Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Plumbing and Sanitation Maintenance interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Plumbing and Sanitation Maintenance Interview

Q 1. Explain the different types of pipe materials and their applications.

Selecting the right pipe material is crucial for a plumbing system’s longevity and efficiency. Different materials offer varying levels of durability, resistance to corrosion, and cost-effectiveness. Here are some common types:

- Copper: Known for its durability, resistance to corrosion, and ability to withstand high water pressure. Ideal for hot and cold water supply lines in residential and commercial settings. However, it’s relatively expensive.

- PVC (Polyvinyl Chloride): A lightweight, inexpensive, and corrosion-resistant plastic pipe. Commonly used for drain, waste, and vent (DWV) systems, as well as water supply lines in less demanding applications. It’s not suitable for high-temperature applications.

- CPVC (Chlorinated Polyvinyl Chloride): A stronger and more heat-resistant version of PVC. Suitable for hot and cold water supply lines, particularly in areas with higher temperatures.

- PEX (Cross-linked Polyethylene): A flexible plastic pipe that’s gaining popularity due to its ease of installation, resistance to freezing, and relatively low cost. Used for both hot and cold water supply lines.

- Cast Iron: A heavy-duty, durable material traditionally used for drain and sewer lines. While less common now due to its weight and susceptibility to corrosion, it’s still found in older buildings.

- Galvanized Steel: Once widely used, galvanized steel pipes are now less common due to the potential for corrosion and the risk of rust particles contaminating water. Often found in older buildings.

The choice of pipe material depends on factors such as the application (water supply, drainage), budget, and local building codes. For example, a new residential construction might use PEX for water supply lines due to its flexibility and ease of installation, while a commercial building might opt for copper for its durability and longevity.

Q 2. Describe your experience with troubleshooting and repairing various plumbing fixtures.

Throughout my career, I’ve tackled a wide range of plumbing fixture repairs. I’ve diagnosed and fixed leaky faucets (cartridge, compression, and ball-type), repaired running toilets (flapper, fill valve, and chain issues), unclogged sinks and showers (hair clogs, soap buildup), and replaced damaged showerheads and spigots. For instance, I recently repaired a constantly running toilet by identifying a faulty fill valve. After replacing it, the toilet functioned correctly, conserving water and saving the homeowner money. Another example involves diagnosing a shower’s low water pressure by checking the showerhead for mineral buildup and then cleaning or replacing it. In each instance, a systematic approach—visual inspection, listening for unusual noises, and using appropriate tools—is paramount to accurate diagnosis and effective repair.

Q 3. How do you identify and resolve common plumbing leaks?

Pinpointing the source of a leak is the first step to resolving it. This involves careful observation and sometimes using specialized tools. Common leak detection methods include:

- Visual Inspection: Check for obvious signs of water damage, such as discoloration on walls or ceilings, damp spots, or dripping pipes.

- Listening for Sounds: A hissing or dripping sound can indicate a leak near the source.

- Water Pressure Test: If a significant drop in water pressure is observed, it can point towards a hidden leak within the piping system.

- Dye Testing: A dye can be added to the water supply to help pinpoint the location of a leak.

- Leak Detectors: Electronic leak detectors use sensors to identify moisture and pinpoint leaks.

Once the leak is identified, the repair method depends on its severity and location. Minor leaks might be fixed by tightening fittings or replacing worn-out washers or O-rings. Major leaks often necessitate replacing sections of pipe or fixtures. For example, a leaky pipe joint might be fixed by replacing the joint with a new one after the old one is properly cut out. Always ensure that the water supply is turned off before any repair work begins.

Q 4. What are the different methods for clearing clogged drains?

Clogged drains are a common plumbing issue, and several methods can be used to clear them. The choice of method depends on the severity and cause of the clog.

- Plunger: A simple and effective method for clearing minor clogs in sinks, tubs, and toilets. Ensure a good seal to create sufficient pressure to dislodge the clog.

- Drain Snake (Plumbing Auger): A flexible tool with a coiled end that can navigate bends in pipes to reach and break up clogs deeper in the drain line.

- Chemical Drain Cleaners: Commercial drain cleaners contain strong chemicals that can dissolve organic matter and break down clogs. Use with caution and always follow the manufacturer’s instructions; these are corrosive and should be used as a last resort.

- Hydro Jetting: A high-pressure water jet is used to blast away clogs and clean the drain line. This is particularly effective for severe clogs and buildup.

In some cases, a combination of methods might be necessary. For instance, a plunger may be used first, followed by a drain snake if the clog persists. It is important to always consider the severity of the clog before choosing a method to prevent potential damage to the drainage system.

Q 5. Explain the principles of water pressure regulation.

Water pressure regulation ensures that water flows through your plumbing system at a safe and efficient rate. Too much pressure can damage pipes and fixtures, while too little pressure leads to insufficient water flow. Pressure regulation is achieved through several methods:

- Pressure Reducing Valves (PRVs): These valves are installed on the main water line and automatically reduce water pressure to a safe level. They’re often set to maintain pressure between 40 and 60 psi (pounds per square inch), the ideal pressure for most household plumbing systems.

- Water Metering: The water meter itself can provide a degree of pressure regulation by controlling the flow rate. However, it does not fully regulate pressure in the system and may not be enough in all cases.

Consistent and proper water pressure is essential for optimal plumbing system performance. A properly functioning PRV will protect pipes and appliances from damage and ensure adequate water flow to all fixtures.

Q 6. Describe your experience with backflow prevention devices.

Backflow prevention devices are critical safety components that prevent contaminated water from flowing back into the clean water supply. This is essential to protect public health. Several types of backflow preventers exist, each designed for specific applications:

- Double Check Valve (DCV): A relatively simple device consisting of two independently operating check valves. It’s suitable for low-hazard applications.

- Reduced Pressure Zone Backflow Preventer (RPZ): A more sophisticated device that provides a higher level of protection against backflow by maintaining a reduced pressure zone between the two check valves. It’s typically used in higher-hazard applications.

- Pressure Vacuum Breaker (PVB): A simpler, less expensive device that is suitable for situations where only a limited level of backflow prevention is required.

Regular inspection and testing of backflow prevention devices are mandated in many areas to ensure they function correctly. Failure to maintain these devices can lead to serious health risks. I have extensive experience in installing, inspecting, and testing all types of backflow prevention devices, ensuring compliance with local codes and regulations.

Q 7. What safety precautions do you take when working with plumbing systems?

Safety is paramount in plumbing work. I always prioritize safety by taking the following precautions:

- Turning off water supply: Before working on any plumbing system, I always turn off the water supply to the affected area to prevent flooding or injury.

- Using appropriate Personal Protective Equipment (PPE): I wear safety glasses, gloves, and protective clothing to prevent cuts, abrasions, and exposure to harmful substances.

- Proper ventilation: When working with chemicals or in confined spaces, proper ventilation is crucial to avoid inhaling hazardous fumes.

- Lockout/Tagout procedures: When working on systems with moving parts or electrical components, lockout/tagout procedures must be followed to prevent accidental activation.

- Awareness of potential hazards: I am always aware of potential hazards such as electric shock, cuts from sharp tools, and exposure to hazardous materials.

- Following all relevant safety codes and regulations: I adhere to all local and national safety regulations and codes of practice relevant to the work being carried out.

Safety isn’t just a checklist; it’s a mindset. Every job starts and ends with a commitment to a safe working environment for myself and others.

Q 8. How do you handle emergency plumbing situations?

Emergency plumbing situations demand immediate action and a calm, methodical approach. My first priority is always safety – securing the area and preventing further damage or injury. This involves turning off the main water supply if necessary to stop water flow. Then, I assess the situation: is it a burst pipe, a clogged drain, a gas leak? The nature of the problem dictates the immediate steps. For instance, a burst pipe needs immediate isolation to minimize water damage; a gas leak requires immediate evacuation and contacting the gas company. Once the immediate danger is mitigated, I’ll implement a temporary fix if possible to contain the problem until a more permanent solution can be applied during regular working hours. I’ve dealt with everything from overflowing toilets in the middle of the night to burst pipes during a winter storm – each demanding a rapid response and on-the-spot problem-solving.

For instance, I once responded to a call about a burst pipe flooding a basement. My immediate action was to locate and shut off the main water supply, preventing further flooding. I then used shop towels and buckets to absorb the standing water, preventing damage to electrical components and flooring. Following that, I applied a temporary clamp to the burst section and arranged for a full pipe repair the next morning. Prioritizing safety and minimizing damage is paramount in every emergency.

Q 9. Explain your understanding of plumbing codes and regulations.

Plumbing codes and regulations are crucial for ensuring safe and functional plumbing systems. They cover aspects like pipe sizing, material specifications, water pressure requirements, drainage slopes, and fixture installations. My understanding encompasses both national codes, like the Uniform Plumbing Code (UPC), and local amendments. I’m familiar with the requirements for fixture installations, backflow preventers, venting systems, and water conservation measures. Staying updated on these codes is a continuous process; I regularly attend workshops and training sessions to keep my knowledge current. Ignoring these regulations can lead to serious consequences, ranging from fines and permit revocation to structural damage and health hazards. For example, improper venting can lead to sewer gases entering the building, posing a health risk, while incorrect pipe sizing could cause slow drainage or even blockages.

In my work, I always ensure that all my installations and repairs adhere strictly to the applicable codes. This involves careful planning, accurate measurements, and the use of approved materials. Before starting any job, I review the relevant codes and ensure my work meets or exceeds the requirements. This careful adherence to regulations not only protects the client’s property and safety, but also ensures the longevity and efficiency of the plumbing system.

Q 10. Describe your experience with installing and maintaining water heaters.

I have extensive experience with both the installation and maintenance of various water heaters, including tank-type and tankless models. Tank-type heaters require regular maintenance, including flushing sediment buildup and anode rod replacement to prolong their lifespan. I’m adept at diagnosing issues like pilot light problems, faulty thermostats, and leaks, performing repairs or replacements as needed. Tankless heaters, while more efficient, require a different skillset – understanding their complex electronic controls and troubleshooting potential issues with flow sensors and heating elements. I am proficient in working with various fuels – gas, electric, and even propane – ensuring safe and efficient installation and operation.

For example, I recently serviced a gas-fired tank-type water heater that had a malfunctioning thermostat. I safely isolated the gas supply, then diagnosed the issue using a multimeter to check the thermostat’s continuity. Replacing the thermostat restored the water heater’s functionality. With tankless systems, I’ve addressed issues related to low hot water flow, often caused by clogged filters or mineral buildup. Regular maintenance and accurate diagnosis are key to ensuring optimal performance and longevity of these systems.

Q 11. How familiar are you with different types of sewer systems?

Sewer systems vary widely, depending on factors like population density, topography, and available resources. I’m familiar with several types. The most common is the sanitary sewer system, which collects wastewater from homes and businesses and conveys it to a wastewater treatment plant. Then there are storm sewer systems, designed to handle rainwater runoff, preventing flooding. These systems are often separate to avoid overwhelming the wastewater treatment plant. Combined sewer systems, more common in older cities, combine both sanitary and storm sewer flows, posing challenges during heavy rainfall. In rural areas, septic systems are prevalent, treating wastewater on-site. I understand the different design principles, materials, and maintenance requirements of each type.

Understanding these differences is vital for troubleshooting. A blockage in a sanitary sewer requires different solutions than one in a storm sewer. For example, a sanitary sewer blockage may involve root intrusion or grease buildup, while a storm sewer blockage could be due to debris accumulation. This knowledge allows for effective diagnosis and repair, preventing environmental damage and property damage.

Q 12. Explain your experience with septic tank maintenance and repair.

Septic tank maintenance and repair are critical for protecting the environment and preventing costly repairs. My experience encompasses regular pumping and inspection, identifying and resolving issues like leach field failures, clogged drain lines, and tank cracks. Regular pumping removes accumulated sludge and scum, preventing backups and ensuring proper system function. Inspections identify potential problems early on, often allowing for less costly preventative repairs. I also know how to assess the condition of the drain field, using soil tests and visual inspection to check for saturation or other issues. I’m proficient in identifying and fixing leaks within the tank itself, and in replacing failed components such as the distribution box or the effluent filter.

I’ve encountered situations where a clogged drain line was causing a septic system backup. By using a plumbing snake and specialized equipment to clear the blockage, I was able to restore the system’s functionality without the need for costly excavation and replacement. Similarly, I’ve repaired cracked septic tanks using epoxy resins, providing a cost-effective solution compared to full tank replacement.

Q 13. What is your experience with different types of pumps used in sanitation systems?

Sanitation systems rely on various pumps, each with specific applications. I’m familiar with submersible pumps used in sump pits and sewage ejector pumps for basement bathrooms. These pumps handle wastewater and prevent backups. I also understand centrifugal pumps, which are often used in larger wastewater treatment plants to move large volumes of liquid. I know the differences in their design, functionality, and maintenance requirements. Troubleshooting issues with these pumps often involves checking for power supply issues, impeller wear, and clogged impellers. I’m familiar with preventative maintenance procedures for each type of pump, maximizing their lifespan and preventing costly breakdowns.

For example, I’ve repaired a failed submersible pump in a residential sump pit by identifying and replacing a faulty motor winding. This prevented water damage to the basement. In another instance, I diagnosed a low flow rate in a sewage ejector pump caused by a partially clogged impeller. A thorough cleaning restored the pump’s performance.

Q 14. How do you diagnose and repair problems with toilets, sinks, and showers?

Diagnosing and repairing problems with toilets, sinks, and showers requires a systematic approach. I start by visually inspecting the fixture and its surrounding area. A running toilet might indicate a faulty flapper or fill valve; a slow-draining sink could be due to a clogged drain or a problem with the P-trap; a low water pressure shower might signal a clogged showerhead or a more significant issue with the water supply line. I use tools such as plungers, snakes, and specialized plumbing cameras to identify blockages and other issues. I’m experienced in replacing parts like faucets, shower cartridges, toilet flappers, and repairing or replacing cracked pipes.

For example, I recently fixed a toilet that was running continuously by replacing the worn-out flapper. I also addressed a slow-draining sink caused by a buildup of hair and soap scum in the P-trap by carefully removing and cleaning the trap. A methodical approach and the right tools allow me to effectively troubleshoot and repair these common plumbing issues.

Q 15. What are your skills in reading and interpreting plumbing blueprints?

Reading plumbing blueprints is fundamental to my work. It’s like reading a map for a house’s plumbing system. I can decipher symbols representing pipes (different sizes and materials), fixtures (toilets, sinks, showers), valves, and other components. I’m proficient in understanding plan views, elevation drawings, and isometric projections. For instance, I can quickly identify the location of a main shut-off valve, trace the path of a drain line, or determine the diameter of a specific pipe based on the blueprint’s notations. My experience extends to interpreting blueprints for both residential and commercial projects, understanding the nuances of different construction codes and standards. I’m comfortable working with both hand-drawn blueprints and digital CAD drawings.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with using various plumbing tools and equipment.

My tool proficiency is comprehensive. I’m experienced with a wide range of equipment, from basic hand tools like pipe wrenches, basin wrenches, and pipe cutters, to more specialized tools such as drain augers, pipe threading machines, and pressure testing equipment. For example, I’m adept at using a drain snake to clear clogs in drain lines, efficiently threading pipes to ensure secure connections, and utilizing pressure testing equipment to identify leaks in underground pipes. I’m also familiar with power tools like reciprocating saws and drills, and understand the importance of safety procedures when using any equipment. I regularly maintain my tools and ensure they are in optimal working order, a key element of efficient and safe work practices.

Q 17. Describe your troubleshooting skills related to low water pressure.

Low water pressure troubleshooting requires a systematic approach. I start by checking the main water meter to see if the pressure is low across the entire system, or isolated to a specific area. If it’s system-wide, I’d investigate the main water supply line for any blockages or restrictions. If the pressure is localized, I would then systematically check the fixtures in that area for issues like clogged aerators, partially closed valves, or mineral deposits restricting water flow. I would also examine the pressure relief valve and check for leaks, which might indicate pressure loss. If the problem isn’t obvious, I might need to use a pressure gauge to accurately measure the water pressure at various points in the system to pinpoint the exact location of the issue, which could be a corroded pipe or a leak in an inaccessible area.

Q 18. How do you handle situations involving gas leaks in plumbing systems?

Gas leaks are extremely serious and require immediate action. My first step is to evacuate the area and ensure everyone is safe. Then, I would shut off the main gas supply to prevent further leakage. I would never attempt to use a flame or any electrical device near a suspected gas leak. After the gas is shut off, I’d carefully investigate the source of the leak. This often involves using specialized leak detection equipment like a gas sniffer to pinpoint the exact location. Once identified, repairs are made immediately, following all safety protocols. If the leak is significant or I’m not confident in addressing it safely, I immediately contact a qualified gas fitter or emergency services to ensure the situation is handled correctly. Safety is the paramount concern in such situations.

Q 19. Describe your experience with water treatment systems.

I have experience with various water treatment systems, including whole-house filtration systems, point-of-use filters (for individual fixtures), and water softeners. I understand how these systems work, their maintenance requirements, and common problems. For instance, I know how to replace filter cartridges in a whole-house system, troubleshoot issues with a water softener’s regeneration cycle, and identify the cause of reduced flow or poor filtration. My experience includes installing and maintaining different types of systems, adapting my approach to the specific needs and water quality issues of each situation.

Q 20. What is your understanding of cross-connections and how to prevent them?

Cross-connections occur when there’s an unintended link between potable (safe drinking) water and non-potable water sources (like wastewater, chemicals, or other contaminated water). This can contaminate the drinking water supply, posing serious health risks. Preventing cross-connections is crucial. It involves ensuring there are proper backflow prevention devices installed, such as air gaps or backflow preventers, at points where there could be a potential risk of contamination. Regular inspections are vital, ensuring these devices are functioning correctly and that no unauthorized connections exist. A good example is preventing a garden hose from siphoning back into the main water supply. We use backflow preventers to physically stop such events.

Q 21. How familiar are you with different types of valves used in plumbing systems?

I’m familiar with a wide array of valves used in plumbing systems. This includes gate valves (for complete shut-off), globe valves (for flow control), ball valves (for quick on/off action), check valves (to prevent backflow), and pressure-reducing valves (to maintain consistent water pressure). I understand their function, how they operate, and their applications. For instance, gate valves are ideal for main shut-offs due to their ability to fully restrict flow, while globe valves are commonly used for regulating the water flow to fixtures. Knowing the different valve types allows me to troubleshoot problems effectively and choose the right valve for a specific application, ensuring the system’s efficiency and safety.

Q 22. Explain your knowledge of different types of drainage systems.

Drainage systems are the backbone of any sanitation system, responsible for efficiently removing wastewater from buildings and communities. They come in various types, each suited to different needs and scales.

- Gravity Drainage Systems: These are the most common type, relying on gravity to move wastewater downhill through pipes. They are simple, reliable, and relatively inexpensive, typically utilizing a network of pipes with varying diameters to accommodate different flow rates. Think of it like a river system – smaller streams feeding into larger ones.

- Pressure Drainage Systems: These systems utilize pumps to force wastewater uphill or over long distances where gravity alone isn’t sufficient. This is often necessary in multi-story buildings or areas with flat topography. They require more complex infrastructure and maintenance but are essential in certain situations. Imagine needing to move wastewater from a basement up to the street level.

- Combined Drainage Systems: These systems handle both sewage and stormwater in a single network of pipes. While simpler to construct, they pose challenges during heavy rainfall, as the increased volume can overwhelm the system leading to backups and overflows. Modern designs are increasingly separating sewage and stormwater to improve efficiency and environmental protection.

- Storm Drainage Systems: Specifically designed for handling rainwater runoff, these systems are crucial for preventing flooding. They consist of a network of drains, gutters, and pipes, often culminating in retention ponds or direct discharge into water bodies. Maintaining their capacity is critical for preventing urban flooding.

Choosing the right drainage system depends on factors like the building’s size, location, and local regulations. A thorough understanding of these factors is critical for efficient and safe wastewater management.

Q 23. Describe your experience with pressure testing plumbing systems.

Pressure testing is a crucial step in ensuring the integrity of plumbing systems. It involves pressurizing the system with water or air to detect leaks before they cause significant damage or disruption. My experience includes using both air and water pressure testing methods.

For water pressure testing, I typically use a pressure pump and gauge to pressurize the system to a specific pressure (depending on pipe material and system design). The system is then monitored for pressure drop, indicating a leak. The location of the leak can often be identified by carefully monitoring pressure gauges at various points in the system.

Air pressure testing is often used for smaller systems or for testing specific sections of pipe. This method requires careful attention to safety as air leaks can be more difficult to locate and can present a potential hazard. The process involves similar steps to water pressure testing, using an air compressor and pressure gauge.

I’ve successfully used pressure testing to identify leaks in a variety of settings, from residential buildings to commercial complexes, significantly reducing costly repairs and water waste.

Q 24. How do you maintain and repair water supply lines?

Maintaining and repairing water supply lines involves a combination of preventative measures and reactive repairs. Preventative maintenance includes regular inspections for leaks, corrosion, or damage. Reactive repairs address issues that arise, which may include pipe bursts, leaks, or low water pressure.

Maintenance includes: visually inspecting pipes for signs of corrosion or damage; checking for leaks by listening for unusual sounds near pipes or checking water meters for unusually high readings; flushing out pipes periodically to remove sediment buildup.

Repairs might involve: replacing damaged sections of pipe; repairing leaks using appropriate methods depending on the material and severity; addressing low water pressure issues through pipe cleaning or replacing components, like pressure regulators.

The choice of materials for repairs – such as copper, PVC, PEX – depends on factors such as the application, budget, and local regulations. For example, PEX is often preferred for its flexibility and ease of installation in renovations, whereas copper might be chosen for its durability in high-pressure applications.

I always ensure that all repairs adhere to relevant building codes and safety standards, prioritizing safety and long-term system reliability.

Q 25. What is your understanding of water conservation techniques?

Water conservation is crucial for environmental sustainability and cost savings. My understanding encompasses both residential and commercial applications.

- Low-Flow Fixtures: Installing low-flow showerheads, faucets, and toilets significantly reduces water consumption without sacrificing functionality. These fixtures are designed to deliver the same level of performance while using less water. The difference can be substantial over time.

- Leak Detection and Repair: Promptly identifying and repairing leaks is vital. Even small leaks can waste significant amounts of water over time. Regular inspections and the use of leak detection tools are essential. A dripping faucet can waste gallons of water a day.

- Water-Efficient Appliances: Using water-efficient washing machines and dishwashers reduces the amount of water used per cycle. Look for appliances with the WaterSense label for assurance of efficiency.

- Landscape Design: Choosing drought-tolerant landscaping and implementing smart irrigation systems greatly reduces outdoor water consumption. Greywater systems, which reuse water from showers and sinks, can also help.

- Water Metering and Monitoring: Regularly monitoring water usage through the use of meters helps identify any anomalies and potential leaks, enabling timely intervention.

Educating clients about water conservation techniques is a key part of my approach, ensuring the implemented solutions are sustainable and cost-effective.

Q 26. Explain your experience with working with different types of plumbing joints.

Plumbing joints are the critical connections within a plumbing system, ensuring watertight seals and the structural integrity of the network. My experience includes working with a wide range of joint types, each with its own advantages and disadvantages.

- Threaded Joints: These joints utilize threaded fittings, offering a reliable and relatively easy-to-assemble connection, particularly with metal pipes. Proper sealant application is crucial to prevent leaks.

- Compression Joints: These employ compression fittings that create a watertight seal by compressing a rubber gasket against the pipe. They’re quick to assemble and are often used with copper and plastic pipes.

- Solvent-Welded Joints: Primarily used for PVC and CPVC pipes, this method involves melting the pipe and fitting ends using a solvent cement, creating a permanent, strong, and leak-proof joint.

- Soldered Joints: Used extensively with copper pipes, this method involves melting solder to fuse the pipes together, creating a strong and durable joint. Proper soldering techniques are essential to ensure a leak-free connection.

- Flange Joints: These use a flange (a circular rim) that bolts together to secure the pipe joint. They are often used in larger diameter pipes or applications requiring frequent disassembly.

Understanding the strengths and weaknesses of each joint type is critical for selecting the appropriate method for specific applications, considering factors such as pipe material, pressure, and accessibility.

Q 27. How do you ensure compliance with environmental regulations related to sanitation?

Compliance with environmental regulations regarding sanitation is paramount. My approach involves understanding and adhering to local, state, and federal guidelines concerning wastewater discharge and disposal. This includes:

- Proper Wastewater Treatment: Ensuring that wastewater is treated appropriately before discharge to prevent environmental contamination. This may involve adhering to specific standards for pollutants like heavy metals and pathogens.

- Grease Trap Maintenance: Regularly inspecting and maintaining grease traps in commercial kitchens to prevent blockages and environmental contamination. Failure to maintain these systems can result in significant environmental damage.

- Septic System Maintenance: Properly maintaining and inspecting septic systems, including regular pumping, to prevent overflows and groundwater contamination. Regular inspections are crucial for preventing expensive repairs and environmental hazards.

- Stormwater Management: Following regulations for managing stormwater runoff to minimize pollutants entering waterways. This includes regular inspection and maintenance of drainage systems.

- Proper Disposal of Hazardous Waste: Understanding and following regulations for handling and disposing of hazardous materials, ensuring safe and environmentally sound disposal practices.

Staying updated on current regulations and best practices is essential to ensuring all work meets legal and environmental standards.

Q 28. Describe your experience with using and interpreting diagnostic tools for plumbing systems.

Diagnostic tools are essential for efficient troubleshooting and repair of plumbing systems. My experience includes using a variety of tools to pinpoint issues quickly and accurately.

- Pipe Cameras: These allow for visual inspection of pipes, identifying blockages, cracks, or other internal damage. This is particularly useful in locating problems that are not easily accessible.

- Electronic Leak Detectors: These utilize acoustic sensors to detect leaks by listening for the sound of escaping water. They are highly sensitive and can locate even small leaks. This can save time and prevent significant water damage.

- Pressure Gauges: These are crucial for pressure testing, determining flow rates, and identifying pressure drops indicative of leaks or blockages.

- Water Meters: Monitoring water meter readings helps identify unusually high usage, potentially pointing to hidden leaks.

- Thermal Imaging Cameras: These cameras detect temperature variations, which can be helpful in finding leaks, as water leaks often create noticeable temperature changes.

Proper interpretation of data obtained from these tools requires experience and knowledge of plumbing systems. The ability to correlate readings from various instruments is critical for effective diagnosis and repair.

Key Topics to Learn for Plumbing and Sanitation Maintenance Interview

- Water Supply Systems: Understanding pressure, flow rates, and common pipe materials (PVC, copper, PEX). Practical application: Troubleshooting low water pressure issues.

- Drainage Systems: Knowledge of gravity and pressure drainage, vent systems, and common drainage problems (blockages, leaks). Practical application: Diagnosing and repairing sewer line clogs.

- Fixture Repair and Installation: Experience with toilets, sinks, faucets, and showers; including repair and replacement techniques. Practical application: Replacing a faulty toilet flapper.

- Water Heater Maintenance: Understanding different types of water heaters (tankless, tank), safety procedures, and troubleshooting common malfunctions. Practical application: Identifying and fixing a leaking water heater.

- Sanitation Systems: Knowledge of septic systems, grease traps, and wastewater treatment basics. Practical application: Inspecting and maintaining a septic tank system.

- Plumbing Codes and Regulations: Familiarity with local and national plumbing codes and safety regulations. Practical application: Ensuring work complies with relevant building codes.

- Troubleshooting and Problem-Solving: Developing systematic approaches to diagnose and resolve plumbing and sanitation issues efficiently. Practical application: Using diagnostic tools to pinpoint the source of a leak.

- Safety Procedures: Understanding and adhering to safety protocols when working with water, electricity, and hazardous materials. Practical application: Proper use of personal protective equipment (PPE).

- Preventive Maintenance: Importance of regular inspections and maintenance to prevent future problems. Practical application: Creating a preventative maintenance schedule for a commercial building.

Next Steps

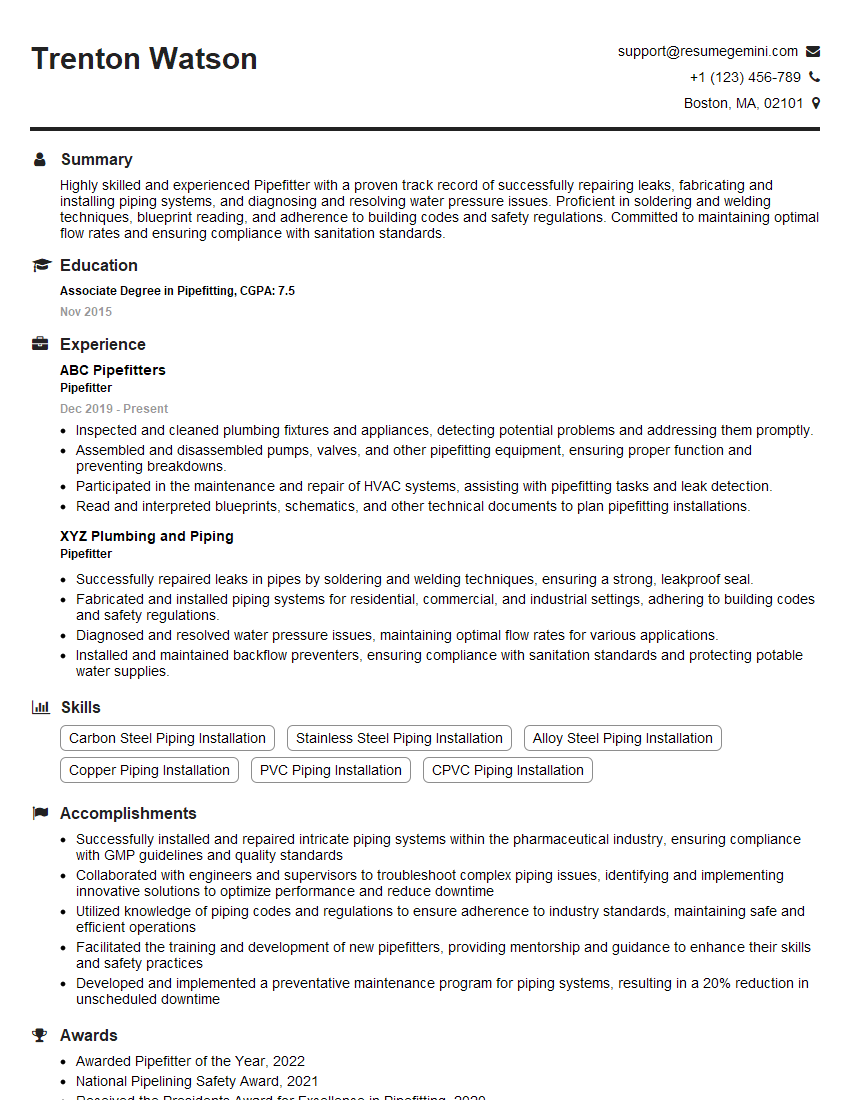

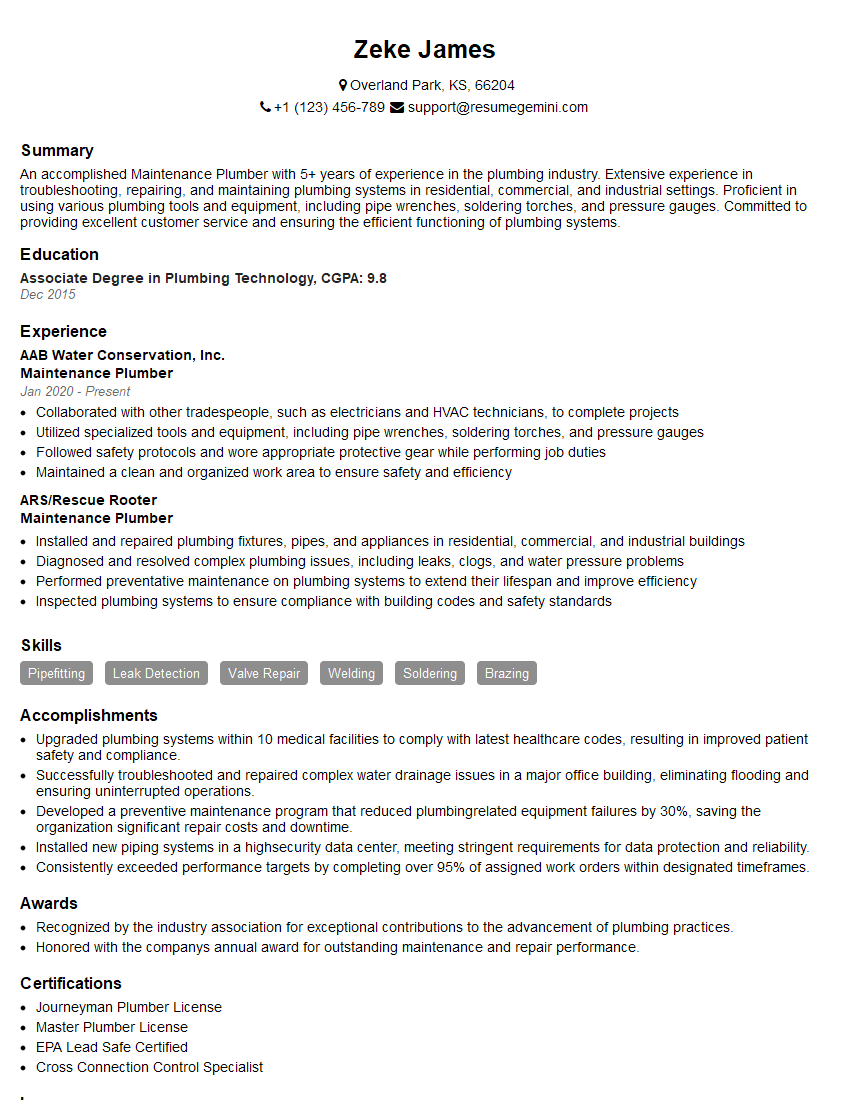

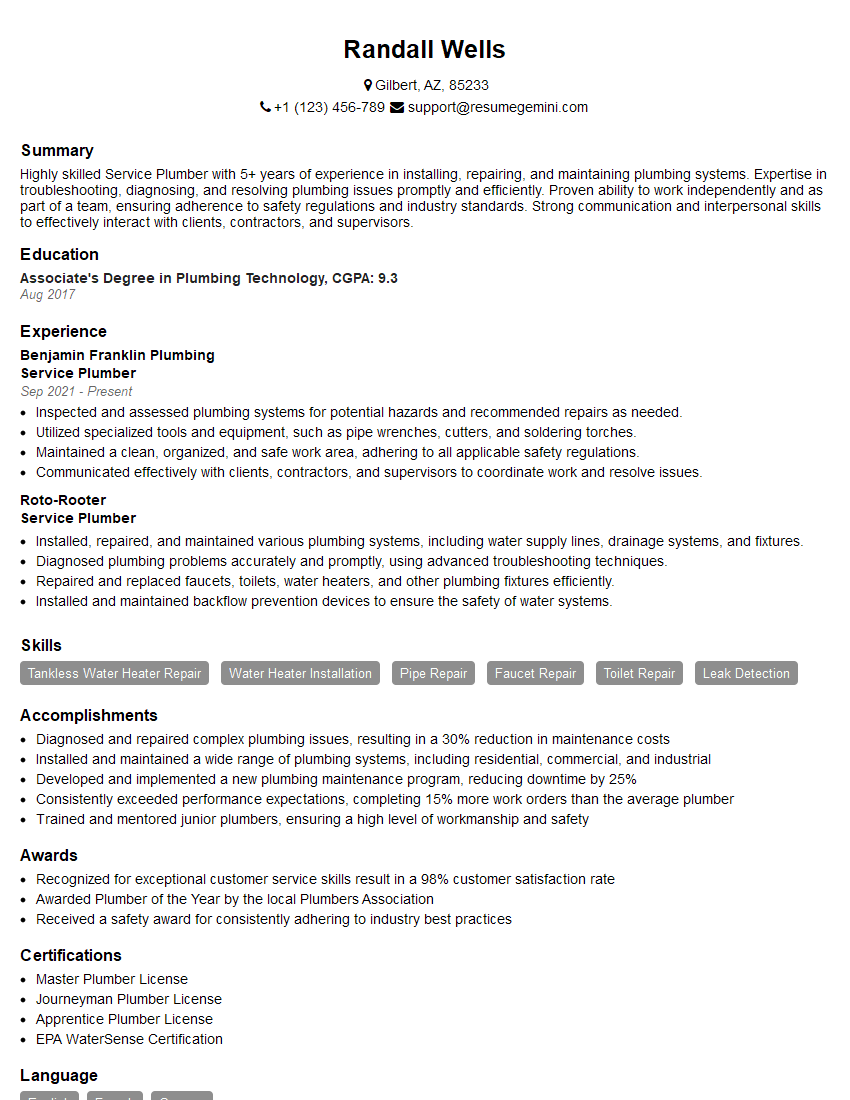

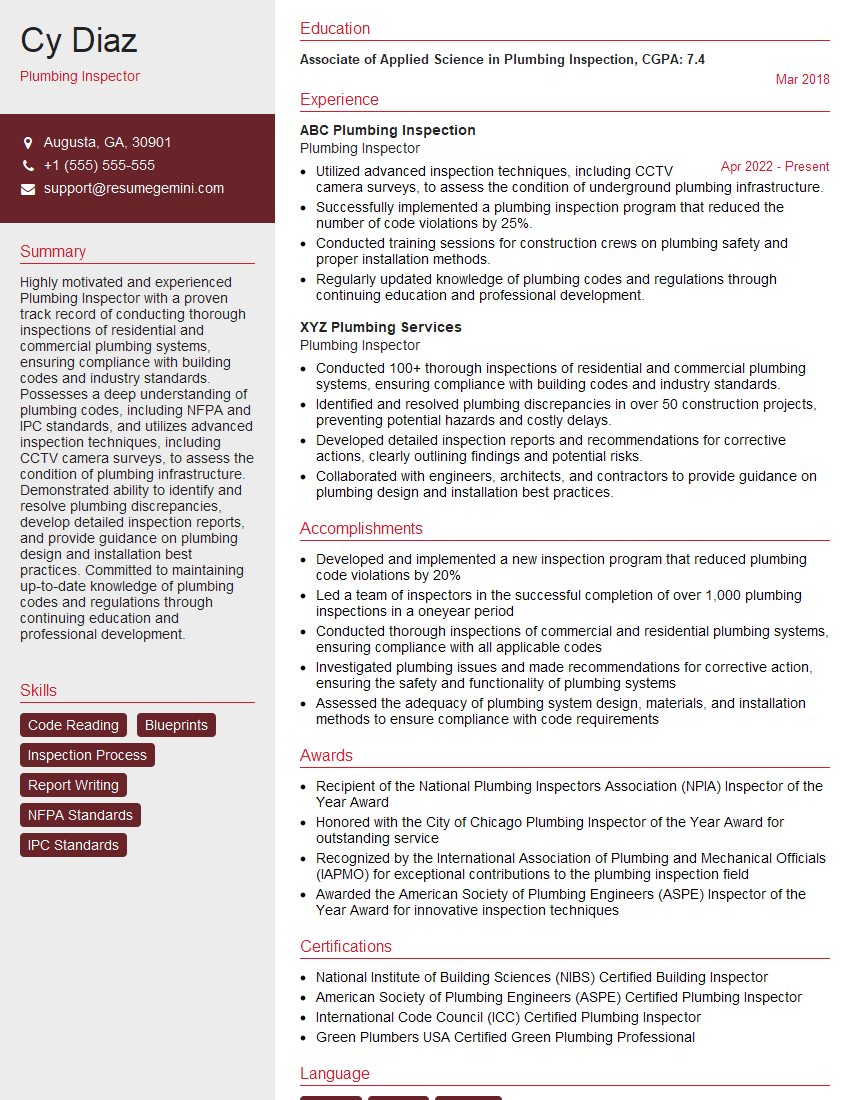

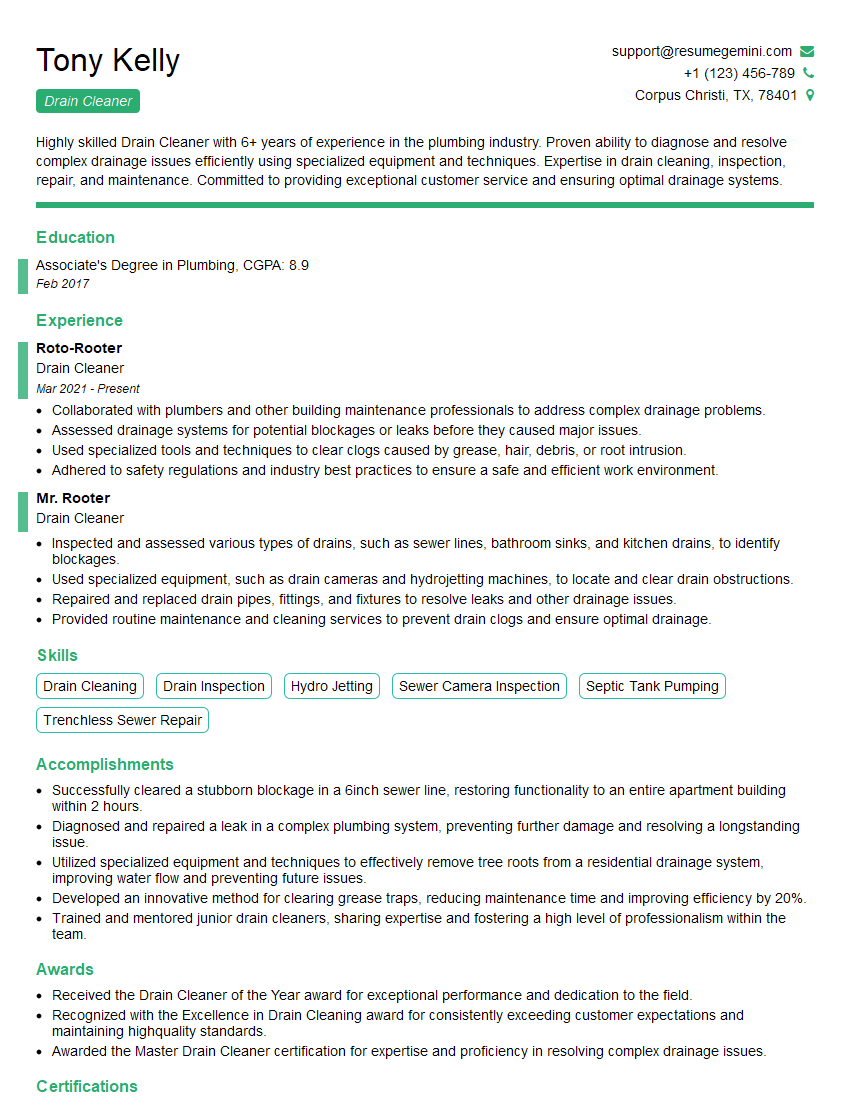

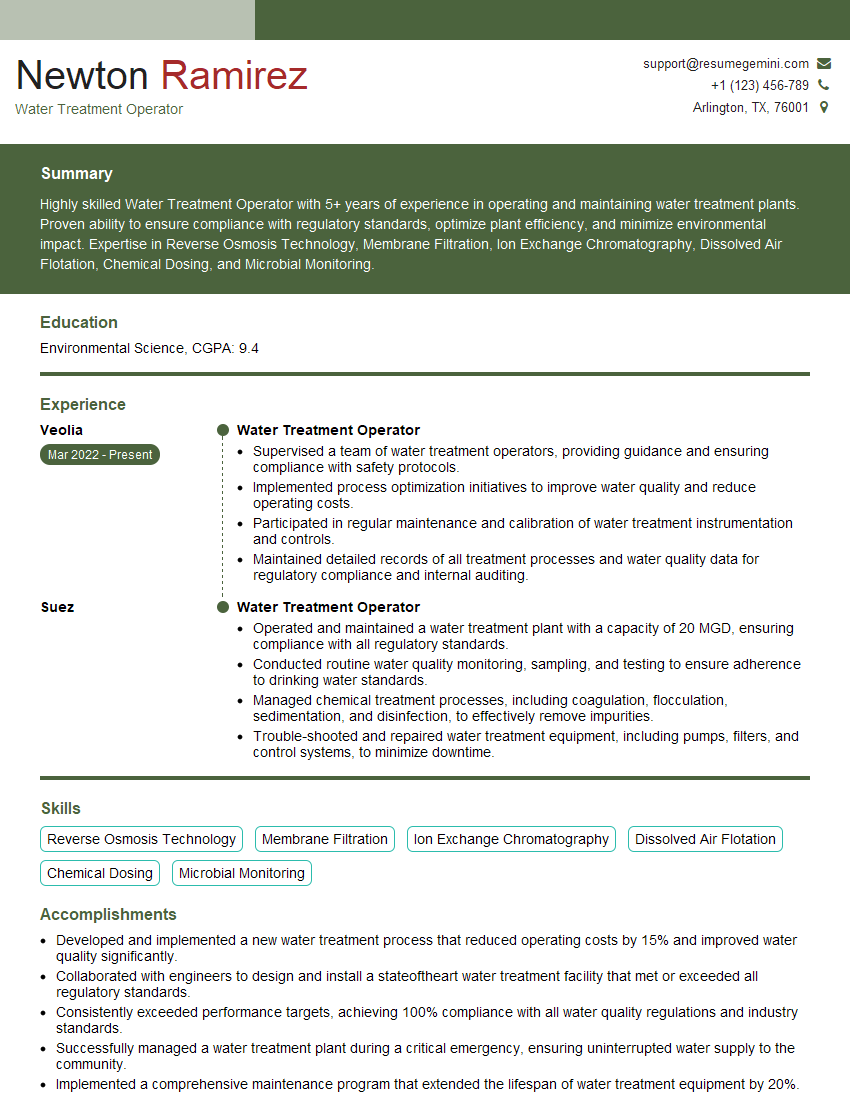

Mastering Plumbing and Sanitation Maintenance opens doors to a rewarding and stable career with excellent growth potential. You can advance to supervisory roles, specialize in specific areas, or even start your own business. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your skills and experience effectively. Examples of resumes tailored to Plumbing and Sanitation Maintenance are available to guide you through the process. Invest in your future – craft a resume that gets you noticed.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO