Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Robotics and Automation Integration interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Robotics and Automation Integration Interview

Q 1. Explain the difference between a robot controller and a PLC.

While both robot controllers and PLCs (Programmable Logic Controllers) are crucial components in automation systems, they serve distinct purposes. Think of a robot controller as the brain specifically designed for controlling a robot’s movements and actions, while a PLC acts as a more general-purpose automation supervisor managing various parts of a system, including robots.

- Robot Controller: Dedicated to controlling robotic arms, manipulators, or other robotic systems. It handles complex motion control, path planning, sensor integration, and interaction with end-effectors. They often have sophisticated programming languages like RAPID (ABB) or KRL (KUKA) tailored for robotics. They excel at real-time control and precision.

- PLC: A programmable device that manages and automates industrial processes. It handles logic, sequencing, timing, and data acquisition from various sensors and actuators across an entire factory floor. They typically use ladder logic programming and are robust in harsh industrial environments. Their strength lies in handling a wide range of inputs and outputs.

In a typical scenario, a PLC might oversee the entire production line, triggering the robot controller to initiate a specific task when certain conditions are met (e.g., parts are available, sensors indicate completion of previous steps). The PLC would handle the overall workflow, while the robot controller focuses on the precise execution of the robot’s movements.

Q 2. Describe your experience with different robotic programming languages (e.g., RAPID, KRL).

I have extensive experience with several robotic programming languages. My proficiency includes RAPID (ABB), KRL (KUKA), and some experience with proprietary languages from Fanuc and Yaskawa. Each language has its own strengths and quirks.

- RAPID (ABB): I’ve used RAPID extensively in projects involving high-speed pick-and-place applications and complex path planning for welding robots. It’s a powerful object-oriented language that allows for modular programming and efficient code reuse. For example, I created a reusable module in RAPID to handle vision-guided pick-and-place operations, significantly reducing development time across multiple projects.

- KRL (KUKA): My experience with KRL includes programming robots for palletizing, material handling, and machine tending. KRL’s structured programming approach is particularly effective in managing complex robot routines. I once used KRL to program a collaborative robot to assist human workers in assembling delicate parts, ensuring safety and efficiency.

My experience spans beyond just writing code. I understand the importance of error handling, debugging, and optimizing code for efficient execution within the constraints of real-time robotic control. Understanding the underlying robot architecture and mechanics helps in troubleshooting and optimizing programs for speed and accuracy.

Q 3. How do you troubleshoot robotic system errors?

Troubleshooting robotic system errors is a systematic process. I typically follow a structured approach:

- Identify the Error: Start by pinpointing the exact nature of the problem. Is the robot moving incorrectly? Are there sensor errors? Are there communication issues? Detailed error messages from the robot controller are critical here.

- Check the Basics: Simple issues often go unnoticed. Check power connections, pneumatic pressure (if applicable), emergency stops, and communication cables. Sometimes a loose connection is the culprit.

- Review the Program: Examine the robot program for errors in logic, syntax, or path planning. Stepping through the program line-by-line using the controller’s debugging tools can pinpoint problem areas. Consider using a simulator to test the code offline.

- Sensor Diagnostics: Verify the accuracy and functionality of all sensors. Sensor calibration and alignment are often overlooked, and misaligned sensors can cause significant errors.

- Communication Checks: If the robot is communicating with other systems (PLC, vision system), test the communication links. Network connectivity, data integrity, and protocols are key.

- Mechanical Inspection: Look for any mechanical issues such as jammed joints, worn-out parts, or misalignments in the robot’s structure. Sometimes, a minor mechanical problem can manifest as a complex software error.

- Systematic Isolation: If the problem is not readily apparent, systematically isolate components to pinpoint the faulty part. This might involve temporarily disconnecting modules, testing individual parts, or using replacement components.

Documentation and proper logging are essential throughout the troubleshooting process. Maintaining detailed records allows for easier future debugging and prevents repetition of errors.

Q 4. What are the key considerations for selecting a robot for a specific application?

Selecting the right robot for an application requires careful consideration of several factors:

- Payload Capacity: The weight the robot can lift and manipulate. This is fundamental to the application’s requirements.

- Reach and Workspace: The robot’s working envelope needs to encompass the entire task area.

- Degrees of Freedom (DOF): The number of axes of motion the robot possesses (typically 6 for general-purpose robots). More DOF allows for greater flexibility and reach but increases complexity.

- Speed and Accuracy: The speed at which the robot needs to perform its tasks and the required precision. High-speed applications require robots designed for that purpose.

- Repeatability: The consistency with which the robot can return to the same position. Critical for precision tasks.

- Environment: The conditions in which the robot will operate (temperature, humidity, dust, etc.). Some robots are designed for harsh environments.

- Integration: The ease of integrating the robot into the existing production line and control system. Compatibility with PLC, vision systems, and other peripherals is vital.

- Cost: The initial purchase price, maintenance costs, and potential ROI. A balance needs to be struck between cost and performance.

For example, a small, fast robot with high repeatability might be ideal for a high-speed pick-and-place operation, whereas a large, heavy-duty robot would be more suitable for material handling in a foundry.

Q 5. Explain the concept of robot kinematics and its importance in automation.

Robot kinematics is the study of robot motion, focusing on the relationship between the robot’s joint angles and its end-effector’s position and orientation in space. It’s the mathematical foundation of robotic control and is crucial for accurate and efficient robot movement.

Imagine a robotic arm. Kinematics allows us to calculate the precise joint angles required to move the end-effector (the hand or tool) to a specific location and orientation. This involves solving forward kinematics (finding the end-effector pose given joint angles) and inverse kinematics (finding joint angles given the desired end-effector pose). These calculations are fundamental to robot programming and path planning.

The importance of robot kinematics in automation cannot be overstated. Accurate kinematic models are essential for:

- Path Planning: Generating smooth and collision-free trajectories for the robot.

- Precise Control: Ensuring the robot moves to the desired location with high accuracy.

- Simulation and Offline Programming: Simulating robot movements in a virtual environment before deploying them in the real world.

- Calibration and Maintenance: Checking for errors in the robot’s mechanical structure and adjusting the kinematic model accordingly.

Without accurate kinematic models, robots would be incapable of performing their tasks reliably and safely. Errors in kinematics can lead to inaccurate movements, collisions, and damage to the robot or its surroundings.

Q 6. Describe your experience with various robot end-effectors and their applications.

My experience encompasses a variety of robot end-effectors, each suited for specific tasks:

- Grippers: From simple two-finger grippers for handling basic parts to complex multi-fingered grippers with force sensors for delicate objects, I’ve worked with various designs. I’ve programmed grippers for different gripping strategies, including force control, position control, and adaptive gripping for objects of varying shapes and sizes.

- Welding Torches: I’ve integrated and programmed welding torches for arc welding applications, focusing on precise control of welding parameters and path planning for complex weld seams.

- Spray Guns: I’ve used spray guns for painting and coating applications, where precise motion control and consistent spray patterns are critical. This involves programming intricate path trajectories and coordinating the spray gun parameters.

- Vacuum Cups: For handling flat or smooth objects, vacuum cups are efficient. I’ve designed systems that use vacuum cups in conjunction with vision systems to identify and pick objects from a conveyor belt.

- Custom End-Effectors: Several projects required designing and implementing custom end-effectors to meet specific application needs. For example, I once developed a custom end-effector for assembling circuit boards, incorporating specialized tooling for precise component placement.

Selecting the appropriate end-effector is crucial for optimizing performance and achieving the desired results. The choice depends heavily on the application’s requirements, including the nature of the objects being handled, the required forces and precision, and the overall system design.

Q 7. How do you ensure the safety of human-robot collaboration (HRC) systems?

Ensuring safety in Human-Robot Collaboration (HRC) systems is paramount. It requires a multi-faceted approach:

- Risk Assessment: A thorough risk assessment is the first step. This involves identifying potential hazards and evaluating the risk level associated with human-robot interaction. This dictates the safety measures required.

- Safety-Rated Sensors: Employing safety-rated sensors such as laser scanners, light curtains, and pressure mats to detect the presence of humans in the robot’s workspace. These sensors trigger safety stops or reduced speed operation to prevent collisions.

- Speed and Force Limiting: Programming the robot to operate at reduced speeds and forces within the collaborative workspace. This minimizes the potential for injury in the event of a collision.

- Power and Force Limiting: Designing the robot and its end-effector with power and force limiting mechanisms to minimize the impact of a potential collision. This can involve compliant actuators or passive safety devices.

- Safety-Rated Controllers: Using safety-rated controllers that comply with relevant safety standards (e.g., ISO 13849, ISO 10218) to ensure proper safety functions are implemented and monitored.

- Safety Training: Providing comprehensive safety training to all personnel working with the HRC system. This is essential to ensure that operators understand the system’s limitations and safe operating procedures.

- Emergency Stop Systems: Implementing redundant emergency stop systems, including physical buttons and software-based emergency stops, to allow for immediate shutdown in case of emergencies.

Beyond these technical measures, a clear safety policy and regular inspections are also critical. Implementing and maintaining these safety measures is vital for preventing accidents and creating a safe collaborative environment for both humans and robots.

Q 8. Explain your understanding of different robot configurations (e.g., articulated, SCARA, delta).

Robot configurations are essentially different mechanical structures designed to achieve specific tasks. The choice depends heavily on the application’s needs in terms of reach, payload, speed, and precision.

- Articulated Robots: These are the most common type, resembling a human arm with multiple rotating joints. They offer high flexibility and dexterity, making them suitable for a wide range of tasks, from welding and painting to assembly and material handling. Think of a factory robot arm assembling a car engine – that’s likely an articulated robot.

- SCARA (Selective Compliance Assembly Robot Arm): These robots have two parallel vertical joints and a rotary joint at the end. They are known for their high speed and accuracy in planar motions, ideal for assembly tasks requiring precise placement in a horizontal plane. Imagine a robot placing tiny components on a circuit board – a SCARA robot excels at this.

- Delta Robots: Also called parallel robots, these have three arms connected to a common base and a wrist at the end. They are incredibly fast and precise, primarily used for pick-and-place operations, especially in high-speed applications like food packaging or sorting. Picture a robot rapidly picking up and placing small items onto a conveyor belt – that’s a prime application for a delta robot.

The selection of a robot configuration is critical for optimal performance and cost-effectiveness. Factors such as workspace requirements, payload capacity, speed and precision needs, and the complexity of the task at hand should carefully be evaluated during the design phase.

Q 9. What experience do you have with vision systems integrated with robots?

I have extensive experience integrating vision systems with robots, primarily using 2D and 3D vision technologies. In one project, we used a 2D vision system with a SCARA robot to inspect and sort electronic components based on their size and shape. The vision system located the components on a conveyor belt, and the robot arm precisely picked and placed them into different bins. We utilized machine vision libraries like OpenCV and integrated them with the robot controller using Ethernet/IP communication. This allowed for real-time feedback and automated quality control.

Another project involved employing a 3D vision system (structured light) with an articulated robot for bin picking. This was more complex because of the need for accurate 3D positional data. The 3D vision system generated point clouds which were then processed to identify and locate randomly oriented parts within a bin. The robot, guided by the vision data, successfully extracted the parts.

My experience includes working with various vision system hardware (cameras, lighting, etc.) and software (image processing algorithms, calibration tools). I am proficient in developing vision-guided robot applications, ensuring precise and reliable operation.

Q 10. How do you perform risk assessments for robotic automation projects?

Risk assessment in robotic automation is crucial for ensuring safety and compliance. I follow a structured approach based on industry standards like ISO 10218 and RIA 15.06. My process typically includes:

- Hazard Identification: This involves systematically identifying potential hazards related to the robot, its environment, and the human-robot interaction. Examples include collision hazards, pinch points, entanglement hazards, and unexpected robot movements.

- Risk Analysis: Once hazards are identified, we evaluate the likelihood and severity of each hazard. This often involves assigning risk levels based on a predefined matrix.

- Risk Reduction: The goal is to reduce identified risks to an acceptable level. This can be achieved through various measures, such as implementing safety features (e.g., safety light curtains, emergency stops, interlocks), implementing appropriate guarding, training personnel, and using collaborative robots with inherent safety features.

- Documentation: A thorough risk assessment report is crucial. It documents the identified hazards, risk levels, mitigation strategies, and residual risks. This serves as a vital reference document throughout the project lifecycle.

Throughout the process, collaboration with safety experts, engineers, and operators is essential. A proactive approach ensures a safe and efficient robotic system that meets all safety standards and minimizes potential accidents.

Q 11. Describe your experience with different types of sensors used in robotic systems.

My experience encompasses a wide range of sensors used in robotic systems. The type of sensor used is heavily dependent on the specific application and the data required.

- Proximity Sensors: These are used to detect the presence of objects without physical contact, often employing technologies like ultrasonic, infrared, or capacitive sensing. They are commonly used for safety applications, avoiding collisions, and triggering actions based on object proximity.

- Force/Torque Sensors: These sensors measure the forces and torques applied to the robot’s end-effector, enabling precise control in delicate tasks requiring interaction with objects. Think of a robot gently assembling a piece of jewelry; this sensor helps it handle the object without damage.

- Laser Scanners/LIDAR: Used for environment mapping and obstacle avoidance, providing detailed 3D information about the robot’s surroundings. They are common in autonomous mobile robots (AMRs).

- Vision Systems (Cameras): These provide visual information for tasks like object recognition, position determination, and inspection, as described in my previous answer.

- Encoders: These are essential for position feedback within the robot’s joints, allowing for precise control and movement.

Selecting the appropriate sensor set is a key aspect of the design process, ensuring the system can accurately perceive its environment and perform its intended tasks reliably.

Q 12. What is your experience with industrial communication protocols (e.g., Ethernet/IP, PROFINET)?

I’m proficient in several industrial communication protocols, including Ethernet/IP and PROFINET. These protocols are essential for seamless data exchange between the robot controller, PLC (Programmable Logic Controller), and other devices in an automated system. Ethernet/IP is widely used in North America, while PROFINET is dominant in Europe. My experience includes:

- Configuring network devices: Setting up IP addresses, subnets, and configuring network settings to ensure proper communication.

- Developing communication programs: Writing code (e.g., in PLC programming languages like Ladder Logic or Structured Text) to send and receive data between the robot and other system components.

- Troubleshooting network issues: Diagnosing and resolving network connectivity problems, ensuring system uptime and reliability.

Understanding these protocols and their nuances is critical for integrating robotic systems into larger automation environments. For instance, I’ve used Ethernet/IP to seamlessly integrate a robotic cell into a larger manufacturing line, allowing real-time data exchange and coordinated control among various machines.

Q 13. Explain your experience with robotic simulation software.

I have significant experience using robotic simulation software, primarily RoboDK and Siemens Process Simulate. These tools allow for offline programming, robot path planning, and virtual commissioning of robotic systems. This approach significantly reduces the time and cost associated with physical commissioning and allows for thorough testing and optimization before deployment.

In a recent project, we utilized RoboDK to simulate a complex robotic welding cell. This enabled us to optimize the robot’s welding path, minimizing cycle time and improving weld quality before deploying the system on the shop floor. The simulation helped identify potential collisions and areas requiring adjustments to tooling or work cell layout. We also used it to train operators on the system’s operation.

Simulation helps to mitigate risks, improve productivity and reduce the overall cost of the project by identifying issues in the early stages, preventing unexpected problems during implementation.

Q 14. How do you handle unexpected downtime or malfunctions in robotic systems?

Unexpected downtime is always a concern in robotic systems. My approach to handling malfunctions involves a structured troubleshooting process:

- Identify the problem: This may involve analyzing error messages from the robot controller, checking sensor readings, inspecting the physical system for mechanical issues, and reviewing recent system logs.

- Isolate the cause: Once the problem is identified, I try to pinpoint the root cause. This may involve systematically testing different components and subsystems to identify the faulty element.

- Implement corrective actions: Corrective actions may include replacing a faulty component, adjusting software settings, or repairing a mechanical issue.

- Prevent future occurrences: Once the problem is resolved, a crucial step is to analyze the root cause and implement preventative measures to avoid similar issues in the future. This may include improved maintenance procedures, enhanced system monitoring, or design modifications.

In addition to this immediate response, preventative maintenance schedules and regular system checks are essential for minimizing downtime. Furthermore, a well-documented system with clear operational procedures and readily accessible spare parts is vital for quick recovery from unexpected issues.

Q 15. Describe your experience with robotic cell design and layout.

Robotic cell design and layout is a crucial aspect of automation integration. It involves strategically placing the robot, its peripherals (like conveyors, vision systems, and end-effectors), and safety components within a defined workspace to optimize efficiency and safety. Think of it like designing a well-organized kitchen – every tool has its place, and the workflow is smooth.

My experience includes designing cells for various applications, from palletizing and packaging to machine tending and welding. A key consideration is minimizing cycle time – the time it takes to complete a task. This often involves optimizing the robot’s reach and movement, minimizing unnecessary travel, and ensuring smooth material flow. For instance, in a palletizing cell, I’d carefully position the conveyor to feed the robot optimally and place the pallet stack efficiently to allow easy access for forklifts.

Another critical factor is safety. I ensure compliance with all relevant safety standards (e.g., ANSI/RIA R15.06) by incorporating light curtains, emergency stops, and interlocks to prevent accidents. Proper layout also considers ergonomics, providing comfortable access for operators for maintenance and programming. For example, I might include clear walkways and well-lit areas surrounding the cell.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the advantages and disadvantages of different robot drive systems?

Robot drive systems significantly influence a robot’s performance, precision, and cost. The primary types are hydraulic, pneumatic, and electric.

- Hydraulic drives offer high power and torque, ideal for heavy-duty applications like lifting and moving large objects. However, they are less precise, require more maintenance, and can be less energy-efficient. Think of the powerful hydraulic arms used in construction equipment.

- Pneumatic drives are suited for simpler, faster movements and are generally cost-effective and require less maintenance. Their lower precision limits them to less demanding tasks like simple pick-and-place operations. Air-powered assembly line robots are a good example.

- Electric drives are increasingly popular due to their high precision, flexibility, energy efficiency, and clean operation. They are commonly used in various applications, from precise assembly to intricate welding. The majority of industrial robots today are electric.

The choice of drive system depends heavily on the specific application. Factors to consider include payload capacity, speed requirements, precision needs, environmental conditions, and budget constraints.

Q 17. How do you ensure the accuracy and repeatability of robotic movements?

Accuracy and repeatability are paramount in robotics. Accuracy refers to how close the robot’s actual position is to the programmed position, while repeatability refers to how consistently the robot can return to the same position. Several strategies ensure both:

- Calibration: Regular calibration using laser trackers or other precise measurement systems is crucial to correct for any drift in the robot’s positional accuracy over time.

- Proper mechanical design: A robust and well-maintained mechanical structure reduces vibrations and backlash, directly affecting accuracy and repeatability.

- High-resolution encoders and sensors: Precise encoders provide feedback on the robot’s joint positions, enabling fine control and improved accuracy. Additional sensors, such as vision systems, can further enhance positioning accuracy by providing external references.

- Advanced control algorithms:Sophisticated algorithms compensate for inaccuracies in the robot’s mechanics and dynamics, enhancing precision and reducing errors.

For example, in a pharmaceutical application, the robot’s ability to accurately place pills in a vial requires extremely high accuracy and repeatability to ensure accurate dosage. Regular calibration and high-precision sensors are crucial here. We might also use a vision system to verify the placement of each pill after it has been placed.

Q 18. Explain your understanding of robotic motion planning and path optimization.

Robotic motion planning involves determining the sequence of movements a robot needs to execute to accomplish a specific task. Path optimization then focuses on finding the most efficient and safe path. This is like planning a road trip – you need to choose your route (motion planning), considering factors like distance, traffic (obstacles), and time (efficiency), then optimize the journey (path optimization).

Motion planning involves algorithms like A*, RRT (Rapidly-exploring Random Trees), and potential field methods. These algorithms consider robot kinematics (how the robot’s links move), workspace constraints (obstacles), and task requirements. Path optimization techniques further refine the planned path, minimizing distance, time, energy consumption, or jerk (rate of change of acceleration), depending on the application. For example, in a welding application, a smooth, jerk-free path is crucial to maintain consistent weld quality. We might use spline interpolation to generate a smooth path.

Software tools like ROS (Robot Operating System) provide libraries and functionalities for motion planning and path optimization. I’ve extensively used such tools to generate optimal paths for robots in diverse applications, including automated guided vehicles (AGVs) in warehousing and collaborative robots (cobots) in assembly lines.

Q 19. Describe your experience with integrating robots into existing manufacturing processes.

Integrating robots into existing manufacturing processes requires careful planning and execution. It’s not just about plugging a robot in; it involves assessing the current process, selecting the right robot and peripherals, and seamlessly integrating them into the workflow. I usually follow a structured approach:

- Process analysis: Thoroughly analyze the existing process to identify bottlenecks, inefficiencies, and areas where automation can improve productivity and quality.

- Robot selection: Choose a robot that meets the specific requirements of the task, including payload capacity, reach, speed, and precision.

- Peripheral selection: Select appropriate end-effectors (grippers, tools), sensors (vision systems, proximity sensors), and other peripherals to ensure smooth operation.

- Safety assessment and integration: Conduct a thorough risk assessment and implement appropriate safety measures to ensure operator safety and compliance with regulations. This often includes installing safety fences, light curtains, and emergency stops.

- System integration: Integrate the robot and peripherals with the existing PLC (Programmable Logic Controller) system and other automation components to ensure coordinated operation.

- Testing and commissioning: Thoroughly test the integrated system to ensure it meets performance requirements and validate safety protocols.

For instance, integrating a robot into an existing painting line requires careful consideration of paint application techniques, safety measures to prevent paint overspray and fires, and integration with the existing conveyor system. The robot may need a specialized paint-applying end-effector and a vision system for precise part location.

Q 20. How do you validate and verify the performance of a robotic system?

Validation and verification are critical to ensure that the robotic system functions as intended and meets all safety requirements. Verification confirms that the system is built according to specifications, while validation confirms that it meets performance requirements and intended functionality.

Verification involves inspections, tests, and simulations to ensure the robot’s design, assembly, and programming are correct. This may include reviewing CAD models, testing individual components, and verifying the control software. Validation involves rigorous testing under real-world operating conditions. This includes testing the robot’s accuracy, repeatability, cycle time, and overall performance. We might use statistical methods to analyze the data and verify that it meets the defined performance criteria.

In the process, we generate comprehensive documentation, including design specifications, test results, and safety assessments. This documentation is vital for ongoing maintenance and troubleshooting. For example, after integrating a robot into a packaging line, we would conduct validation tests to verify that the packaging speed, accuracy, and integrity meet specifications and that the process meets safety standards.

Q 21. What are the different types of robot grippers and when would you use each?

Robot grippers are end-effectors that allow robots to grasp and manipulate objects. Different grippers are designed for different applications and object types.

- Two-finger grippers: Simple and versatile, suitable for a wide range of objects, particularly those with a defined shape. These are widely used in many pick-and-place applications.

- Three-finger grippers: Provide better dexterity than two-finger grippers, suitable for handling objects with irregular shapes or fragile items. These might be used in delicate assembly tasks.

- Vacuum grippers: Ideal for handling smooth, flat objects or those with a consistent surface texture. They’re commonly used for handling cardboard boxes or sheet metal.

- Magnetic grippers: Used for handling ferrous metal objects. They are efficient but limited to magnetic materials.

- Adaptive grippers: Employ soft materials or adjustable mechanisms to accommodate objects of varying shapes and sizes. They are ideal for handling delicate or irregularly shaped objects, like fruits or vegetables.

The choice of gripper depends on the object’s characteristics (size, shape, weight, material), the required force, and the speed of operation. For instance, a delicate electronics assembly might use a three-fingered gripper or an adaptive gripper to prevent damage to components, whereas a palletizing application might use a vacuum gripper to lift boxes quickly and efficiently.

Q 22. Explain your experience with implementing safety features in robotic systems.

Implementing safety features in robotic systems is paramount to ensuring a safe working environment for human collaborators and preventing equipment damage. My approach is multi-faceted and follows a risk assessment-based methodology. It begins with a thorough hazard analysis, identifying potential risks associated with the robot’s operation, including collisions, pinch points, and unexpected movements.

Based on this analysis, I select and implement appropriate safety features. This can include:

- Physical guards and barriers: These create physical separation between the robot and human workers, preventing direct contact. For example, light curtains, safety fences, and interlocked access doors are commonly used.

- Safety sensors and scanners: These detect the presence of humans or obstacles in the robot’s workspace and trigger an immediate stop or slowdown. Examples include laser scanners, proximity sensors, and vision systems.

- Emergency stop buttons: Easily accessible emergency stops are crucial for immediate shutdown in case of unforeseen events. These are typically strategically placed throughout the workspace.

- Speed and power limiting: Reducing the robot’s speed and power during collaborative operations minimizes the potential for injury during a collision.

- Software-based safety systems: These systems monitor the robot’s operation and enforce safety limits. For example, a PLC (Programmable Logic Controller) can monitor sensor inputs and control the robot’s actions based on safety protocols.

Finally, regular safety audits and training are crucial to ensure that the implemented measures remain effective and workers are aware of safe operating procedures. In one project involving a palletizing robot, we used a combination of laser scanners and a safety PLC to ensure the robot stopped safely if a worker entered its workspace. This eliminated the need for complete physical guarding, improving productivity while maintaining safety.

Q 23. How do you manage projects involving multiple robotic systems?

Managing projects with multiple robotic systems requires meticulous planning, coordination, and a robust project management framework. I typically employ a phased approach:

- Detailed system design: This phase involves defining the individual roles of each robot, their interactions, and the overall system architecture. We need to consider factors like communication protocols, data sharing, and synchronization between robots.

- Simulation and modeling: Simulating the entire system before physical implementation helps identify potential bottlenecks, conflicts, and safety issues. Software like ROS (Robot Operating System) provides a powerful environment for system simulation.

- Modular design: Designing each robotic system as a modular unit simplifies integration, testing, and maintenance. This approach allows us to swap out or upgrade individual components without affecting the entire system.

- Iterative testing: This is a crucial stage involving gradual testing and integration of individual robots and subsystems, followed by comprehensive system testing. We continuously monitor performance metrics and make adjustments as needed.

- Centralized control system: For complex systems, implementing a centralized control system helps manage and monitor all robots from a single point, facilitating efficient control and troubleshooting.

In a recent project involving a warehouse automation system with multiple mobile robots and robotic arms, we utilized a ROS-based architecture with a centralized control server. This allowed for efficient coordination of the robots, optimizing workflow and minimizing potential collisions.

Q 24. Describe your experience with different types of robot teaching methods.

Robot teaching methods vary depending on the robot’s complexity and the application. I have experience with several techniques:

- Lead-through programming: This involves manually guiding the robot through the desired movements. The robot records the path, which is then used for subsequent operation. This is ideal for simple tasks and is commonly used with smaller, less complex robots.

- Off-line programming (OLP): This utilizes specialized software to program the robot’s movements without directly interacting with the physical robot. This is advantageous for complex tasks and allows for simulation and optimization before deployment. Software like RoboDK is a common tool used for OLP.

- Teach pendants: These hand-held devices provide a user interface for programming and controlling the robot. They are useful for both lead-through programming and more complex programming tasks, allowing for adjustments and fine-tuning of the robot’s movements.

- Vision-guided programming: This approach leverages computer vision to guide the robot’s actions. The robot uses cameras to locate and identify objects, allowing it to adapt to variations in the environment and workpieces. This is very useful in tasks like bin picking or assembly where object location may vary.

For example, in a project involving welding robotic arms, we employed off-line programming to simulate and optimize the welding paths, ensuring consistent weld quality and minimizing programming errors. On the other hand, in a simple pick-and-place operation, lead-through programming was sufficiently efficient and effective.

Q 25. Explain your understanding of the different types of robot control architectures.

Robot control architectures dictate how the robot’s actions are planned, controlled, and executed. Different architectures offer varying degrees of flexibility, complexity, and performance. Common architectures include:

- Joint-level control: This approach controls each joint of the robot independently. It’s simpler to implement but might not be as efficient for complex movements.

- Cartesian control: This controls the robot’s end-effector in Cartesian coordinates (X, Y, Z). This is easier to program for tasks involving spatial positioning.

- Hybrid control: This combines joint-level and Cartesian control, leveraging the advantages of both approaches. It offers flexibility for complex tasks involving both joint and spatial control.

- Hierarchical control: This organizes control into layers, with higher levels handling task planning and lower levels managing low-level motor control. This is beneficial for complex tasks requiring significant coordination and planning.

- Decentralized control: Involves distributing the control logic across multiple processors or controllers, leading to greater robustness and scalability.

The choice of architecture depends on factors such as the robot’s mechanical design, the complexity of the task, and real-time requirements. In one project involving a highly dexterous robotic arm performing delicate assembly tasks, we utilized a hierarchical control system to manage the intricate movements and coordination needed for precise assembly operations.

Q 26. What is your experience with implementing predictive maintenance strategies for robots?

Predictive maintenance strategies for robots aim to minimize downtime and extend the lifespan of robotic systems by anticipating potential failures. My approach involves a combination of techniques:

- Data acquisition and analysis: We collect data from various sensors on the robot (e.g., temperature, vibration, current) and use machine learning algorithms to identify patterns and anomalies indicating potential issues. These anomalies might include increased vibration, unusual temperature fluctuations, or changes in current draw.

- Condition monitoring: Continuous monitoring of critical components allows for early detection of degradation or abnormal behavior. This early detection can prevent catastrophic failures.

- Proactive maintenance scheduling: Based on the analysis, we proactively schedule maintenance tasks before a component fails, minimizing downtime and preventing unexpected disruptions. This is unlike reactive maintenance where repairs are performed only when failure occurs.

- Sensor fusion: Combining data from multiple sensors provides a more comprehensive picture of the robot’s condition, improving the accuracy of predictive models.

In a previous project involving a high-speed pick-and-place robot, we implemented a predictive maintenance system using vibration sensors and current monitoring. By analyzing this data, we could predict bearing wear and schedule maintenance before it led to a breakdown, resulting in a significant reduction in downtime and improved operational efficiency.

Q 27. How would you approach optimizing the cycle time of a robotic process?

Optimizing the cycle time of a robotic process requires a systematic approach that focuses on identifying and eliminating bottlenecks. My strategy involves:

- Time and motion study: A detailed analysis of each step in the robotic process to identify time-consuming activities.

- Bottleneck identification: Pinpointing the specific steps or processes that limit the overall cycle time. This could involve slow movements, inefficient gripping mechanisms, or inadequate part feeding systems.

- Process optimization: Implementing changes to improve efficiency. Examples include optimizing robot trajectories, utilizing faster actuators, improving gripper design, and optimizing part feeding mechanisms.

- Path planning optimization: Optimizing the robot’s movements to reduce travel time and increase efficiency.

- Parallel processing: Exploring the possibility of parallel operations, where different robots or subsystems work simultaneously to reduce overall cycle time.

In a project involving a robotic painting process, we identified a bottleneck in the paint dispensing system. By implementing a faster dispensing system and optimizing the robot’s path, we reduced the cycle time by 15%, significantly improving productivity.

Q 28. Describe your experience with integrating robots with MES/ERP systems.

Integrating robots with MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning) systems is crucial for real-time data exchange and efficient manufacturing management. My experience involves using various communication protocols and software interfaces to achieve seamless integration:

- Data exchange protocols: Utilizing standards like OPC UA (Open Platform Communications Unified Architecture) or MQTT (Message Queuing Telemetry Transport) for robust and reliable data exchange between the robot controller and the MES/ERP systems. These protocols ensure reliable and efficient data transmission.

- API development: Creating custom APIs (Application Programming Interfaces) to interface with the robot controller and the MES/ERP system. This allows for tailored data exchange to meet specific requirements.

- Data mapping: Establishing clear mappings between data points in the robot controller and the MES/ERP systems. This ensures that data is interpreted correctly by both systems.

- Real-time data monitoring: Integrating dashboards for real-time visualization of robot performance, production status, and error logs. This enables proactive monitoring and quick response to any anomalies.

- Automated reporting: Generating automated reports on production metrics, robot performance, and maintenance needs. This streamlines reporting processes and allows for data-driven decision-making.

In one project, we integrated a fleet of collaborative robots with a MES system to track production progress, monitor robot performance, and trigger automatic alerts for maintenance needs. This improved production visibility and reduced downtime by proactively identifying potential issues.

Key Topics to Learn for Robotics and Automation Integration Interview

- Robotics Fundamentals: Understand robot kinematics, dynamics, control systems (PID, trajectory planning), and common robot architectures (articulated, SCARA, delta). Consider exploring different programming languages used in robotics (e.g., ROS, Python).

- Automation Technologies: Familiarize yourself with PLC programming (ladder logic, structured text), HMI design, industrial communication protocols (Profinet, Ethernet/IP, Modbus), and sensor integration (vision systems, force/torque sensors).

- Integration Strategies: Learn about different approaches to integrating robots into existing manufacturing processes or workflows. This includes topics like cell design, safety considerations (risk assessment, safety standards), and system validation.

- Programming and Simulation: Develop proficiency in robotic programming languages and simulation software. Understanding the process of creating, testing, and deploying robotic programs is vital.

- Case Studies and Applications: Explore real-world examples of robotics and automation integration in various industries (automotive, logistics, healthcare). Analyze successful implementations and understand the challenges overcome.

- Troubleshooting and Maintenance: Demonstrate your understanding of common robotic issues and troubleshooting techniques. Knowledge of preventative maintenance procedures and diagnostic tools is also beneficial.

- Industry Standards and Safety: Be prepared to discuss relevant industry safety standards and regulations pertaining to robotics and automation. This shows awareness of responsible integration practices.

Next Steps

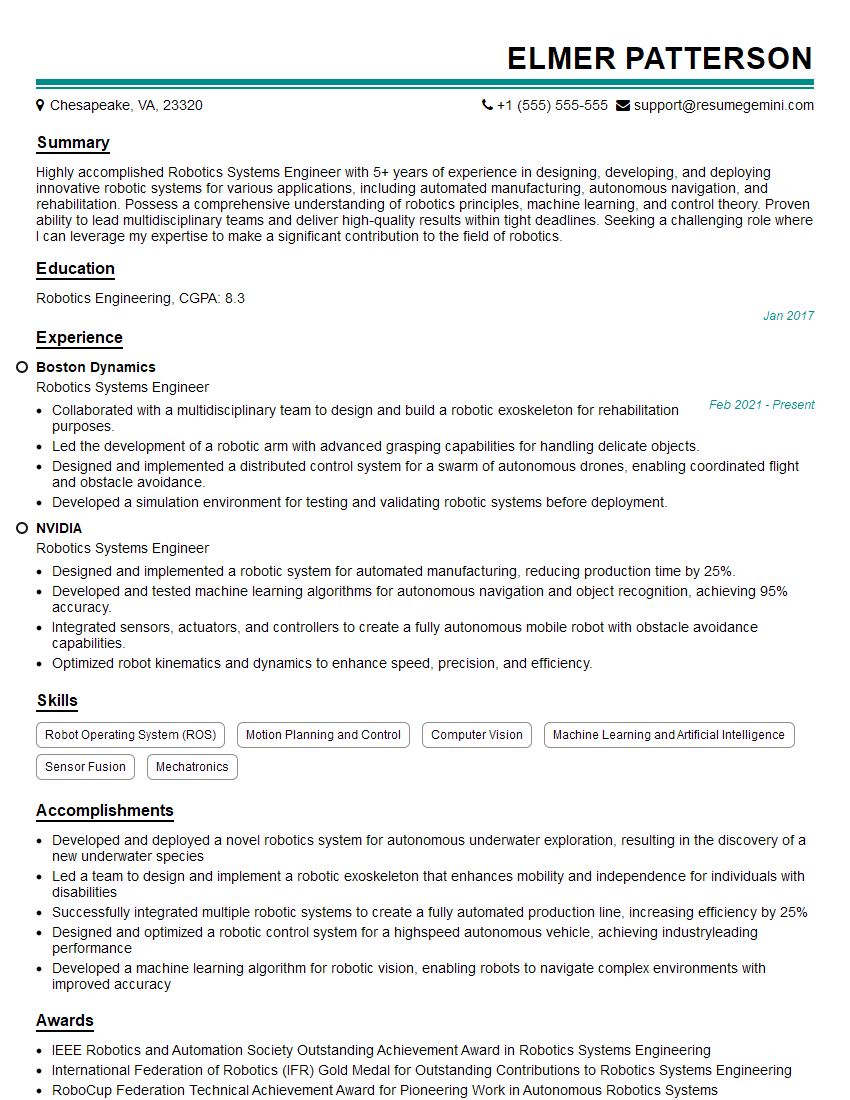

Mastering Robotics and Automation Integration opens doors to exciting and high-demand careers in a rapidly evolving field. To maximize your job prospects, a strong and ATS-friendly resume is crucial. ResumeGemini can significantly enhance your resume-building experience, ensuring your skills and experience shine through to potential employers. We offer examples of resumes tailored to Robotics and Automation Integration to help you create a compelling application that gets noticed. Invest time in crafting a professional and targeted resume – it’s your first impression and a key to unlocking your future career success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO