Unlock your full potential by mastering the most common Operate Various Forklift Attachments interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Operate Various Forklift Attachments Interview

Q 1. Describe your experience operating different types of forklifts.

Throughout my career, I’ve operated a wide variety of forklifts, from the common sit-down counterbalanced units to reach trucks, order pickers, and even specialized sideloaders. My experience encompasses both gas-powered and electric models, with varying load capacities and mast heights. For instance, I spent three years operating sit-down propane forklifts in a warehouse environment, moving pallets of building materials. This required precision maneuvering in tight spaces and careful weight distribution. More recently, I’ve been utilizing reach trucks in a high-bay warehouse, requiring a different skillset focused on vertical stacking and safe operation at height. This diverse experience has given me a comprehensive understanding of the nuances of each type and their appropriate applications.

Q 2. What are the different types of forklift attachments you are familiar with?

My familiarity with forklift attachments is extensive. I’ve used many, including:

- Clamps: For handling various materials like lumber, pipes, and rolls of paper, ensuring secure gripping and safe transport.

- Carriage forks: These extend the forks’ reach, ideal for unloading long materials.

- Paper roll clamps: Specialized for handling rolls with minimal damage. I’ve used these extensively in a paper distribution center.

- Side shifters: Allow for precise lateral adjustment of the load, invaluable for aligning pallets in tight spaces.

- Rotators: Rotate loads 360 degrees, useful for orienting goods for efficient stacking or placement. I found this especially helpful in a manufacturing setting where parts needed specific orientation.

- Push-pull attachments: Useful for moving loads that might not be easily lifted by standard forks, such as large crates or bins.

The choice of attachment depends heavily on the load’s characteristics and the task at hand. Selecting the wrong attachment can compromise safety and efficiency.

Q 3. Explain the safety procedures for operating a forklift.

Safety is paramount in forklift operation. My adherence to safety procedures is unwavering. It starts with a pre-operational inspection (detailed in the next answer), followed by:

- Wearing appropriate PPE: Safety shoes, high-visibility vest, and hearing protection are always worn.

- Understanding load capacity: Never exceeding the forklift’s rated capacity is crucial and I always check the load weight before lifting.

- Safe travel and speed: Maintaining a safe speed appropriate for the conditions, avoiding sudden movements, and following established traffic patterns are vital.

- Proper load handling: Ensuring the load is securely attached and balanced to prevent tipping or falling.

- Awareness of surroundings: Constantly monitoring the environment for pedestrians, obstacles, and other equipment.

- Communication: Using horns, hand signals, and two-way radios to communicate with others, especially in congested areas.

- Following company procedures: Always adhering to specific company rules and regulations for forklift operation and safety.

One memorable incident involved a near-miss with a pedestrian. I immediately stopped, confirmed their safety, and reviewed my actions to understand what could have been done differently. This emphasized the importance of constant awareness.

Q 4. How do you inspect a forklift before operation?

Before every operation, I conduct a thorough pre-operational inspection, a critical step to prevent accidents. This involves:

- Checking fluids: Engine oil, hydraulic fluid, coolant levels—ensuring they’re within the acceptable range.

- Inspecting tires: Checking for proper inflation, wear and tear, and any damage.

- Examining the brakes: Testing responsiveness and ensuring they function correctly.

- Checking lights and horns: Verifying that all lights and horns are in working order for visibility and communication.

- Assessing mast and forks: Checking for any damage, cracks, or loose components.

- Inspecting the safety features: Confirming that seatbelts, horn, and other safety mechanisms are functioning properly.

- Reviewing the load capacity and stability: Ensuring the machine can safely handle the intended load.

If any issue is found, I immediately report it to the supervisor and do not operate the forklift until it is repaired.

Q 5. What are the load capacity limits for the forklifts you’ve operated?

The load capacity limits vary significantly depending on the forklift type. I’ve operated forklifts with capacities ranging from 3,000 lbs to 15,000 lbs. For instance, a standard counterbalanced forklift I frequently used had a 5,000 lb capacity, while a reach truck I used in a warehouse had a 4,000 lb capacity. I always check the forklift’s data plate for the exact capacity before starting any operation and never exceed this limit. Overloading is a major safety hazard.

Q 6. How do you handle different load types and weights using various attachments?

Handling diverse loads and weights efficiently and safely requires careful consideration. The choice of attachment is critical. For instance:

- Pallets of varying weights: A standard forklift with forks is sufficient, ensuring the weight is evenly distributed and within the capacity limits. I would use a side shifter for precise placement.

- Long, unwieldy materials: Carriage forks extend the reach, while clamps provide secure handling of bundles of lumber or pipes.

- Rolls of paper or other cylindrical objects: Paper roll clamps are essential, preventing damage and ensuring stability during transport.

- Heavy, oddly shaped loads: Specialty attachments or multiple forklifts might be required for safe handling. In such cases, a thorough risk assessment should be conducted first.

Regardless of the attachment or load type, I always prioritize safety and ensure the load is properly secured and balanced before lifting or moving.

Q 7. Describe your experience with pallet jacks and other manual material handling equipment.

My experience extends beyond forklifts to encompass various manual material handling equipment. I’m proficient in operating pallet jacks, both manual and electric. I understand the importance of proper technique to avoid strains or injuries. I’ve also used hand trucks, dollies, and even conveyor systems to move materials. This experience is valuable, as it provides a broader understanding of material handling processes and enhances the ability to select the most appropriate equipment for a given task. This also helps in collaborating more effectively with colleagues who might primarily use manual handling equipment.

Q 8. Explain the proper techniques for loading and unloading cargo.

Loading and unloading cargo safely and efficiently involves a systematic approach. It begins with a thorough pre-operation check of the forklift and the attached equipment, ensuring everything is in optimal working condition. Next, I assess the load – its weight, dimensions, and center of gravity – to determine the best approach. This includes understanding the load’s stability and potential shifting during transport. I would always consult the load’s documentation or markings to confirm weight limits and handling instructions.

For loading, I’d position the forklift strategically, ensuring a stable base and clear access to the loading area. I’d engage the forks smoothly and carefully, ensuring they’re positioned under the load’s center of gravity, lifting slowly and smoothly to avoid any sudden jerks or movements. During transport, I maintain a slow and controlled speed, avoiding sudden braking or acceleration. The unloading process mirrors the loading, prioritizing careful placement and consideration for the receiving area’s capacity and stability.

For example, when loading pallets onto a truck, I’d always check that the pallet is securely stacked and adequately wrapped. I’d also consider the truck’s ramp or dock height to ensure a smooth transition and avoid any potential damage to the goods or the equipment.

Q 9. How do you ensure the safety of pedestrians and other equipment operators in a warehouse environment?

Warehouse safety is paramount. My approach is proactive, emphasizing constant awareness of my surroundings and adherence to established safety protocols. This includes maintaining a safe speed, especially in areas with high pedestrian traffic. I always use audible warnings – such as the forklift’s horn – to alert pedestrians of my presence and planned movements. I avoid blind corners and intersections as much as possible. If visibility is restricted, I’d proceed with extreme caution and ask for assistance if necessary. I’m also mindful of the safe operating distance around other equipment. This involves keeping a safe and appropriate distance from other forklifts, automated guided vehicles (AGVs), and any other equipment operating in the warehouse. We regularly have safety meetings to reinforce these guidelines.

Furthermore, I always ensure that my forklift’s load is stable and secured before moving, preventing any accidental drops or spills. I meticulously follow traffic rules and designated pathways, avoiding unnecessary maneuvers that may pose risks to other personnel. I never operate a forklift without proper training or authorization and always wear appropriate safety gear like high-visibility vests and safety shoes.

Q 10. What are the common causes of forklift accidents, and how can they be prevented?

Forklift accidents stem from several common causes, including operator error, equipment malfunction, and inadequate training. Operator error includes speeding, reckless driving, operating the forklift in an unsafe manner (like carrying loads higher than the designated capacity), and poor load securing. Equipment malfunction often results from inadequate maintenance or ignoring warning signs; this can lead to sudden stops or failures in the hydraulic system.

Preventing these accidents requires a multi-pronged approach: comprehensive training programs that emphasize safety awareness and proper operating procedures, regular equipment inspections and maintenance schedules to catch potential problems early, and strict adherence to safety regulations and policies. Furthermore, a robust reporting system for near-miss incidents enables us to proactively address potential hazards and prevent future accidents. For example, a thorough pre-shift inspection would immediately reveal hydraulic fluid leaks and prevent potential failures and accidents. Regular training keeps operators up-to-date on latest safety procedures.

Q 11. How do you maintain a safe working distance from other equipment and personnel?

Maintaining a safe working distance from other equipment and personnel is crucial. I always follow the established traffic rules and designated pathways within the warehouse. I never cut corners or make sudden movements. I am observant and predict others’ movements to avoid collision. Before making any turns, I always check my blind spots, making sure it’s clear. If visibility is poor, I proceed at significantly reduced speed.

Specific distances vary depending on the situation, but a good rule of thumb is to maintain at least several feet of distance from other equipment and a greater distance in areas with higher traffic density. For example, when approaching an intersection or narrow aisle, I slow down and carefully assess my surroundings before proceeding. When operating near pedestrians, I always sound the horn to warn them, proceeding only when assured that they are aware of my presence. Communication is key.

Q 12. Describe your experience with radio frequency (RF) scanners and warehouse management systems (WMS).

I have extensive experience utilizing radio frequency (RF) scanners and warehouse management systems (WMS). RF scanners streamline the process of tracking and managing inventory, enabling quick and accurate data entry. I use them for receiving shipments, verifying inventory, and locating goods within the warehouse. The data collected is instantly updated to the WMS, providing real-time visibility into the warehouse’s inventory levels and location of goods.

The WMS provides a centralized platform for managing all aspects of the warehouse operation, from receiving and putaway to picking, packing, and shipping. I use the WMS to locate items efficiently by accessing its guided instructions and directions; it helps me optimize picking routes and improves overall efficiency. This integrated system enhances accuracy and efficiency, improving productivity and reducing errors significantly. For instance, using the WMS, I can easily locate a specific pallet, verify its contents, and generate shipping labels automatically.

Q 13. How do you handle damaged goods or equipment?

Handling damaged goods or equipment involves several steps, beginning with proper documentation. I immediately report the damage to my supervisor, providing detailed information about the extent of the damage, including photos and notes on potential causes (if possible). This documentation is crucial for insurance claims and internal investigations. I then follow the company’s established procedures for handling damaged goods and equipment, which usually involves segregating them from undamaged items to prevent further damage or contamination.

Depending on the type and extent of the damage, the goods might be repaired, discarded, or returned to the supplier. For example, if a pallet is slightly damaged, it might be repaired; however, significantly damaged goods or equipment would be disposed of following safety protocols and relevant environmental regulations. The WMS plays a crucial role here too, ensuring that the damaged items are accurately recorded and removed from the active inventory.

Q 14. What is your experience with different types of forklifts (e.g., sit-down, stand-up, reach truck)?

My experience encompasses various forklift types, including sit-down counterbalance forklifts, stand-up reach trucks, and order pickers. Sit-down counterbalance forklifts are ideal for heavy-duty tasks and provide excellent stability for larger loads. Stand-up reach trucks offer maneuverability in tight spaces and are suitable for higher racking operations, while order pickers are perfect for picking items from multiple levels in warehouses. I am proficient in operating each type, understanding their strengths and limitations. My experience includes operating different makes and models, adapting to varying control systems and safety features.

This diverse experience allows me to choose the most appropriate forklift for a given task. For instance, for transporting heavy pallets across a large warehouse, I’d choose a sit-down counterbalance forklift; conversely, for picking smaller items from high shelves, I would opt for a stand-up reach truck. This ensures the work is carried out efficiently and safely.

Q 15. How do you manage challenging situations, such as narrow aisles or limited visibility?

Navigating narrow aisles and operating in low-visibility conditions requires a combination of skill, caution, and awareness. It’s not just about maneuvering the forklift; it’s about anticipating potential hazards.

- Slow and Steady Wins the Race: Speed is the enemy in tight spaces. I always reduce my speed significantly, focusing on precise control. Jerky movements are a recipe for disaster.

- Strategic Positioning: Before even starting a maneuver, I carefully assess the aisle’s width, identifying potential obstructions like racking, support columns, or other equipment. I plan my route meticulously, ensuring I have enough clearance on either side.

- Spotter Assistance: In situations with extremely limited visibility, such as loading docks at night, I always request a spotter. A second pair of eyes can significantly reduce the risk of accidents. Clear communication is paramount – using hand signals or radios to coordinate movements.

- Horn Usage: I utilize the horn frequently to alert pedestrians and other workers to my presence, especially around blind corners or in areas with significant foot traffic. A gentle tap can be as effective as a loud blast in preventing collisions.

- Mirrors and Cameras: Modern forklifts often have excellent visibility aids. I make sure I understand how to effectively use these, adjusting mirrors to optimize my view.

For example, once I had to move a pallet of fragile items down a particularly narrow aisle in a warehouse. By slowing down and using my mirrors effectively, I navigated the tight space without incident. The job would have been far more risky and potentially damaging without careful planning and cautious execution.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with load stabilization techniques.

Load stabilization is critical for safety and preventing damage. It’s not just about picking up and putting down a load; it’s about ensuring it stays secure throughout the entire process.

- Proper Load Centering: The weight should be evenly distributed across the forks. Off-center loads can lead to instability and tipping. I always visually check and if necessary adjust the load to be centered before lifting.

- Secure Attachment: Depending on the load type, I use appropriate attachments – clamps for bundles, rotators for awkward shapes, etc. Each attachment has specific safety procedures that I follow diligently.

- Appropriate Lifting Height: Lifting too high can lead to instability. I only lift to the height necessary for safe transport and placement.

- Smooth Movements: Sudden acceleration, deceleration, or jerky turns can cause the load to shift. I maintain a slow and steady pace when moving a load.

- Load Weight Awareness: I always check the load weight to ensure it’s within the forklift’s capacity. Overloading is a major safety hazard.

Imagine transporting a stack of glass sheets. Without proper load centering and slow, controlled movements, the stack could easily shift and break, causing potential damage and injury. My experience ensures I avoid such scenarios by prioritizing safety and precision.

Q 17. How do you handle emergency situations, such as equipment malfunctions or accidents?

Emergency situations demand quick thinking and decisive action. My training emphasizes preparedness and the importance of following established procedures.

- Equipment Malfunctions: If I notice a malfunction, such as hydraulic leaks, strange noises, or steering problems, I immediately shut down the forklift and report the issue to my supervisor. I never attempt to operate a malfunctioning forklift.

- Accidents: In case of an accident, my first priority is to ensure the safety of all involved. I secure the area, assess injuries, and call emergency services if needed. I then follow company protocols to report the accident, providing a detailed account of the events.

- Fire Safety: I am familiar with the location of fire extinguishers and evacuation routes. I know how to use a fire extinguisher and follow company procedures in case of fire.

- First Aid: I have basic first aid training and am prepared to offer immediate assistance to those injured until professional help arrives.

For instance, I once experienced a sudden hydraulic failure while lifting a heavy pallet. I immediately shut down the machine, preventing a potential accident. A swift response is crucial in these scenarios.

Q 18. What is your experience with preventative maintenance procedures for forklifts?

Preventative maintenance is crucial for ensuring forklift safety and longevity. My experience encompasses a comprehensive approach to keeping equipment in top condition.

- Daily Inspections: Before each shift, I perform a thorough visual inspection, checking for leaks, tire pressure, fluid levels, and any signs of damage or wear and tear. I meticulously document my findings.

- Scheduled Maintenance: I am aware of and adhere to the company’s scheduled maintenance program. This involves regular servicing, including oil changes, filter replacements, and component checks.

- Battery Care (for electric forklifts): For electric forklifts, I’m proficient in proper battery charging and maintenance procedures. This includes ensuring proper ventilation and checking for signs of damage.

- Reporting Issues: I promptly report any problems or anomalies discovered during inspections to my supervisor. Early detection of problems can prevent larger, more costly issues down the line.

For example, I regularly check the condition of the forks, ensuring they are free from cracks or bending, because damaged forks could lead to load instability and accidents. Preventative maintenance is an investment in safety.

Q 19. How familiar are you with OSHA regulations related to forklift operation?

I am very familiar with OSHA regulations concerning forklift operation. Safety is my utmost priority, and I ensure all my actions comply with these regulations.

- Operator Training and Certification: I hold the necessary certifications and have completed all required safety training. I understand the implications of operating a forklift without proper training.

- Pre-Operational Inspection: I am fully aware of the pre-operational inspection requirements and conduct thorough checks before each use, documenting any issues.

- Load Capacity Limits: I strictly adhere to the forklift’s load capacity limits, never exceeding the recommended weight. I understand the potential consequences of overloading.

- Safe Operating Procedures: I follow all safe operating procedures, including speed limits, appropriate travel routes, and safe handling techniques.

- Personal Protective Equipment (PPE): I always wear the required PPE, including safety glasses, gloves, and steel-toed boots.

OSHA regulations are not just rules, they are safety guidelines, and I am committed to their thorough implementation for my own safety and the safety of those around me.

Q 20. Describe your experience with different types of forklift attachments (e.g., clamps, side-shifters, rotators).

My experience includes operating forklifts with various attachments, each designed for specific tasks. Understanding their unique features and limitations is essential for safety and efficiency.

- Clamps: I have extensive experience using clamps for handling various materials like paper, lumber, and other bundled goods. I know how to adjust the clamp’s width and pressure to securely hold the load.

- Side-Shifters: Side-shifters allow for precise lateral movement of the forks, which is incredibly helpful when placing pallets in tight spaces or aligning loads accurately. I’m skilled in their safe and efficient operation.

- Rotators: Rotators allow for the rotation of the load, useful for handling long items or materials requiring specific orientations. I understand how to properly secure the load during rotation to avoid tipping or damage.

- Carriage Movers: I am also familiar with Carriage Movers which helps adjust the position of the forks independently. This can be helpful for handling different sized pallets or materials.

- Other Attachments: Depending on the facility or job site, other attachments might include forks extensions, fork positioners, and others, each with their own operational nuances.

For instance, using a side-shifter allowed me to efficiently load a container in a very narrow space, a task that would have been extremely challenging, if not impossible, without it.

Q 21. How do you select the appropriate attachment for a given task?

Selecting the right attachment is crucial for efficient and safe operation. It depends entirely on the characteristics of the load and the task at hand.

- Load Type: The type of material being handled (e.g., paper rolls, steel coils, lumber) dictates the appropriate attachment. Some attachments are designed for specific load types and weights.

- Load Size and Shape: The dimensions and shape of the load will determine the best attachment. For example, long items might need rotators, while bundled items are best handled with clamps.

- Task Requirements: The specific task, such as stacking, transporting, or placing the load, will also influence the attachment choice. Some attachments optimize for specific placement configurations.

- Forklift Compatibility: It is critical to ensure the selected attachment is compatible with the forklift’s specifications and capacity.

For example, when handling large rolls of carpet, I’d opt for paper roll clamps to avoid damage and ensure stability. But when moving heavy steel coils, I’d use a coil clamp, designed specifically for that task and material. The wrong attachment could lead to accidents or product damage.

Q 22. Explain the proper techniques for attaching and detaching forklift attachments.

Attaching and detaching forklift attachments safely and efficiently is crucial for productivity and safety. The process generally involves several key steps, and these steps vary slightly depending on the specific attachment and forklift model. Always consult the manufacturer’s manual for precise instructions.

- Pre-Attachment Checks: Before anything, inspect both the attachment and the forklift’s carriage for damage, ensuring all pins, levers, and hydraulic connections are in good working order.

- Secure Attachment: Carefully position the attachment on the carriage, ensuring proper alignment with the mounting points. Use the appropriate lifting mechanism (hydraulic or manual) to raise the attachment into place. This often involves securing pins or locking mechanisms.

- Hydraulic Connections: If the attachment requires hydraulics, connect the lines carefully, ensuring a tight and leak-free seal. Never force connections.

- Testing and Verification: Once attached, test the attachment’s functionality gently before engaging in any heavy lifting. Verify the hydraulic functions and the stability of the attachment.

- Safe Detachment: Lower the attachment completely to the ground. Disconnect any hydraulic lines carefully. Securely detach any pins or locking mechanisms. Inspect the attachment and carriage for any signs of damage before storing.

Example: Attaching a clamp attachment might involve aligning the clamp’s forks with the carriage’s forks, inserting locking pins, and then activating the hydraulics to ensure the clamp is securely mounted and functional.

Q 23. How do you ensure the stability of a load when using different attachments?

Load stability is paramount when using forklift attachments. Maintaining stability prevents accidents, damage to goods, and injuries. Several techniques contribute to a stable load:

- Proper Load Centering: The load center is the point where the weight of the load is evenly distributed. Keeping the load center close to the forklift’s mast ensures stability and prevents tipping. This is crucial and is covered in detail in question 5.

- Attachment Selection: Choosing the right attachment for the job is critical. Using a pallet fork for small, irregularly shaped items is inefficient and potentially dangerous. The correct attachment will allow for better load distribution.

- Load Securing: Many attachments offer ways to secure the load, like straps, chains or netting. These prevent shifting during transport.

- Smooth Operation: Avoid jerky movements. Accelerate and decelerate slowly. This prevents the load from shifting and helps maintain stability.

- Load Weight Limits: Never exceed the rated capacity of the forklift or attachment. Overloading is a major cause of accidents.

Example: When using a side shifter attachment, carefully adjust the load position to keep the center of gravity balanced over the forklift’s wheels. This prevents a dangerous situation where the weight might swing out beyond the forklift’s base.

Q 24. What is your experience with working in different warehouse environments (e.g., cold storage, freezer)?

I’ve had extensive experience working in diverse warehouse environments, including cold storage and freezer facilities. Working in these conditions demands specific precautions and adjustments to standard operating procedures.

- Cold Storage: In cold storage environments (e.g., around 40°F), I’ve adapted to wearing appropriate cold weather gear to avoid hypothermia, and I’m aware of how cold temperatures can affect the forklift’s battery and hydraulic systems, requiring more frequent checks.

- Freezer Facilities: Working in freezers (-10°F to 0°F) requires even more stringent safety protocols. This includes shorter work intervals and regular breaks to prevent frostbite, wearing appropriate protective clothing, and carefully monitoring the forklift’s performance, as extreme cold can severely impact battery life and hydraulic fluid viscosity.

- Other Environments: My experience extends to standard ambient temperature warehouses as well, demonstrating adaptability and proficiency across different environments.

In all environments, safety is the top priority. I maintain a strong awareness of potential hazards unique to each setting. This includes potential for slippery floors and ice formation in cold storage areas.

Q 25. How do you prioritize tasks and manage your time effectively in a busy warehouse environment?

Prioritizing tasks and managing time effectively in a busy warehouse is essential for maximizing efficiency. I use a combination of strategies:

- Prioritization Matrix: I use a simple matrix to categorize tasks by urgency and importance. Urgent and important tasks are addressed immediately, followed by important but non-urgent tasks, and then less critical ones.

- Route Optimization: I plan my routes efficiently to minimize travel time and maximize the number of tasks completed within a given timeframe. This might include grouping similar tasks together in a specific area of the warehouse.

- Communication: I communicate regularly with supervisors and colleagues to ensure that all tasks are properly assigned and prioritized, and any unexpected issues or delays are addressed promptly.

- Time Tracking: I track my progress throughout the day, which helps to identify potential bottlenecks and areas where I might be able to improve my efficiency.

Example: If an urgent order needs to be shipped, I’ll prioritize that task over other non-urgent movements. This ensures meeting deadlines and customer expectations.

Q 26. What is your understanding of load center and its importance?

The load center is the point at which the weight of a load is evenly distributed. It’s crucial for forklift safety and stability. Think of it as the balance point of the load.

Importance: If the load center is too far forward or backward, the load can shift, causing the forklift to become unstable and potentially tip over. This is especially important when dealing with uneven loads or high centers of gravity.

Determining Load Center: The load center isn’t always obvious and sometimes requires calculation, especially with unusual or asymmetric loads. Manufacturers provide load center information for standard pallets. For other loads, it might need to be estimated based on weight and dimensions.

Practical Application: Maintaining a balanced load center involves carefully positioning loads on the forks, avoiding overloading, and using attachments designed for the specific type of load. Using a load leveler attachment or side-shifter can help adjust the load’s position to achieve a proper load center.

Q 27. Describe a time you had to troubleshoot a forklift issue. What was the problem, and how did you resolve it?

During a busy shift, I encountered an issue with a forklift’s hydraulic system. The forklift started exhibiting a slow lift and lowering action and a noticeable leak under the mast.

Troubleshooting Steps:

- Safety First: I immediately shut off the forklift and ensured the area was safe, preventing anyone from getting hurt.

- Initial Assessment: I visually inspected the hydraulic lines and cylinder for any visible damage or leaks.

- Leak Identification: I pinpointed the leak to a damaged hydraulic hose near the mast.

- Reporting and Repair: I reported the issue to my supervisor immediately and followed the company’s established procedures for reporting equipment malfunction. The malfunctioning forklift was tagged out of service and maintenance was promptly scheduled to replace the damaged hydraulic hose.

This experience highlighted the importance of regular preventative maintenance and prompt reporting of any mechanical issues to ensure both the safety and productivity of operations.

Q 28. How do you maintain accurate records of your work, such as load manifests or delivery receipts?

Maintaining accurate records is critical for accountability, inventory management, and efficient warehouse operations. I use several methods for this:

- Electronic Systems: Many warehouses employ digital systems for tracking loads, including scanners to update inventory in real-time and tablets or handheld devices for logging shipments and deliveries.

- Load Manifests and Delivery Receipts: I carefully fill out all paperwork accurately, confirming information before signing delivery receipts or confirming load manifests. I carefully inspect any paperwork to ensure accurate information.

- Data Entry: I consistently and accurately input all data into the required systems. This often includes load details, timestamps, and any relevant information regarding damage or discrepancies.

- Verification: I cross-check all information carefully, comparing paper records to digital entries to guarantee accuracy and identify any potential errors.

Accuracy is paramount. Errors in documentation can lead to costly mistakes in inventory control, accounting, and shipping.

Key Topics to Learn for Operate Various Forklift Attachments Interview

- Safe Operation Procedures: Understanding and applying all relevant safety regulations and company policies for operating forklifts and various attachments.

- Attachment Types and Applications: Knowing the function and proper use of common attachments like clamps, side-shifters, rotators, and forks for different materials and tasks (e.g., pallet handling, roll handling, drum handling).

- Pre-Operational Checks and Maintenance: Thoroughly inspecting the forklift and attachments before each use, identifying potential hazards, and performing basic maintenance checks.

- Load Stability and Center of Gravity: Calculating load weight and distribution to ensure safe and stable lifting and transportation; understanding the impact of attachment type on load stability.

- Operational Techniques: Mastering smooth and controlled movements, efficient load placement, and maneuvering in tight spaces with different attachments.

- Troubleshooting and Problem Solving: Identifying and addressing common mechanical issues with the forklift or attachments; applying problem-solving skills in various operational scenarios.

- Load Securing and Transportation: Properly securing loads using appropriate straps, chains, or other methods; understanding transportation regulations and safe handling procedures.

- Communication and Teamwork: Effective communication with supervisors, coworkers, and pedestrians in a warehouse environment; working collaboratively to ensure safe and efficient operations.

Next Steps

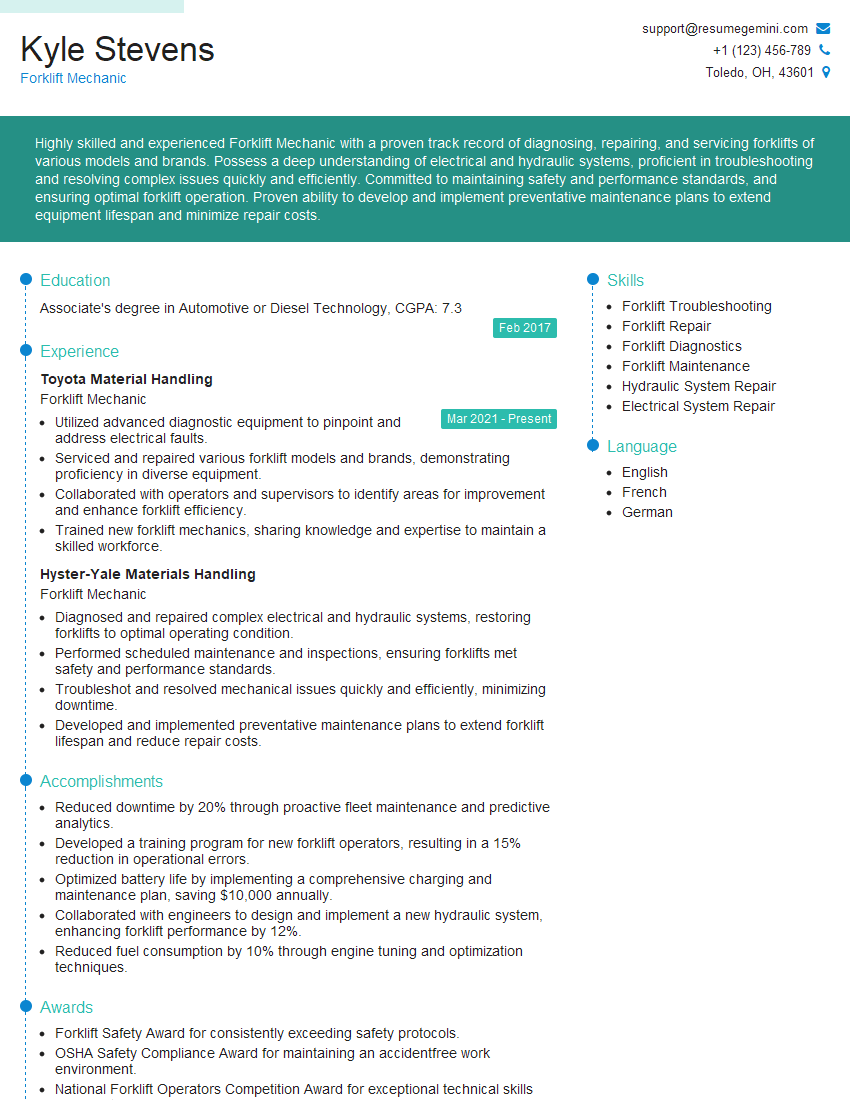

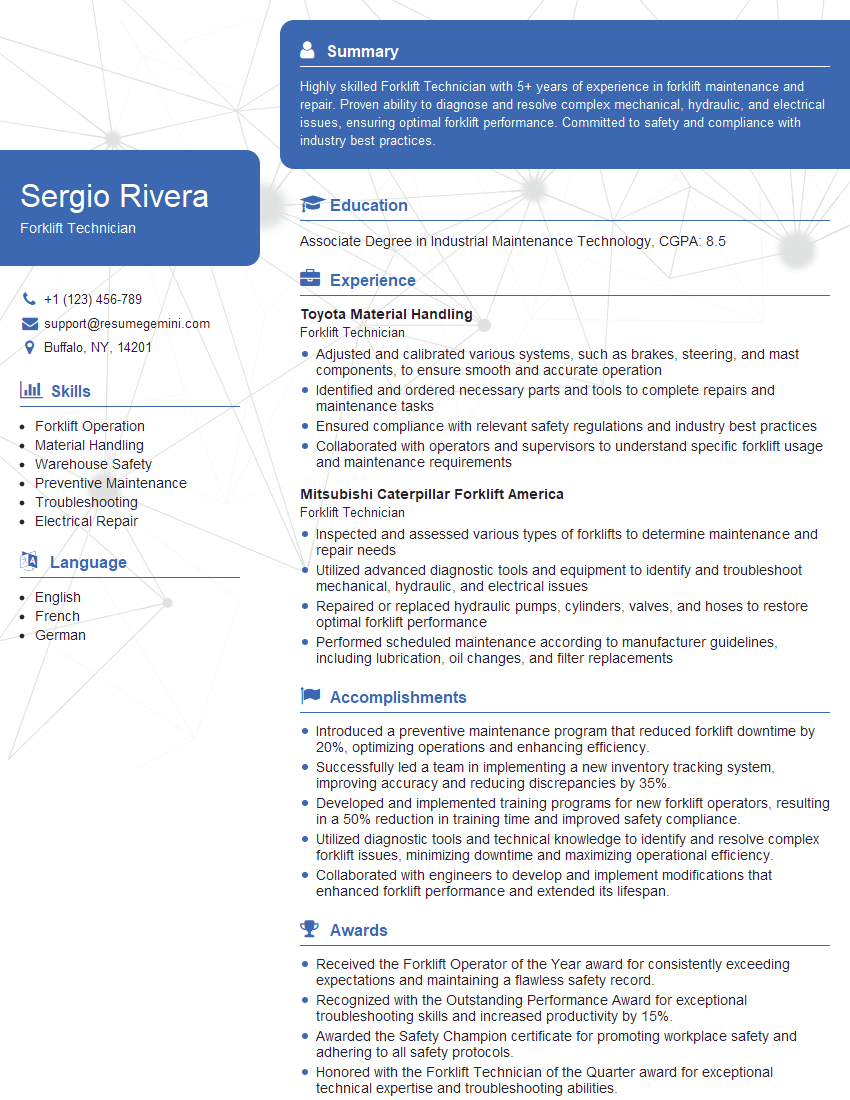

Mastering the operation of various forklift attachments significantly enhances your value to any employer in the logistics, warehousing, or manufacturing sectors, opening doors to higher-paying positions and increased responsibility. To maximize your job prospects, create a powerful and ATS-friendly resume that showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that highlights your abilities effectively. We provide examples of resumes tailored to “Operate Various Forklift Attachments” to guide you in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO