Preparation is the key to success in any interview. In this post, we’ll explore crucial Rim truing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Rim truing Interview

Q 1. Explain the process of truing a bicycle wheel.

Truing a bicycle wheel is the process of adjusting the spoke tension to make the rim perfectly round and centered in the frame. Think of it like fine-tuning a clock – each tiny adjustment makes a difference. It involves systematically tightening or loosening individual spokes to correct any lateral or radial deviations.

The process usually involves using a truing stand to hold the wheel securely while you make adjustments. You’ll visually inspect the rim, identifying high and low points, then use spoke wrenches to adjust the spokes accordingly. It’s an iterative process; you make small adjustments, checking your progress after each one, until the wheel is perfectly true.

Q 2. What tools are essential for effective rim truing?

Essential tools for effective rim truing include:

- Truing stand: This holds the wheel securely and allows for accurate assessment of the rim’s alignment.

- Spoke wrench: This tool is used to tighten or loosen the spokes; having multiple sizes is helpful.

- Magnetic base and indicator: Useful for quickly checking the trueness of the rim.

- Rim gauge: A tool to check the rim’s lateral trueness.

- Spoke tension meter (optional): Helps ensure even spoke tension across the wheel for optimal strength and durability.

While a truing stand isn’t strictly necessary for minor adjustments, it’s highly recommended for any significant truing work or for achieving optimal results.

Q 3. How do you identify a wobbly rim?

A wobbly rim is easily identified by visually inspecting the wheel while it rotates. You’ll notice areas where the rim is significantly closer or further away from the center of the wheel than other areas. This wobble can be seen as lateral (side-to-side) or radial (in and out) runout. Another way to check for wobble is to spin the wheel and use a dial indicator to measure the runout precisely.

A common analogy is comparing it to a car tire – if a tire is out of round, it’ll vibrate while driving. Similarly, a wobbly rim will lead to uneven rolling and potentially damage to other components over time.

Q 4. Describe different types of rim imperfections and their corrections.

Rim imperfections can range from minor lateral and radial deviations to more serious issues like dents or broken spokes.

- Lateral Runout: The rim wobbles side-to-side. This is corrected by adjusting the spoke tension on the side opposite the deviation.

- Radial Runout: The rim wobbles in and out. This is corrected by adjusting spokes both on the affected side to bring the rim back into a true circle.

- Dents: These require careful assessment. Minor dents might be able to be partially corrected through truing, but severe dents may require rim replacement.

- Broken Spokes: These need immediate replacement and usually necessitates a complete re-truing of the wheel.

Correction often involves a combination of tightening and loosening spokes in a controlled manner. The key is making small adjustments, checking your progress frequently, and aiming for an even spoke tension.

Q 5. What is the significance of spoke tension in rim truing?

Spoke tension is crucial for a strong, reliable, and true wheel. Uneven spoke tension can lead to premature spoke breakage, rim instability, and compromised wheel performance. Proper spoke tension contributes to a wheel’s strength, durability and ability to withstand stress while riding. Ideally, all spokes should be tensioned as evenly as possible. A spoke tension meter can be used to measure this, although experienced wheel builders can often get very close through feel and observation. In many cases, re-truing a wheel involves equalizing the tension in all the spokes, rather than just correcting deviations.

Q 6. How do you address a severely damaged rim?

A severely damaged rim, such as one with significant dents, cracks, or severe bends, is generally not repairable. Attempting to true such a rim could lead to further damage or catastrophic failure. In such cases, rim replacement is the only safe and effective solution. The cost of repair usually outweighs the cost of a new rim.

Safety is paramount; a compromised rim could result in a dangerous accident. Always prioritize safety over attempting complex and potentially risky repairs.

Q 7. Explain the concept of dishing a wheel.

Dishing a wheel refers to the process of centering the rim laterally between the two dropouts of the frame. Imagine your wheel as a clock face. A properly dished wheel will have the rim centered; it will not be closer to one side of the frame than the other. This is crucial for both aesthetics and performance. An improperly dished wheel will lead to uneven braking and poor handling.

Dishing is often adjusted during wheel building and is also part of the wheel truing process if a significant offset is needed, typically accomplished by adjusting the spoke tension on one side more than the other. This ensures that the rim sits squarely in the frame, preventing uneven wear and providing optimal braking performance.

Q 8. How do you true a wheel with broken spokes?

Truing a wheel with broken spokes is a more involved process than simply adjusting spoke tension. It requires careful assessment of the damage and may necessitate spoke replacement.

- Assessment: First, identify the broken spoke(s) and the severity of the break. A clean break near the nipple is easier to manage than a break further down the spoke, possibly damaging the rim.

- Removal: Carefully remove the broken spoke(s) using spoke wrenches. Be mindful not to damage adjacent spokes or the rim.

- Replacement (if needed): Obtain replacement spokes matching the original in length, gauge, and type (e.g., butted, straight-pull). If you’re unsure, consult a wheel building guide or professional.

- Installation: Thread the new spoke through the hub, ensuring it’s seated correctly. Then, thread the nipple onto the spoke and carefully tighten it. This stage may require patience, as you must balance spoke tension while ensuring the rim remains centered.

- Re-truing: Once all replacement spokes are installed, proceed with truing the wheel as you would normally, using a truing stand. This will help achieve optimal wheel balance and roundness.

Remember, replacing spokes requires skill and precision. If unsure, seeking professional help is always advisable. A poorly replaced spoke can lead to further damage or compromise the wheel’s integrity.

Q 9. What are the signs of a poorly trued wheel?

A poorly trued wheel presents several noticeable signs, impacting both performance and safety.

- Lateral Wobble (Side-to-Side): The rim noticeably deviates from a perfectly straight line when spun. This is a common issue often seen as a “hop” when riding.

- Radial Wobble (Up-and-Down): The rim exhibits a vertical wobble as it spins. This can cause the tire to rub against the brake pads or frame.

- Hop or Jump: A distinct jump or vibration in the wheel’s rotation, usually caused by a severely out-of-true section or a loose spoke.

- Uneven Spoke Tension: Spokes exhibiting significantly different tension, detectable by feel or using a tension meter. This can lead to premature spoke breakage or rim damage.

- Tire Rubbing: The tire rubs against the frame, brake pads, or other parts of the bike, usually due to extreme lateral or radial wobble.

These indicators point to the need for wheel truing to restore wheel integrity, ride quality, and safety.

Q 10. How do you determine the correct spoke tension?

Determining the correct spoke tension is crucial for a durable and reliable wheel. While precise tension varies based on wheel design and spoke count, aiming for consistent tension across all spokes is paramount.

- Spoke Tension Meter: This specialized tool provides a numerical measurement of spoke tension (in pounds or Newton-meters). It’s the most accurate method for determining spoke tension, enabling precise adjustments.

- Park Tool Tension Chart/Calculator: Using spoke length, nipple material and wheel specs, these tools calculate the desired tension of each individual spoke.

- Sound Test (Experienced Users): Experienced wheel builders can estimate tension by listening to the sound a spoke makes when plucked; consistently similar sounds across spokes suggest similar tension.

- Visual Inspection: Inspect spokes for significant deviation in how much they bend (e.g., comparing spoke deflection with your eye). Spokes under tension have less deflection. This method is not as accurate but can indicate discrepancies.

It’s crucial to keep in mind that the target tension should be consistent across all spokes to prevent uneven stress on the rim and hub. For optimal results, especially in complex builds, consult detailed documentation from the manufacturer or wheel builder.

Q 11. What are the safety precautions when truing a wheel?

Safety is paramount during wheel truing. Failure to take precautions could lead to injury or damage to your equipment.

- Use a Truing Stand: A truing stand securely holds the wheel, allowing for precise adjustments without risk of pinching fingers or damaging the wheel.

- Eye Protection: Wear safety glasses to protect your eyes from flying debris or broken spokes.

- Proper Tools: Use the correct tools, such as spoke wrenches that fit your nipples, to avoid damaging either.

- Work in a Well-Lit Area: Ensure sufficient lighting to clearly see the wheel’s imperfections.

- Work Slowly and Deliberately: Make small adjustments, regularly checking the wheel’s trueness to avoid over-correcting.

- Take Breaks: Avoid fatigue, which can lead to mistakes and injuries.

Proper safety measures prevent injury and ensure the quality of your work.

Q 12. How do you true different types of rims (e.g., alloy, carbon fiber)?

Truing alloy and carbon fiber rims shares some similarities but has key differences due to their material properties. Carbon fiber rims are significantly more delicate.

- Alloy Rims: Alloy rims are generally more forgiving and can withstand more aggressive truing adjustments. Traditional truing techniques apply, focusing on gradual adjustments to spokes to address lateral and radial imperfections.

- Carbon Fiber Rims: Carbon fiber rims are much more susceptible to damage from over-tightening or improper adjustments. They require a lighter touch and more precise adjustments. Use a torque wrench to control spoke tension. Always consult the manufacturer’s guidelines for truing carbon fiber rims. It’s even more critical to use a truing stand.

The biggest difference is the impact resistance. Excessive force on a carbon rim can cause micro-fractures that weaken the structure over time.

Q 13. Describe the difference between radial and lateral truing.

Radial and lateral truing address different aspects of wheel trueness. Both must be addressed for a perfectly true wheel.

- Lateral Truing: This corrects side-to-side wobble. Adjustments are made by tightening or loosening spokes on one side of the wheel to bring the rim into alignment.

- Radial Truing: This corrects up-and-down wobble. Adjustments are made by tightening or loosening spokes to even out the spoke tension resulting in an overall flatter rim profile.

Think of it like this: lateral truing straightens the wheel; radial truing makes the wheel round.

Q 14. How do you diagnose and fix a wheel that hops or jumps?

A wheel that hops or jumps indicates a significant trueness issue, likely caused by a combination of factors.

- Diagnosis: Rotate the wheel slowly, carefully observing the point where the hop occurs. Often, a visually noticeable imperfection will be present at the jumping point. This could be a severely bent section of the rim or a loose spoke, usually at this point. Also, check the spoke tension at this area using a tension meter if possible.

- Fixing a Hop/Jump:

- Bent Rim: If the rim is severely bent, professional repair or replacement might be needed. A very slight bend might be addressed by carefully adjusting the spoke tension in the affected area. Make small adjustments, frequently checking for improvement.

- Loose Spoke: Tighten any loose spokes found. Use a spoke wrench and tighten in small increments to avoid stressing the rim.

- Uneven Spoke Tension: If the spoke tension is uneven in the affected area, adjust the spokes, aiming for even tension across the wheel. Use a spoke tension meter for accuracy.

- Damaged Nipple: Examine the nipple threads; damaged ones might need replacement, or the spoke may be broken just below the nipple.

If you are not confident in your ability to repair this complex problem, seek professional help. It is better to avoid further damage.

Q 15. Explain how to use a spoke tension meter.

A spoke tension meter measures the tension of individual spokes in a bicycle wheel. It’s crucial for building strong, reliable, and true wheels. Think of it like a scale for your spokes; it tells you how tightly each spoke is strung.

Most meters use a small clamp that grips the spoke, then a gauge indicates the tension in pounds or Newton-meters. There are different types – some are simpler, offering a relative tension reading (comparing spokes to each other), while others provide absolute tension values.

How to use it:

- Clamp the meter onto the spoke: Ensure the clamp is securely attached, but avoid damaging the spoke nipple.

- Read the gauge: Note the tension reading. Repeat this for all spokes in a given section, or even for the entire wheel to ensure even tension.

- Compare readings: Identify spokes with significantly different tension from their neighbors. This indicates where adjustments are needed. Most meters will have a chart which relates their readings to your wheel and allow you to match tension to the chart, this is the best way to know the actual tension of your spokes.

Practical Application: After truing a wheel, use the tension meter to check for consistent spoke tension across the wheel. Uneven tension will lead to premature wear, spoke breakage, and the wheel going out of true again.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of rim damage?

Rim damage is a common problem stemming from various impacts and stresses. Think of your rim as the backbone of the wheel; damage here weakens the entire structure.

- Hard impacts: Potholes, curbs, rocks – these can cause dents, buckles, or cracks in the rim.

- Overinflation: Excessively high tire pressure puts undue stress on the rim, making it more susceptible to damage.

- Improper spoke tension: Uneven spoke tension can warp the rim over time.

- Sidewall impacts: Impacts on the tire’s sidewall can transfer significant forces to the rim, potentially causing damage.

- Manufacturing defects: While rare, some rims might have flaws from the manufacturing process.

Example: A cyclist hitting a particularly nasty pothole might end up with a severely dented rim, requiring repair or replacement.

Q 17. How do you maintain trueness after a wheel build?

Maintaining wheel trueness after a build isn’t a one-time fix; it’s ongoing maintenance. Regular checks prevent issues from becoming major problems.

- Regular Inspections: Visually inspect your wheels regularly, looking for any signs of misalignment or spoke loosening. A quick spin of the wheel is sufficient for most circumstances.

- Tighten Loose Spokes: Use a spoke wrench to tighten any loose spokes. Don’t over-tighten; evenly tighten the affected spokes.

- Avoid Over-tightening: Over-tightening spokes can lead to rim damage, so always apply gentle, measured adjustments.

- Periodic Truing: Even with careful maintenance, wheels gradually lose trueness over time. Minor truing adjustments might be necessary periodically.

- Proper Tire Pressure: Maintaining correct tire pressure minimizes stress on the rim and helps preserve the wheel’s trueness.

Example: A cyclist noticing a slight wobble in their front wheel should check for any loose spokes and possibly perform minor truing adjustments.

Q 18. How do you handle a rim with a dent or buckle?

Dealing with a dented or buckled rim requires careful assessment and potentially professional help. The severity dictates the approach.

- Minor Dents/Buckles: For minor imperfections, a rim truing stand and patience might suffice. Small dents can often be gently worked out using specialized tools.

- Severe Dents/Buckles: Significant damage usually requires professional attention. The rim may need to be replaced. Sometimes it’s possible to use a rim straightener, but these require the correct skill and knowledge.

- Cracked Rims: Cracked rims are dangerous and must be replaced immediately. They are a major structural failure and cannot be repaired.

Important Note: Attempting to repair severe damage without experience can exacerbate the problem and lead to dangerous riding conditions.

Q 19. What’s the difference between trueing and tensioning a wheel?

Truing and tensioning are closely related but distinct processes in wheel building. Truing is about correcting the lateral and radial alignment of the rim, while tensioning involves adjusting the tension of individual spokes to achieve and maintain trueness.

Truing: This focuses on the rim’s shape. You’re aiming for a perfectly round and centered wheel. You correct lateral deviations (side-to-side wobble) and radial deviations (wobble towards and away from the hub).

Tensioning: This adjusts individual spoke tension. Even spoke tension across the wheel is essential for maintaining trueness and preventing damage. It’s often done in conjunction with truing.

Analogy: Truing is like adjusting the position of a picture frame on a wall to make it hang straight; tensioning is like ensuring all the screws holding the frame to the wall are equally tight to keep it from warping.

Q 20. Explain how to use a rim truing stand.

A rim truing stand is a crucial tool for wheel building and repair. It holds the wheel securely, allowing for precise adjustments to the rim’s alignment. Think of it as a precision workbench specifically designed for wheels.

How to use it:

- Mount the wheel: Securely mount the wheel on the truing stand’s cones or skewers.

- Adjust the wheel: Use the truing stand’s knobs to rotate the wheel. The wheel can be tightened via clamping mechanisms or quick-releases.

- Identify the High and Low Spots: Observe the wheel’s alignment using the stand’s indicators and the rim alignment.

- Use spoke wrench: Adjust spokes using a spoke wrench to correct these high and low spots.

- Check for trueness: Continuously check the wheel’s trueness, making small adjustments until the wheel is perfectly round and centered.

Important Note: Practice is crucial for mastering the use of a truing stand. Start with small adjustments to prevent over-correction.

Q 21. Describe the process of building a wheel from scratch.

Building a wheel from scratch is a rewarding but challenging process that requires patience and precision. It’s a detailed undertaking but the end result is a wheel built to your exact specifications.

The Process:

- Prepare the components: Gather all necessary components: hub, rim, spokes, nipples, spoke wrench.

- Determine spoke pattern: Decide on the spoke pattern (radial, 3-cross, etc.) based on the hub and rim.

- Install spokes: Thread the spokes through the hub flanges and rim eyelets, following the chosen pattern.

- Tighten nipples: Use the spoke wrench to tighten the nipples, creating a preliminary tension.

- Initial truing: Use a truing stand to perform an initial truing, addressing major deviations.

- Tensioning: Use a spoke tension meter and adjust individual spoke tensions to achieve even tension throughout the wheel.

- Final truing and stress relieving: Perform final truing adjustments, ensuring the rim is perfectly centered and round. Stress relieving may be needed.

- Secure the nipples: Ensure that all nipples are snug and secure against the rim.

- Clean and test: Clean the wheel thoroughly and test it for trueness and responsiveness.

Example: Building a wheel with a specific spoke count and lacing pattern that’s optimized for a particular riding style.

Important Note: Wheel building requires specialized tools and a good understanding of wheel mechanics. If you’re not comfortable building a wheel from scratch, it’s best to seek the expertise of a professional bike mechanic.

Q 22. How do you assess the quality of a trued wheel?

Assessing a trued wheel involves a multi-step process focusing on both lateral and radial trueness. A high-quality trued wheel will exhibit minimal lateral wobble (side-to-side movement) and radial runout (wobble in and out).

- Visual Inspection: Spin the wheel and observe it from different angles. Look for any significant wobbles or deviations from a perfectly circular path. Even slight imperfections will be noticeable with close observation.

- Lateral Trueness: Use a truing stand and a gauge to measure the lateral runout of the wheel. Ideally, it should be within acceptable tolerances (typically less than 1mm, though this can vary depending on the wheel type and intended use). A slight wobble is often acceptable.

- Radial Trueness: Check for spoke tension inconsistencies by gently pressing on each spoke. Uneven tension will contribute to radial runout. The wheel should rotate smoothly without any noticeable bumps or jumps.

- Hop Test: Gently lift and drop the wheel. A well-trued wheel will stay centered and stable. A significant hop indicates problems that might be subtle during slow rotation.

Think of it like balancing a bicycle wheel; a perfectly balanced wheel spins smoothly and true, while an unbalanced one will wobble significantly. The same principle applies to a rim.

Q 23. How would you handle a customer who is dissatisfied with your wheel truing work?

Customer satisfaction is paramount. If a customer is dissatisfied, I first listen carefully to their concerns without interrupting. Understanding their perspective is key. I’d then visually inspect the wheel again, checking for any issues that might have been missed initially.

- Open Communication: Explain the truing process clearly and demonstrate how it addresses the wheel’s original problems.

- Problem Solving: If a problem persists, I would offer to re-true the wheel at no additional cost. If the issue isn’t truing-related, we’d discuss alternative solutions – for instance, determining whether rim damage is beyond repair or whether a replacement would be more appropriate.

- Transparency: Honesty is vital. If there’s a possibility the issue could be due to factors beyond my control (pre-existing damage, manufacturing defects), I explain this transparently.

- Compromise: If a complete re-true doesn’t resolve the issue, I might offer a partial refund or a discount on future services.

My goal is always to ensure the customer leaves happy and confident in the quality of my work. A dissatisfied customer can damage a reputation quickly, so resolving the issue amicably is my top priority.

Q 24. What are some common mistakes to avoid when truing a wheel?

Several common mistakes can lead to poorly trued wheels. Avoiding these ensures efficiency and high-quality results.

- Over-Tightening Spokes: This can cause spoke breakage or damage to the rim. It’s crucial to tighten spokes gradually and evenly.

- Ignoring Trueing Stand Adjustments: Proper adjustments to the stand are crucial. Using a poorly adjusted or misaligned stand can lead to inaccurate truing.

- Focusing on One Area Too Much: Working on one section of the wheel excessively might create imbalances elsewhere. It is more effective to take a holistic approach to truing.

- Truing While Spokes Are Loose: Truing should only be done after proper spoke tension has been achieved. Loose spokes will not hold their adjustments.

- Not Checking for Radial Trueness: Focusing solely on lateral trueness can leave the wheel with radial wobbles, resulting in poor performance.

Think of it as building with LEGOs – you need a careful, balanced approach to create a strong and stable structure.

Q 25. Describe your experience with different types of spoke patterns.

I have extensive experience with various spoke patterns, each with its strengths and weaknesses. Understanding these patterns is crucial for wheel building and truing.

- Radial: Simplest pattern, easiest to true but less strong laterally. Suitable for low stress applications.

- Three-Cross: Common and strong pattern, provides a balance between strength and ease of truing. Widely used across many applications.

- Four-Cross: Strongest and most robust pattern, offering superior lateral strength but more challenging to true.

- Other Variations: There are many variations like two-cross and more complex patterns often found on high-performance wheels; each adds its complexities to the truing process.

The choice of spoke pattern influences the wheel’s strength, weight, and how it behaves during truing. My experience allows me to adapt my techniques to achieve optimal trueness regardless of the pattern.

Q 26. How do you deal with a rim that is out of round?

A rim that’s out of round presents a more challenging truing situation. The process starts with assessing the extent of the damage.

- Minor Out-of-Round: If the rim’s deviation from true is relatively small, the truing process can often compensate for this. Careful and even tension adjustments are key. This is often done by carefully adjusting the spoke tension.

- Significant Out-of-Round: Severe dents or imperfections might require more extensive adjustments. A significant degree of out-of-roundness might require specialized techniques or suggest that the rim might be beyond economical repair.

- Trueing Limits: It’s essential to know the limitations. If the rim is severely damaged, the stresses on the spokes during truing could risk failure, even if it appears somewhat true afterward. In this case, rim replacement is recommended.

Imagine trying to straighten a bent piece of metal; you can sometimes fix it, but if it’s severely bent, it’s better to replace it. The same principle applies to rims.

Q 27. How do you assess if a rim needs replacement or just truing?

Determining whether a rim needs replacement or just truing involves a thorough assessment of the damage.

- Visual Inspection: Examine the rim for dents, cracks, deep scratches, or any significant deformations that might indicate structural compromise.

- Truing Evaluation: Attempt to true the wheel. If after careful truing, the wheel retains significant wobble or shows signs of stress on the spokes, it suggests the damage is beyond simple truing.

- Stress Test: Gently apply pressure to the rim. If it flexes excessively or creaks, it likely needs replacing.

- Cost Analysis: Consider the cost of truing versus replacement. Sometimes, replacing the rim is more economical, especially if repeated truing is required.

Think of it as deciding whether to repair a small crack in a wall versus demolishing and rebuilding the entire wall – depending on the damage, replacing might be the most practical solution.

Q 28. How do you troubleshoot a wheel that is still wobbly after truing?

If a wheel remains wobbly after truing, a systematic troubleshooting process is crucial.

- Re-check Spoke Tension: Ensure all spokes are properly tensioned and evenly distributed. Even slight inconsistencies can cause wobble.

- Rim Assessment: Carefully inspect the rim for hidden damage that may have been missed initially. Small cracks or dents can cause the wheel to wobble even after truing.

- Hub Inspection: Check the hub for any play or looseness. A damaged hub can cause imperfections to remain in the wheel.

- Trueing Stand Calibration: Double-check that the truing stand is properly aligned and calibrated. Misalignment can lead to inaccurate truing.

- Re-Truing Process: Go through the entire truing process again, carefully observing the wheel’s behavior. Take your time, re-assess, and make adjustments carefully and methodically.

Troubleshooting requires a methodical and patient approach. It’s like solving a puzzle – each step helps to pinpoint the root cause of the problem.

Key Topics to Learn for Rim Truing Interview

- Wheel Building Fundamentals: Understanding spoke tension, lacing patterns, and the relationship between these elements and wheel trueness.

- Truing Techniques: Mastering the use of truing stands, spoke wrenches, and various truing methods (e.g., radial, lateral). Practical application includes identifying and correcting common wheel imperfections like wobbles and hops.

- Diagnosing Wheel Problems: Learning to identify the root cause of wheel issues beyond simple truing, including bent rims, broken spokes, and improper tension. This includes understanding how to assess the severity of damage and determine appropriate repair strategies.

- Rim and Spoke Materials: Understanding the properties of different rim and spoke materials (e.g., aluminum, carbon fiber, steel) and their impact on wheel strength, weight, and durability. This includes knowing how material properties influence truing techniques.

- Safety Procedures: Understanding and adhering to safety protocols while working with wheels and tools. This includes proper handling of sharp tools and the importance of maintaining a clean and organized workspace.

- Advanced Truing Concepts: Exploring more complex scenarios like dishing wheels, building wheels from scratch, and addressing unique challenges presented by different rim and hub configurations.

Next Steps

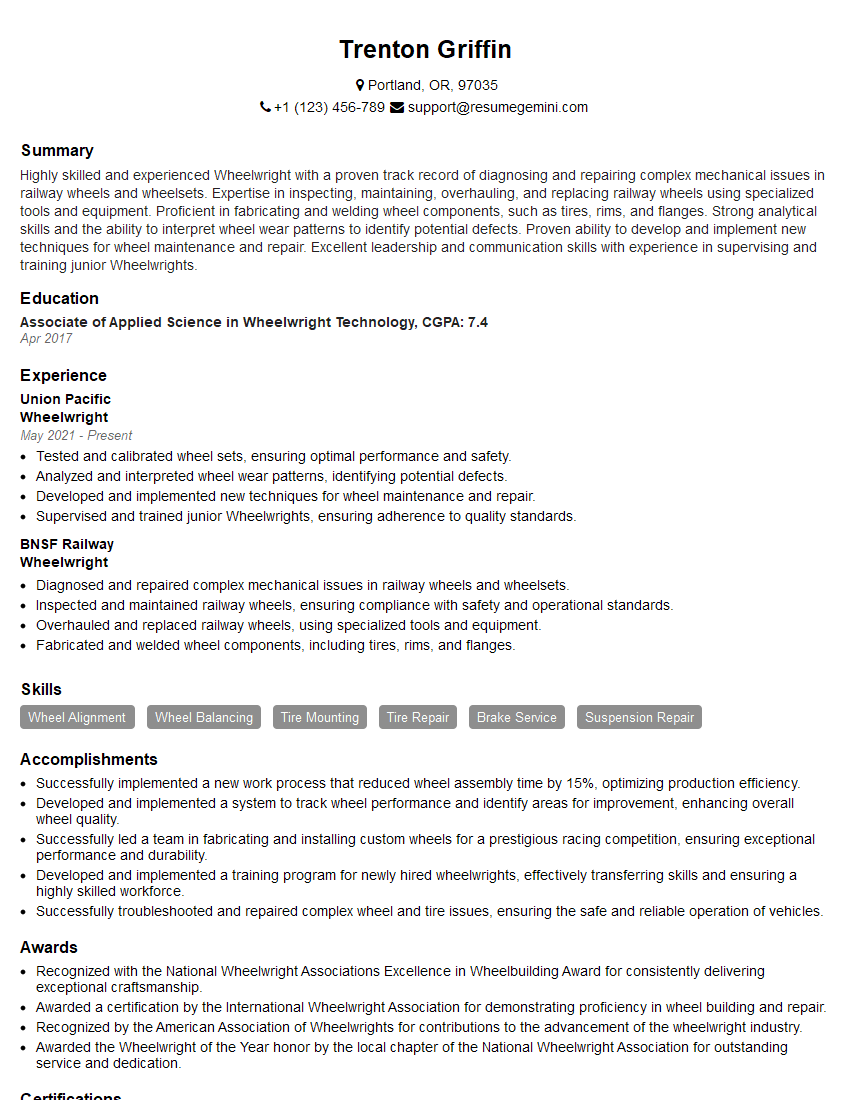

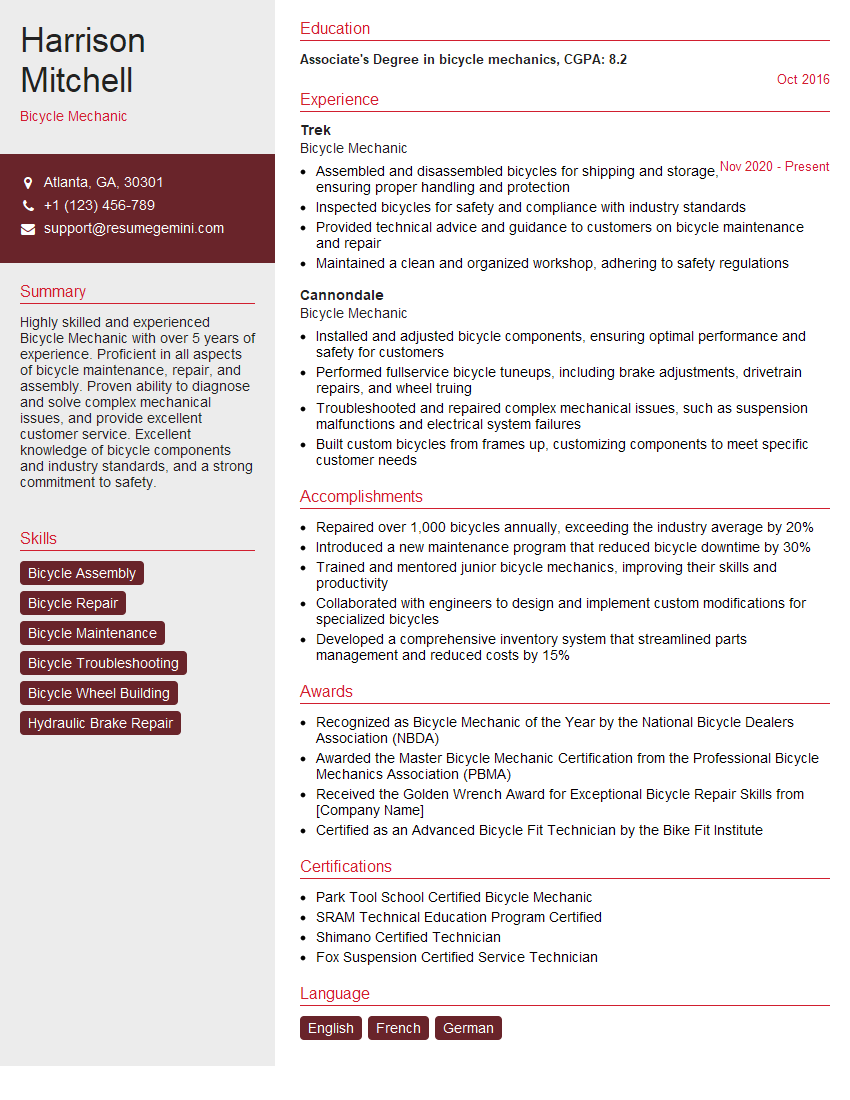

Mastering rim truing is a valuable skill that opens doors to various exciting opportunities in the cycling industry, from bike mechanics to specialized wheel building. To increase your chances of landing your dream job, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key for getting noticed by potential employers. We strongly recommend using ResumeGemini to build a compelling resume that highlights your expertise in rim truing. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored specifically to the Rim Truing field, giving you a head start in crafting the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO