The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to PreTrip Inspection interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in PreTrip Inspection Interview

Q 1. What are the key components of a comprehensive PreTrip Inspection?

A comprehensive pre-trip inspection is crucial for ensuring the safe operation of any vehicle, particularly large commercial trucks. It’s a systematic check of all critical vehicle components before commencing a journey. Think of it as a vital health check for your vehicle. Failing to conduct a thorough inspection can lead to accidents, breakdowns, and costly repairs. Key components include:

- Tires: Checking tire pressure, tread depth, and sidewall condition for damage.

- Brakes: Inspecting brake lines, pads, drums, and testing the effectiveness of the braking system.

- Lights and Signals: Verifying the functionality of headlights, taillights, brake lights, turn signals, and hazard lights.

- Steering: Checking for free play (loose steering), responsiveness, and any signs of damage.

- Wipers and Washers: Ensuring that wipers clear the windshield effectively, and the washer fluid system works properly.

- Fuel System: Checking for leaks and ensuring the fuel tank is secure.

- Undercarriage: Inspecting for leaks, damage to the exhaust system, and loose components.

- Cargo Securement: Ensuring that cargo is properly secured to prevent shifting during transit (relevant for trucks carrying cargo).

Remember, this isn’t just a checklist; it’s a safety procedure. Thorough inspections save lives and prevent costly downtime.

Q 2. Describe the proper procedure for inspecting tires, including tread depth and sidewall condition.

Tire inspection is paramount. Inadequate tires are a major cause of accidents. Here’s how to do it properly:

- Visual Inspection: Walk around the vehicle and visually inspect each tire. Look for cuts, bulges, embedded objects, uneven wear, or any other signs of damage. Imagine you’re looking for any imperfection that could compromise the tire’s integrity.

- Tread Depth: Use a tread depth gauge or the penny test (insert a penny into the tread groove – if you can see the top of Lincoln’s head, the tread is too shallow and needs replacing). The minimum legal tread depth varies by jurisdiction, so always check local regulations. Low tread depth significantly reduces braking and traction.

- Sidewall Condition: Carefully examine the sidewalls for cracks, cuts, or bulges. Even small cracks can weaken the sidewall and lead to a blowout. Remember, the sidewall is crucial for maintaining tire shape and pressure.

- Tire Pressure: Check the tire pressure using a reliable gauge and compare it to the recommended pressure listed in your vehicle’s owner’s manual or on the tire sidewall. Underinflation or overinflation can lead to uneven wear and decreased fuel efficiency.

Always remember to inflate tires to the correct pressure when needed. Proper tire inflation improves fuel economy and handling.

Q 3. How do you check for brake system leaks and malfunctions?

Checking the brake system is critical; faulty brakes are a serious safety hazard. The inspection should involve:

- Visual Inspection: Examine brake lines and hoses for leaks, damage, or corrosion. Look for any signs of fluid leakage – wet spots or discoloration on components are key indicators.

- Brake Pad/Shoe Wear: Check the thickness of brake pads or shoes (if applicable). Worn-out brake components reduce braking effectiveness, posing a significant risk. Follow manufacturer guidelines for acceptable wear limits.

- Brake Pedal Test: Gently press the brake pedal several times. A spongy or low pedal indicates a potential leak or other brake system problem. A hard pedal could suggest a problem with the master cylinder or another component.

- Parking Brake Test: Engage the parking brake and try to move the vehicle. It should hold securely, indicating a functioning parking brake.

If you detect any leaks or abnormalities, it’s crucial to address them immediately before operation. A small leak can quickly become a major issue.

Q 4. Explain the process of inspecting lights and turn signals.

Lights and signals are vital for communicating your intentions to other drivers. The inspection should be done both visually and functionally:

- Visual Inspection: Check the condition of all lights, including headlights (high and low beams), taillights, brake lights, turn signals, and hazard lights. Ensure the lenses are clean and undamaged, and the bulbs are securely seated.

- Functional Test: Turn on each light individually and visually check their operation from outside the vehicle. Ask a colleague to assist if needed. Have someone walk around the vehicle to confirm all lights are working as expected.

- Turn Signals: Activate the left and right turn signals and verify that they flash correctly. The indicators inside the vehicle should also illuminate.

Remember, functioning lights are essential for safe driving, especially at night or in low-visibility conditions. Clear communication prevents accidents.

Q 5. How do you verify the functionality of wipers and washers?

Functional wipers and washers provide clear visibility, significantly improving safety. Here’s how to verify their operation:

- Wiper Operation: Turn on the wipers and ensure they move smoothly across the windshield, clearing the entire area without streaking or skipping. Check all speed settings.

- Washer Fluid Operation: Activate the washer fluid spray and verify that the fluid is dispensed evenly across the windshield. Ensure the fluid reservoir is sufficiently filled.

- Visual Inspection: Check for any signs of leaks or damage to the washer fluid system components.

Clear visibility is paramount for safe driving, especially in adverse weather conditions.

Q 6. What are the steps involved in inspecting the steering mechanism?

The steering mechanism is responsible for controlling the vehicle’s direction; a malfunction here can be catastrophic. Inspect it as follows:

- Free Play: Grab the steering wheel at the 9 and 3 o’clock positions and gently try to move it back and forth. There should be minimal free play (movement before the wheels begin to turn). Excessive play indicates worn or loose components and requires immediate attention.

- Steering Responsiveness: Move the steering wheel from side to side. It should respond smoothly and accurately, allowing you to control the vehicle’s direction effectively. Any stiffness or binding suggests potential issues.

- Visual Inspection: Visually inspect the steering linkages, tie rod ends, and other steering components for damage, wear, or leaks. Look for bent or damaged parts.

- Power Steering Fluid (if applicable): Check the power steering fluid level and condition. Low fluid levels or discolored fluid often indicate leaks or issues within the power steering system.

Remember that a properly functioning steering mechanism provides precise control and is critical for safe handling.

Q 7. How do you check for fuel leaks?

Fuel leaks are hazardous and can lead to fires. Checking for fuel leaks involves a combination of visual and olfactory inspections:

- Visual Inspection: Carefully examine the fuel tank, fuel lines, and fuel connections for any signs of leakage, such as wet spots, discoloration, or fuel dripping. Pay close attention to areas where fuel lines connect to the tank and the engine.

- Smell Test: Carefully sniff around the fuel tank and fuel lines for the distinct odor of gasoline or diesel fuel. A strong smell indicates a potential leak. If you detect a strong odor of fuel, don’t start the engine immediately.

- Cleanliness: Wipe down suspected areas with a clean cloth to check for fuel residue. Even small amounts of residue can indicate a leak.

Addressing fuel leaks promptly is crucial to prevent potential fires and environmental damage. Even a small leak can pose a serious safety risk.

Q 8. Describe the procedure for inspecting the exhaust system.

Inspecting the exhaust system is crucial for safety and environmental compliance. It involves a visual check for leaks, damage, and proper connections. Think of it like checking the plumbing of your car; a leak could be dangerous or lead to costly repairs.

- Visual Inspection: Look for cracks, holes, rust, or signs of significant wear and tear in the exhaust pipe, muffler, catalytic converter, and tailpipe. Pay close attention to the connections between these components – loose or damaged connections can lead to leaks.

- Leak Detection: Carefully examine the exhaust system for any signs of soot or discoloration, indicating possible leaks. You might even use a small mirror to get a better view of hard-to-reach areas.

- Secure Mounts: Ensure that the exhaust system is securely mounted and doesn’t hang too low, which could pose a risk of dragging on the ground.

- Proper Routing: Verify that the exhaust system is routed correctly and doesn’t interfere with other vehicle components.

For example, during a recent inspection, I discovered a significant crack in the muffler of a delivery truck. This could have led to dangerous carbon monoxide leaks, highlighting the importance of thorough exhaust system checks.

Q 9. How do you assess the condition of the suspension system?

Assessing the suspension system requires a combination of visual inspection and physical checks. Imagine the suspension as your vehicle’s shock absorbers; they are critical for safe and comfortable handling. A faulty suspension can lead to dangerous loss of control.

- Visual Check: Examine the springs, shocks/struts, and linkages for any signs of damage, leaks, or rust. Look for cracks, broken components, and excessive wear.

- Bounce Test: Gently push down on each corner of the vehicle and observe how it rebounds. Excessive bouncing or slow return indicates worn or damaged shock absorbers.

- Steering and Tire Wear: Uneven tire wear or a wandering steering wheel may indicate suspension problems. These need further investigation by a qualified mechanic.

- Check for Leaks: Inspect shock absorbers and struts for any signs of leaking fluid, indicating potential failure.

In one instance, I noticed a severely cracked spring during a pre-trip. This meant the vehicle was unsafe to operate until it was repaired, preventing a potential accident.

Q 10. What are the key components of a PreTrip Inspection report?

A comprehensive PreTrip Inspection report is essential for safety and legal compliance. Think of it as your vehicle’s health record, documenting everything from tires to lights.

- Vehicle Identification: Make, model, VIN, and license plate number.

- Driver Information: Name and driver’s license number.

- Date and Time: Of the inspection.

- Inspection Items: A detailed checklist covering all major vehicle systems, including brakes, lights, tires, steering, suspension, wipers, mirrors, and exhaust system. Each item should indicate whether it passed or failed the inspection.

- Deficiencies: A clear description of any defects or problems found, with severity levels noted (e.g., minor, major, critical).

- Corrective Actions: Details on any repairs or adjustments made to address the deficiencies.

- Signature: Of the driver and/or inspector.

A well-documented report protects both the driver and the company by providing a clear record of the vehicle’s condition before operation.

Q 11. How do you handle a situation where a critical safety issue is discovered during a PreTrip Inspection?

Discovering a critical safety issue during a PreTrip Inspection requires immediate and decisive action. Safety always comes first!

- Identify the Issue: Clearly identify the nature and severity of the critical safety issue. For example, a completely worn brake pad would be critical.

- Report the Issue: Immediately report the issue to your supervisor or designated authority. Do not operate the vehicle until the problem is resolved.

- Document Everything: Record the details of the defect in your inspection report, including photos or videos if possible.

- Prevent Operation: Do not operate the vehicle until the problem is fixed by a qualified mechanic. This is non-negotiable.

- Follow Company Procedure: Adhere to your company’s established procedures for reporting and handling critical safety defects.

In one case, I discovered a brake line leak. Following the correct procedure, I reported it to my supervisor. The truck was taken out of service and repaired, preventing a potential catastrophic brake failure.

Q 12. What is your experience with using electronic logging devices (ELDs)?

Electronic Logging Devices (ELDs) have become an integral part of modern trucking operations. I have extensive experience with ELDs, including data entry, record-keeping, and troubleshooting minor issues. These devices streamline the logging process and ensure accurate Hours-of-Service (HOS) compliance.

- Data Entry: I’m proficient in accurately entering driving time, on-duty time, and off-duty time into the ELD system.

- Record Keeping: I understand the importance of maintaining accurate records and know how to access and manage ELD data efficiently.

- Troubleshooting: I can troubleshoot common ELD problems, such as connectivity issues or data errors, and know when to seek assistance from technical support.

- Compliance: I understand the regulatory requirements associated with ELD use and ensure compliance with all applicable rules and regulations.

Using an ELD has made my job easier, helping me manage my hours and stay compliant with DOT regulations.

Q 13. How familiar are you with DOT regulations regarding PreTrip Inspections?

I am very familiar with DOT regulations regarding PreTrip Inspections. These regulations are paramount for ensuring vehicle safety and preventing accidents. My knowledge covers the Federal Motor Carrier Safety Administration (FMCSA) regulations and the detailed requirements for inspecting various vehicle components.

- FMCSA Regulations: I have a thorough understanding of the specific regulations pertaining to PreTrip Inspections, including the frequency, required items to check, and documentation requirements.

- Vehicle-Specific Requirements: I am aware of the variations in inspection requirements based on vehicle type and the goods being transported.

- Consequences of Non-Compliance: I understand the potential consequences of failing to perform a proper PreTrip Inspection, including fines, out-of-service orders, and potential legal liability.

Staying up-to-date with these regulations is crucial, as they can be subject to changes. Regular review and training help ensure safe operation and compliance.

Q 14. Explain the importance of documenting all PreTrip Inspection findings.

Documenting all PreTrip Inspection findings is paramount for several critical reasons. It’s not just about filling out a form; it’s about creating a verifiable record to support your commitment to safety.

- Legal Protection: A detailed report protects both the driver and the company in case of an accident or regulatory audit. It demonstrates due diligence in maintaining vehicle safety.

- Problem Tracking: Consistent documentation allows for tracking of recurring issues, facilitating proactive maintenance and reducing the likelihood of future problems.

- Improved Maintenance: Detailed records help identify potential maintenance needs before they escalate into major breakdowns or safety hazards.

- Safety Improvement: By carefully recording defects, you contribute to a system of continuous improvement that prioritizes the safety of the driver and the public.

Imagine a situation where a critical component fails. A well-maintained log, showing routine inspections and timely addressing of any issues, significantly strengthens your position.

Q 15. Describe your experience using a PreTrip Inspection checklist.

Pre-trip inspection checklists are my indispensable tool for ensuring vehicle safety. I’ve used them extensively throughout my career, ranging from simple checklists provided by my employers to more detailed, company-specific forms. My experience encompasses using both paper-based and digital checklists, each with its advantages and disadvantages. Paper-based checklists are readily available even without electronic devices, but digital ones often offer features like automated reporting and easier data tracking. A typical checklist covers everything from tire pressure and tread depth to fluid levels, lights, wipers, and brakes. I systematically follow each item, meticulously checking and recording my findings. For instance, I’ll use a tire tread depth gauge to ensure compliance with regulations and note any unusual wear patterns. I’m also adept at identifying potential issues beyond the checklist, such as unusual noises or vibrations. The consistent use of checklists ensures a standardized approach and minimizes the risk of overlooking crucial safety components.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your approach to ensuring a thorough and consistent PreTrip Inspection?

My approach to ensuring a thorough and consistent pre-trip inspection is based on a structured, methodical process. First, I conduct a visual inspection, systematically walking around the vehicle, checking all external components such as lights, tires, and undercarriage. I pay close attention to detail, such as checking for leaks, damage, or missing parts. I then move to the interior, checking gauges, mirrors, seatbelts, and controls. Secondly, I utilize a comprehensive checklist which serves as a guide and prompts for items I might otherwise miss. I use a combination of visual inspection and hands-on checks where appropriate (e.g., checking brake pedal firmness). Thirdly, I document every finding accurately and completely, including photos when necessary. Consistency is maintained by strictly adhering to the established checklist procedure, performing the inspection in the same order every time, and meticulously documenting every step. This helps identify trends or recurring issues, allowing for proactive maintenance. Finally, I review my findings, ensuring there are no discrepancies or ambiguities before signing off on the inspection report.

Q 17. How do you prioritize repairs identified during a PreTrip Inspection?

Prioritizing repairs after a pre-trip inspection is crucial for safety and efficiency. I use a risk-based approach. Safety-critical issues, like brake failure, steering problems, or significant tire damage, are always top priority. These require immediate attention and may ground the vehicle until repaired. Secondly, I prioritize issues that could lead to further damage or breakdowns, such as low fluid levels, worn components, or leaks. Addressing these prevents more extensive and costly repairs down the line. Finally, I address less critical issues, such as minor cosmetic damage or small fluid leaks that don’t pose immediate safety risks, in a more flexible timeframe. This tiered approach allows me to quickly address urgent safety concerns while managing the overall maintenance needs of the vehicle.

Q 18. What are the potential consequences of failing to conduct a proper PreTrip Inspection?

The consequences of failing to conduct a proper pre-trip inspection can be severe, ranging from minor inconveniences to catastrophic accidents. Neglecting the inspection could lead to breakdowns on the road, causing delays, loss of revenue, and potential damage to the vehicle. More critically, it poses significant safety risks. Faulty brakes, malfunctioning lights, or worn tires can lead to accidents resulting in injuries, fatalities, and significant legal and financial repercussions. Failure to perform a pre-trip inspection may lead to fines and violations of regulations. The driver may be held liable for any accident resulting from overlooked mechanical issues. In summary, skipping a pre-trip inspection is not only irresponsible but can have serious and far-reaching consequences.

Q 19. How do you handle discrepancies between your findings and the previous inspection report?

Discrepancies between my findings and previous inspection reports require careful investigation. I first review both reports thoroughly to identify the differences. If the discrepancies are minor, such as a slightly different fluid level reading, I might simply document the current status. However, if there are significant differences, I carefully examine the areas of concern. I might re-check my initial findings and consult with the mechanic or another inspector. Sometimes, the previous report might have missed an issue, and my inspection helps rectify that oversight. In other instances, there might be a genuine change in the vehicle’s condition that requires attention. Documentation is critical here, noting the discrepancies, my investigation steps, and any actions taken. This process ensures transparency and accountability while contributing to a comprehensive history of the vehicle’s maintenance and safety.

Q 20. Describe a time you identified a potentially serious safety issue during a PreTrip Inspection.

During a pre-trip inspection of a refrigerated truck, I discovered a significant crack in the chassis frame near the rear axle. This was not noted in the previous inspection report. The crack was subtle but, upon closer examination, appeared quite extensive and posed a severe safety risk. This could easily lead to a catastrophic axle failure, causing a loss of control and a potential rollover accident. I immediately reported the finding to my supervisor, preventing the truck from being used until the repair was made. This incident underscored the importance of meticulous inspection and highlighted that even seemingly minor observations can reveal serious safety issues. The crack was expertly repaired, preventing a potentially devastating accident.

Q 21. How do you maintain your knowledge of current regulations and best practices for PreTrip Inspections?

Maintaining my knowledge of current regulations and best practices is an ongoing process. I regularly consult official government websites and industry publications for updates on relevant safety regulations and guidelines. I also participate in regular training sessions and workshops conducted by safety experts and industry professionals. Furthermore, I keep up-to-date with changes in technology and best practices by attending conferences and engaging in professional development activities. This commitment to continuous learning helps me stay informed and perform my duties efficiently and safely. Staying current ensures that my pre-trip inspections are in compliance with all relevant laws and regulations, maximizing safety and minimizing risks.

Q 22. What is your experience working in a fast-paced environment conducting multiple PreTrip Inspections?

In my previous role at a large logistics company, I routinely conducted upwards of 20 PreTrip Inspections daily, often under tight deadlines. This fast-paced environment honed my efficiency and attention to detail. I developed a system of prioritizing critical checks based on vehicle type and recent maintenance records, ensuring quick but thorough inspections. For example, on days with a high volume of refrigerated trucks, I prioritized checks related to the refrigeration unit’s functionality and temperature control, knowing this is critical for cargo integrity. I also learned to effectively multitask, completing paperwork and communicating findings simultaneously while maintaining a high level of accuracy. This experience instilled in me the ability to remain calm and focused under pressure, adapting quickly to changing priorities and unexpected issues.

Q 23. What software or tools have you used to manage PreTrip Inspection data?

Throughout my career, I’ve utilized various software and tools to streamline PreTrip Inspection data management. Initially, this involved primarily paper-based checklists and manual data entry into spreadsheets. However, in more recent roles, I’ve had experience with digital solutions such as Fleet Management Software (FMS). These systems often incorporate electronic checklists, automated reporting features, and GPS tracking capabilities. The FMS allows for immediate recording of findings, automatic generation of reports for supervisors, and easy identification of trends or recurring issues with specific vehicles. This reduces administrative time and enhances overall efficiency, enabling more proactive maintenance planning. Furthermore, I’ve used mobile applications specifically designed for PreTrip Inspections, these apps allow for quick and convenient data input directly on the vehicle, minimizing errors and maximizing accessibility.

Q 24. How do you communicate inspection findings effectively to supervisors and other relevant personnel?

Effective communication of inspection findings is crucial for safety and operational efficiency. My approach involves a multi-faceted strategy. For minor issues, I typically communicate directly with the driver, explaining the problem and suggesting immediate solutions. For more significant issues requiring immediate attention or repairs, I immediately escalate the findings to my supervisor through the appropriate channels – this may be a phone call, email, or directly through the FMS platform, depending on the urgency and company policy. I always ensure my reports are clear, concise, and objective, using photographic evidence when necessary. I utilize structured reporting formats that highlight critical defects, providing clear descriptions and specific vehicle locations. For example, instead of stating ‘brake issue’, I’d specify ‘worn brake pads on rear left axle, requiring immediate replacement’. This level of detail ensures clarity and facilitates rapid decision-making by supervisors and maintenance personnel.

Q 25. What steps do you take to ensure the accuracy and completeness of your inspection reports?

Accuracy and completeness are paramount in PreTrip Inspections. I employ several strategies to ensure both. First, I follow a standardized checklist meticulously, using a methodical approach to cover all aspects of the vehicle. I use visual aids and double-checking measures, such as confirming tire pressure readings twice, to avoid omissions. Second, I utilize photography to document any discrepancies or damage. Pictures provide irrefutable evidence and enhance the clarity of my report. Third, I cross-reference my findings against previous inspection data (often available through the FMS) to identify trends and potential systemic issues. Finally, before submitting my report, I conduct a thorough review, ensuring all data is accurate and complete, including correct vehicle identification and driver details. This multi-layered approach ensures the integrity and reliability of my inspection records.

Q 26. How do you adapt your inspection techniques to different types of vehicles or equipment?

My inspection techniques adapt to the specific requirements of different vehicles and equipment. For instance, inspecting a semi-trailer truck requires a different approach than inspecting a small delivery van. With a semi-trailer, I prioritize the condition of tires, brakes, coupling systems, and cargo securing mechanisms. Conversely, with a delivery van, I may focus more on lights, wipers, and overall body condition. For specialized equipment like forklifts or construction machinery, I focus on the functional components specific to that type of equipment, such as hydraulic systems or lifting mechanisms, often using manufacturer-specific checklists. My adaptability stems from extensive training and practical experience working with a wide range of vehicles and equipment, ensuring I am equipped to identify and report any safety concerns specific to the unit being inspected.

Q 27. Describe your experience working with different types of PreTrip Inspection checklists or forms.

I have experience with a variety of PreTrip Inspection checklists and forms, ranging from simple paper-based forms to sophisticated digital solutions. I’m proficient in using both DOT (Department of Transportation) compliant forms and company-specific checklists. The key is understanding the information required by each form and adapting my inspection process accordingly. Regardless of the format, my approach remains consistent: methodical, detailed, and focused on safety. I’ve also worked with checklists tailored for different vehicle types (e.g., heavy-duty trucks vs. passenger vehicles) and even those integrated with mobile device applications, highlighting the importance of technological advancements in the field. This versatility ensures that I can efficiently and accurately complete inspections regardless of the format provided.

Q 28. How would you explain the importance of PreTrip Inspections to someone unfamiliar with the process?

Think of a PreTrip Inspection as a vital safety check for a vehicle before it embarks on a journey – much like a pre-flight checklist for an airplane. It ensures the vehicle is in optimal working condition and safe to operate, minimizing the risk of accidents or breakdowns. The inspection covers critical systems like brakes, tires, lights, and steering, checking for any defects that could compromise safety. Ignoring this critical step can lead to serious consequences such as accidents, costly repairs, and even fatalities. Therefore, a thorough PreTrip Inspection is not just a routine task but a crucial measure to prevent potential problems and prioritize safety for the driver and the public.

Key Topics to Learn for PreTrip Inspection Interview

- Vehicle Exterior Inspection: Understanding the critical components to check (tires, lights, mirrors, fluids) and identifying potential safety hazards. Practical application includes describing your systematic approach to a visual inspection and explaining how you’d document any issues found.

- Vehicle Interior Inspection: Knowing how to check gauges, controls, safety equipment (seatbelts, emergency brake), and warning lights. Practical application includes explaining how to identify malfunctions based on gauge readings or warning light indicators and detailing appropriate next steps.

- Documentation and Reporting: Mastering the proper procedures for recording pre-trip inspection findings, including using electronic logging devices (ELDs) or paper logs. Practical application includes detailing your experience with different documentation methods and explaining how to accurately and completely report any discrepancies.

- Safety Regulations and Compliance: Familiarity with relevant regulations and legal requirements concerning pre-trip inspections and vehicle maintenance. Practical application includes explaining how adherence to these regulations contributes to overall road safety and prevents potential legal issues.

- Problem-Solving and Troubleshooting: Demonstrating the ability to identify, analyze, and address potential mechanical issues during the pre-trip inspection. This includes describing your troubleshooting approach for common problems and knowing when to escalate concerns to mechanics or supervisors.

- Preventive Maintenance: Understanding the importance of pre-trip inspections in preventing breakdowns and costly repairs. Practical application includes explaining how early identification of problems during the inspection contributes to proactive maintenance and operational efficiency.

Next Steps

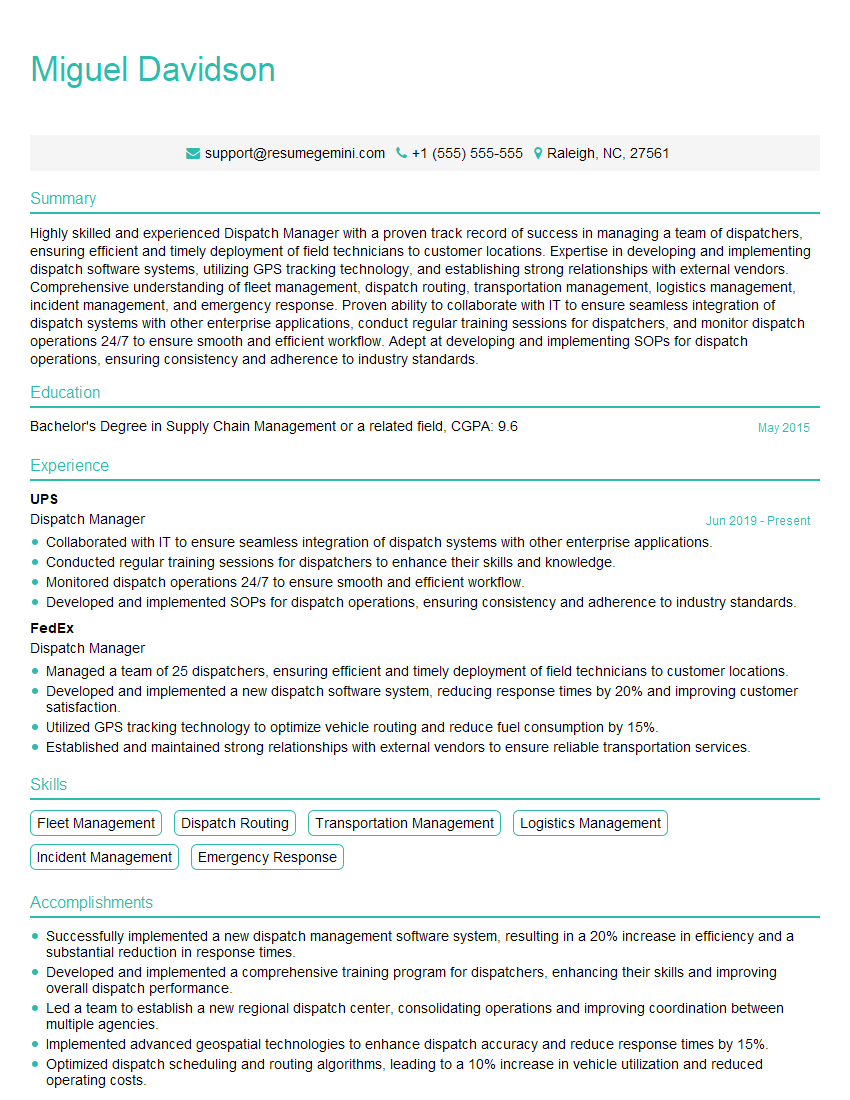

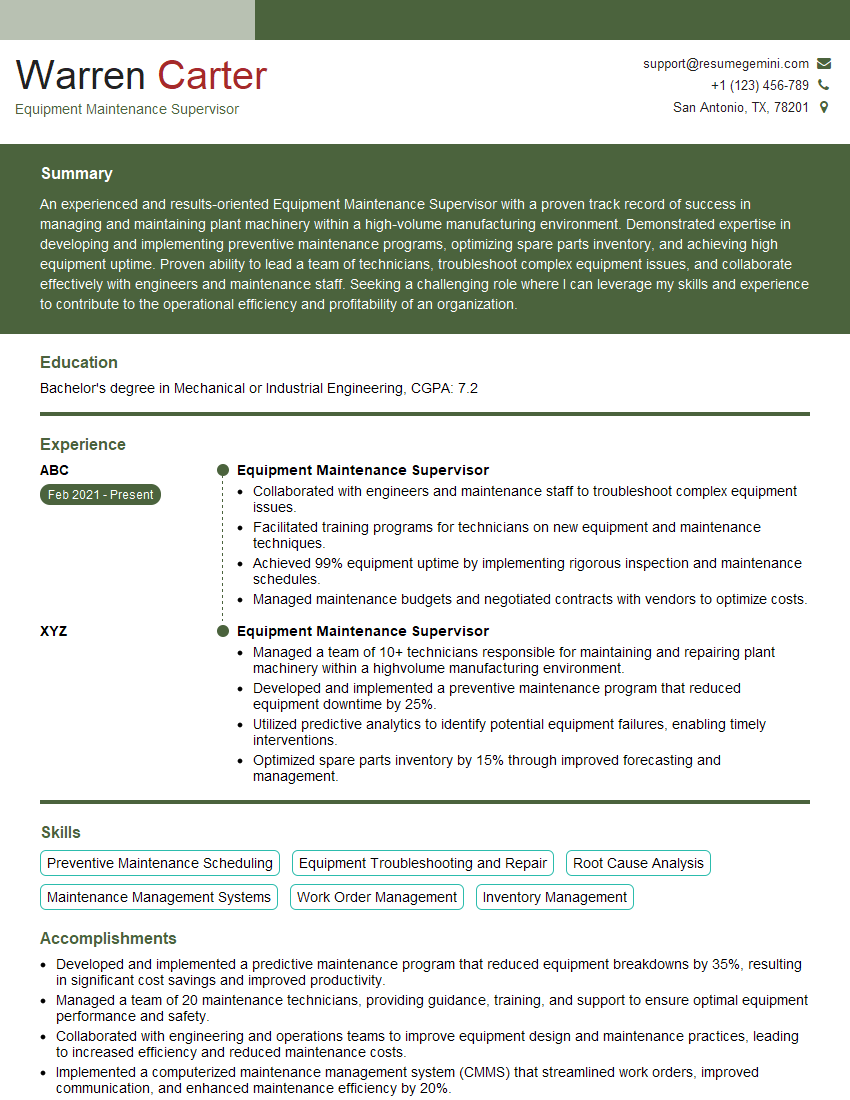

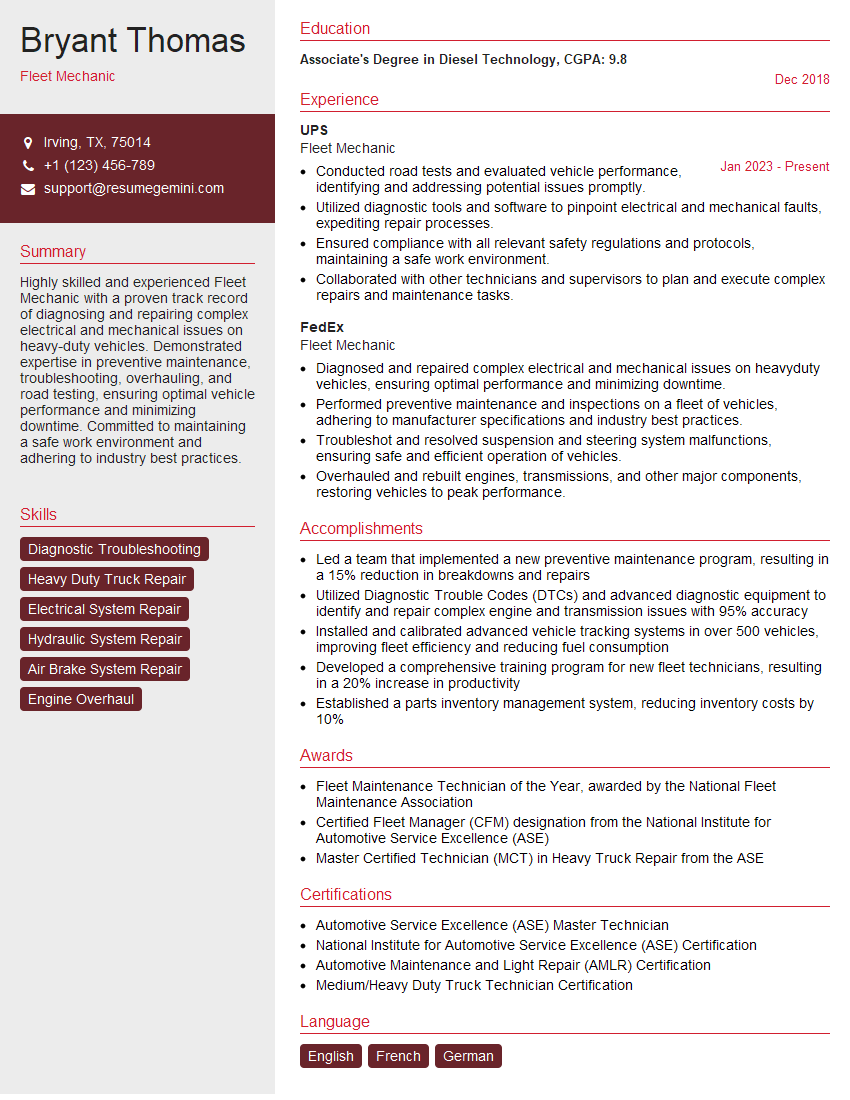

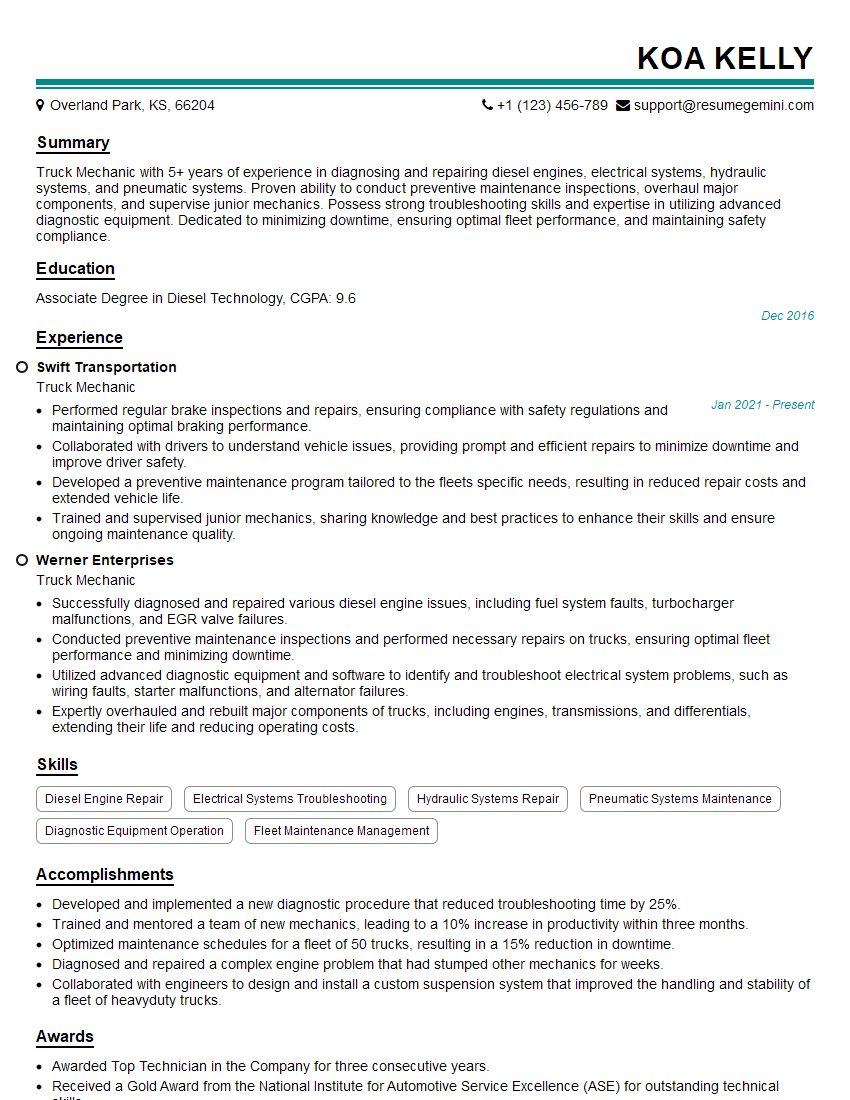

Mastering Pre-Trip Inspection demonstrates a commitment to safety and operational efficiency, significantly enhancing your value to any transportation company. This skill is highly sought after, opening doors to diverse and rewarding career opportunities. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to PreTrip Inspection roles are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO