Preparation is the key to success in any interview. In this post, we’ll explore crucial Quality Control and Accuracy Assurance interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Quality Control and Accuracy Assurance Interview

Q 1. Explain the difference between Quality Control and Quality Assurance.

Quality Control (QC) and Quality Assurance (QA) are often confused, but they represent distinct yet complementary approaches to ensuring product or service quality. Think of it like this: QA is about preventing defects, while QC is about detecting them.

Quality Assurance (QA) is a proactive process focused on establishing and maintaining a system to prevent defects from occurring in the first place. It involves planning, designing, and implementing processes, procedures, and training to ensure quality is built into the product or service from the outset. This includes things like defining quality standards, conducting regular audits, and reviewing processes for improvement.

Quality Control (QC), on the other hand, is a reactive process. It focuses on inspecting the finished product or service to identify and correct defects that have already occurred. QC methods include testing, inspections, and statistical analysis to ensure the final output meets predetermined standards.

For example, in software development, QA might involve establishing coding guidelines, conducting code reviews, and using automated testing frameworks. QC would involve testing the completed software for bugs, usability issues, and performance problems after development.

Q 2. Describe your experience with various quality control methodologies (e.g., Six Sigma, ISO 9001).

I have extensive experience with several quality control methodologies, including Six Sigma and ISO 9001.

Six Sigma is a data-driven approach that aims to minimize variation and defects in processes. I’ve utilized Six Sigma’s DMAIC (Define, Measure, Analyze, Improve, Control) methodology in various projects, for instance, streamlining a manufacturing process that reduced defect rates by 70% by identifying and eliminating the root causes of variability through data analysis and process optimization. We used control charts and process capability analysis (Cp/Cpk) extensively.

ISO 9001 is a widely recognized international standard for quality management systems. In my previous role, I led the implementation of ISO 9001, which involved documenting processes, conducting internal audits, and managing corrective and preventative actions. This resulted in improved traceability, reduced non-conformances, and enhanced customer satisfaction. The implementation involved a significant team effort and careful attention to detail in documenting every step of our processes.

Q 3. How do you identify and prioritize quality issues?

Identifying and prioritizing quality issues is crucial for effective QC. My approach involves a multi-step process:

- Data Collection: Gathering data from various sources, including customer feedback, defect reports, internal audits, and process performance metrics.

- Analysis: Analyzing the collected data to identify trends, patterns, and root causes of quality issues using tools like Pareto charts (to identify the vital few causes) and fishbone diagrams (to understand cause-and-effect relationships).

- Prioritization: Prioritizing quality issues based on factors such as severity (impact on customers), frequency (how often the issue occurs), and cost (financial impact of the issue). A risk matrix can be used effectively here.

- Action Planning: Developing and implementing action plans to address the prioritized issues. This includes assigning responsibility, setting deadlines, and allocating resources.

For example, if customer complaints about a specific product feature are consistently high, I would prioritize addressing this issue due to its significant impact on customer satisfaction.

Q 4. What are some common quality control tools and techniques you’ve used?

I’ve used a variety of quality control tools and techniques, including:

- Control Charts: Used to monitor process performance over time and detect deviations from the desired level (e.g., X-bar and R charts).

- Pareto Charts: Used to identify the vital few causes of quality problems that contribute to the majority of defects.

- Check Sheets: Simple forms used to collect data on the frequency of specific quality issues.

- Histograms: Used to visualize the distribution of data and identify potential process problems.

- Scatter Diagrams: Used to investigate the relationship between two variables, helping to uncover potential causes of quality issues.

- Flowcharts: Used to visually represent processes and identify potential bottlenecks or areas for improvement.

The choice of tool depends on the specific context and the type of data available. For example, I’d use control charts to monitor the weight of products in a manufacturing process, while a Pareto chart might be used to analyze the types of customer complaints received.

Q 5. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a powerful set of tools used to monitor and improve process performance. My experience with SPC includes using control charts to monitor key process parameters, analyzing process capability (Cp/Cpk) to assess the ability of a process to meet specifications, and implementing process improvements based on statistical analysis.

In one project, we used control charts to monitor the yield of a chemical reaction. By analyzing the data from the charts, we identified a specific temperature range that consistently resulted in higher yields. This discovery allowed us to optimize the process and increase our overall efficiency.

Understanding control limits, identifying assignable causes versus common causes of variation, and utilizing different chart types (e.g., X-bar and R chart, p-chart, c-chart) are essential components of my SPC expertise.

Q 6. How do you handle discrepancies or non-conformances?

When discrepancies or non-conformances arise, I follow a structured approach to address them:

- Immediate Containment: First, I take steps to prevent further production of non-conforming items or services. This might involve isolating defective products or temporarily halting a process.

- Root Cause Analysis: I conduct a thorough investigation using tools like the 5 Whys or fishbone diagrams to determine the underlying causes of the non-conformances.

- Corrective Action: I implement corrective actions to address the immediate problem, such as repairing defective products or retraining employees.

- Preventative Action: I take steps to prevent similar issues from occurring in the future, such as revising processes, improving equipment, or updating training materials. This step is crucial in preventing recurrence.

- Documentation: I meticulously document the entire process, including the non-conformances, root cause analysis, corrective and preventative actions, and the effectiveness of those actions. This documentation is essential for continuous improvement.

For instance, if a batch of products fails a quality inspection, I would immediately quarantine that batch, investigate the cause (perhaps a malfunctioning machine), repair the machine, and re-inspect the products before releasing them.

Q 7. Explain your process for developing and implementing quality control plans.

Developing and implementing a quality control plan is a systematic process. It typically involves:

- Defining Quality Standards: Clearly define the quality characteristics and standards that need to be met. This includes specifying acceptable tolerances, performance metrics, and other requirements.

- Identifying Key Process Parameters: Determine the critical parameters that affect product or service quality. These parameters will be monitored closely during the process.

- Selecting Appropriate QC Tools and Techniques: Choose the appropriate QC tools and techniques based on the nature of the product or service and the type of data collected.

- Developing Monitoring Procedures: Establish procedures for monitoring key process parameters and identifying potential problems.

- Implementing Corrective and Preventative Actions: Establish procedures for addressing non-conformances and preventing future occurrences.

- Review and Improvement: Regularly review the quality control plan to ensure its effectiveness and make necessary improvements.

A successful quality control plan is tailored to the specific needs of the organization and is regularly reviewed and updated based on performance data and changing customer needs. It’s a living document, not a static one.

Q 8. How do you measure the effectiveness of your quality control efforts?

Measuring the effectiveness of quality control is crucial for continuous improvement. We don’t just look at the number of defects found; instead, we employ a multi-faceted approach. This includes key performance indicators (KPIs) like defect rate (the percentage of defective units compared to the total), process capability indices (Cp and Cpk, measuring how well a process meets specifications), and customer satisfaction scores. For example, a low defect rate might initially seem positive, but a low customer satisfaction score alongside it suggests that our quality checks might be missing critical customer-centric aspects. Therefore, we also analyze the types of defects found, their severity, and their root causes. This helps us understand where our control measures are working well and where they need improvement. We might use control charts to visualize trends and identify areas for process adjustments or further training. Ultimately, a truly effective quality control program demonstrates a consistent reduction in defects, improved process efficiency, and enhanced customer satisfaction over time.

Q 9. Describe a time you had to deal with a major quality issue. What was your approach?

In a previous role, we faced a significant issue with a batch of manufactured components. A critical dimension was consistently outside the tolerance limits, leading to potential assembly failures and costly rework. My approach was systematic. First, we immediately halted production to prevent further defective units. We then implemented a containment strategy – isolating the affected batch and ensuring it wouldn’t enter the supply chain. Second, we launched a comprehensive investigation using root cause analysis tools like the 5 Whys and a fishbone diagram (Ishikawa diagram). This helped us identify the root cause: a malfunctioning calibration setting on a key piece of machinery. Third, we corrected the calibration, implemented a stricter calibration verification procedure, and conducted thorough retraining of the operators. Finally, we established a more robust quality check at each stage of the manufacturing process to prevent recurrence. This incident highlighted the importance of proactive monitoring, rapid response, and thorough root cause analysis in mitigating major quality issues. We also revised our standard operating procedures to include redundant checks for critical dimensions.

Q 10. How do you ensure accuracy and precision in your work?

Accuracy and precision are paramount. I ensure accuracy by using calibrated equipment, adhering to standardized procedures, and double-checking my work meticulously. For example, using a micrometer for precise measurements and comparing readings from multiple instruments ensures accuracy. Precision involves minimizing variability in measurements. This is achieved through controlled environments, consistent techniques, and appropriate sample sizes. In statistical analysis, for example, I always utilize methods which provide confidence intervals – giving a quantitative estimate of uncertainty in my results. Proper data logging, clear labeling, and documentation are crucial for maintaining both accuracy and traceability. Regular audits and calibrations of equipment are also key components of this process.

Q 11. What are some common sources of error in your field, and how do you mitigate them?

Common sources of error include human error (misreadings, incorrect data entry), equipment malfunction (calibration drift, faulty sensors), and variations in materials or processes. To mitigate these, we implement multiple layers of control. For human error, we use checklists, cross-checking, and peer reviews. For equipment issues, we perform regular calibration and maintenance, using preventive maintenance schedules to avoid unexpected breakdowns. For material and process variations, we use statistical process control (SPC) techniques like control charts to monitor and detect deviations early on. Additionally, investing in training and development for personnel improves consistency and reduces the likelihood of human error. A strong quality management system (QMS) acts as a framework to address these potential errors proactively.

Q 12. Describe your experience with root cause analysis.

Root cause analysis (RCA) is a cornerstone of my work. I’m proficient in various techniques, including the 5 Whys, fishbone diagrams, and fault tree analysis. For example, if a product fails consistently, I’d start with the 5 Whys: ‘Why did the product fail?’ ‘Why was that component faulty?’ ‘Why was the manufacturing process flawed?’ and so on, until we uncover the underlying root cause. A fishbone diagram helps visually organize potential contributing factors, while fault tree analysis allows a systematic evaluation of potential failure points and their probabilities. The key is to be objective, gather data from multiple sources, and involve diverse team members to broaden perspectives. The goal isn’t just to identify the immediate problem but to understand the systemic issues that allowed it to happen. Implementing corrective actions based on the root cause analysis is essential to preventing recurrence.

Q 13. How do you document and track quality control activities?

Documentation and tracking are crucial for maintaining traceability and demonstrating compliance. We use a combination of methods, including digital records management systems, databases, and physical files. All quality control activities, from inspections and tests to calibration records and corrective actions, are meticulously documented, including dates, times, personnel involved, and specific findings. We often utilize digital systems, ensuring data integrity and easy retrieval. This allows us to track trends, identify recurring issues, and continually improve our processes. Clear documentation also helps with audits and regulatory compliance. Think of it as a detailed story of our quality control efforts, allowing for a complete and transparent understanding of what happened and why.

Q 14. How do you stay current with best practices and industry standards?

Staying current is vital in this field. I actively participate in professional organizations like ASQ (American Society for Quality), attend conferences and webinars, and regularly review industry publications and journals. I also actively seek out training opportunities in new technologies and methodologies relevant to quality control. For example, I’ve recently completed training on advanced statistical process control techniques and lean manufacturing principles. Staying abreast of changes in regulations and standards, such as ISO 9001, is also critical to ensure our practices remain compliant and competitive. Continuous learning is essential to adapting to evolving industry best practices and technologies.

Q 15. Explain your understanding of different types of audits (internal, external).

Audits are systematic and independent examinations to determine whether quality activities and results comply with planned arrangements and whether these arrangements are effectively implemented and maintained. Internal audits are conducted by an organization’s own personnel to assess its own quality management system (QMS). They are crucial for proactive identification of weaknesses before they become major issues. External audits, conversely, are performed by independent third-party organizations or certification bodies. These audits verify the organization’s claims of conformity to standards like ISO 9001, and provide an unbiased assessment of the QMS.

- Internal Audits: Think of these as a self-check-up. For example, a manufacturing company might internally audit its production line to ensure adherence to safety protocols and product specifications. They identify areas for improvement within the team and systems.

- External Audits: These are more like a doctor’s checkup. The external auditor examines the company’s processes and documents objectively, ensuring compliance with external standards. A successful external audit leads to certifications, demonstrating compliance and enhancing credibility.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with ISO 9001 standards?

I am very familiar with ISO 9001 standards. It’s a globally recognized standard for Quality Management Systems (QMS). My understanding extends beyond simply knowing the clauses; I’ve applied its principles in various practical settings. ISO 9001 focuses on continuous improvement, customer satisfaction, and risk-based thinking. I understand its requirements related to documentation, internal audits, management review, corrective and preventive actions (CAPA), and management responsibility. I have directly contributed to the implementation and maintenance of ISO 9001 compliant QMS in previous roles. For instance, I led the implementation of a new QMS in a previous company, resulting in a successful certification audit.

Q 17. Describe your experience with corrective and preventive actions (CAPA).

Corrective and Preventive Actions (CAPA) are crucial elements of any effective QMS. Corrective actions address existing problems, while preventive actions anticipate and prevent future problems. My experience includes developing and implementing CAPA procedures, investigating root causes of nonconformities using tools like 5 Whys and fishbone diagrams, and verifying the effectiveness of implemented corrective and preventive actions. I have a proven track record of reducing defects and improving processes through systematic CAPA implementation. For instance, I once investigated a recurring defect in a production process. Through root cause analysis, we identified a problem with a specific machine setting. By correcting the setting and implementing regular checks, we successfully eliminated the defect and prevented its recurrence.

Q 18. How do you communicate quality issues to different stakeholders?

Effective communication is essential in quality control. I tailor my communication to the audience and the nature of the issue. For example, I might use concise email reports for routine updates to management, while holding more detailed meetings with the involved team to discuss corrective actions. I always strive for clarity and transparency, avoiding technical jargon whenever possible. When communicating critical issues, I prioritize timely notification, outlining the problem, its impact, proposed solutions, and next steps. Using visual aids like graphs and charts can significantly aid understanding and improve communication efficiency. For example, if reporting a high defect rate, I might present a graph showing the trend over time to help stakeholders understand the scope and urgency of the problem.

Q 19. How do you manage and motivate a quality control team?

Managing and motivating a quality control team requires a blend of leadership, technical expertise, and people skills. I focus on fostering a collaborative environment where team members feel valued and empowered. Clear communication, setting achievable goals, and providing regular feedback are crucial. I delegate tasks effectively, allowing team members to develop their skills and take ownership. Recognition and rewards for accomplishments, both individual and team-based, are also vital for maintaining morale and motivation. I also encourage continuous learning and professional development by providing opportunities for training and attending relevant conferences. In my previous role, I implemented a peer-recognition program, significantly improving team engagement and performance.

Q 20. What are your strengths and weaknesses regarding quality control?

One of my greatest strengths is my systematic and analytical approach to problem-solving. I am adept at identifying root causes of quality issues and developing effective solutions. My experience with various quality tools and methodologies equips me to tackle complex challenges efficiently. I’m also a strong communicator and collaborator, able to work effectively with diverse teams. However, one area I am continuously working on is delegating tasks more efficiently. I sometimes tend to handle tasks myself when I could empower my team members to take on more responsibility. I actively address this through self-reflection and mentorship to better delegate and empower my team.

Q 21. How do you prioritize tasks when dealing with multiple quality control issues?

Prioritizing quality control issues requires a structured approach. I typically use a risk-based prioritization framework. This involves assessing the severity, probability, and impact of each issue. Issues with higher severity, higher probability of occurrence, and higher potential impact are prioritized first. For example, a critical safety defect in a product would take precedence over a minor cosmetic issue. I also utilize tools like a task management system to track progress and ensure transparency. Regular review meetings ensure that priorities are adjusted based on new information or changing circumstances. This ensures a data-driven approach and aids in managing competing demands effectively.

Q 22. Describe your experience with calibration and validation processes.

Calibration and validation are cornerstones of ensuring accuracy and reliability in any measurement system. Calibration involves comparing a measuring instrument to a known standard to correct any discrepancies, while validation confirms that the entire process or system consistently produces accurate and reliable results. Think of it like this: calibration is adjusting your watch to an atomic clock (the standard), while validation is confirming that your watch consistently tells the correct time under various conditions.

In my previous role at Acme Pharmaceuticals, I was responsible for the calibration of all high-performance liquid chromatography (HPLC) systems used in drug analysis. This involved regular calibration checks using certified reference materials, documenting all results, and generating calibration certificates. Any deviation beyond acceptable tolerances triggered corrective actions, from instrument adjustments to potential repairs. We followed a strict schedule, ensuring each system was calibrated at least once a month, often more frequently based on usage.

Validation, on the other hand, was a more extensive process. For a new HPLC method used for a drug assay, we performed comprehensive validation studies, assessing parameters such as accuracy, precision, linearity, range, limit of detection, and robustness. We documented all steps, using standardized protocols and generating comprehensive validation reports which were crucial for regulatory compliance. One key challenge was validating a new method for a particularly unstable drug compound. We developed a robust methodology that minimized degradation and ensured reliable results, and the process was meticulously documented to meet regulatory requirements.

Q 23. How do you handle pressure and tight deadlines when managing quality control?

Managing quality control under pressure requires a strategic and systematic approach. Tight deadlines don’t compromise quality; they necessitate efficient planning and prioritization. I thrive under pressure, and my experience has honed my skills in time management, resource allocation, and effective communication.

My strategy begins with a clear understanding of priorities. I use tools like Gantt charts and project management software to visualize timelines and allocate resources effectively. When faced with conflicting priorities, I employ a risk-based approach, focusing on the most critical quality control aspects first. Open communication with the team is essential to ensure everyone is informed and works collaboratively. I firmly believe that a well-informed and motivated team can overcome any challenge. For instance, during a critical product launch with an extremely tight deadline, we used daily stand-up meetings to track progress, address roadblocks promptly, and maintain team morale. This proactive approach ensured that we met the deadline without sacrificing quality.

Q 24. Describe a time you had to make a difficult decision related to quality.

In my previous role, we detected a significant anomaly during the final quality control check of a large batch of a vital medical component. Initial testing indicated a slight deviation from specifications that was technically within acceptable tolerances. However, my experience and intuition suggested a potential underlying issue. While releasing the batch wouldn’t have violated the strict letter of our protocols, I decided to halt the release and launch a thorough investigation.

This was a difficult decision because of the significant production delays and potential financial implications. However, I felt the risk of releasing potentially substandard components was far too great. The investigation uncovered a minor equipment malfunction that had subtly affected a larger portion of the batch than initially suspected. The early detection and subsequent disposal of this batch prevented a potentially disastrous recall down the line. The decision, while initially met with some resistance due to the costs involved, was ultimately lauded for preventing significant damage to the company’s reputation and customer safety.

Q 25. How do you use data analysis to improve quality control processes?

Data analysis is integral to improving quality control processes. It allows us to move beyond reactive problem-solving and towards proactive prevention. I leverage data analytics to identify trends, pinpoint areas for improvement, and ultimately optimize our processes.

For example, I use statistical process control (SPC) charts to monitor key process parameters. By analyzing these charts, we can identify patterns and deviations early on, allowing for timely corrective actions. We might find that a specific machine consistently produces higher error rates during certain shifts or that a particular step in the manufacturing process is more prone to errors. This data allows for targeted interventions such as operator retraining, equipment maintenance, or process optimization.

Furthermore, I use data to track key quality metrics such as defect rates, customer complaints, and yield percentages. Analyzing this data helps in identifying root causes of quality problems and in measuring the effectiveness of improvement initiatives. We use this data to create dashboards and reports that provide a clear and concise overview of quality performance, enabling data-driven decision-making.

Q 26. What are your salary expectations?

My salary expectations are commensurate with my experience and skills in quality control and assurance. Considering my background and the scope of this position, I am targeting a salary range of $[Lower Bound] to $[Upper Bound] annually. I’m open to discussing this further and believe we can reach an agreement that is mutually beneficial.

Q 27. Do you have any questions for me?

Yes, I do have a few questions. First, could you elaborate on the company’s current quality control processes and any ongoing initiatives? Secondly, what are the primary challenges the company faces in maintaining high quality standards? Finally, what opportunities are there for professional development within the company?

Key Topics to Learn for Quality Control and Accuracy Assurance Interview

- Understanding Quality Management Systems (QMS): Explore different QMS frameworks like ISO 9001 and their practical implementation in various industries. Consider how these systems ensure consistent product or service quality.

- Statistical Process Control (SPC): Learn about control charts (e.g., Shewhart, CUSUM), process capability analysis (Cp, Cpk), and their application in identifying and reducing process variation. Practice interpreting SPC data to make informed decisions.

- Root Cause Analysis (RCA) Techniques: Master methods like the 5 Whys, Fishbone diagrams, and Pareto analysis to effectively identify the underlying causes of quality issues and implement corrective actions. Prepare examples of your problem-solving skills using these techniques.

- Auditing and Inspection Procedures: Familiarize yourself with different audit types (internal, external), inspection methodologies, and documentation requirements. Understand the importance of objective evidence and reporting findings accurately.

- Data Analysis and Reporting: Develop skills in data collection, analysis, and presentation. Practice creating clear and concise reports that communicate quality metrics and trends effectively to stakeholders.

- Continuous Improvement Methodologies: Explore Lean principles, Six Sigma methodologies (DMAIC, DMADV), and Kaizen events. Understand how these approaches contribute to ongoing quality enhancements.

- Risk Management in Quality Assurance: Learn to identify, assess, and mitigate potential risks that could impact product or service quality. Discuss strategies for proactively managing risks throughout the product lifecycle.

Next Steps

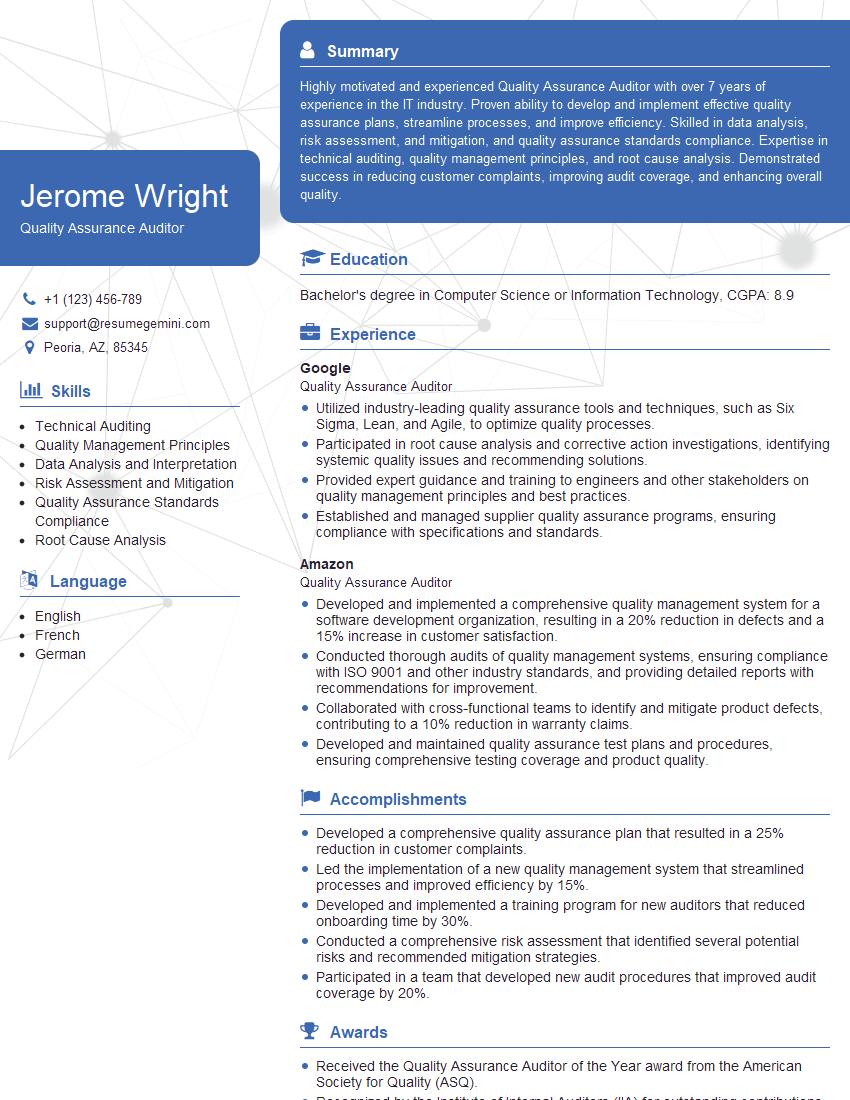

Mastering Quality Control and Accuracy Assurance is crucial for career advancement, opening doors to leadership roles and higher earning potential. A strong resume is your key to unlocking these opportunities. Make sure your resume is ATS-friendly to ensure it gets noticed by recruiters. ResumeGemini is a trusted resource to help you craft a compelling and effective resume. We provide examples of resumes tailored to Quality Control and Accuracy Assurance to give you a head start. Invest time in building a professional resume that showcases your skills and experience—it’s an investment in your future success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO