Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Operating Cranes and Winches interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Operating Cranes and Winches Interview

Q 1. Describe your experience operating different types of cranes.

My experience encompasses a wide range of crane operation, including tower cranes, mobile cranes (both hydraulic and crawler), overhead cranes, and gantry cranes. I’ve worked on construction sites, industrial plants, and port facilities, lifting and placing diverse loads, from prefabricated building sections weighing several tons to delicate machinery requiring precision placement. Operating tower cranes, for instance, requires precise control and anticipation during high-rise construction, demanding careful consideration of wind speed and load swing. Conversely, operating a mobile crane for heavy lifting requires a different skillset focusing on stability and maneuvering within confined spaces. Each crane type presents unique challenges and demands a thorough understanding of its operating characteristics and limitations.

For example, I once used a crawler crane to lift and position a massive transformer in a power plant. The terrain was uneven, necessitating careful consideration of ground conditions and crane stability. Contrast this with using an overhead crane in a factory setting, where efficiency and precision in repetitive lifting are paramount. This diverse experience has given me a comprehensive understanding of various crane types and their applications.

Q 2. Explain the different types of crane hooks and their applications.

Crane hooks are designed with specific shapes and functionalities to suit various loads and lifting situations. The most common type is the standard hook, a simple, robust design suitable for general-purpose lifting. However, other specialized hooks exist, such as:

- Grab Hooks: Used for lifting bulk materials like timber, scrap metal, or other irregularly shaped objects.

- Clevis Hooks: Feature a clevis (a U-shaped metal fitting) at the end, allowing for quick connection to shackles or other lifting devices.

- Swivel Hooks: Incorporate a swivel mechanism to prevent load twisting and wire rope damage during lifting.

- Special Purpose Hooks: Include hooks designed for specific tasks, such as those with safety latches to prevent accidental disengagement or hooks tailored to handling specific materials.

The choice of hook depends largely on the load’s characteristics. For delicate items, a soft jaw hook may be preferred, minimizing damage to the load. Heavy loads require heavy-duty hooks with high tensile strength. Understanding the load and selecting the appropriate hook is crucial for safe and efficient lifting operations.

Q 3. What are the key safety procedures before operating a crane?

Safety is paramount in crane operation. Before even attempting to operate a crane, a comprehensive checklist must be followed:

- Pre-Operational Inspection: A thorough visual inspection of the crane’s structure, mechanisms, and safety devices is crucial. This includes checking for any damage, wear, or loose parts.

- Load Assessment: The load’s weight, dimensions, and center of gravity must be accurately determined. This ensures the crane’s capacity is sufficient and the load is stable during lifting.

- Work Area Assessment: The area surrounding the crane must be clear of obstructions and personnel. Designated signal persons are essential for directing the crane operator.

- Weather Conditions: Wind speed and direction are critical factors. High winds can affect crane stability and create dangerous situations. Lifting operations are usually halted in adverse weather.

- Personal Protective Equipment (PPE): Both the crane operator and signal persons must wear appropriate safety equipment, including helmets, safety shoes, and high-visibility clothing.

- Permit-to-Work System: In many organizations, a formal permit-to-work system outlines the steps and approvals needed before commencing lifting operations.

Failing to adhere to these procedures can lead to accidents, injuries, and significant financial losses.

Q 4. How do you perform a pre-operational inspection of a crane?

A pre-operational inspection is a systematic examination of the crane to identify any potential hazards before operation. This is not a cursory glance but a detailed check covering all critical components:

- Structural Inspection: Examination of the crane’s boom, jib, slewing mechanism, and supporting structures for any signs of damage, cracks, or deformation. This includes checking welds and fasteners.

- Mechanical Inspection: Verification of the proper functioning of the hoisting mechanism, brakes, winches, and other mechanical components. This may involve testing the braking system and checking for smooth operation.

- Electrical Inspection: Inspection of wiring, switches, controls, and electrical connections for any damage or faults. Ensuring proper grounding and insulation are critical.

- Safety Device Inspection: Checking the functioning of load limiters, overload protection systems, and emergency stops. These devices are crucial for preventing accidents.

- Hydraulic Inspection (for Hydraulic Cranes): Inspection of hydraulic cylinders, hoses, and fluid levels for leaks or damage. Checking for proper hydraulic pressure is essential.

The inspection should be documented using a standardized checklist, ensuring all points are addressed. Any defects found should be reported and rectified before the crane is operated.

Q 5. What are the limitations and capacities of different crane types?

Different crane types have varying limitations and capacities based on their design and construction. For example:

- Tower Cranes: High lifting heights but limited reach and mobility. Their capacity is usually determined by the type of jib and the location of the load relative to the crane’s base.

- Mobile Cranes (Hydraulic and Crawler): Offer greater mobility than tower cranes but have limited lifting heights. Their capacity varies greatly depending on the crane’s size, boom length, and load radius.

- Overhead Cranes: Suitable for indoor applications, featuring high lifting capacities within a limited area. Their capacity is typically defined by the crane’s design and the type of hoisting mechanism.

- Gantry Cranes: Used for lifting heavy loads over relatively short distances. They often have very high load capacities, but limited mobility.

Understanding the specific limitations of each crane type is vital for safe operation. Attempting to lift loads exceeding the crane’s capacity can lead to catastrophic failures.

Q 6. Explain the concept of load charts and their importance.

A load chart is a graphical representation of a crane’s lifting capacity at different radii (distances from the crane’s center). It shows the maximum weight a crane can safely lift at various boom lengths and angles. The importance of load charts cannot be overstated; they are essential for determining the safe working load (SWL) for any given lifting operation.

Load charts account for the crane’s stability and structural limitations. As the radius increases, the crane’s capacity decreases due to increased leverage effects. Ignoring the load chart and exceeding the capacity can lead to structural failure, resulting in serious accidents. Load charts are typically provided by the manufacturer and should be readily available to the crane operator.

Q 7. How do you calculate the safe working load of a crane?

Calculating the safe working load (SWL) of a crane involves consulting the crane’s load chart and considering the specific conditions of the lift. The SWL is never a simple calculation but rather a determination based on several factors:

- Load Weight: The actual weight of the load being lifted, considering any additional weight from lifting accessories like slings or shackles.

- Radius: The horizontal distance between the crane’s center of rotation and the load’s center of gravity.

- Boom Angle: The angle of the crane’s boom relative to the horizontal.

- Wind Speed: Wind can significantly impact the crane’s stability, reducing its capacity. The wind speed should be considered along with the load chart.

- Ground Conditions: Uneven terrain or soft ground can reduce the crane’s stability and hence its capacity.

To determine the SWL, consult the crane’s load chart for the specific boom length and radius of the lift. Then, factor in any derating factors due to wind, ground conditions, or other relevant factors. The SWL should always be less than or equal to the crane’s rated capacity under the prevailing conditions.

For instance, if the load chart shows a capacity of 10 tons at a 10-meter radius with a 45-degree boom angle, but the wind is strong, a derating factor might reduce the SWL to 8 tons to maintain safety. Failure to properly account for these factors can lead to dangerous situations and potential accidents.

Q 8. Describe your experience with different types of winch systems.

My experience encompasses a wide range of winch systems, from simple hand-operated units to sophisticated electric and hydraulic winches used in heavy lifting applications. I’ve worked with:

- Mechanical Winches: These rely on gears and a drum to provide lifting power. I’ve operated both manual and power-driven mechanical winches, understanding the importance of proper gearing for different load capacities and the need for regular lubrication to prevent wear and tear. For example, I used a hand-crank mechanical winch during a bridge inspection, its simplicity proving reliable in a limited-access environment.

- Electric Winches: These offer precise control and higher lifting capacities. My experience includes working with both AC and DC electric winches, familiar with their motor controls, braking systems (such as dynamic and mechanical brakes), and safety features like overload protection. A project involving the installation of large HVAC units required the use of a high-capacity electric winch for precise positioning.

- Hydraulic Winches: These provide immense power and smooth operation, ideal for heavy-duty applications. I’m proficient in operating and maintaining hydraulic winches, including understanding hydraulic fluid levels, pressure gauges, and potential leak points. I utilized a hydraulic winch during a large-scale demolition project, where the precise control was crucial for safely lowering heavy debris.

My experience extends beyond mere operation; I also understand the intricacies of different winch configurations (e.g., single-drum, double-drum, and multi-drum) and their suitability for specific tasks. Selecting the right winch for a job is paramount to safety and efficiency.

Q 9. What are the common causes of crane accidents and how can they be prevented?

Crane accidents often stem from a combination of factors, but some common causes include:

- Operator Error: This is often the leading cause, encompassing issues like exceeding load capacity, improper rigging, insufficient training, and failure to follow safety procedures. For instance, an overloaded crane can lead to structural failure and catastrophic accidents.

- Mechanical Failure: Malfunctioning brakes, worn cables, structural defects, and hydraulic system failures can all contribute to accidents. Regular inspections and maintenance are crucial to prevent these issues. A sudden brake failure, for example, can result in uncontrolled descent of the load.

- Environmental Factors: High winds, extreme temperatures, and poor visibility can significantly impact crane stability and operation, making careful planning and risk assessment vital. Operating a crane in high winds can cause it to tip over.

- Inadequate Planning and Supervision: Poorly planned lifts, insufficient communication between the crane operator and riggers, and lack of adequate supervision increase the risk of accidents. For example, a poorly planned lift might result in a collision with another structure or object.

Prevention involves a multi-pronged approach:

- Thorough Training and Certification: Operators must be properly trained and certified, demonstrating competency in all aspects of safe crane operation.

- Regular Inspections and Maintenance: Scheduled inspections and maintenance of all crane components are crucial to identify and address potential issues before they lead to accidents.

- Strict Adherence to Safety Procedures: Safety procedures should be clearly defined and strictly followed at all times. This includes load capacity checks, pre-lift inspections, and proper signaling protocols.

- Effective Communication and Supervision: Clear communication between the operator, riggers, and supervisors is crucial to ensure safe and efficient lifting operations.

Q 10. How do you handle emergency situations during crane operation?

My approach to emergency situations during crane operation is based on a structured and prioritized response:

- Immediate Shutdown: The first step is to immediately stop all crane operations to prevent further damage or injury.

- Assess the Situation: Carefully assess the nature and extent of the emergency. This might involve checking for injuries, identifying the source of the problem (e.g., malfunctioning equipment, unexpected wind gusts), and determining the potential hazards.

- Implement Emergency Procedures: Initiate the appropriate emergency procedures, which might involve activating emergency brakes, lowering the load safely, or evacuating personnel from the area.

- Secure the Area: Isolating the affected area and preventing unauthorized access are crucial for preventing further injuries or accidents.

- Call for Assistance: Contact emergency services (if necessary) and report the incident to the appropriate authorities. Depending on the severity, this might also involve informing supervisors or safety officers.

- Post-Incident Investigation: After the immediate danger has passed, conduct a thorough investigation to determine the cause of the incident, identify contributing factors, and implement corrective measures to prevent future occurrences. This involves documenting everything.

My training includes emergency response procedures for various scenarios, including equipment failure, load instability, and weather-related emergencies. I’ve practiced these procedures in simulated and real-world situations, ensuring I can act swiftly and decisively in any unexpected event.

Q 11. Explain your understanding of crane signaling procedures.

Crane signaling procedures are critical for safe and efficient crane operations, especially in situations with limited visibility or when communicating with the operator from a distance. I am proficient in standard hand signals and radio communication protocols.

Standard hand signals involve clear, unambiguous gestures to convey instructions regarding hoisting, lowering, swinging, and other crane movements. These signals are usually governed by industry standards and regulations. For example, a hand signal to raise the load involves a slow upward movement of the hand.

Radio communication is used for more complex operations or when hand signals are impractical (e.g., in noisy or obstructed environments). Clear and concise communication is essential, with the operator confirming the signal before executing the command. For example, a clear call ‘Hoist the load’ followed by confirmation from the operator reduces the risk of miscommunication.

My training covers both these methods. I understand the importance of confirming every instruction and ensuring the operator understands the intended movement before acting. Effective communication prevents misunderstanding which can lead to accidents.

Q 12. What are the different types of crane control systems?

Crane control systems vary greatly depending on the size, type, and application of the crane. Common types include:

- Mechanical Controls: These use levers, wheels, and other mechanical devices to control the crane’s movements. They are often found in older or smaller cranes and require significant physical effort from the operator.

- Electrical Controls: These systems use electrical motors and switches to operate the crane’s functions. Electrical controls provide more precise control and are common in many modern cranes. They often incorporate safety features like limit switches and overload protection.

- Hydraulic Controls: Hydraulic systems use hydraulic fluid to power the crane’s movements. They’re capable of lifting very heavy loads and often used in large, industrial cranes. These controls offer smooth and powerful movement.

- Computerized/PLC Controls: Advanced cranes utilize programmable logic controllers (PLCs) and computer systems for sophisticated control, allowing for precise positioning, load monitoring, and automated operation. These systems incorporate advanced safety features and can log operational data for analysis.

- Remote Controls: These systems allow operation of the crane from a distance via radio or wired controls. They are particularly useful in dangerous or difficult-to-reach environments.

My experience includes operating cranes with both electrical and hydraulic control systems, giving me a strong understanding of their strengths and limitations. I am also familiar with the safety protocols associated with each control type, prioritizing safe operation regardless of the system used.

Q 13. How do you maintain a crane’s logbook and records?

Maintaining accurate crane logbooks and records is crucial for ensuring compliance with safety regulations and facilitating effective maintenance. The logbook serves as a comprehensive history of the crane’s operation and maintenance activities.

My approach involves meticulous recording of the following information:

- Operational Data: This includes dates and times of operation, the number of lifts performed, types of loads handled, and any unusual events or incidents during operation.

- Maintenance Records: This section documents all scheduled and unscheduled maintenance activities, including inspections, repairs, and component replacements. This also includes details of any parts used, and the technicians who performed the work.

- Inspection Reports: Results of regular safety inspections, highlighting any defects or issues detected, along with any corrective actions taken.

- Operator Information: Details of the operator(s) who used the crane on each occasion. This facilitates tracing operational data back to a specific operator.

- Testing and Certification Data: Results of load tests, safety inspections and any other certifications relevant to operation.

The logbook must be kept in a clean, organized manner and accessible to authorized personnel. I adhere strictly to all relevant regulations and ensure the logbook is a reliable, readily-available historical record of the crane’s condition and operational history.

Q 14. Describe your experience working with different types of rigging equipment.

My experience with rigging equipment includes a wide range of components used for safely lifting and suspending loads. This includes:

- Wire Ropes: I am familiar with different wire rope constructions (e.g., 6×19, 6×36), their strength ratings, and the importance of regular inspections for wear and damage. I know how to identify signs of wear, such as broken wires or corrosion.

- Chains: I understand the different types of chain (e.g., grade 80, grade 100) and how to inspect them for damage, stretch, or deformation. I’m also aware of the importance of proper chain lubrication.

- Shackles, Hooks, and Slings: I’m proficient in using and inspecting shackles, hooks, and various types of slings (e.g., wire rope slings, chain slings, synthetic web slings). I can identify damaged or defective components and understand the importance of using appropriate slings for specific loads and environments.

- Eye Bolts and Other Lifting Points: I understand the correct methods for attaching lifting points to loads, ensuring they are adequately secured and capable of handling the weight.

- Load Spreader Beams: I’ve worked with spreader beams to distribute the weight of heavy loads over multiple lifting points, ensuring more balanced and safer lifting operations.

Rigging is critical to crane safety. My experience isn’t just limited to using these items, but also knowing how to inspect them for wear, damage, and correct usage. I always prioritize safe rigging practices to minimize risk.

Q 15. What are the regulations and standards you follow during crane operation?

Crane operation adheres to a strict regime of regulations and standards to ensure safety and prevent accidents. These vary by location but generally include national and international standards like OSHA (Occupational Safety and Health Administration) regulations in the US, or equivalent standards in other countries. These regulations cover aspects like operator licensing, pre-use inspections, load capacity limits, safe operating procedures, and emergency response plans. For example, a crucial regulation often mandates daily inspections of the crane’s critical components, including the hoisting mechanism, brakes, and structural integrity. Failure to comply with these standards can lead to severe penalties, including fines and operational shutdowns.

- Pre-Operational Checks: Before every lift, I meticulously check the crane’s operational readiness. This includes verifying the load capacity, inspecting the crane’s structure for any damage, ensuring proper functioning of all safety mechanisms (brakes, limit switches), and checking the condition of ropes and slings.

- Load Capacity: I always ensure the load weight is well within the crane’s certified capacity, taking into account the lifting angle and wind conditions. Overloading is a major cause of accidents, and I never compromise on safety in this regard.

- Emergency Procedures: I’m fully trained in emergency procedures, including how to shut down the crane in case of malfunctions and how to handle various emergency scenarios like power outages or load swings.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the stability of the crane during lifting operations?

Maintaining crane stability during lifting is paramount. It involves understanding and mitigating factors that can affect the crane’s stability, such as the load’s weight and distribution, ground conditions, wind speed and direction, and the crane’s own configuration. Think of it like balancing a seesaw: the heavier the load, the more careful you need to be about where you place the fulcrum (the crane’s base).

- Proper Outriggers: For mobile cranes, fully extending and properly positioning the outriggers is crucial to distributing the load evenly across the ground. Uneven ground requires careful consideration and often necessitates using additional support materials.

- Load Centering: Precisely centering the load under the crane’s hook minimizes side loads and prevents instability. This involves careful planning and execution, sometimes using specialized equipment for precise positioning.

- Wind Conditions: High winds significantly impact crane stability. Operations are often suspended during high winds or when gusts exceed acceptable limits specified in the crane’s operating manual. The wind’s effect on the load itself is also a key consideration.

- Ground Conditions: The stability of the ground beneath the crane is also very important. Soft or uneven ground can cause the crane to tilt or sink, compromising the entire operation. Measures may be needed to reinforce the ground, such as using mats or cribbing.

Q 17. Explain your understanding of load swing and how to mitigate it.

Load swing refers to the pendulum-like motion of a suspended load during lifting or lowering. It’s a significant safety hazard that can lead to collisions, damage to property or equipment, and even injuries. Imagine swinging a heavy bag of sand – the longer the rope and the faster the movement, the wider the swing.

- Smooth Operations: The key to mitigating load swing is smooth and controlled movements. Avoid sudden starts, stops, or changes in direction. Gradual acceleration and deceleration are crucial.

- Load Radius: Minimizing the distance between the load and the crane’s pivot point reduces the pendulum effect. Keeping the load close reduces the amplitude of the swing.

- Wind Considerations: High winds greatly exacerbate load swing. Lifting operations should ideally be halted during windy conditions or the load should be secured using additional measures like taglines.

- Taglines: Using taglines (guide ropes) can help control load swing, particularly during delicate maneuvers or in windy conditions. Trained personnel operate the taglines to guide and stabilize the load.

Q 18. What are the different types of crane maintenance procedures?

Crane maintenance is a multi-faceted process aimed at ensuring safe and reliable operation. It encompasses both preventative and corrective maintenance. Preventative maintenance involves regularly scheduled inspections and servicing to avoid potential problems, like changing oil, lubricating moving parts, and inspecting wire ropes. Corrective maintenance addresses issues that arise unexpectedly, like fixing a broken component. Regular maintenance is like regularly servicing a car; it prevents costly repairs down the line.

- Daily Inspections: A thorough daily inspection is mandatory before each shift. This covers visual checks of all components for damage, wear and tear, and proper functioning of safety systems. Any defects are immediately reported.

- Periodic Inspections: More comprehensive inspections are carried out at regular intervals (e.g., monthly, quarterly, annually), often by certified inspectors, to thoroughly assess the crane’s condition and identify potential issues before they become critical.

- Major Overhauls: Major overhauls are scheduled at longer intervals, depending on the crane’s usage and type. These involve a complete dismantling and inspection of the crane’s major components and the replacement of worn-out parts.

- Lubrication and Cleaning: Regularly scheduled lubrication of moving parts and cleaning of the crane prevent wear and tear and ensure smooth operation.

Q 19. How do you identify and report defects in a crane?

Identifying and reporting defects is a critical aspect of crane safety. It requires a keen eye for detail and a thorough understanding of the crane’s components and their normal operating conditions. Any deviation from the norm is a potential defect that must be addressed promptly.

- Visual Inspection: Careful visual inspections are the first line of defense. This involves checking for visible damage, wear, cracks, corrosion, loose bolts, or any other signs of deterioration in the crane’s structure, hoisting mechanism, and control systems.

- Functional Testing: Beyond visual checks, functional testing is vital to verify the proper working of safety mechanisms such as brakes, limit switches, and emergency stops. Testing ensures they respond as intended.

- Documentation: All identified defects, no matter how minor they may seem, are meticulously documented in a standardized format. This documentation includes the nature of the defect, its location, the date of discovery, and the action taken or planned to rectify the issue.

- Reporting Procedures: A clear reporting chain is essential to promptly communicate the defects to the appropriate personnel. This may involve reporting to a supervisor, maintenance team, or safety officer, depending on the severity of the defect.

Q 20. How do you work effectively with other team members during crane operations?

Effective teamwork is crucial for safe and efficient crane operations. Clear communication, mutual respect, and shared understanding of roles and responsibilities are essential. Think of it as a well-orchestrated symphony, where each instrument (team member) plays their part perfectly to create a harmonious whole.

- Clear Communication: Consistent and clear communication is paramount. Using standardized hand signals, radios, or other communication methods ensures everyone understands instructions and potential hazards. Before starting any lift, we confirm the load’s weight, destination, and any potential obstructions.

- Designated Roles: Each team member has clearly defined roles and responsibilities – crane operator, signal person, rigger, etc. This ensures everyone knows their task and avoids confusion.

- Pre-Lift Planning: Before commencing any lifting operation, the team holds a brief meeting to plan the lift, considering potential challenges and developing a safe lifting sequence. This includes confirming the load’s weight, centre of gravity and the lifting path.

- Emergency Procedures: The team is well-versed in emergency procedures and understands their roles during emergency situations. We regularly practice emergency drills to ensure preparedness.

Q 21. Describe your experience with different types of lifting plans.

Lifting plans are crucial documents that outline the safe and efficient execution of any lifting operation. They are tailored to the specific circumstances of each lift, considering factors like the load’s characteristics, the crane’s capabilities, and the environmental conditions. They are essential for ensuring the safety of personnel and equipment.

- Simple Lifts: For straightforward lifts, a simple plan might suffice. This would detail the load weight, the crane to be used, the lifting points, and the lifting sequence.

- Complex Lifts: Complex lifts involving multiple cranes, heavy loads, or challenging environments require detailed plans. These might include engineering calculations, risk assessments, detailed lifting sequences, emergency procedures, and specific safety precautions.

- Critical Lifts: For exceptionally critical lifts, such as those involving large or delicate equipment, specialized lifting plans are developed. These often involve expert input from engineers and experienced riggers to minimize risks and ensure a successful lift.

- Software and Simulations: Advanced lifting plans may utilize software for simulations to predict load behaviour and optimize lifting procedures. This helps identify potential hazards before the actual lift takes place.

Q 22. What is your experience with using load monitoring devices?

Load monitoring devices are crucial for safe and efficient crane operations. They provide real-time data on the weight being lifted, preventing overloading and potential accidents. My experience encompasses using a variety of load monitoring systems, from simple load cells integrated into the hoist mechanism to sophisticated systems with digital displays and data logging capabilities. I’m proficient in interpreting the data provided by these devices, understanding the implications of weight variations, and adjusting lifting procedures accordingly. For instance, I once used a load cell system to lift a particularly heavy piece of machinery. The system alerted me to an unexpected increase in weight mid-lift, possibly due to a shifting load. This allowed me to immediately stop the lift, investigate the cause (a loose securing strap), and rectify the issue before any damage or injury occurred. This highlights the importance of proactive monitoring and immediate response to any deviations from the planned load.

Q 23. How do you handle unexpected weather conditions during crane operations?

Unexpected weather conditions pose significant risks during crane operations. My approach prioritizes safety and adherence to established protocols. High winds, for example, necessitate a halt to operations until wind speeds fall below safe operating limits, as specified in the crane’s operational manual and relevant safety regulations. Heavy rain or snow can affect visibility and create slippery conditions, requiring adjustments to lifting techniques and increased caution. I’ve personally experienced situations where heavy fog significantly reduced visibility. In such cases, we implemented additional safety measures, including the use of spotters and communication systems to ensure that all personnel were aware of the crane’s movements. A clear communication plan is crucial in these conditions, ensuring that all crew members are informed of the changing conditions and the subsequent alterations to the lifting strategy.

Q 24. What is your experience with troubleshooting crane malfunctions?

Troubleshooting crane malfunctions requires a systematic and methodical approach. My experience includes diagnosing and resolving issues ranging from simple hydraulic leaks to complex electrical faults. I begin by carefully assessing the nature of the malfunction and gathering information. This might involve checking warning lights, reviewing operational logs, and interviewing operators to understand the sequence of events. For example, I once encountered a situation where a crane’s hoist mechanism failed to function. My troubleshooting involved checking the hydraulic fluid levels, inspecting the hydraulic lines for leaks, and testing the electrical components. I eventually identified a faulty hydraulic pump as the root cause. This highlighted the importance of a thorough investigation, encompassing all potential areas of failure.

I am familiar with various diagnostic tools and techniques, including the use of multimeters for electrical diagnostics and pressure gauges for hydraulic systems. Safety is paramount throughout this process, ensuring the crane is securely isolated and power is disconnected before any repairs or investigations are undertaken.

Q 25. Describe your knowledge of different types of wire ropes and their maintenance.

Wire ropes are the critical load-bearing components of cranes and winches. Different types of wire rope exist, each with its own characteristics and applications. For instance, 6×19 and 6×36 constructions are common, with the numbers referring to the number of strands and wires within each strand, impacting flexibility and strength. I’m knowledgeable about the properties of different wire rope materials such as steel, and their resistance to corrosion, fatigue, and abrasion. Regular maintenance is essential to ensure the safety and longevity of wire ropes. This includes visual inspections for broken wires, corrosion, or deformation; checking for correct lubrication; and conducting load testing according to manufacturer specifications. I have extensive experience in conducting these inspections and documenting the findings, adhering to strict safety regulations. Replacing worn or damaged wire ropes is crucial and is always done according to established procedures.

Q 26. Explain the importance of regular crane inspections.

Regular crane inspections are paramount for safety and operational efficiency. They prevent catastrophic failures and minimize downtime. Inspections should be conducted according to a pre-defined schedule, including daily pre-operational checks, periodic thorough inspections, and regular load testing. These inspections cover all critical components, including the structural members, hoisting mechanisms, braking systems, and electrical systems. Visual inspections identify obvious issues such as cracks, corrosion, or loose fasteners. More detailed inspections involve testing the functionality of various systems and components. Proper documentation of these inspections is vital, creating a comprehensive record of the crane’s condition. Neglecting regular inspections greatly increases the risk of accidents and equipment failure, potentially leading to serious injuries and significant financial losses. Think of it like a regular health check-up for a human; prevention is always better than cure.

Q 27. What is your understanding of the different types of crane brakes and their function?

Cranes utilize various braking systems to ensure safe and controlled movement. Common types include mechanical brakes (e.g., drum brakes, disc brakes), hydraulic brakes, and electric brakes. Each type serves a distinct purpose and has its own advantages and disadvantages. Mechanical brakes provide fail-safe redundancy, while hydraulic brakes offer smoother and more precise control. Electric brakes are often integrated into motor control systems. Understanding the operating principles of each type is vital for safe and effective operation and maintenance. For instance, I’m proficient in inspecting and maintaining drum brakes, ensuring proper lining wear, adjustment, and functionality. Regular maintenance of all braking systems is key to preventing accidents and ensuring consistent performance.

Q 28. Describe your experience with working at heights and adhering to fall protection regulations.

Working at heights is an inherent part of crane operation and demands strict adherence to fall protection regulations. My experience includes extensive training and practical application of fall protection measures. This includes the proper use of harnesses, lanyards, and fall arrest systems. I’m proficient in setting up and inspecting fall protection systems, ensuring they are correctly installed and compliant with relevant safety standards. Before any work begins at height, I always conduct a thorough risk assessment, identifying potential hazards and implementing appropriate safety controls. Furthermore, I always make sure to check that the equipment is regularly inspected and maintained, as per the manufacturers guidelines. A critical aspect is regular training and awareness, ensuring that all personnel involved understand the procedures, emergency response plans, and the implications of any deviation from safety protocols. Neglecting these safety measures could lead to devastating consequences.

Key Topics to Learn for Operating Cranes and Winches Interview

- Crane Types and Mechanisms: Understanding the different types of cranes (tower, mobile, overhead), their operational mechanisms (hydraulic, electric, pneumatic), and their respective strengths and limitations.

- Load Handling and Safety Procedures: Practical application of safe load calculations, weight distribution techniques, proper rigging methods, and emergency procedures in various scenarios (e.g., load sway, unexpected equipment malfunction).

- Signal Communication and Teamwork: Mastering effective hand signals, radio communication protocols, and collaborative techniques for safe and efficient crane operation in a team environment.

- Pre-Operational Checks and Maintenance: Thorough understanding of pre-shift inspections, daily maintenance routines, and recognizing potential mechanical issues to ensure optimal safety and operational efficiency.

- Regulations and Compliance: Familiarity with relevant safety regulations, industry best practices, and legal requirements concerning crane operation and load handling.

- Troubleshooting and Problem-Solving: Developing the ability to identify and resolve common operational challenges, from minor mechanical issues to complex load-handling situations, using systematic problem-solving approaches.

- Winch Operation and Maintenance: Understanding different winch types, their operational principles, safety features, maintenance procedures, and troubleshooting common problems.

- Advanced Concepts (depending on the role): Depending on the seniority of the position, you may want to explore topics such as load charts, stress analysis, specialized rigging techniques, and advanced safety management systems.

Next Steps

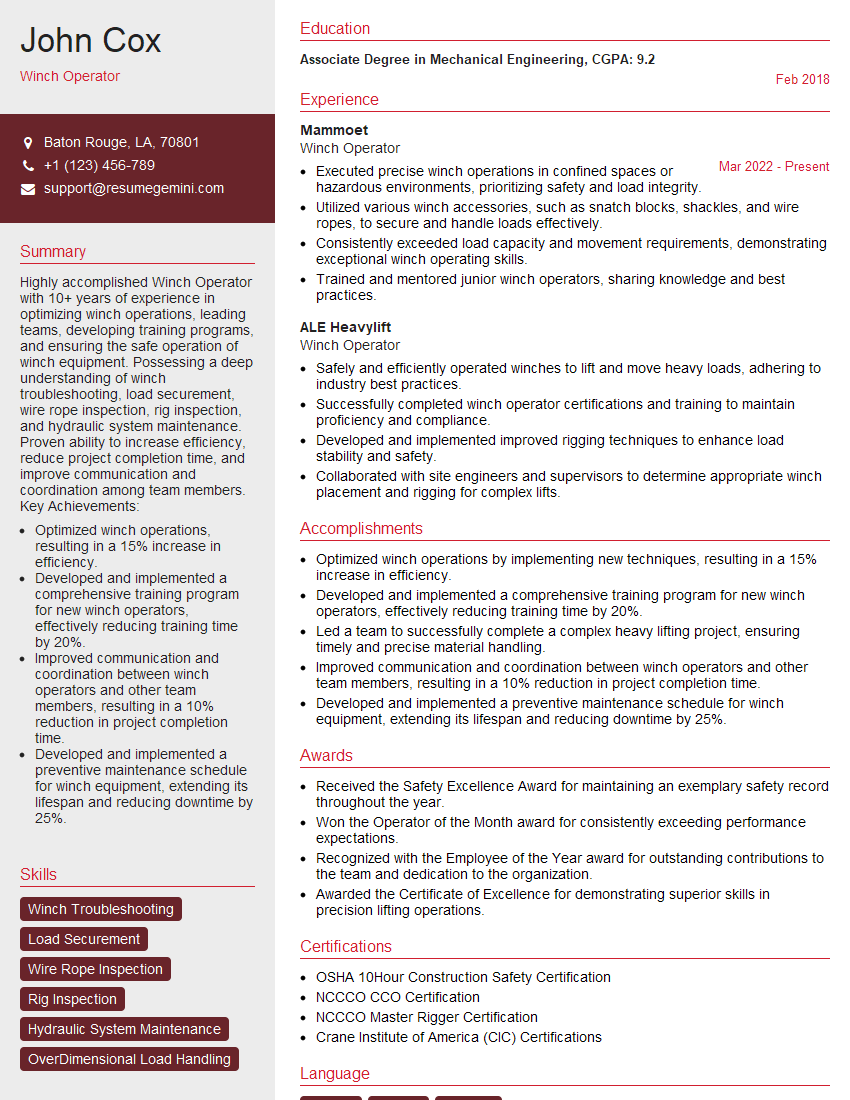

Mastering the operation of cranes and winches opens doors to a rewarding career with excellent growth potential in various industries like construction, manufacturing, and logistics. A strong understanding of these skills is highly valued by employers. To maximize your job prospects, it’s crucial to present your qualifications effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your experience. We offer examples of resumes specifically designed for candidates in Operating Cranes and Winches to guide you in showcasing your skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO