The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Roller Repair interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Roller Repair Interview

Q 1. Describe your experience with different types of roller bearings.

My experience encompasses a wide range of roller bearings, from the simplest cylindrical rollers to more complex tapered and spherical designs. I’ve worked extensively with various materials, including steel, ceramic, and even specialized polymers for high-temperature or corrosive environments. Understanding the nuances of each type is crucial. For instance, cylindrical rollers are ideal for radial loads, while tapered rollers excel in handling both radial and thrust loads. Spherical rollers, with their self-aligning capabilities, are perfect for applications where misalignment is a concern. I’ve personally dealt with applications in industrial machinery, automotive components, and even precision instruments, each demanding a unique understanding of the bearing’s capabilities and limitations.

- Cylindrical Roller Bearings: These are commonly used in applications requiring high radial load capacity, such as in conveyor systems or motor shafts.

- Tapered Roller Bearings: These bearings are excellent for applications involving both radial and thrust loads, such as in wheel hubs or gearboxes.

- Spherical Roller Bearings: Their self-aligning capabilities make them suitable for applications where shaft misalignment might occur, like in agricultural machinery or heavy-duty equipment.

Q 2. Explain the process of diagnosing a faulty roller.

Diagnosing a faulty roller involves a systematic approach. It begins with a thorough visual inspection, looking for obvious signs of damage like pitting, scoring, or excessive wear. Next, I’d check for play or looseness in the bearing using a feeler gauge or dial indicator. Abnormal noise, such as rumbling, grinding, or squealing during operation, is another key indicator. Further investigation might involve removing the roller and inspecting the raceways for damage. Measuring the roller’s dimensions using precise instruments helps determine if it’s within tolerance. Finally, vibration analysis can pinpoint subtle irregularities that might not be apparent through other methods. Remember, a precise diagnosis is crucial for selecting the right repair strategy.

For example, I once diagnosed a faulty roller in a large industrial fan. The initial visual inspection revealed minimal damage, but upon closer examination and vibration analysis, I discovered microscopic pitting causing increased friction and vibration, leading to eventual failure. This required precision cleaning and replacement of the affected rollers.

Q 3. What are the common causes of roller failure?

Roller failure can stem from several factors. Lubrication issues are a common culprit. Insufficient lubrication leads to excessive friction and heat, causing premature wear. Contamination, such as dust or debris entering the bearing, acts like sandpaper, grinding away at the roller and raceways. Overloading beyond the bearing’s design capacity causes stress fractures and eventual failure. Improper installation, such as misalignment or damage during fitting, can also lead to rapid deterioration. Finally, material fatigue from repeated stress cycles eventually weakens the roller and contributes to failure. It’s essential to address all these potential causes to prevent future problems.

Q 4. How do you determine the appropriate repair method for a damaged roller?

The appropriate repair method depends on the extent of the damage. Minor surface wear might only require cleaning, lubrication, and reassembly. For more significant damage like pitting or cracking, roller replacement is usually necessary. In cases of extensive damage to the raceways, the entire bearing assembly may need to be replaced. The decision also involves considering the cost and downtime associated with each repair option. Replacing only the damaged component is usually more cost-effective than replacing the whole assembly, provided the rest of the system is in good working order. However, safety and longevity should always take precedence.

For instance, a roller with minor surface scratches might be repaired by honing and relubrication, while a roller with significant pitting necessitates replacement.

Q 5. Describe your experience with roller alignment procedures.

Roller alignment is critical for proper functionality and longevity. Improper alignment leads to uneven load distribution, increased wear, and premature failure. My experience includes using various alignment tools, from simple alignment bars to sophisticated laser alignment systems. Precise measurements are crucial, using dial indicators or laser alignment equipment to ensure that all components are properly positioned relative to one another. During the installation process, I carefully monitor for any misalignment using these tools and make adjustments as needed. It’s a delicate balance between precision and the efficient completion of the task. The methods vary based on the complexity of the system.

In one instance, I worked on aligning the rollers in a large printing press. Using a laser alignment system, we were able to precisely adjust the rollers, improving print quality and reducing wear significantly.

Q 6. What tools and equipment are essential for effective roller repair?

Effective roller repair necessitates a range of specialized tools and equipment. These include precision measuring instruments like dial indicators and micrometers for accurate measurements. Specialized wrenches and sockets are essential for disassembling and reassembling components. Cleaning equipment, such as ultrasonic cleaners and degreasers, are critical for removing contaminants. Lubrication tools, including grease guns and oil dispensers, are vital for applying the correct type and amount of lubricant. Depending on the extent of repair, additional tools like honing tools or bearing pullers may also be necessary. Finally, safety equipment, including safety glasses, gloves, and appropriate clothing, is paramount.

Q 7. How do you ensure the safety of yourself and others during roller repair?

Safety is always my top priority. Before beginning any roller repair, I carefully assess the situation, identifying potential hazards. I always use appropriate personal protective equipment (PPE), including safety glasses, gloves, and protective clothing, to prevent injuries from sharp edges, flying debris, or hazardous materials. I ensure the area is properly secured to prevent accidental contact with moving parts or energized equipment. I also follow lockout/tagout procedures to ensure machinery is de-energized before beginning any work. Finally, I follow all relevant safety regulations and guidelines to minimize risks and protect both myself and others.

One crucial safety measure is to always have a second person present when working with heavy or complex machinery. A second pair of eyes helps ensure safety and efficiency.

Q 8. Explain your experience with preventative maintenance for rollers.

Preventative maintenance is crucial for extending the lifespan of rollers and preventing costly downtime. It’s like regular check-ups for your car – much better than waiting for a breakdown. My approach involves a structured process:

- Regular Inspections: I visually inspect rollers for wear, tear, cracks, or misalignment at scheduled intervals, the frequency depending on the roller’s usage and environment. For high-usage rollers in demanding applications, this might be weekly; for others, it could be monthly.

- Lubrication: Proper lubrication is key. I use the appropriate lubricant recommended by the manufacturer, ensuring all moving parts are adequately lubricated to reduce friction and wear. I carefully document the type and amount of lubricant used, and the date of application.

- Cleaning: Rollers can accumulate dirt, debris, and corrosive materials. Regular cleaning, using appropriate solvents and brushes, prevents these from interfering with performance and causing premature damage. I ensure the rollers are thoroughly cleaned and dried before re-installation.

- Tightening and Adjustment: I check all bolts and fasteners for tightness and adjust them as necessary, preventing vibrations and ensuring proper alignment. Misalignment is a common cause of roller damage.

- Record Keeping: Meticulous record-keeping is essential. I maintain a detailed log of all inspections, maintenance activities, and any observed anomalies. This history helps anticipate potential problems and optimize maintenance schedules.

For instance, I once prevented a major production halt at a paper mill by identifying slight misalignment during a routine inspection of their large-diameter rollers. A timely adjustment prevented a catastrophic failure that would have cost thousands of dollars in repairs and lost production.

Q 9. How do you handle emergency roller repairs?

Emergency roller repairs require immediate action and often involve quick thinking and problem-solving under pressure. My approach is systematic:

- Safety First: I prioritize safety by ensuring the area is secured, power is isolated if necessary, and appropriate personal protective equipment (PPE) is used.

- Assessment: A rapid assessment of the damage is crucial. This determines the extent of the problem and whether a temporary fix or a full replacement is needed. I identify the root cause of the failure, if possible.

- Temporary Fix (if feasible): In some cases, a temporary fix – like welding a crack or using a temporary bearing – can restore limited functionality while a proper repair is planned. This minimizes downtime.

- Replacement/Repair: If a temporary fix isn’t feasible, I proceed with the appropriate repair or replacement. This might involve disassembling the roller, replacing damaged parts, and reassembling it. I always follow the manufacturer’s instructions and specifications.

- Documentation: I thoroughly document all emergency repairs, including the cause of failure, actions taken, and any necessary follow-up.

For example, I once handled a broken roller shaft on a conveyor belt in a warehouse late at night. Using a temporary support structure and a quick fix with high-strength epoxy, I got the conveyor operational within hours, preventing significant disruption to their overnight shipping operations.

Q 10. Describe your troubleshooting skills related to roller malfunctions.

Troubleshooting roller malfunctions is a blend of observation, analysis, and experience. I follow a logical process:

- Gather Information: I start by gathering information about the symptoms – what’s wrong, when did it start, and under what conditions. I also review maintenance logs.

- Visual Inspection: I carefully inspect the roller for visible signs of damage – cracks, wear, misalignment, or loose components. This often reveals the source of the problem.

- Testing: Depending on the roller type and application, various tests might be needed, such as measuring runout, checking bearing play, or evaluating the lubrication. Specialized tools may be employed.

- Systematic Elimination: I systematically eliminate possible causes until the root problem is identified. This is often a process of deduction.

- Documentation: I document the entire troubleshooting process, including the symptoms, tests performed, and conclusions drawn. This helps in future diagnosis and preventive maintenance.

A recent case involved a roller exhibiting excessive vibration. Through systematic testing, I pinpointed the problem to a damaged bearing, which was quickly replaced, solving the issue.

Q 11. What are the different types of roller materials and their applications?

Roller materials vary widely, depending on the application and the forces involved. The choice of material is crucial for performance and longevity.

- Steel: A common material due to its strength and durability. Used in high-load applications such as steel mills and heavy machinery.

- Cast Iron: Offers good wear resistance and is often used in less demanding applications. It’s cost-effective compared to steel.

- Polyurethane: A versatile material known for its abrasion resistance and shock absorption. Frequently used in conveyor systems handling abrasive materials.

- Nylon: Offers good abrasion resistance and is often used in lighter-duty applications, such as office equipment or packaging machinery.

- Rubber: Provides cushioning and vibration damping. Ideal for applications requiring smooth operation and shock absorption.

The selection of material depends heavily on factors such as load, speed, operating temperature, and the nature of the material being conveyed. For example, a roller handling hot steel would require a high-temperature steel alloy, while a roller in a food processing plant would need a material approved for food contact.

Q 12. How do you assess the condition of a roller before repair?

Assessing the condition of a roller before repair is crucial to determine the extent of the work needed. My process combines visual inspection with measurements and testing:

- Visual Inspection: I visually examine the roller for any signs of wear, cracks, corrosion, or damage to the surface, bearings, or mounting hardware. This is the first step, providing a good overview of the roller’s condition.

- Dimensional Measurements: I use precision measuring tools like calipers and micrometers to check the roller’s diameter, length, and other critical dimensions. Any deviation from the original specifications indicates wear or damage.

- Bearing Inspection: I check the bearings for play, noise, or signs of wear. A damaged bearing is a common cause of roller malfunction.

- Runout Measurement: For rotating rollers, I measure runout using a dial indicator to detect any imbalance or misalignment. Excessive runout can lead to vibration and premature failure.

- Material Testing (if necessary): In some cases, more in-depth material testing – such as hardness testing or metallurgical analysis – may be needed to assess material degradation.

For instance, detecting a slight reduction in diameter during a pre-repair inspection can prevent a seemingly minor problem from developing into a major failure down the line.

Q 13. What safety precautions do you take when working with heavy rollers?

Safety is paramount when working with heavy rollers. My safety precautions include:

- Lockout/Tagout: Before any work begins, I ensure the roller is properly de-energized and locked out to prevent accidental start-up. This is particularly critical for powered rollers.

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, including safety glasses, gloves, steel-toed boots, and hearing protection, as needed. The specific PPE required depends on the task and the potential hazards.

- Lifting Equipment: When handling heavy rollers, I use appropriate lifting equipment such as hoists, cranes, or forklifts, ensuring they are correctly rated for the load. I follow all safety procedures for using this equipment.

- Proper Handling Techniques: I use proper lifting techniques to prevent injury. This includes maintaining a stable base, using proper posture, and avoiding twisting or reaching.

- Work Area Safety: I ensure the work area is clean, well-lit, and free of obstacles to minimize the risk of trips or falls. I use safety cones or barriers to secure the area.

Neglecting safety precautions can lead to serious accidents. By adhering strictly to these measures, I guarantee a safe working environment for myself and others.

Q 14. How do you interpret engineering drawings and specifications for rollers?

Interpreting engineering drawings and specifications is essential for accurate roller repair. I have extensive experience in reading and understanding technical drawings and specifications. This includes:

- Understanding Dimensions and Tolerances: I meticulously examine the dimensions and tolerances specified on the drawings. Understanding tolerances is vital for ensuring proper fit and function after repair.

- Material Specifications: I carefully review the material specifications to identify the correct type of steel, alloy, or other material for replacement parts. Using the wrong material can compromise the roller’s performance and lifespan.

- Bearing Specifications: I review the bearing specifications, including size, type, and load rating, to ensure that replacement bearings meet the required performance characteristics.

- Surface Finish Requirements: I pay attention to surface finish specifications to ensure the repaired roller meets the required smoothness and tolerances. Surface finish can significantly impact the roller’s performance.

- Assembly Drawings: I use assembly drawings to understand how the various components of the roller fit together and to ensure proper reassembly after repairs.

Accurate interpretation of these drawings is not just about reading numbers; it’s about understanding the design intent and ensuring that the repair maintains the integrity and functionality of the roller. A seemingly minor discrepancy can have significant consequences.

Q 15. Describe your experience with repairing rollers in different industrial settings.

My experience spans a wide range of industrial settings, from paper mills and steel plants to conveyor systems in distribution centers and printing facilities. Each environment presents unique challenges. For instance, in a paper mill, rollers often face high humidity and the abrasive action of paper pulp, requiring specialized repair techniques and materials resistant to corrosion. In steel plants, the extreme temperatures and potential for heavy impact necessitate robust repairs using high-temperature alloys and advanced welding techniques. I’ve repaired various roller types, including those used in conveying, printing, and winding operations, adapting my approach to the specific application and material of each roller.

- Paper Mill: Repaired numerous rollers damaged by corrosive pulp, implementing corrosion-resistant coatings and precision machining to restore their surface integrity.

- Steel Plant: Successfully repaired rollers subjected to high temperatures and impact damage using specialized welding and heat-treating processes to maintain dimensional accuracy and structural strength.

- Conveyor System: Addressed roller wear and tear due to continuous operation, replacing worn bearings, bushings, and shafts to ensure smooth, efficient material handling.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with various types of roller lubrication?

Roller lubrication is critical for longevity and performance. My familiarity covers a wide spectrum of lubricants, each suited for different applications and operating conditions. This includes:

- Grease Lubrication: Common for heavier-duty applications, offering excellent protection against wear and contamination. The choice of grease depends on factors like operating temperature, load, and speed. I’ve worked with lithium-based, calcium-based, and synthetic greases, selecting the optimal type based on the specific roller and environment.

- Oil Lubrication: Generally used in high-speed, low-load applications where a continuous supply of lubricant is necessary. This can involve oil bath systems, oil mist lubrication, or even pressurized oil delivery systems. The viscosity and additives in the oil are crucial for effective lubrication and preventing oxidation.

- Solid Lubrication: Used in extreme conditions where traditional lubricants might fail, such as high temperatures or vacuum environments. This might involve materials like molybdenum disulfide (MoS2) or graphite, applied as coatings or incorporated into the roller material itself.

Understanding the chemical compatibility of lubricants with the roller material is essential to prevent degradation or unexpected reactions.

Q 17. Explain the importance of proper roller installation.

Proper roller installation is fundamental to preventing premature wear and ensuring operational efficiency. A poorly installed roller can lead to misalignment, increased friction, vibrations, and ultimately, catastrophic failure. Key aspects include:

- Accurate Alignment: Ensuring the roller is perfectly aligned with its supporting structures is crucial. Misalignment generates excessive stress and uneven wear, significantly reducing the roller’s lifespan. Laser alignment tools are often used for precise alignment.

- Proper Mounting: Rollers must be securely mounted to their shafts and bearings, preventing slippage or movement during operation. This may involve using appropriate shims, locknuts, or keyways to ensure a tight, stable fit.

- Bearing Installation: Bearings must be properly seated and lubricated. Improper installation can damage the bearings, leading to premature failure and costly replacements.

- Surface Finish: Inspecting the roller’s mounting surfaces for any damage or imperfections is crucial, ensuring a smooth and consistent contact surface.

Ignoring these steps can lead to significant downtime and repair costs, highlighting the importance of adherence to manufacturer’s specifications and best practices.

Q 18. What is your experience with roller balancing procedures?

Roller balancing is essential for high-speed applications to minimize vibrations and ensure smooth operation. Unbalanced rollers generate centrifugal forces that can lead to premature bearing wear, shaft fatigue, and even structural damage. My experience includes both static and dynamic balancing techniques:

- Static Balancing: A simpler method suitable for smaller rollers where the imbalance is relatively large. It involves mounting the roller on a horizontal shaft and identifying the heavy side by observing its resting position. Material is then removed or added to achieve balance.

- Dynamic Balancing: Used for larger, higher-speed rollers to account for both static and dynamic imbalances. This involves using specialized balancing machines that precisely measure the imbalance at various points around the roller’s circumference. Corrective weights are then carefully added to counteract the imbalance.

I’m proficient in using various balancing machines and interpreting the results to achieve optimal balance and minimal vibration.

Q 19. How do you document the repair process and maintain accurate records?

Meticulous documentation is paramount. I maintain detailed records of every repair, including:

- Inspection Reports: Detailed descriptions of the roller’s condition before and after repair, including measurements, photographs, and any identified defects.

- Repair Procedures: Step-by-step accounts of the repair process, including parts replaced, materials used, and tools employed.

- Testing Results: Documentation of post-repair testing, such as balance reports, runout measurements, and surface roughness tests.

- Maintenance Logs: Tracking of all maintenance performed on the roller throughout its lifespan.

This ensures traceability, facilitates future maintenance, and helps identify potential problems or trends in roller performance. I utilize both digital and physical records, maintaining a secure and easily accessible archive.

Q 20. What are your methods for quality control in roller repair?

Quality control is a continuous process, not just a final check. It begins with a thorough inspection to accurately diagnose the problem and ends with verification that the repair meets or exceeds original specifications. My quality control methods include:

- Visual Inspection: Careful examination of the roller’s surface for cracks, wear, corrosion, or other defects.

- Dimensional Measurements: Using precision measuring tools to check the roller’s diameter, length, and runout.

- Surface Roughness Measurement: Determining the surface finish to ensure it meets the required specifications.

- Balance Testing: Verifying that the repaired roller is properly balanced to minimize vibrations.

- Functional Testing: Testing the roller under simulated operating conditions to ensure it meets performance requirements.

Adhering to strict tolerances and utilizing calibrated equipment is critical for consistently high-quality repairs.

Q 21. Describe your experience with working with different roller manufacturers.

My experience encompasses a wide range of roller manufacturers, each with its unique designs and manufacturing processes. This includes working with both large multinational corporations and smaller specialized manufacturers. I’ve worked on rollers made from various materials such as steel, cast iron, rubber, and various polymers. Understanding the specific materials and design features of different manufacturers’ rollers allows for more effective diagnosis and repair strategies. For example, repairing a roller from manufacturer A might require a different approach compared to one from manufacturer B, due to differences in material composition, bearing types, or shaft designs. This necessitates accessing manufacturer documentation, technical specifications, and where needed, consulting directly with the manufacturers to ensure repairs are carried out correctly and to guarantee the integrity of the repaired roller.

Q 22. How do you handle difficult or unexpected roller repair challenges?

Unexpected challenges in roller repair are commonplace. My approach involves a systematic troubleshooting process. First, I carefully examine the roller and its surrounding components to identify the root cause of the problem. This often involves visual inspection, using measuring tools like calipers and micrometers, and sometimes even specialized equipment like ultrasonic flaw detectors to identify internal damage.

Once the problem is identified, I draw on my experience with various repair techniques – from simple lubrication and adjustment to more complex welding or machining solutions. For example, I once encountered a roller with severe pitting and corrosion. Initial assessment suggested replacement, which would be costly and time-consuming. However, after carefully evaluating the damage, I opted for a combination of precision grinding to remove the damaged surface and a specialized hard chrome plating to restore the roller’s original dimensions and surface hardness. This solution saved significant time and money. If a solution isn’t immediately apparent, I leverage my network of colleagues and industry resources to find the best approach, ensuring the repaired roller meets the highest quality standards.

Q 23. Explain your knowledge of different roller shaft repair techniques.

Roller shaft repair techniques vary depending on the nature and extent of the damage. Common methods include:

- Grinding and Polishing: Used for removing minor surface imperfections, scratches, or pitting. This restores the roller’s surface finish and improves its operational efficiency.

- Welding: Applied for repairing cracks, fractures, or significant material loss. I’m experienced in various welding processes, including TIG and MIG welding, selecting the most suitable technique based on the roller material and the type of damage. Proper pre- and post-weld heat treatments are critical to prevent distortion and ensure optimal strength.

- Hard Chrome Plating: Builds up the roller shaft’s diameter to compensate for wear or erosion. This process improves surface hardness and corrosion resistance, extending the roller’s lifespan significantly.

- Machining: Involves using lathes or milling machines to reshape or resize a damaged roller shaft. This is a precise technique requiring careful measurement and control to maintain the roller’s original specifications.

- Sleeve Repair: Involving the installation of a precision-machined sleeve over a damaged shaft, effectively restoring its diameter and surface finish. This is a particularly useful method for severely worn or damaged shafts where other repair methods are not feasible.

The choice of technique depends on factors such as the material of the roller, the severity of the damage, and the required tolerances. I always prioritize the most cost-effective and durable solution while adhering to safety regulations.

Q 24. How do you stay updated on the latest technologies and advancements in roller repair?

Staying current in roller repair necessitates continuous professional development. I actively participate in industry conferences and workshops, attending seminars on new materials, techniques, and equipment. I also subscribe to trade publications and online resources focused on mechanical engineering and industrial maintenance. This allows me to keep abreast of advancements in areas like advanced materials, automated repair systems, and improved diagnostics. Furthermore, I actively engage in online forums and communities dedicated to roller repair, exchanging knowledge and best practices with other experts in the field. Continuous learning is essential to ensuring I am providing the most efficient and effective repair solutions.

Q 25. What are the common causes of roller misalignment?

Roller misalignment stems from several sources. Common causes include:

- Improper installation: Incorrect mounting, lack of proper alignment during installation, or using worn or damaged mounting hardware.

- Wear and tear: Over time, bearings and other components can wear out, leading to misalignment of the roller.

- Structural damage: Physical damage to the roller shaft, frame, or supporting structure can cause misalignment.

- External forces: Vibrations, impacts, or uneven loads can cause the roller to shift from its proper alignment.

- Thermal expansion: Uneven heating of the system causing parts to expand differentially leading to misalignment.

Careful inspection and precise measurement are crucial to identify the root cause. Addressing the underlying issue, rather than just symptoms, is key to preventing recurrence.

Q 26. How do you measure roller diameter and surface roughness?

Precise measurement of roller diameter and surface roughness is critical. For diameter, I utilize a set of high-precision vernier calipers or a digital micrometer, depending on the size and required accuracy. Multiple measurements are taken at different points around the roller’s circumference to ensure uniformity. For surface roughness, I use a surface roughness tester, also known as a profilometer. This device measures the surface texture using a stylus that traverses the surface. The results are expressed in Ra (average roughness) or Rz (maximum height of the surface irregularities). This data is vital for assessing the wear and tear on the roller and determining the appropriate repair or replacement strategy.

Q 27. What is your experience with weld repair of damaged rollers?

Weld repair of damaged rollers requires specialized skills and expertise. I’m proficient in various welding techniques, including TIG and MIG welding, selecting the appropriate method based on the roller’s material and the type of damage. Before welding, the damaged area is carefully prepared by cleaning, grinding, and possibly preheating to ensure proper fusion. I employ specialized filler materials to match the roller’s composition, maintaining its strength and preventing cracking. Post-weld heat treatment is often necessary to relieve internal stresses and improve the weld’s structural integrity. The repaired area is then meticulously inspected for defects using techniques like visual inspection, dye penetrant testing, or magnetic particle testing to ensure the weld is sound and capable of withstanding the intended loads.

Q 28. Describe your experience with hydraulic roller systems.

My experience encompasses a range of hydraulic roller systems. I understand the critical role of hydraulic pressure and flow control in their operation. I am familiar with various system components, including pumps, valves, actuators, and pressure sensors. Troubleshooting hydraulic roller system issues often involves a systematic approach, checking for leaks, pressure drops, and component malfunctions. I am experienced in diagnosing problems ranging from simple seal replacements to complex hydraulic circuit issues and can identify and correct problems related to hydraulic fluid contamination, pump wear, and valve malfunctions. Maintaining proper fluid levels, regular filtration, and preventive maintenance is crucial to prevent costly breakdowns and ensuring the efficient operation of these systems.

Key Topics to Learn for Roller Repair Interview

- Roller Types and Mechanisms: Understanding different roller designs (e.g., cylindrical, conical, spherical), their functionalities, and the mechanics of their operation within various systems.

- Common Roller Failures: Identifying wear and tear, defects, misalignments, and other issues leading to roller malfunction. This includes practical understanding of visual inspection and diagnostic techniques.

- Repair Techniques and Procedures: Mastering different repair methods, including cleaning, lubrication, replacement of damaged parts, and surface restoration techniques. This should cover both manual and potentially automated repair processes.

- Materials Science and Selection: Understanding the materials used in roller construction (metals, polymers, etc.), their properties, and appropriate material selection for specific applications and operating conditions.

- Troubleshooting and Problem-Solving: Developing a systematic approach to diagnosing roller-related problems, including root cause analysis and effective solutions.

- Safety Procedures and Regulations: Familiarity with relevant safety protocols and industry regulations pertaining to roller repair and maintenance.

- Maintenance and Preventative Measures: Understanding preventative maintenance schedules, lubrication strategies, and inspection techniques to extend roller lifespan and minimize downtime.

- Specialized Tools and Equipment: Familiarity with the tools and equipment commonly used in roller repair, including their proper usage and maintenance.

Next Steps

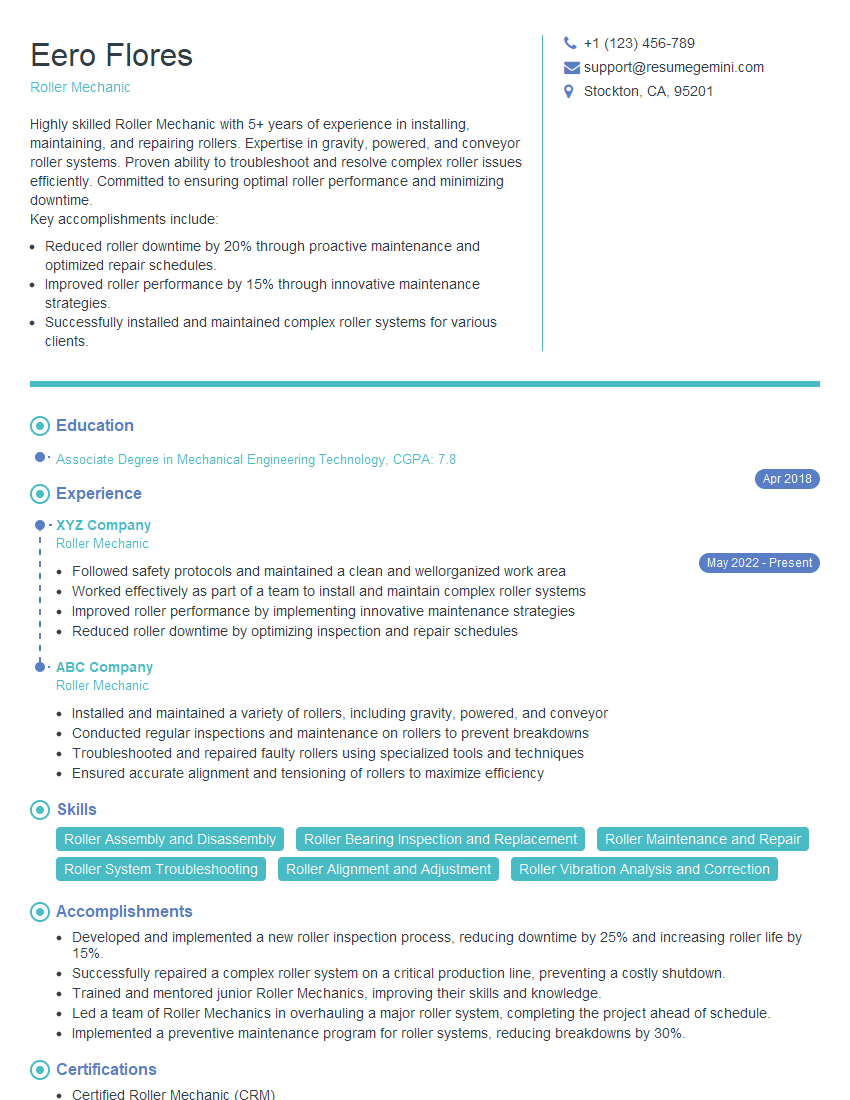

Mastering roller repair skills opens doors to rewarding and diverse career opportunities in manufacturing, industrial maintenance, and related fields. A strong understanding of these principles is highly valued by employers. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini can help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to the Roller Repair field are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO