Preparation is the key to success in any interview. In this post, we’ll explore crucial Protection and Control System Monitoring and Troubleshooting interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Protection and Control System Monitoring and Troubleshooting Interview

Q 1. Explain the difference between differential and distance protection schemes.

Differential protection and distance protection are both crucial schemes for safeguarding transmission lines and transformers, but they operate based on different principles. Differential protection compares currents entering and leaving a protected zone (like a transformer winding or a transmission line section). If there’s a significant difference, it indicates an internal fault. Think of it like a bank account – if the money going in doesn’t match the money coming out, there’s a problem. Distance protection, on the other hand, measures the impedance to the fault along the line. If the impedance falls within a pre-defined range, indicating a fault within the protected zone, the relay operates. Imagine it like measuring the distance to a fire – if it’s within your property, you need to act.

In short: Differential protection is highly sensitive to internal faults but less effective for external faults. Distance protection excels at detecting both internal and external faults along a transmission line, but it’s slightly less sensitive to internal faults within a very short distance from the relay.

Q 2. Describe the function of a protective relay.

A protective relay is the brain of a power system’s protection scheme. Its primary function is to detect faults (short circuits, ground faults, etc.) and initiate appropriate actions to isolate the faulty section of the power system quickly and safely. This prevents cascading failures, minimizes damage to equipment, and ensures the safety of personnel. Protective relays are essentially sophisticated measuring devices that continuously monitor voltage and current levels. They compare these measurements against pre-set thresholds. When a fault occurs, resulting in abnormal current or voltage values, the relay identifies the fault type and location and sends a trip signal to circuit breakers to isolate the faulty section.

Think of it as a security guard for the power system. It constantly monitors for anything unusual, and if a threat (fault) is detected, it immediately takes action to contain the situation.

Q 3. What are the common types of protective relays used in power systems?

Numerous types of protective relays exist, each tailored to specific applications and fault conditions. Some of the most common include:

- Overcurrent Relays: These relays operate when the current exceeds a pre-set threshold for a specified time. They’re simple, reliable, and widely used for backup protection.

- Differential Relays: As discussed earlier, these compare currents entering and leaving a protected zone.

- Distance Relays: These measure the impedance to the fault along a transmission line.

- Directional Relays: These determine the direction of fault current flow, preventing tripping on faults outside the protected zone.

- Pilot Wire Relays: These use communication channels (pilot wires) between two ends of a line to coordinate tripping actions.

- Busbar Protection Relays: These protect the busbars, the central connecting points of the power system.

- Transformer Protection Relays: These are specifically designed to protect transformers from various types of faults.

The selection of a relay type depends on factors like the type of equipment being protected, system configuration, fault characteristics, and cost considerations.

Q 4. How does a distance relay measure impedance?

A distance relay measures impedance using the relationship between voltage and current at the relay location. It essentially calculates the impedance ‘seen’ by the relay towards the fault point. This is done using a combination of voltage and current transformers (PTs and CTs) that supply the relay with scaled-down replicas of the system’s voltage and current. The relay then uses these scaled values to compute the impedance using Ohm’s Law (Z = V/I), where Z represents impedance, V represents voltage, and I represents current. The calculation is not a simple division but involves advanced algorithms to account for various factors and system conditions. Different types of distance relays use different algorithms, such as mho, reactance, or impedance characteristics, to improve accuracy and selectivity in fault detection. The measured impedance is then compared to pre-defined zones; if the impedance falls within the zone, it indicates a fault within that zone, triggering the relay’s operation.

Imagine you’re using a radar to detect an object. The radar sends out a signal and measures the time it takes for the signal to return. The distance to the object is calculated based on the time it took for the signal to come back. Distance relay does something similar, using voltage and current as its signals to measure the ‘electrical distance’ to the fault.

Q 5. Explain the operation of a current transformer (CT) and potential transformer (PT).

Current transformers (CTs) and potential transformers (PTs) are essential components in protection and measurement systems. They provide scaled-down replicas of the high voltage and high current levels in the power system to the protective relays and other measuring devices. These scaled-down signals are safe to handle and suitable for use by the relays and meters. CTs step down the high current to a lower value (typically 5A or 1A), while PTs step down the high voltage to a lower value (typically 110V). The transformation ratio is fixed and accurately known. This ratio is critical for accurate measurement and relay operation.

Think of them as transformers in a radio. They take a high-power signal and convert it into a lower-power signal that can be safely processed and amplified.

CT Operation: CTs operate on the principle of electromagnetic induction. When current flows through the primary winding (connected to the power system), it induces a current in the secondary winding (connected to the relay). The ratio of primary to secondary current is the CT ratio.

PT Operation: PTs operate on the principle of electromagnetic induction, similar to CTs. High voltage is applied to the primary winding and induced into the secondary winding with a much lower voltage value.

Q 6. What are the different communication protocols used in substation automation?

Several communication protocols are used in substation automation, each with its strengths and weaknesses. Common protocols include:

- IEC 61850: This is a widely adopted, object-oriented standard that enhances interoperability and data exchange between various devices in the substation. It’s designed for robust communication in harsh environments and supports both process bus and station bus communication.

- Modbus: A simpler and widely used protocol, especially in older systems. It offers good interoperability but is less feature-rich than IEC 61850.

- DNP3: A popular protocol for distributed network protocol, often used in North America for SCADA and power system applications.

- PROFINET: An industrial Ethernet-based communication protocol used in various industrial automation settings, including substations.

The choice of protocol depends on factors like the age of the system, budget, required features, and the vendor’s equipment compatibility. Modern substations increasingly favor IEC 61850 for its advanced capabilities and interoperability.

Q 7. Describe the architecture of a typical SCADA system.

A typical SCADA (Supervisory Control and Data Acquisition) system for a power system has a hierarchical architecture. It comprises:

- Remote Terminal Units (RTUs)/Intelligent Electronic Devices (IEDs): These are located at substations and other remote locations. They collect data from various devices (circuit breakers, transformers, meters, etc.) and send it to the master station.

- Communication Network: This network connects RTUs/IEDs to the master station. It can be a combination of different communication technologies like fiber optics, microwave links, and Ethernet.

- Master Station: This is the central control center, which receives data from RTUs/IEDs, displays it on human-machine interfaces (HMIs), allows operators to monitor and control the power system, and manages alarms and events.

- Databases: These store historical data for analysis and reporting.

- Engineering Workstations: These provide tools for engineering, configuration, and maintenance of the SCADA system.

The architecture allows for centralized monitoring and control of geographically dispersed assets. The master station provides an overview of the entire power system, allowing operators to respond effectively to faults and disturbances.

Q 8. How do you troubleshoot a faulty protective relay?

Troubleshooting a faulty protective relay involves a systematic approach combining diagnostic tools and a deep understanding of the relay’s operation. It’s like detective work, tracing clues to pinpoint the problem.

- Initial Inspection: Begin by visually inspecting the relay for obvious signs of damage, loose connections, or burn marks. Check the relay’s status indicators and any accompanying alarm messages.

- Review Relay Settings: Verify that the relay’s settings are correctly configured to match the protected equipment’s characteristics. Incorrect settings are a surprisingly common source of malfunctions. Think of it like setting the wrong alarm time on your clock – it won’t work as intended.

- Examine Relay Logs: Most modern relays have internal event logs recording trip events, faults, and operational data. Analyze these logs to understand the sequence of events leading to the malfunction. This is your crime scene log, providing crucial evidence.

- Test Inputs and Outputs: Use a relay test set to simulate various fault conditions and observe the relay’s response. This verifies the relay’s internal logic and its reaction to different fault scenarios. This is like performing controlled experiments to isolate the problem.

- Check Communication Links: Ensure the relay is communicating correctly with the substation’s control system and other protective devices. Communication failures can cause misoperation or prevent the relay from reporting its status.

- Consult the Manufacturer’s Documentation: Detailed schematics, wiring diagrams, and troubleshooting guides provided by the manufacturer are crucial in more complex scenarios. These are your expert witness testimonies.

For example, a distance relay might be mis-tripping due to a wrong setting of the reach, or a current transformer might be saturated, leading to inaccurate measurements and relay malfunction. A systematic approach helps efficiently pinpoint the root cause.

Q 9. Explain the importance of grounding in power systems.

Grounding in power systems is absolutely critical for safety and proper operation. It provides a low-impedance path for fault currents to flow to the earth, preventing dangerous voltage build-up on equipment and protecting personnel. Think of it as the earth acting as a giant sink for excess electrical energy.

- Personnel Safety: Grounding prevents dangerous voltages from appearing on equipment enclosures, protecting personnel from electric shock. It’s your first line of defense against electrocution.

- Equipment Protection: Grounding helps limit the duration and magnitude of fault currents, reducing damage to equipment during a fault. It prevents over-voltages and protects expensive transformers and generators.

- System Stability: A properly grounded system helps maintain system stability and prevents voltage surges, which could lead to cascading outages. It ensures the system is operating within safe limits.

- Lightning Protection: Grounding provides a path for lightning strikes to dissipate safely to the earth, preventing damage to power system equipment. It’s like a lightning rod for your power grid.

A lack of proper grounding can lead to serious consequences, from equipment damage and fires to fatal electric shocks. A well-designed grounding system is fundamental for the safety and reliability of any power system.

Q 10. What are the common causes of power system faults?

Power system faults can be categorized broadly as either insulation failures or short circuits. Many factors can contribute. Imagine a power system as a complex network of highways – a fault is like a road closure.

- Insulation Failures: These occur due to aging, environmental factors (humidity, temperature), or mechanical stress on insulation. This can lead to flashovers and ground faults. It’s like the road surface degrading.

- Short Circuits: These are caused by accidental contact between conductors, often due to faulty equipment, animal intrusion, or tree branches. This causes a surge of fault current. This is like a head-on collision between vehicles.

- Overloads: Excessive current drawn by equipment can lead to overheating and failure. Think of the road being overloaded with traffic.

- Switching Surges: Switching operations can produce transient overvoltages that damage insulation. It’s like sudden traffic jams created by road works.

- Lightning Strikes: Direct lightning strikes can cause significant damage to power system equipment. This is a major disruption affecting the highway network.

Identifying the root cause of a fault is crucial for effective preventive maintenance and system reliability. It requires analyzing fault recordings, investigating affected equipment, and using diagnostic tools.

Q 11. Describe the process of testing and commissioning a protective relay.

Testing and commissioning a protective relay is a critical process ensuring its proper operation and integration into the power system. It’s like a final check before deploying a new system to ensure it works as intended.

- Pre-commissioning Checks: Verify the relay’s physical installation, wiring, and settings against the design specifications. This is a preliminary inspection to verify that everything is in place.

- Individual Relay Testing: Use a dedicated relay test set to systematically test the relay’s various functions, including its response to different types of faults. This simulates real-world scenarios.

- Protective Relay Setting Calculation and Review: Calculate the relay settings based on the system parameters and ensure that they are correctly entered into the relay. This is a critical step in the whole process.

- Integration Testing: Verify the relay’s proper communication and coordination with other protective devices in the system. This tests how it interacts with the bigger system.

- System Testing and Commissioning: Conduct system tests to verify that the entire protection system performs as intended. This is a fully integrated test of the whole setup.

- Documentation: Meticulously document all test procedures, results, and configurations for future reference. This provides a complete record of the commissioning process.

Thorough testing and commissioning are essential for ensuring the reliable and safe operation of the power system and to prevent unnecessary outages.

Q 12. What safety precautions should be taken when working on power system equipment?

Safety is paramount when working on power system equipment. Treat every task as potentially lethal. The following measures should be followed meticulously:

- Lockout/Tagout Procedures: Always follow strict lockout/tagout procedures to de-energize equipment before working on it. This prevents accidental energization.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, arc flash suits (where necessary), and insulated tools. This protects you from potential hazards.

- Grounding: Ensure that the equipment is properly grounded before commencing any work. This is critical for preventing electric shock.

- Safety Training: Ensure personnel are adequately trained in safe work practices and are aware of the risks involved. Thorough training reduces accidents.

- Permit-to-Work System: Implement and adhere to a formal permit-to-work system for all high-risk tasks. This ensures that all safety checks have been completed before commencing work.

- Emergency Procedures: Ensure that emergency response plans and procedures are in place and that all personnel are familiar with them. This covers unexpected situations.

Never compromise on safety. A momentary lapse in concentration can have devastating consequences. Always prioritize safety above all else.

Q 13. Explain the concept of fault current limiting.

Fault current limiting aims to reduce the magnitude of fault currents in a power system. High fault currents can damage equipment and endanger personnel. Think of it as a safety valve for the power system.

Several techniques achieve this:

- Series Reactors: These are inductors placed in the power system to limit the flow of fault current by increasing the system impedance. It’s like adding resistance to a water pipe, reducing the flow.

- Current Limiting Circuit Breakers: These breakers have special features that interrupt the fault current rapidly, minimizing damage to the system. They act like a fast-acting valve.

- Fault Current Limiters (FCLs): These are sophisticated devices that actively limit fault currents using superconducting or saturable reactor technologies. They are highly effective but more costly.

Effective fault current limiting improves system reliability, reduces equipment damage, and enhances safety. It is an important aspect of power system design and operation.

Q 14. What are the different types of protective devices used in power systems?

Various protective devices are used in power systems to detect and respond to faults. They are each suited for different types of faults and parts of the system. Imagine them as different first responders to various emergencies.

- Overcurrent Relays: These are used to protect against overcurrents caused by short circuits or overloads. They are the most basic and widely used type of protection.

- Differential Relays: These compare the currents entering and leaving a protected zone and trip if there’s a mismatch, indicating an internal fault. This is a very sensitive protection scheme.

- Distance Relays: These measure the impedance to a fault and trip if the impedance falls within a predetermined range. They are used for long transmission lines.

- Ground Fault Relays: These detect ground faults and trip the circuit to isolate the fault. They focus on one type of fault.

- Busbar Protection: These schemes protect the main busbars in substations from faults. They are crucial to overall system integrity.

- Transformer Protection: These devices protect transformers from various faults, including overcurrent, differential, and overtemperature faults. They safeguard large and expensive equipment.

- Circuit Breakers: These are electromechanical switches that interrupt the flow of current during a fault. They are the physical actuators for the protection system.

The selection of appropriate protective devices depends on several factors, including the type of equipment being protected, the fault currents expected, and the system’s overall design. Proper coordination between these devices is also essential for effective protection.

Q 15. Explain the role of a breaker failure protection scheme.

A breaker failure protection scheme is crucial for ensuring the continued safety and reliability of a power system. Imagine a circuit breaker that’s supposed to trip to isolate a fault, but it fails to do so. This can lead to cascading failures, widespread outages, and significant damage to equipment. The protection scheme’s role is to detect this failure and initiate alternative actions to clear the fault.

Essentially, it acts as a backup to the primary circuit breaker. If the breaker fails to operate within a specified time, the protection scheme identifies the fault and utilizes other devices, such as backup circuit breakers or other protective relays, to isolate the faulty section. This prevents the fault from spreading and causing extensive damage. It usually involves fast-acting relays that monitor the breaker’s status (open/closed) and the current flow. If the current persists beyond the acceptable timeframe after a fault is detected, the scheme commands the backup protection to clear the fault.

For example, a backup protection relay might detect sustained high current and trip a backup breaker on a different feeder to isolate the faulty section. This prevents further damage and minimizes the impact of the primary breaker’s failure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret protective relay settings?

Interpreting protective relay settings requires a thorough understanding of the relay’s operating characteristics and the specific requirements of the power system it protects. It’s not just about looking at numbers; it’s about understanding what those numbers mean in the context of fault currents, operating times, and system stability.

Relay settings are typically expressed in terms of:

- Pickup Current (Ipickup): The minimum current required to initiate the relay’s operation.

- Time Delay (t): The time delay before the relay trips after the pickup current is exceeded. This is often inversely proportional to fault current magnitude (e.g., using an inverse-time characteristic).

- Operating Time: The total time from fault inception until the relay trips.

- Zone of Protection: The area of the power system the relay protects.

To interpret these settings, consider:

- Fault Current Calculations: Accurate short circuit calculations are vital. They determine the expected fault current magnitude at various locations within the protected zone.

- Coordination: Relay settings need to be carefully coordinated with other relays in the system to ensure that the correct relay trips first in the event of a fault. This prevents unwanted tripping and allows for selective protection.

- System Stability: The settings must not compromise system stability. Unnecessary or delayed tripping can lead to widespread outages.

For instance, a poorly coordinated system might see healthy lines trip due to overcurrent from a fault elsewhere, causing unnecessary outages. Proper interpretation and coordination are crucial for a reliable and efficient power system.

Q 17. Describe the different types of communication failures in SCADA systems.

Communication failures in SCADA (Supervisory Control and Data Acquisition) systems can significantly impact the monitoring and control of the power system. These failures can broadly be categorized as:

- Physical Layer Failures: These involve problems with the physical communication infrastructure, such as:

- Broken or damaged cables: This can result in complete loss of communication.

- Radio interference: Noise can corrupt or prevent signal transmission.

- Hardware malfunctions: Failures in communication equipment like modems or routers.

- Data Link Layer Failures: These are problems at the level of data transmission and reception:

- Incorrect addressing: Devices may not recognize each other due to address configuration issues.

- Protocol violations: Improperly formatted messages.

- Packet loss: Data packets might get lost during transmission.

- Network Layer Failures: These involve problems with routing and network connectivity:

- Network congestion: Excessive data traffic can lead to delays or dropped packets.

- Routing failures: Problems with routing protocols can prevent data from reaching its destination.

- Network outages: Failures in the network infrastructure itself.

- Application Layer Failures: These are failures in the software applications interacting with the SCADA system:

- Software bugs: Errors in the SCADA software can disrupt communication.

- Data corruption: Incorrect data interpretation.

- Database failures: Issues with the database used to store SCADA data.

Understanding the type of failure is crucial for effective troubleshooting and restoration of communication. Techniques like network monitoring and analysis tools are often used to diagnose these failures.

Q 18. What are the advantages and disadvantages of using numerical relays?

Numerical relays, unlike electromechanical relays, use microprocessors to perform protection functions. This provides significant advantages, but also introduces some disadvantages.

Advantages:

- Increased Functionality: Numerical relays can perform a wide range of protection functions (distance protection, differential protection, overcurrent protection, etc.) often within a single unit.

- Improved Accuracy and Sensitivity: They offer superior accuracy in measurement and can detect faults more reliably.

- Advanced Communication Capabilities: They can easily integrate with SCADA systems and other communication networks.

- Self-Monitoring and Diagnostics: They often include self-testing and diagnostic capabilities to identify potential problems.

- Flexibility and Configurability: Settings can be easily adjusted and modified in the field, often without requiring hardware changes.

Disadvantages:

- Higher Initial Cost: Numerical relays are generally more expensive than electromechanical relays.

- Complexity: Their functionality can be more complex to understand and configure compared to simpler relays.

- Dependency on Software and Microprocessors: They are susceptible to software glitches and hardware failures.

- Cybersecurity Concerns: They may be vulnerable to cyberattacks, especially if not properly secured.

- Specialized Expertise Required: Their configuration and maintenance might require specialized training and expertise.

The choice between numerical and electromechanical relays depends on the specific application and system requirements. In modern power systems, numerical relays are increasingly preferred due to their enhanced capabilities and flexibility, despite their higher initial cost.

Q 19. How do you perform a protective relay setting calculation?

Protective relay setting calculation is a critical task requiring a detailed understanding of power system parameters and protection principles. It’s not a simple calculation but a systematic process involving several steps:

- System Studies: Short-circuit studies are essential to determine the fault current magnitudes at various points in the system. These studies usually involve software tools that model the network and calculate fault currents under various fault scenarios.

- Relay Selection: Choose the appropriate relay type for the application based on factors like fault current levels, required operating times, and coordination needs.

- Coordination Studies: Ensure that the relays in the system coordinate properly to ensure selective tripping. This means that the relay closest to the fault trips first, while the others remain unaffected.

- Setting Calculations: Calculate the relay settings (pickup current, time dial setting, etc.) based on the fault current calculations, coordination requirements, and the relay’s operating characteristics. This often involves iterative calculations and adjustments to meet system stability requirements.

- Testing and Verification: Thoroughly test the relay settings using simulation software or physical testing to ensure they operate correctly and that the protection system is adequately coordinated.

- Documentation: Carefully document the final settings and rationale behind them for future reference and maintenance.

Software tools are often used to simplify and automate much of this process, but the engineer needs to understand the underlying principles and make sure the software inputs and outputs are correctly interpreted. Errors in relay settings can have severe consequences, so accuracy and thoroughness are essential.

Q 20. Explain the concept of power system stability.

Power system stability refers to the ability of the power system to maintain synchronism between generators and remain in a steady-state operating condition following a disturbance. Think of it like a balancing act: generators are constantly trying to maintain a synchronized rotation speed, providing power to the grid. Disturbances (faults, loss of generation, etc.) disrupt this balance. Stability ensures the system can recover from these disturbances and return to a stable operating point.

There are several aspects to power system stability:

- Angle Stability (Rotor Angle Stability): Relates to the ability of synchronous generators to maintain synchronism (steady rotation) after a disturbance. This is primarily concerned with the rotor angles of the generators.

- Frequency Stability: Refers to the system’s ability to maintain its nominal frequency. Large disturbances can cause frequency deviations, impacting the stability of the entire system.

- Voltage Stability: Deals with the ability of the system to maintain voltage levels within acceptable limits following a disturbance. Voltage collapse can occur if the voltage levels drop too low.

Maintaining stability is critical for reliable power delivery. Instability can lead to cascading outages, widespread blackouts, and significant economic losses.

Q 21. What are the common causes of power system instability?

Power system instability can stem from various causes, often interconnected and complex:

- Large Disturbances: These include short circuits, loss of generation, or sudden changes in load. These can severely impact the system’s ability to maintain synchronism and voltage.

- Insufficient Reactive Power Support: Lack of sufficient reactive power can lead to voltage instability and collapse, especially in remote areas or during peak loads. Reactive power is crucial for maintaining voltage levels.

- Weak Transmission Network: A weak transmission network with low transfer capacity can amplify disturbances and make the system more prone to instability.

- Generator Control System Malfunctions: Failures in the automatic voltage regulators (AVRs) or governor systems of generators can worsen instability.

- Protection System Failures: Incorrect operation or failure of protection relays can lead to cascading outages and instability.

- Load Changes: Sudden or unexpected large changes in load (e.g., starting a large industrial motor) can overload parts of the system and cause instability.

- Insufficient Generation Reserve: If there is not enough reserve generation capacity to compensate for lost generation or unexpected load increases, the system can become unstable.

Analyzing the causes of instability often involves sophisticated simulations and investigations to determine the contributing factors and prevent future incidents.

Q 22. Describe the function of a synchronizing device.

A synchronizing device ensures that generators or other power sources are connected to the electrical grid at the same frequency, voltage, and phase angle. Think of it like perfectly aligning two spinning gears – you can’t just slam them together; they need to be moving in sync to avoid damage. This prevents damaging surges and ensures a smooth transfer of power.

In practice, this is achieved by comparing the incoming source’s parameters (frequency, voltage, and phase) with those of the existing grid. The device only allows connection when the differences fall within acceptable tolerances, typically within a few hertz, volts, and degrees. This synchronization process is critical for maintaining grid stability and avoiding system disturbances.

For example, imagine a large power plant coming online. The synchronizing device carefully monitors the generator’s output and waits until it perfectly matches the grid before establishing the connection. This avoids a major power surge that could damage equipment or disrupt service to consumers.

Q 23. How does a power system stabilizer (PSS) work?

A Power System Stabilizer (PSS) enhances the stability of a power system by dampening oscillations in generator rotor angle and frequency. These oscillations, often caused by disturbances like sudden load changes or faults, can lead to system instability and even blackouts. The PSS acts as a ‘shock absorber’ for the generator.

It works by measuring the system frequency and/or generator’s rotor speed and providing an additional control signal to the generator’s excitation system. This signal modifies the generator’s internal voltage, thereby influencing its output power and helping to counteract the oscillations. It’s like a feedback loop – it senses a problem, then corrects it before it escalates.

Imagine a pendulum swinging – the PSS is like a mechanism that gradually reduces the swing until the pendulum comes to rest. This prevents the pendulum from swinging wildly and potentially causing damage.

Q 24. Explain the concept of load shedding.

Load shedding is a deliberate reduction in electrical load during emergencies to prevent a complete system collapse (a blackout). It’s a last resort measure used when the demand for power exceeds the available supply, often due to a major system failure or unexpected load increase. Think of it as selectively turning off lights in a house to avoid blowing a fuse.

Load shedding prioritizes critical loads, such as hospitals and emergency services, ensuring they remain operational. Non-critical loads are shed in a controlled manner, usually in stages, to gradually reduce the overall system load. This is achieved through automated systems that detect system overload and initiate a pre-defined shedding sequence.

For example, during a heatwave, the demand for electricity can surge dramatically. If the grid is close to its capacity limit, load shedding might be initiated to prevent a widespread outage. This could involve temporarily interrupting power to some residential areas, while keeping essential services running.

Q 25. Describe the different types of arc flash hazards.

Arc flash hazards are a significant risk in electrical systems. An arc flash is a sudden, high-temperature electrical arc that occurs when an electrical fault develops, typically involving a short circuit. These are extremely dangerous, producing intense heat, light, and pressure, and can cause severe burns, blindness, and even death.

There are several types of arc flash hazards:

- Thermal Hazards: Intense heat from the arc causes severe burns to skin and eyes.

- Pressure Hazards: The rapid expansion of air due to the arc’s heat creates a blast wave that can cause injuries.

- Light Hazards: The intense light emitted by the arc can cause blindness or retinal damage.

- Acoustic Hazards: The arc produces a loud bang that can damage hearing.

- Magnetic Hazards: The magnetic field created by the arc can induce currents in nearby metal objects.

The severity of the hazard depends on factors such as the voltage level, the available fault current, and the system’s impedance.

Q 26. What safety precautions should be taken to prevent arc flash incidents?

Preventing arc flash incidents requires a multi-layered approach focusing on engineering controls, administrative controls, and personal protective equipment (PPE).

- Engineering Controls: These are designed to minimize the energy available during a fault. Examples include proper grounding, equipment isolation, arc-flash reduction equipment, and the use of current-limiting devices.

- Administrative Controls: These involve establishing safe work practices, providing proper training, implementing lockout/tagout procedures, and ensuring that qualified personnel perform electrical work.

- Personal Protective Equipment (PPE): Arc-flash PPE includes flame-resistant clothing, face shields, and insulated gloves rated for the appropriate arc-flash boundary. PPE should be selected based on the arc flash incident energy level calculated for the specific work location.

Regular inspection and maintenance of electrical equipment are essential to prevent potential faults that could trigger arc flash incidents.

For instance, before working on any energized equipment, a thorough risk assessment needs to be performed to identify potential arc flash hazards and determine the appropriate PPE and safety procedures. Lockout/Tagout procedures are vital to ensure that equipment remains de-energized during maintenance.

Q 27. How does a digital fault recorder (DFR) work?

A Digital Fault Recorder (DFR) is a crucial piece of equipment that captures high-resolution data during electrical power system faults. It acts like a high-speed video camera for electrical events, recording detailed information that helps engineers understand and analyze what happened during a fault and allows for swift troubleshooting and preventing future problems.

It works by continuously monitoring various parameters within the power system, including voltage, current, and frequency. When a fault occurs, the DFR automatically triggers and records the data at a high sampling rate (often several microseconds). This data is then stored digitally, allowing for detailed analysis of the event’s waveform, helping pinpoint the exact location and type of fault.

This recorded data allows engineers to determine the fault’s magnitude, duration, and location, which is crucial for preventing future occurrences, improving system design and maintenance strategies and can even help with insurance claims.

Q 28. Explain the importance of cyber security in substation automation.

Cybersecurity is paramount in substation automation due to the critical role substations play in the power grid’s reliability and resilience. Substations are increasingly reliant on networked devices and control systems, making them vulnerable to cyberattacks. A successful attack could have far-reaching consequences, disrupting power supply, causing financial losses, and even posing threats to national security.

The importance of cybersecurity lies in safeguarding the integrity, confidentiality, and availability of substation automation systems. This involves implementing various security measures, including:

- Network Security: Implementing firewalls, intrusion detection systems, and virtual private networks (VPNs) to protect against unauthorized access.

- Device Security: Ensuring that all devices within the substation automation system have strong passwords, regular security updates, and robust authentication mechanisms.

- Data Security: Implementing encryption and access control measures to protect sensitive data from unauthorized access or modification.

- Physical Security: Protecting the physical infrastructure of the substation from unauthorized access and tampering.

- Incident Response Planning: Developing and regularly testing incident response plans to address security breaches effectively.

A well-defined cybersecurity strategy is essential to mitigate risks and ensure the continued reliable operation of the power grid in the face of evolving cyber threats.

Key Topics to Learn for Protection and Control System Monitoring and Troubleshooting Interview

- Relay Protection Fundamentals: Understanding different types of relays (differential, distance, overcurrent), their operating principles, and settings. Practical application: Analyzing relay settings to ensure adequate protection for specific equipment.

- SCADA Systems and HMI Interfaces: Familiarity with Supervisory Control and Data Acquisition (SCADA) systems, human-machine interfaces (HMIs), and their role in monitoring and controlling power systems. Practical application: Interpreting SCADA data to identify potential problems and take corrective actions.

- Communication Protocols: Knowledge of communication protocols used in protection and control systems (e.g., IEC 61850, DNP3). Practical application: Troubleshooting communication issues between different devices in the system.

- Fault Analysis and Diagnosis: Developing systematic approaches to identify and diagnose faults in protection and control systems. Practical application: Using diagnostic tools and techniques to isolate and resolve system malfunctions.

- Cybersecurity in Protection Systems: Understanding the vulnerabilities and security threats to protection and control systems. Practical application: Implementing security measures to protect against cyberattacks.

- Protection System Testing and Maintenance: Knowledge of various testing methods and procedures for protection relays and other system components. Practical application: Performing routine testing and maintenance to ensure system reliability.

- Power System Stability and Transient Analysis: Understanding the impact of protection system operation on power system stability. Practical application: Analyzing system response to faults and disturbances.

- Protective Device Coordination: Ensuring proper coordination between different protective devices to avoid undesirable tripping or malfunction. Practical application: Developing and implementing coordination schemes for optimal protection.

Next Steps

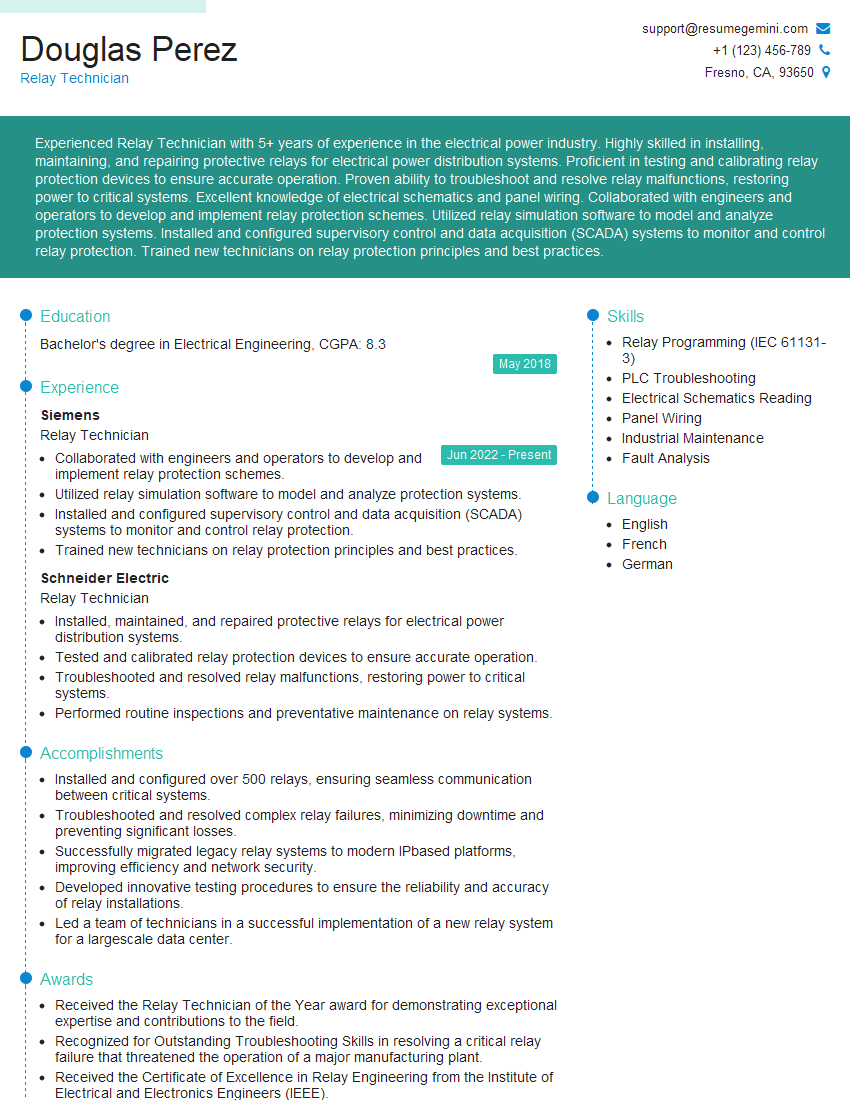

Mastering Protection and Control System Monitoring and Troubleshooting is crucial for career advancement in the power industry, opening doors to specialized roles and increased earning potential. A well-crafted resume is your key to unlocking these opportunities. Make sure your resume is ATS-friendly to maximize its visibility to potential employers. We highly recommend using ResumeGemini to build a professional and impactful resume that showcases your skills and experience effectively. ResumeGemini provides examples of resumes tailored specifically to Protection and Control System Monitoring and Troubleshooting roles, giving you a head start in crafting a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO