Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Rapid Prototyping and Manufacturing interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Rapid Prototyping and Manufacturing Interview

Q 1. Explain the difference between subtractive and additive manufacturing.

Subtractive and additive manufacturing represent fundamentally different approaches to creating objects. Think of sculpting versus 3D printing.

Subtractive manufacturing, also known as machining, starts with a larger block of material (like a metal block or a piece of wood) and removes material to create the desired shape. This involves processes like milling, turning, drilling, and cutting. Examples include carving a statue from marble or CNC machining a metal part. The process is precise but generates waste material.

Additive manufacturing, or 3D printing, builds an object layer by layer from a digital design. Material is added, not removed. Different additive techniques use various materials and processes, ranging from plastics (FDM, SLS) to metals (SLM, DMLS) and resins (SLA). This approach minimizes waste but can be slower for complex geometries and larger objects.

Q 2. Describe your experience with various rapid prototyping technologies (e.g., FDM, SLA, SLS, MJF).

My experience spans a broad range of rapid prototyping technologies. I’ve extensively worked with:

- Fused Deposition Modeling (FDM): A cost-effective method using a thermoplastic filament. I’ve used FDM for rapid prototyping of functional parts, conceptual models, and jigs. For example, I created a functional prototype of a phone case using PLA filament to test its ergonomic design before moving to injection molding.

- Stereolithography (SLA): This technology uses a UV laser to cure liquid resin, creating incredibly detailed prototypes with smooth surfaces. I utilized SLA for creating highly accurate models of medical implants, where precision is paramount. The smooth finish allowed for better analysis of surface features.

- Selective Laser Sintering (SLS): Ideal for creating strong, durable parts from powdered materials like nylon or metal. I used SLS to produce prototypes of a complex gear system that needed to withstand significant stress. Its capability to create intricate internal structures proved invaluable.

- MultiJet Fusion (MJF): A high-speed, high-resolution technology that produces parts with excellent surface finish and mechanical properties. I leveraged MJF for producing durable prototypes for consumer products, ensuring that they met both aesthetic and functional requirements before mass production.

Each technology offers unique advantages; the choice depends heavily on the project’s specific demands.

Q 3. What are the limitations of rapid prototyping technologies?

Rapid prototyping, while revolutionary, has limitations:

- Material constraints: Not all materials are compatible with every technique. For instance, achieving high-strength metal parts directly via FDM is impossible.

- Size limitations: The build volume of many 3D printers restricts the size of the prototypes that can be created. Large parts often require multiple prints and assembly.

- Surface finish and accuracy: While improving, the surface finish of some prototypes may not be suitable for direct production without post-processing. Dimensional accuracy can also vary depending on the technology and material.

- Cost: Some rapid prototyping methods, like MJF, can be expensive, particularly for high-volume prototyping runs. However, the cost savings from avoiding costly tooling for traditional manufacturing often outweighs the prototyping cost.

- Post-processing: Many prototypes need post-processing steps (e.g., cleaning, sanding, painting) which add time and cost.

Understanding these limitations is vital to selecting the appropriate technology and managing project expectations.

Q 4. How do you select the appropriate rapid prototyping method for a given project?

Choosing the right rapid prototyping method involves a systematic process. I consider several factors:

- Design complexity: Intricate designs might require SLA or MJF for fine details.

- Material properties: Strength, flexibility, heat resistance, and biocompatibility are key considerations that influence material and method selection.

- Cost and budget: FDM is generally cost-effective, while MJF is more expensive but faster for high-quality parts.

- Lead time: Urgent projects benefit from quicker methods like MJF, while less time-sensitive projects might use FDM or SLS.

- Production volume: For high-volume prototyping, processes capable of producing several parts simultaneously might be more efficient.

- Surface finish requirements: SLA provides excellent surface finish, while FDM may require additional finishing.

I often create a decision matrix weighing these factors to select the most suitable method for a given project. For instance, for a medical device requiring high strength and biocompatibility, SLS with a biocompatible material would likely be the best option.

Q 5. Explain the Design for Manufacturing (DFM) process.

Design for Manufacturing (DFM) is a crucial iterative process that optimizes a product’s design for efficient and cost-effective manufacturing. It involves considering manufacturing constraints early in the design phase. It aims to reduce manufacturing costs, improve product quality, and shorten lead times.

The process typically involves:

- Analyzing the design: Identifying potential manufacturing challenges, such as complex geometries, difficult-to-reach areas, and material limitations.

- Material selection: Choosing appropriate materials that are readily available, cost-effective, and meet the performance requirements.

- Simplification of design: Streamlining the design to reduce the number of parts, simplify assembly, and minimize tooling costs. Consider using standardized components.

- Tolerance analysis: Establishing acceptable dimensional tolerances to ensure consistent product quality and manufacturability.

- Process simulation: Using software to simulate the manufacturing process, identify potential issues, and optimize the design for manufacturability.

- Collaboration: Working closely with manufacturing engineers to incorporate their expertise and feedback.

A successful DFM process ensures that the final product is not only functional and aesthetically pleasing but also economically viable to produce.

Q 6. How do you ensure the quality and accuracy of prototypes?

Quality and accuracy are paramount in rapid prototyping. I employ several methods to ensure both:

- Careful CAD modeling: Precise CAD models are the foundation of any successful prototype. I use advanced CAD software to ensure the model accurately represents the final design.

- Appropriate technology selection: Choosing the right rapid prototyping method for the project’s specific needs significantly impacts quality and accuracy.

- Calibration and maintenance of equipment: Regular calibration and maintenance of the 3D printers ensure consistent results.

- Quality control checks: I regularly inspect prototypes throughout the process, checking for dimensional accuracy, surface finish, and any defects. Tools like CMM (Coordinate Measuring Machines) can be used for precise measurements.

- Use of Design of Experiments (DOE): DOE helps optimize printing parameters, ensuring consistent and high-quality output.

- Post-processing techniques: Implementing appropriate post-processing steps, such as sanding, polishing, or painting, improves the surface finish and overall quality.

By implementing these strategies, I can consistently deliver prototypes that meet the required quality standards and accurately reflect the intended design.

Q 7. Describe your experience with CAD/CAM software.

My proficiency in CAD/CAM software is extensive. I’m highly experienced with industry-standard software such as SolidWorks, Autodesk Inventor, and Fusion 360 for CAD modeling. For CAM (Computer-Aided Manufacturing), I have used Mastercam and other specialized software to generate toolpaths for subtractive manufacturing processes. My expertise includes:

- 3D modeling: Creating detailed and accurate 3D models of components and assemblies.

- Surface modeling: Developing complex curved surfaces and freeform shapes.

- Feature-based modeling: Creating parametric models that are easily modified and updated.

- Assembly modeling: Creating realistic assemblies of multiple components.

- CAM programming: Generating toolpaths for CNC machining, optimizing for speed, efficiency, and surface finish.

- Simulation and analysis: Utilizing simulation tools to verify the functionality and structural integrity of the design.

I have used these skills to generate detailed designs that have been successfully manufactured, demonstrating a solid understanding of how the digital design translates into the physical world.

Q 8. How do you manage project timelines and budgets in rapid prototyping?

Managing timelines and budgets in rapid prototyping requires a structured approach. It’s crucial to start with a well-defined scope, breaking down the project into smaller, manageable tasks with clear deliverables and deadlines. This allows for better tracking and identification of potential delays. We use tools like Gantt charts or project management software (like Asana or Jira) to visualize the schedule and dependencies between tasks. Budgeting involves a thorough estimation of material costs, labor costs (including design, prototyping, and testing), and equipment usage. Contingency buffers should be built into the budget to accommodate unexpected issues. Regular progress meetings and performance reviews against the baseline plan help keep the project on track. For instance, in a recent project developing a new ergonomic keyboard, we allocated specific timelines for 3D modeling, material selection, initial prototyping, user testing, and iterative design refinements, meticulously tracking expenses against each phase.

In another project involving a medical device prototype, we utilized Agile methodologies, breaking the project into sprints, allowing for flexible adaptation to feedback and changing requirements without significantly impacting the overall timeline or budget. This iterative approach helps ensure we deliver a product that satisfies user needs within the stipulated constraints.

Q 9. What are some common challenges in rapid prototyping, and how have you overcome them?

Rapid prototyping presents several challenges. One common hurdle is the inherent trade-off between speed and quality. Quick iterations often necessitate compromises in precision and material selection. Another challenge involves managing design iterations based on user feedback. Integrating multiple feedback loops efficiently, without exceeding the budget or timeline, can be difficult. I’ve overcome these challenges by employing a structured iterative process. First, define a Minimum Viable Product (MVP) that incorporates the core functionalities, allowing for quick prototyping and early user testing. This focuses resources on essential elements. For example, in developing a new phone case prototype, we began with a simple 3D-printed model focusing on ergonomics before moving to more advanced materials and features in later iterations. Secondly, leveraging digital design tools and simulation software allows for early detection of design flaws and reduces the need for extensive physical prototyping iterations. Finally, communicating transparently with stakeholders about trade-offs and potential delays fosters collaborative problem-solving and avoids misunderstandings.

Q 10. Explain your experience with different materials used in rapid prototyping.

My experience spans a broad range of materials. For early-stage prototypes, I frequently use 3D printing materials like ABS (Acrylonitrile Butadiene Styrene) for its durability and ease of printing, or PLA (Polylactic Acid) for its biodegradability. For more refined prototypes, I utilize materials closer to the final product. This might involve injection molding-grade plastics like polycarbonate or nylon, or even metal alloys (aluminum, stainless steel) if the application demands high strength and precision. Selection depends heavily on factors such as required mechanical properties (strength, flexibility, temperature resistance), aesthetic requirements, and cost. In one project, we started with a 3D-printed ABS model to evaluate the form factor and ergonomics of a new hand tool before using CNC machining to create prototypes in aluminum for testing durability and strength. Then, we finalized the design with injection molded nylon for mass production.

Q 11. How do you handle design iterations and feedback during the prototyping process?

Design iterations and feedback are central to rapid prototyping. We usually employ iterative design methodologies, incorporating user feedback at each stage. This starts with initial concept sketches and progresses through digital modeling, physical prototyping, and user testing. Online collaboration tools and cloud-based design platforms greatly facilitate sharing designs and gathering feedback. We typically use structured feedback questionnaires and in-person user testing sessions, carefully analyzing the collected data. This data informs design improvements, refining the prototype’s functionality and usability. For example, in developing a new coffee maker prototype, user testing revealed that the button placement was inconvenient. This feedback led to an immediate redesign in the subsequent iteration, illustrating the value of iterative cycles.

Q 12. Describe your experience with tolerance analysis in prototyping.

Tolerance analysis is crucial to ensure the prototype functions correctly and is manufacturable. It involves defining acceptable variations in dimensions and tolerances during manufacturing. We often use Computer-Aided Design (CAD) software with built-in tolerance analysis tools, or specialized software like GD&T (Geometric Dimensioning and Tolerancing) checkers, to ensure dimensions are within acceptable ranges. This helps to identify potential assembly issues or functional limitations early on. For instance, in designing a precise gear mechanism for a robot arm, we meticulously defined tolerances for each gear tooth to ensure smooth operation and avoid jamming. A rigorous tolerance analysis ensures that the manufacturing process can deliver prototypes that meet the specified performance requirements.

Q 13. How do you ensure the scalability of a prototype design for mass production?

Ensuring scalability for mass production requires careful consideration during the prototyping phase. Design for Manufacturing (DFM) principles are applied, considering the chosen manufacturing processes (injection molding, casting, etc.). The prototype’s design should be optimized for efficient manufacturing, reducing material waste and assembly complexity. This may involve simplifying the geometry, standardizing parts, and selecting appropriate materials that are readily available and cost-effective at scale. For example, features like undercuts, which are difficult and expensive to produce via injection molding, would be avoided. We also conduct Design for Assembly (DFA) analysis to optimize part count and assembly process for high-volume manufacturing. Collaboration with manufacturing engineers is key to ensuring the prototype’s successful transition into mass production.

Q 14. Explain your understanding of different manufacturing processes (e.g., injection molding, casting).

I have extensive experience with various manufacturing processes. Injection molding is a high-volume process ideal for producing complex plastic parts with high precision. The molten plastic is injected into a mold cavity, producing parts with consistent quality. Casting involves pouring molten material (metal or plastic) into a mold cavity, often used for less complex parts or for materials that are difficult to injection mold. Other processes I’m familiar with include CNC machining (for high-precision parts in metals or plastics), 3D printing (for rapid prototyping and low-volume production), and sheet metal forming (for producing thin metal parts). Each process has its own advantages and limitations, and the choice depends on factors like part complexity, material properties, required volume, and budget. Understanding these processes is critical for designing prototypes that are both feasible and cost-effective to manufacture at scale.

Q 15. What are the key considerations for selecting materials for manufacturing?

Selecting the right materials is paramount in manufacturing, impacting everything from product performance and cost to the entire manufacturing process. It’s not simply about choosing the cheapest option; instead, it’s a balancing act considering several critical factors.

- Functionality: The material must meet the required mechanical properties (strength, flexibility, durability), thermal properties (heat resistance, conductivity), chemical resistance (corrosion, degradation), and electrical properties (conductivity, insulation) depending on the product’s intended use. For example, a high-strength polymer is needed for a structural component, while a biocompatible material is crucial for medical implants.

- Manufacturing Process Compatibility: The chosen material must be compatible with the selected manufacturing method. Injection molding requires materials that flow well under high pressure, while 3D printing necessitates materials with specific melting points or curing properties. Trying to use a brittle material in a process requiring flexibility will lead to failure.

- Cost: Material cost is a significant factor, especially during prototyping. However, cheap materials might compromise quality or require more complex processing, increasing overall costs. A cost analysis needs to balance initial material cost against manufacturing and potential scrap.

- Availability and Sustainability: The material’s availability, sourcing, and environmental impact should be considered. Choosing sustainable and ethically sourced materials is becoming increasingly important.

- Aesthetics: For consumer products, appearance matters. The material’s color, texture, and finish should meet the design requirements. This might involve using special coatings or finishes.

For example, in a recent project developing a wearable fitness tracker, we initially considered using a less expensive ABS plastic. However, due to its susceptibility to scratching and its less-than-ideal biocompatibility, we opted for a more durable, slightly more expensive polycarbonate, improving the product’s longevity and user experience.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

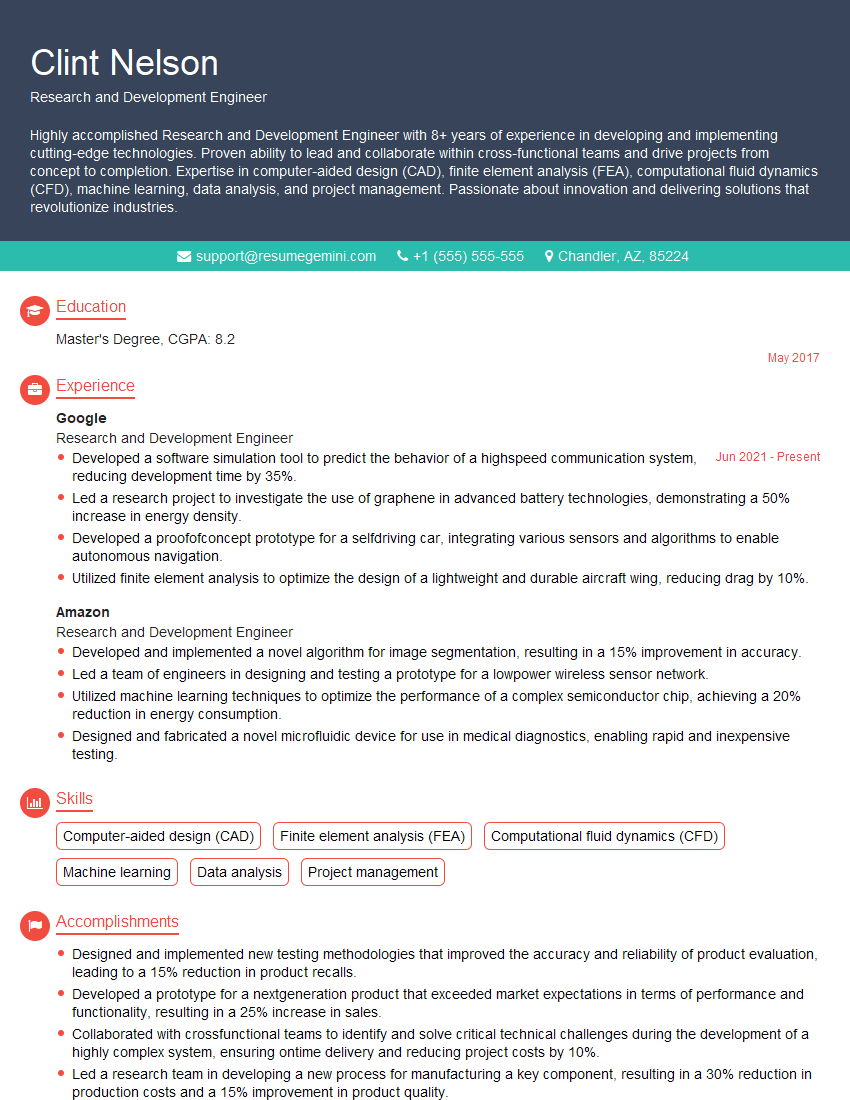

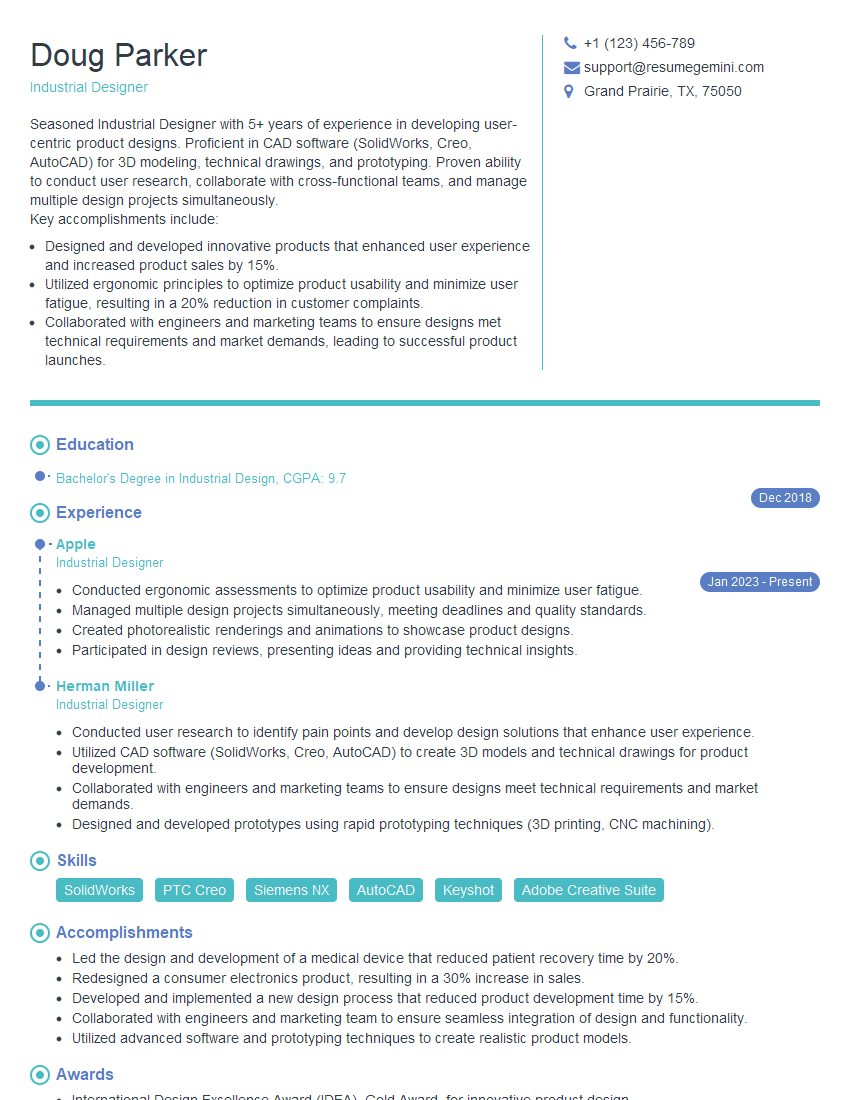

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you assess the cost-effectiveness of different prototyping methods?

Assessing the cost-effectiveness of different prototyping methods requires a detailed comparison of various factors. It’s not just about the initial cost of the prototype; we need to consider the speed, accuracy, material costs, tooling costs, and potential scalability to mass production.

- 3D Printing (Additive Manufacturing): Offers fast prototyping with relatively low tooling costs, ideal for complex geometries. However, material costs can be high, and surface finish might require post-processing.

- CNC Machining (Subtractive Manufacturing): Precise and suitable for high-quality prototypes, but tooling costs can be significant, especially for complex parts. It’s slower than 3D printing for complex parts.

- Injection Molding: Excellent for mass production, but requires expensive tooling, making it less cost-effective for low-volume prototypes.

- Casting: Relatively inexpensive for simple geometries, but surface finish may be rough, requiring post-processing.

To compare cost-effectiveness, I usually create a spreadsheet detailing the costs for each method, including material, labor, tooling, and post-processing. We then weigh this against the prototype’s required accuracy, speed of production, and scalability. For instance, for a simple functional prototype, 3D printing might be the most cost-effective. For high-volume production later, injection molding would likely be preferred.

Q 17. Describe your experience with quality control procedures in manufacturing.

Quality control is crucial throughout the entire manufacturing process, from material inspection to final product testing. My experience involves implementing and managing a multi-stage quality control system.

- Incoming Inspection: Verifying the quality of raw materials, ensuring they meet specifications. This includes dimensional checks, material testing, and visual inspection.

- In-Process Inspection: Monitoring the manufacturing process at various stages to identify and correct defects early. This is done through regular sampling and testing.

- Final Inspection: Thorough testing of the finished product to ensure it meets all specifications. This might include functional testing, performance testing, and dimensional inspection.

- Statistical Process Control (SPC): Using statistical methods to monitor and control the manufacturing process, minimizing variations and improving quality.

- Root Cause Analysis (RCA): Investigating the causes of defects to implement corrective actions and prevent recurrence. We use methods such as the 5 Whys and fishbone diagrams.

In one project involving the production of precision medical devices, we implemented a rigorous quality control system, including automated optical inspection and dimensional measurement. This reduced the defect rate by 80% and significantly improved product reliability.

Q 18. How do you use data analysis to improve the prototyping and manufacturing process?

Data analysis plays a critical role in optimizing the prototyping and manufacturing process. By collecting and analyzing data from various sources, we can identify bottlenecks, improve efficiency, and enhance quality.

- Process Monitoring Data: Data from sensors and machines (e.g., cycle times, temperature, pressure) can be analyzed to identify variations and potential issues in the manufacturing process.

- Quality Control Data: Data from inspections and testing (e.g., defect rates, dimensional accuracy) helps identify areas requiring improvement.

- Material Data: Analyzing material properties and performance data can lead to better material selection and process optimization.

We use statistical software and data visualization tools to analyze this data. For example, control charts help identify trends and variations in the process, while regression analysis can reveal relationships between process parameters and product quality. In one project, we used data analysis to optimize the injection molding process, reducing cycle time by 15% and improving the dimensional accuracy of the parts.

Q 19. Explain your experience with lean manufacturing principles.

Lean manufacturing focuses on eliminating waste and maximizing efficiency throughout the production process. My experience incorporates several key lean principles.

- Value Stream Mapping: Identifying and visualizing all the steps involved in the manufacturing process to pinpoint areas of waste and inefficiencies.

- 5S Methodology: Organizing the workplace to improve efficiency and reduce errors. This involves sorting, setting in order, shining, standardizing, and sustaining.

- Kaizen (Continuous Improvement): Implementing small, incremental improvements to continuously enhance the manufacturing process. This involves regular review and feedback loops.

- Just-in-Time (JIT) Inventory: Minimizing inventory levels by ordering materials only when needed, reducing storage costs and waste.

In a previous role, we implemented lean manufacturing principles in our production line, resulting in a 20% reduction in lead time and a 10% decrease in inventory costs. This involved streamlining the workflow, reducing material handling, and improving communication across teams.

Q 20. How do you collaborate with cross-functional teams in a prototyping project?

Successful prototyping requires effective collaboration across multiple disciplines. My approach focuses on clear communication, shared goals, and well-defined roles.

- Regular Meetings: Holding frequent meetings to discuss project progress, address challenges, and ensure alignment between teams.

- Shared Communication Platforms: Using collaborative tools (e.g., project management software, shared document repositories) to facilitate information sharing.

- Well-Defined Roles and Responsibilities: Clearly defining each team member’s role and responsibilities to avoid confusion and ensure accountability.

- Open Communication: Encouraging open communication and feedback across teams to address issues promptly.

In a recent project, we had a team composed of engineers, designers, and marketers. Using Agile methodologies, we held daily stand-up meetings to review progress and address roadblocks, allowing seamless collaboration and quick adjustments. This significantly reduced the time needed for the prototyping process.

Q 21. Describe your experience with project management methodologies (e.g., Agile, Scrum).

I have extensive experience with Agile and Scrum methodologies, particularly in the context of rapid prototyping. These frameworks allow for flexibility and adaptability, which are essential in the face of evolving project requirements.

- Agile: Focuses on iterative development, frequent feedback loops, and adapting to changing requirements. It promotes collaboration and continuous improvement.

- Scrum: A specific Agile framework that uses sprints (short, time-boxed iterations) to deliver incremental progress. It emphasizes teamwork, daily stand-up meetings, sprint reviews, and retrospectives.

In a recent project, we employed a Scrum framework for a complex medical device prototype. The use of sprints allowed us to frequently assess progress, incorporate feedback, and adapt to changes in design or functionality. This iterative approach ensured a successful outcome and avoided significant rework, ultimately shortening the overall project timeline.

Q 22. How do you troubleshoot problems encountered during prototyping or manufacturing?

Troubleshooting in rapid prototyping and manufacturing is a systematic process. It involves a combination of analytical thinking, practical problem-solving skills, and a deep understanding of the materials and processes involved. I typically follow a structured approach:

- Identify the Problem: Clearly define the issue. Is it a dimensional inaccuracy? A material defect? A process failure? Detailed documentation, including photos and measurements, is crucial at this stage.

- Isolate the Root Cause: Use various techniques like the 5 Whys analysis to drill down to the underlying cause. This might involve analyzing process parameters, inspecting raw materials, checking equipment calibration, or even reviewing the design itself. For example, if a 3D-printed part is warping, the root cause could be insufficient cooling, improper support structures, or inherent material properties.

- Develop and Test Solutions: Based on the root cause, propose potential solutions. These could range from adjusting process parameters (e.g., printing temperature, layer height) to modifying the design, changing materials, or even investing in new equipment. Prototyping solutions is key here, quickly testing and iterating to refine until success.

- Implement and Validate: Once a solution is identified, implement it and carefully monitor the results. Collect data to verify that the problem is resolved and that the solution doesn’t introduce new issues.

- Document Findings: Meticulously document the problem, the troubleshooting process, the implemented solution, and the results. This creates a valuable knowledge base for future reference and helps prevent similar problems from recurring.

For example, I once encountered delamination in a CNC-machined part. By analyzing the toolpaths, material properties and cutting parameters, I discovered the issue stemmed from excessive cutting speeds causing the material to overheat and delaminate. Reducing the speed and using a coolant resolved the problem.

Q 23. What are your strategies for optimizing the manufacturing process?

Optimizing the manufacturing process is about maximizing efficiency, minimizing waste, and improving quality. My strategies include:

- Lean Manufacturing Principles: Implementing lean methodologies such as eliminating waste (muda), optimizing workflow (kaizen), and just-in-time inventory management can significantly improve efficiency and reduce costs. This involves carefully analyzing every step of the process to identify and remove bottlenecks.

- Process Mapping and Value Stream Mapping: Visually mapping the entire manufacturing process helps pinpoint areas for improvement. This allows for identification of non-value-added steps that can be eliminated or streamlined.

- Statistical Process Control (SPC): Using SPC techniques to monitor key process variables helps detect variations and prevent defects. Control charts are invaluable in maintaining consistency and quality.

- Automation: Automating repetitive or labor-intensive tasks through robotics or specialized machinery can increase throughput, reduce human error, and enhance consistency. This also allows for improved scalability.

- Design for Manufacturing (DFM): Integrating DFM principles in the design phase ensures that the product is easily and cost-effectively manufacturable. This involves considering material selection, tolerances, assembly methods, and overall manufacturability during the design phase.

For instance, in a previous project, we used value stream mapping to identify a bottleneck in the assembly process. By rearranging workstations and implementing a simple Kanban system, we reduced assembly time by 20%.

Q 24. Describe your experience with automation in manufacturing.

My experience with automation in manufacturing spans several areas, including robotic process automation (RPA), Computer Numerical Control (CNC) machining, and automated assembly lines. I’ve worked with both industrial robots for tasks such as welding, painting and material handling, and programmable logic controllers (PLCs) for controlling automated systems.

I understand the importance of integrating automation effectively, considering factors like return on investment (ROI), safety protocols, and the need for human oversight in many manufacturing processes. For example, in a previous project, we implemented a robotic arm for automated pick-and-place operations in an electronics assembly line. This significantly increased production speed and reduced human error associated with manual placement of components. Successful automation requires careful planning, programming, and rigorous testing to ensure reliability and safety.

Q 25. How familiar are you with industry standards and regulations related to manufacturing?

I am very familiar with relevant industry standards and regulations. My knowledge covers areas such as:

- ISO 9001: Quality management systems.

- ISO 14001: Environmental management systems.

- OSHA regulations: Occupational safety and health standards for manufacturing environments.

- Industry-specific standards: Depending on the industry, there will be more specific standards relating to materials, processes, and product safety. For example, in the medical device industry, the FDA’s regulations are paramount.

I understand the importance of adhering to these standards not only for compliance but also to ensure product quality, worker safety, and environmental responsibility. My experience includes working with audits and ensuring that manufacturing processes are compliant with all relevant regulations.

Q 26. Explain your understanding of sustainable manufacturing practices.

Sustainable manufacturing is crucial for the long-term viability of any manufacturing operation. My understanding encompasses several key aspects:

- Reduce, Reuse, Recycle: Minimizing waste generation through efficient processes, reusing materials whenever possible, and implementing robust recycling programs are fundamental. This extends to minimizing energy consumption and water usage.

- Green Materials: Utilizing eco-friendly materials and reducing the use of hazardous substances minimizes environmental impact. This involves considering the entire lifecycle of the material, from extraction to disposal.

- Energy Efficiency: Implementing energy-efficient equipment and processes, optimizing energy consumption, and exploring renewable energy sources significantly reduce a manufacturing operation’s carbon footprint.

- Waste Management: Developing efficient waste management strategies, including waste reduction, segregation, and proper disposal, are essential for environmental responsibility.

- Lifecycle Assessment (LCA): Conducting LCAs to evaluate the environmental impact of a product throughout its entire lifecycle, from raw material acquisition to disposal, allows for informed decision-making and continuous improvement in sustainability.

For example, in a past project, we successfully integrated a closed-loop water recycling system, significantly reducing our water consumption and waste discharge.

Q 27. How do you stay updated with the latest advancements in rapid prototyping and manufacturing technologies?

Staying updated in the rapidly evolving fields of rapid prototyping and manufacturing is essential. My strategies include:

- Professional Organizations: Active participation in professional organizations such as ASME, SME, and IEEE provides access to conferences, publications, and networking opportunities.

- Industry Publications and Journals: Regularly reading industry publications and journals keeps me informed about the latest technological advancements, research breakthroughs, and industry trends.

- Conferences and Workshops: Attending industry conferences and workshops provides valuable opportunities for learning about cutting-edge technologies and networking with experts.

- Online Courses and Webinars: Utilizing online learning platforms and attending webinars offers convenient and flexible ways to learn about new techniques and technologies.

- Industry News and Blogs: Following industry news websites and blogs helps me stay informed about the latest developments and emerging technologies.

Continuous learning is vital in this dynamic field. I actively seek out opportunities to expand my knowledge and keep abreast of the latest innovations.

Q 28. Describe a time you had to solve a complex problem related to prototyping or manufacturing.

During the development of a new medical device, we encountered a significant challenge with the biocompatibility of a specific polymer used in the device’s housing. Initial prototypes exhibited unacceptable levels of cytotoxicity, rendering the device unsafe for human use.

To solve this, I implemented a structured problem-solving approach:

- Root Cause Analysis: We performed extensive testing to determine the specific components of the polymer responsible for the cytotoxic reaction. This involved collaborating with materials scientists and conducting various biocompatibility tests.

- Material Substitution: Based on the analysis, we identified several alternative polymers that met the necessary mechanical properties while exhibiting improved biocompatibility. We created prototypes using these materials.

- Iterative Testing and Refinement: We tested each prototype rigorously, iteratively refining the material selection and processing parameters to optimize both biocompatibility and mechanical performance. This involved numerous iterations of testing and refinement.

- Regulatory Compliance: Throughout the process, we ensured compliance with all relevant regulatory requirements related to medical device biocompatibility.

Ultimately, we identified a suitable polymer that met all biocompatibility and performance requirements. This resulted in a successful product launch and demonstrated the importance of meticulous problem-solving and thorough testing in the medical device industry.

Key Topics to Learn for Rapid Prototyping and Manufacturing Interview

- Additive Manufacturing Processes: Understanding various techniques like Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Melting (SLM), and their respective strengths and weaknesses. Consider the materials used and their properties.

- Subtractive Manufacturing Processes: Familiarize yourself with CNC machining, milling, and turning. Be prepared to discuss tolerances, surface finishes, and material selection considerations.

- Design for Manufacturing (DFM): This is crucial! Understand how design choices impact manufacturability, cost, and lead time. Be able to discuss design considerations for different manufacturing processes.

- Rapid Prototyping Software and Tools: Gain proficiency in CAD software (SolidWorks, AutoCAD, Fusion 360, etc.) and CAM software for generating toolpaths. Understanding file formats (STL, STEP) is also important.

- Material Selection: Know the properties of common prototyping and manufacturing materials (plastics, metals, composites) and how to choose the right material for a specific application, considering factors like strength, durability, and cost.

- Process Optimization and Troubleshooting: Be ready to discuss common challenges in rapid prototyping and manufacturing and how to overcome them. This shows problem-solving skills.

- Quality Control and Inspection: Understanding quality control methods and inspection techniques is essential for ensuring the quality of prototypes and manufactured parts.

- Cost Estimation and Project Management: Discuss your experience in estimating costs for rapid prototyping and manufacturing projects and managing projects effectively.

Next Steps

Mastering rapid prototyping and manufacturing opens doors to exciting and innovative roles in diverse industries. To maximize your job prospects, crafting a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Rapid Prototyping and Manufacturing, helping you present your qualifications in the best possible light. Take the next step towards your dream career – build a resume that gets noticed!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO