Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Optical Polishing interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Optical Polishing Interview

Q 1. Explain the difference between fine grinding and polishing in optical fabrication.

Fine grinding and polishing are sequential stages in optical fabrication, both aiming to achieve a precise surface finish, but differing significantly in their approach and outcome. Fine grinding removes relatively large amounts of material, leaving behind a surface with scratches and irregularities visible under a microscope. Think of it like sanding wood – you’re removing substantial imperfections. Polishing, on the other hand, is a much gentler process focusing on removing the fine scratches left by grinding and achieving a mirror-like surface with extremely low surface roughness. It’s the equivalent of carefully refining the wood surface with increasingly fine sandpaper, ultimately achieving a smooth, polished finish.

In short: Grinding is about material removal; polishing is about surface perfection.

Q 2. What are the various polishing techniques used for different optical materials (e.g., glass, crystals, metals)?

Optical polishing techniques vary greatly depending on the material being polished. For example:

- Glass: Commonly uses pitch polishing, where the optical component is rubbed against a pitch polisher charged with cerium oxide abrasive. This is a slow but effective method that yields excellent results. Magnetorheological finishing (MRF) is another popular technique offering better control and faster processing speeds for some applications.

- Crystals: Often require more specialized approaches due to their sensitivity to scratching and etching. Chemically-Mechanically Polished (CMP) techniques, involving chemical reactions and mechanical action, are sometimes employed to achieve a highly precise surface. The specific choice of abrasive and polishing pad is critical and depends on the crystal type. For example, sapphire might require a different approach than softer crystals like Calcium Fluoride.

- Metals: Polishing metals for optics frequently involves diamond-based techniques, starting with coarse diamond suspensions and progressing to finer ones. Electrolytic polishing is also used, leveraging electrochemical reactions to remove material and achieve a highly reflective surface. This method is particularly beneficial when maintaining the original shape is crucial.

The selection of the optimal technique is dictated by factors such as material hardness, desired surface finish, and the acceptable level of material removal.

Q 3. Describe the role of different abrasives in the optical polishing process.

Abrasives play a crucial role in optical polishing, acting as the cutting agents that remove material from the optical surface. The size and type of abrasive dictate the level of material removal and surface finish achieved. Common abrasives include:

- Cerium oxide (CeO2): A very fine abrasive commonly used in pitch polishing of glass, producing excellent surface quality.

- Diamond slurries: Used in various grades (e.g., 9µm, 6µm, 3µm, 1µm) for progressively finer polishing stages. Diamond’s exceptional hardness makes it suitable for harder materials such as crystals and metals.

- Alumina (Al2O3): A relatively less expensive abrasive used for pre-polishing stages and coarser surface finishing.

- Silicon carbide (SiC): Used in earlier grinding stages before fine polishing begins. It removes significant amounts of material quickly.

The choice of abrasive and its concentration in the polishing slurry directly impact the rate of material removal and the final surface quality. Using too coarse an abrasive can result in scratches, whereas using an abrasive that’s too fine might result in an excessively slow polishing process.

Q 4. How do you determine the appropriate polishing pressure and speed for a given material and desired surface finish?

Determining appropriate polishing pressure and speed is crucial for achieving the desired surface finish without inducing defects. It’s a balance – too much pressure can lead to scratches or digs, whereas insufficient pressure results in slow material removal. Similarly, excessive speed can lead to uneven polishing or heating of the component, while low speed will increase processing time.

The optimal values depend on several factors:

- Material hardness: Harder materials require higher pressure and potentially faster speeds, while softer materials necessitate gentler parameters.

- Abrasive type and size: Coarser abrasives might tolerate higher pressures, but finer ones require lower pressures to avoid surface damage.

- Desired surface finish: A higher quality finish usually requires lower pressures and potentially slower speeds to ensure controlled material removal.

Often, these parameters are determined experimentally. Initial trials using a range of pressures and speeds are conducted, and the results (e.g., surface roughness, material removal rate) are analyzed to determine the optimum parameters for a specific material and surface quality requirement. Precise control and monitoring of these variables are key to success.

Q 5. What are the common defects encountered during optical polishing and how are they addressed?

Several defects can occur during optical polishing. Some common ones include:

- Scratches: Caused by excessive pressure, coarse abrasives, or contaminants in the polishing process. They can be mitigated by careful control of polishing parameters and maintaining a clean environment.

- Dings and digs: Result from impacts or excessive localized pressure. Careful handling and precise polishing techniques help prevent these defects. For smaller digs, further polishing might be possible; larger defects may require re-fabrication.

- Uneven polishing: Can occur due to inconsistent polishing pressure or speed. Maintaining constant pressure and speed, together with a proper polishing tool setup, is crucial to avoid this.

- Edge chipping: Often caused by improper support or holding of the workpiece during polishing. Proper workholding techniques and adequate support are essential.

Addressing defects often involves identifying the root cause. For example, scratches might require repeating the polishing process with finer abrasives, while digs might necessitate more radical interventions. Prevention is key – careful planning and execution minimize defect occurrence.

Q 6. Explain the importance of pitch polishing and its applications.

Pitch polishing is a traditional yet highly effective method used primarily for glass optics. It involves using a pitch polisher, which is a tool consisting of a layer of pitch (a naturally occurring resin) molded into a specific shape and loaded with an abrasive, typically cerium oxide. The optical component is then rubbed against this pitch polisher.

The importance of pitch polishing stems from its ability to:

- Achieve extremely fine surface finishes: Pitch conforms to the surface of the optical component, ensuring even pressure distribution and highly uniform material removal.

- Provide excellent scratch-free surfaces: The pitch polisher itself is quite compliant, minimizing the risk of introducing scratches.

- Be relatively cost-effective: Pitch is a relatively inexpensive material, although the fabrication of the pitch polisher can be time-consuming and requires some skill.

Pitch polishing finds applications in high-precision optics manufacturing, where extremely smooth surfaces are necessary for applications such as laser optics, telescopes, and high-quality lenses.

Q 7. What are the key parameters to control during the polishing process to ensure high surface quality?

Ensuring high surface quality during polishing necessitates precise control over several parameters:

- Polishing pressure: Maintaining consistent and appropriate pressure is essential to prevent scratches and achieve uniform material removal. Pressure sensors or controlled actuators can help ensure consistent pressure.

- Polishing speed: The rotational speed of the polishing tool affects the material removal rate and surface quality. An optimal speed must be determined for the material and abrasive used.

- Abrasive concentration: The concentration of the abrasive slurry impacts the material removal rate. Precise control of the slurry concentration is crucial for achieving a uniform surface finish.

- Temperature: Excessive heat generation can cause damage to the optical component. Monitoring and controlling temperature, perhaps through cooling systems, is critical.

- Environmental conditions: Maintaining a clean environment is vital to prevent contamination and scratching. This involves careful control of humidity and dust levels.

Monitoring these parameters during polishing is often achieved through in-situ sensors and automated control systems. This provides feedback on the polishing process, enabling adjustments to maintain high-quality surface finish.

Q 8. How do you measure the surface roughness and flatness of a polished optical component?

Measuring the surface roughness and flatness of a polished optical component is crucial for ensuring its performance. We employ several non-destructive techniques to achieve this. For roughness, the most common method is using an atomic force microscope (AFM) or a profilometer. An AFM scans the surface at the atomic level, providing incredibly detailed information about the height variations, allowing us to calculate parameters like Ra (average roughness) and Rz (maximum peak-to-valley height). Profilometers, on the other hand, use a stylus to trace the surface profile, generating a roughness profile. The choice depends on the required level of detail and the scale of the roughness. For very smooth surfaces, AFM is preferred. For flatness, we use interferometry. An interferometer uses interference patterns of light to measure deviations from a perfectly flat surface. This gives us a map showing the surface ‘figure error’ – how much the surface deviates from an ideal shape (we’ll discuss figure error in more detail later). Common interferometers include Fizeau and Twyman-Green types. The choice of instrument depends on the required accuracy and the size of the component. For large components, specialized setups might be necessary.

For example, when polishing a high-precision lens for a telescope, AFM might be used to measure the microscopic roughness of the lens surface after polishing to ensure it meets stringent specifications, while a Fizeau interferometer would be used to assess the overall flatness of the lens surface, checking for any significant deviations that would affect its imaging capabilities. These measurements allow us to assess whether the component meets the desired specifications, identify areas requiring further polishing and even predict the final optical performance of the component.

Q 9. What are the different types of polishing machines used in optical fabrication?

Optical polishing machines vary greatly depending on the size and shape of the optical component and the required precision. Common types include:

- Pitch Polishing Machines: These are traditional machines that use a rotating pitch polisher (a soft, viscous material) to polish the optic. They are ideal for smaller, high-precision components because of their ability to conform to the shape of the optic. The pitch polisher must be carefully prepared and maintained for even polishing.

- Magnetorheological Finishing (MRF) Machines: MRF uses a magnetic field to control the shape and stiffness of a polishing fluid, enabling precise and adaptive polishing. It’s suitable for a wide range of components and offers good control over the surface figure and finish.

- Ion Beam Figuring (IBF) Machines: IBF uses a beam of ions to remove material from the optical surface, providing exceptional control and accuracy. IBF is particularly suitable for polishing complex shapes and achieving extremely smooth surfaces. However, it’s also more expensive and complex to operate.

- Computer Controlled Optical Surfacing (CCOS) Machines: This advanced technology uses computer control to automate the entire polishing process, optimizing polishing parameters in real-time to achieve the desired surface figure and finish. It enables high throughput and precise control over the polishing process, though typically requiring significant initial investments.

The selection of the machine depends greatly on the specific application and the desired level of precision. For instance, a small, high-precision lens might be polished on a pitch polisher, while a large, less precision-critical mirror might be polished on a MRF machine. The selection will impact overall cost and speed of production, along with the surface quality of the output.

Q 10. How do you select the appropriate polishing pad and slurry for a specific application?

Selecting the appropriate polishing pad and slurry is critical for achieving the desired surface quality and minimizing defects. The choice depends on several factors:

- Material of the Optic: Different materials require different polishing techniques. Harder materials like sapphire may require a more aggressive polishing pad and slurry than softer materials like glass.

- Desired Surface Finish: A finer surface finish requires a finer polishing pad and slurry. For instance, achieving a scratch-free surface necessitates finer polishing steps with decreasing abrasive size in the slurry.

- Removal Rate: The desired rate of material removal influences the choice of abrasive particle size. Faster removal rates generally require coarser abrasives.

- Type of Polishing Machine: Different machines have different compatibility with specific pad and slurry types. For example, pitch polishers require specific pitch formulations while MRF machines use specialized fluids.

The selection process is often iterative. We start with a coarser pad and slurry to remove significant amounts of material and gradually transition to finer ones to refine the surface. For example, when polishing a silicon wafer for a high-precision application, one might start with a diamond slurry of a larger particle size with a relatively stiff polishing pad, then transition to progressively finer diamond slurries with softer pads, followed by cerium oxide slurry for final polishing. This approach removes significant material initially and gradually refines the surface roughness to meet the specific requirements. Careful selection and monitoring is crucial to preventing unwanted scratches and ensuring the desired surface quality.

Q 11. What are the safety precautions necessary while working with optical polishing equipment and materials?

Safety is paramount in optical polishing. Several precautions must be taken:

- Eye Protection: Always wear safety glasses or goggles to protect against flying particles and splashes.

- Respiratory Protection: Some polishing slurries and compounds can release harmful dust or fumes. A respirator may be necessary, particularly when working with abrasive powders.

- Skin Protection: Wear gloves to prevent skin irritation from polishing compounds and chemicals.

- Machine Safety: Ensure the polishing machine is properly grounded and maintained. Never reach into a moving machine. Follow all manufacturer’s safety instructions.

- Proper Handling of Chemicals: Use chemicals in a well-ventilated area and follow proper disposal procedures. Always consult the Safety Data Sheet (SDS) for each chemical.

- Waste Disposal: Handle and dispose of polishing waste materials according to relevant regulations and guidelines. This includes proper collection of used slurry and polishing pads.

A detailed risk assessment should be performed before commencing any polishing work to identify potential hazards and develop appropriate control measures. Regular safety training is essential for all personnel working with optical polishing equipment and materials. For example, before starting work, you may need to perform a safety check on the polishing machine, inspect the chemicals and their safety data sheets, and ensure the proper protective equipment is worn by the operators. Neglecting safety protocols can lead to severe injury or damage to the equipment.

Q 12. Describe the process of cleaning and handling polished optical components to prevent damage.

Cleaning and handling polished optical components requires meticulous care to avoid damaging the delicate surface. The process generally involves:

- Initial Cleaning: Remove loose particles using a soft brush or compressed air (filtered to avoid introducing further contaminants). Avoid applying excessive pressure which could scratch the surface.

- Washing: Use a solution of isopropyl alcohol (IPA) or other suitable cleaning solvent. Apply the solvent with a lint-free swab or cloth, gently wiping in one direction to avoid scratching. Never use harsh chemicals, abrasive cloths, or excessive pressure.

- Drying: Allow the component to air dry in a clean environment. Avoid using compressed air as it can introduce impurities onto the surface.

- Storage: Store polished components in clean, dust-free environments in protective containers (e.g., petri dishes or cleanrooms), with antistatic features for added protection.

- Handling: Use clean cotton gloves while handling and avoid touching the optical surfaces. Use lens paper or other specialized cleaning materials, specifically designed for optical components, when cleaning.

Contamination can severely impact the performance of optical components. For example, a fingerprint on a high-precision lens can cause significant scattering or absorption of light. Using inappropriate cleaning techniques, or simply poor handling can ruin weeks of careful polishing work. Meticulous care throughout handling, cleaning, and storage stages is therefore crucial to preserve the optical quality of the polished component.

Q 13. Explain the concept of figure error and how it relates to optical polishing.

Figure error refers to the deviation of an optical surface from its ideal shape. In optical polishing, our goal is to minimize this figure error to achieve the desired optical performance. Figure error can manifest in various forms, including:

- Spherical Aberration: Deviation from a perfect spherical shape.

- Astigmatism: Unequal curvature in different meridians.

- Curvature of Field: Image plane not flat.

- Distortion: Image magnification varies across the field.

Figure error is directly related to optical polishing because the polishing process aims to shape the optical surface to its designed specifications. Techniques such as interferometry are employed to measure figure error. The measurements guide the polishing process, allowing us to iteratively refine the surface until the figure error is reduced to an acceptable level. For example, if an interferogram reveals a significant amount of astigmatism in a lens, we adjust the polishing process (e.g., by changing the polishing pad or slurry) to address this. The goal is to bring the measured surface form as close as possible to the design specifications. The acceptable level of figure error depends on the application; high-precision optics require much lower figure error than those used in less demanding applications.

Q 14. How do you determine the optimal polishing time to achieve the desired surface quality?

Determining the optimal polishing time is crucial for achieving the desired surface quality without over-polishing. It’s a complex interplay of several factors:

- Material Removal Rate: The rate at which the material is removed depends on the polishing pad, slurry, pressure, and speed of the machine. This rate can be calibrated through experiments.

- Desired Surface Finish: A finer finish requires a longer polishing time but with appropriate materials and controlled parameters.

- Monitoring Techniques: Regularly monitoring the surface using interferometry and profilometry gives real-time feedback on the polishing progress.

- Experience and Expertise: Experienced optical polishers develop a sense of how long it takes to achieve a specific surface quality for particular materials and machine setups.

The optimal polishing time isn’t determined through a single formula. It’s more of an iterative process. We might start with an estimated time based on past experience and then adjust it based on regular surface measurements. The goal is to remove the required amount of material without over-polishing, which can lead to surface damage or an undesirable figure. It’s a balance between efficiency and achieving optimal surface quality. For example, a complex aspheric lens might need multiple stages of polishing, each with progressively finer polishing materials and longer polishing times to achieve the desired form and surface finish. We continuously measure the surface and adjust the parameters (time, pressure, etc.) as needed to prevent over-polishing.

Q 15. What is the role of metrology in optical polishing and quality control?

Metrology in optical polishing is crucial for ensuring the quality and precision of the finished optical components. It involves a suite of techniques and instruments used to measure and analyze the surface properties of the polished optics. This includes measuring parameters like surface roughness (Ra, Rz), surface figure (deviation from ideal shape), and transmitted wavefront error. Without precise metrology, it’s impossible to guarantee the performance of the finished optical component, as even microscopic imperfections can significantly impact its function in applications like lasers, telescopes, or microscopes.

For example, in the fabrication of a high-precision telescope mirror, metrology techniques like interferometry are employed to measure the surface figure accuracy down to fractions of a wavelength of light. This allows for iterative polishing adjustments to achieve the desired level of surface precision. Similarly, non-contact profilometry helps to precisely map the surface roughness, critical for assessing scattering losses.

In quality control, metrology data guides the entire process. If a component fails to meet specifications after a polishing stage, the metrology data pinpoints the problem area, be it uneven material removal, residual subsurface damage, or other defects. This feedback loop allows for process optimization and defect correction, ensuring that only high-quality optics leave the production line.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you address scratches or digs that occur during the polishing process?

Scratches and digs are undesirable defects in optical polishing, significantly impacting surface quality and optical performance. Addressing them depends on their severity and location. Minor scratches might be removed by further polishing with progressively finer abrasives, gradually reducing the depth and size of the scratch. However, this process can be time-consuming and might lead to excessive material removal in the surrounding area. If the scratch is too deep, it might require advanced techniques such as ion-beam figuring to remove the damaged layer without causing significant surface deformation.

For deeper digs or pits, which are more challenging to address, the approach is slightly different. In some cases, if the dig is small and the optical component has enough material allowance, it can be filled and then repolished to smooth the surface, this involves adding material and then employing fine polishing to create a smooth, continuous surface. Alternatively, depending on the application and location of the defect, the component might be discarded because the removal of the deep dig may impact the intended use. The choice depends on the cost versus benefit and the optical component’s tolerance.

Q 17. Explain the concept of subsurface damage and how it affects optical performance.

Subsurface damage (SSD) refers to microscopic damage extending below the surface of an optical component, induced during prior processing steps like grinding or coarse polishing. This damage layer consists of microcracks and dislocations, which scatter light, reduce transmission, and degrade the overall optical performance. The depth and extent of SSD depend on the materials and the processing parameters used.

The presence of SSD significantly affects optical performance by increasing light scattering, leading to reduced transmission and increased surface roughness. It can also impact the material’s mechanical strength and durability. For high-precision optical applications, like those used in lasers or high-resolution imaging systems, even a small amount of SSD can be unacceptable. Minimizing SSD is typically addressed by careful selection of processing parameters and the use of appropriate polishing techniques, such as chemical-mechanical polishing (CMP), which achieves a superior surface quality with minimized SSD compared to traditional methods.

Imagine trying to polish a table with a very rough sandpaper and then a fine one. The rough sandpaper creates small cracks and imperfections deep below the surface, which the fine sandpaper might not completely remove. This is analogous to subsurface damage. Advanced techniques are then needed to rectify the damage caused by the rough treatment.

Q 18. What are the different types of optical materials you have experience polishing?

My experience encompasses a wide range of optical materials, including:

- Crystalline materials: Such as fused silica (SiO2), which is widely used for its high transparency and excellent thermal stability. I have extensively polished various grades of fused silica for use in high-power laser systems and telescopes.

- Glass materials: Including BK7 (borosilicate glass), a common choice for its good refractive index and ease of polishing; and N-BK7, a higher refractive index counterpart. I’ve worked with these in applications ranging from lenses to prisms.

- Single-crystal materials: Like calcium fluoride (CaF2) and zinc selenide (ZnSe), often used in infrared optical systems. These materials present unique polishing challenges due to their inherent crystal structure and hardness.

- Metals: Such as copper and aluminum, often employed in reflective optics. Polishing metals demands specialized techniques to achieve the desired surface finish and reflectivity.

Each material possesses distinct properties, requiring specialized polishing techniques to achieve optimal surface quality and performance. For example, fused silica demands different polishing conditions than softer materials like calcium fluoride, necessitating a nuanced understanding of material science and polishing techniques.

Q 19. Describe your experience with different polishing compounds and their properties.

I have extensive experience working with various polishing compounds, each with its unique properties and applications. The choice of polishing compound is crucial and directly impacts the surface finish achieved:

- Diamond slurries: Used for initial grinding and coarse polishing stages, providing high material removal rates. Different diamond particle sizes are used progressively, from coarse to fine, to achieve the required surface roughness.

- Cerium oxide (CeO2): A commonly used polishing compound for glass and crystalline materials, known for its excellent polishing ability and relatively low cost.

- Colloidal silica: Used in final polishing stages for achieving extremely smooth, low-scatter surfaces. Its fine particle size allows for very precise material removal.

- Pitch polishing: Utilizing pitch as the polishing tool, often used for specialized applications and final polishing of highly precise optics. It is effective in generating highly accurate and smooth surfaces.

The selection of the appropriate polishing compound relies on the desired surface finish, material being polished, and the stage of the polishing process. For instance, using a coarse diamond slurry on the final polishing stage would introduce surface scratches, while using colloidal silica during the rough stages would result in extremely slow material removal.

Q 20. How do you troubleshoot issues related to uneven polishing or poor surface quality?

Troubleshooting uneven polishing or poor surface quality requires a systematic approach. It starts with a thorough investigation of the metrology data to pinpoint the areas affected and the nature of the defects. Possible causes include:

- Improper polishing pad preparation: Uneven pad surface can result in non-uniform material removal.

- Inconsistent polishing pressure: Variations in pressure during polishing lead to uneven surfaces.

- Contamination of the polishing slurry: Foreign particles in the slurry scratch the surface.

- Incorrect polishing parameters: Inappropriate slurry concentration, polishing speed, and stroke length impact surface quality.

- Subsurface damage: Unremoved damage from preceding processing steps.

The solution often involves adjusting polishing parameters, such as pressure, speed, and slurry concentration, to address specific problems. Improving pad conditioning or changing the polishing compound can also resolve uneven polishing. In cases of severe subsurface damage, repolishing with techniques that minimize SSD is required.

I would always start by examining the process parameters, meticulously analyzing the equipment and the polishing slurry. Then, based on the metrology data identifying the problem areas, I would systematically alter the variables to solve the specific problem. This iterative process allows for refining the polishing process to achieve consistently high-quality results.

Q 21. What are your strategies for improving the efficiency and productivity of the optical polishing process?

Improving the efficiency and productivity of optical polishing requires a multi-pronged approach:

- Process optimization: This involves meticulous analysis of the polishing parameters to identify optimal settings that yield high material removal rates while maintaining high surface quality. This often involves experimentation and careful monitoring of metrology data.

- Automation and robotics: Implementing automated polishing systems with precise control over polishing parameters can significantly increase productivity and reduce human error.

- Advanced polishing techniques: Employing techniques like magnetorheological finishing (MRF) or ion beam figuring for specific applications can speed up the process and achieve high precision.

- Improved polishing compounds and pads: Utilizing new materials and formulations of polishing compounds and pads that provide higher removal rates and improve surface finish can improve efficiency.

- Predictive modeling: Utilizing simulation and predictive modeling can assist in optimizing polishing parameters and reducing the time spent on trial and error.

For example, in a high-volume production environment, implementing automated polishing machines with computer-controlled parameters drastically increases throughput compared to manual polishing. Similarly, employing predictive modeling can greatly reduce the experimentation required to find ideal polishing parameters.

Q 22. Describe your experience with different types of polishing machines (e.g., CNC, manual).

My experience spans both Computer Numerical Control (CNC) and manual optical polishing. CNC machines offer unparalleled precision and repeatability, particularly for high-volume production or complex geometries. I’ve worked extensively with machines like those from Precitech and Moore Nanotechnology, utilizing their software to program intricate polishing paths for aspheric lenses and freeform optics. This allows for extremely fine control over surface figure and roughness. For example, I used a Precitech Nanoform 350 to polish a series of high-precision telescope mirrors, achieving surface roughness of less than 1 nm RMS. Manual polishing, on the other hand, provides a higher degree of tactile feedback and adaptability for one-off pieces or delicate components. It’s essential for handling challenging materials or correcting minor imperfections missed by automated systems. My manual polishing experience involves the use of various pitch laps and polishing compounds, demanding a high level of skill and patience to achieve the desired results. For instance, I once manually polished a delicate interferometer component with a highly sensitive coating, requiring meticulous attention to pressure, speed, and compound selection.

Q 23. How do you maintain the cleanliness and precision of your polishing tools and equipment?

Maintaining cleanliness and precision is paramount in optical polishing. We employ a multi-faceted approach. Firstly, a dedicated and rigorously controlled cleanroom environment is essential. This includes HEPA filtration to minimize airborne particulate contamination. Secondly, all tools and equipment, including laps, polishing pads, and spindles, are thoroughly cleaned after each use using appropriate solvents and ultrasonic cleaning baths. For example, we utilize isopropyl alcohol (IPA) and deionized water for cleaning, followed by nitrogen drying to prevent residue. Thirdly, regular calibration and maintenance of the machines themselves are crucial. This includes checking the accuracy of the CNC machine’s positioning systems and regularly replacing worn polishing pads. We maintain meticulous logs and records of all cleaning and maintenance activities, ensuring traceability and consistency. Finally, we regularly inspect the tools for any signs of damage or wear which can impact the quality of the polished surface. For instance, microscopic abrasions on a polishing lap can create surface defects on the optic being polished.

Q 24. What software or tools have you used for optical design and simulation?

I’ve extensively used several software packages for optical design and simulation. Zemax OpticStudio is my primary tool for designing optical systems, predicting performance, and generating polishing specifications. I utilize its tolerancing capabilities to determine acceptable deviations from the ideal surface figure. Code V is another valuable tool used for verifying designs and performing ray tracing simulations. Furthermore, I use specialized software for integrating with CNC polishing machine controls, allowing me to directly import surface data from the design software for automated polishing. These integrations ensure that the polishing process closely aligns with the intended optical design.

Q 25. Describe your experience with non-traditional polishing methods.

My experience includes working with non-traditional polishing methods such as magnetorheological finishing (MRF) and ion beam figuring (IBF). MRF utilizes a magnetorheological fluid to remove material selectively, providing precise control and adaptability. It’s particularly useful for polishing freeform optics and correcting subtle surface errors. I’ve used MRF to polish complex aspheric lenses with exceptional accuracy. IBF, on the other hand, uses a focused ion beam to erode material, allowing for sub-nanometer precision. This is typically used for final figure correction or for polishing extremely delicate or brittle substrates. I’ve been involved in projects where IBF was crucial in achieving the required surface quality for high-power laser optics.

Q 26. How do you ensure the consistency of the polished surface across multiple components?

Consistency across multiple components is achieved through a rigorous process control system. This starts with careful selection and preparation of polishing laps and compounds. We use statistical process control (SPC) methods to monitor key parameters such as polishing time, pressure, and the rate of material removal, ensuring consistency throughout the polishing process. Regular metrology checks using interferometry and profilometry are vital to verify the surface quality of each component. We also employ standardized operating procedures (SOPs) for every step of the process. For instance, a specific sequence of polishing steps and compounds might be used consistently across all components. By meticulously controlling every variable and implementing robust quality control mechanisms, we ensure all components meet the specified surface figure, roughness, and other quality criteria.

Q 27. What are your experience with the different types of polishing laps?

My experience encompasses a wide range of polishing laps, each tailored to specific applications. Pitch laps are commonly used for fine polishing, particularly for optical glasses. The hardness and characteristics of the pitch can be adjusted to control the polishing rate and surface finish. I’ve used both cast and pre-manufactured pitch laps. Diamond laps, on the other hand, are more aggressive and suitable for initial stages of polishing or for materials that are difficult to polish with pitch. They offer greater material removal rates. I also have experience with polyurethane laps, which are known for their flexibility and ability to conform to complex shapes. The selection of the appropriate lap type is critical for achieving the desired surface quality, and the choice depends heavily on the material being polished, the desired surface finish, and the stage of the polishing process. For example, a soft pitch lap would be chosen for a final polish of a delicate optical component, while a diamond lap might be used initially on a much harder material.

Q 28. How do you handle and document non-conformances during the polishing process?

Handling and documenting non-conformances is a crucial aspect of our quality management system. When a non-conformance occurs—such as scratches, pits, or deviations from the specified surface figure—we immediately stop the polishing process and initiate a thorough investigation to determine the root cause. This often involves a detailed review of the polishing parameters, the condition of the polishing tools, and the environment. We document all findings using a standardized non-conformance report, including photographs and measurements. Corrective actions are then implemented to prevent similar issues from recurring. These actions might involve adjusting the polishing parameters, replacing worn-out tools, or implementing further training for the personnel involved. All non-conformances and corrective actions are reviewed and tracked within our quality management system to ensure continuous improvement in our processes.

Key Topics to Learn for Optical Polishing Interview

- Surface Preparation Techniques: Understanding different methods for preparing substrates before polishing (e.g., lapping, grinding), their impact on final surface quality, and choosing the appropriate technique for specific applications.

- Polishing Processes and Materials: Knowledge of various polishing techniques (e.g., loose abrasive polishing, fixed abrasive polishing, magnetorheological finishing), the properties of different polishing compounds and their selection based on material being polished and desired surface finish.

- Optical Metrology and Characterization: Familiarity with techniques used to measure surface quality (e.g., interferometry, profilometry), interpreting metrology data to assess the success of the polishing process and identify areas for improvement. Understanding key parameters like surface roughness (Ra, Rq), waviness, and scatter.

- Process Optimization and Control: Understanding the factors influencing polishing efficiency and surface quality (e.g., pressure, speed, slurry concentration, temperature). Ability to troubleshoot common problems and optimize processes for consistent results. Experience with statistical process control (SPC) methodologies is a plus.

- Materials Science: Knowledge of the properties of optical materials (e.g., glass, crystals, polymers) and how these properties influence the polishing process. Understanding material removal mechanisms during polishing.

- Safety Procedures and Practices: Awareness of safety protocols and best practices in a polishing environment, including handling hazardous materials and operating machinery safely.

- Precision and Accuracy: Demonstrating a thorough understanding of the importance of precision and accuracy in optical polishing and the implications of errors on optical performance.

Next Steps

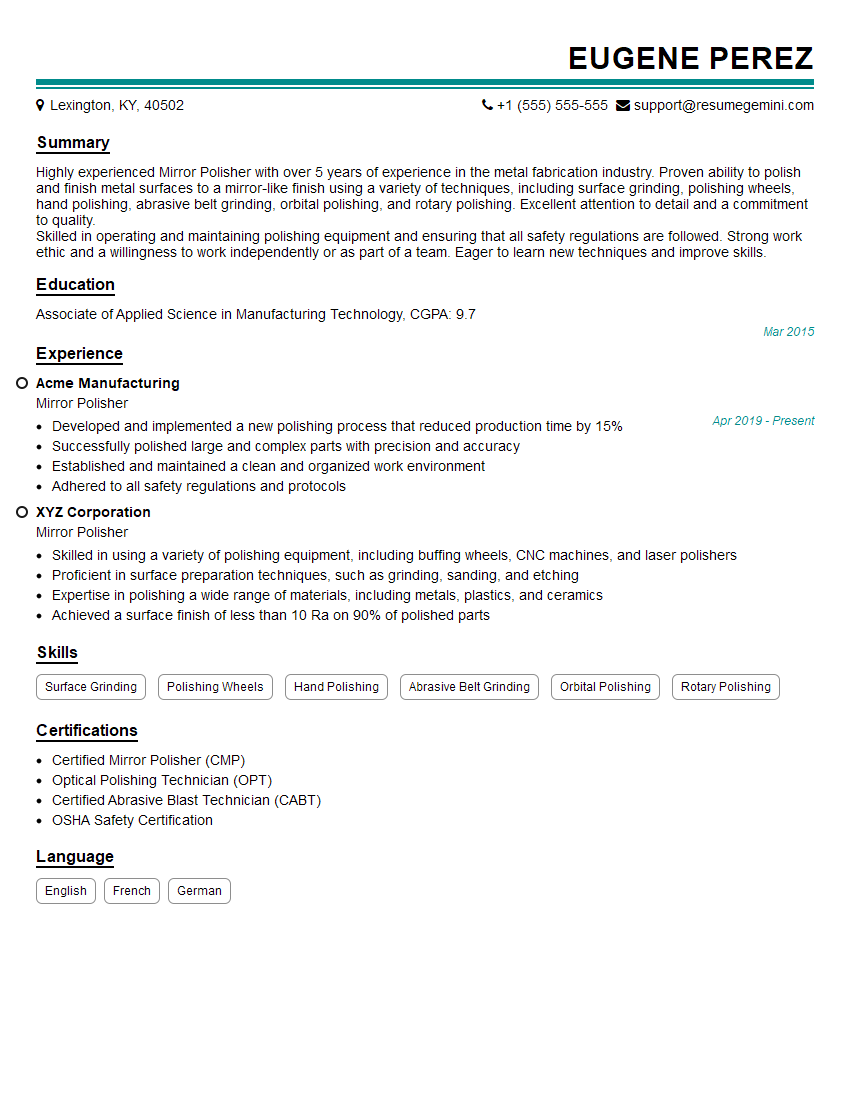

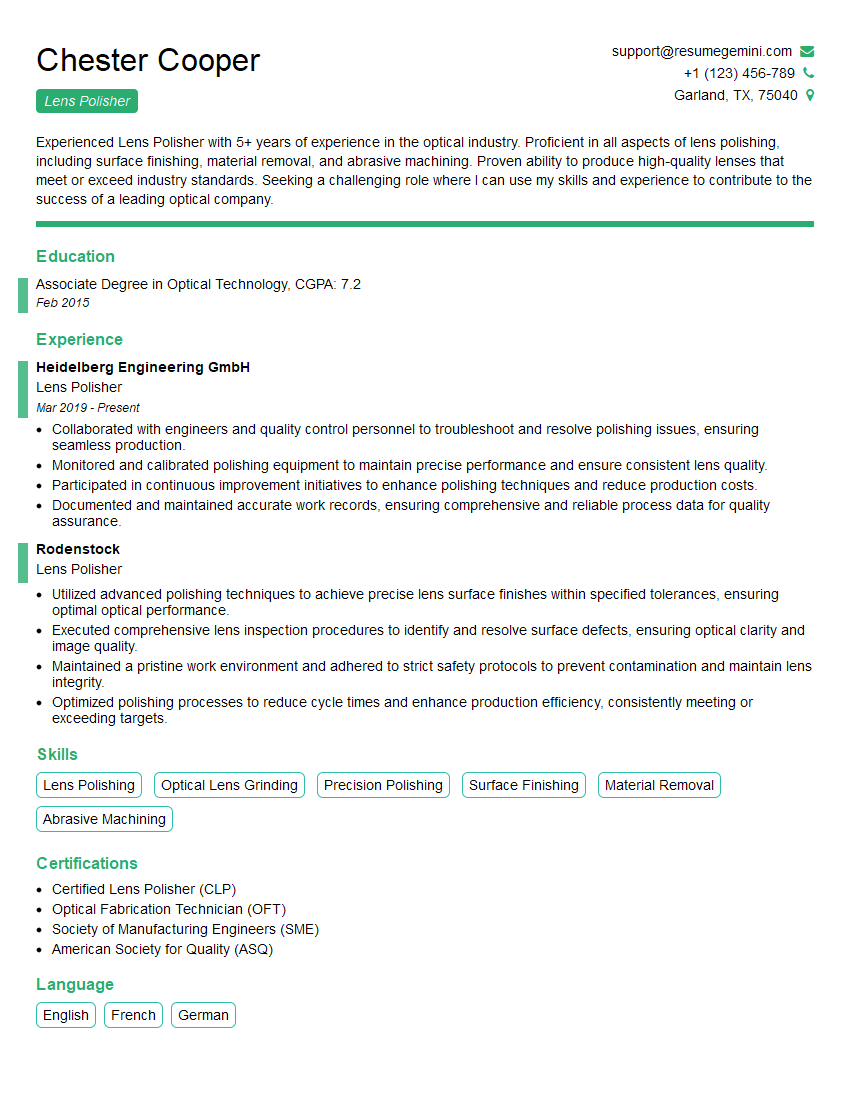

Mastering optical polishing opens doors to exciting career opportunities in advanced manufacturing, research, and development within the optics and photonics industries. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume designed to get noticed. We provide examples of resumes tailored to Optical Polishing to guide you in showcasing your skills and experience effectively. Take the next step towards your dream career – craft a compelling resume that highlights your expertise in optical polishing with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO