a global supply chain or optimizing manufacturing efficiency.

- Data Analysis & Reporting: Ability to analyze vehicle performance data, identify trends, and create reports to improve efficiency and decision-making. Think about how you would present data to stakeholders and use it to support recommendations.

- Customer Service & Communication: Excellent communication skills to interact effectively with customers, colleagues, and stakeholders. Prepare examples showcasing your ability to handle customer complaints or communicate complex technical information clearly.

Next Steps

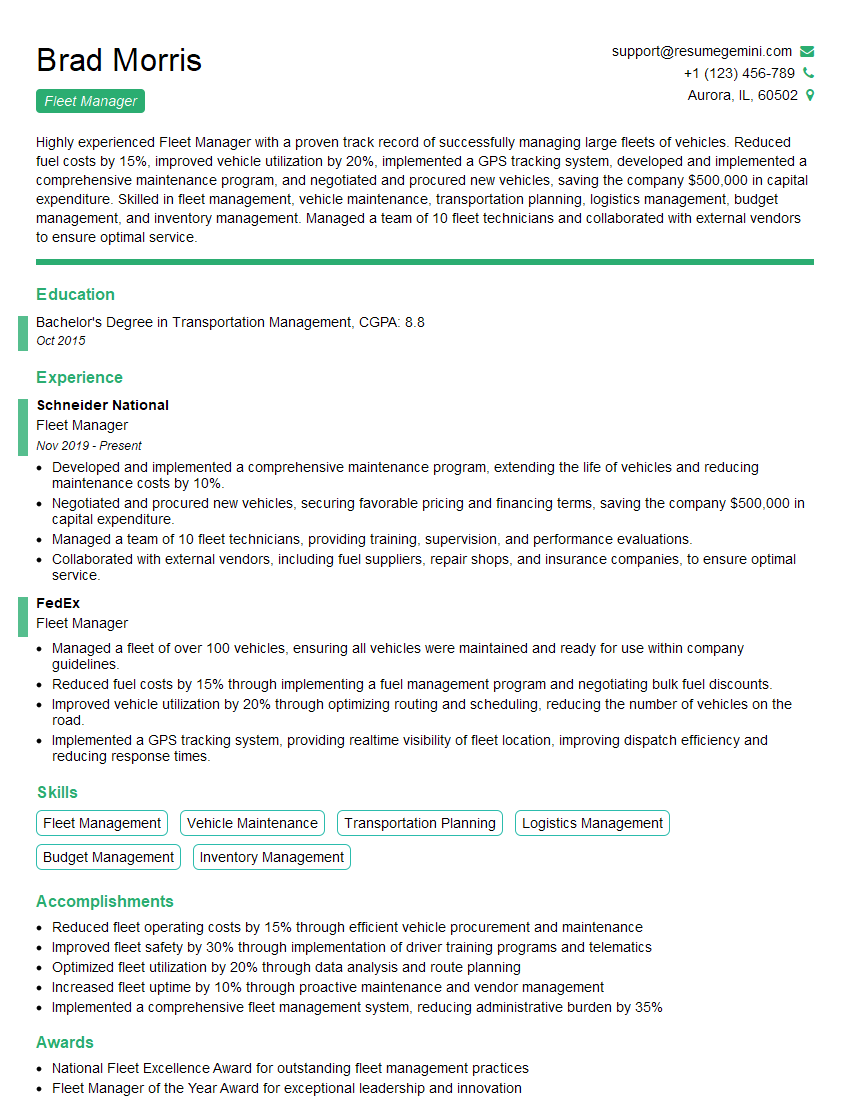

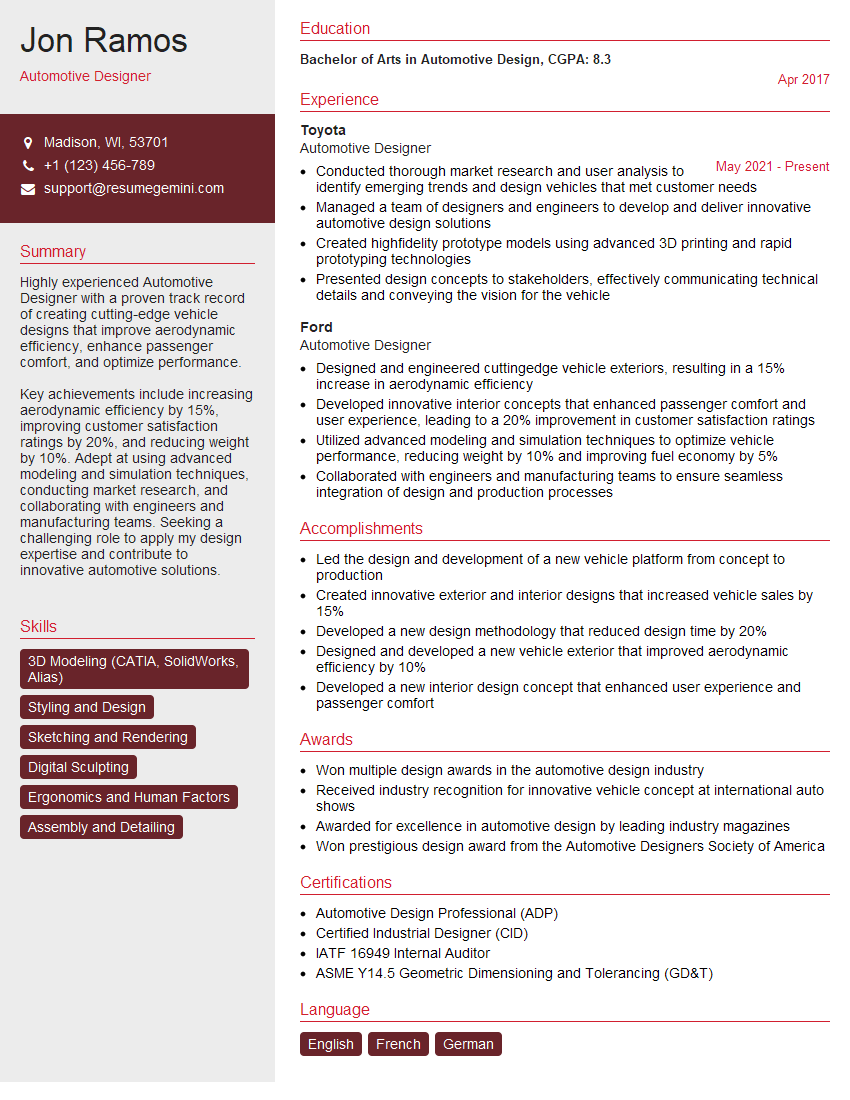

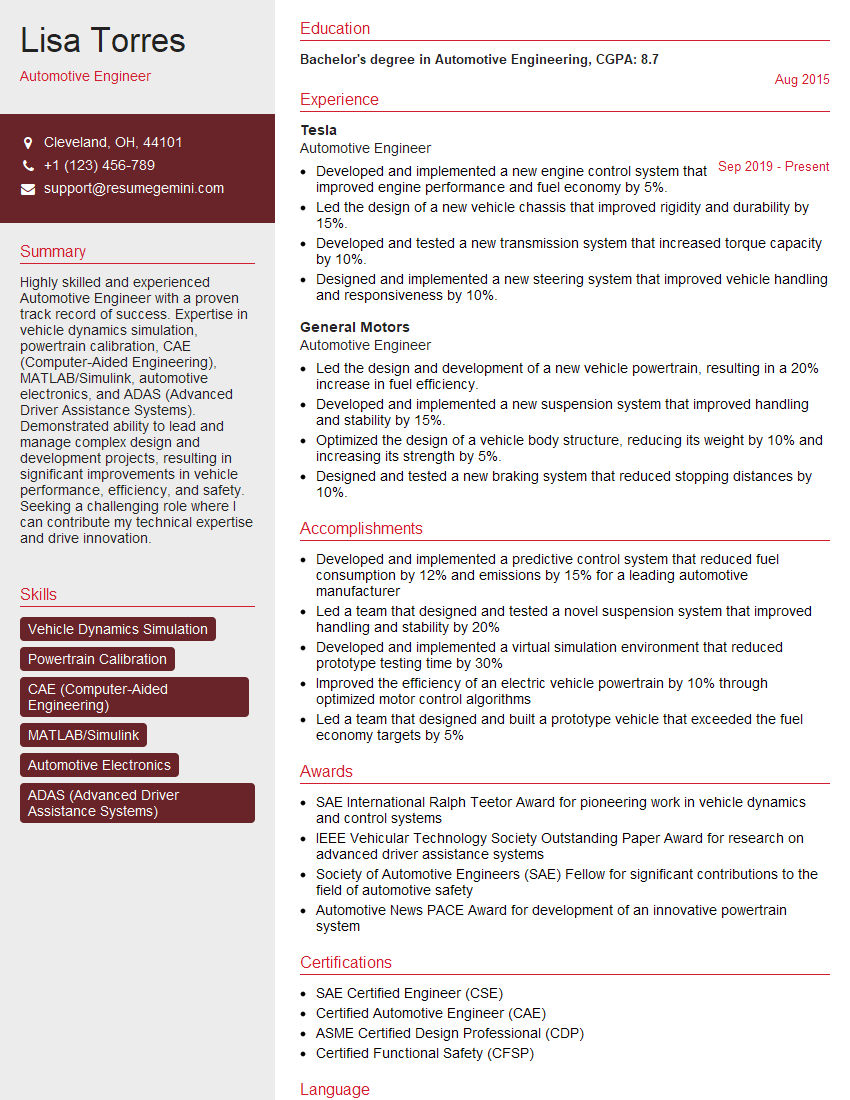

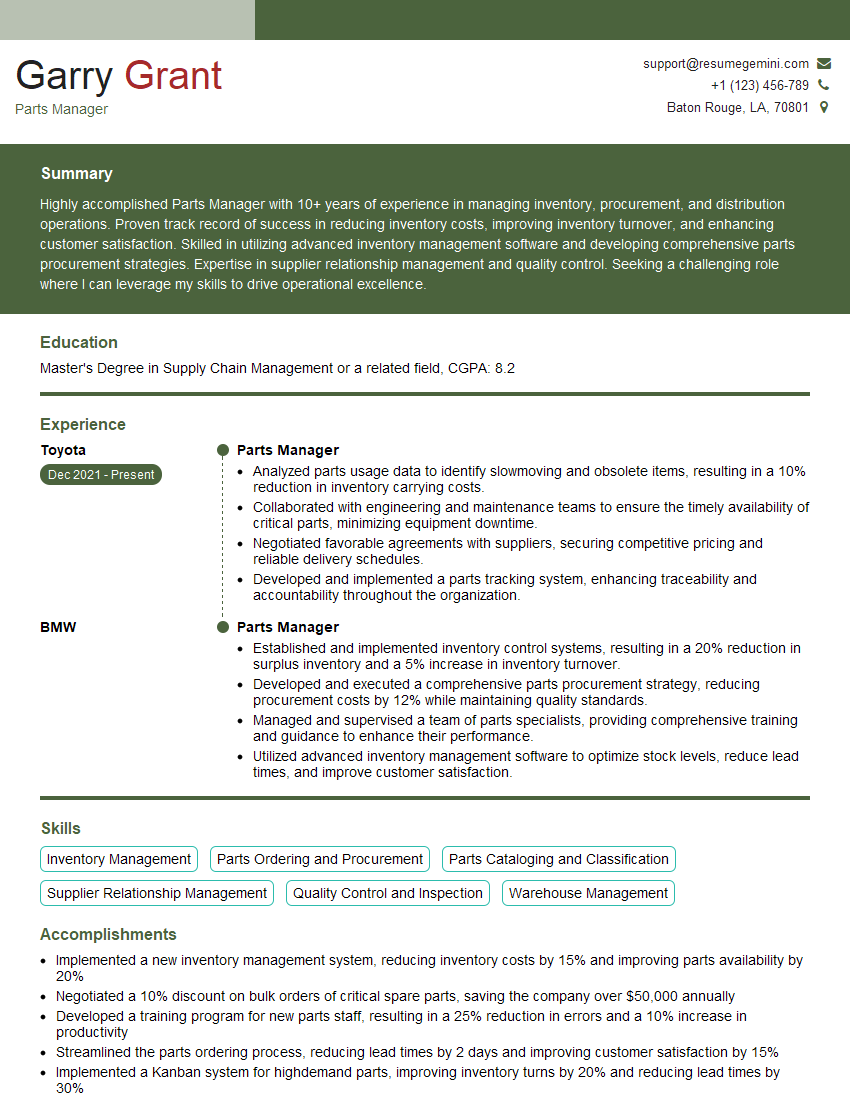

Mastering the intricacies of the Motoring industry opens doors to exciting and rewarding career opportunities. To significantly boost your job prospects, focus on creating a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to the Motoring sector to guide you in showcasing your unique qualifications. Take the next step towards your dream career in Motoring – build a resume that gets noticed!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO