Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Proficient in the operation and maintenance of marine propulsion systems interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Proficient in the operation and maintenance of marine propulsion systems Interview

Q 1. Explain the different types of marine propulsion systems.

Marine propulsion systems are the heart of any vessel, responsible for generating thrust and enabling movement. There’s a wide variety of systems, each with its strengths and weaknesses depending on the vessel’s size, speed, and operational requirements. Broadly, we can categorize them as follows:

- Diesel Engines: The workhorse of the industry, particularly for medium to large vessels. They’re known for their reliability, fuel efficiency (relatively speaking), and relatively low maintenance compared to some alternatives. Think of cargo ships, ferries, and many tugboats.

- Gas Turbines: These offer high power-to-weight ratios, making them ideal for high-speed applications like warships and fast ferries. However, they consume more fuel than diesels at lower speeds and can be more expensive to maintain.

- Electric Propulsion: This involves using electric motors driven by generators (often diesel or gas turbine-powered). This offers superior controllability and efficiency in certain situations, plus reduced noise and vibrations. Cruise ships and some specialized vessels frequently utilize electric propulsion systems.

- Waterjets: These systems use a pump to draw water in and propel it out at high velocity, creating thrust. Excellent for shallow-draft vessels and maneuverability, but generally less efficient than propeller systems at higher speeds.

- Podded Propulsion: This integrates the propeller and motor into a single unit that can rotate 360 degrees. This allows for remarkable maneuverability and increased efficiency, especially in demanding environments like ice-breaking operations. Common on cruise ships and advanced vessels.

The choice of propulsion system depends on a complex interplay of factors, including budget, operational profile, environmental regulations, and space constraints.

Q 2. Describe the operation of a diesel engine.

A diesel engine operates on the principle of internal combustion, converting the chemical energy in diesel fuel into mechanical energy. Think of it as a precisely controlled explosion that pushes pistons, which in turn rotate a crankshaft connected to the propeller.

The four-stroke cycle is typical: Intake (air is drawn into the cylinder), Compression (the air is compressed, increasing its temperature and pressure), Power (fuel is injected and ignites spontaneously due to the high temperature, forcing the piston down), and Exhaust (the burnt gases are expelled from the cylinder).

This cycle repeats continuously for each cylinder, with the coordinated movement of the pistons generating the rotational force needed for propulsion. Larger marine diesel engines often have multiple cylinders arranged in a V or inline configuration to produce the necessary power.

Modern diesel engines incorporate sophisticated control systems, fuel injection technologies, and emission control measures to optimize performance and minimize environmental impact. For example, common rail injection systems precisely control fuel delivery for improved efficiency and reduced emissions.

Q 3. How does a gas turbine propulsion system work?

A gas turbine propulsion system uses a continuous combustion process to generate high-velocity gas that spins a turbine. This turbine, in turn, drives a shaft connected to the propeller or a reduction gear. Think of a jet engine, but adapted for marine use.

The process typically involves a compressor that draws in air, compressing it before entering the combustion chamber. Fuel is injected and ignited continuously, producing hot, expanding gases. These gases then strike the turbine blades, spinning the turbine and generating power.

Unlike diesel engines that operate through cyclical combustion, gas turbines maintain continuous combustion, providing rapid acceleration and high power output. However, their fuel consumption is generally higher at lower speeds. A common application would be a high-speed warship requiring quick bursts of speed and maneuverability.

Q 4. What are the common maintenance procedures for marine propulsion systems?

Regular maintenance is crucial for the longevity and reliability of marine propulsion systems. This involves a combination of preventative and corrective actions. Common procedures include:

- Regular Oil Changes: Essential to remove contaminants and ensure proper lubrication.

- Filter Replacements: Filters remove debris and contaminants from fuel, oil, and air systems.

- Cooling System Checks: Monitoring coolant levels, temperature, and flow is vital to prevent overheating.

- Exhaust System Inspections: Checking for leaks, corrosion, and blockages.

- Vibration Monitoring: Detecting unusual vibrations can indicate potential problems.

- Shaft Alignment Checks: Ensuring proper alignment of the propeller shaft minimizes wear and tear.

- Corrosion Prevention: Applying protective coatings and performing regular inspections to mitigate corrosion.

- Propeller Inspections: Checking for damage, wear, and fouling.

The frequency of these procedures varies based on the type of system, operating hours, and environmental conditions. A well-maintained logbook is essential for tracking maintenance activities and identifying potential issues early on.

Q 5. Explain the importance of lubrication in marine propulsion systems.

Lubrication is paramount in marine propulsion systems, acting as the lifeblood of moving parts. It serves several critical functions:

- Reducing Friction: Minimizes wear and tear on moving components, extending their lifespan and reducing the risk of failures.

- Cooling: Helps dissipate heat generated during operation, preventing overheating and damage.

- Cleaning: Helps remove contaminants and debris from the system.

- Sealing: Lubricants help create seals, preventing leaks and contamination.

Without proper lubrication, friction would generate excessive heat, leading to premature wear, component failure, and costly repairs. The choice of lubricant depends on factors like operating temperature, load, and the type of components being lubricated. Using the wrong lubricant can be detrimental and even catastrophic.

For example, a failure in the main engine’s lubrication system could lead to a complete engine seizure, stranding the vessel and potentially causing significant damage.

Q 6. Describe the process of troubleshooting a malfunctioning propulsion system.

Troubleshooting a malfunctioning propulsion system requires a systematic approach. It’s akin to detective work, gathering clues and systematically eliminating possibilities. The process typically involves:

- Identifying the Symptom: Pinpoint the exact problem – loss of power, unusual noise, excessive vibration, overheating, etc.

- Gathering Information: Review operational logs, alarm history, and witness accounts to understand the circumstances leading to the malfunction.

- Visual Inspection: Thoroughly inspect the system for obvious signs of damage, leaks, or loose connections. This could involve checking fuel lines, oil levels, cooling systems, and the propeller itself.

- Diagnostic Testing: Use diagnostic tools to assess system parameters such as oil pressure, temperature, fuel flow, and vibration levels. This often involves sophisticated equipment.

- Systematic Elimination: Based on the information gathered, systematically test different components to isolate the fault. This may involve isolating sections of the system and testing individual components.

- Repair or Replacement: Once the faulty component is identified, repair or replace it, ensuring proper reassembly and testing.

Throughout this process, safety is paramount. Always follow established safety procedures and use appropriate personal protective equipment.

Q 7. How do you perform a shaft alignment check?

Shaft alignment is critical for preventing premature wear and tear on bearings and seals. Misalignment can lead to vibrations, noise, and ultimately, catastrophic failure. A proper alignment check ensures the propeller shaft is perfectly aligned with the engine’s output shaft and the stern tube.

The process often employs specialized tools like dial indicators or laser alignment systems. Here’s a simplified overview:

- Preparation: Ensure the vessel is stable and the shafts are accessible. The engine and propeller should be in their normal operating positions.

- Mounting Indicators: Carefully mount dial indicators at various points along the shafts to measure any misalignment.

- Taking Measurements: Record readings at several locations along the shafts in both the vertical and horizontal planes. These readings represent the offset between the shafts.

- Analysis: Analyze the measurements to determine the extent and nature of any misalignment (angular or parallel). This often involves specialized calculations or software.

- Correction: Adjust shims or couplings to correct the misalignment, bringing the shafts into perfect alignment.

- Verification: After adjustments, re-check the alignment to ensure the corrections were effective.

Laser alignment systems offer greater precision and speed, providing a more accurate assessment of shaft alignment. Incorrect alignment can lead to significant problems ranging from increased vibration and noise to premature bearing failure and even shaft breakage, so precision is paramount. Regular checks, as part of the preventative maintenance schedule, are essential for minimizing these risks.

Q 8. What are the safety precautions when working on marine propulsion systems?

Safety is paramount when working on marine propulsion systems. These systems operate under high pressure, high temperature, and contain hazardous materials like lubricants and fuels. Before commencing any work, a comprehensive risk assessment must be carried out. This includes identifying potential hazards, assessing their risks, and implementing control measures.

- Lockout/Tagout Procedures: Always follow strict lockout/tagout procedures to isolate power sources (electrical, hydraulic, pneumatic) before performing any maintenance or repairs. This prevents accidental energization and serious injury.

- Personal Protective Equipment (PPE): Appropriate PPE is crucial, including safety glasses, gloves, hearing protection, and flame-resistant clothing. The specific PPE will depend on the task but always err on the side of caution.

- Confined Space Entry: If working in confined spaces like engine rooms, ensure proper ventilation, gas detection, and entry/exit procedures are followed. A buddy system is essential.

- Hot Work Permits: For tasks involving welding, cutting, or other hot work, obtain the necessary hot work permits and implement fire prevention measures.

- Emergency Procedures: Be familiar with emergency procedures including fire response, spill response, and first aid. Ensure communication systems are in place.

- Proper Lifting Techniques: Many components of marine propulsion systems are heavy. Use proper lifting techniques and equipment like cranes or hoists to avoid injuries.

A strong safety culture, thorough training, and adherence to established safety protocols are vital for preventing accidents and ensuring the well-being of personnel.

Q 9. Explain the principles of propeller theory.

Propeller theory explains how a propeller generates thrust to propel a vessel. It’s based on the principles of fluid dynamics, specifically the interaction between the propeller blades and the surrounding water. The propeller’s blades are designed with an airfoil shape, similar to an airplane wing. As the propeller rotates, the blades accelerate the water backwards, creating a reaction force that pushes the vessel forward – Newton’s third law of motion (action and reaction).

Key factors influencing propeller performance include:

- Blade Shape and Angle (Pitch): The shape and angle of the blades determine how effectively the water is accelerated. A higher pitch generally results in higher speed at the cost of efficiency.

- Diameter and Number of Blades: Larger diameter propellers can move more water, creating greater thrust. The number of blades affects efficiency and cavitation (formation of vapor bubbles).

- Rotational Speed: Higher rotational speed increases thrust, but it can also lead to cavitation and reduced efficiency.

- Water Flow and Resistance: The surrounding water’s speed, density, and viscosity affect the propeller’s performance. Hull design and other underwater appendages also influence this.

Understanding propeller theory is essential for selecting the appropriate propeller for a vessel, optimizing its performance, and diagnosing problems like vibration or cavitation.

Q 10. Describe the different types of marine gears.

Marine gears are crucial for transmitting power from the engine to the propeller. They are necessary because most marine engines operate at much higher speeds than the optimal speed of the propeller. Different types of marine gears exist, each with its own advantages and disadvantages:

- Reduction Gears: These are the most common type, reducing the engine’s high speed to a lower, more efficient propeller speed. They typically use gear trains with different gear ratios to achieve the desired speed reduction. They can be spur gears, helical gears, or planetary gears.

- Reversing Gears: These gears allow the propeller to rotate in either direction, enabling the vessel to move forward or backward. Common types include clutches, hydraulic reversing systems, and reversing gearboxes.

- Cycloidal Gears: These are specialized gears providing high torque at low speeds and are often used in applications requiring exceptional maneuverability like tugboats.

- Electric Drives: Though not strictly gears, electric drives offer speed control and reversing capabilities. They use electric motors to drive the propeller and are becoming increasingly common in modern vessels.

The choice of gear type depends on factors like vessel size, engine type, required speed range, and specific operational needs.

Q 11. What is the function of a reduction gear?

A reduction gear’s primary function is to reduce the rotational speed of the engine while simultaneously increasing its torque. Marine engines typically operate at high speeds (RPM) to generate sufficient power. However, propellers operate most efficiently at lower speeds. The reduction gear acts as an intermediary, matching the engine’s output to the propeller’s optimal operating speed.

This speed reduction is crucial for several reasons:

- Increased Propeller Efficiency: Lower propeller speeds generally result in higher propeller efficiency, meaning less energy is wasted and fuel consumption is reduced.

- Reduced Wear and Tear: Lower speeds lessen stress on the propeller and its components, extending their lifespan.

- Improved Maneuverability: In some cases, a reduction gear can improve the vessel’s maneuverability by providing higher torque at lower speeds.

The gear ratio (the ratio of the input speed to the output speed) is carefully selected to optimize the entire propulsion system’s performance.

Q 12. How do you diagnose and resolve problems with a propulsion system’s cooling system?

Diagnosing cooling system problems in a marine propulsion system requires a systematic approach. The cooling system is critical as it prevents overheating, which could lead to catastrophic engine failure. A typical approach involves:

- Visual Inspection: Check for leaks, corrosion, loose connections, and blockages in hoses, pipes, and heat exchangers.

- Temperature Monitoring: Use temperature gauges to monitor the engine coolant, lubricating oil, and sea water temperatures. Excessive temperatures indicate a problem.

- Flow Rate Measurement: Check the flow rate of the coolant and sea water using flow meters. Low flow rates suggest blockages or pump issues.

- Pressure Checks: Monitor system pressures; abnormal pressure readings might indicate a leak, blockage, or pump failure.

- Testing Components: If necessary, test individual components like pumps, thermostats, and sensors to identify the faulty part. This often involves pressure testing or using diagnostic tools.

Once the problem is identified, the solution depends on the specific issue. This might involve:

- Repairing or Replacing Leaky Hoses or Pipes: This is a common repair involving replacing the damaged sections.

- Cleaning or Replacing Heat Exchangers: Fouling (buildup of marine organisms or debris) can reduce efficiency and needs cleaning or replacement.

- Replacing Faulty Pumps or Sensors: Replacing malfunctioning components is often necessary to restore proper function.

Remember to always follow proper safety procedures when working on a marine propulsion system’s cooling system, especially when handling hot fluids under pressure.

Q 13. Explain the importance of regular inspections and preventative maintenance.

Regular inspections and preventative maintenance are crucial for ensuring the reliability, safety, and longevity of marine propulsion systems. Neglecting maintenance can lead to costly repairs, system failures, and potential safety hazards. Preventative maintenance involves a scheduled approach to identify and address potential problems *before* they cause significant damage.

The benefits of a robust maintenance program include:

- Reduced Downtime: Preventative maintenance minimizes unexpected breakdowns, reducing costly downtime and keeping the vessel operational.

- Extended System Lifespan: Regular servicing helps prevent premature wear and tear, extending the useful life of components and reducing replacement costs.

- Improved Fuel Efficiency: A well-maintained propulsion system operates at optimal efficiency, reducing fuel consumption and saving money.

- Enhanced Safety: Regular inspections identify potential safety hazards before they become major issues, preventing accidents and ensuring crew safety.

- Compliance with Regulations: Many maritime regulations require regular inspections and maintenance documentation.

A well-structured maintenance program typically includes visual inspections, performance checks, lubrication, cleaning, and component replacement as needed. A logbook meticulously documenting all maintenance activities is crucial for tracking system health and regulatory compliance.

Q 14. What are the environmental regulations regarding marine propulsion systems?

Environmental regulations regarding marine propulsion systems are increasingly stringent globally. These regulations aim to minimize the environmental impact of shipping, focusing on reducing emissions and preventing pollution.

Key areas of focus include:

- Exhaust Gas Emissions: Regulations like those from the International Maritime Organization (IMO) limit the emission of harmful gases like sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM). This often involves using cleaner fuels (like low-sulfur fuels or LNG) or installing emission control systems (scrubbers, selective catalytic reduction).

- Oil Pollution: Regulations prohibit the discharge of oil and oily wastewater into the sea. Vessels must have effective oil-water separators and oil spill response plans.

- Ballast Water Management: Regulations target the control and management of ballast water to prevent the introduction of invasive species. This often involves using ballast water treatment systems.

- Noise Pollution: Regulations aim to reduce underwater noise pollution from vessels, which can negatively affect marine life. This includes measures to reduce propeller cavitation and engine noise.

Compliance with these regulations is mandatory, and failure to comply can result in significant fines and penalties. Ship operators must stay informed about the constantly evolving environmental regulations and implement the necessary measures to ensure compliance.

Q 15. Describe your experience with different types of marine fuels.

My experience encompasses a wide range of marine fuels, from traditional heavy fuel oils (HFO) to more environmentally friendly alternatives like marine gas oil (MGO), liquefied natural gas (LNG), and even biofuels. HFO, while cost-effective, requires careful handling due to its high viscosity and sulfur content. MGO is cleaner burning and easier to manage but more expensive. LNG presents unique challenges in storage and handling due to its cryogenic nature, demanding specialized equipment and safety protocols. Biofuels offer a sustainable alternative, but their availability and compatibility with existing engine designs are still developing.

I’ve worked extensively with fuel oil treatment systems, ensuring the fuel’s quality meets engine specifications. This involves managing fuel purification processes (using centrifuges and coalescers) to remove water, sediment, and other contaminants that can damage engine components. For example, I once successfully troubleshooted a situation where contaminated fuel led to a significant reduction in engine power, identifying the issue through systematic analysis of fuel quality and implementing corrective actions that included a complete fuel system flush and filter replacement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage fuel efficiency in marine propulsion systems?

Fuel efficiency is paramount in marine operations, significantly impacting both operating costs and environmental impact. My approach to managing fuel efficiency involves a multi-pronged strategy. This begins with careful voyage planning – optimizing speed and route to minimize fuel consumption based on weather conditions and sea state. Regular monitoring of engine performance parameters, such as fuel consumption rates, exhaust temperatures, and cylinder pressures, allows for early detection of inefficiencies.

Regular maintenance plays a crucial role. Clean and properly functioning fuel systems, lubricated engines, and optimized propeller performance all contribute to improved fuel economy. Furthermore, I utilize advanced monitoring systems and data analysis tools to identify trends and opportunities for improvement. For example, I once identified a pattern of increased fuel consumption linked to hull fouling by analyzing continuous fuel flow data. Addressing the fouling through hull cleaning resulted in a noticeable reduction in fuel consumption.

Q 17. What is your experience with marine automation and control systems?

I possess extensive experience with various marine automation and control systems, including integrated automation systems (IAS), engine room monitoring systems (ERMS), and programmable logic controllers (PLCs). My experience ranges from troubleshooting and maintaining these systems to programming and configuration. I’m proficient in using various diagnostic software and tools to identify and rectify faults in these systems. For instance, I’ve been involved in the commissioning and integration of new automation systems onto vessels, ensuring seamless communication between different onboard systems.

This includes hands-on experience with systems from different manufacturers, including their specific communication protocols (e.g., Profibus, CANbus). A recent project involved upgrading an older vessel’s ERMS to a more advanced system, which improved monitoring capabilities, reduced downtime, and provided better operational insights. This required a deep understanding of the legacy system, careful planning for integration, and rigorous testing to ensure system stability and reliability.

Q 18. Describe your troubleshooting experience with propulsion system alarms and indicators.

Troubleshooting propulsion system alarms and indicators requires a systematic approach. I start by identifying the specific alarm or indicator, consulting the relevant manuals and schematics to understand its meaning and potential causes. This is followed by a thorough visual inspection of the associated components, checking for any obvious damage or malfunctions. Then, I systematically check the relevant parameters – for example, checking oil pressure, temperature, and fuel flow – using appropriate diagnostic tools.

For example, a high-temperature alarm might indicate a problem with the cooling system, a clogged filter, or a faulty sensor. My process would involve checking the coolant level and temperature, inspecting the cooling system for leaks or blockages, and testing the temperature sensor. I always prioritize safety and follow established lockout/tagout procedures before undertaking any maintenance or repairs. Documentation of all troubleshooting steps and findings is crucial for future reference and continuous improvement.

Q 19. Explain the use of diagnostic tools and equipment in marine propulsion maintenance.

Diagnostic tools and equipment are indispensable for efficient marine propulsion maintenance. These tools allow for precise measurements, early detection of potential problems, and improved troubleshooting. I routinely use various tools, including vibration analyzers to detect imbalances in rotating equipment, infrared thermometers to monitor temperatures, and pressure gauges to check fluid pressures.

Furthermore, advanced diagnostic systems, often integrated with the ship’s automation system, provide real-time data on engine performance and other parameters. These systems can identify trends and predict potential failures, enabling proactive maintenance and minimizing downtime. For instance, the use of sophisticated diagnostic software allowed me to identify an impending bearing failure in a main engine by analyzing vibration data, allowing for scheduled maintenance before a catastrophic breakdown.

Q 20. How do you ensure compliance with safety regulations during maintenance?

Safety is paramount during all maintenance activities. Compliance with international maritime safety regulations, such as SOLAS and MARPOL, is strictly adhered to. This involves implementing and following established safety procedures, using appropriate personal protective equipment (PPE), and ensuring proper lockout/tagout procedures are in place before commencing any work on energized equipment. Regular safety briefings and training are essential to maintain a high level of safety awareness among the maintenance team.

Permit-to-work systems are employed for all major maintenance tasks, ensuring a clear understanding of the risks involved and the necessary precautions. For example, before working on a propeller, a thorough risk assessment would be conducted, and a permit-to-work would be issued, outlining safety measures, such as the use of safety harnesses and appropriate fall protection equipment.

Q 21. What are the common causes of propeller damage and how to prevent them?

Propeller damage is a common problem in marine propulsion, resulting in decreased efficiency and potential operational downtime. Common causes include striking submerged objects (like rocks or debris), cavitation (formation of vapor bubbles due to low pressure), and fatigue cracking due to repetitive stress. Improper handling during maintenance or repairs can also lead to damage.

Prevention strategies include regular inspections for damage, particularly after transit through shallow or congested waters. Maintaining proper propeller alignment and ensuring the shaft is adequately lubricated helps prevent fatigue and damage. Careful navigation and adherence to depth charts are crucial to avoid striking submerged objects. Using propeller guards or other protective devices can also help mitigate damage. Regular underwater inspections using remotely operated vehicles (ROVs) or divers enable early detection of any damage, enabling timely repairs and preventing major problems.

Q 22. Explain your understanding of shaft bearings and their maintenance.

Shaft bearings are crucial components in a marine propulsion system, supporting the propeller shaft and minimizing friction during rotation. Their proper maintenance is essential for preventing damage, extending the lifespan of the system, and ensuring safe operation. There are several types, including journal bearings (often hydrodynamic, relying on an oil film for lubrication) and thrust bearings (designed to handle axial thrust from the propeller).

Maintenance involves regular inspections for wear, scoring, or misalignment. This often includes visual checks, vibration monitoring, and oil analysis. We check the oil level and quality regularly, looking for contamination or excessive wear particles. If the oil is contaminated or shows signs of degradation, it needs immediate attention, including possibly an oil change. Bearings themselves are checked for play or unusual noises. Any signs of excessive wear necessitates replacement or repair to prevent catastrophic failure. A key aspect is ensuring proper lubrication, using the correct type and grade of oil at the specified pressures. Failure to do so leads to overheating, scoring, and ultimately, bearing failure.

For example, during a recent survey on a vessel, we discovered slightly increased vibration levels in the stern tube bearing. Through detailed analysis, including oil sampling and a visual inspection, we identified minor scoring on the bearing surface. This was addressed by polishing the shaft and replacing the bearing with a reconditioned one, instead of a complete overhaul, saving both time and cost. This proactive approach prevented a more significant issue in the future.

Q 23. Describe your experience with different types of seals in marine propulsion systems.

Marine propulsion systems utilize various seals to prevent leakage of lubricating oil or seawater into the engine room or the environment. The choice of seal depends on factors such as pressure, temperature, and the type of fluid being sealed. Common seal types include:

- Lip Seals (or Shaft Seals): These are relatively simple and inexpensive seals, commonly used for low-pressure applications, often as primary seals in stern tube systems. They rely on a flexible lip to create a seal against the shaft.

- Mechanical Seals: These more complex seals are generally used in higher-pressure applications, offering superior sealing performance and longer lifespan compared to lip seals. They consist of stationary and rotating faces that maintain contact, preventing leakage. They’re often found in pumps and other high-pressure components.

- Stuffing Boxes (Packing Gland Seals): Older systems sometimes utilize stuffing boxes, employing packing material (e.g., braided flax or synthetic materials) compressed around the shaft to create a seal. These require frequent adjustment and maintenance and are less efficient than modern seal designs.

My experience includes maintaining and troubleshooting all three types. I’ve successfully diagnosed and resolved leakage issues in mechanical seals through careful inspection, identifying and replacing worn components, and ensuring proper alignment. In one instance, we determined that a lip seal failure was due to shaft misalignment and corrected the issue, preventing further seal damage.

Q 24. How do you handle emergency situations involving propulsion system failures?

Propulsion system failures are serious events. My immediate response focuses on safety and damage limitation. The first step is to assess the situation, identify the nature of the failure and its potential consequences. Then, depending on the severity, we follow a protocol. For minor issues (e.g., a minor leak or vibration), temporary repairs or adjustments are possible, aiming to restore partial functionality. More significant failures may necessitate emergency shutdown of the main engine, employing secondary propulsion methods if available (e.g., auxiliary generators, emergency steering).

After securing the vessel and crew, I will initiate communication with the shore-based support team, reporting the situation, and requesting guidance if needed. Then, we begin troubleshooting, systematically checking various components and systems to identify the root cause of the failure. This could involve checks of fuel supply, lubricating oil systems, cooling systems, or propeller condition, depending on symptoms. Once the cause is identified, repairs can be initiated or a plan for replacement/repair during port call established. Throughout this process, maintaining accurate records of actions taken is crucial for future analysis and preventing recurrence. For example, in a case of engine failure at sea, we used the emergency generator to maintain essential services, and implemented our emergency procedures effectively. Post-incident investigations led us to address a critical deficiency in the fuel injection system of that main engine.

Q 25. Explain the process of conducting a pre-voyage inspection of the propulsion system.

A pre-voyage inspection of the propulsion system is a critical step to ensure safe and efficient operation. The scope of this inspection varies depending on the vessel and its recent history but generally includes:

- Visual Inspection: Checking for any visible damage, leaks, corrosion, or loose connections throughout the entire propulsion train—from main engine to propeller.

- Lubrication Systems: Verifying oil levels, quality, and pressure in all relevant systems (main engine, gearboxes, bearings). Checking filters and coolers.

- Cooling Systems: Assessing the integrity of the cooling water system and checking for leaks or blockages. This also includes checking the seawater system that cools the main engine, gearboxes, and shaft bearings.

- Fuel System: Inspecting fuel tanks, lines, and filters for contamination or leaks. Verifying fuel supply and quality.

- Shaft Alignment: Checking for any misalignment in the propulsion shafting. Misalignment can cause excessive vibration and bearing wear.

- Vibration Monitoring: Checking vibration levels at key points in the system. Excessive vibration can indicate a problem.

- Propeller: Examining the propeller for damage, including damage to the blades or hub.

Detailed records are kept of the inspection, including any findings and actions taken. Any identified problems must be addressed before the voyage commences. This proactive approach avoids potential breakdowns at sea and ensures the vessel operates safely and efficiently.

Q 26. Describe your experience with various types of propulsion system monitoring systems.

Modern marine propulsion systems utilize various monitoring systems to track performance and detect potential problems early. My experience encompasses several types:

- Engine Monitoring Systems (EMS): These systems provide real-time data on engine parameters such as RPM, temperature, pressure, and fuel consumption. They often include alarm systems that alert the crew to abnormal operating conditions.

- Vibration Monitoring Systems: These systems continuously monitor vibration levels at critical points in the propulsion system, providing early warning of potential problems such as bearing wear, shaft misalignment, or propeller damage.

- Condition-Based Monitoring (CBM): More advanced systems use algorithms and machine learning techniques to analyze data from various sensors and predict potential failures before they occur.

- Remote Monitoring Systems: These allow shore-based personnel to monitor the performance of the propulsion system remotely, providing expert support to the crew.

I’m proficient in interpreting data from these systems and using the information to diagnose problems and schedule preventative maintenance. For example, an anomaly detected by our CBM system led to the early identification of a cracked connecting rod in the main engine during a routine inspection, preventing a potentially catastrophic failure.

Q 27. What is your experience with vibration analysis in marine propulsion systems?

Vibration analysis is a critical tool for diagnosing problems in marine propulsion systems. Excessive vibration can indicate a variety of issues, including bearing wear, shaft misalignment, propeller imbalance, or cavitation. Vibration analysis involves measuring the frequency and amplitude of vibrations at various points in the system using accelerometers. This data is then analyzed using specialized software to identify the source and severity of the problem. Different frequencies correspond to different potential faults within the machinery. For example, a high-frequency vibration may indicate a bearing problem, while a low-frequency vibration might suggest shaft misalignment.

My experience includes conducting vibration surveys, analyzing the data using specialized software (e.g., condition monitoring software), and interpreting the results to identify the root cause of the problem. We often use the collected data to pinpoint exact machinery requiring attention. I have used this technique to successfully diagnose and resolve issues ranging from minor bearing wear to major shaft alignment problems. For instance, on one occasion, vibration analysis revealed a subtle propeller imbalance, which was corrected through propeller balancing, thus preventing further damage and maintaining smooth vessel operation. Proactive vibration monitoring helps in minimizing maintenance costs and preventing major breakdowns.

Q 28. Explain your knowledge of different types of marine propellers and their applications.

Marine propellers come in various designs, each with its own advantages and disadvantages. The choice of propeller depends on factors such as vessel type, speed requirements, and operational conditions:

- Fixed-Pitch Propellers (FPP): These are the simplest type of propeller, with blades that are fixed at a specific angle. They are relatively inexpensive but less efficient than other types, especially at varying speeds.

- Controllable-Pitch Propellers (CPP): These propellers allow the blade pitch to be adjusted while the propeller is rotating, optimizing efficiency at different speeds and maneuvering conditions. They offer superior maneuverability and efficiency but are more complex and expensive.

- Ducted Propellers: These propellers are enclosed in a duct or nozzle, which improves propulsion efficiency, particularly at low speeds. They are often used in vessels requiring good maneuverability at low speeds (e.g., tugboats).

- Supercavitating Propellers: Designed for high-speed applications, these propellers operate partially or fully in a cavitation bubble, reducing drag. They are complex and expensive.

My experience includes working with all these types. Understanding the characteristics of each type is essential for selecting the appropriate propeller for a specific application and for troubleshooting performance issues. For example, I once assisted in the selection of a CPP for a new vessel designed for long-range voyages, prioritizing efficiency and fuel economy. In another case, I diagnosed reduced propulsion efficiency in a ducted propeller due to damage inside the duct, leading to efficient repairs to restore performance.

Key Topics to Learn for Proficient in the operation and maintenance of marine propulsion systems Interview

- Diesel Engine Systems: Understanding various diesel engine types (e.g., 2-stroke, 4-stroke), their operational principles, and common maintenance procedures. This includes fuel systems, lubrication systems, and cooling systems.

- Gas Turbine Systems: Knowledge of gas turbine operation, maintenance, and troubleshooting. Focus on the principles of combustion, power generation, and component lifespan.

- Propulsion System Components: Deep understanding of shafts, propellers, gears, and other key components within the propulsion train. This includes their functionality, potential failure points, and maintenance strategies.

- Electrical Systems Integration: How the propulsion system interacts with the ship’s electrical systems, including power generation, distribution, and control systems relevant to propulsion.

- Troubleshooting and Diagnostics: Practical experience in diagnosing and resolving propulsion system malfunctions. This includes understanding fault codes, utilizing diagnostic tools, and applying effective problem-solving methodologies.

- Safety Procedures and Regulations: Familiarity with relevant safety regulations and procedures for operating and maintaining marine propulsion systems, emphasizing risk mitigation and compliance.

- Preventive Maintenance: Developing a strong understanding of scheduled maintenance, lubrication practices, and the importance of adhering to manufacturer guidelines to prevent major failures.

- Performance Monitoring and Optimization: Knowledge of monitoring propulsion system performance parameters (e.g., fuel consumption, RPM, vibration) and strategies for optimization and efficiency improvements.

Next Steps

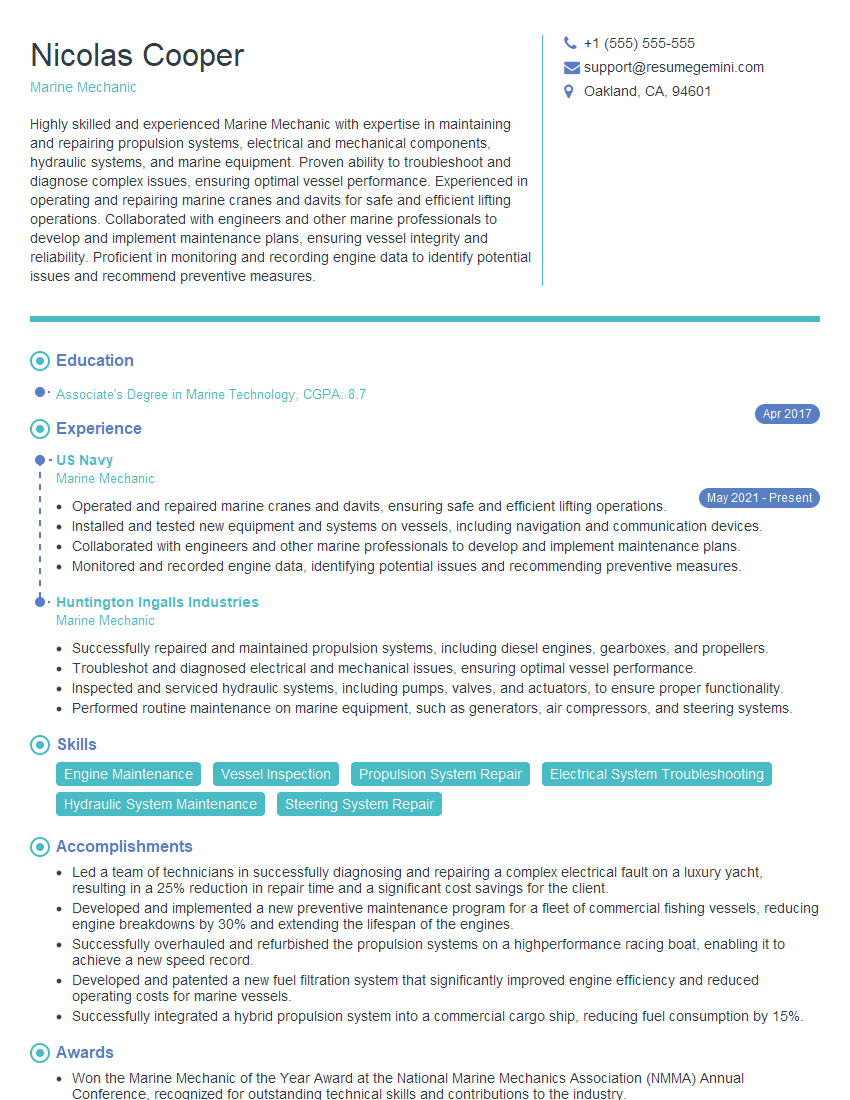

Mastering the operation and maintenance of marine propulsion systems is crucial for career advancement in the maritime industry, opening doors to higher-paying roles with increased responsibility. A well-crafted resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential to ensure your application gets noticed by potential employers. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. We offer examples of resumes tailored to roles requiring proficiency in the operation and maintenance of marine propulsion systems, to give you a head start.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO