The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Purchasing and Sourcing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Purchasing and Sourcing Interview

Q 1. Explain the difference between purchasing and sourcing.

While often used interchangeably, purchasing and sourcing are distinct processes within the procurement function. Purchasing is the transactional aspect, focusing on the actual acquisition of goods or services at the best possible price. Think of it as the act of placing an order and receiving the goods. Sourcing, on the other hand, is a more strategic process that encompasses the entire lifecycle of identifying, selecting, and managing suppliers. It’s about finding the right supplier, not just the cheapest one.

Imagine you need office chairs. Purchasing is simply buying the chairs from a chosen supplier. Sourcing, however, involves researching various chair manufacturers, evaluating their quality, lead times, and pricing, negotiating contracts, and establishing a long-term relationship with a selected supplier – potentially even influencing design or specifications.

- Purchasing: Transactional, reactive, focused on price.

- Sourcing: Strategic, proactive, focused on long-term value and risk mitigation.

Q 2. Describe your experience with supplier negotiation and contract management.

Supplier negotiation and contract management are critical components of my role. I have extensive experience negotiating favorable terms with suppliers, considering factors like pricing, payment terms, quality standards, and delivery schedules. My approach is collaborative but assertive; I aim for win-win outcomes that benefit both parties. I’ve successfully negotiated volume discounts, reduced lead times, and improved quality standards through strategic negotiation.

Contract management involves more than just signing a document; it’s about ongoing monitoring and enforcement. I utilize contract management software to track key performance indicators (KPIs), ensure compliance, and promptly address any discrepancies. For example, I once renegotiated a contract with a key supplier after market analysis revealed better pricing from a competitor, leading to significant cost savings for the company without compromising quality.

Q 3. How do you identify and mitigate supply chain risks?

Identifying and mitigating supply chain risks is paramount. I employ a risk assessment framework that considers various factors, including geopolitical instability, natural disasters, supplier financial health, and disruptions to transportation. We regularly conduct supplier audits to assess their capabilities and identify potential weaknesses. This often involves onsite visits to evaluate their facilities and production processes.

Mitigation strategies include diversifying our supplier base to avoid over-reliance on a single source, building strong relationships with key suppliers, establishing contingency plans for potential disruptions, and holding sufficient safety stock of critical materials. For instance, during a recent global pandemic, our proactive risk assessment and diversification strategy allowed us to secure alternative sources of essential components, minimizing production downtime.

Q 4. What are your preferred methods for supplier selection and evaluation?

My preferred methods for supplier selection and evaluation involve a multi-stage process. It starts with identifying potential suppliers through market research, industry directories, and online platforms. This is followed by a pre-qualification process where we assess their financial stability, technical capabilities, and quality management systems. Shortlisted suppliers then undergo a detailed evaluation, often involving requests for information (RFIs) and requests for proposals (RFPs) to compare their offerings and capabilities.

We also utilize weighted scoring models to objectively evaluate suppliers based on pre-defined criteria such as price, quality, delivery performance, and sustainability practices. Supplier site visits and reference checks are integral parts of the process, allowing us to verify information and assess their overall suitability. This rigorous process ensures we choose suppliers that align with our quality standards and business objectives.

Q 5. Explain your experience with different purchasing methods (e.g., RFP, RFQ, reverse auction).

I have extensive experience with various purchasing methods, including RFPs (Request for Proposals), RFQs (Request for Quotations), and reverse auctions. RFPs are used for complex procurements requiring detailed proposals from suppliers; RFQs are simpler and more suitable for standardized goods or services where price is the primary consideration; and reverse auctions are competitive bidding processes ideal for high-volume, commodity items.

The choice of method depends on the specific procurement needs. For instance, procuring a complex software solution would necessitate an RFP, while purchasing office supplies might involve an RFQ or even a reverse auction. My expertise lies in designing the right purchasing strategy and choosing the method that best suits the situation, ensuring transparency, fairness, and value for money.

Q 6. How do you manage supplier relationships and performance?

Managing supplier relationships and performance is an ongoing process. I leverage a combination of techniques, including regular performance reviews based on pre-agreed KPIs, open communication channels, and collaborative problem-solving. I focus on building strong, mutually beneficial relationships based on trust and transparency. This often involves regular meetings, performance feedback sessions, and collaborative efforts to improve processes.

We use a performance scorecard to track key metrics such as on-time delivery, quality defects, and responsiveness. Suppliers with consistently poor performance receive targeted support and improvement plans. Conversely, high-performing suppliers are rewarded through preferential treatment and potentially longer-term contracts, fostering a culture of collaboration and continuous improvement.

Q 7. Describe your experience with e-procurement systems and technologies.

I’m proficient in using various e-procurement systems and technologies, including electronic catalogs, online marketplaces, and procurement software platforms. These tools streamline the procurement process, improve efficiency, and enhance transparency. For example, we use a centralized e-procurement system that automates purchase order creation, invoice processing, and supplier communication. This reduces manual effort, minimizes errors, and enables better tracking of spending.

My experience extends to using these systems to manage supplier relationships, track performance metrics, and facilitate collaboration. I understand the importance of data analytics in e-procurement and regularly use these platforms to identify trends, optimize spending, and gain valuable insights into supplier performance and market dynamics. The implementation and management of these systems have significantly improved our procurement efficiency and cost savings.

Q 8. How do you handle urgent or unexpected purchasing needs?

Handling urgent purchasing needs requires a swift and efficient process. It’s all about prioritizing speed without compromising quality or compliance. My approach involves a three-pronged strategy:

- Immediate Assessment: First, I quickly assess the urgency and the impact of the delay. Is this a critical production shutdown, or a minor inconvenience? This dictates the speed and resources allocated.

- Strategic Sourcing: I leverage existing supplier relationships and explore expedited shipping options. For truly urgent needs, I might need to negotiate premium pricing or explore alternative, potentially higher-cost, suppliers who can meet the deadline. I’ve used this approach successfully in a situation where a critical component for a major product launch was delayed by a primary supplier. Switching to a backup supplier, despite the higher cost, avoided a significant production halt and saved the company millions in potential lost revenue.

- Documentation and Follow-up: Even in urgent situations, proper documentation is crucial. This means meticulously recording all communication, agreements, and any deviations from standard purchasing procedures. Following up is key to ensuring the order is tracked, delivered promptly, and that any outstanding invoices are handled effectively. For instance, I always send confirmation emails and track the shipment in real-time for urgent orders.

Q 9. What is your experience with cost reduction strategies in purchasing?

Cost reduction is a continuous process, not a one-time project. My experience incorporates various strategies, including:

- Negotiation and Value Engineering: I consistently negotiate better pricing with suppliers. This isn’t just about haggling; it’s about building strong relationships and understanding their cost structures. Value engineering involves collaborating with suppliers and internal teams to identify opportunities to reduce costs without compromising quality. For example, I once worked with a supplier to change the packaging material, resulting in a 15% reduction in overall cost without impacting product integrity.

- Supplier Consolidation: Reducing the number of suppliers can lead to economies of scale, better negotiation power, and improved efficiency. However, it must be carefully managed to avoid supply chain risks. For a previous company, consolidating our number of printing suppliers from five to two resulted in significantly better pricing and easier contract management.

- Strategic Sourcing: This involves a thorough analysis of the market to identify the most cost-effective suppliers and the best procurement methods. For example, leveraging online marketplaces and competitive bidding has often yielded significant cost savings.

- Lean Principles: Applying lean principles to the purchasing process, such as reducing waste and improving efficiency, can significantly reduce costs. This includes streamlining approval processes and automating tasks where possible.

Q 10. How do you ensure compliance with purchasing regulations and policies?

Compliance is paramount. My approach to ensuring adherence to purchasing regulations and policies involves:

- Thorough Understanding: I begin by thoroughly understanding all applicable regulations (e.g., Sarbanes-Oxley Act, environmental regulations) and internal policies. This understanding is crucial to prevent costly mistakes and ensure ethical procurement practices.

- Pre-emptive Risk Management: I proactively identify potential compliance risks and implement measures to mitigate them. For example, conducting thorough due diligence on suppliers to ensure they comply with ethical sourcing and labor practices.

- Documentation and Audits: Maintaining meticulous records of all purchasing transactions, contracts, and communications is essential for audits and demonstrates transparency. I regularly participate in internal audits to identify areas for improvement and ensure continuous compliance.

- Training and Education: I contribute to training programs to educate colleagues on purchasing policies and regulations, reinforcing a culture of compliance throughout the organization.

Q 11. Explain your understanding of Total Cost of Ownership (TCO).

Total Cost of Ownership (TCO) goes beyond the initial purchase price. It encompasses all direct and indirect costs associated with acquiring, using, and disposing of a product or service throughout its entire lifecycle. This includes:

- Acquisition Costs: Purchase price, taxes, shipping, and handling.

- Operational Costs: Maintenance, repairs, energy consumption, and downtime.

- Disposal Costs: Recycling, disposal fees, and environmental remediation.

Understanding TCO allows for more informed purchasing decisions, moving beyond the lowest initial price to consider long-term value. For example, choosing a more expensive piece of equipment with lower maintenance costs and a longer lifespan can ultimately result in a lower TCO than a cheaper option that requires frequent repairs and replacements.

Q 12. How do you prioritize purchasing requests and manage competing demands?

Prioritizing purchasing requests with competing demands requires a structured approach. I use a combination of factors including:

- Urgency and Criticality: Requests that impact critical operations or deadlines are prioritized. I use a simple rating system (e.g., high, medium, low) to categorize requests based on urgency and impact.

- Strategic Alignment: Requests that support company strategy or key initiatives receive higher priority. This ensures resources are allocated to projects that contribute most significantly to business goals.

- Budgetary Constraints: Available budget plays a crucial role in prioritization. Requests that exceed budget limits may require adjustments, rescheduling, or alternative solutions.

- Communication and Transparency: Keeping all stakeholders informed about the prioritization process is crucial to manage expectations and build consensus.

I often use a Kanban board or similar visual management tool to track the progress of different purchasing requests and their priority status.

Q 13. Describe your experience with forecasting and demand planning.

Forecasting and demand planning are crucial for efficient purchasing. My experience involves:

- Data Analysis: Utilizing historical data, sales forecasts, and market trends to predict future demand for goods and services. This involves identifying seasonal patterns, growth trends, and potential disruptions.

- Collaboration: Closely working with sales, marketing, and operations teams to gather accurate demand information and incorporate their insights into the forecasting process. Effective communication is vital to ensure accuracy.

- Forecasting Techniques: Applying various forecasting techniques, such as moving averages, exponential smoothing, and regression analysis, to generate accurate demand predictions. Choosing the appropriate technique depends on the nature of the product and the availability of data.

- Risk Management: Identifying and mitigating potential risks that could impact demand, such as economic downturns, supply chain disruptions, or changes in consumer preferences. This often involves developing contingency plans.

For instance, in my previous role, accurate forecasting helped us avoid stockouts during peak seasons and minimize excess inventory during slow periods, saving the company significant costs.

Q 14. How do you build strong relationships with internal stakeholders?

Building strong relationships with internal stakeholders is essential for effective purchasing. My approach includes:

- Proactive Communication: Regularly communicating with stakeholders to keep them informed about purchasing activities, challenges, and successes. This builds trust and transparency.

- Understanding Needs: Taking the time to understand the specific needs and priorities of each stakeholder. This helps tailor purchasing solutions to meet their unique requirements.

- Collaboration and Teamwork: Working collaboratively with stakeholders to identify and solve problems, rather than acting in isolation. This ensures buy-in and mutual support.

- Feedback and Improvement: Regularly seeking feedback from stakeholders to identify areas for improvement in the purchasing process. This demonstrates a commitment to continuous improvement.

For example, I regularly hold meetings with key stakeholders to discuss upcoming projects and ensure alignment on procurement strategies. This proactive approach helps prevent misunderstandings and ensures a smooth process.

Q 15. What are your experience with inventory management and optimization?

Inventory management and optimization are crucial for maintaining the right balance of stock to meet customer demand while minimizing storage costs and waste. My experience encompasses implementing and managing various inventory control systems, from simple ABC analysis to sophisticated ERP systems with demand forecasting capabilities.

For example, in my previous role at Acme Corp, we transitioned from a first-in, first-out (FIFO) inventory system to a more nuanced approach utilizing data analytics to predict demand spikes and optimize reorder points. This involved analyzing historical sales data, seasonality, and market trends to refine our forecasting accuracy. We integrated our inventory management system with our sales and production systems, enabling real-time inventory visibility and reducing stockouts. The result was a 15% reduction in inventory holding costs and a significant improvement in order fulfillment time.

Another key aspect of my work involves cycle counting and inventory audits to ensure data accuracy and identify discrepancies. Regular audits are essential to maintain a healthy inventory system and catch potential issues early. I’ve also led initiatives to improve warehouse efficiency through process optimization and improved material handling procedures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you measure the success of your purchasing strategies?

Measuring the success of purchasing strategies requires a multi-faceted approach that considers both qualitative and quantitative factors. Key performance indicators (KPIs) are essential in this process.

- Cost Savings: This is often the primary metric, measuring the reduction in procurement costs compared to previous periods or industry benchmarks. I typically track this through cost per unit, total cost of ownership (TCO), and savings achieved through negotiations.

- Supplier Performance: This includes on-time delivery, quality of goods, and responsiveness to issues. I regularly monitor supplier performance through scorecards that track these metrics and actively engage with suppliers to address underperformance.

- Inventory Turnover: This indicates how efficiently we manage inventory. A higher turnover rate generally suggests effective inventory management and reduced holding costs.

- Lead Time Reduction: Shorter lead times translate to faster order fulfillment and improved responsiveness to customer demand. I track this metric closely and implement strategies to optimize the supply chain.

- Risk Mitigation: Effective purchasing strategies proactively address potential supply chain disruptions. This includes diversifying suppliers, establishing strong relationships with key suppliers, and developing contingency plans. Success is measured by successfully navigating unexpected events and minimizing their impact.

Beyond KPIs, qualitative aspects such as building strong supplier relationships and fostering innovation are also vital for long-term purchasing success.

Q 17. Describe your experience with different types of contracts (e.g., fixed-price, cost-plus).

My experience encompasses a broad range of contract types, each suitable for different situations.

- Fixed-Price Contracts: These are ideal for projects with well-defined specifications and minimal uncertainty. The price is fixed upfront, providing certainty for both the buyer and the supplier. However, they offer less flexibility if requirements change.

- Cost-Plus Contracts: These contracts are suitable for projects with a higher degree of uncertainty or when the scope of work is not fully defined. The supplier is reimbursed for all allowable costs, plus a predetermined fee or profit margin. This offers flexibility, but requires careful monitoring to avoid cost overruns.

- Time and Materials Contracts: These contracts are typically used for projects where the scope of work is not fully defined upfront. The supplier is paid for the time spent and materials used. This allows for flexibility, but requires meticulous tracking of time and materials to ensure accurate billing.

- Blanket Purchase Orders: These are used for ongoing purchases of items or services from a supplier over a defined period. This streamlines the purchasing process and can lead to better pricing due to volume discounts.

I have experience in negotiating and managing contracts across these various types, ensuring that the chosen contract aligns with project needs and risk tolerance. I also understand the importance of clear contractual language and dispute resolution mechanisms.

Q 18. How do you manage supplier diversity initiatives?

Supplier diversity initiatives are crucial for ethical and business reasons. They promote fairness, competition, and innovation within the supply chain. My approach involves a multi-pronged strategy.

- Developing a Diversity Policy: This sets clear goals and targets for engaging with diverse suppliers, including those owned by women, minorities, veterans, and people with disabilities.

- Supplier Outreach: Actively seeking and engaging with diverse suppliers through networking events, industry associations, and online databases. I’ve found success in attending targeted conferences and trade shows.

- Mentorship and Support: Providing support and resources to help diverse suppliers build capacity and successfully compete for contracts. This might include technical assistance, financial support, or business development training.

- Performance Monitoring: Tracking the progress of supplier diversity initiatives and adjusting strategies as needed. This involves regular reporting and analysis of key metrics.

- Collaboration: Working with other companies and organizations to share best practices and resources.

I believe that supplier diversity is not just an ethical imperative but also a strategic advantage, leading to innovation, improved reputation, and stronger supply chains.

Q 19. What is your experience with global sourcing?

My experience with global sourcing spans several years and includes working with suppliers in various countries across different continents. This involves navigating the complexities of international trade, cultural differences, and regulatory environments.

Key aspects of my global sourcing experience include:

- Supplier Selection: Rigorous evaluation of potential suppliers based on factors such as quality, cost, capacity, and compliance with ethical and environmental standards.

- International Logistics and Transportation: Managing the complexities of shipping goods across borders, including customs clearance, documentation, and incoterms.

- Currency Fluctuations and Risk Management: Mitigating the risks associated with currency exchange rate fluctuations through hedging and other risk management strategies.

- Cultural Sensitivity: Understanding and respecting cultural differences in communication styles, business practices, and expectations.

- Compliance and Regulatory Issues: Ensuring compliance with international trade regulations and labor laws in different countries.

For instance, at Beta Inc, I was instrumental in establishing relationships with suppliers in Southeast Asia, leading to a significant reduction in manufacturing costs. This required extensive research to identify reputable suppliers, negotiate favorable terms, and manage the logistics of transporting the finished goods.

Q 20. How do you address supplier performance issues?

Addressing supplier performance issues requires a proactive and collaborative approach. My strategy typically involves these steps:

- Identifying the Problem: Clearly define the performance issue, gathering data and evidence to support the claim. This might involve analyzing delivery performance data, quality inspection reports, or feedback from internal stakeholders.

- Communication with the Supplier: Openly and constructively communicating the issue with the supplier, providing specific examples and data to support the concerns. I focus on collaborative problem-solving rather than blame.

- Root Cause Analysis: Working with the supplier to identify the root cause of the problem, using techniques like the 5 Whys or fishbone diagrams. This helps to prevent recurrence.

- Developing a Corrective Action Plan: Establishing a clear plan to address the issue, outlining specific actions, timelines, and responsibilities. This plan must include measurable outcomes.

- Monitoring and Follow-up: Regularly monitoring the supplier’s performance to ensure that the corrective actions are effective. This includes establishing key performance indicators (KPIs) and reviewing progress on a regular basis.

- Escalation if Necessary: If the supplier fails to address the performance issues, escalating the matter to higher management and considering alternative suppliers.

It’s crucial to build strong relationships with suppliers, fostering open communication and mutual trust, to proactively address and prevent potential performance issues.

Q 21. Explain your understanding of lean purchasing principles.

Lean purchasing principles focus on eliminating waste and improving efficiency throughout the procurement process. It’s about optimizing the flow of materials and information to meet customer demand while minimizing costs and lead times.

Key lean principles applied to purchasing include:

- Value Stream Mapping: Analyzing the entire procurement process to identify and eliminate non-value-added activities. This helps to optimize the flow of goods and information.

- Just-in-Time (JIT) Inventory: Receiving materials only when needed, minimizing inventory holding costs and reducing waste from obsolescence.

- Supplier Collaboration: Building strong relationships with key suppliers to foster collaboration, improve communication, and enhance responsiveness. This often involves partnering with suppliers to achieve shared goals.

- Continuous Improvement (Kaizen): Continuously seeking ways to improve the purchasing process, identifying areas for optimization and implementing changes on a regular basis.

- Waste Reduction: Identifying and eliminating various forms of waste, such as overproduction, excess inventory, defects, waiting, transportation, motion, and over-processing.

Implementing lean purchasing requires a cultural shift toward continuous improvement and a commitment to collaboration across the supply chain. It’s not just about cost reduction, but about improving the overall efficiency and effectiveness of the procurement process.

Q 22. How do you ensure the quality of purchased goods and services?

Ensuring the quality of purchased goods and services is paramount. It’s a multi-faceted process that starts long before a purchase order is issued and continues through delivery and even beyond. My approach involves a robust system incorporating several key elements:

- Supplier Selection & Qualification: I rigorously vet potential suppliers, evaluating their capabilities, certifications (like ISO 9001), past performance, and financial stability. This often includes site visits to assess their facilities and processes. For example, when sourcing critical components for a medical device, I wouldn’t compromise on a supplier lacking the necessary FDA certifications.

- Detailed Specifications & Contracts: Clearly defined specifications outlining quality requirements, acceptance criteria, and testing procedures are crucial. Contracts should explicitly address quality expectations, including penalties for non-compliance and remedies for defects. This might include clauses regarding material traceability or regular quality audits.

- Inspection & Testing: Depending on the product’s criticality and supplier history, various inspection methods are employed, including incoming inspections, in-process inspections, and final product inspections. This could range from visual inspections to sophisticated lab testing, depending on the requirements.

- Performance Monitoring & Feedback: Continuous monitoring of supplier performance through key performance indicators (KPIs) like defect rates, on-time delivery, and customer satisfaction is vital. Regular feedback loops with suppliers allow for proactive issue resolution and continuous improvement.

- Corrective Actions & Preventative Measures: A robust system for identifying and addressing quality issues is necessary. This involves root cause analysis to prevent recurrence and implementing corrective actions to mitigate the impact of defects.

In essence, it’s about building strong relationships with reliable suppliers, establishing clear expectations, and continuously monitoring performance to ensure consistent quality.

Q 23. Describe your experience with risk assessment and mitigation in procurement.

Risk assessment and mitigation are fundamental to effective procurement. I approach it systematically, using a framework that considers various potential risks throughout the procurement lifecycle. This involves:

- Identifying Potential Risks: This involves brainstorming potential issues across various categories such as supplier risks (financial instability, capacity issues), operational risks (supply chain disruptions, quality issues), and legal and regulatory risks (compliance issues, intellectual property).

- Assessing Risk Probability and Impact: Each identified risk is analyzed based on its likelihood of occurrence and potential impact on the project or organization. This often involves assigning numerical scores or using a risk matrix to prioritize risks.

- Developing Mitigation Strategies: For high-priority risks, specific mitigation strategies are developed. These strategies could include diversifying suppliers, implementing contingency plans (e.g., having alternative sourcing options), negotiating favorable contract terms, or purchasing insurance.

- Monitoring and Review: Risks are continuously monitored, and mitigation strategies are adjusted as needed. Regular reviews of the risk assessment ensure its relevance and effectiveness.

For example, during a project involving a unique, specialized component, I identified a high risk of supplier failure due to limited supplier options. My mitigation strategy involved developing a detailed qualification process for the supplier, negotiating long-term contracts with guaranteed supply volumes, and identifying a secondary potential supplier as a backup option.

Q 24. How do you utilize data analytics to improve purchasing decisions?

Data analytics plays a crucial role in optimizing purchasing decisions. I leverage data to gain insights into spending patterns, supplier performance, and market trends. This includes:

- Spend Analysis: Analyzing historical purchasing data to identify areas for cost savings, such as consolidating purchases or negotiating better pricing with high-volume suppliers.

- Supplier Performance Measurement: Using data to track key performance indicators (KPIs) like on-time delivery, quality rates, and lead times to evaluate supplier performance and identify areas for improvement. For example, we can identify which suppliers consistently exceed expectations and which need attention.

- Market Trend Analysis: Monitoring market prices, supply and demand dynamics, and competitor activities to make informed decisions about pricing strategies and sourcing alternatives.

- Predictive Analytics: Using forecasting techniques to anticipate future demand, optimize inventory levels, and proactively mitigate potential supply chain disruptions.

By employing data-driven insights, we can identify cost-saving opportunities, improve supplier relationships, and make more strategic purchasing decisions. For instance, by analyzing spend data, we identified an opportunity to negotiate a volume discount with a key supplier, resulting in significant cost savings.

Q 25. What are your strengths and weaknesses in procurement?

My strengths lie in my strategic thinking, analytical skills, and strong negotiation abilities. I excel at building strong relationships with suppliers and navigating complex procurement processes. I am adept at identifying and mitigating risks and leveraging data to improve purchasing decisions. I also possess a keen eye for detail and a commitment to continuous improvement.

One area I am continually working to improve is delegation. While I’m comfortable handling complex projects independently, I recognize the importance of effectively delegating tasks to empower team members and optimize efficiency. I am actively seeking opportunities to develop my delegation skills through mentorship and training.

Q 26. What are your salary expectations?

My salary expectations are in line with my experience and the requirements of this role. I am open to discussing a competitive compensation package that reflects my skills and contributions.

Q 27. What are your long-term career goals?

My long-term career goals involve progressing to a senior leadership position in procurement, where I can leverage my expertise to lead and mentor teams, develop and implement innovative procurement strategies, and contribute to the overall success of an organization. I am particularly interested in exploring opportunities in strategic sourcing and supply chain management.

Q 28. Why are you interested in this position?

I am highly interested in this position because it aligns perfectly with my career aspirations and provides an opportunity to contribute my expertise to a dynamic and forward-thinking organization. The challenges presented by this role, particularly [mention specific aspects of the job description that excite you], are particularly appealing, and I am confident that my skills and experience make me a strong candidate.

Key Topics to Learn for Purchasing and Sourcing Interview

- Supplier Relationship Management (SRM): Understanding the principles of building and maintaining strong relationships with suppliers, including negotiation strategies and performance evaluation.

- Strategic Sourcing: Developing and implementing strategies to optimize the sourcing process, focusing on cost reduction, risk mitigation, and supply chain efficiency. Practical application: Analyze a case study on selecting a supplier based on various criteria (cost, quality, lead time, risk).

- Negotiation and Contract Management: Mastering negotiation techniques to achieve favorable terms and conditions in purchasing agreements. Practical application: Practice negotiating scenarios, focusing on win-win outcomes and understanding contract legalities.

- Procurement Processes and Procedures: Understanding the entire procurement cycle, from requisition to payment, including compliance with relevant regulations and internal policies. Practical application: Outline the steps involved in a typical procurement process for a specific product or service.

- Spend Analysis and Cost Optimization: Analyzing spending data to identify areas for cost savings and efficiency improvements. Practical application: Develop a plan for reducing procurement costs in a specific area of a business.

- Risk Management in Procurement: Identifying and mitigating potential risks throughout the supply chain, including geopolitical instability, supplier disruptions, and quality issues. Practical application: Develop a risk mitigation plan for a key supplier.

- Technology in Procurement (e.g., e-procurement systems): Familiarity with different procurement software and technologies to streamline processes and improve efficiency. Practical application: Research and compare different e-procurement platforms.

- Sustainability and Ethical Sourcing: Understanding the importance of sustainable and ethical sourcing practices, including fair labor standards and environmental considerations. Practical application: Develop a strategy for incorporating sustainable sourcing principles into procurement practices.

Next Steps

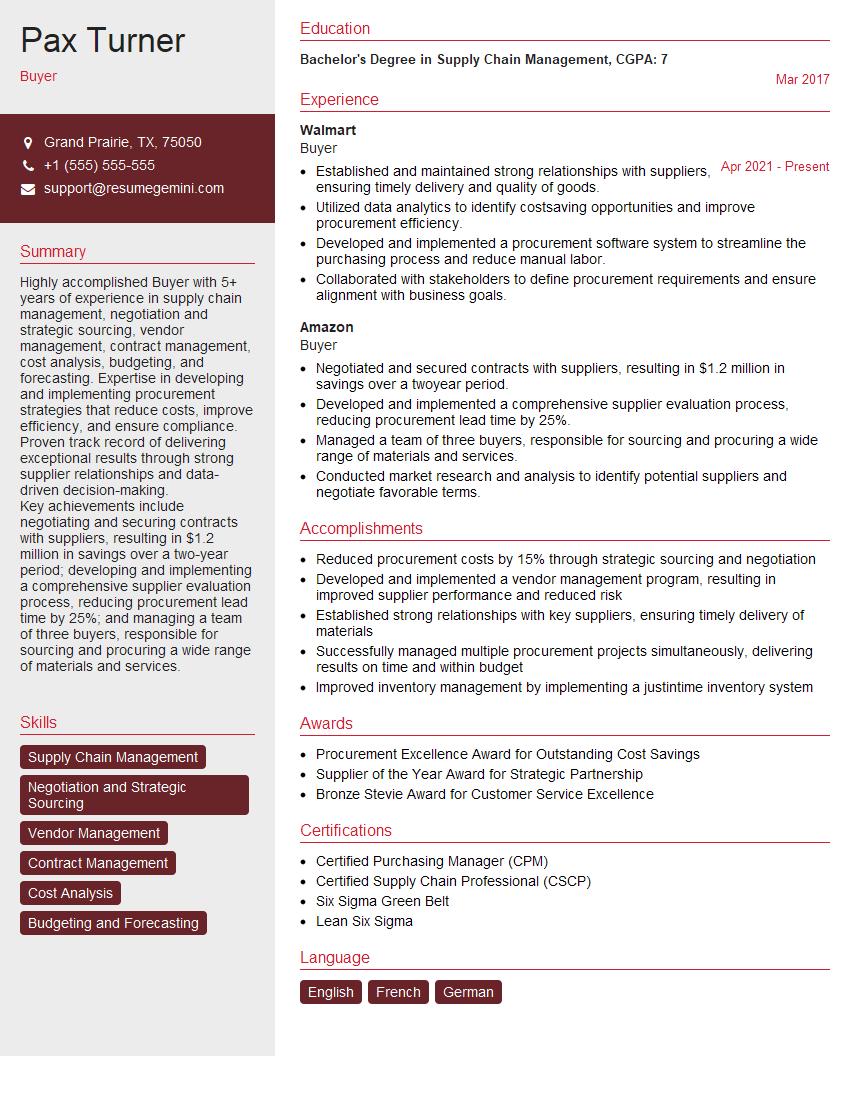

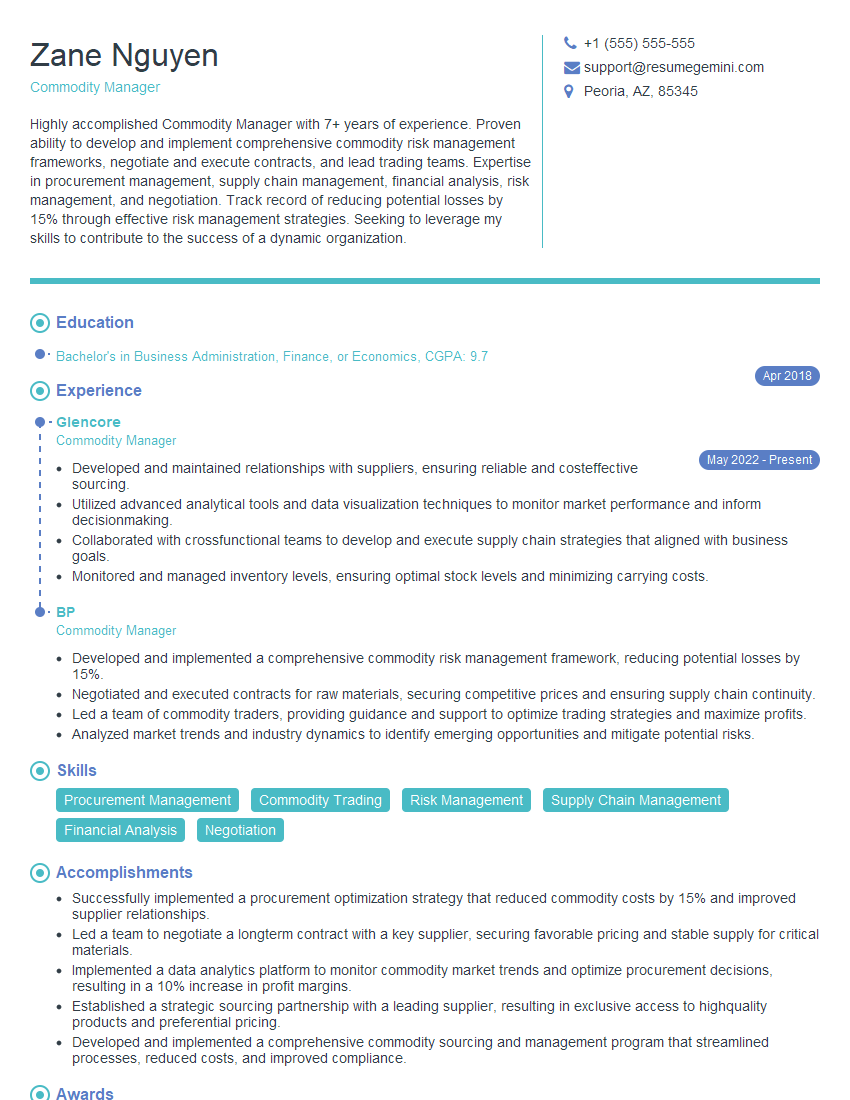

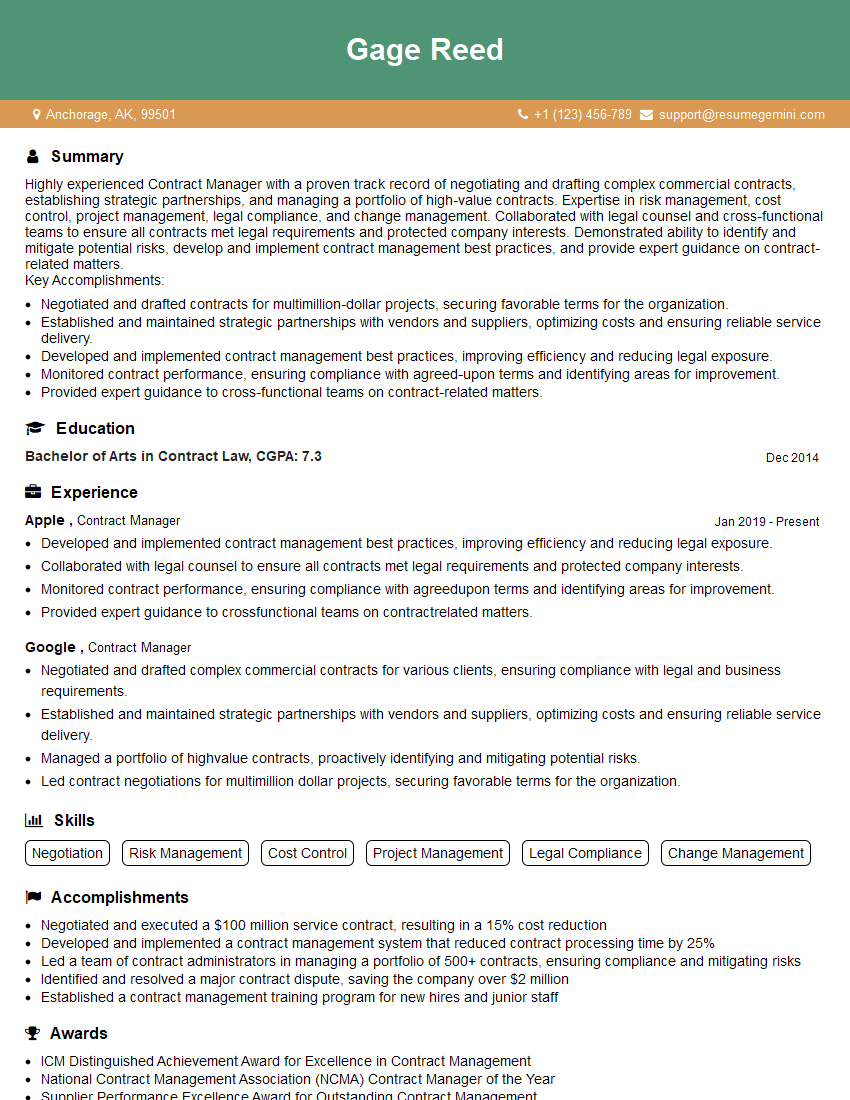

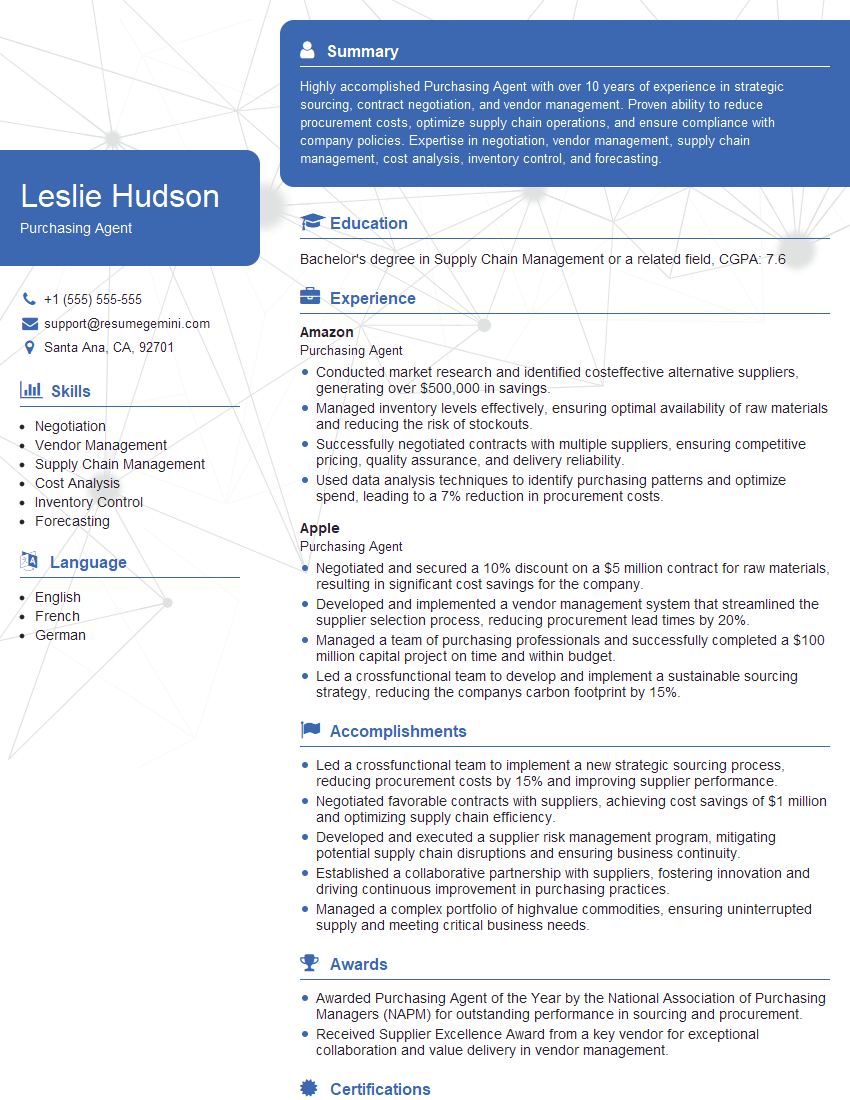

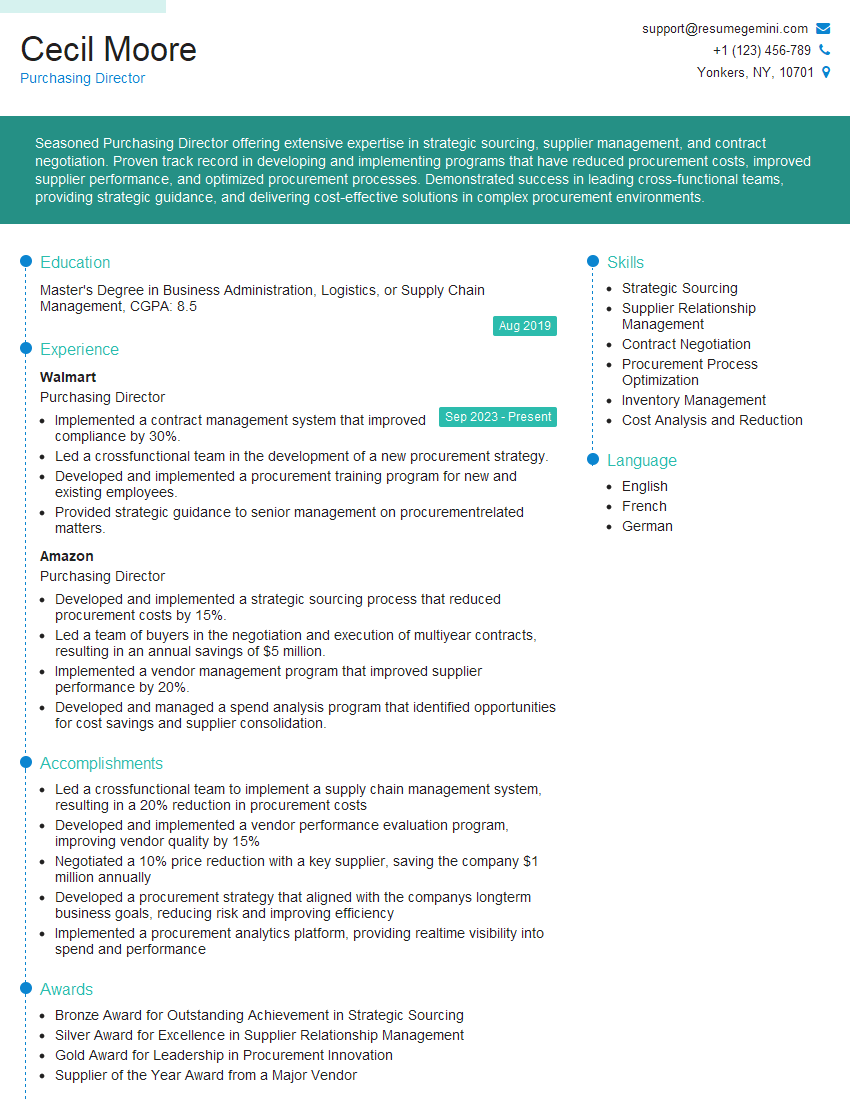

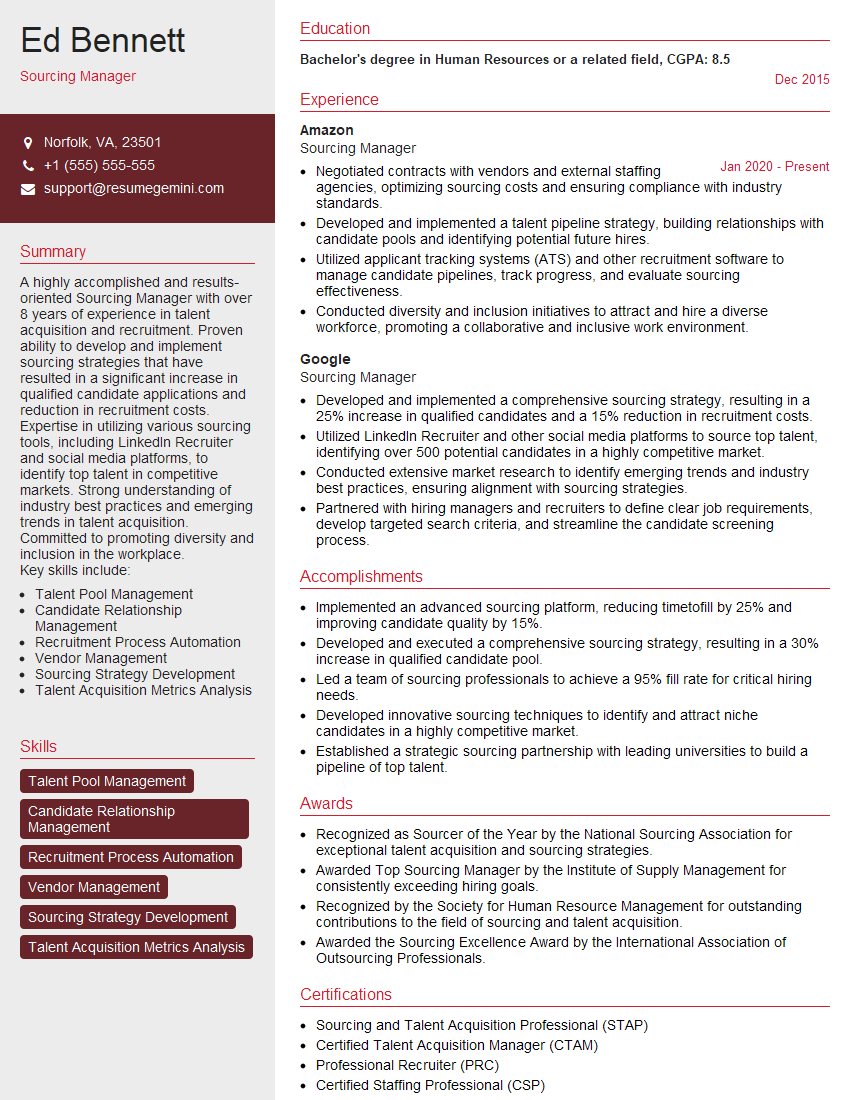

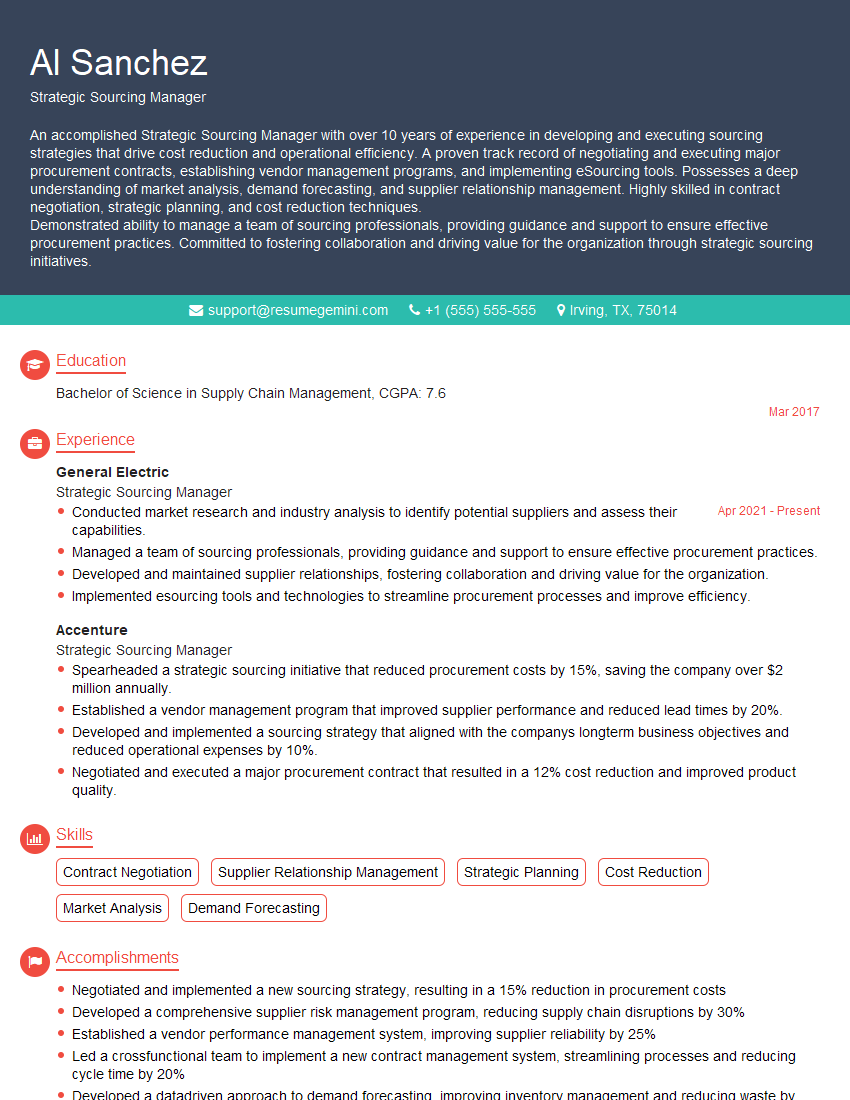

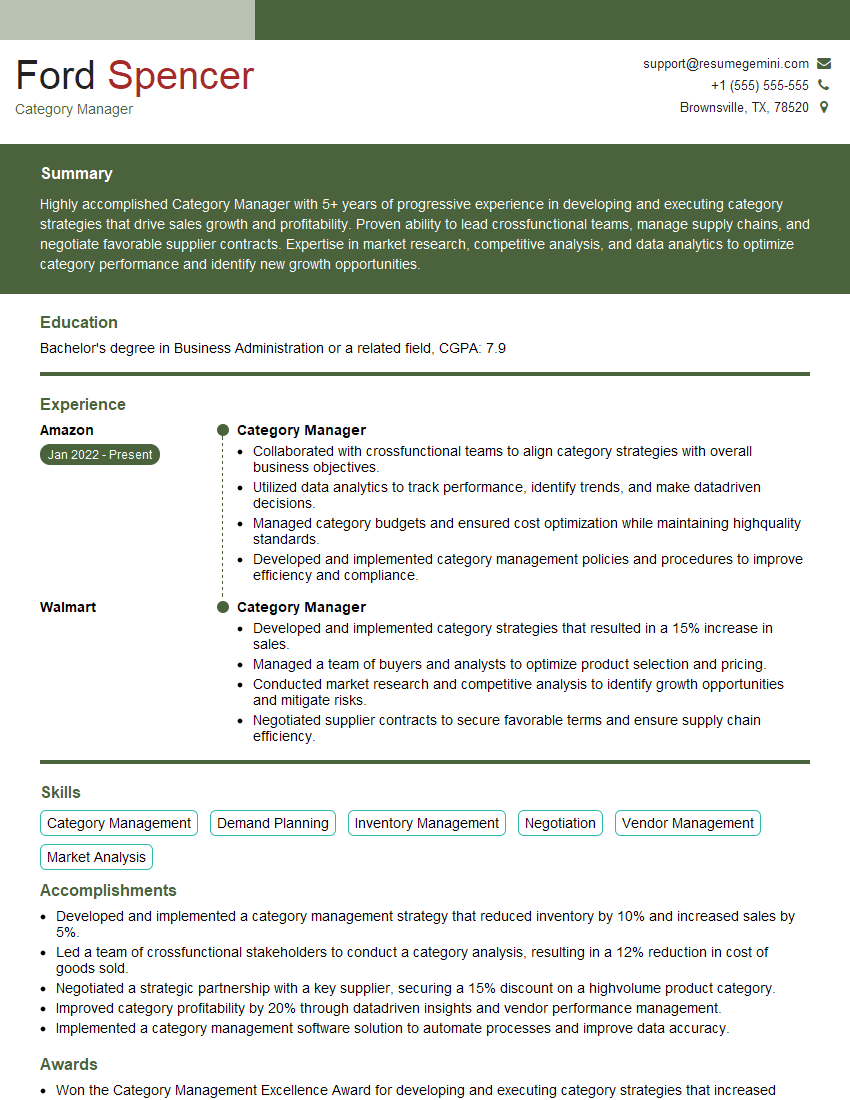

Mastering Purchasing and Sourcing opens doors to exciting career opportunities and significant professional growth, offering challenges and rewards in a dynamic field. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is crucial for maximizing your job prospects. We recommend using ResumeGemini, a trusted resource, to build a professional and effective resume. ResumeGemini provides examples of resumes tailored to Purchasing and Sourcing roles, guiding you to present your skills and experience in the best possible light. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO