Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Physical Ability to Lift Heavy Items interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Physical Ability to Lift Heavy Items Interview

Q 1. Describe your experience lifting heavy objects (specify weight and frequency).

Throughout my career, I’ve regularly lifted objects ranging from 25 to 100 pounds, with the frequency varying depending on the task. For instance, during my time as a warehouse worker, I lifted an average of 50-75 pounds approximately 20-30 times per hour for 8 hours daily, involving boxes of varying sizes and contents. In construction projects, I’ve moved heavier items – up to 100 pounds – less frequently, maybe 5-10 times a shift, focusing more on proper technique and teamwork for larger or bulkier loads. I always prioritize safety and adjust my lifting frequency according to the weight and my physical condition. I believe in consistently assessing my physical capabilities and avoiding overexertion.

Q 2. What safety measures do you employ when lifting heavy items?

Safety is paramount. Before any lift, I assess the object’s weight, stability, and the surrounding environment. This includes checking for obstructions, ensuring a clear path, and wearing appropriate personal protective equipment (PPE), such as steel-toed boots and gloves when necessary. I always use proper lifting techniques and if the object is too heavy or awkward, I request assistance or utilize appropriate lifting equipment.

- Proper Lifting Technique: This is always my first priority (explained further in the next answer).

- Teamwork: For exceptionally heavy items, I work with colleagues to distribute the load and lift safely.

- Equipment Use: Leveraging equipment like dollies, hand trucks, or hoists for larger or heavier items minimizes risk.

- Environmental Assessment: Checking for hazards like uneven ground, slippery surfaces, or obstacles before attempting the lift.

Q 3. Explain proper lifting techniques, including posture and body mechanics.

Proper lifting techniques are essential to prevent injuries. The core principle involves minimizing strain on the back and utilizing leg muscles for strength. Imagine lifting a heavy object as if you are performing a squat.

- Assess the weight and size: Get a feel for the object’s weight and shape to plan your approach.

- Position yourself close: Stand directly facing the object with your feet shoulder-width apart.

- Bend your knees and hips: Lower your body by bending your knees and hips, keeping your back straight. Avoid bending at the waist.

- Grip firmly: Get a secure grip on the object, using both hands if necessary.

- Lift smoothly and slowly: As you lift, engage your leg muscles to push upwards. Keep the object close to your body.

- Maintain a straight back: Keep your back straight throughout the lift; avoid twisting or jerking movements.

- Look ahead: Focus on where you’re going to place the object.

- Set down gently: Slowly lower the object by bending your knees and hips.

Example: Lifting a heavy box from the floor to a shelf should involve bending down, gripping the box tightly, keeping your back straight, and using your leg muscles to lift it up, maintaining the box close to your body throughout the movement. This helps avoid undue strain on your back.

Q 4. How do you assess the weight of an object before lifting?

Assessing an object’s weight before lifting involves a combination of visual inspection and physical assessment.

- Visual cues: Size and material give clues about the weight. A large, dense object will likely be heavier than a smaller, less dense one.

- Physical assessment: Gently try to lift a corner or edge of the object. This gives an immediate sense of its weight. If it feels significantly heavier than anticipated, I may opt for assistance or lifting equipment.

- Weight markings: Sometimes, boxes or containers are labeled with their weight; this can be a helpful indicator.

Using a combination of these methods ensures a reasonable estimate before lifting, helping prevent accidents or strains. If uncertain, I always err on the side of caution and seek assistance.

Q 5. What are the signs of a potentially unsafe lifting situation?

Several signs indicate a potentially unsafe lifting situation:

- Object too heavy: The object is clearly beyond my capacity to lift safely.

- Awkward shape: The object’s shape makes it difficult to grip securely.

- Poor footing or unstable ground: Uneven or slippery surfaces increase the risk of slips and falls.

- Poor visibility or obstructions: Inability to see the path ahead or presence of obstacles.

- Insufficient support or assistance: Lifting a heavy item alone when teamwork would be safer.

- Physical limitations: I may have pre-existing conditions or fatigue that compromises my lifting ability.

In any of these situations, I would halt the lift and find a safer way to move the object, either by seeking assistance, using equipment, or re-evaluating the entire process.

Q 6. How do you handle unexpected weight imbalances during lifting?

Unexpected weight imbalances are dangerous. If I encounter this, my immediate response is to:

- Maintain a firm grip: I try to regain control and balance by gripping the object more firmly.

- Get assistance immediately: I call for help to stabilize the load and prevent injury.

- Lower the object slowly and carefully: I attempt to carefully lower the object to a stable position instead of risking a sudden drop.

- Re-evaluate the lifting technique: For future lifts, I analyze what contributed to the imbalance and adjust my technique accordingly.

Preventing this often involves a careful assessment of the object’s weight distribution and the chosen lifting technique before lifting begins.

Q 7. Describe your experience using lifting aids (e.g., dollies, hand trucks).

I have extensive experience using various lifting aids, significantly improving safety and efficiency.

- Dollies: Ideal for moving large, bulky, or heavy objects across long distances. I’m proficient in securing loads and maneuvering dollies on various surfaces.

- Hand trucks: Excellent for transporting heavy, upright objects, such as boxes or barrels. I’m experienced in loading, securing, and maneuvering these trucks effectively.

- Hoists and cranes: For exceptionally heavy loads, hoists and cranes ensure safe handling. I have used these under the supervision of trained personnel, always adhering to safety protocols.

Utilizing these aids reduces strain on my body, enhances efficiency, and minimizes the risk of injury. Proper training and knowledge of equipment operation are crucial for safe and effective use.

Q 8. What is your understanding of ergonomic principles in lifting?

Ergonomic principles in lifting focus on minimizing strain and injury by optimizing the body’s mechanics. It’s about using your body efficiently to reduce the risk of musculoskeletal disorders. This involves understanding factors like posture, leverage, and the weight distribution of the object.

- Posture: Maintaining a neutral spine (natural curves) is crucial. Avoid twisting or bending at the waist. Keep your back straight and lift with your legs.

- Leverage: Get as close to the object as possible to reduce the distance the load needs to travel. The shorter the distance, the less strain on your back.

- Weight Distribution: Distribute the weight evenly. If the object is asymmetrical, adjust your grip to compensate and maintain balance.

- Foot Placement: Maintain a wide, stable base of support with feet shoulder-width apart. This enhances balance and stability during the lift.

Imagine trying to lift a heavy box from the floor. A poor ergonomic approach would involve bending over at the waist, twisting your body, and lifting with your back. This puts immense strain on your spine. The correct approach involves bending at the knees and hips, keeping your back straight, and lifting with your leg muscles.

Q 9. How do you prioritize safety over speed when lifting heavy objects?

Prioritizing safety over speed when lifting heavy objects is paramount. Speed compromises form and increases the risk of injury. My approach involves a deliberate and controlled movement, focusing on proper technique before considering speed.

- Assessment: Before lifting, I assess the weight, size, and shape of the object. I check the pathway to ensure it’s clear of obstructions.

- Proper Technique: I always use the most appropriate lifting technique (e.g., power lift, stoop lift – explained later). I maintain a stable base, engage my core muscles, and lift using my legs.

- Controlled Movement: I lift slowly and smoothly, avoiding sudden movements or jerky transitions. I maintain a neutral spine throughout the lift.

- Breaks: For multiple heavy lifts, I take regular breaks to avoid fatigue, which impairs judgment and increases injury risk.

Think of it like driving a car; speed isn’t always better. A slow, controlled lift is safer and protects your body.

Q 10. Explain your process for obtaining assistance when lifting excessively heavy items.

Obtaining assistance is critical when lifting excessively heavy items. My process involves a clear and concise communication strategy:

- Assessment: I honestly assess whether I can safely lift the object alone. If there’s any doubt, I seek help immediately.

- Communication: I communicate clearly and directly with my team, explaining the weight and nature of the object. I specify the type of assistance needed (e.g., ‘Need a hand with this heavy crate’).

- Coordination: We coordinate our efforts, ensuring everyone understands their role. We establish a clear lifting plan to maintain balance and avoid collisions.

- Safety Checks: Before we lift, we perform a safety check to confirm proper lifting techniques and clear pathways.

Using teamwork helps avoid individual strain and protects everyone involved. It is a sign of strength, not weakness, to ask for help.

Q 11. Have you ever experienced a lifting-related injury? If so, describe the incident and what you learned.

Yes, I once suffered a minor back strain while lifting a heavy equipment component improperly. I was rushing to meet a deadline and did not use correct lifting technique. I bent at my waist instead of using my legs. This resulted in muscle strain and discomfort for several days.

This experience reinforced the importance of proper lifting techniques and the need to prioritize safety over speed. I learned to always assess the weight and consider asking for assistance, no matter the pressure. It also taught me the value of preventative measures, like regular stretching and maintaining good physical fitness.

Q 12. Describe your experience with different lifting techniques (e.g., power lift, stoop lift).

I have experience with various lifting techniques, each suited for different situations:

- Power Lift (or Squat Lift): This is excellent for heavy objects from the ground. You stand with your feet shoulder-width apart, bend your knees and hips, keeping your back straight, and lift the object by straightening your legs. This leverages your strong leg muscles.

- Stoop Lift: Used for objects that are slightly above knee height. You bend at the hips and knees, keeping your back straight, and lift the object closer to your body.

- Golfer’s Lift: Suitable for lighter objects. You bend one knee, keeping your back straight, and use the other leg to support you as you lift.

The choice of technique depends on the object’s weight, height, and my own physical capabilities.

Q 13. How do you adapt your lifting technique based on the object’s shape and size?

Adapting lifting techniques to the object’s shape and size is crucial. The object’s dimensions dictate both the lifting technique and the grip. For example:

- Long, Narrow Objects: Require a two-handed grip with your hands spread apart to maintain balance and control.

- Bulky, Irregular Objects: Might need a different grip or the use of lifting aids to secure the object.

- Awkward Shaped Objects: May necessitate using a different technique or seeking additional help to ensure stability and prevent twisting movements.

My approach involves careful evaluation before lifting, including the size, shape, weight, and center of gravity of the object, determining the most effective and safest method for handling it.

Q 14. How do you communicate with your team regarding heavy lifting tasks?

Communication is key for safe heavy lifting tasks. I ensure clear and proactive communication:

- Pre-Lift Briefing: Before lifting any heavy object, I discuss the task with my team, outlining the plan and ensuring everyone understands their roles.

- Clear Instructions: I provide clear and concise instructions, specifying the lifting technique to use and any potential hazards.

- Non-Verbal Cues: We use hand signals to coordinate our movements, ensuring we lift and move the object in unison.

- Post-Lift Check-in: After the lift, I check in with the team to make sure everyone is safe and hasn’t experienced any strain or discomfort.

Effective communication prevents misunderstandings, ensures safety, and enhances teamwork.

Q 15. What is your understanding of weight limits and regulations?

Weight limits and regulations are crucial for preventing injuries and ensuring workplace safety. These limits are determined by factors like the type of load (is it awkward, bulky, or fragile?), the distance it needs to be moved, and the individual’s physical capabilities. Regulations often come from government agencies (like OSHA in the US) and specify maximum permissible weights for lifting, carrying, and pushing/pulling, often with adjustments for specific tasks or worker characteristics. For instance, there might be stricter limits for overhead lifting or repetitive movements. Ignoring these limits can lead to serious consequences, including back injuries, muscle strains, and even fatalities. Companies often establish their own internal weight limits that are even stricter than regulatory minimums, to foster a safety-first culture.

For example, a regulation might state that a single worker cannot lift more than 50 pounds without mechanical assistance. However, a company might set its internal limit to 35 pounds, taking into account factors like worker fatigue and the variability in individual strength.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working in a physically demanding environment.

I’ve spent over ten years working in warehouse environments, specifically in the logistics sector. My roles have consistently involved physically demanding tasks such as loading and unloading trucks, stacking pallets, and moving heavy machinery components. This experience has given me a deep understanding of the challenges associated with heavy lifting, including proper techniques, the importance of teamwork, and the need for mechanical assistance when dealing with excessively heavy loads. I’ve routinely handled items weighing upwards of 100 pounds, often in environments with limited space and challenging conditions like uneven surfaces or extreme temperatures.

One memorable project involved the manual relocation of large industrial motors, each weighing approximately 400 pounds. This required careful planning, precise teamwork, and the utilization of specialized lifting equipment to ensure safety and efficiency.

Q 17. How do you maintain your physical fitness for heavy lifting tasks?

Maintaining physical fitness for heavy lifting isn’t just about brute strength; it’s about overall body conditioning and injury prevention. My routine focuses on building strength, endurance, and flexibility. This involves a combination of:

- Strength training: Exercises targeting major muscle groups (back, legs, core) are essential. I incorporate deadlifts, squats, and lunges to build functional strength directly applicable to lifting tasks.

- Cardiovascular exercise: Maintaining cardiovascular health improves stamina and reduces fatigue, crucial for prolonged heavy lifting. I incorporate running, cycling, or swimming into my weekly routine.

- Flexibility and mobility exercises: Yoga and stretching help to prevent muscle stiffness and improve range of motion, minimizing risk of injury. This is often overlooked but absolutely vital.

Regular check-ups with my physician and physical therapist help me monitor my progress and address any potential issues early on.

Q 18. How do you prepare your body before starting a day of heavy lifting?

Preparing my body before a day of heavy lifting involves a multi-faceted approach focusing on warming up muscles, improving blood flow and minimizing the risk of injury. This includes:

- Hydration: I start the day with plenty of water to stay hydrated throughout the day. Dehydration significantly impacts performance and increases injury risk.

- Dynamic stretching: I perform dynamic stretches, such as arm circles, leg swings, and torso twists, to increase blood flow to muscles and improve range of motion. This is in contrast to static stretching which should be done *after* the activity.

- Light cardio: A short period of light cardio, like a brisk walk or some jumping jacks, further prepares the body for physical exertion.

This warm-up routine takes about 15-20 minutes, preparing my body both physically and mentally for the tasks ahead.

Q 19. Describe a time you had to improvise a solution for a heavy lifting challenge.

During a warehouse move, we needed to relocate a massive server rack, far heavier than our standard lifting equipment could handle safely. Our initial plan was scrapped due to the weight and the unusual shape of the rack. Instead of delaying the operation, we improvised a solution using a combination of dollies, strong ropes, and careful teamwork. We secured the rack to the dollies, using the ropes to distribute the weight and prevent any shifting. We then coordinated our efforts to maneuver the rack to its new location, ensuring everyone was synchronized and the weight was evenly distributed. This collaborative improvisation ensured the successful and safe relocation of the server rack.

Q 20. How do you ensure the safety of yourself and others during heavy lifting?

Ensuring safety during heavy lifting involves a proactive and multi-layered approach:

- Proper lifting techniques: This includes maintaining a straight back, bending at the knees, keeping the load close to the body, and avoiding twisting movements. I always emphasize lifting with the legs and not with the back.

- Mechanical assistance: Whenever possible, I use lifting equipment like forklifts, pallet jacks, or hoists. This minimizes the physical strain on individuals and prevents injury.

- Teamwork and communication: For heavy loads, I always work with a team, ensuring clear communication and coordinated movements. Clear signals and verbal communication are essential.

- Environmental awareness: I assess the workspace for hazards, like obstacles or uneven surfaces, before initiating the lift. I also ensure proper lighting and clear pathways.

Regular safety briefings and training refresh our knowledge of best practices and remind us of the importance of a safe working environment.

Q 21. What is your understanding of workplace safety regulations regarding heavy lifting?

Workplace safety regulations regarding heavy lifting vary depending on the jurisdiction, but common themes include:

- Weight limits: Regulations specify maximum permissible weights for lifting and carrying, often differentiated based on the task and worker characteristics.

- Lifting techniques: Regulations often require employers to provide training on proper lifting techniques to minimize risks of injury.

- Mechanical assistance: Regulations may mandate the use of mechanical lifting devices for loads exceeding a certain weight or those posing particular ergonomic challenges.

- Personal Protective Equipment (PPE): Regulations may require the use of appropriate PPE, such as safety gloves or back supports, depending on the task and potential hazards.

- Reporting and record-keeping: Employers are usually required to track and report workplace injuries, especially those related to heavy lifting, to prevent future incidents.

Understanding and adhering to these regulations is not just a legal obligation but a crucial aspect of creating a safe and healthy work environment.

Q 22. Describe your experience working with different types of lifting equipment.

My experience encompasses a wide range of lifting equipment, from basic hand trucks and pallet jacks to more complex machinery like overhead cranes and forklifts. I’m proficient in operating and maintaining these tools safely and efficiently. For example, I’ve extensively used pallet jacks in warehouse environments to move heavy pallets of goods, ensuring proper load distribution and stability to prevent tipping. With overhead cranes, my expertise lies in correctly attaching slings, calculating load weights, and coordinating movements to avoid collisions and structural damage. Similarly, my forklift experience includes safe operation within designated areas, adhering strictly to weight limits and following all safety protocols.

- Hand Trucks: Maneuvering heavy, awkward loads across uneven terrain, requiring proper technique to avoid strain and injury.

- Pallet Jacks: Efficiently moving palletized materials, understanding weight distribution and stability to prevent accidents.

- Overhead Cranes: Lifting and positioning heavy loads with precision, ensuring safe operation and preventing damage to equipment and personnel.

- Forklifts: Operating forklifts within designated areas, adhering to weight limits and safety guidelines.

Q 23. How do you handle situations where lifting equipment malfunctions?

Equipment malfunctions are handled with immediate caution and adherence to established safety procedures. My first step is to immediately shut down the equipment and secure the load, if possible. Then, I assess the situation to identify the nature of the malfunction, making sure to keep myself and others at a safe distance. Depending on the severity, I either initiate repairs myself (if qualified and within my capabilities), or I report the malfunction to the appropriate maintenance personnel and follow their instructions. For example, if a forklift’s hydraulic system fails mid-lift, I would immediately lower the forks as safely as possible and then contact maintenance. I would then create a barrier to prevent anyone from approaching the machine until it has been inspected and repaired.

Q 24. What is your experience with using personal protective equipment (PPE) during heavy lifting?

Personal Protective Equipment (PPE) is paramount in heavy lifting. I consistently use appropriate PPE, including safety shoes with steel toes to protect against falling objects, safety glasses to prevent eye injuries from debris, and gloves to enhance grip and prevent hand injuries. In situations involving high-risk loads or confined spaces, I’ll also utilize hard hats and potentially hearing protection. For instance, when working with overhead cranes, I always wear a hard hat to protect myself from falling objects. The type of gloves used depends on the specific task – for example, when handling sharp or abrasive materials, I would use cut-resistant gloves.

Q 25. Describe a time you identified a potential safety hazard related to heavy lifting.

During a warehouse reorganization, I noticed that a section of the floor had become uneven due to repeated heavy equipment traffic. This created a significant trip hazard, particularly risky for individuals handling heavy loads. The uneven floor presented a potential for dropped loads, serious injuries, and damage to equipment.

Q 26. How did you rectify that hazard?

I immediately reported the uneven floor to my supervisor, highlighting the potential safety risk. We temporarily cordoned off the area to prevent access until repairs could be made. Following that, we collaborated to develop a temporary solution—using strategically placed wooden planks to create a level path—before the permanent repair could be completed. This ensured a safer working environment while minimizing disruption to operations.

Q 27. What are the potential risks associated with improper lifting techniques?

Improper lifting techniques lead to a variety of serious risks, including muscle strains, sprains, back injuries, hernias, and even fractures. For example, bending at the waist instead of squatting to lift a heavy object puts immense strain on the lower back, potentially causing long-term damage. Similarly, twisting while lifting can seriously injure your spine. Ignoring weight limits can lead to injury or the damage of goods.

- Musculoskeletal Injuries: Strains, sprains, and back injuries are common.

- Dropped Loads: Leading to damage to property or injury to personnel.

- Equipment Damage: Improper handling can damage lifting equipment.

Q 28. How do you stay updated on best practices for safe heavy lifting?

I stay updated on best practices through several channels. I regularly attend safety training sessions and workshops offered by the company and external organizations. I also actively seek out and read industry publications, safety manuals, and online resources focusing on safe lifting techniques and equipment updates. Staying certified in the operation of all equipment I utilize is another key method for keeping my knowledge up to date. Furthermore, I actively participate in safety meetings and contribute to discussions on improving our workplace safety practices.

Key Topics to Learn for Physical Ability to Lift Heavy Items Interview

- Proper Lifting Techniques: Understanding and applying safe lifting mechanics to minimize injury risk. This includes knowing the correct posture, foot placement, and body movements for different lifting scenarios.

- Ergonomics and Workplace Safety: Applying ergonomic principles to prevent injuries and optimize lifting efficiency. This involves understanding the role of equipment, workstation setup, and work environment in safe lifting practices.

- Understanding Weight Limits and Load Capacity: Knowing your personal limitations and the safe weight limits for various equipment and tasks. This includes being aware of potential hazards associated with exceeding weight limits.

- Teamwork and Communication in Lifting: Recognizing the importance of clear communication and collaboration when lifting heavy objects with others. This encompasses understanding roles and responsibilities during team lifts.

- Equipment Usage and Safety: Demonstrating knowledge of using and maintaining lifting equipment such as forklifts, pallet jacks, or hoists safely and efficiently. This includes understanding safety protocols and maintenance procedures.

- Injury Prevention and First Aid: Understanding common lifting injuries, their prevention, and basic first aid procedures in case of an accident. This demonstrates a commitment to workplace safety.

- Adaptability to Varying Lifting Conditions: Describing how you adapt your lifting techniques based on different physical environments, load types, and available equipment.

Next Steps

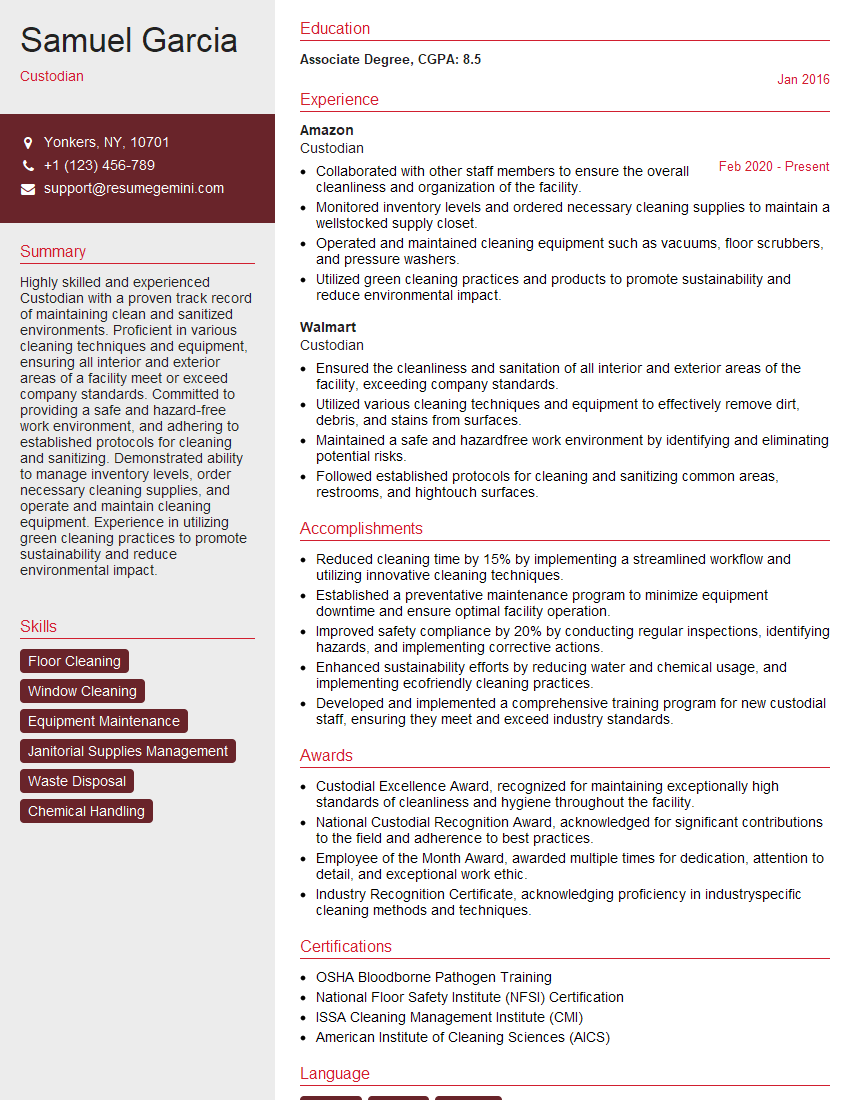

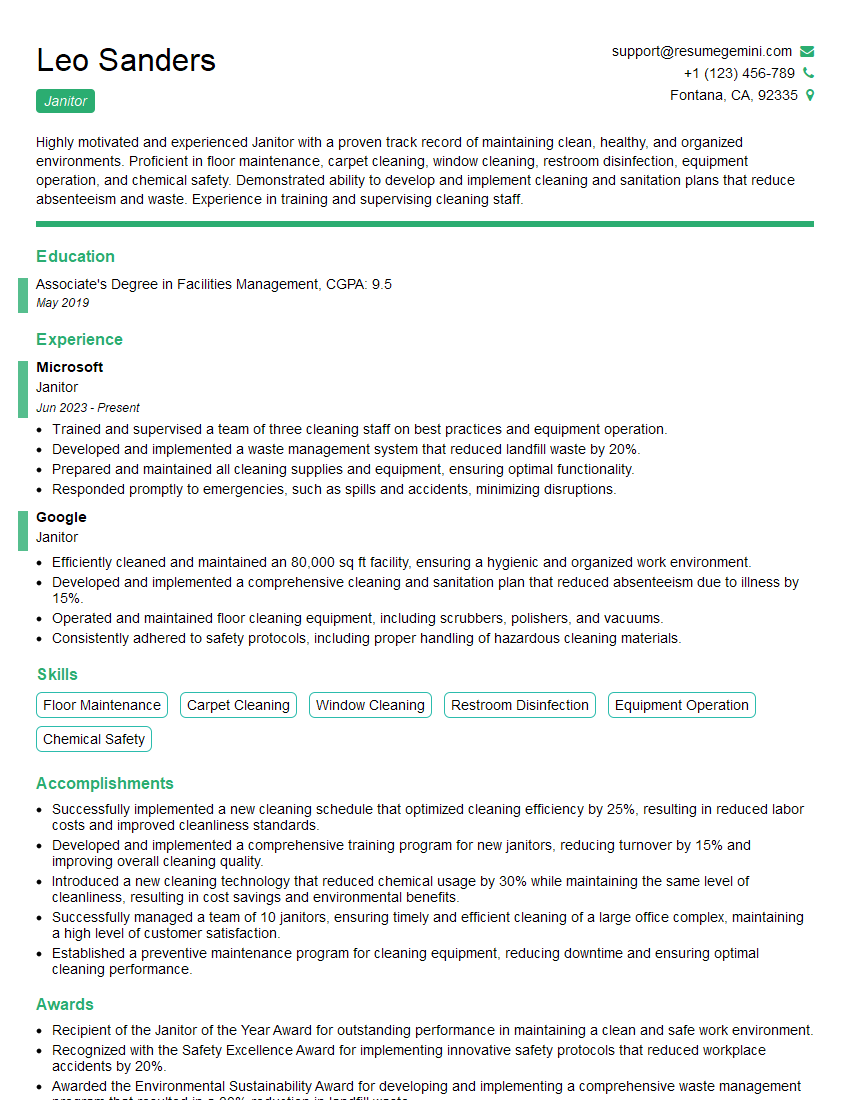

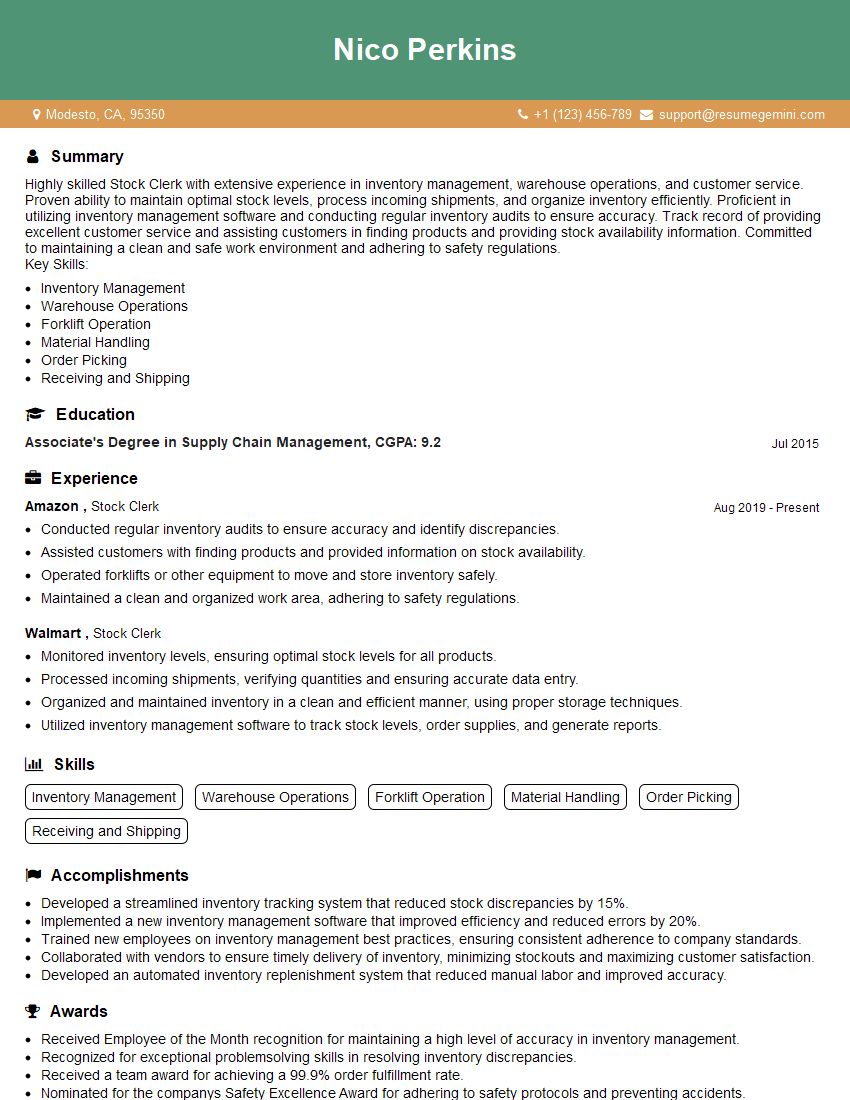

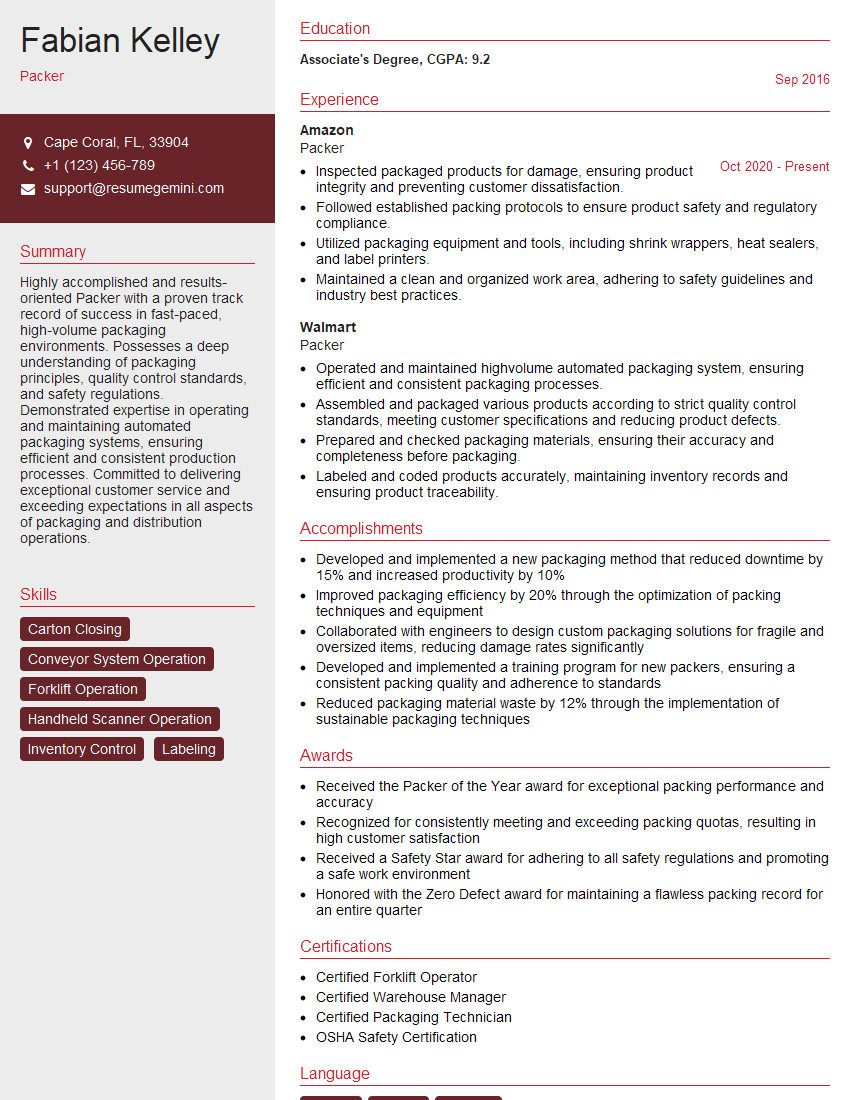

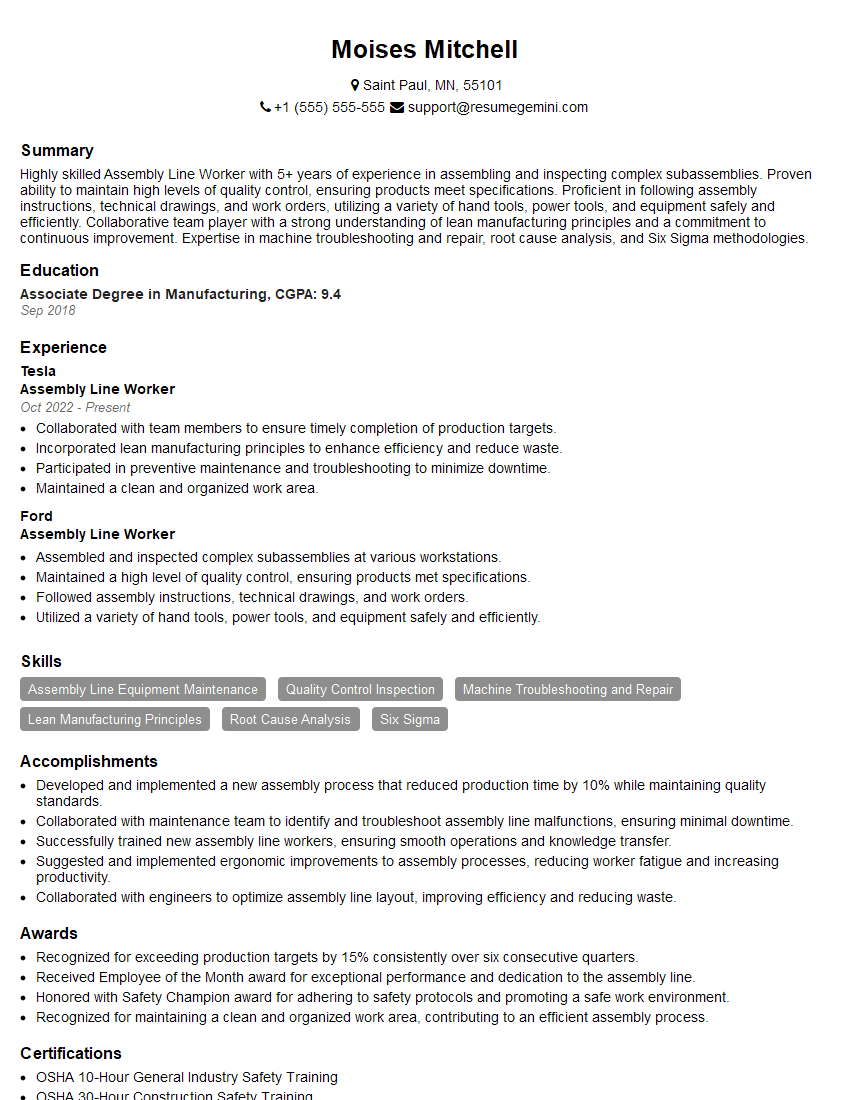

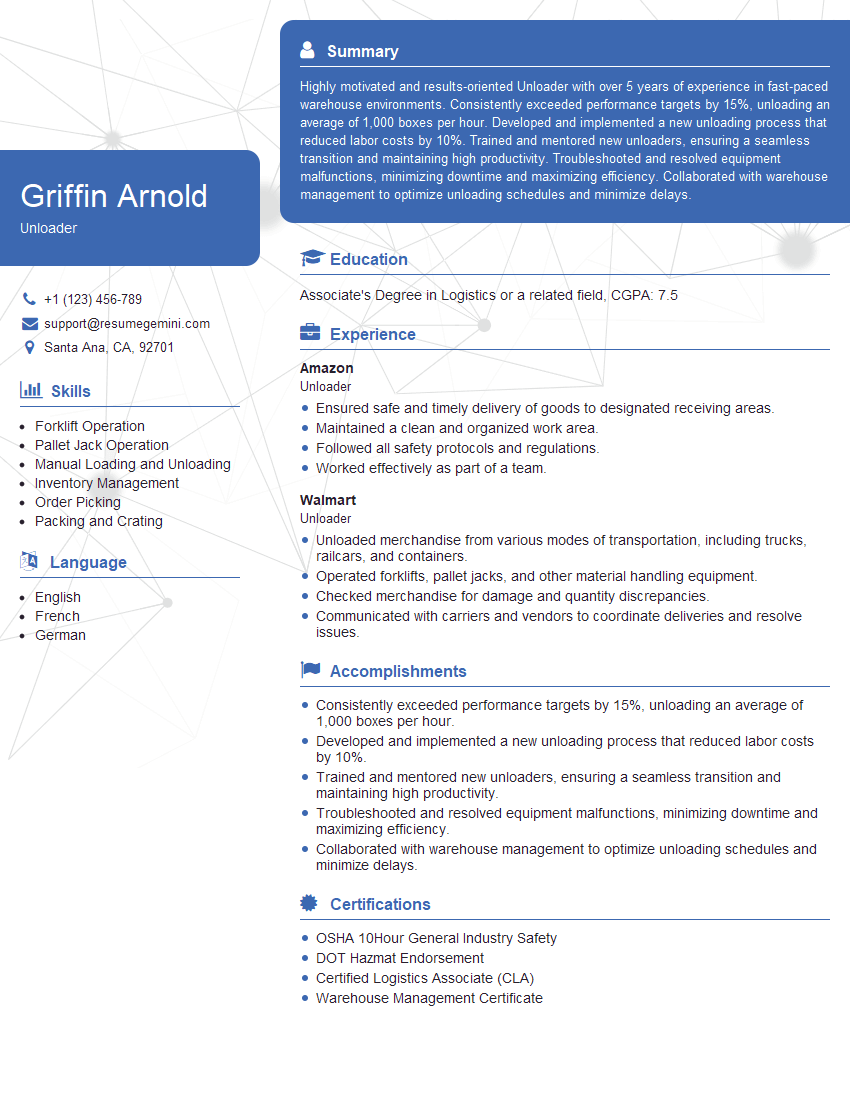

Mastering safe and efficient heavy lifting techniques is crucial for career advancement in many physically demanding roles. It demonstrates your commitment to safety, efficiency, and teamwork. To significantly enhance your job prospects, invest time in crafting a compelling and ATS-friendly resume that highlights these skills. ResumeGemini is a trusted resource for building professional resumes that attract recruiters. We provide examples of resumes tailored to highlight your Physical Ability to Lift Heavy Items skills, helping you stand out from the competition and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO