Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Oil and Gas Exploration and Production interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Oil and Gas Exploration and Production Interview

Q 1. Explain the difference between conventional and unconventional oil and gas reservoirs.

The key difference between conventional and unconventional oil and gas reservoirs lies in how the hydrocarbons are trapped and extracted. Conventional reservoirs are characterized by porous and permeable rock formations, like sandstone or limestone, where oil and gas accumulate in easily accessible underground traps. Think of it like a sponge holding water – the oil and gas naturally flow to the wellbore upon drilling. Unconventional reservoirs, on the other hand, hold hydrocarbons in low-permeability rocks such as shale or tight sandstone. These resources are not easily accessible and require advanced extraction techniques like hydraulic fracturing (fracking) or horizontal drilling to release the hydrocarbons.

Example: A typical conventional reservoir might be a large anticline (an upward fold in rock layers) trapping oil and gas beneath an impermeable caprock. An unconventional reservoir, like the Bakken shale, requires horizontal drilling and fracking to create permeability and extract the dispersed oil and gas.

Q 2. Describe the process of hydraulic fracturing (fracking).

Hydraulic fracturing, or fracking, is a technique used to extract hydrocarbons from unconventional reservoirs. The process involves drilling a well vertically, then horizontally into the shale formation. Once the horizontal section reaches the target zone, a high-pressure mixture of water, sand, and chemicals is pumped into the well. This high-pressure fluid creates fractures within the shale, increasing its permeability. The sand, called proppant, keeps the fractures open, allowing oil and gas to flow more easily into the wellbore. Imagine using a high-pressure water jet to crack a hard nut, creating pathways for the nut’s contents to be extracted.

The process is carefully monitored and controlled to ensure safety and environmental protection. After the fracking fluid is pumped in, a portion is recovered, and the remaining fluid remains in the formation.

Q 3. What are the key factors influencing reservoir pressure?

Reservoir pressure is the pressure exerted by the fluids (oil, gas, and water) within a reservoir. Several key factors influence it:

- Hydrostatic pressure: The pressure exerted by the weight of the overlying fluids and rock column. Deeper reservoirs have higher hydrostatic pressure.

- Pore pressure: The pressure within the pore spaces of the reservoir rock. It can be less than, equal to, or greater than hydrostatic pressure.

- Capillary pressure: The pressure difference between the non-wetting and wetting phases (e.g., oil and water). This is significant in reservoirs with multiple fluid phases.

- Reservoir temperature: Temperature affects the density and viscosity of fluids, influencing the pressure.

- Reservoir geometry and size: The shape and size of the reservoir impact the pressure distribution.

- Production history: As oil and gas are extracted, the reservoir pressure declines.

Understanding these factors is crucial for accurate reservoir simulation and production forecasting.

Q 4. Explain the concept of Darcy’s Law and its application in reservoir engineering.

Darcy’s Law is an empirical relationship that describes the flow of fluids through porous media. It states that the volumetric flow rate (Q) of a fluid through a porous medium is directly proportional to the hydraulic gradient (Δh/L) and the cross-sectional area (A) and inversely proportional to the fluid viscosity (μ) and the permeability (k) of the medium.

The formula is expressed as: Q = -kA(Δh/μL)

Where:

- Q = Volumetric flow rate

- k = Permeability

- A = Cross-sectional area

- Δh = Pressure difference

- μ = Dynamic viscosity

- L = Length of flow path

Application in Reservoir Engineering: Darcy’s Law is fundamental to reservoir simulation. It helps predict fluid flow patterns in the reservoir during production, assess the productivity of a well, and optimize reservoir management strategies. For example, by knowing the permeability of a reservoir, we can predict how quickly oil will flow towards a wellbore.

Q 5. How do you determine the porosity and permeability of a reservoir rock?

Porosity and permeability are crucial reservoir rock properties that determine how much hydrocarbon a reservoir can hold and how easily it can be extracted. These properties are determined using laboratory core analysis and well logging techniques.

- Porosity: The ratio of the volume of void spaces (pores) in a rock to its total volume. It represents the storage capacity of the reservoir. It is typically expressed as a percentage. Laboratory methods involve measuring the volume of a rock sample and then saturating it with a fluid to determine the pore volume.

- Permeability: A measure of how easily fluids can flow through the rock. It’s influenced by the size, shape, and interconnectedness of the pore spaces. It is measured in Darcy or millidarcy. Laboratory measurements involve using techniques like gas permeametry, where gas is passed through a core sample under controlled pressure, measuring the flow rate to determine permeability.

Well logging provides in-situ measurements of porosity and permeability, complementing lab measurements. Techniques like nuclear magnetic resonance (NMR) logging provide detailed pore size distribution, which is useful in understanding fluid flow characteristics.

Q 6. Describe different types of drilling fluids and their functions.

Drilling fluids, also known as mud, are crucial in drilling operations. They serve several vital functions:

- Water-based muds: The most common type, consisting of water, clay, and various additives. They are relatively inexpensive but may not be suitable for all formations.

- Oil-based muds: Utilize oil as the continuous phase, offering better lubricity and shale stability. They are more expensive and pose greater environmental concerns.

- Synthetic-based muds: Employ synthetic oils instead of mineral oils, providing similar benefits to oil-based muds with reduced environmental impact.

Functions of Drilling Fluids:

- Lubrication and cooling: Reduce friction between the drill bit and the wellbore.

- Carrying cuttings: Transport rock cuttings from the wellbore to the surface.

- Controlling wellbore pressure: Prevent formation fluids from entering the wellbore.

- Shale inhibition: Prevent swelling and sloughing of shale formations.

- Maintaining wellbore stability: Prevent collapse of the wellbore.

The choice of drilling fluid depends on the geological conditions, environmental considerations, and drilling parameters.

Q 7. What are the challenges associated with drilling in deepwater environments?

Drilling in deepwater environments presents several significant challenges:

- High pressure and high temperature (HPHT): Deepwater reservoirs often experience extreme conditions, requiring specialized equipment and drilling fluids.

- Water depth and remoteness: Access to deepwater locations is challenging, demanding specialized vessels and logistics.

- Environmental concerns: Protecting the marine ecosystem is paramount, necessitating strict regulations and safety measures.

- Complex geological formations: Deepwater reservoirs can have complex geological structures, making drilling and well completion more difficult.

- Cost and logistics: Deepwater drilling is exceptionally expensive, involving sophisticated technology and significant logistical planning.

- Severe weather conditions: Deepwater operations are susceptible to hurricanes and other severe weather events, requiring careful planning and potential evacuation procedures.

Overcoming these challenges requires advanced technology, rigorous safety protocols, and skilled personnel. Successful deepwater drilling necessitates meticulous planning and execution, and specialized equipment like dynamic positioning systems and riser systems are essential for maintaining operational integrity.

Q 8. Explain the concept of well testing and its importance.

Well testing is a crucial process in oil and gas exploration and production. It involves systematically measuring the pressure, flow rate, and other properties of a reservoir to determine its productivity and properties. Think of it like a doctor performing tests to assess the health of a patient; well testing helps us understand the health and potential of a reservoir.

Its importance lies in providing critical data for several key decisions:

- Reservoir characterization: Well testing helps determine reservoir pressure, permeability, and fluid properties, which are crucial for accurate reservoir modeling and production forecasting.

- Production optimization: The data obtained helps engineers design optimal production strategies, including choosing appropriate artificial lift methods and well completion designs to maximize hydrocarbon recovery.

- Economic evaluation: Accurate well test data provides a more reliable basis for assessing the economic viability of a reservoir.

- Reservoir management: Ongoing well testing throughout the production lifecycle monitors reservoir performance, helping to identify and address issues like water or gas coning that may reduce production.

For instance, a pressure buildup test helps determine the reservoir’s permeability and the skin factor (a measure of near-wellbore damage). This information directly impacts the design of the well completion and future production planning.

Q 9. Describe different well completion methods.

Well completion is the process of preparing a well for production after drilling. The choice of method depends heavily on the reservoir characteristics (e.g., pressure, temperature, and fluid properties) and the well’s expected production rate. Common methods include:

- Openhole completion: The simplest method, where the wellbore is left open to the reservoir. Suitable for high-permeability reservoirs with strong formation stability. Think of it as simply leaving a hole in the ground to let the hydrocarbons flow.

- Cased and perforated completion: A steel casing is cemented into the wellbore, and perforations are created at desired intervals to allow hydrocarbon flow. This offers better zonal control and protection against wellbore instability.

- Packed-off completion: This isolates different reservoir zones using packers (inflatable seals) within the casing, allowing for individual production control. Ideal for reservoirs with multiple layers of varying pressure and permeability.

- Gravel-pack completion: A layer of gravel is placed around the wellbore to prevent formation sand from entering the well and damaging equipment. This is crucial for unconsolidated formations.

- Horizontal well completion: Involves drilling a horizontal section to contact more reservoir area and improve hydrocarbon recovery. These often incorporate multiple perforations and may utilize other methods such as multilateral wells (branching from a main horizontal bore).

The selection of the optimal completion method is a critical engineering decision influencing production efficiency and reservoir longevity.

Q 10. What are the common causes of wellbore instability?

Wellbore instability refers to the tendency of a wellbore to collapse or deform during drilling or production. This can lead to significant problems, including stuck pipe, lost circulation, and ultimately, well failure. Common causes include:

- Formation pressure: High pore pressure in the reservoir can cause the formation to swell or fracture, leading to instability.

- Formation strength: Weak or fractured formations are inherently susceptible to collapse, especially under the stress of drilling and production.

- Drilling fluids: Incompatible drilling muds can cause formation swelling or shale disintegration. The mud’s density and chemical properties must be carefully selected.

- Temperature and pressure gradients: Changes in temperature and pressure can alter formation properties and contribute to instability. This is particularly prevalent in deep wells.

- Stress concentration: Changes in stress around the wellbore during drilling and production can cause fracturing or collapse.

Managing wellbore instability often involves using specialized drilling fluids, employing casing and cementing techniques, and implementing real-time monitoring of formation pressure and stress.

Q 11. How do you manage risks associated with oil and gas production?

Risk management in oil and gas production is paramount. It’s a multifaceted process involving identifying, assessing, and mitigating potential hazards. A systematic approach often involves:

- Hazard identification: This includes identifying potential risks related to equipment failure, environmental impacts, human error, geological uncertainties, and regulatory compliance.

- Risk assessment: Evaluating the likelihood and consequence of each identified hazard using techniques like fault tree analysis or HAZOP (Hazard and Operability) studies.

- Risk mitigation: Implementing strategies to reduce the likelihood or severity of hazards. This can involve using redundant equipment, developing emergency response plans, implementing safety protocols, and adopting robust quality control procedures.

- Monitoring and review: Continuously monitoring performance, reviewing risk assessments periodically, and adapting strategies as needed.

For example, using blowout preventers (BOPs) significantly mitigates the risk of a well blowout. Regular equipment inspections reduce the chance of mechanical failure. Environmental impact assessments and robust spill response plans minimize environmental risks.

Q 12. Explain the concept of artificial lift and describe different techniques.

Artificial lift is used when the reservoir pressure is insufficient to bring hydrocarbons to the surface at an economically viable rate. Several techniques exist:

- Rod pumping: A subsurface pump is driven by a surface-mounted pumping unit. This is a mature, reliable technology suitable for moderate production rates.

- Gas lift: Injecting gas into the wellbore reduces the fluid column density and improves flow. It’s effective for wells with sufficient gas availability.

- Electric submersible pumps (ESPs): These submersible pumps are placed in the wellbore and driven by electricity. ESPs offer high efficiency and are suitable for a wide range of production rates and fluid types.

- Progressive cavity pumps (PCPs): These positive displacement pumps are especially useful for viscous fluids and those containing solids.

- Hydraulic jet pumps: Use high-pressure fluid to lift hydrocarbons. Often employed in high-viscosity or high-pressure situations.

The selection of the most suitable artificial lift method depends on factors such as fluid properties, reservoir pressure, production rate, and well depth. It’s a critical decision influencing the economics and operational efficiency of a well.

Q 13. What are the different types of oil and gas pipelines and their applications?

Oil and gas pipelines are the arteries of the industry, transporting hydrocarbons vast distances from production sites to refineries and consumers. Types include:

- Gathering pipelines: Relatively small-diameter lines that collect hydrocarbons from individual wells and transport them to processing facilities. Think of them as capillaries, carrying hydrocarbons from the reservoir to larger pipelines.

- Trunk pipelines: Larger-diameter pipelines that transport large volumes of hydrocarbons over long distances. They are the major arteries of the system.

- Product pipelines: Transport refined products like gasoline and diesel from refineries to distribution centers.

- Offshore pipelines: Subsea pipelines located on the seabed that transport oil and gas from offshore platforms to onshore processing facilities. These are usually more complex and expensive than onshore pipelines due to environmental concerns.

Pipeline materials include steel, which is commonly used for its strength and durability; however, other materials such as plastic or composite materials are also being used in some applications to minimize corrosion or environmental impact.

Pipeline design and operation must adhere to stringent safety and environmental regulations to prevent leaks and spills.

Q 14. Describe the process of oil and gas processing and refining.

Oil and gas processing and refining transforms raw hydrocarbons into marketable products. The process is complex and involves several stages:

- Oil and Gas Separation: Initially, oil and gas are separated at the wellhead. The gas undergoes further processing to remove impurities, while crude oil is transported to refineries.

- Gas Processing: Natural gas processing involves removing water vapor, carbon dioxide, hydrogen sulfide (a highly toxic component), and other impurities. This is crucial for safety and pipeline integrity.

- Crude Oil Refining: Refining crude oil involves a series of processes like distillation, cracking, and reforming to separate it into various products like gasoline, diesel, jet fuel, and petrochemicals. This is a complex process and different refinery configurations exist based on demand for various products.

- Product Blending: After refining, products are blended to meet specific specifications before distribution.

The entire process requires sophisticated equipment, precise control systems, and highly skilled personnel. Refineries represent a significant capital investment and are optimized for efficient processing and maximizing valuable product yields.

Q 15. Explain the significance of pressure transient analysis in reservoir characterization.

Pressure transient analysis (PTA) is a crucial technique in reservoir characterization that helps us understand the reservoir’s properties by analyzing the pressure changes in a wellbore during production or injection. Think of it like taking the well’s ‘pulse’ to diagnose its health and the surrounding reservoir’s characteristics.

By analyzing how pressure changes over time after a production or injection event, we can deduce important reservoir parameters. These parameters include:

- Porosity: The percentage of void space in the rock, indicating how much fluid it can hold.

- Permeability: The rock’s ability to transmit fluids, essential for determining flow rates.

- Skin factor: A measure of near-wellbore damage or stimulation, affecting productivity.

- Reservoir pressure: The initial pressure within the reservoir, vital for understanding resource potential.

For example, a rapid pressure decline might indicate high permeability, while a slower decline might suggest lower permeability. We use specialized software and mathematical models to interpret the pressure data and extract these parameters. This information is then integrated with other geological and geophysical data to build a comprehensive reservoir model for production planning and optimization.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental concerns associated with oil and gas exploration and production?

Oil and gas exploration and production present several significant environmental concerns. These activities can impact the environment at various stages, from exploration to production and even decommissioning.

- Greenhouse gas emissions: The burning of fossil fuels releases greenhouse gases (GHGs) like carbon dioxide (CO2) and methane (CH4), contributing to climate change. Methane leaks during production are particularly problematic due to its high global warming potential.

- Water pollution: Spills, leaks, and produced water (water brought up with the oil and gas) can contaminate surface and groundwater sources, impacting aquatic life and potentially human health. Proper management of produced water is critical.

- Habitat disruption: Seismic surveys, drilling, and pipeline construction can damage habitats and ecosystems, affecting wildlife and biodiversity. Careful site selection and mitigation measures are crucial.

- Air pollution: Flaring (burning excess gas) and venting release pollutants into the atmosphere, impacting air quality and potentially human health.

- Waste management: The industry generates significant amounts of waste, including drilling muds, cuttings, and produced water, which needs proper disposal or recycling to minimize environmental impacts.

Minimizing these impacts requires stringent environmental regulations, advanced technologies (like carbon capture and storage), and a commitment to sustainable practices throughout the entire lifecycle of an oil and gas project.

Q 17. How do you ensure compliance with HSE regulations in oil and gas operations?

Ensuring compliance with Health, Safety, and Environment (HSE) regulations is paramount in oil and gas operations. It’s not just a matter of legal compliance, but a fundamental commitment to protecting human life and the environment.

Our approach involves a multi-layered strategy:

- Robust HSE Management System: Implementing a comprehensive system based on international standards (e.g., ISO 14001 for environmental management) and industry best practices.

- Risk Assessment and Mitigation: Regularly identifying and assessing potential hazards, developing control measures, and implementing emergency response plans. This often involves using HAZOP (Hazard and Operability Study) and bow-tie analysis methods.

- Training and Competency Assurance: Providing comprehensive training to all personnel on HSE procedures and emergency response, ensuring everyone is competent to perform their tasks safely.

- Regular Inspections and Audits: Conducting routine inspections and internal/external audits to monitor compliance with regulations and identify areas for improvement.

- Incident Reporting and Investigation: Establishing a clear system for reporting and investigating all incidents, near misses, and accidents to identify root causes and prevent recurrence. This often involves thorough root cause analysis.

- Emergency Response Planning and Drills: Developing comprehensive emergency response plans and conducting regular drills to ensure personnel are prepared to handle emergencies effectively.

- Stakeholder Engagement: Engaging with local communities and regulatory bodies to build trust and ensure transparent communication about HSE performance.

Ultimately, a strong HSE culture is essential—one where safety is prioritized above all else and every employee feels empowered to raise concerns and stop unsafe work practices.

Q 18. Describe the different methods for reservoir simulation.

Reservoir simulation is a powerful tool used to predict the performance of oil and gas reservoirs under various operating conditions. It involves using mathematical models to represent the complex physical processes within the reservoir, allowing us to optimize production strategies and make informed decisions about field development.

There are several methods for reservoir simulation, broadly categorized as:

- Analytical models: These are simpler models that use mathematical equations to represent reservoir behavior. They are useful for initial assessments and quick estimations but often lack the detail of numerical models.

- Numerical models: These are more complex models that divide the reservoir into a grid of cells and solve equations numerically for each cell. They can capture more detail about reservoir heterogeneity and complex flow patterns. Common methods include:

- Finite difference method: Approximates the solution by dividing the reservoir into a grid and solving the equations at each grid point.

- Finite element method: Divides the reservoir into elements with different shapes and sizes, allowing for better representation of complex geometries.

- Finite volume method: Conserves mass, momentum, and energy within each control volume, making it suitable for complex flow simulations.

The choice of method depends on the complexity of the reservoir, the available data, and the desired level of accuracy. For instance, a simple reservoir might be adequately modeled using an analytical model, while a complex fractured reservoir would require a more sophisticated numerical model.

Q 19. Explain the concept of production optimization.

Production optimization aims to maximize the recovery of hydrocarbons from a reservoir while minimizing operational costs and environmental impact. It’s a continuous process of monitoring, analyzing, and adjusting production parameters to achieve the best possible results.

This involves:

- Real-time monitoring: Using sensors and data analytics to track production rates, pressures, and other key parameters in real-time.

- Data analysis: Analyzing production data to identify bottlenecks and areas for improvement.

- Reservoir simulation: Using reservoir simulation models to predict the effects of different operating strategies on production.

- Well testing and intervention: Performing well tests to evaluate reservoir performance and carrying out well interventions (such as stimulation or workovers) to improve productivity.

- Artificial lift optimization: Optimizing artificial lift systems (such as pumps or gas lift) to enhance fluid flow from the well.

- Production allocation optimization: Optimizing production from multiple wells to maximize overall field production.

Imagine it like managing a complex symphony orchestra: each instrument (well) needs to be tuned and played in harmony to create the best overall performance. Production optimization is the conductor ensuring everything works together efficiently and effectively.

Q 20. What are the challenges associated with enhanced oil recovery techniques?

Enhanced oil recovery (EOR) techniques aim to increase the amount of oil that can be extracted from a reservoir beyond what’s achievable with primary and secondary recovery methods. While offering significant potential, EOR presents several challenges:

- High costs: EOR methods, such as chemical injection or thermal recovery, are often capital-intensive, requiring substantial upfront investments.

- Technological complexity: Implementing EOR techniques requires specialized expertise and advanced technology, presenting operational challenges.

- Reservoir heterogeneity: EOR methods’ effectiveness can be significantly impacted by the reservoir’s heterogeneity, making it difficult to predict their performance in complex reservoirs.

- Environmental concerns: Some EOR techniques, particularly those involving chemical injection, can raise environmental concerns related to water pollution and waste disposal.

- Scalability: Scaling up EOR projects to larger fields can be challenging, requiring significant logistical and operational expertise.

- Uncertainty in performance prediction: Predicting the performance of EOR methods accurately can be difficult due to the complex interactions between the injected fluids and the reservoir rock.

Addressing these challenges requires careful reservoir characterization, robust project planning, advanced technology, and a strong focus on risk management.

Q 21. Describe the role of seismic interpretation in hydrocarbon exploration.

Seismic interpretation plays a vital role in hydrocarbon exploration by providing a subsurface image of the geological formations. Think of it as a 3D ultrasound of the Earth, revealing structures that could trap oil and gas.

Seismic data is acquired by generating sound waves and measuring their reflections from subsurface layers. These reflections are processed and interpreted to create images that show the:

- Structure of the subsurface: Identifying folds, faults, and other geological structures that can trap hydrocarbons.

- Stratigraphy: Determining the layering of rocks and identifying potential reservoir rocks (porous and permeable rocks capable of holding hydrocarbons).

- Hydrocarbon indicators: Identifying indirect indicators of hydrocarbons, such as bright spots (reflecting gas), amplitude anomalies, and changes in seismic velocity.

Geophysicists and geologists work together to interpret these seismic images, integrating them with other geological and geophysical data to identify potential drilling locations. For example, a seismic section showing a faulted anticline (a fold in the rock layers shaped like an arch) with a bright spot could indicate a potential hydrocarbon trap. The interpretation process involves sophisticated software and techniques, requiring expertise in both geophysics and geology.

Q 22. Explain the different types of logging tools and their applications.

Well logging involves running various tools down a borehole to measure different properties of the formations. Think of it as giving the subsurface a thorough physical exam. There are many types, each providing valuable data:

- Resistivity Logs: Measure the ability of the formation to conduct electricity. High resistivity usually indicates hydrocarbons (oil and gas), while low resistivity suggests water. For example, the laterolog measures resistivity in a more focused way than older techniques, improving accuracy in complex formations.

- Porosity Logs: Determine the pore space within the rock, crucial for estimating the volume of hydrocarbons that can be stored. Neutron and density logs are commonly used, with neutron logs measuring hydrogen content (indicative of porosity) and density logs measuring the bulk density of the formation. A higher porosity generally means more space for hydrocarbons.

- Gamma Ray Logs: Measure the natural radioactivity of the formations. High gamma ray readings often indicate shale (clay-rich rock), while lower readings usually signify more permeable and potentially productive layers. This helps to differentiate between productive and non-productive zones.

- Acoustic Logs: Measure the speed of sound waves traveling through the formation. This is related to the rock’s properties, including porosity and lithology (rock type). The information helps characterize the formation’s mechanical properties.

- Nuclear Magnetic Resonance (NMR) Logs: Provide detailed information on the pore size distribution and fluid properties within the formation. This advanced technique gives insights into the flow characteristics of the reservoir, helping to optimize production.

These logs, used individually or in combination, provide a comprehensive picture of the subsurface, guiding decisions on well completion, reservoir management, and production optimization. Imagine trying to understand a building’s internal structure without blueprints; well logs are the blueprints for subsurface exploration.

Q 23. What is the significance of well logging data in reservoir evaluation?

Well logging data is absolutely crucial for reservoir evaluation. It provides the foundation for understanding the reservoir’s characteristics and predicting its performance. Here’s why:

- Identifying Hydrocarbon Zones: Resistivity, porosity, and gamma ray logs help pinpoint zones containing hydrocarbons.

- Estimating Reservoir Properties: Porosity, permeability (ability of the rock to allow fluids to flow), and saturation (the proportion of pore space filled with hydrocarbons) are estimated using log data, essential for calculating hydrocarbon volume.

- Determining Reservoir Geometry: Logs provide information on the thickness and extent of the reservoir layers.

- Characterizing the Reservoir Rock: Lithology (rock type), clay content, and other rock properties are determined using log data, providing insight into the reservoir’s heterogeneity.

- Monitoring Reservoir Performance: Logs run over time can track changes in fluid saturation and pressure during production, allowing for optimized production strategies.

In essence, well logging data transforms raw subsurface information into a quantitative understanding of the reservoir, which guides exploration and production decisions, reducing risk and optimizing profitability. Without it, reservoir development would be akin to building a house without any plans.

Q 24. How do you interpret core data to characterize a reservoir?

Core data, obtained by physically retrieving rock samples from the wellbore, is essential for detailed reservoir characterization. Analysis of core samples provides information not always accessible through logs alone:

- Visual Description: Detailed visual examination helps identify rock types, layering, and the presence of fractures.

- Petrophysical Analysis: Measurements of porosity, permeability, and fluid saturation on core samples provide more precise data than logs, especially in complex formations.

- Fluid Analysis: Analysis of fluids extracted from the core confirms the type of hydrocarbon (oil, gas, condensate) and its properties.

- Geomechanical Analysis: Tests on core samples determine rock strength, stress state, and other geomechanical properties, crucial for wellbore stability and reservoir management.

- Geochemical Analysis: Analyzing the chemical composition of the rock and fluids can provide insights into the formation’s origin, maturation history, and hydrocarbon generation processes.

By integrating core data with well logs and seismic data, we can build a highly detailed 3D model of the reservoir, accurately predicting its behavior and optimizing production strategies. This detailed analysis is like having a high-resolution image of the reservoir compared to the general overview provided by well logs alone.

Q 25. Describe different methods for predicting reservoir performance.

Predicting reservoir performance is a crucial aspect of reservoir engineering. Several methods are employed:

- Material Balance Calculations: These calculations use basic principles of fluid flow and mass conservation to estimate reservoir pressure and hydrocarbon volumes over time.

- Numerical Reservoir Simulation: Sophisticated computer models simulate fluid flow within the reservoir, considering factors such as porosity, permeability, fluid properties, and well configurations. This allows for predicting production rates and reservoir pressure depletion under various operating scenarios.

- Decline Curve Analysis: This empirical method analyzes the historical production data to predict future production rates. Various decline curve models exist, each suitable for different reservoir types and production mechanisms.

- Analog Reservoir Studies: By comparing the reservoir under study to similar reservoirs with established production history, we can make informed predictions of its performance.

- Artificial Neural Networks (ANNs): These machine learning techniques can analyze large datasets of reservoir and production data to identify patterns and predict reservoir behavior more accurately than traditional methods.

Each method has its strengths and weaknesses. The choice of method depends on the data availability, reservoir complexity, and the desired level of accuracy. Often, a combination of methods is used to gain a more robust prediction.

Q 26. Explain the concept of water influx and its impact on reservoir production.

Water influx is the movement of water from the surrounding aquifer into the producing reservoir. It’s a common phenomenon, and its impact on reservoir production can be significant:

- Reduced Hydrocarbon Production: As water enters the reservoir, it displaces hydrocarbons, reducing the amount of oil or gas that can be extracted.

- Increased Water Cut: The proportion of water in the produced fluid increases, requiring more extensive water handling and treatment facilities.

- Reduced Reservoir Pressure: Water influx can reduce reservoir pressure, affecting the driving mechanisms for hydrocarbon production and potentially leading to premature abandonment.

- Increased Operating Costs: Dealing with increased water production increases operating costs associated with water handling and disposal.

Predicting and managing water influx is essential for optimizing reservoir production. This is often achieved by using reservoir simulation models to assess the potential for water influx and to evaluate strategies to mitigate its impact. Ignoring water influx can lead to significant economic losses and compromise the overall profitability of the project. Imagine trying to fill a bucket with water while simultaneously having another source pouring water out; that is similar to the effect water influx can have on reservoir production.

Q 27. What are the key performance indicators (KPIs) used in oil and gas production?

Key Performance Indicators (KPIs) in oil and gas production provide a concise overview of operational efficiency and profitability. Some critical KPIs include:

- Production Rate (Oil, Gas, Water): The volume of oil, gas, and water produced per unit time (e.g., barrels per day, cubic meters per day).

- Water Cut: The percentage of water in the total produced fluid.

- Operating Costs: The cost of operating the wells and facilities.

- Net Present Value (NPV): A measure of the profitability of the project, considering the time value of money.

- Return on Investment (ROI): A measure of the profitability of the project relative to the investment.

- Production Efficiency: The ratio of the actual production to the potential production of the reservoir.

- Health, Safety, and Environmental (HSE) Performance: Measures related to incidents, injuries, and environmental impacts.

- Drilling Efficiency: (Relevant during the exploration and appraisal phase) Measured by metrics such as drilling speed, rig uptime, and cost per meter drilled.

Monitoring and analyzing these KPIs provide critical feedback on operational performance and allow for timely adjustments to optimize production and enhance profitability. Regular KPI reporting is essential for effective decision-making at all levels of the organization.

Q 28. How do you handle unexpected issues during oil and gas operations?

Unexpected issues during oil and gas operations are inevitable. A robust response plan is essential for mitigating their impact. Here’s a step-by-step approach:

- Immediate Response: Prioritize safety. Ensure the well is secured and personnel are evacuated if necessary.

- Assessment: Determine the nature and extent of the issue, including the cause and potential consequences.

- Emergency Response Plan Activation: Follow established emergency procedures and protocols to address the immediate threat.

- Root Cause Analysis: Investigate the root cause of the issue to prevent recurrence. This often involves detailed data analysis and input from multiple experts.

- Corrective Actions: Implement corrective actions to address the immediate problem and prevent similar issues in the future. This may include equipment repairs, process improvements, or changes to operating procedures.

- Communication: Maintain clear and transparent communication with stakeholders (regulatory agencies, partners, and the public).

- Documentation: Thoroughly document all aspects of the event, including the root cause analysis, corrective actions, and lessons learned.

Effective handling of unexpected issues requires a proactive approach, detailed emergency response plans, highly trained personnel, and robust communication networks. It’s crucial to remember that safety should always be the top priority. Lessons learned from past incidents should inform future strategies and improve operational resilience. Each situation requires a tailored response and decision-making, making prior preparation and effective communication crucial for smooth navigation through unexpected challenges.

Key Topics to Learn for Oil and Gas Exploration and Production Interview

- Reservoir Engineering Fundamentals: Understanding reservoir properties (porosity, permeability, saturation), fluid flow mechanisms, and reservoir simulation techniques. Practical application includes predicting reservoir performance and optimizing production strategies.

- Drilling and Completion Engineering: Knowledge of drilling techniques (conventional, directional, horizontal), wellbore stability, casing design, and completion methods (perforating, fracturing). Practical application involves minimizing drilling risks and maximizing hydrocarbon recovery.

- Production Operations: Familiarity with artificial lift methods (pumping units, ESPs), flow assurance (pipeline design, hydrate prevention), and production optimization. Practical application includes maintaining efficient and safe production operations.

- Petroleum Geology: Understanding sedimentary basins, structural geology, stratigraphy, and subsurface mapping. Practical application includes identifying and characterizing potential hydrocarbon reservoirs.

- Petrophysics: Interpreting well logs (gamma ray, resistivity, porosity), evaluating reservoir properties from log data, and integrating data from different sources. Practical application involves accurate reservoir characterization and resource estimation.

- Health, Safety, and Environment (HSE): Demonstrating awareness of HSE regulations and best practices in the oil and gas industry. Practical application involves prioritizing safety in all operations and minimizing environmental impact.

- Project Management and Economics: Understanding project lifecycle, cost estimation, risk assessment, and economic evaluation of oil and gas projects. Practical application includes planning and executing projects efficiently and profitably.

- Data Analysis and Interpretation: Proficiency in using software and tools for data analysis, visualization, and interpretation. Practical application includes extracting valuable insights from large datasets to inform decision-making.

Next Steps

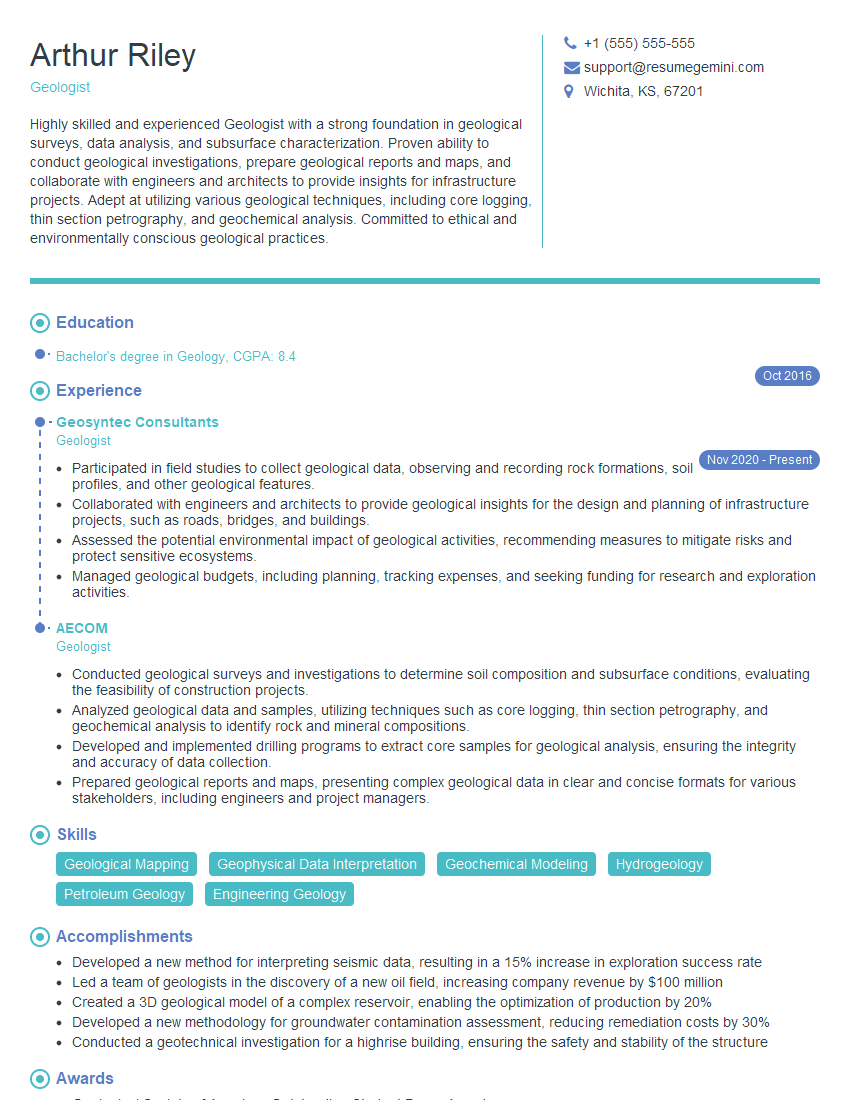

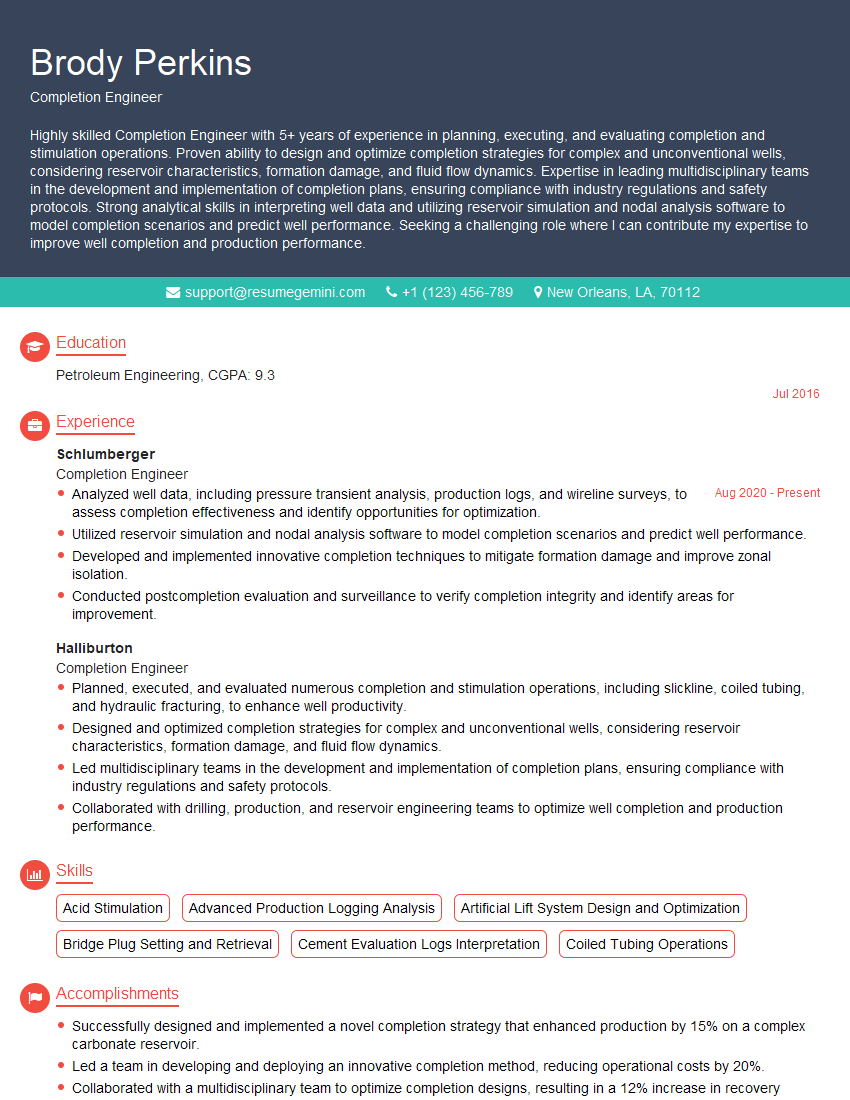

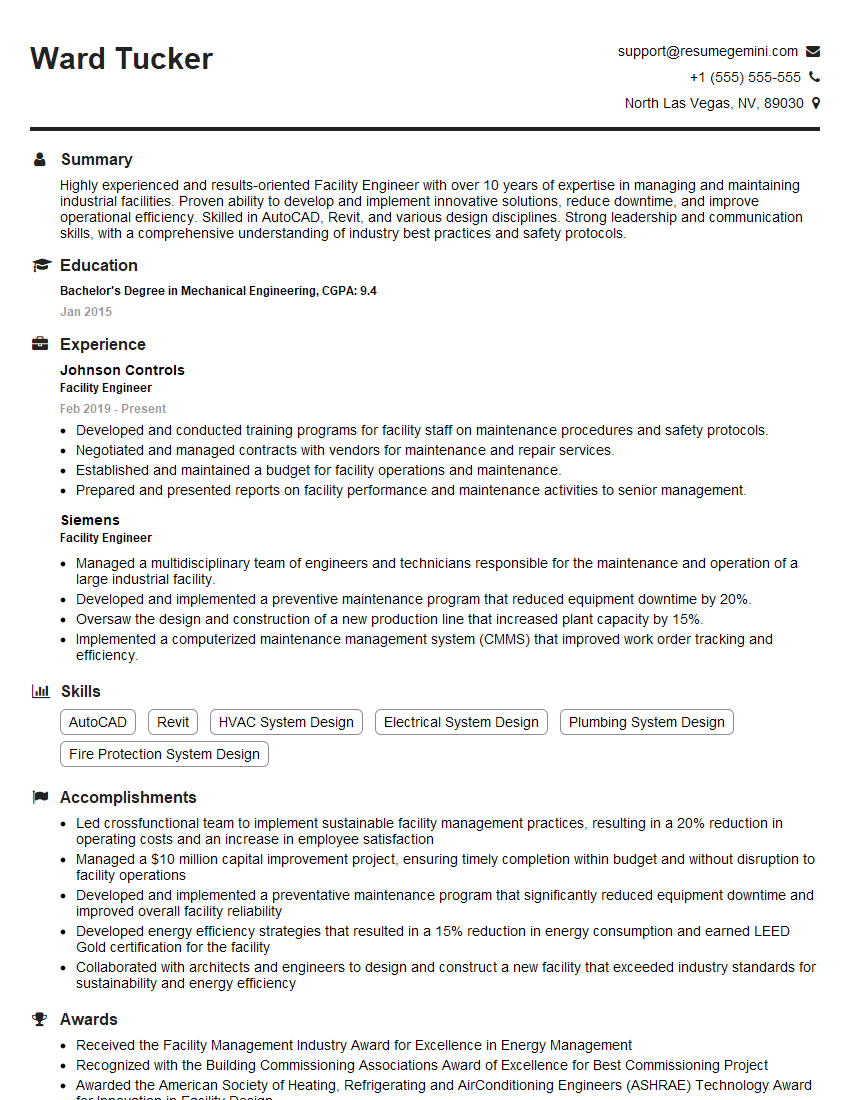

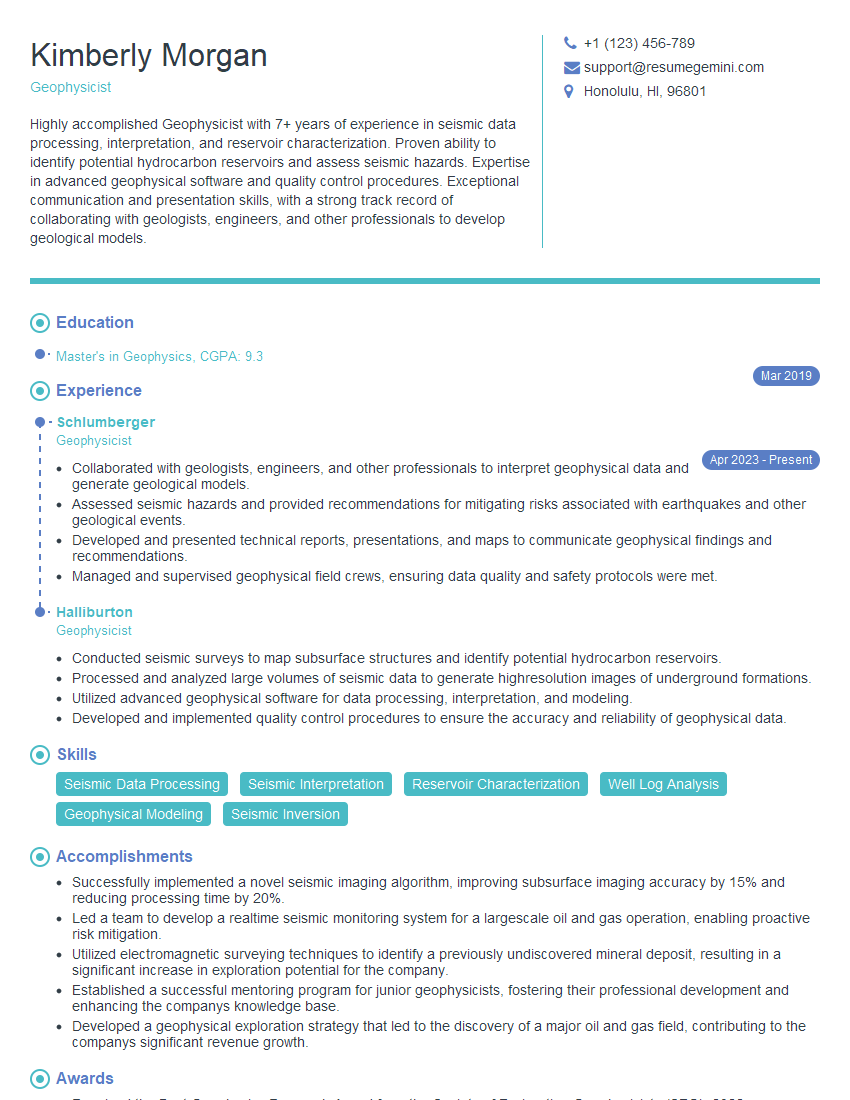

Mastering Oil and Gas Exploration and Production principles is crucial for a successful and rewarding career in this dynamic industry. A strong understanding of these concepts will significantly enhance your interview performance and open doors to exciting opportunities. To increase your chances of securing your dream role, creating a compelling and ATS-friendly resume is essential. ResumeGemini can be a valuable tool in this process, helping you craft a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to the Oil and Gas Exploration and Production sector, ensuring you present yourself in the best possible light to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO