Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Proficient in the use of quality control techniques interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Proficient in the use of quality control techniques Interview

Q 1. Explain the different types of quality control charts you are familiar with.

Quality control charts are visual tools used to track and analyze process variation over time. They help identify trends, patterns, and anomalies that might indicate a process is out of control. Several types exist, each suited to different data types and scenarios:

- Control Charts for Variables: These charts track continuous data, like weight, temperature, or length. The most common are:

- X-bar and R chart:

X-bartracks the average of subgroups, whileRtracks the range (difference between the highest and lowest values) within each subgroup. This helps monitor both the central tendency and the variability of the process. - X-bar and s chart: Similar to X-bar and R, but uses the standard deviation (

s) instead of the range.sis more statistically efficient but requires more calculation. - Control Charts for Attributes: These charts track discrete data, like the number of defects or the percentage of non-conforming units.

- p-chart: Tracks the proportion of non-conforming units in a sample. Useful for monitoring defect rates.

- np-chart: Similar to the p-chart, but tracks the actual number of non-conforming units instead of the proportion. Useful when the sample size is consistent.

- c-chart: Tracks the number of defects per unit. Ideal for situations where defects can occur multiple times on a single unit.

- u-chart: Tracks the average number of defects per unit. Useful when the sample size varies.

The choice of chart depends on the data type and the specific quality characteristic being monitored. For example, in a manufacturing setting, an X-bar and R chart might be used to monitor the diameter of a manufactured part, while a p-chart could monitor the percentage of defective parts in a batch.

Q 2. Describe your experience with Statistical Process Control (SPC).

Statistical Process Control (SPC) is a powerful methodology I’ve used extensively to monitor and improve process performance. My experience includes designing and implementing control charts, analyzing data for patterns of variation, and identifying assignable causes (special causes) of variation that require investigation and corrective action. I’ve successfully utilized SPC in various projects, such as optimizing a production line to reduce defect rates, improving the accuracy of a laboratory testing process, and enhancing the consistency of a service delivery process. A key part of my SPC implementation involves training personnel on data collection, chart interpretation, and the importance of timely corrective actions. For example, in one project, we identified a specific machine malfunction as the root cause of increased variation by analyzing X-bar and R charts. Addressing this malfunction resulted in a significant improvement in the process capability.

Q 3. How do you identify and prioritize quality control issues?

Identifying and prioritizing quality control issues requires a systematic approach. I typically start with data analysis, using control charts and other statistical methods to highlight areas of concern. Next, I investigate the severity and frequency of each issue. Severity considers the potential impact on the customer, the business, and safety. Frequency considers how often the issue occurs. I then use a prioritization matrix, often a risk assessment matrix, which plots severity against frequency. Issues with high severity and high frequency get prioritized first. For example, a recurring defect causing product failure would be ranked higher than a minor cosmetic flaw. This prioritization helps focus resources on the issues with the most significant impact.

Q 4. What are your preferred methods for root cause analysis?

My preferred methods for root cause analysis (RCA) include the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and Fault Tree Analysis (FTA). The 5 Whys involves repeatedly asking “Why?” to drill down to the root cause. This is a simple yet effective method, particularly for straightforward problems. Fishbone diagrams help organize potential causes into categories (e.g., people, methods, materials, machines, environment). FTA is more complex and suitable for complex systems, graphically illustrating the various failures that can lead to a specific undesirable event. I select the appropriate method based on the complexity of the problem. For example, a simple process hiccup might warrant the 5 Whys, while a complex system failure might require FTA.

Q 5. Explain your experience with different quality control methodologies (e.g., Six Sigma, Lean).

I have significant experience with Six Sigma and Lean methodologies. Six Sigma, with its DMAIC (Define, Measure, Analyze, Improve, Control) framework, provides a structured approach to process improvement. I’ve led projects using DMAIC to reduce defects and improve efficiency. Lean focuses on eliminating waste and maximizing value. I’ve implemented Lean principles such as Value Stream Mapping to identify and eliminate non-value-added steps in processes. Often, I combine elements of both methodologies. For instance, in a recent project, we used Six Sigma DMAIC to identify the root causes of defects in a manufacturing process, then applied Lean principles to streamline the process and eliminate waste, resulting in a significant reduction in both defects and cycle time. The synergy between these two approaches greatly enhances the impact of quality control efforts.

Q 6. How do you develop and implement quality control plans?

Developing and implementing quality control plans involves several key steps. First, I clearly define the objectives and scope of the plan, identifying the specific quality characteristics that need to be monitored and controlled. Next, I select appropriate quality control tools and techniques, such as control charts, checklists, and inspection procedures. Then, I define the sampling plan, determining the sample size, frequency, and method of sampling. I also develop acceptance criteria, establishing clear limits for acceptable variation. Finally, I document the entire plan, including procedures, responsibilities, and reporting requirements. Crucially, I involve stakeholders in the development process to ensure buy-in and effective implementation. For instance, in one project, we developed a quality control plan for a new product launch by involving manufacturing, engineering, and quality assurance teams, ensuring all aspects of the product were thoroughly considered.

Q 7. Describe your experience with quality audits and inspections.

I’ve extensive experience conducting quality audits and inspections. Audits involve a systematic review of a process or system to evaluate its compliance with standards and requirements. Inspections focus on verifying the quality of individual products or services. I use checklists and documented procedures to ensure consistency and thoroughness. During audits, I examine documentation, observe processes, and interview personnel. In inspections, I use appropriate measurement tools and techniques to verify that products or services meet specifications. I document findings, report non-conformances, and follow up on corrective actions. For example, I recently conducted an audit of a supplier’s manufacturing process, identifying several areas for improvement that were addressed by the supplier, leading to enhanced product quality and a stronger supplier relationship.

Q 8. How do you ensure compliance with relevant quality standards (e.g., ISO 9001)?

Ensuring compliance with quality standards like ISO 9001 requires a multifaceted approach. It’s not just about ticking boxes; it’s about embedding quality into the very fabric of the organization.

- Implementing a Quality Management System (QMS): This involves documenting processes, establishing clear roles and responsibilities, and defining procedures for everything from product development to customer service. Think of it as a detailed instruction manual for consistently achieving high quality.

- Regular Internal Audits: We conduct regular internal audits to assess our conformity to the standard. These audits identify gaps and areas for improvement, ensuring we’re not just meeting the minimum requirements but striving for excellence.

- Management Review: Senior management regularly reviews the performance of the QMS. This ensures that the system remains effective and aligned with business objectives. It’s like having a steering committee that guides the quality journey.

- Corrective and Preventive Actions (CAPA): Any identified nonconformities are addressed through a structured CAPA process. This ensures that issues are not only fixed but also prevented from recurring. This is critical for continuous improvement.

- Training and Awareness: All personnel are trained on the requirements of the standard and their roles in maintaining it. A well-trained workforce is the backbone of a successful QMS.

For example, in a previous role, we implemented a comprehensive training program on ISO 9001, resulting in a significant reduction in nonconformities during our subsequent audits.

Q 9. How do you handle conflict or disagreement regarding quality standards?

Disagreements regarding quality standards are inevitable. However, a structured approach ensures that these conflicts are resolved constructively.

- Focus on Data and Facts: The key is to avoid emotional arguments and instead focus on objective evidence. Data analysis, inspection reports, and customer feedback can help to support different perspectives.

- Collaborative Problem-Solving: I facilitate discussions, encouraging open communication and a collaborative approach to finding a solution that satisfies all stakeholders. Think of it as a brainstorming session with a common goal: improved quality.

- Escalation Process: If a consensus can’t be reached at a lower level, there should be a clearly defined escalation process to involve senior management for mediation or decision-making.

- Documentation: The outcome of any conflict resolution process should be documented, including the decisions made and the actions taken to implement them. This creates transparency and accountability.

In one instance, a disagreement arose over the acceptance criteria for a new product. By analyzing test data and customer requirements, we reached a compromise that satisfied both engineering and marketing teams, leading to a successful product launch.

Q 10. Describe your experience with quality control documentation and reporting.

Quality control documentation and reporting are crucial for maintaining a traceable and auditable record of quality activities. It’s like having a comprehensive history of all quality-related events.

- Inspection Reports: These reports detail the findings of inspections, including any defects or nonconformities identified. They provide a snapshot of the quality status at a specific point in time.

- Test Data: This includes all data collected from testing and inspections, providing evidence of the product’s performance and compliance with specifications. This is the raw evidence that backs up any claims about quality.

- Control Charts: These charts visually display process variations over time. They can help to identify trends and predict potential problems before they escalate.

- Nonconformance Reports: These documents record deviations from standards, including root cause analysis and corrective actions. It’s our ‘lessons learned’ repository.

- Quality Management System Documentation: This includes the QMS manual, procedures, and work instructions. This is the foundational documentation for our quality system.

- Management Reports: Regular reports summarize key quality metrics, trends, and performance indicators to management.

I’m proficient in using various software tools to generate and manage this documentation, ensuring it’s accurate, complete, and easily accessible. For example, I’ve used statistical software like Minitab to analyze data and create control charts to monitor key quality characteristics.

Q 11. How do you measure the effectiveness of quality control initiatives?

Measuring the effectiveness of quality control initiatives requires a combination of quantitative and qualitative measures. It’s not just about numbers; it’s about the overall impact on the business.

- Defect Rate: This measures the number of defects found per unit of product. A reduction in defect rate indicates improvement in quality control.

- Customer Satisfaction: This is a crucial qualitative measure. High customer satisfaction is a strong indicator of effective quality control.

- Process Capability: This assesses the ability of a process to consistently produce products within specified limits. High process capability suggests robust quality control measures.

- Cost of Poor Quality (COPQ): This measures the financial impact of quality issues, including rework, scrap, and customer complaints. A reduction in COPQ is a direct indication of improved quality control effectiveness.

- Audit Findings: The number and severity of audit findings can indicate the effectiveness of the quality management system.

In a previous role, we implemented a new quality control procedure that reduced our defect rate by 25% and customer complaints by 15%, demonstrating its significant positive impact. We tracked these improvements using dashboards and regular reports.

Q 12. What are the key performance indicators (KPIs) you use to track quality?

The specific KPIs used to track quality will vary depending on the industry and the type of product or service. However, some common KPIs include:

- Defect Rate: The percentage of defective units produced.

- Yield Rate: The percentage of units produced that meet specifications.

- Customer Return Rate: The percentage of products returned due to quality issues.

- Customer Satisfaction Score (CSAT): A measure of customer satisfaction with product quality.

- Net Promoter Score (NPS): A measure of customer loyalty and willingness to recommend the product or service.

- Process Capability Indices (Cpk, Pp): Measures of process capability and consistency.

- Mean Time Between Failures (MTBF): For products, this indicates reliability.

- First Pass Yield: Percentage of units passing inspection on the first attempt.

The choice of KPIs should be driven by business objectives. It’s essential to regularly monitor and analyze these KPIs to identify trends and opportunities for improvement. For example, a high customer return rate might signal a need for improved quality control at a specific stage of the production process.

Q 13. How do you use data analysis to improve quality control processes?

Data analysis is essential for driving continuous improvement in quality control processes. It provides insights that would otherwise be impossible to obtain.

- Statistical Process Control (SPC): Using control charts to monitor process variation and identify areas for improvement. This helps detect shifts in process behavior before they lead to defects.

- Root Cause Analysis (RCA): Using techniques like the ‘5 Whys’ or fishbone diagrams to identify the underlying causes of quality problems. This helps to prevent recurring issues.

- Regression Analysis: Identifying the relationships between different process variables and quality characteristics. This can help optimize processes to minimize variability and maximize quality.

- Data Mining: Analyzing large datasets to identify patterns and anomalies that may indicate quality issues. This is particularly useful in complex manufacturing processes.

For instance, in one project, we used regression analysis to identify a strong correlation between ambient temperature and the defect rate in a specific manufacturing process. By controlling the ambient temperature, we significantly reduced the defect rate.

Q 14. Describe a time you identified a significant quality issue. How did you resolve it?

In a previous project involving the production of a medical device, we identified a significant increase in the failure rate of a critical component. This posed a serious risk to patient safety and product reputation.

Problem Identification: Initial analysis showed a surge in failures linked to a specific batch of the component from our supplier. The failure mode was a subtle crack appearing after a period of use.

Root Cause Analysis: We conducted a thorough RCA, involving supplier audits, material analysis, and design reviews. We discovered a flaw in the supplier’s manufacturing process—a subtle variation in the heat treatment of the component.

Resolution: We worked collaboratively with the supplier to correct their process. This involved retraining their staff, updating their equipment, and implementing stricter quality checks. We also implemented a more stringent incoming inspection procedure to detect affected components.

Preventive Measures: We developed a new, more robust design for the component to mitigate the risk of failure even if similar issues arose again. This included using a different material with higher fatigue strength.

Outcome: The failure rate dropped significantly after these interventions. The entire episode resulted in improved supplier relationships, a robust design change, and a more stringent quality control system, thereby preventing similar issues from reoccurring. We documented the entire process meticulously as a case study, shared widely within the company and with relevant stakeholders.

Q 15. How do you communicate quality control issues to different stakeholders?

Communicating quality control issues effectively requires tailoring the message to the audience. For instance, a detailed technical report might be appropriate for engineers, while a concise summary with key action items would suffice for upper management. I utilize different communication channels depending on the urgency and complexity of the issue. For minor issues, a simple email might be sufficient. For critical issues requiring immediate action, I would utilize a combination of email, phone calls, and potentially even an emergency meeting. Visual aids like charts and graphs are incredibly helpful in summarizing data and illustrating the impact of the issue. I always ensure the communication is clear, concise, and objective, focusing on the facts and avoiding emotional language. For example, instead of saying ‘the product is a disaster,’ I might say ‘the product failed to meet specification X, resulting in Y consequence.’ Finally, I always follow up to confirm the issue has been addressed and to ensure everyone is on the same page.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common quality control challenges you’ve faced, and how did you overcome them?

One common challenge is balancing the cost of quality control with the potential risks of defects. In one project, we were under immense pressure to meet a tight deadline. Initially, we considered cutting corners on some quality control checks to save time and resources. However, recognizing the potential for significant rework and customer dissatisfaction down the line, I proposed a prioritized risk assessment. We identified the most critical quality parameters and focused our resources on those, while accepting a slightly higher risk on less critical aspects. This allowed us to meet the deadline without sacrificing overall product quality. Another challenge is dealing with human error. To mitigate this, I implemented a robust training program and a multi-step verification process, where each step is checked by a different individual. We also introduced checklists to minimize human error in repetitive tasks. Finally, clear and readily accessible documentation for every process helped ensure consistency and avoid errors.

Q 17. Describe your experience with calibration and verification of equipment.

My experience with calibration and verification is extensive. I’ve been responsible for managing the calibration schedule for various types of equipment, ranging from precision measuring instruments (like micrometers and calipers) to complex automated testing systems. We use a traceable calibration system, ensuring that all instruments are calibrated against national or international standards. This involves sending instruments to accredited calibration laboratories and maintaining meticulous records of calibration certificates. Verification, on the other hand, involves independently checking the equipment’s performance against its specifications to ensure it’s functioning correctly. This is done both before and after calibration and at regular intervals throughout its use. For example, we might use standard weights to verify the accuracy of a balance scale, or known samples to check the accuracy of a spectrophotometer. We maintain detailed logs of all calibration and verification procedures, including any corrective actions taken if discrepancies are detected. This ensures traceability and compliance with relevant standards and regulations.

Q 18. What is your approach to continuous improvement in quality control?

My approach to continuous improvement in quality control centers around the Plan-Do-Check-Act (PDCA) cycle. We regularly review our quality control processes, looking for areas where improvements can be made. This involves analyzing defect data, customer feedback, and internal audits to identify root causes of problems. For example, if we see a recurring issue with a particular component, we investigate the process involved in making that component to find the source of the defect. Once we have identified the root cause, we develop and implement corrective actions (Plan), then test the changes (Do). We then monitor the results to see if the changes have been effective (Check). Finally, if the changes are successful, we standardize the improved process (Act), thus completing the cycle and continuously improving our processes. We also actively encourage employee involvement in identifying opportunities for improvement, creating a culture of continuous improvement within the team.

Q 19. Explain your understanding of Total Quality Management (TQM).

Total Quality Management (TQM) is a holistic approach to managing quality throughout an organization. It’s not just about meeting specifications; it’s about exceeding customer expectations and continuously improving processes to achieve perfection. Key principles of TQM include customer focus, continuous improvement, employee empowerment, process improvement, and data-driven decision making. In essence, TQM aims to create a culture where everyone in the organization is responsible for quality. I’ve applied TQM principles by implementing cross-functional teams to address quality issues, empowering employees to stop the line when a defect is identified and focusing on preventative measures to avoid defects in the first place rather than just reacting to them. For example, we might implement statistical process control (SPC) charts to monitor key process parameters and identify potential problems before they lead to defects.

Q 20. How do you ensure the accuracy and reliability of quality control data?

Ensuring the accuracy and reliability of quality control data is paramount. We employ several strategies to achieve this. First, we use calibrated and verified equipment. Second, we implement rigorous data collection procedures, including clear instructions, standardized forms, and well-trained personnel. Third, we use statistical methods to analyze the data and identify any outliers or inconsistencies. We also regularly audit our data collection and analysis processes to detect and correct any errors. Finally, we maintain a secure and organized system for storing and managing our quality control data, protecting it from loss or corruption. We use a combination of paper-based and electronic systems, depending on the specific needs. Data traceability is maintained through documented procedures and automated systems. All this helps maintain integrity and avoid misinterpretations of results.

Q 21. How do you manage and mitigate quality control risks?

Managing and mitigating quality control risks involves a proactive approach that includes risk identification, assessment, and mitigation. We start by identifying potential risks throughout the entire process, from raw materials to finished products. This might involve brainstorming sessions, failure mode and effects analysis (FMEA), or reviewing historical data. Once risks are identified, we assess their likelihood and potential impact. Then, we develop and implement mitigation strategies to reduce the likelihood or impact of these risks. These strategies might include implementing additional quality checks, improving training programs, upgrading equipment, or changing processes. We regularly monitor the effectiveness of our mitigation strategies and make adjustments as necessary. Finally, we document all our risk management activities, including the identified risks, the assessment results, and the mitigation strategies implemented. This documentation helps to ensure consistent application of risk management procedures and to continuously improve our risk management process.

Q 22. Describe your experience with quality control in a specific industry.

My extensive experience in quality control stems from my seven years working in the pharmaceutical industry. Specifically, I was involved in ensuring the sterility and efficacy of injectable medications. This required meticulous attention to detail across every stage of production, from raw material inspection to final product release. We employed a robust system of Good Manufacturing Practices (GMP) compliant procedures, including visual inspections, sterility testing using microbial assays, and rigorous documentation at each step. For instance, we used statistical process control (SPC) charts to monitor critical parameters like fill volume and particle count, enabling proactive identification and correction of deviations. Any deviation from established parameters triggered an immediate investigation, documented thoroughly and reviewed by quality assurance. This rigorous approach ensured that our products consistently met the highest quality standards and regulatory requirements, resulting in zero product recalls during my tenure.

Q 23. What software or tools are you proficient in using for quality control?

I’m proficient in using several software and tools for quality control. My expertise includes Statistical Process Control (SPC) software like Minitab and JMP, which I’ve used extensively to analyze production data, identify trends, and predict potential quality issues. I’m also adept at using LIMS (Laboratory Information Management Systems) for managing laboratory data and ensuring traceability throughout the testing process. Additionally, I have experience with Enterprise Resource Planning (ERP) systems for tracking materials and inventory, crucial for ensuring the quality of incoming raw materials. Finally, I utilize various specialized testing software depending on the specific testing methodology, including software designed for analyzing images from non-destructive testing methods such as X-ray inspection.

Q 24. How do you train and mentor others on quality control best practices?

Training and mentoring others on quality control is a significant part of my role. I employ a blended learning approach, combining theoretical knowledge with hands-on practical experience. I begin by presenting the fundamental concepts of quality control, including statistical methods, root cause analysis, and quality management systems like ISO 9001. I then lead practical workshops where they can apply these concepts to real-world scenarios, using case studies and simulations. Mentorship is an ongoing process. I provide regular feedback, encourage peer learning, and ensure ongoing access to resources and training materials. For example, I developed a training module focused on using SPC charts to improve the fill accuracy of a particular medication, which significantly improved efficiency and reduced waste.

Q 25. What is your experience with non-destructive testing methods?

My experience with non-destructive testing (NDT) methods encompasses several techniques. I’ve worked extensively with visual inspection, utilizing borescopes and magnifying glasses for detailed examinations of components, particularly for detecting surface defects. I have also used ultrasonic testing (UT) to detect internal flaws in materials like welds and castings. Furthermore, I’m familiar with radiographic testing (RT), using X-rays to identify internal defects, and dye penetrant testing (PT) for detecting surface cracks. Each method has its specific applications, and selecting the appropriate technique relies on the material, component type, and potential defect types. For example, during an inspection of pressure vessels, we used a combination of UT and RT to ensure integrity and safety.

Q 26. How do you balance quality control with production efficiency?

Balancing quality control with production efficiency is a constant challenge that requires a strategic approach. It’s not a trade-off, but rather an optimization. Implementing effective quality control measures proactively reduces downstream problems like rework, scrap, and customer complaints which ultimately boosts efficiency. For instance, investing in automation for inspection tasks and implementing real-time process monitoring can accelerate inspection times while simultaneously improving accuracy. Additionally, continuous improvement initiatives such as Kaizen events, focused on identifying and eliminating bottlenecks in the production process without compromising quality, are crucial. Regularly evaluating and updating quality control procedures ensures they remain efficient and effective.

Q 27. Describe your experience working with cross-functional teams on quality control initiatives.

I’ve consistently worked collaboratively with cross-functional teams on quality control initiatives. This typically involves engineers, production personnel, and regulatory affairs specialists. Effective communication and a shared understanding of quality goals are paramount. I often facilitate meetings and workshops, using tools like process mapping and root cause analysis to identify areas for improvement collaboratively. For example, while addressing a consistent defect in a specific product component, our team worked together, combining engineering knowledge to modify the manufacturing process and quality control expertise to implement improved inspection protocols, significantly reducing the defect rate.

Q 28. How do you stay updated on the latest quality control techniques and technologies?

Staying updated on the latest quality control techniques and technologies is critical in this rapidly evolving field. I actively participate in professional organizations like ASQ (American Society for Quality), attending conferences and workshops to network and learn about cutting-edge developments. I regularly read industry publications and journals, and I subscribe to several newsletters focusing on quality management. Additionally, I leverage online resources, including webinars and online courses, to deepen my knowledge in specific areas. This continuous learning ensures my skills remain relevant and I can effectively implement the best practices in my work.

Key Topics to Learn for Proficient in the use of Quality Control Techniques Interview

- Statistical Process Control (SPC): Understanding control charts (e.g., Shewhart, CUSUM), process capability analysis (Cp, Cpk), and their application in identifying and addressing process variations.

- Quality Management Systems (QMS): Familiarity with ISO 9001 or other relevant standards, including documentation, internal audits, and continuous improvement methodologies.

- Root Cause Analysis (RCA): Mastering techniques like the 5 Whys, Fishbone diagrams, and fault tree analysis to effectively identify the underlying causes of quality defects.

- Six Sigma Methodology: Understanding DMAIC (Define, Measure, Analyze, Improve, Control) and its application in process optimization and defect reduction.

- Inspection and Testing Methods: Knowledge of various inspection techniques, sampling plans, and testing procedures relevant to your industry. Be prepared to discuss practical examples.

- Quality Metrics and Reporting: Understanding key performance indicators (KPIs) related to quality, and the ability to analyze and present data effectively to stakeholders.

- Problem-Solving and Decision-Making: Demonstrate your ability to approach quality challenges systematically, using data-driven approaches and proposing effective solutions.

- Continuous Improvement Initiatives: Discuss your experience with Lean manufacturing principles, Kaizen events, or other continuous improvement methodologies.

Next Steps

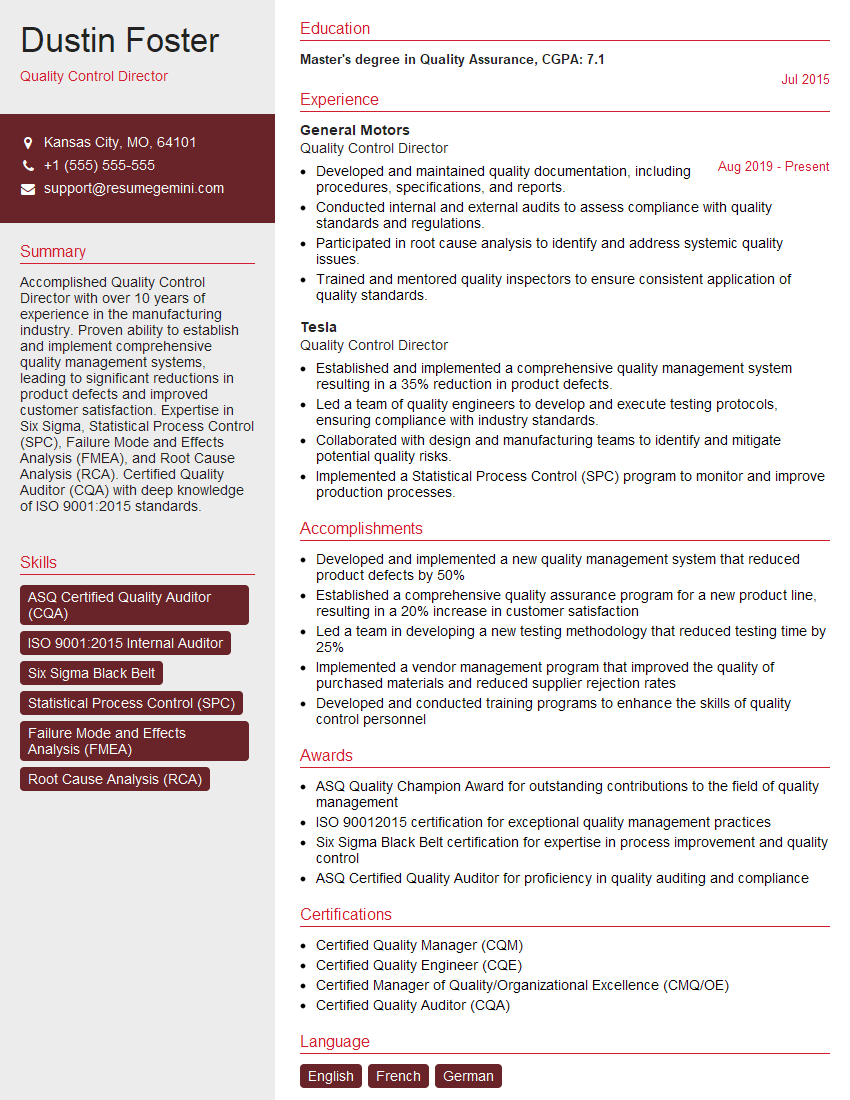

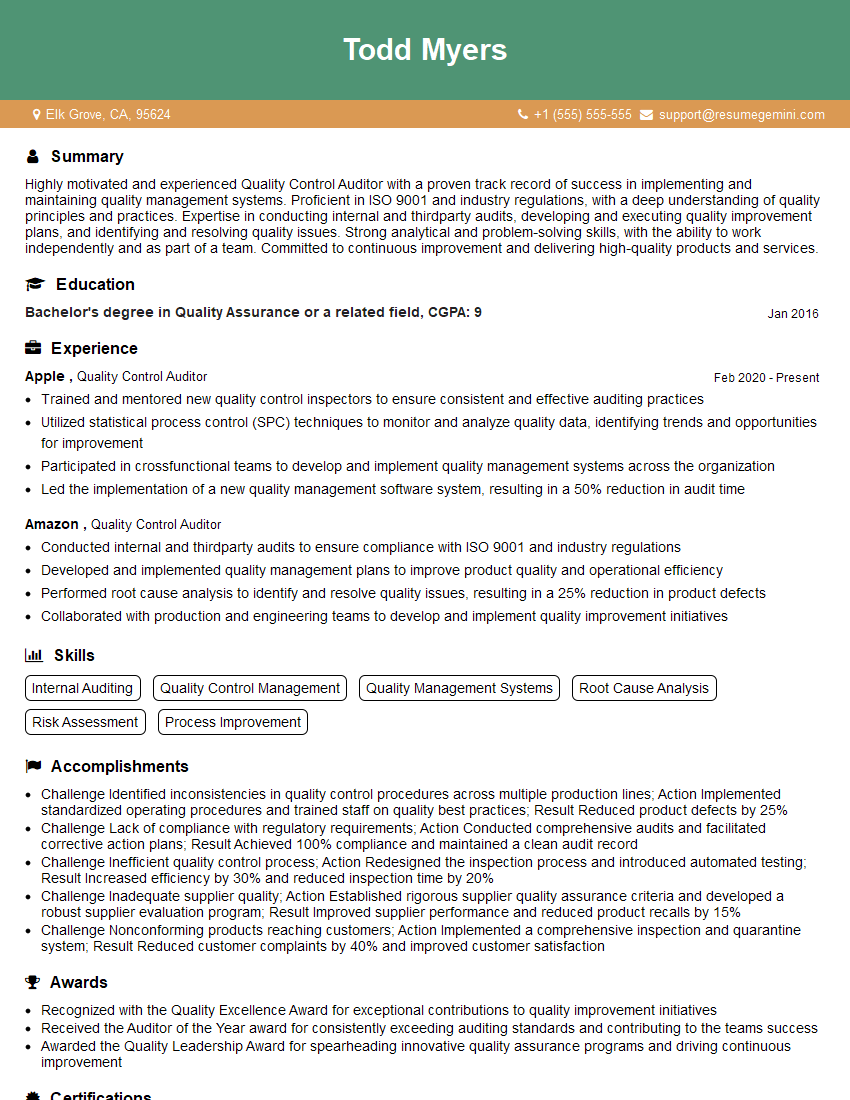

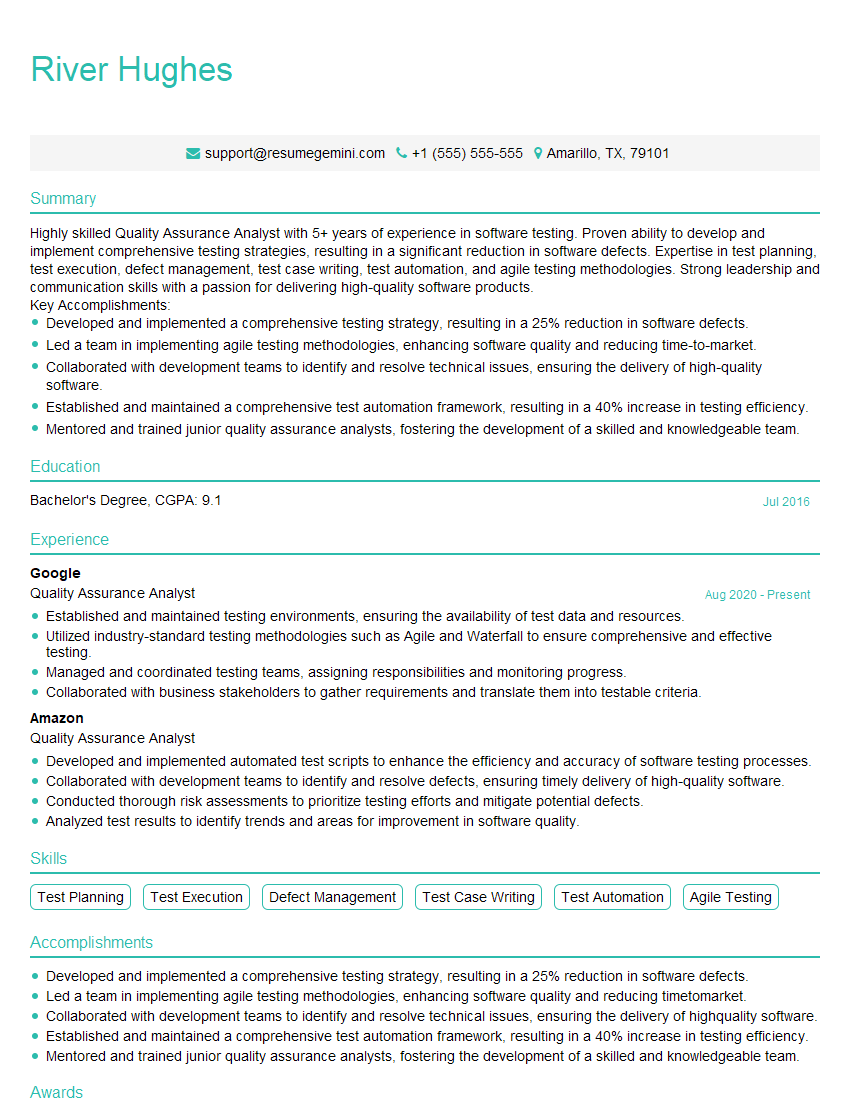

Mastering quality control techniques is crucial for career advancement in almost any industry. Demonstrating proficiency in these areas showcases your commitment to excellence and problem-solving abilities – highly valued attributes in today’s competitive job market. To significantly increase your chances of landing your dream role, crafting an ATS-friendly resume is essential. ResumeGemini can help you build a compelling and effective resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to showcasing proficiency in quality control techniques, helping you present your qualifications in the best possible light. Take the next step towards your career goals – build a winning resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO