Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Paint Correction interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Paint Correction Interview

Q 1. Explain the difference between single-stage and multi-stage paint correction.

The difference between single-stage and multi-stage paint correction lies in the approach to defect removal. Single-stage correction attempts to remove imperfections with a single step, using a relatively aggressive compound and pad combination. Think of it like trying to clean a messy room all at once. It’s fast, but you might miss some details.

Multi-stage correction, on the other hand, is a more refined and controlled process. It involves multiple steps, each using progressively finer abrasives and pads. This approach is similar to meticulously cleaning a room, starting with a general tidy and then going through finer cleaning with each step. This allows for more precise defect removal, minimizing the risk of damage and achieving a superior finish. Multi-stage is more time-consuming, but yields better results, especially on heavily damaged paint. For example, you might start with a heavy cut compound and a coarser pad to remove deep scratches, followed by a medium cut compound and a less aggressive pad, then finally a polishing compound and a finishing pad for ultimate gloss and clarity.

Q 2. What are the different types of paint defects you can correct?

Paint correction targets a variety of defects. These include:

- Scratches: From minor swirl marks (fine scratches) to deep gouges, these are common issues.

- Swirl Marks (Holograms): These are microscopic scratches creating a hazy appearance, often caused by improper washing or machine polishing.

- Water Spots (Etching): Hard water deposits can etch into the clear coat, leaving behind permanent marks.

- Orange Peel: A textured surface resembling an orange peel, often a manufacturing defect.

- Bird Droppings/Insect Remains: Acidic substances that etch the clear coat, requiring careful removal.

- RIDS (Random Isolated Defects): These are blemishes that don’t follow any particular pattern and can include paint chips, runs, or other imperfections.

The severity of the defect determines the correction method needed.

Q 3. Describe your experience with various abrasive compounds and polishes.

My experience spans a wide range of abrasive compounds and polishes, from coarse compounds like those from 3M and Rupes, designed to remove deep scratches, to extremely fine polishes for ultimate gloss and clarity. I’m familiar with various brands including Meguiar’s, Chemical Guys, and Griot’s Garage, each with unique properties and applications. I have worked extensively with compounds graded by their cut (aggressive to fine) and have experimented with different polish types including:

- Compound (Cutting): For removing heavier defects.

- Polish (Finishing): For refining the surface and enhancing gloss.

- Glaze (Enhancing): For filling in minor imperfections and adding depth to the paint.

Understanding the abrasive properties of each product and its effect on paint is crucial for successful correction.

Q 4. How do you choose the right cutting pad and polish for a specific paint defect?

Pad and polish selection hinges on the severity of the defect. For deep scratches, I’d use a coarser cutting pad (e.g., a heavy-cut wool or foam pad) with a heavy cutting compound. The wool is particularly aggressive at removal. For lighter imperfections, a less aggressive foam pad with a polishing compound is suitable. For finishing, a very fine polishing pad with a finishing polish or a glaze would enhance gloss and clarity. Always remember to test in an inconspicuous area before committing to the entire panel. This ensures compatibility and allows for adjustments if needed. Incorrect pad-polish combinations might not correct the defects efficiently or could potentially damage the paint. For instance, using a heavy cutting compound with a light cutting pad would result in minimal correction and wasted effort, while a heavy cutting pad with finishing polish would not achieve desired results or even cause unwanted scratches

Q 5. Explain the process of assessing paint depth and choosing appropriate correction methods.

Assessing paint depth is crucial to avoid burn-through (removing all the clear coat). I use a paint depth gauge to measure the clear coat thickness in various areas. This gives a baseline for how aggressively I can correct. Once I know the paint depth, I tailor the correction methods accordingly. If the paint depth is thin, I may opt for more conservative methods, using less aggressive compounds and pads. If the depth is sufficient, I can take a more aggressive approach to correct more stubborn defects. This process is vital to prevent irreversible damage to the paint.

Q 6. How do you ensure proper paint correction technique to avoid burn-through?

Avoiding burn-through requires meticulous technique and attention to detail. Key strategies include:

- Proper lubrication: Using ample lubricant (polish or compound) keeps the cutting pad from overheating and prevents it from digging into the paint.

- Moderate pressure: Excessive pressure is the enemy of precision. The weight of the machine itself is often sufficient. Overdoing it increases the risk of burn-through.

- Multiple passes with overlapping sections: Working in small overlapping sections helps ensure even correction.

- Frequent pad inspection: Regularly inspecting the pad for clogging or damage helps prevent excessive material removal. I usually replace the pad periodically.

- Monitoring the surface temperature: Overheating is a strong indicator of potential issues and should trigger a pause. Using a temperature gun can help prevent this.

Burn-through is something you always want to avoid, as it can require costly repairs. Practice and precision are vital to mastering paint correction.

Q 7. What are the signs of a properly corrected paint surface?

A properly corrected paint surface exhibits several key characteristics:

- Uniform gloss and clarity: The finish should be even and reflective, without any hazy or dull areas.

- Absence of defects: Scratches, swirl marks, and other imperfections should be minimized or eliminated.

- Smooth surface texture: The paint should feel smooth to the touch, without any roughness or texture irregularities.

- Improved depth and clarity: The paint should look richer and more vibrant.

- Absence of holograms or buffer trails: These are visible marks left behind by improper buffing techniques.

Achieving these results requires skill, patience, and the right tools, but the end result is a stunning improvement in the vehicle’s appearance.

Q 8. Describe your experience with machine polishing techniques (rotary, DA).

My experience with machine polishing encompasses both rotary and dual-action (DA) polishers. Rotary polishers offer aggressive cutting power, ideal for removing heavy defects like deep scratches, but require significantly more skill and precision to avoid burn-through. Think of it like a powerful but delicate scalpel. I use rotaries sparingly, primarily on areas with severe damage after carefully assessing the paint’s thickness. DA polishers, on the other hand, are less aggressive but much safer, making them my go-to for most paint correction tasks. They offer excellent control, minimizing the risk of damage while still achieving impressive results. The DA’s oscillating motion spreads the abrasive evenly, reducing heat build-up. I often compare this to sanding wood – you’d use a coarser grit for rough work and a finer grit for refinement, and DA polishers allow for this level of controlled aggression.

I regularly switch between different polisher speeds, pad types, and compounds depending on the severity of the defect and the paint’s hardness. For example, I might start with a coarse compound and a heavy-cutting pad on a rotary polisher for deep scratches, then switch to a DA polisher with a finer compound and pad for refining and blending. The choice is always guided by the paint’s condition and my goal for the finish.

Q 9. How do you maintain consistent correction results across different vehicle types and paint finishes?

Maintaining consistent correction results across diverse vehicle types and paint finishes involves a meticulous approach. It begins with a thorough assessment. I use a variety of tools like paint thickness gauges and high-intensity lighting to understand the paint’s condition, hardness, and the severity of defects. Each vehicle, whether it’s a classic car with delicate lacquer or a modern vehicle with a multi-layer clear coat, needs a tailored approach. I wouldn’t use the same technique on a 1967 Mustang as I would on a brand new Tesla.

My process involves careful selection of compounds, pads, and polishers based on the paint’s hardness and the defects present. I meticulously document my steps for each vehicle, including the products used and the polishing techniques applied. This allows me to reproduce consistent results and refine my process over time. It’s about understanding the nuances of different paint systems and adapting my techniques accordingly. For instance, a harder paint might require a more aggressive compound and a lower polishing speed, while a softer paint needs a more gentle approach.

Q 10. What safety precautions do you take during paint correction?

Safety is paramount in paint correction. My safety protocols begin with proper personal protective equipment (PPE), including safety glasses, a respirator (to prevent inhalation of polishing dust), and gloves. I work in a well-ventilated area to avoid excessive dust and fumes. Before starting any correction work, I always test my chosen compounds and pads in an inconspicuous area to ensure they are suitable for the paint.

I regularly check the temperature of the paint during the polishing process to prevent overheating, which can lead to paint damage. I use a variety of techniques to keep the surface cool, including sectioning my work and using multiple passes with minimal pressure. I also ensure the power supply is safely grounded and the equipment is in good working condition.

Q 11. How do you handle challenging paint defects like deep scratches or swirl marks?

Handling challenging paint defects like deep scratches or swirl marks requires a phased approach. I start by assessing the depth and severity of the damage. For deep scratches that penetrate the clear coat, I might need to employ wet sanding with progressively finer grits to level the scratch before polishing. This is a delicate process, demanding precision and patience.

Swirl marks, on the other hand, often respond well to compound polishing. I may start with a more aggressive compound and pad on a DA polisher, and then follow up with a less aggressive compound and polishing pad for refinement. The process involves multiple passes, checking the correction progress frequently. I always prioritize patience and safety; rushing the process can cause irreversible damage.

In certain cases, particularly with very deep scratches, complete removal may not be possible, and I would inform the client of this limitation and the potential for remaining minor imperfections.

Q 12. What are your preferred methods for removing water spots and etching?

Water spots and etching require careful attention. Water spots, typically caused by mineral deposits left behind after water evaporates, are usually tackled using a dedicated water spot remover or a combination of chemical cleaners and polishing. The process often involves multiple steps, including washing, chemical decontamination, and then polishing with a fine compound to remove the remaining stains.

Etching, on the other hand, which is a more severe form of water damage, can require more aggressive methods. In some cases, wet sanding with very fine grits is necessary before polishing. This process requires high levels of skill and precision to avoid creating further damage. The approach is very much dependent on the severity of the etching – sometimes, it may be impractical to completely remove deep etching.

Q 13. How do you deal with different paint hardness levels during correction?

Dealing with different paint hardness levels is crucial for successful paint correction. Harder paints, like those found on some German and Japanese vehicles, can withstand more aggressive polishing techniques, allowing for quicker defect removal. However, even with harder paints, caution is necessary to avoid burn-through. Softer paints are more susceptible to damage and require gentler polishing compounds and techniques. Aggressive methods on soft paints can quickly lead to holograms or burn-through, creating further problems.

I use a paint thickness gauge to determine the clear coat thickness and assess the paint’s hardness. This informs my choice of polishing pads and compounds. I always start with a less aggressive approach and gradually increase the intensity if necessary. A common analogy is that of working with clay – you’d use different tools for working with different types of clay, and similarly, I adjust my approach according to the paint’s properties.

Q 14. Explain your experience with various types of paint sealant and ceramic coatings.

My experience with paint sealants and ceramic coatings is extensive. I’ve worked with a wide range of products, from traditional carnauba waxes which offer a fantastic shine but are less durable, to high-end synthetic sealants that provide longer-lasting protection. Ceramic coatings provide the most durable protection, often lasting for years, offering superior hydrophobic properties and UV protection. The application process for each is different, requiring careful attention to detail and proper surface preparation.

The decision to use a sealant or coating depends heavily on the client’s needs and budget. A sealant might suffice for someone looking for a quick and affordable solution offering several months of protection, whereas a ceramic coating is ideal for those seeking the ultimate in protection and longevity. I always explain the pros and cons of each option to my clients so they can make an informed decision.

Q 15. Describe your process for preparing a vehicle for paint correction.

Preparing a vehicle for paint correction is crucial for achieving optimal results. It’s like preparing a canvas before painting a masterpiece – a smooth, clean surface is essential. My process involves several key steps:

- Thorough Washing: I begin with a two-bucket wash method using a dedicated wash mitt and grit guards to prevent scratching. This removes loose dirt and grime. I follow up with a high-quality wash soap designed for automotive use.

- Decontamination: Next, I use a clay bar or iron remover to lift embedded contaminants like iron particles (from brake dust) and tar. These can interfere with the polishing process and cause swirls if left behind. Think of this as gently exfoliating the paint’s surface.

- Drying: I meticulously dry the vehicle using a plush microfiber drying towel, working in small sections to avoid water spots. Speed is the enemy here; patience is key to a spotless finish.

- Inspection: Under bright, even lighting (ideally in a garage), I conduct a thorough inspection, noting the type and severity of defects – swirls, scratches, holograms, etc. This dictates the next steps.

- Masking: Finally, I mask sensitive areas like trim, lights, and rubber seals to protect them from the abrasive compounds and polishes used during the correction process.

This meticulous preparation ensures that the paint correction process is as effective and efficient as possible, leading to a superior final result. Skipping any step can compromise the end result and add more work down the line.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate level of correction needed for a vehicle?

Determining the appropriate level of correction involves a careful assessment of the paint’s condition. It’s not a one-size-fits-all approach. I use a combination of techniques:

- Visual Inspection: Under strong, consistent lighting, I examine the paint for defects. The severity and density of scratches, swirls, and other imperfections dictate the level of correction. A car with only light swirls might require a single-step polish, while a heavily damaged car might require multiple stages of correction.

- Paint Depth Gauge (PDT): I use a paint depth gauge to measure the clear coat thickness. This helps determine how much material I can safely remove during the correction process. This is crucial to avoid burning through the clear coat and exposing the base coat.

- Test Spotting: I always conduct test spots with different polishing compounds and pads on an inconspicuous area to see how the paint reacts. This helps me determine the optimal combination of products for each stage.

For instance, a car with light swirls might only require a light polish using a medium-cut compound and a soft polishing pad. However, a car with deep scratches and heavy marring might require a more aggressive approach, starting with a heavy-cut compound and a more aggressive polishing pad, followed by multiple refining steps using progressively less aggressive compounds.

Q 17. Explain your experience using paint depth gauges.

Paint depth gauges (PDTs) are essential tools in paint correction. They provide critical information about the clear coat thickness, which allows me to work safely and avoid damaging the paint. My experience with PDTs involves understanding their limitations as well as their strengths:

- Accuracy and Calibration: PDTs need regular calibration to ensure accurate readings. I calibrate mine regularly according to the manufacturer’s instructions.

- Proper Technique: I use a consistent and gentle approach, making sure the gauge is perpendicular to the surface to get reliable readings. Taking multiple readings in each area helps me establish the paint’s thickness more reliably.

- Understanding Variations: Paint thickness can vary across different panels and areas of the vehicle. I’m careful to take multiple measurements to establish a range and avoid over-correction in thinner areas.

- Interpreting Data: I understand that a low reading doesn’t always indicate immediate danger. Combined with visual assessment, it informs my choice of compounds and polishing techniques.

For example, if I find a particularly thin area, I’ll use a less aggressive polishing compound and take extra precautions to avoid removing too much clear coat. This careful approach is fundamental to my ability to achieve optimal results without compromising the vehicle’s paint.

Q 18. How do you manage your time and workload during paint correction projects?

Managing time and workload effectively in paint correction is crucial. I employ several strategies:

- Detailed Pre-Inspection: A thorough pre-inspection allows me to accurately estimate the time required for each stage of the correction. This helps in creating a realistic timeline for the project and managing client expectations.

- Prioritization: I prioritize areas of the vehicle requiring more intense correction. This ensures that I efficiently tackle the most challenging aspects before moving on to less demanding areas.

- Sectioning: I work on sections of the car at a time, ensuring complete attention to detail in each area before moving to the next. This approach minimizes errors and prevents inconsistencies.

- Project Scheduling: I use project management software to schedule appointments and track my progress. This system allows me to manage multiple jobs concurrently and avoid scheduling conflicts.

I always strive for consistent productivity and deliver on time and within budget. Being realistic about the time involved upfront prevents stressful situations later on.

Q 19. What are your methods for maintaining your tools and equipment?

Maintaining my tools and equipment is paramount to ensuring quality and longevity. My maintenance routine includes:

- Regular Cleaning: After each use, I thoroughly clean my polishing machines, pads, and applicators. I use appropriate cleaning solutions and ensure everything is completely dry before storage.

- Pad Care: I carefully inspect polishing pads for wear and tear. I replace worn or damaged pads to avoid scratching the paint. I also properly wash and store them.

- Machine Maintenance: I follow the manufacturer’s guidelines for maintaining my polishing machines. This includes checking and replacing components as needed.

- Storage: I store all my tools and equipment in a clean, dry, and organized manner. This prevents damage and allows for easy access when needed.

Think of it as maintaining your surgical tools—sterile conditions are paramount. Ignoring maintenance would be like using dull instruments: it increases the risk of damage and leads to inefficient work.

Q 20. How do you address customer concerns or dissatisfaction with paint correction results?

Addressing customer concerns is a critical aspect of my job. My approach focuses on open communication and problem-solving:

- Open Dialogue: I encourage open communication with the client throughout the process. This helps manage expectations and address concerns early on.

- Honest Assessment: If there’s a genuine issue, I honestly assess the situation, determining the cause and the best way to resolve it.

- Collaborative Solutions: I work collaboratively with the client to find a mutually agreeable solution, whether it involves re-polishing a section, making adjustments to the process, or offering a partial refund.

- Documentation: I meticulously document the entire process, including before-and-after photos and notes on the work performed. This is valuable if any disputes arise.

My goal is to build trust and ensure client satisfaction. Even a small detail overlooked can be magnified, so addressing issues proactively demonstrates my dedication to quality.

Q 21. Describe your experience with different types of polishing machines (e.g., Rupes, Griot’s Garage).

I have extensive experience with various polishing machines, including Rupes and Griot’s Garage. Each has its own strengths and weaknesses:

- Rupes: Rupes machines are known for their smooth, consistent operation and excellent finishing capabilities. They produce less heat and vibration compared to some other brands. I find them ideal for achieving a high-gloss finish and correcting even the most stubborn defects when paired with the correct pad and compound.

- Griot’s Garage: Griot’s Garage machines offer a good balance between power and control. They’re versatile and suitable for both light and heavy correction. I often use them for larger areas or for initial stages of correction on heavily damaged paint.

The choice of machine depends on several factors, including the level of correction required, the size of the vehicle, and my personal preference. I’m comfortable working with either. Understanding the unique characteristics of each tool is key to maximizing its potential and optimizing the workflow.

Q 22. How do you stay up-to-date with the latest trends and techniques in paint correction?

Staying current in the dynamic world of paint correction requires a multi-pronged approach. It’s not just about knowing the latest polish or machine, but understanding the evolving science behind paint correction techniques.

- Industry Publications and Websites: I regularly follow leading detailing publications and websites. These platforms often feature articles, reviews, and tutorials on new products and methods. This helps me understand emerging trends and technologies.

- Continuing Education: I actively participate in workshops, seminars, and online courses offered by renowned detailers and industry experts. This hands-on learning is invaluable for mastering new skills and refining existing techniques.

- Networking with Peers: I engage with other detailers through online forums and in-person events. Sharing experiences, discussing challenges, and learning from others’ successes is a continuous process of professional development.

- Manufacturer Training: I seek out training programs directly from manufacturers of polishing compounds, machines, and other relevant products. This allows me to gain in-depth knowledge of their specific applications and optimal usage.

- Hands-on Experimentation: While always prioritizing client safety, I’ll carefully test new products and techniques on my own vehicles or samples before using them on a client’s car. This controlled environment minimizes risk and allows for thorough assessment.

This combination of formal and informal learning ensures I’m always at the forefront of paint correction innovation.

Q 23. What is your experience with paint correction on different types of vehicle surfaces (e.g., clear bra, vinyl wrap)?

My experience extends to various vehicle surfaces, and I adapt my approach based on the material’s characteristics. Each surface requires a tailored technique to avoid damage.

- Clear Bra: Working on a clear bra demands extra care due to its delicate nature. I use less aggressive polishing compounds and pads to prevent scratching or marring the film. The goal is to restore clarity and remove minor imperfections without damaging the protective layer. I always perform a thorough test in an inconspicuous area before proceeding.

- Vinyl Wrap: Vinyl wrap is also sensitive. I choose products specifically designed for vinyl and employ gentle polishing techniques. Excessive pressure or aggressive compounds can tear or damage the wrap. I focus on lubrication and careful attention to detail.

- Factory Paint: This presents a wider range of challenges depending on the paint’s hardness and the depth of imperfections. I meticulously assess the paint’s condition before selecting the appropriate compounds, pads, and polishing techniques to achieve optimal results.

Regardless of the surface, a thorough pre-assessment is critical. This ensures I select the right tools and techniques for a safe and effective paint correction process.

Q 24. How do you handle unexpected challenges during a paint correction job?

Unexpected challenges are part of the job, and my approach is grounded in methodical problem-solving and risk mitigation.

- Thorough Inspection: A detailed pre-correction inspection helps identify potential issues upfront. This may uncover hidden damage or paint defects that would otherwise cause complications during the process.

- Testing: Before applying any product or technique to a large area, I always test it in an inconspicuous spot to assess its compatibility with the vehicle’s paint or protective film. This avoids costly mistakes.

- Layered Approach: I work in sections and always reassess progress. This allows for course correction if unexpected issues arise, such as a stubborn scratch or an unforeseen paint defect.

- Communication: Open and honest communication with the client is crucial. If I encounter a problem that affects the project’s timeline or outcome, I immediately explain the situation and collaborate on a solution.

- Documentation: I meticulously document the process, including photos and notes of any challenges encountered and the steps taken to overcome them. This is invaluable for future reference and learning.

Think of it like building a house – unforeseen issues like a hidden pipe or weak foundation can occur. Preparation, methodical execution, and client communication help navigate these challenges successfully.

Q 25. What are your strategies for marketing your paint correction services?

Marketing paint correction services requires a strategic blend of online and offline approaches.

- High-Quality Photography and Videography: Before and after photos are essential to showcasing the transformative power of paint correction. I invest in professional photography to highlight the quality of my work.

- Social Media Marketing: Platforms like Instagram and Facebook are ideal for visually showcasing projects and building a following. Consistent posting of high-quality images and engaging content is key.

- Local Partnerships: Collaborating with local car dealerships, auto detailers, and car clubs can generate referrals and expand my client base.

- Online Advertising: Targeted advertising on platforms like Google Ads can reach potential clients actively searching for paint correction services.

- Word-of-Mouth Referrals: Excellent customer service and high-quality workmanship are the best forms of advertising. Happy clients are more likely to recommend my services.

- Website with Portfolio: A professional website is crucial for showcasing my expertise and experience. A gallery of before-and-after photos helps potential clients visualize the results.

The combination of these strategies creates a comprehensive marketing plan to attract and retain clients.

Q 26. How do you price your paint correction services?

Pricing paint correction services depends on several factors, including the vehicle’s size, the extent of damage, and the level of correction required.

- Vehicle Size and Condition: A smaller car with minor imperfections will naturally have a lower price than a large SUV with extensive swirl marks and scratches.

- Level of Correction: Single-stage correction focuses on addressing minor imperfections, whereas multi-stage correction addresses more severe defects and requires more time and effort, hence a higher price.

- Product Costs: High-quality products are essential for achieving superior results. The cost of these products is factored into the final price.

- Labor Costs: The time invested in the process significantly impacts the final price. This includes the assessment, preparation, correction, and detailing.

- Market Research: I conduct market research to understand the prevailing rates in my area, ensuring my prices are competitive and reflective of the value I provide.

I typically provide detailed quotes to clients after a thorough assessment of their vehicle’s condition. Transparency is vital – they understand what they are paying for.

Q 27. What is your experience with different lighting conditions and their impact on paint correction?

Lighting is absolutely critical in paint correction. Different light sources reveal different defects, impacting the assessment and correction process.

- Natural Light: While ideal for initial assessment, natural light can vary significantly throughout the day and due to weather conditions. This makes consistency challenging.

- Artificial Lighting: I utilize specialized lighting systems in my workshop, including high-intensity LED panels, to provide consistent and controlled illumination. These help reveal imperfections not readily visible under natural light.

- Polarized Light: Utilizing polarized lighting aids in identifying holograms (fine scratches) often missed under standard lighting. This level of precision ensures a flawless finish.

- Multiple Light Angles: I examine the vehicle’s surface from different angles and under varying light conditions. This helps me to fully understand the extent of the damage and to plan my correction strategy.

Think of it like a detective examining a crime scene – different angles and lighting reveal different clues. In paint correction, proper lighting is essential to ‘see’ the full extent of damage and ensure thorough correction.

Q 28. Describe your process for documenting your paint correction work (e.g., before and after photos).

Comprehensive documentation is key to showcasing results, tracking progress, and improving future work.

- Before Photos: Multiple photos from various angles under consistent lighting are taken to document the initial condition of the vehicle’s paint. This includes close-up shots of defects.

- During Process Photos: Photos are taken to document progress at different stages of the correction process. This is useful for troubleshooting and refining future techniques.

- After Photos: High-quality photos are taken to showcase the improved paint condition under the same controlled lighting conditions as the before photos. These vividly demonstrate the results.

- Video Documentation: In some cases, I also create short videos highlighting specific challenges, techniques, or the final results. This is especially effective for marketing purposes.

- Written Notes: I keep detailed written notes for each job, including product information, techniques employed, challenges encountered, and solutions implemented. This information serves as a valuable reference point for ongoing improvements.

My documentation is more than just pretty pictures – it’s a record of the entire process, invaluable for improving my skills, demonstrating expertise to clients, and aiding in future projects.

Key Topics to Learn for Paint Correction Interview

- Understanding Paint Defects: Learn to identify and classify common paint imperfections like scratches, swirls, holograms, and oxidation. This includes understanding their causes and severity.

- Paint Correction Techniques: Master various techniques including machine polishing (rotary and dual-action), hand polishing, and compounding. Understand the differences and when to apply each method.

- Abrasive Selection: Gain expertise in choosing the right compounds, polishes, and pads based on paint hardness, defect severity, and desired finish. Practice safe and effective abrasive selection.

- Paint Depth Measurement: Understand the importance of measuring paint depth to avoid burn-through during correction. Familiarize yourself with different measurement tools and techniques.

- Product Knowledge: Develop in-depth knowledge of various paint correction products, their properties, and application methods. Be prepared to discuss the pros and cons of different brands and formulations.

- Surface Preparation: Learn the proper procedures for washing, drying, and prepping a vehicle’s surface for paint correction. This includes decontamination techniques to remove contaminants.

- Inspection and Assessment: Develop your skills in thoroughly inspecting a vehicle’s paintwork to determine the best course of action for correction. Learn to accurately assess the level of correction needed.

- Finishing Techniques: Master techniques for achieving a flawless, high-gloss finish, including methods for removing dust and achieving perfect clarity.

- Troubleshooting and Problem Solving: Be ready to discuss common issues encountered during paint correction, such as holograms, buffer trails, and uneven finishes, and how to resolve them effectively.

- Safety Procedures: Demonstrate a thorough understanding of all safety precautions associated with paint correction, including proper personal protective equipment (PPE) and machine operation.

Next Steps

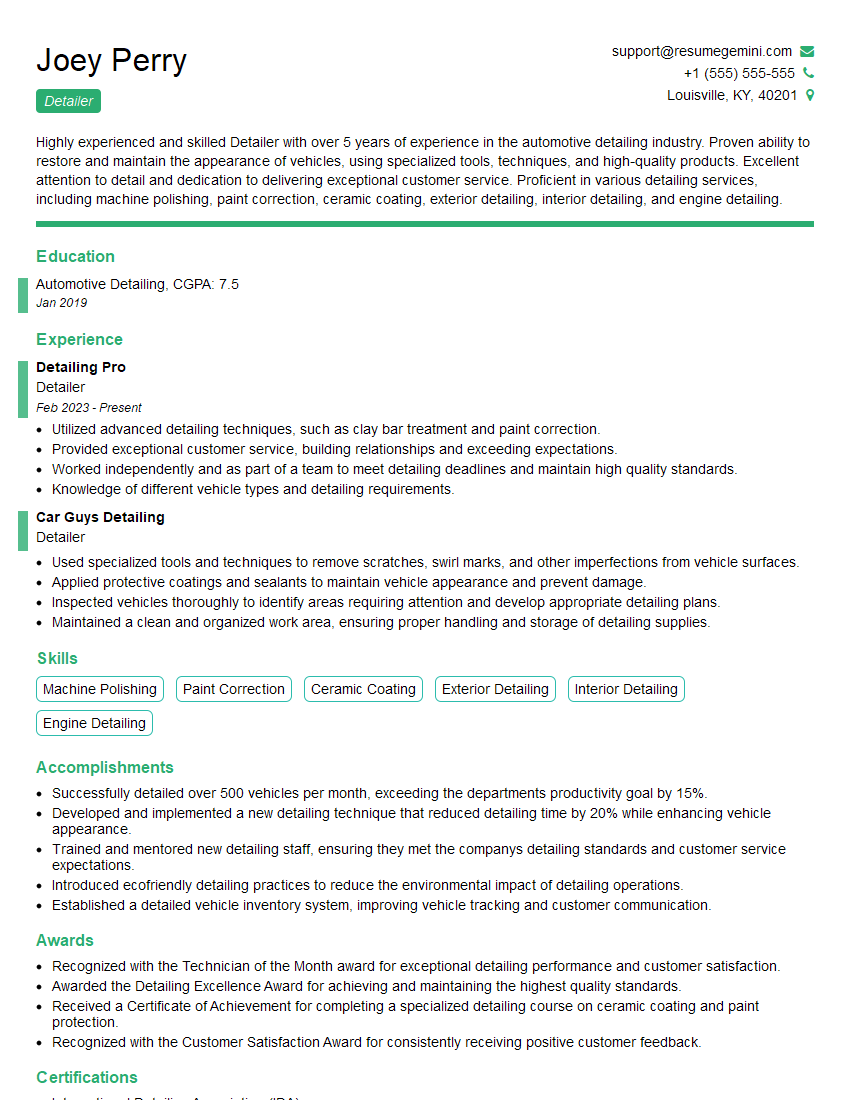

Mastering paint correction opens doors to exciting career opportunities with higher earning potential and increased job satisfaction. To maximize your chances of landing your dream job, it’s crucial to present yourself effectively. Creating an ATS-friendly resume is key to getting noticed by potential employers. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience in paint correction. We offer examples of resumes tailored to the Paint Correction field to guide you in creating a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO