Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Personal Protective Equipment (PPE) Use interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Personal Protective Equipment (PPE) Use Interview

Q 1. What are the different types of personal protective equipment (PPE)?

Personal Protective Equipment (PPE) encompasses a wide range of items designed to protect individuals from various workplace hazards. These hazards can range from physical dangers like cuts and impacts to chemical exposures and biological threats. PPE can be broadly categorized into several types:

- Eye and Face Protection: Safety glasses, goggles, face shields, and welding helmets protect against flying objects, chemical splashes, and intense light.

- Head Protection: Hard hats protect against falling objects and impacts to the head. Different classes offer varying levels of protection.

- Hearing Protection: Earplugs and earmuffs reduce exposure to excessive noise levels that can cause hearing damage.

- Respiratory Protection: Respirators, including N95 masks and more sophisticated systems, filter out harmful airborne particles, gases, or vapors. The selection depends critically on the specific hazard.

- Hand Protection: Gloves come in various materials (e.g., latex, nitrile, leather) and designs to protect against cuts, abrasions, chemicals, and biological hazards.

- Foot Protection: Safety shoes or boots protect feet from punctures, crushing, and electrical hazards. Steel-toe boots are a common example.

- Body Protection: This includes items like aprons, coveralls, and full-body suits to protect against chemical splashes, cuts, and radiation.

The appropriate PPE selection is crucial for effective hazard control and depends heavily on the specific risks present in the workplace.

Q 2. Explain the hierarchy of hazard control measures. Where does PPE fit?

The hierarchy of hazard control is a fundamental principle in occupational safety and health. It prioritizes the most effective and safest methods to eliminate or minimize risks. The hierarchy generally follows this order:

- Elimination: Completely removing the hazard is the most effective control. For example, automating a process to eliminate manual handling.

- Substitution: Replacing a hazardous substance or process with a safer alternative. Replacing a solvent with a water-based cleaner.

- Engineering Controls: Implementing physical changes to the workplace to reduce or eliminate hazards. Installing ventilation systems to remove airborne contaminants.

- Administrative Controls: Implementing policies and procedures to manage the risk. Implementing job rotation to limit exposure.

- Personal Protective Equipment (PPE): Used as a last resort when other control measures are not feasible or sufficient to eliminate the risk. PPE protects the individual worker.

PPE should never be the primary method of hazard control; it should only be used as a supplementary measure after other control measures have been implemented to the greatest extent possible. It’s the final layer of defense for the worker.

Q 3. Describe the selection process for appropriate PPE for a given hazard.

Selecting appropriate PPE involves a systematic process:

- Hazard Identification and Risk Assessment: Identify all potential hazards in the workplace and assess the associated risks. This will determine the level and type of protection required.

- PPE Selection: Choose PPE that addresses the identified hazards. Consult relevant standards and regulations (e.g., OSHA guidelines) to ensure compliance and effectiveness.

- User Evaluation and Training: Ensure the selected PPE is comfortable, fits correctly, and is easy to use. Provide comprehensive training on proper use, maintenance, and limitations of the PPE.

- Inspection and Maintenance: Regularly inspect PPE for damage or wear. Implement procedures for cleaning, repair, or replacement as needed.

- Record Keeping: Maintain records of PPE selection, training, inspection, and maintenance. This documentation is vital for compliance and accountability.

For example, if working with corrosive chemicals, the selection would involve chemical-resistant gloves, eye protection, and potentially a chemical-resistant apron or suit, based on the level of risk.

Q 4. What are the limitations of PPE?

While PPE is essential, it has inherent limitations:

- Dependence on the User: PPE effectiveness relies heavily on correct selection, proper use, and diligent maintenance by the worker. Human error is a significant factor.

- Limited Protection: PPE might not provide complete protection against all hazards. A failure in the PPE could lead to serious injury.

- Comfort and Usability Issues: Some PPE can be uncomfortable or restrict movement, potentially leading to non-compliance.

- Cost and Maintenance: PPE can be expensive to purchase and maintain, especially for specialized equipment.

- Environmental Impact: Some PPE, like disposable gloves and masks, contributes to environmental waste if not properly disposed of.

These limitations highlight the importance of prioritizing other control measures in the hierarchy and emphasizing training and proper use of PPE.

Q 5. How do you ensure PPE is properly fitted and used?

Ensuring proper fit and use of PPE involves several key steps:

- Proper Fit: PPE should be correctly sized and adjusted to fit the individual user snugly but comfortably. Ill-fitting PPE can compromise protection. For respirators, fit testing may be required.

- Training and Education: Workers must receive thorough training on the correct use, limitations, and maintenance of their PPE. This training should include both theoretical knowledge and practical demonstrations.

- Regular Inspection: Workers should inspect their PPE before each use, checking for damage or wear. Damaged PPE should be immediately replaced.

- Maintenance Procedures: Establish clear procedures for cleaning, storing, and maintaining PPE. This will extend its lifespan and ensure its continued effectiveness.

- Enforcement and Monitoring: Supervisors should monitor PPE use and enforce the established procedures. Regular inspections and safety audits are crucial.

Think of it like wearing a seatbelt – if it doesn’t fit properly or isn’t used correctly, it won’t provide the intended protection.

Q 6. What are the common hazards requiring respiratory protection?

Respiratory protection is necessary when workers are exposed to airborne hazards that can cause harm to the lungs or respiratory system. Common hazards requiring respiratory protection include:

- Dusts: Silica dust (from construction), asbestos fibers, wood dust, and metal dusts can cause lung diseases like silicosis or asbestosis.

- Mists: Fine droplets of liquids, such as acids or pesticides, suspended in the air can irritate or damage the lungs.

- Fumes: Metal fumes produced during welding or soldering can be toxic and cause metal fume fever.

- Gases and Vapors: Many gases and vapors, such as carbon monoxide, chlorine, and solvents, are harmful if inhaled.

- Biological Agents: Bacteria, viruses, and fungi can be transmitted through the air, requiring respiratory protection in healthcare and other settings.

The type of respirator needed depends on the specific hazard and its concentration in the air.

Q 7. What are the different types of respirators and their limitations?

Respirators are categorized into several types based on their function and filtering capabilities:

- Filtering Facepieces (FFPs): These are disposable respirators that filter out particles. Examples include N95, N99, and R95 respirators (the number indicates the filtering efficiency). N95 masks are widely used for protection against airborne particles.

- Air-Purifying Respirators (APRs): These respirators filter out airborne contaminants but rely on the surrounding air for oxygen. They are not suitable for oxygen-deficient environments.

- Supplied-Air Respirators (SARs): These provide a continuous supply of clean air from an external source, either through an airline or a self-contained breathing apparatus (SCBA). They are used in hazardous environments with low oxygen levels or high concentrations of contaminants.

- Self-Contained Breathing Apparatus (SCBAs): SCBAs are completely self-contained and provide breathable air in a sealed system, protecting the user from all airborne hazards.

Limitations: Each type of respirator has limitations. FFPs offer limited protection against gases and vapors, while APRs are ineffective in oxygen-deficient environments. All respirators require proper fit and maintenance for optimal performance. Improper selection or use can significantly reduce the level of protection.

Q 8. Explain the proper donning and doffing procedures for respirators.

Donning and doffing respirators correctly is crucial to ensure they provide adequate protection. Improper handling can compromise the respirator’s seal and effectiveness, exposing you to hazardous substances. Think of it like putting on a spacesuit – each step is vital.

Donning (Putting on):

- Step 1: Hand Hygiene: Wash your hands thoroughly.

- Step 2: Inspect the Respirator: Check the respirator for any damage (tears, cracks, etc.).

- Step 3: Position the Head Straps: Place the respirator over your nose and mouth, ensuring a snug fit.

- Step 4: Adjust the Straps: Securely fasten the head straps, adjusting them for a proper seal.

- Step 5: Perform a Seal Check: Cover your respirator and gently exhale. You should feel inward pressure. If you feel air leakage, readjust the straps and try again.

Doffing (Taking off):

- Step 1: Remove in a Controlled Environment: Move to a designated clean area before removing the respirator.

- Step 2: Avoid Touching the Front: Unfasten the head straps from the back, avoiding touching the front of the respirator.

- Step 3: Dispose or Clean: Dispose of single-use respirators immediately in an appropriate container. Reusable respirators should be cleaned and stored according to the manufacturer’s instructions.

- Step 4: Hand Hygiene: Wash your hands thoroughly.

Example: Imagine working with asbestos. Incorrect donning could lead to asbestos fibers entering your lungs, causing serious health problems. Following these steps ensures you’re protected.

Q 9. What are the requirements for hand protection selection?

Hand protection selection depends entirely on the hazards present. You wouldn’t use the same gloves for handling chemicals as you would for handling sharp objects. The process involves a thorough hazard assessment. This assessment identifies the specific risks, such as chemical exposure, cuts, abrasions, or extreme temperatures.

Requirements typically include:

- Material Compatibility: The glove material must resist the specific chemicals or substances you’ll be handling. For instance, nitrile gloves are often preferred for chemical resistance over latex.

- Durability and Dexterity: The gloves must provide sufficient protection without compromising dexterity. Thick gloves offer better protection but may reduce hand movement.

- Fit and Comfort: Gloves that are too tight or too loose can compromise protection and lead to discomfort.

- Regulatory Compliance: Select gloves that meet relevant industry standards and regulations.

Example: A lab technician handling strong acids requires chemical-resistant gloves, likely neoprene or nitrile, whereas a mechanic might need cut-resistant gloves made from Kevlar or steel mesh.

Q 10. What are the different types of gloves and their applications?

Gloves come in a wide variety of materials, each suited for specific tasks. The choice depends heavily on the hazards faced.

- Latex Gloves: Common, relatively inexpensive, but some individuals have allergies. Suitable for general purpose tasks where high chemical resistance isn’t required.

- Nitrile Gloves: Excellent chemical resistance, more durable than latex, and less likely to cause allergic reactions. Ideal for handling chemicals, solvents, and other hazardous materials.

- Neoprene Gloves: Very durable and offer good resistance to many chemicals, oils, and solvents. Often used in more demanding industrial settings.

- Butyl Rubber Gloves: Highly resistant to a wide range of chemicals, including strong acids and bases. Primarily used for handling highly corrosive substances.

- Cut-Resistant Gloves: Made from materials like Kevlar or steel mesh, providing protection against cuts and lacerations. Essential for tasks involving sharp objects.

Example: A nurse might use latex or nitrile gloves during patient care, while a worker in a chemical plant would need much more robust neoprene or butyl gloves.

Q 11. When are eye and face protection required?

Eye and face protection is mandatory whenever there’s a risk of eye or face injury from flying particles, chemical splashes, or intense light. It’s about preventing permanent damage.

Examples of when eye and face protection are required:

- Working with chemicals: To protect against splashes or fumes.

- Using power tools: To prevent flying debris from striking the eyes.

- Welding or cutting metal: To shield eyes from intense light and sparks.

- Handling corrosive materials: To prevent chemical burns.

Consider it this way: Your eyes are irreplaceable. Investing in the right eye protection is an investment in your long-term well-being.

Q 12. What are the different types of eye and face protection?

Various types of eye and face protection are available, each designed for specific hazards:

- Safety Glasses: Provide basic protection against impact from small particles. Often used in general workplaces.

- Goggles: Offer more complete protection, sealing around the eyes to prevent splashes and dust from entering.

- Face Shields: Protect the entire face, often used in conjunction with safety glasses or goggles for enhanced protection against larger debris or chemical splashes.

- Welding Helmets: Specialised helmets with dark lenses to protect against intense light and ultraviolet radiation during welding.

Example: A machinist operating a lathe would need safety glasses or goggles to protect against flying metal chips, while a chemist working with corrosive liquids would require goggles and potentially a face shield.

Q 13. What are the risks associated with improper PPE usage?

Improper PPE usage can lead to a range of serious consequences, impacting both individual safety and potentially the wider workplace. The risks are substantial and far-reaching.

- Injuries: Exposure to hazardous substances, cuts, burns, eye injuries, and other physical trauma.

- Illnesses: Respiratory problems, chemical poisoning, skin infections, and long-term health issues from exposure to hazardous materials.

- Reduced Productivity: Injuries and illnesses can lead to time off work, impacting productivity and potentially causing project delays.

- Legal Liability: Employers can face legal consequences for failing to provide adequate PPE or ensure its correct usage. Employees may also have legal recourse if they suffer injuries due to negligence.

Example: A construction worker not wearing a hard hat could suffer a serious head injury from falling debris. A laboratory technician neglecting to wear gloves could experience chemical burns or allergic reactions.

Q 14. How do you conduct a PPE inspection?

PPE inspection is a critical step in ensuring worker safety. It’s a systematic check of the PPE’s condition and suitability for use before each use. It’s not just a quick glance; it needs to be thorough.

A typical PPE inspection includes:

- Visual Inspection: Check for any visible damage, such as cracks, tears, holes, or signs of wear and tear.

- Functionality Check: Verify that all components of the PPE are working correctly. For example, check respirator seals, glove integrity, or helmet straps.

- Cleanliness Check: Ensure the PPE is clean and free from contamination. This is especially important for reusable PPE.

- Proper Fit: Ensure the PPE fits the user properly. Loose-fitting PPE can compromise protection.

- Documentation: Maintain accurate records of inspections, noting any damage or defects found. This provides a clear audit trail and supports claims if something were to go wrong.

Example: Before starting work, a construction worker should check their hard hat for cracks and ensure the straps are securely fastened. Similarly, a healthcare worker should inspect their gloves for holes before performing a procedure.

Q 15. How do you maintain and store PPE?

Maintaining and storing PPE effectively is crucial for ensuring its continued effectiveness and the safety of workers. It involves a multi-step process focusing on cleanliness, proper storage conditions, and regular inspection.

Cleanliness: PPE should be cleaned regularly according to the manufacturer’s instructions. For example, reusable respirators require specific cleaning protocols, while disposable gloves are discarded after use. Failure to clean PPE can lead to contamination and reduce its protective capabilities.

Storage: PPE needs to be stored in a clean, dry, and well-ventilated area, away from direct sunlight, extreme temperatures, and potential contaminants. This protects its integrity and extends its lifespan. Specific storage requirements vary depending on the type of PPE; for instance, helmets should be stored upright to prevent damage.

Inspection: Regular inspections are vital. This involves checking for any signs of damage, wear, or degradation. Damaged PPE should be immediately replaced. For example, a cracked safety helmet is immediately unusable and needs replacing.

Inventory Management: Keeping an accurate inventory of PPE helps ensure adequate supplies are available and prevents shortages. This includes tracking expiration dates for items with a limited shelf life, such as disposable masks.

Think of it like maintaining a valuable tool – proper care ensures it functions correctly and protects the user.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the legal requirements for PPE use in your industry?

Legal requirements for PPE use vary depending on the specific industry and location, but generally, they stem from overarching occupational safety and health regulations. These regulations mandate the employer’s responsibility to provide and ensure the proper use of PPE to protect workers from identified hazards.

For example, OSHA (Occupational Safety and Health Administration) in the US sets comprehensive standards, requiring employers to conduct hazard assessments, select appropriate PPE, provide training, and enforce its use. Similar regulations exist in other countries, often with specific requirements for particular industries, such as construction or healthcare. Non-compliance can result in significant fines and legal repercussions.

Specific regulations frequently cover aspects like:

- Hazard assessment and risk management.

- Selection of appropriate PPE based on identified hazards.

- Provision of PPE to workers free of charge.

- Training and competency assessments.

- Maintenance and replacement of damaged PPE.

- Enforcement of PPE usage policies.

Staying updated on the relevant regulations is crucial for maintaining a safe and compliant workplace.

Q 17. How do you communicate PPE requirements to workers?

Communicating PPE requirements effectively involves a multi-pronged approach that ensures understanding and compliance across the workforce. It’s not enough just to post a sign; engagement is key.

Training: Comprehensive training programs that are tailored to the specific hazards and PPE used within the workplace. This includes hands-on demonstrations and practice sessions.

Visual Aids: Using clear and concise visual aids like posters, diagrams, and videos to supplement training and highlight critical information. Pictures make it easier to understand than just words.

Written Materials: Providing written instructions and guidelines on PPE use, maintenance, and storage, including readily accessible reference materials.

Regular Communication: Holding regular toolbox talks and safety meetings to reinforce PPE requirements, address any questions or concerns, and discuss relevant incidents or near misses.

Demonstrations and Modeling: Supervisors and managers should model correct PPE use to set a positive example for workers.

Language Accessibility: Ensure all materials and communication are accessible to all workers, regardless of their native language or literacy level. Consider translations and visual aids.

Effective communication ensures everyone understands their responsibilities and the importance of using PPE correctly.

Q 18. How do you address non-compliance with PPE usage?

Addressing non-compliance with PPE usage requires a progressive approach that emphasizes education and prevention, but also includes consequences for repeated or willful violations.

Education and Retraining: The first step is to understand the reasons for non-compliance. Is it lack of training, discomfort with the PPE, or simply forgetfulness? Retraining and addressing individual concerns are often the most effective solutions.

Coaching and Mentoring: Supervisors can provide coaching and mentoring to help workers understand and implement the proper use of PPE.

Progressive Discipline: For repeated or willful violations, a progressive discipline process should be implemented, starting with verbal warnings and escalating to written warnings, suspension, and potentially termination. This needs to be clearly defined and consistently applied.

Improved PPE Selection: Sometimes non-compliance is due to uncomfortable or impractical PPE. If this is the case, explore alternative options to enhance comfort and usability.

Incentive Programs: Consider incorporating incentive programs to recognize and reward compliance. This can significantly improve overall engagement and safety culture.

The goal is not punishment, but rather to create a safe work environment where everyone understands and values the importance of PPE.

Q 19. Describe a situation where you had to troubleshoot a PPE-related problem.

In my previous role, we experienced a significant increase in reported eye injuries despite the mandatory use of safety glasses. After investigation, we found that many workers were not wearing their safety glasses correctly, often pushing them up onto their foreheads or removing them completely while performing tasks.

To troubleshoot this issue, we implemented the following steps:

Improved Training: We conducted additional hands-on training emphasizing proper fitting and adjustment of safety glasses, highlighting the crucial protection areas.

Comfort Evaluation: We surveyed workers about the comfort and practicality of the current safety glasses, finding that many felt they were uncomfortable or interfered with their work. This led to the evaluation of different models and selection of a new, more comfortable type.

Regular Inspections and Feedback: Supervisors increased their frequency of workplace inspections to monitor compliance and provide immediate feedback. This helped to improve compliance and catch issues before they became problems.

Visual Reminders: We placed additional posters and reminders in the workspace, emphasizing the importance of eye protection and showing the correct way to wear the glasses.

After implementing these changes, we saw a significant reduction in reported eye injuries.

Q 20. Explain the importance of regular PPE training.

Regular PPE training is paramount for ensuring worker safety and compliance. It goes beyond simply handing out equipment; it’s about building a safety-conscious culture.

The importance lies in:

Hazard Awareness: Training educates workers about the specific hazards they face and how PPE mitigates those risks.

Proper Use: It demonstrates the correct way to put on, adjust, use, and remove PPE, ensuring maximum effectiveness.

Maintenance and Storage: Workers learn how to properly maintain, clean, and store their PPE to extend its lifespan and prevent damage.

Limitations and Replacement: Understanding the limitations of PPE and when replacement is necessary is critical. A damaged respirator provides no protection, and workers must know to replace it immediately.

Emergency Procedures: Training covers what to do in case of PPE failure or an emergency.

Compliance and Accountability: It reinforces the importance of compliance and the consequences of non-compliance. This fosters a culture of responsibility.

Regular refresher training helps to maintain knowledge and skills over time, ensuring that workers remain up-to-date with the latest safety procedures and advancements in PPE technology.

Q 21. How do you evaluate the effectiveness of PPE programs?

Evaluating the effectiveness of PPE programs involves both quantitative and qualitative measures. A comprehensive approach provides a well-rounded view of program success.

Incident Rates: Tracking the number of workplace injuries and illnesses related to the hazards that PPE is designed to protect against. A significant decrease in incident rates is a key indicator of program effectiveness.

Compliance Rates: Monitoring the rate of PPE use among workers through observations, audits, and self-reporting. High compliance rates show that workers understand and utilize the provided PPE.

Worker Feedback: Gathering feedback from workers through surveys, interviews, or focus groups to gauge their understanding of the program, the comfort and usability of the PPE, and any challenges encountered.

Training Effectiveness: Evaluating the effectiveness of training programs through tests, assessments, and observations to ensure workers retain the knowledge and skills necessary for proper PPE use.

Program Audits: Conducting regular audits to verify adherence to established policies and procedures, and to identify areas for improvement.

By combining these methods, a comprehensive picture of the PPE program’s effectiveness emerges, leading to continuous improvement and ultimately, a safer workplace.

Q 22. What are the different standards and regulations relevant to PPE?

The standards and regulations governing PPE vary depending on the industry and geographic location, but several key frameworks exist. In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role, setting standards for workplace safety, including PPE use. OSHA’s regulations aren’t specific to individual PPE types but mandate employers to provide appropriate PPE where hazards exist. Similarly, in Europe, the EU’s Personal Protective Equipment Regulation (Regulation (EU) 2016/425) sets essential health and safety requirements for PPE, focusing on design, testing, and conformity assessment. Specific standards, such as those published by ANSI (American National Standards Institute) and EN (European Norms), address the performance requirements for different PPE categories (e.g., ANSI Z87.1 for eye protection, EN 388 for gloves). These standards often involve rigorous testing procedures to ensure the PPE’s effectiveness against specific hazards.

- OSHA: Sets general requirements for employer-provided PPE.

- EU Regulation (EU) 2016/425: Focuses on PPE design, testing, and conformity.

- ANSI/EN standards: Detail performance requirements for specific PPE types (e.g., eye protection, gloves, respirators).

Understanding these regulations is crucial for ensuring compliance and worker safety. For example, a construction company must adhere to OSHA standards for hard hats, eye protection, and safety footwear, while a healthcare facility must comply with relevant regulations when selecting and using gloves, gowns, and respirators to prevent infection transmission. The specific standards applicable will be determined by the particular hazards present in the workplace.

Q 23. What are the key components of a comprehensive PPE program?

A robust PPE program isn’t just about providing equipment; it’s a holistic system designed to protect workers. Key components include:

- Hazard Assessment: A thorough identification of all workplace hazards requiring PPE.

- PPE Selection: Choosing the right PPE for each hazard, considering factors like comfort, fit, and compatibility with other equipment.

- Training: Comprehensive training on proper PPE selection, use, maintenance, and limitations. This includes demonstrating the correct donning and doffing procedures, explaining the limitations of the PPE and when it may not offer sufficient protection.

- Fit Testing: Ensuring that respirators and other PPE fit properly for optimal protection (especially important for respiratory protection). Improper fit can significantly reduce effectiveness.

- Maintenance and Inspection: Regular inspection and maintenance of PPE to ensure it remains in good working condition.

- Record Keeping: Maintaining detailed records of PPE training, inspections, and incidents involving PPE failures.

- Evaluation and Improvement: Regular review and improvement of the PPE program based on performance data, incident reports, and feedback from workers.

Think of it like building a house: Each component (hazard assessment, training, maintenance) is essential for a strong, safe structure. Neglecting even one component can compromise the overall effectiveness and safety of the program. For instance, providing workers with respirators without proper fit testing renders the equipment nearly useless.

Q 24. How do you ensure PPE compatibility with other safety equipment?

PPE compatibility is critical for ensuring worker safety and preventing interference. Incompatibility can lead to reduced protection, discomfort, and even injuries. Consider these factors:

- Physical Compatibility: Will the PPE interfere with the movement and functionality of other safety equipment? For example, bulky gloves might make it difficult to operate machinery safely.

- Chemical Compatibility: Are the materials of different PPE items compatible? Mixing certain chemicals or materials can lead to degradation or reactions that compromise protection.

- Thermal Compatibility: Does one piece of PPE impede the heat dissipation or regulation of another, leading to overheating or discomfort? For example, wearing multiple layers of protective clothing in a hot environment could cause heat stress.

- Ergonomic Compatibility: The combination of PPE must be comfortable and allow for efficient movement. Uncomfortable or restrictive PPE can lead to fatigue and potential errors.

For instance, when using a full-face respirator, ensuring compatibility with safety glasses or goggles is crucial for protecting the eyes without creating gaps or obstructing vision. Similarly, a safety harness should not interfere with the movement and operation of fall protection equipment.

Q 25. What are the disposal procedures for contaminated PPE?

Disposal of contaminated PPE depends on the type of contaminant and the specific regulations. The process must always prioritize the safety of disposal personnel and the environment. Generally, it involves these steps:

- Decontamination (if necessary): Depending on the type of contaminant, PPE may require decontamination before disposal. This might involve autoclaving, chemical disinfection, or other appropriate methods.

- Proper Containment: Place contaminated PPE in leak-proof bags or containers to prevent the spread of contaminants.

- Labeling: Clearly label containers to indicate the type of contaminant and any special handling requirements.

- Disposal Method: Follow local, state, and federal regulations for disposal, which might include incineration, landfill disposal, or specialized waste treatment facilities.

For example, used needles and other sharps must be disposed of in designated sharps containers to prevent accidental injury. Contaminated clothing might require special handling and disposal in accordance with infectious waste regulations. Always consult relevant guidelines and regulations before disposing of any contaminated PPE.

Q 26. How do you stay updated on the latest PPE technologies and best practices?

Staying current in the dynamic field of PPE requires a multifaceted approach:

- Professional Organizations: Join relevant professional organizations like the American Society of Safety Professionals (ASSP) or similar organizations in your region. These groups often host conferences, webinars, and offer publications on the latest advancements and best practices.

- Industry Publications and Journals: Read trade publications and peer-reviewed journals focused on occupational safety and health. These resources often feature articles on new technologies and research findings.

- Manufacturer Websites and Training: Consult the websites of PPE manufacturers for updates on product specifications, training materials, and relevant certifications.

- Regulatory Updates: Regularly review updates from regulatory bodies like OSHA or the equivalent in your country to stay informed of any changes to standards and regulations.

- Continuing Education: Participate in continuing education courses and workshops focused on PPE selection, use, and maintenance.

Staying updated is not just about knowing the latest materials; it’s about understanding evolving hazards and the most effective ways to mitigate them. This continual learning ensures you’re making informed decisions and providing optimal protection for workers.

Q 27. Describe your experience working with different types of PPE.

My experience encompasses a wide range of PPE, including:

- Respiratory Protection: I’ve worked extensively with various respirators, from N95 masks to full-face respirators, ensuring proper fit testing and training for different applications and contaminants.

- Protective Clothing: My experience includes selecting and utilizing different types of protective clothing, such as chemical protective suits, flame-resistant clothing, and high-visibility garments, ensuring they meet the requirements for specific hazards.

- Eye and Face Protection: I’ve worked with safety glasses, goggles, face shields, and welding helmets, ensuring proper selection based on the nature of the eye and face hazards present.

- Hand Protection: I’ve selected and implemented various glove types, including chemical-resistant gloves, cut-resistant gloves, and insulated gloves, considering the specific risks and ensuring proper fit and dexterity.

- Head Protection: I have experience selecting and implementing hard hats and other head protection, considering the specific risks and ensuring proper fit.

In each case, I’ve emphasized the importance of proper training, inspection, and maintenance to ensure the ongoing effectiveness of the PPE. For instance, I once assisted a company in transitioning from a less effective glove type to one providing superior chemical resistance, resulting in a significant reduction in chemical exposure incidents.

Q 28. What are the potential health effects associated with prolonged PPE use?

Prolonged PPE use can lead to various health effects, depending on the type of PPE and the duration of use. These effects can be broadly categorized as:

- Physical Discomfort: Restricting movement and limiting dexterity can lead to muscle strain, fatigue, and discomfort. This is particularly true for bulky or ill-fitting PPE.

- Skin Irritation: Certain PPE materials can cause allergic reactions or skin irritations. This is a common issue with gloves and protective clothing, especially with prolonged wear.

- Heat Stress: Wearing multiple layers of PPE, especially in hot or humid environments, can lead to heat stress, heat exhaustion, and even heat stroke. This is a critical concern in industries like construction and firefighting.

- Respiratory Problems: While respirators protect against airborne hazards, they can also cause discomfort, breathing difficulties, and skin irritation. Poorly fitted respirators can lead to increased breathing resistance.

- Psychological Effects: The constant use of PPE, especially in high-stress situations like healthcare, can lead to claustrophobia, anxiety, and psychological fatigue.

Mitigating these effects requires careful PPE selection, proper training on donning and doffing procedures, regular breaks, and monitoring of worker well-being. Implementing strategies to reduce heat stress such as cooling vests or providing ample hydration can also improve worker comfort and reduce the risk of heat-related illnesses.

Key Topics to Learn for Personal Protective Equipment (PPE) Use Interview

- Types of PPE: Understanding the different categories of PPE (e.g., respiratory protection, eye protection, hand protection, head protection, body protection) and their appropriate applications.

- Selection Criteria: Knowing the factors influencing PPE selection, including hazard assessment, workplace conditions, and regulatory compliance (OSHA, etc.).

- Proper Donning and Doffing Procedures: Mastering the correct techniques for putting on and removing PPE to minimize contamination risks and ensure effectiveness.

- Limitations of PPE: Recognizing the inherent limitations of PPE and understanding when it’s insufficient to protect against specific hazards. This includes knowing when additional controls are necessary.

- Maintenance and Inspection: Understanding the importance of regular inspection and maintenance of PPE to ensure its continued functionality and effectiveness.

- PPE Regulations and Standards: Familiarity with relevant safety regulations and standards governing PPE use in your industry.

- Practical Application: Be prepared to discuss real-world scenarios where you had to select, use, and maintain PPE, highlighting problem-solving and decision-making skills.

- Emergency Procedures: Understanding procedures for dealing with PPE failures or emergencies involving PPE use.

- Training and Communication: Demonstrating knowledge of the importance of proper training and clear communication regarding PPE use within a team.

Next Steps

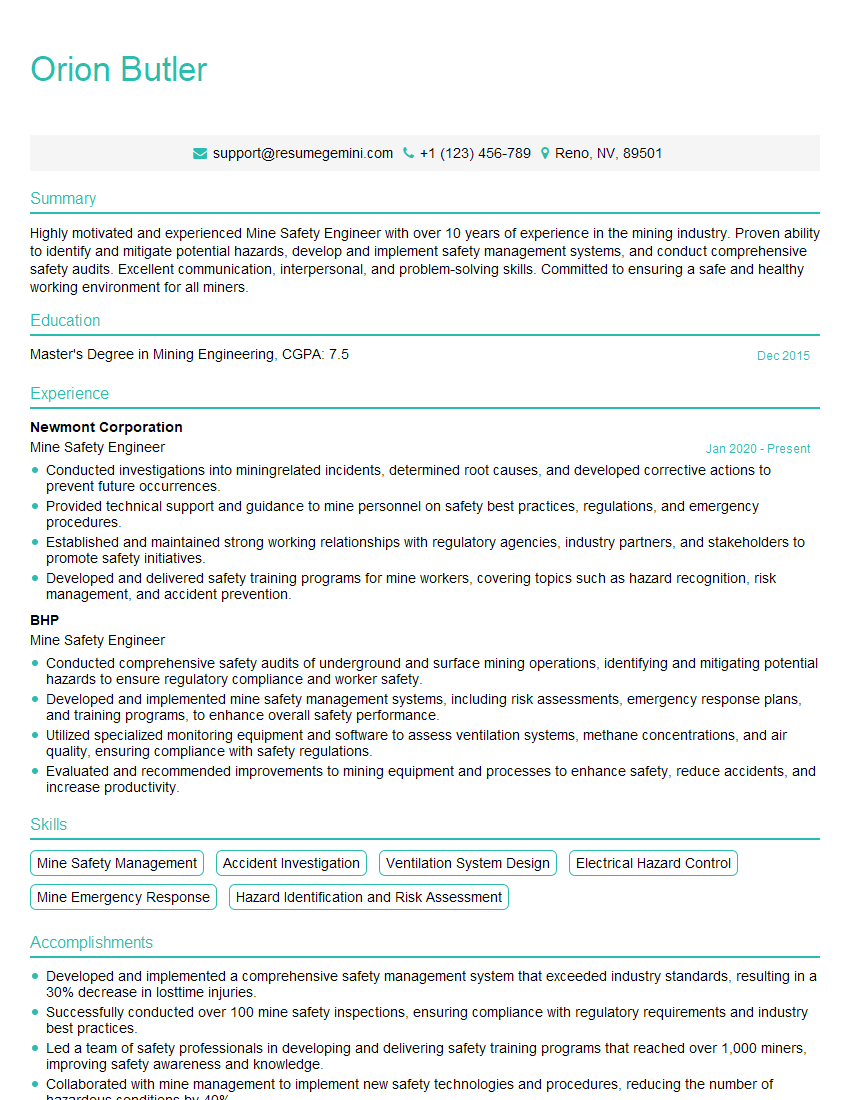

Mastering Personal Protective Equipment (PPE) use is crucial for career advancement in many safety-critical industries. A strong understanding of PPE selection, usage, and regulations demonstrates your commitment to safety and will significantly enhance your job prospects. To stand out to potential employers, creating a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. We offer examples of resumes tailored to Personal Protective Equipment (PPE) Use to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO