Cracking a skill-specific interview, like one for Resolve Conflicts and Ensure Safety, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Resolve Conflicts and Ensure Safety Interview

Q 1. Describe your experience in developing and implementing safety protocols.

Developing and implementing safety protocols involves a systematic approach encompassing risk assessment, policy creation, training, and ongoing monitoring. It’s not just about creating a document; it’s about embedding a safety culture.

In my previous role at a construction firm, I led the development of a new safety protocol for working at heights. This involved a thorough risk assessment identifying potential hazards like falls, equipment failure, and weather conditions. We then created detailed procedures outlining proper harness usage, fall protection systems, and emergency response plans. This was followed by mandatory training for all personnel, including practical demonstrations and simulations. Finally, we implemented a system of regular inspections and audits to ensure compliance and make necessary adjustments.

Another example involved implementing a lockout/tagout (LOTO) procedure for machinery maintenance. LOTO ensures that energy sources are isolated before any maintenance work begins, preventing accidental starts. This required extensive training, clear labeling systems, and regular audits to confirm the procedure was consistently followed.

Q 2. How do you identify and assess workplace hazards?

Identifying and assessing workplace hazards requires a proactive and multi-faceted approach. It’s about anticipating potential problems before they occur. This includes regular workplace inspections, utilizing hazard checklists, and actively involving employees in the process.

- Walkthrough Inspections: Regular physical inspections of the workplace to identify immediate hazards like tripping hazards, exposed wiring, or unsafe equipment.

- Hazard Checklists: Using pre-designed checklists tailored to specific work areas to ensure consistent identification of potential risks.

- Job Hazard Analysis (JHA): A systematic process of identifying hazards specific to individual tasks and developing control measures.

- Employee Input: Encouraging employees to report hazards, as they are often the ones who best understand the risks they face daily. This can be achieved through suggestion boxes, regular safety meetings, or informal conversations.

Once hazards are identified, we assess their severity and likelihood using a risk matrix. This allows us to prioritize our efforts and allocate resources effectively. For example, a high-severity, high-likelihood hazard (like unguarded machinery) would require immediate corrective action, while a low-severity, low-likelihood hazard (like a minor trip hazard) may be addressed through a longer-term improvement plan.

Q 3. Explain your approach to conflict resolution in a high-pressure environment.

Conflict resolution in high-pressure environments requires a calm, assertive approach focused on de-escalation and finding mutually acceptable solutions. My approach is based on active listening, clear communication, and collaborative problem-solving.

Firstly, I prioritize creating a safe space for open communication where individuals feel comfortable expressing their concerns without fear of reprisal. Then I actively listen to understand each party’s perspective, clarifying any misunderstandings and focusing on the underlying issues, not just the symptoms. I avoid taking sides and encourage parties to collaborate towards a solution.

For example, during a project deadline crunch, two team members had a disagreement over resource allocation, leading to tension. Instead of assigning blame, I facilitated a discussion where each member articulated their needs and concerns. We then brainstormed solutions, such as adjusting task assignments or re-allocating resources, leading to a mutually agreed-upon resolution that maintained project timelines and improved team morale.

If a resolution cannot be reached through collaboration, I might involve a neutral third party as a mediator to facilitate the process.

Q 4. What methods do you use to investigate workplace accidents?

Investigating workplace accidents involves a methodical approach to determine the root cause and prevent recurrence. This usually involves gathering information from multiple sources, analyzing data, and implementing corrective actions.

- Secure the Scene: The immediate priority is to secure the area to prevent further injury and preserve evidence.

- Witness Interviews: Conduct interviews with witnesses to gather their accounts of the event. It’s crucial to avoid leading questions and to document the information accurately.

- Data Collection: Collect evidence such as photos, videos, maintenance logs, and any relevant documentation.

- Root Cause Analysis: Use tools like the “5 Whys” technique to identify the underlying cause of the accident, going beyond the immediate cause to understand the systemic factors that contributed to the event.

- Corrective Actions: Based on the findings, implement corrective actions to prevent similar accidents from happening in the future. This may involve modifying procedures, improving equipment, or enhancing training.

For instance, if an employee was injured while operating a machine, the investigation would involve inspecting the machine for malfunctioning parts, reviewing the employee’s training records, and examining the work procedures to identify any gaps in safety protocols.

Q 5. How do you ensure effective communication during a safety crisis?

Effective communication during a safety crisis is paramount. It requires a clear, concise, and consistent message delivered through multiple channels to ensure everyone is informed and knows their role. This involves designating communication leads, establishing clear communication channels, and using multiple methods to reach a wide audience.

In a crisis, I would establish a central communication hub to coordinate the flow of information. This hub would use various methods to disseminate information, such as: email alerts, text messages, public address systems, and even emergency response apps. The messages would be consistently updated to keep everyone informed and to avoid the spread of misinformation. Clear and concise messages, free from jargon, are key. The messaging should outline the nature of the crisis, the immediate actions required, and the location of any assembly points.

Regular updates are critical, both during and after the event. Post-incident, it’s important to debrief the team to evaluate the response and identify areas for improvement in future emergency response plans.

Q 6. Describe your experience in conducting safety training.

Conducting safety training involves more than just lecturing; it needs to engage participants and foster a safety-conscious mindset. My approach combines various methods to ensure effective knowledge transfer and skill development.

- Needs Assessment: Identifying specific training needs based on the risks faced by employees in their roles.

- Interactive Methods: Using diverse techniques, such as case studies, simulations, hands-on exercises, and group discussions to enhance engagement and learning retention.

- Practical Demonstrations: Providing real-world demonstrations of safe working procedures and the use of safety equipment.

- Regular Refreshers: Offering periodic refresher courses to reinforce learning and to address any changes in procedures or equipment.

- Assessment and Feedback: Evaluating participant learning through quizzes, practical tests, and providing constructive feedback to identify areas for improvement.

For example, when training on the use of forklifts, I would include both classroom instruction on operating procedures and safety regulations, followed by hands-on practice in a controlled environment. This practical experience allows employees to apply their knowledge and build confidence before operating equipment independently.

Q 7. How do you prioritize safety risks and allocate resources accordingly?

Prioritizing safety risks and allocating resources involves a structured approach that considers both the likelihood and severity of potential hazards. This usually involves using a risk matrix, conducting cost-benefit analysis, and considering regulatory compliance.

I typically begin with a comprehensive risk assessment to identify all potential hazards and their associated risks. Then I use a risk matrix to rate each hazard based on its likelihood and severity. This provides a clear picture of the relative importance of each risk. Hazards with high likelihood and severity are prioritized, while low-likelihood/low-severity risks may be addressed through less intensive measures.

Following the prioritization, we conduct a cost-benefit analysis to evaluate the cost of implementing control measures against the potential costs of not implementing them (e.g., injury, legal fees, production downtime). This helps ensure resources are allocated effectively. Additionally, we must consider regulatory compliance – ensuring our actions meet or exceed all legal and industry standards. For example, investing in high-quality safety equipment is crucial, even if expensive, if it significantly reduces the risk of serious injury.

Q 8. What are your strategies for mitigating safety risks?

Mitigating safety risks involves a proactive and multi-layered approach. It’s not just about reacting to accidents but preventing them in the first place. My strategy focuses on three key areas: hazard identification, risk assessment, and control implementation.

Hazard Identification: This involves systematically identifying potential hazards in the workplace. This could be through regular workplace inspections, job hazard analyses (JHAs), or even employee feedback. For example, in a manufacturing plant, a JHA might reveal that a particular machine poses a risk of crushing injuries if safety guards aren’t properly maintained.

Risk Assessment: Once hazards are identified, we need to assess the likelihood and severity of potential harm. This helps prioritize which hazards need immediate attention. We use a risk matrix to categorize risks (low, medium, high) and decide on appropriate control measures. For instance, a high risk might warrant immediate machine shutdown and repair, while a low risk might only need a simple procedural change.

Control Implementation: This is where we put preventative measures in place. This could involve engineering controls (e.g., machine guarding, ventilation systems), administrative controls (e.g., safety procedures, training programs), or personal protective equipment (PPE) like safety glasses or gloves. Regular monitoring and review are crucial to ensure these controls remain effective.

Essentially, it’s a continuous cycle of identifying, assessing, controlling, and monitoring. This proactive approach minimizes risk and fosters a culture of safety.

Q 9. How do you handle disagreements between employees regarding safety procedures?

Disagreements about safety procedures are inevitable, but they can be valuable opportunities for improvement if handled constructively. My approach emphasizes open communication, collaboration, and a focus on finding a solution that ensures safety for everyone.

Facilitated Discussion: I would facilitate a discussion between the disagreeing employees, ensuring a safe and respectful environment where everyone feels heard. The goal is to understand the root of the disagreement – is it a misunderstanding of the procedure, a concern about its practicality, or something else?

Data-Driven Decision Making: If the disagreement is about the effectiveness of a procedure, I would rely on data to support a decision. Accident reports, near-miss incidents, and productivity data can all provide valuable insights. For example, if one employee argues for a different procedure that has demonstrably improved safety in other areas, this data should be considered.

Collaborative Solution: Ultimately, the solution should be developed collaboratively. Involving everyone ensures buy-in and ownership of the revised safety procedure. The aim is to find the safest and most practical approach, not to simply enforce a particular viewpoint.

Documentation and Training: Once a solution is agreed upon, it needs to be properly documented and communicated to all relevant personnel. Refresher training might be needed to ensure everyone understands the updated procedure.

This process prioritizes safety while also fostering a team environment where everyone feels empowered to contribute to safety improvements.

Q 10. Explain your experience in working with regulatory agencies on safety compliance.

I’ve had extensive experience working with regulatory agencies, particularly OSHA (Occupational Safety and Health Administration). This involved maintaining detailed safety records, conducting regular inspections to ensure compliance, and responding to agency inquiries. My experience has shown me the importance of understanding and adhering to all relevant regulations.

Record Keeping: Meticulous record-keeping is crucial. This includes documenting all safety training, inspections, accident investigations, and corrective actions. Having this information readily available is essential for demonstrating compliance during audits.

Proactive Compliance: Rather than waiting for inspections, we proactively identify areas where improvements are needed and address them immediately. This demonstrates a commitment to safety and reduces the likelihood of citations.

Effective Communication: Open and honest communication with regulatory agencies is key. Promptly addressing any concerns or deficiencies builds trust and fosters a collaborative relationship.

My approach to working with regulatory agencies is to be proactive, transparent, and collaborative, demonstrating a commitment to upholding the highest safety standards.

Q 11. Describe a situation where you had to negotiate a solution to a safety-related conflict.

In a previous role, a disagreement arose between the maintenance crew and the operations team regarding the lockout/tagout (LOTO) procedure for a high-speed production line. The maintenance crew preferred a faster, less rigorous procedure, while the operations team was concerned about the increased risk of accidental start-up. This could have led to serious injury.

To resolve this, I facilitated a meeting between both teams, bringing in a safety consultant with LOTO expertise. We reviewed the existing procedure, examined incident reports, and discussed the potential consequences of different approaches. The consultant provided data demonstrating that the more stringent procedure, while time-consuming, significantly reduced the risk of accidents. Through a collaborative discussion, we agreed on a slightly modified version of the operations team’s preferred procedure that addressed the maintenance team’s concerns about efficiency, using clearly defined steps and time-saving techniques while maintaining the necessary safety level. This collaborative process led to improved safety and increased teamwork between both teams. We documented the revised procedure and provided additional training.

Q 12. How do you use data to improve safety performance?

Data is crucial for improving safety performance. It allows us to identify trends, pinpoint problem areas, and measure the effectiveness of our initiatives. I use data in several ways:

Accident and Incident Reporting: Analyzing accident and near-miss reports reveals patterns and contributing factors. For example, a high number of slips and falls might indicate a need for improved floor maintenance or additional safety training.

Safety Inspections: Data from regular safety inspections highlights areas that require attention. Tracking the frequency and nature of deficiencies helps to identify recurring problems and implement targeted solutions.

Performance Indicators (KPIs): Tracking KPIs like lost-time injury rates (LTIR) and total recordable incident rates (TRIR) helps monitor overall safety performance and identify areas for improvement.

Employee Surveys: Collecting feedback from employees about safety concerns and perceptions can provide valuable insights.

By analyzing this data, I can develop targeted interventions, measure the impact of safety initiatives, and demonstrate a continuous improvement approach.

Q 13. How do you measure the effectiveness of your safety initiatives?

Measuring the effectiveness of safety initiatives requires a multi-faceted approach. I use both leading and lagging indicators:

Lagging Indicators: These reflect past performance and include metrics like LTIR, TRIR, and the number of accidents. While important, they only tell us about what has already happened.

Leading Indicators: These predict future performance and include metrics such as the number of safety training hours completed, the number of safety inspections conducted, and employee safety survey scores. These metrics provide early warnings of potential problems.

By tracking both leading and lagging indicators, I can gain a comprehensive understanding of our safety performance, identify areas for improvement, and demonstrate the return on investment of our safety initiatives.

Q 14. Describe your experience in creating and maintaining a safe work environment.

Creating and maintaining a safe work environment is an ongoing process, not a one-time event. My experience involves establishing a strong safety culture, implementing robust safety procedures, and providing continuous training and support.

Safety Culture: A strong safety culture is paramount. This involves fostering a sense of shared responsibility for safety, empowering employees to identify and report hazards, and recognizing and rewarding safe behaviors. Regular safety meetings, toolbox talks, and employee involvement in safety committees are crucial.

Safety Procedures: Clear, concise, and well-communicated safety procedures are essential. These procedures should cover all aspects of the workplace, from machine operation to emergency response. Regular reviews and updates are vital to ensure their effectiveness.

Training and Support: Comprehensive safety training is crucial, encompassing both initial training and regular refresher courses. Providing ongoing support and resources to employees is essential to maintain a high level of safety awareness and competence.

Hazard Control and PPE: This involves proactively identifying and mitigating hazards through engineering controls, administrative controls, and the provision of appropriate PPE.

Ultimately, creating a safe work environment requires a commitment to continuous improvement, employee involvement, and a belief that safety is everyone’s responsibility.

Q 15. How do you ensure employees are following safety regulations?

Ensuring employee adherence to safety regulations requires a multi-pronged approach that combines proactive measures with consistent monitoring and reinforcement. It’s not just about handing out a rulebook; it’s about building a culture of safety.

- Regular Training and Education: We start with comprehensive safety training tailored to each role and updated regularly to reflect changes in regulations or best practices. This training isn’t a one-time event; it’s integrated into onboarding and supplemented with refresher courses and workshops.

- Clear Communication Channels: Open communication is key. We utilize a variety of methods, from regular safety meetings and email updates to visual aids like posters and safety checklists, to disseminate information effectively. We also encourage employees to voice concerns without fear of retribution.

- Regular Audits and Inspections: We conduct routine workplace inspections to identify potential hazards and ensure compliance with safety protocols. These audits are documented and followed up with corrective actions. This shows employees that safety is a top priority, not just a suggestion.

- Incentive Programs and Recognition: Recognizing and rewarding employees who demonstrate a commitment to safety creates a positive feedback loop. We might offer awards, bonuses, or public acknowledgment for contributions to a safe work environment.

- Consequences for Non-Compliance: While positive reinforcement is crucial, we also have a clear system of consequences for violations of safety regulations. This isn’t about punishment, but about accountability and ensuring the safety of everyone.

For example, in a previous role, we implemented a peer-to-peer safety observation program where employees could report unsafe practices anonymously. This generated valuable insights and improved overall safety awareness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with incident reporting and investigation?

My experience with incident reporting and investigation is extensive. I’ve developed and implemented incident reporting systems in various settings, always emphasizing accuracy, timeliness, and thoroughness. The process is crucial not just for legal reasons but also for learning and preventing future incidents.

- Immediate Response: My first priority is to ensure the safety and well-being of those involved in any incident. Then, I initiate a thorough investigation as quickly as possible, to minimize disruption and preserve evidence.

- Data Collection: We gather data from multiple sources, including eyewitness accounts, injury reports, equipment logs, and any relevant documentation. Interviews are conducted in a neutral and unbiased manner.

- Root Cause Analysis: We don’t just focus on the immediate cause; we dig deeper to understand the underlying factors that contributed to the incident. This often involves using techniques like the ‘5 Whys’ to identify systemic issues.

- Corrective Actions: Once the root causes are identified, we develop and implement corrective actions to prevent similar incidents from occurring in the future. These actions are documented and tracked to ensure effectiveness.

- Reporting and Communication: We prepare comprehensive reports that detail the incident, the investigation findings, and the corrective actions taken. These reports are shared with relevant stakeholders, including management, employees, and regulatory agencies (as required).

In one instance, a near-miss incident revealed a flaw in our training program. By thoroughly investigating, we identified the gap and revised the training, thereby preventing a potential serious accident.

Q 17. How do you communicate safety information to employees effectively?

Effective communication of safety information requires a tailored approach that takes into account different learning styles and communication preferences. It’s about making safety information accessible, engaging, and memorable.

- Multi-Channel Approach: We don’t rely on a single method. We use a combination of methods—safety meetings, email newsletters, posters, videos, interactive training modules—to reach a wider audience and cater to various learning preferences.

- Visual Aids: Visual aids, such as diagrams, infographics, and videos, are highly effective in conveying complex information. They make safety information easier to understand and retain.

- Interactive Training: Hands-on training, simulations, and interactive exercises make the learning process more engaging and improve knowledge retention. This could involve scenarios, quizzes, or practical demonstrations.

- Plain Language: We avoid technical jargon and use plain language that everyone can understand. Safety information should be clear, concise, and easy to follow.

- Feedback and Reinforcement: We encourage feedback from employees to ensure the information is understood and relevant. Regular reminders and reinforcement through different channels are essential.

For instance, we once used a short, engaging video to demonstrate the proper use of personal protective equipment (PPE). This proved far more effective than a written manual.

Q 18. Describe your approach to promoting a safety-conscious culture.

Promoting a safety-conscious culture is not a one-off project; it’s an ongoing process that requires consistent effort and commitment from all levels of the organization. It’s about embedding safety into the fabric of the company.

- Leadership Commitment: Visible and consistent leadership support is paramount. Leaders must actively champion safety initiatives, participate in safety programs, and hold themselves and their teams accountable.

- Employee Engagement: Employees need to feel empowered and involved in the safety process. This means actively soliciting their input, recognizing their contributions, and providing them with the resources and support they need.

- Open Communication: Open and honest communication about safety concerns is crucial. We create a culture where employees feel comfortable reporting hazards or near misses without fear of reprisal.

- Recognition and Rewards: Recognizing and rewarding safe behavior strengthens a safety-conscious culture. We celebrate successes and highlight individuals or teams that demonstrate exceptional safety practices.

- Continuous Improvement: Safety is a journey, not a destination. We continuously review and improve our safety programs based on data, feedback, and best practices.

In a past role, we implemented a ‘Safety Suggestion Box’ where employees could anonymously submit safety recommendations. This fostered a sense of ownership and led to several significant improvements in our safety procedures.

Q 19. How do you handle resistance to safety initiatives?

Resistance to safety initiatives can stem from various factors, including lack of understanding, inconvenience, or even fear of change. Addressing resistance requires empathy, understanding, and a collaborative approach.

- Understand the Root Cause: First, we try to understand why there is resistance. We conduct discussions to identify the underlying concerns and address them directly.

- Open Communication and Education: We clearly explain the rationale behind the safety initiatives, highlighting the benefits and addressing any misunderstandings. We emphasize the importance of safety for everyone.

- Collaboration and Participation: We involve employees in the process of implementing safety initiatives. This ensures they feel heard, valued, and a part of the solution.

- Address Concerns and Provide Support: We address specific concerns, offering solutions and providing necessary support to overcome challenges. This might include additional training, resources, or adjustments to procedures.

- Positive Reinforcement and Recognition: Acknowledging and rewarding those who embrace safety initiatives encourages others to follow suit. We celebrate early successes to build momentum.

Once, I encountered resistance to wearing new safety goggles. By involving the employees in selecting a more comfortable model and highlighting the long-term benefits of eye protection, I successfully overcame the resistance.

Q 20. What are your experience with different conflict resolution models (e.g., mediation, arbitration)?

My experience encompasses various conflict resolution models, each with its strengths and weaknesses. The choice of model depends on the nature of the conflict, the parties involved, and the desired outcome.

- Mediation: I’m skilled in mediation, a process where a neutral third party helps disputing parties reach a mutually acceptable agreement. Mediation is particularly effective in resolving interpersonal conflicts, fostering collaboration and communication.

- Arbitration: I understand and have utilized arbitration, a process where a neutral third party hears evidence and makes a binding decision. Arbitration is more formal than mediation and is often used when parties are unable to reach a resolution through other means.

- Negotiation: This is a fundamental skill; I employ various negotiation techniques, including principled negotiation and integrative bargaining, to help parties reach mutually beneficial outcomes. This involves careful listening, clear communication, and identifying shared interests.

- Collaborative Problem Solving: This approach focuses on identifying the underlying interests of all involved parties and working together to find a solution that satisfies everyone’s needs. It emphasizes a win-win outcome.

In one case, a conflict between two teams over resource allocation was effectively resolved through mediation, resulting in a mutually agreeable solution that avoided disruption to both projects.

Q 21. How do you ensure confidentiality when dealing with safety incidents?

Maintaining confidentiality when handling safety incidents is paramount. It’s essential for protecting the privacy of individuals involved and fostering open reporting. We adhere strictly to ethical guidelines and legal regulations regarding data privacy.

- Data Protection Policies: We have robust data protection policies in place, including access control measures, data encryption, and secure storage of sensitive information. We only share information with authorized personnel on a need-to-know basis.

- Anonymity: Where possible, we maintain anonymity to protect the identity of individuals involved in incidents. This encourages open reporting and reduces the fear of reprisal.

- Legal Compliance: We ensure full compliance with relevant data privacy laws and regulations, such as HIPAA or GDPR (depending on the context). We follow specific procedures for data handling and retention.

- Training and Awareness: Employees involved in incident reporting and investigation receive training on data privacy and confidentiality. We emphasize the importance of protecting sensitive information.

- Secure Reporting Systems: We utilize secure reporting systems to ensure the confidentiality of reported incidents. This includes encrypted communication channels and password-protected access.

We treat all safety incident reports with the utmost confidentiality, releasing information only as required by law or with the explicit consent of those involved.

Q 22. How do you adapt your approach to conflict resolution depending on the situation and individuals involved?

My approach to conflict resolution is highly adaptable and hinges on understanding the specific context and personalities involved. I don’t believe in a one-size-fits-all solution. Instead, I employ a flexible methodology that draws upon several established conflict resolution models, including collaborative problem-solving, mediation, and arbitration, tailoring my approach to the unique dynamics of each situation.

- Understanding the Individuals: I start by assessing the personalities and communication styles of those involved. Are they assertive, passive, or aggressive? Do they prefer direct communication or a more nuanced approach? This helps me choose the right communication strategy – direct and frank discussions might work with some individuals, while others may respond better to a more empathetic and understanding approach.

- The Nature of the Conflict: The nature of the conflict itself dictates my approach. Is it a simple misunderstanding, a clash of personalities, or a deeper-seated issue related to power dynamics or resources? For instance, a minor workplace disagreement might be resolved through informal mediation, while a more serious conflict might require a formal investigation and potentially disciplinary action.

- The Context: The workplace environment also plays a vital role. Is the conflict impacting productivity significantly? Are there safety concerns? These factors determine the urgency and intensity of my intervention. For example, a conflict that threatens safety will require immediate and decisive action, whereas a low-impact disagreement can be handled more gradually.

- Example: In a past project, I encountered a conflict between two team members with very different working styles. One was highly organized and detail-oriented, while the other was more creative and less structured. Instead of forcing conformity, I helped them appreciate each other’s strengths and find ways to complement each other’s working styles, leading to a more productive and harmonious collaboration.

Q 23. Describe your experience in working with diverse teams on safety-related projects.

I have extensive experience working with diverse teams on safety-related projects across various industries. My approach emphasizes inclusivity and leveraging the unique perspectives and cultural backgrounds of each team member. I believe diverse teams bring a wider range of expertise and experience, leading to more robust and effective safety solutions.

- Communication: Clear, consistent communication is paramount, especially with diverse teams. I ensure all team members understand the project’s safety objectives and their individual roles. I utilize multiple communication channels and actively seek feedback to address any language barriers or cultural misunderstandings.

- Cultural Sensitivity: I’m acutely aware of the importance of cultural sensitivity. I make an effort to understand the cultural norms and communication styles prevalent within the team, adapting my approach accordingly. This includes being mindful of non-verbal cues and ensuring communication is culturally appropriate.

- Shared Goals: I emphasize the importance of shared safety goals. By focusing on the common objective of maintaining a safe working environment, I can build a sense of collective responsibility and ownership among team members, regardless of their background.

- Example: On a recent international project, I worked with a team comprising members from the US, UK, and Japan. I had to be very careful to consider cultural differences in communication styles and approaches to conflict resolution. This involved actively seeking feedback, allowing ample time for discussion and decision-making, and clearly outlining expectations for participation in safety procedures.

Q 24. How do you stay up-to-date on current safety regulations and best practices?

Staying updated on current safety regulations and best practices is a continuous process. I utilize a multi-pronged approach to ensure my knowledge remains current and relevant.

- Professional Organizations: I’m an active member of several professional organizations focused on safety, such as [mention relevant organizations]. These organizations offer regular updates, webinars, and conferences that keep me informed about the latest regulations and best practices.

- Industry Publications: I regularly read industry-specific journals and publications that provide in-depth analysis of safety trends and emerging issues.

- Online Resources: I leverage online resources such as government websites and reputable safety websites for information on new regulations and best practices.

- Training and Certifications: I actively seek out and participate in relevant training courses and certification programs to update my skills and knowledge. This allows me to stay abreast of evolving safety standards and technologies.

- Networking: Networking with other professionals in the field is crucial. Attending conferences and workshops provides opportunities to learn from the experiences of others and discuss emerging trends.

Q 25. Describe a time you had to make a difficult decision that impacted safety.

In a previous role, I had to make a difficult decision regarding the implementation of a new safety protocol. The new protocol, while significantly improving safety, would temporarily reduce productivity. Initially, there was significant resistance from the production team who felt the impact on output would be unacceptable.

My approach was to transparently explain the rationale behind the new protocol, highlighting the potential safety risks involved if it wasn’t implemented. I presented data on previous near-miss incidents and potential costs associated with accidents. I also engaged the production team in the process, inviting their input on how to minimize the impact on productivity. We collaborated to devise a phased implementation plan, allowing for a gradual transition and minimizing disruption. The outcome was a more secure working environment, and although initial productivity was slightly affected, it quickly recovered and eventually surpassed previous levels due to reduced downtime from accidents.

Q 26. How do you handle situations where safety procedures are not followed?

When safety procedures are not followed, I employ a progressive disciplinary approach, prioritizing corrective action and education over immediate punishment. My goal is to prevent future incidents and foster a culture of safety.

- Identifying the Root Cause: My first step is to understand why the procedure was not followed. Was it due to a lack of training, unclear instructions, inadequate equipment, or a deliberate disregard for safety? This helps me address the underlying issue.

- Coaching and Training: If the non-compliance stems from a lack of understanding or training, I provide additional training and coaching to ensure the individual understands and can follow the safety procedures correctly.

- Disciplinary Action: In cases of deliberate disregard for safety rules or repeated non-compliance, I’ll implement disciplinary action, in accordance with company policy. This may range from verbal warnings to written reprimands, suspension, or termination depending on the severity of the infraction.

- Reporting and Documentation: All incidents of non-compliance are thoroughly documented and reported. This ensures that issues are tracked and addressed promptly and serves as a record for future reference.

Q 27. What are your strategies for preventing workplace violence?

Preventing workplace violence requires a multi-faceted approach that addresses both proactive measures and reactive responses. My strategies focus on creating a positive and supportive work environment, while also establishing clear protocols for managing violent situations.

- Zero-Tolerance Policy: A clear zero-tolerance policy for violence and harassment is paramount. This policy must be communicated effectively to all employees and enforced consistently.

- Training and Education: Regular training programs that educate employees on identifying and responding to potentially violent situations are essential. This includes conflict resolution techniques, de-escalation strategies, and awareness of warning signs.

- Reporting Mechanisms: Establishing confidential and accessible reporting mechanisms empowers employees to report incidents or concerns without fear of retribution. This may include an anonymous reporting system or designated personnel.

- Workplace Assessments: Conducting regular workplace assessments can help identify potential risks and hazards that could contribute to violence. This could include reviewing security protocols, assessing lighting and access control, and implementing measures to improve workplace security.

- Conflict Resolution: Providing training in conflict resolution techniques helps employees manage disagreements peacefully and constructively, reducing the likelihood of violence escalating.

Q 28. How do you balance safety concerns with productivity requirements?

Balancing safety concerns with productivity requirements is a critical aspect of my role. It’s not a question of choosing one over the other; it’s about finding a synergy where both are optimized. I achieve this through proactive planning, effective communication, and a focus on long-term goals.

- Prioritizing Safety: Safety should always be the top priority. Compromising safety for short-term gains is unacceptable and potentially disastrous. Cutting corners on safety procedures may lead to accidents, which will inevitably result in significant loss of productivity, not to mention the potential for serious injury or even death.

- Proactive Risk Assessment: A thorough risk assessment is critical. By identifying potential hazards and implementing preventative measures, I can minimize risks before they result in accidents or disruptions to productivity.

- Process Optimization: Often, improvements in safety measures can also lead to improvements in efficiency. By streamlining processes and implementing ergonomic improvements, I can enhance both safety and productivity.

- Open Communication: Open communication is crucial to foster a culture of safety and avoid conflicts. Keeping all stakeholders informed about safety initiatives, potential risks, and productivity projections enables transparency and cooperation.

- Investing in Safety: Investing in appropriate safety equipment, training, and processes may seem costly upfront but will pay off significantly in the long run by preventing accidents, reducing downtime, and improving morale.

Key Topics to Learn for Resolve Conflicts and Ensure Safety Interview

- Conflict Resolution Models: Understanding different approaches like mediation, negotiation, and arbitration, and knowing when to apply each.

- De-escalation Techniques: Practical skills in calming tense situations, active listening, and empathetic communication to prevent escalation.

- Risk Assessment and Mitigation: Identifying potential hazards, evaluating risks, and implementing preventative measures to ensure safety.

- Communication Strategies: Effective verbal and nonverbal communication to address concerns, build rapport, and foster collaboration in challenging situations.

- Safety Protocols and Procedures: Familiarity with relevant safety regulations, emergency response plans, and reporting procedures.

- Ethical Considerations: Understanding the ethical implications of decision-making in conflict resolution and safety scenarios.

- Legal Frameworks: Basic understanding of relevant laws and regulations pertaining to safety and liability.

- Teamwork and Collaboration: Demonstrating the ability to work effectively with others to address conflicts and ensure a safe environment.

- Problem-Solving and Critical Thinking: Applying analytical skills to identify root causes of conflicts and develop effective solutions.

- Documentation and Reporting: Accurately recording incidents, investigations, and actions taken to resolve conflicts and ensure safety.

Next Steps

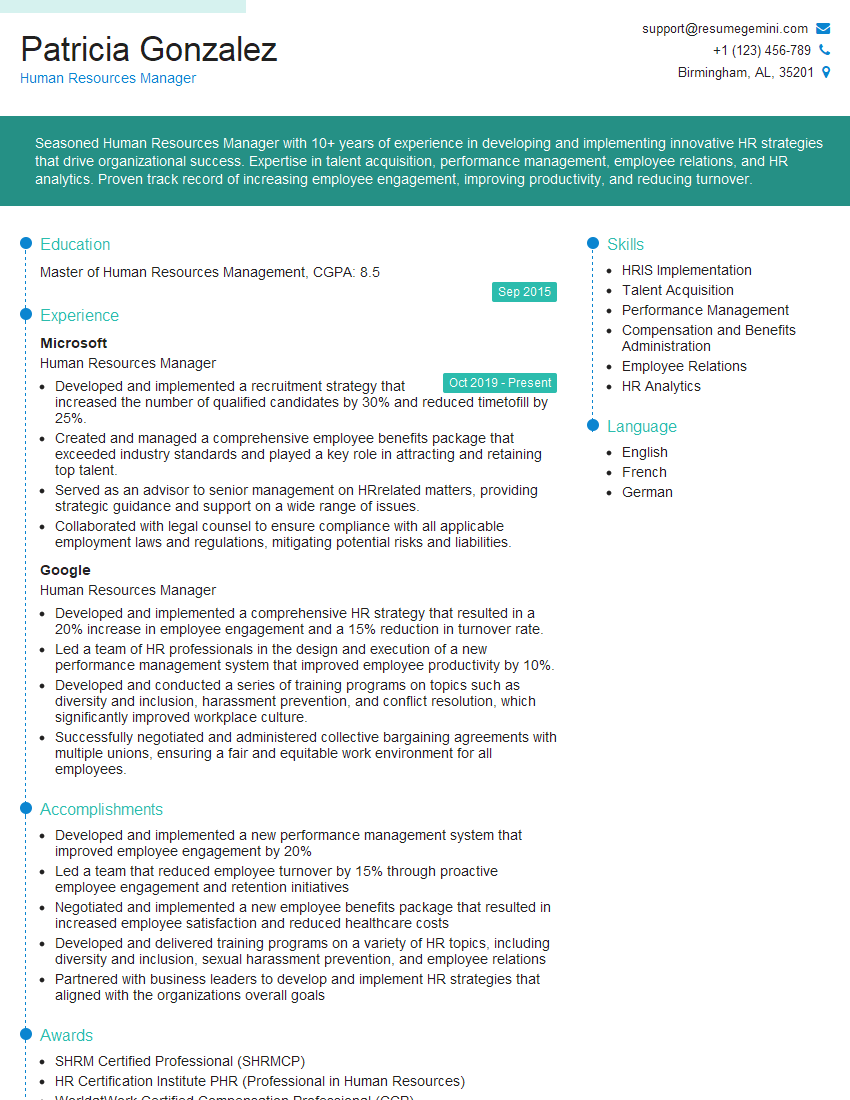

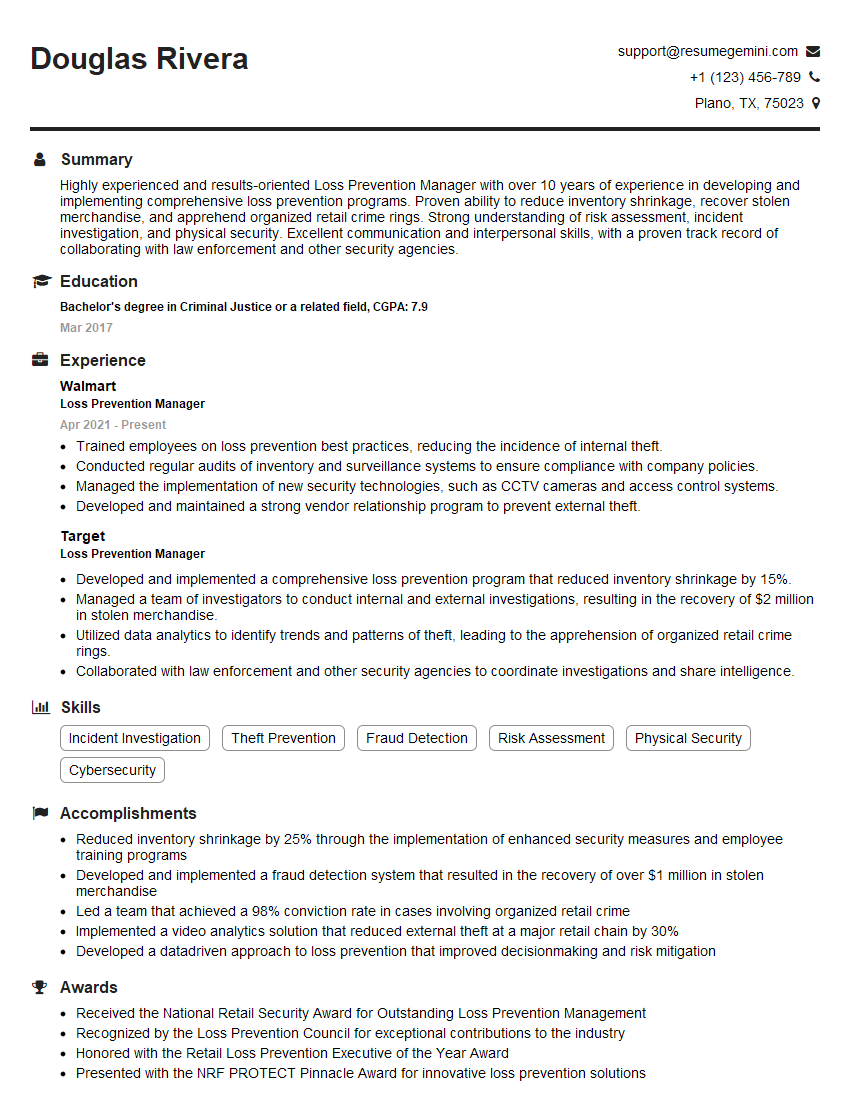

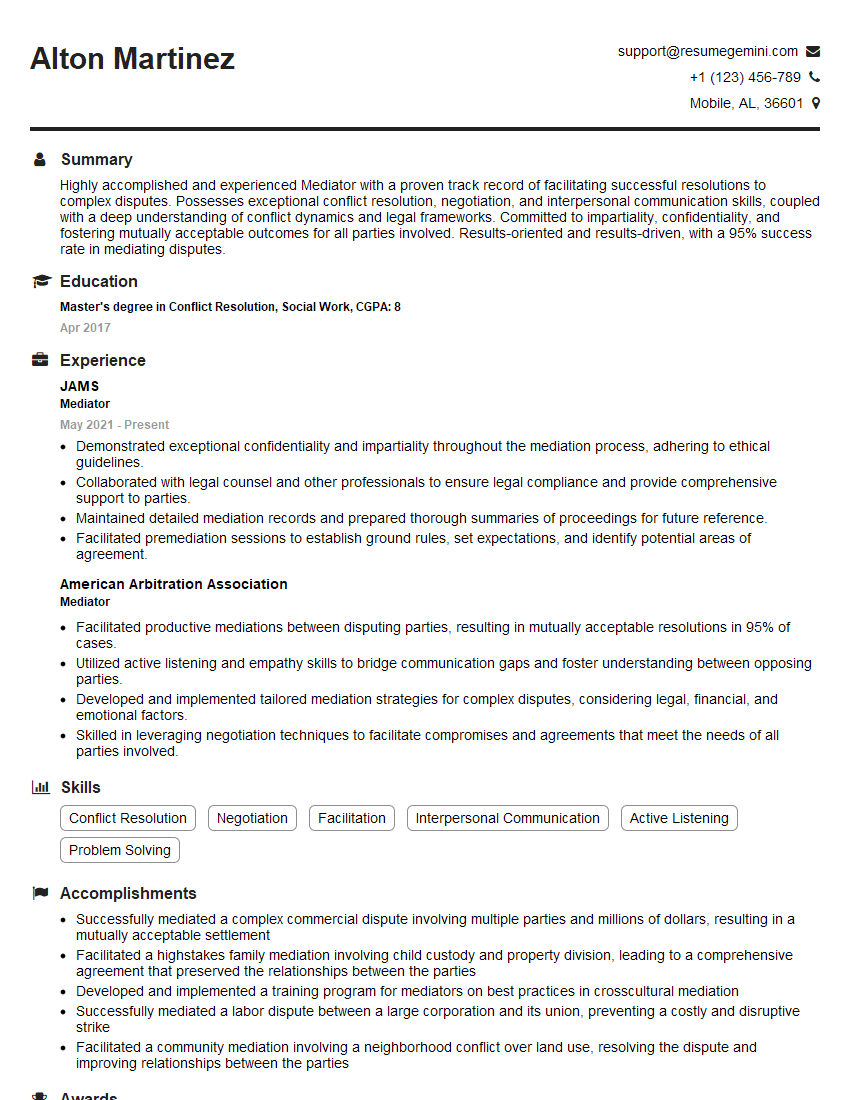

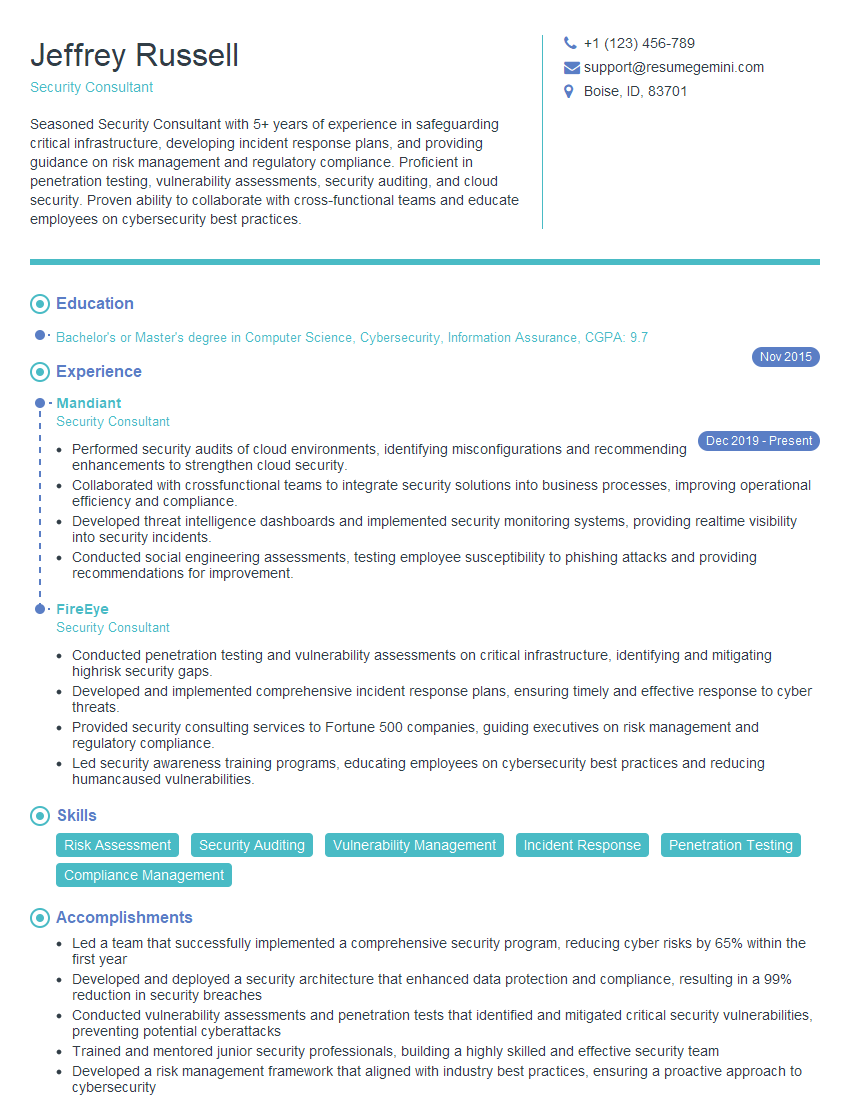

Mastering conflict resolution and safety procedures is crucial for career advancement in almost any field. These skills demonstrate maturity, responsibility, and a commitment to creating positive and productive work environments. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. We provide examples of resumes tailored to highlight expertise in Resolve Conflicts and Ensure Safety; take a look to gain inspiration and see how to best showcase your capabilities.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO