Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Roustabout Operations interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Roustabout Operations Interview

Q 1. Explain the safety procedures for working on a drilling rig.

Safety on a drilling rig is paramount. It’s not just about following rules; it’s about a mindset of constant vigilance and proactive risk mitigation. Every action involves assessing potential hazards and taking precautions.

- Personal Protective Equipment (PPE): This is the cornerstone. It includes hard hats, safety glasses, steel-toed boots, gloves, and hearing protection – always worn. Specific PPE requirements change based on the task, for instance, using a respirator during painting or a face shield when grinding.

- Emergency Procedures: We must know the location of emergency shut-off valves, fire extinguishers, and muster points. Drills are crucial for effective response. Knowing how to react to a well kick, fire, or equipment malfunction is vital – it’s not just theoretical knowledge; we’ve regularly practiced these scenarios.

- Fall Protection: Heights are inherent to rig work. Harnesses, lanyards, and guardrails are essential when working at heights. We never take shortcuts – proper anchoring points and regular inspections are a must.

- Hazardous Materials Handling: Drilling fluids, chemicals, and fuels present significant risks. We follow strict handling protocols, including proper labeling, storage, and disposal. Understanding the Material Safety Data Sheets (MSDS) for all substances is essential.

- Communication: Clear and constant communication is vital. Using radios and hand signals is crucial, especially in noisy environments. We follow standardized communication procedures to avoid misunderstandings, which can lead to accidents.

- Toolbox Talks: Regular safety meetings focusing on specific hazards and best practices are commonplace. These discussions make everyone aware of the current risks and how to avoid them.

For instance, during a pipe-handling operation, we’d always ensure proper lifting techniques are used, and everyone is aware of the load’s weight and trajectory. A near miss reporting system encourages open communication about potential hazards, which helps us prevent accidents before they happen.

Q 2. Describe your experience with different types of drilling equipment.

My experience spans various drilling equipment, from top drives to mud pumps, and I’m familiar with their operation, maintenance, and safety procedures.

- Top Drives: I’m proficient in operating and maintaining various top drive systems, including those used in both land and offshore drilling. This includes understanding the hydraulic systems, controlling the rotary speed and torque, and performing routine maintenance to ensure optimal operation.

- Mud Pumps: I’ve extensive experience with triplex and duplex mud pumps, including their operation, maintenance, troubleshooting, and safety protocols. This involves understanding the pump’s hydraulic systems, optimizing mud flow rates and pressures, and detecting and resolving problems like fluid leaks or valve issues.

- Drawworks: My experience includes operating and maintaining drawworks systems, crucial for controlling the hoisting and lowering of drilling pipes. This includes handling different types of hoisting lines and brakes, performing routine maintenance, and troubleshooting mechanical issues.

- Rotary Table: I have worked extensively with both mechanical and hydraulic rotary tables, understanding their functions in rotating the drill string. This includes performing regular maintenance, handling different sizes of drill pipes, and troubleshooting mechanical problems.

For example, I once had to troubleshoot a malfunctioning top drive during a critical operation. By systematically checking the hydraulic system and power supply, I quickly identified a faulty pressure sensor, resolving the issue and minimizing downtime. This experience highlighted the importance of a thorough understanding of the equipment’s inner workings.

Q 3. How do you handle heavy lifting and manual labor tasks?

Heavy lifting and manual labor are integral parts of the roustabout role. It’s about technique, teamwork, and understanding your physical limitations.

- Proper Lifting Techniques: We always use proper lifting techniques to avoid injuries. This involves keeping the back straight, bending at the knees, and using our legs to lift rather than our backs. We employ lifting aids such as cranes, hoists, or come-alongs wherever possible.

- Teamwork: Heavy lifting tasks are rarely solo efforts. We coordinate our efforts to lift safely and efficiently. Clear communication and coordination are paramount.

- Mechanical Advantage: We leverage mechanical advantage through tools like chain blocks, levers, and other lifting devices to make difficult tasks manageable.

- Safety Precautions: We always secure loads to prevent accidental slippage or falls. We also ensure adequate space and clearance around the lifting operation to avoid collisions.

- Physical Fitness: Maintaining good physical fitness is essential to handle the demands of the job. This enables us to perform tasks more efficiently and safely.

I remember once, we had to manually lift a heavy section of pipe. By employing the buddy system and careful lifting techniques, we were able to move it without incident. This showed the importance of teamwork and safe work practices, especially with heavier items that might push physical limitations.

Q 4. What are your knowledge of different mud types and their properties?

Drilling mud, or drilling fluid, is crucial for wellbore stability and efficiency. Different mud types have unique properties tailored to specific geological formations and drilling conditions.

- Water-Based Muds: These are the most common and relatively inexpensive. They can be further categorized into clear, polymer, or weighted muds, each with different properties impacting viscosity, density, and filtration control. Clear muds are good for initial drilling, while weighted muds help to control pressure.

- Oil-Based Muds: These are used when drilling through formations prone to shale instability or when higher lubricity is needed. They offer excellent shale inhibition and reduced friction, but their environmental impact is higher.

- Synthetic-Based Muds: These are environmentally friendly alternatives to oil-based muds. They provide similar performance benefits with a reduced environmental footprint.

The properties of each mud type are vital. Density (weight) is crucial for controlling pressure; viscosity affects the mud’s flow rate and ability to carry cuttings; filtration control minimizes fluid loss into the formation, which can cause instability. We constantly monitor these parameters to adjust mud properties for optimal drilling performance.

For example, when drilling through a shale formation, selecting an oil-based or synthetic-based mud with excellent shale inhibition properties is essential to prevent wellbore collapse.

Q 5. What are the common causes of well control incidents and how to prevent them?

Well control incidents, like kicks (influx of formation fluids into the wellbore), are serious and potentially catastrophic. Preventing them requires rigorous adherence to procedures and proactive monitoring.

- Pressure Control Equipment Malfunction: Failures in the blowout preventer (BOP), valves, or other pressure control equipment are significant contributors. Regular maintenance and testing are crucial. Equipment must be inspected regularly, and testing should be done according to safety procedures.

- Improper Drilling Practices: Drilling too quickly or failing to monitor well pressures closely can lead to kicks. Maintaining precise control over drilling parameters and frequent mud weight checks are essential.

- Incorrect Mud Weight: An inadequate mud weight can’t counteract the formation pressure, leading to kicks. Regular monitoring and adjustment of mud weight are vital based on real-time data.

- Formation Fracturing: If the formation pressure is exceeded, the formation may fracture, causing an influx of fluids. This requires proper pressure calculations and monitoring prior to drilling operations.

Prevention involves constant monitoring of well pressure, following established drilling procedures, conducting regular equipment inspections, and maintaining clear communication among the drilling crew. We conduct regular well control training, which includes simulated kicks to enhance response strategies. A well-planned and executed well control plan is mandatory for any drilling operation.

Q 6. Explain your experience with pipe handling and racking procedures.

Pipe handling and racking procedures are critical for safety and efficiency. It’s about organized and methodical movements to prevent accidents.

- Lifting and Lowering: We use cranes, derricks, or other lifting equipment for handling pipes. Safety chains, proper slings, and careful signaling are essential. We always ensure the load is properly secured and balanced.

- Racking Procedures: Pipes are racked systematically to optimize space and prevent damage. Proper racking ensures easy accessibility and prevents pipes from falling or rolling.

- Manual Handling: Even with machinery, manual handling is sometimes necessary. We adhere strictly to proper lifting techniques, avoiding twisting or bending motions.

- Inspection: Before handling any pipe, we inspect it for damage. Damaged pipes are clearly marked and handled with extra care to prevent further damage or accidents. This might involve utilizing special equipment or procedures to prevent injury.

I’ve personally overseen countless pipe handling operations, ensuring the safe and efficient movement of drill pipe, casing, and tubing. For instance, on one occasion, we were carefully transferring heavy drill pipe in a confined space. Efficient teamwork, clear communication, and precise coordination of the crane and ground crew prevented any incidents. This demonstrated the importance of well-defined procedures and the coordination between different crew members.

Q 7. How do you ensure the proper maintenance and operation of rig equipment?

Rig equipment maintenance is crucial for safety and operational efficiency. It’s a proactive approach to prevent breakdowns and ensure everything works correctly.

- Preventative Maintenance: We follow scheduled maintenance plans for all equipment. This includes regular inspections, lubrication, and part replacements as needed. We follow manufacturer’s recommendations and maintain detailed records of all maintenance activities.

- Corrective Maintenance: When equipment malfunctions, prompt repair is essential. We troubleshoot problems, identify faulty parts, and replace or repair them efficiently. This often requires a deep understanding of the equipment’s inner workings.

- Equipment Inspections: Daily and regular inspections are conducted to identify potential problems before they become major issues. This might involve checking for leaks, wear and tear, or other signs of damage.

- Communication: Maintaining open communication between the roustabouts and the mechanics is key to ensuring timely repairs and preventing problems from escalating. Reporting any issues or concerns is paramount.

For example, we regularly lubricate the crown block and hook on the drilling derrick to prevent wear and tear. If a mud pump starts making unusual noises, we’ll immediately report it to the mechanics to ensure any potential damage is addressed quickly. Proactive maintenance not only prevents major breakdowns but also contributes to a safer working environment and enhances overall drilling efficiency.

Q 8. Describe your experience working in a team environment under pressure.

Teamwork under pressure is crucial in roustabout operations. Imagine a situation where a critical piece of equipment malfunctions during a well completion operation – a significant delay could cost the company thousands of dollars. In such scenarios, I’ve consistently demonstrated the ability to remain calm, prioritize tasks effectively, and leverage the strengths of my team members. For example, during a challenging wellhead repair, we faced a sudden influx of mud, threatening to delay the operation significantly. Instead of panicking, I coordinated the team, assigning individuals to specific tasks based on their expertise: one to manage the mud flow, another to assist with the repair, and a third to monitor safety parameters. Through clear communication and collaborative problem-solving, we managed to mitigate the issue, minimize the delay, and complete the operation safely and efficiently.

This experience underscores my ability to work effectively under pressure while empowering others to contribute their best work. I believe in fostering an environment where open communication and mutual respect are paramount, leading to better team performance and problem-solving capabilities.

Q 9. How familiar are you with emergency response procedures on a drilling rig?

Emergency response procedures on a drilling rig are paramount to safety and are drilled into every member of the team. My familiarity extends to all aspects, from recognizing the signs of an emergency (e.g., fire, well control issues, equipment malfunction) to executing the established protocols. I am proficient in using various emergency equipment, including fire extinguishers, first-aid kits, and personal protective equipment (PPE).

For instance, I’ve participated in multiple emergency drills, practicing scenarios such as well kicks and fires. These drills helped solidify my understanding of the company’s emergency response plan (ERP), which includes the evacuation procedures, communication protocols, and the roles and responsibilities of each team member. My experience also includes assisting in actual emergency situations – we once had a minor fire during a night shift that we quickly extinguished, following the proper procedures, thanks to our constant vigilance and rigorous training. My training includes detailed knowledge of the emergency shutdown systems (ESD) and their proper activation procedures.

Q 10. Describe your experience with different types of well completion operations.

Well completion operations encompass a wide range of activities, and I have experience with several types. This includes running and pulling tubing, setting and retrieving downhole tools, and performing various cementing operations. I’m also familiar with different completion techniques, such as gravel packing, sand control, and the use of various types of packers and completion plugs.

- Tubing Operations: I’ve participated in numerous operations involving running and pulling tubing strings of varying sizes and lengths, ensuring proper make-up and break-out procedures are followed to prevent damage and accidents.

- Cementing Operations: I understand the importance of properly mixing and placing cement to achieve a good bond in the wellbore, and I’ve assisted with various cementing techniques, such as primary cementing and squeeze cementing.

- Downhole Tools: My experience includes handling and running various downhole tools, such as packers, plugs, and other specialized equipment, always prioritizing safety and efficiency.

Each operation requires meticulous attention to detail and strict adherence to safety protocols. A thorough understanding of the procedures and the equipment is essential for successful and safe well completion.

Q 11. How do you identify and report safety hazards on the rig site?

Identifying and reporting safety hazards is a top priority. I proactively scan the rig site, observing for potential dangers such as tripping hazards, unsafe equipment, and breaches in safety procedures. My approach includes both visual inspections and engaging with fellow roustabouts to gather information.

My reporting method involves using the company’s established safety reporting system, which often includes filling out detailed incident reports and communicating directly with supervisors. For example, if I notice a damaged piece of equipment or an unsafe work practice, I immediately report it to my supervisor, providing detailed information about the location, nature, and potential consequences of the hazard. I will then follow up to ensure that corrective actions have been taken. I believe that a culture of proactive safety reporting is essential to maintain a safe working environment on the rig.

Q 12. Explain your understanding of the importance of environmental compliance.

Environmental compliance is non-negotiable in our industry. I understand that our operations can significantly impact the environment, and it’s our collective responsibility to minimize that impact. This includes adhering to all relevant environmental regulations and company policies related to waste disposal, emissions control, and spill prevention.

For instance, I’m familiar with procedures for handling drilling fluids and cuttings, ensuring their proper disposal in accordance with environmental regulations. I also understand the importance of preventing and responding to spills promptly and efficiently. My experience includes participating in environmental training programs and actively contributing to the rig’s environmental management system. The consequences of non-compliance can be severe, including hefty fines and reputational damage, but also environmental harm. Therefore, I consider environmental stewardship a vital aspect of my work.

Q 13. How do you maintain accurate records and documentation on your tasks?

Maintaining accurate records is crucial for efficient operations and regulatory compliance. I meticulously document all my tasks, including the time spent, materials used, and any notable incidents or observations. I utilize both digital and paper-based systems, depending on company policy and the specific task.

For example, I regularly update daily work logs, detailing activities, equipment used, and any issues encountered. These records are essential for tracking progress, identifying trends, and facilitating accurate reporting to management and regulatory bodies. I also use company-provided software and databases for more complex tasks and documentation. Accuracy in recording information ensures the company maintains a clear and auditable record of its operations, aiding in both efficiency and compliance.

Q 14. What is your understanding of different types of drilling fluids?

Drilling fluids, or muds, are crucial for various aspects of drilling operations. My understanding covers several types, each tailored to specific well conditions and challenges.

- Water-based muds: These are the most common and are relatively inexpensive. They are suitable for many drilling applications but may have limitations in certain formations.

- Oil-based muds: These offer better lubricity and shale stability, making them suitable for challenging formations, but they are more expensive and have environmental considerations.

- Synthetic-based muds: These combine the benefits of oil-based muds with reduced environmental impact. They are often used where environmental regulations are stringent.

The choice of mud depends on factors like formation type, pressure, temperature, and environmental regulations. A proper understanding of mud properties, including viscosity, density, and filtration characteristics, is crucial for optimizing drilling performance and wellbore stability.

Q 15. Describe your experience with pressure control equipment.

My experience with pressure control equipment is extensive, encompassing both preventative maintenance and emergency response. I’m proficient in operating and maintaining various pressure control devices, including BOPs (Blowout Preventers), annular preventer systems, and choke manifolds. This includes understanding the function of each component, conducting regular inspections for wear and tear, and performing preventative maintenance according to manufacturer specifications and industry best practices. For instance, I’ve been involved in several well control exercises, where my understanding of the equipment and its operational limitations was critical in successfully managing a simulated well blowout. I’m also familiar with the safety procedures and emergency shutdown protocols associated with this equipment, ensuring the safety of personnel and the environment. This includes regularly testing the equipment and documenting the procedures.

Furthermore, I’m skilled in troubleshooting malfunctions and identifying potential issues proactively. I’m adept at interpreting pressure readings, identifying leaks, and executing repairs efficiently. A specific example includes a scenario where we identified a malfunction in the annular preventer during a pressure test. By systematically checking each component, I pinpointed a faulty hydraulic valve, leading to its prompt replacement and preventing a potential safety hazard.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage your time effectively during a busy work shift?

Effective time management on a busy roustabout shift hinges on prioritizing tasks, proactive planning, and efficient execution. I start each shift with a briefing to understand the day’s objectives and potential challenges. I then prioritize tasks based on urgency and importance, focusing on critical activities that directly impact safety and operational efficiency. Think of it like a well-orchestrated symphony – each instrument (task) needs to play its part in harmony. I delegate tasks appropriately when possible, ensuring everyone on the team understands their roles and responsibilities. This prevents bottlenecks and delays. I also proactively anticipate potential delays or issues, and have contingency plans in place to minimize their impact. For example, if I anticipate a delay in receiving a specific part, I’ll work on a different task in the meantime to keep the work moving.

Communication is key. Regularly updating my supervisor and team members on progress ensures that everyone is on the same page and can assist if needed. Finally, I meticulously track my time, ensuring the job is completed safely and efficiently. This allows for accurate reporting of work progress and identification of areas for potential improvement. Through experience, I’ve learned that proactive planning saves time in the long run, leading to safer and more productive shifts.

Q 17. What is your experience with using various hand tools and equipment?

My experience with hand tools and equipment is comprehensive, covering a wide range of instruments commonly used in roustabout operations. This includes various wrenches (socket, open-end, adjustable), pipe wrenches, hammers, impact wrenches, torque wrenches, and specialized tools for handling drilling equipment and rigging components. I’m comfortable using cutting and welding equipment safely and efficiently. I’m also experienced in using pneumatic and hydraulic tools, such as impact wrenches, drills, and pumps. Beyond just the basic use, I understand the proper maintenance and storage of these tools to ensure their longevity and optimal performance. For example, regular cleaning and lubrication of moving parts prevents wear and tear, extending tool life and ensuring workplace safety.

Safety is paramount. I understand the importance of using the right tool for the job and following all safety procedures when operating any equipment. This involves wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and steel-toed boots. My experience includes safely handling and operating various lifting equipment, understanding weight limits and safe lifting techniques to prevent accidents. It is critical that I fully understand the capabilities of each piece of equipment and operate it according to manufacturer specifications.

Q 18. How do you handle working in challenging weather conditions?

Working in challenging weather conditions is an inherent part of roustabout operations. My approach emphasizes safety and preparedness. This starts with always being aware of the weather forecast before commencing work and dressing appropriately for the expected conditions. I understand the limitations imposed by different weather events like extreme heat, cold, rain, wind, and even snow. For example, in extreme heat, we increase hydration breaks and employ heat stroke prevention strategies. In freezing conditions, we utilize appropriate warming measures to minimize the risk of frostbite. Safety protocols are strictly followed during heavy rain or snowfall to prevent slips, trips, and falls. We take the time to clean up slippery areas and ensure work surfaces are clear.

I’m skilled in adapting work procedures to the prevailing conditions. This could involve modifying equipment usage or adjusting work schedules to maximize safety and efficiency. Clear communication with the team is essential during challenging conditions, so everyone is aware of potential hazards and ready to respond if necessary. In short, I prioritize safety and adapt my approach, understanding that successful completion of the work must always be secondary to safe execution and team well-being.

Q 19. Describe your experience with well servicing operations.

My experience in well servicing operations is significant, encompassing various aspects of well maintenance, repair, and workover activities. I’m proficient in assisting with the installation and removal of tubing and casing, running and retrieving tools, and handling various wellhead components. I have been involved in numerous well interventions, including the preparation for and execution of workovers that might involve replacing a downhole component, running a logging tool, or conducting other interventions to maintain well productivity. This requires a deep understanding of well construction, the types of fluids involved, and potential safety hazards.

I’m familiar with the procedures and safety protocols associated with well servicing, including the proper use of lifting equipment and pressure control devices. A key component is understanding the importance of well integrity, and adhering to safety standards to minimize any risks to personnel, equipment, or the environment. My experience spans various types of wells, from onshore to offshore platforms, and I’m adaptable to varying operational procedures. Understanding the specific needs and potential challenges of a given well site is a key part of my approach to well servicing operations. Each well presents unique issues, and thorough understanding of the well’s history and current condition is critical to safe and successful well servicing.

Q 20. How familiar are you with various types of drilling bits and their applications?

My familiarity with drilling bits extends to various types, including roller cone bits, diamond bits (PDC and impregnated), and polycrystalline diamond compact (PDC) bits. I understand the applications and advantages of each type. Roller cone bits are effective in softer formations, while diamond bits are better suited for harder formations. PDC bits are particularly efficient in harder, abrasive formations and can provide longer life compared to traditional roller cone bits. The choice of bit depends heavily on the geological formation, the expected drilling rate, and the overall cost-effectiveness. I’m able to assist in the selection process by providing input based on my experience and knowledge of the specific well’s geology.

Beyond the types of bits, I also understand how to inspect drilling bits for wear and tear, ensuring appropriate maintenance is performed and recognizing when a bit needs to be replaced. This prevents drilling inefficiencies and potential complications. Knowing how to properly handle and store different types of bits, to prevent damage and ensure readiness for future drilling operations, is vital. For example, improper storage can result in damage to the cutting surfaces, leading to decreased bit life and increased drilling costs.

Q 21. Explain your experience with different types of casing and tubing.

My experience encompasses various types of casing and tubing used in well construction and completion. This includes understanding their different grades, specifications, and applications. I’m familiar with different casing types such as conductor pipe, surface casing, intermediate casing, and production casing. Each has a specific role in securing the wellbore and protecting different subsurface formations. Tubing, which is used to convey fluids to and from the wellbore, comes in various grades and configurations depending on the well’s requirements. I’m knowledgeable about the properties of various steel alloys, their resistance to corrosion, and their suitability for different drilling environments. Understanding the differences in wall thickness and other specifications is also critical.

Beyond the material properties, I’m also familiar with the procedures involved in handling, installing, and inspecting casing and tubing. This includes understanding the importance of proper connections and ensuring the integrity of the wellbore. For instance, I can identify and address potential issues such as leaks, corrosion, or damage to casing or tubing. Identifying potential issues early can significantly reduce the risk of more serious problems later.

Q 22. How do you maintain a clean and organized work environment on the rig floor?

Maintaining a clean and organized rig floor is paramount for safety and efficiency. Think of it like a well-organized kitchen – if everything has its place, you can work quickly and avoid accidents. We achieve this through a multi-pronged approach.

- Designated storage areas: Every tool and piece of equipment has a designated spot. This prevents clutter and makes it easy to find what you need, especially in an emergency.

- Regular cleanup schedules: We have scheduled cleanups throughout the day, focusing on high-traffic areas and removing debris immediately. This prevents build-up and reduces the risk of slips, trips, and falls.

- Proper disposal of waste: Hazardous materials are handled and disposed of according to strict safety regulations, and regular trash removal keeps the area tidy.

- 5S methodology: We often implement elements of the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain), which helps create a visual workplace and promotes good housekeeping practices. For example, color-coding tools or using shadow boards makes it immediately clear where everything belongs.

For example, after a particularly messy connection operation, we’d immediately sweep up the mud and debris, store away the tools, and ensure the area is visually clear before moving on to the next task.

Q 23. How do you communicate effectively with other crew members during operations?

Effective communication is the backbone of safe and efficient roustabout operations. Miscommunication can have disastrous consequences. On the rig floor, we rely on a combination of verbal and non-verbal communication techniques.

- Clear and concise language: We avoid jargon whenever possible and use plain language that everyone can understand. If using technical terms, we ensure everyone is familiar with the definition.

- Visual cues: Hand signals are crucial, especially in noisy environments. We use standardized hand signals to convey instructions quickly and accurately. For example, a specific hand signal indicates that a connection is ready to be made.

- Two-way communication: We always confirm that instructions are understood by repeating them or asking clarifying questions. It’s not about simply giving orders; it’s about ensuring everyone is on the same page.

- Regular briefings: Before any operation, we hold briefings to discuss the plan, potential hazards, and emergency procedures. This ensures everyone is prepared and knows their roles.

- Use of communication technology: We leverage radios and other communication tools for efficient communication across the rig floor, particularly in different locations.

I recall an incident where a crew member misunderstood a verbal instruction, leading to a minor near-miss. After that incident, we emphasized the importance of confirming instructions and using hand signals to ensure everyone is clear.

Q 24. What is your understanding of weight and balance procedures on a drilling rig?

Weight and balance procedures are critical for rig safety. Understanding these procedures ensures the stability of the drilling rig, preventing accidents and potential equipment damage. It’s essentially about managing the weight distribution across the rig.

- Load calculations: Before lifting any heavy equipment or materials, precise weight calculations are performed to ensure the crane’s capacity isn’t exceeded. These calculations take into account the weight of the object, the length of the lift, and any other factors that could affect stability.

- Center of gravity: We carefully consider the center of gravity of the load to prevent imbalances. An improperly balanced load could cause the crane to tip or swing wildly.

- Rigging procedures: Proper rigging techniques are essential to ensure the safe and secure lifting of heavy objects. This includes using appropriate slings, shackles, and other rigging hardware.

- Monitoring during lifts: During lifting operations, constant monitoring is performed to ensure that the load remains stable and balanced. Any issues are immediately addressed.

- Documentation: All weight and balance calculations and procedures are carefully documented. This record-keeping is essential for safety audits and incident investigations.

For example, before installing a heavy piece of equipment on the derrick, we carefully calculated the weight and center of gravity, ensuring that it was within the rig’s safe operating limits. We used specialized software for detailed weight calculations and collaborated with the rig’s engineers to confirm the safety and stability of the operation.

Q 25. Describe your experience with troubleshooting equipment malfunctions.

Troubleshooting equipment malfunctions is a regular part of roustabout work. It requires a systematic approach and a good understanding of the equipment’s workings. My approach involves the following steps:

- Identify the problem: Carefully observe the malfunction and gather all relevant information. This might include listening for unusual noises, checking gauges, or reviewing operating logs.

- Isolate the cause: Once the problem is identified, I work to isolate the potential cause. This often involves checking connections, inspecting components, and running diagnostic tests.

- Consult resources: I’ll often refer to manuals, schematics, or experienced colleagues for guidance. We have detailed documentation and maintenance logs readily available.

- Implement a solution: Based on the identified cause, I implement a solution, making any necessary repairs or replacements.

- Test and verify: After making repairs, I thoroughly test the equipment to ensure that the malfunction has been resolved and that the equipment is functioning correctly.

- Report and document: Finally, I report the malfunction and the solution taken, documenting everything in the appropriate logs. This information is invaluable for preventative maintenance.

One time, we had a malfunction with the mud pump. By systematically checking valves, pressure gauges, and lines, I identified a blockage in one of the discharge lines. After clearing the blockage, the pump resumed normal operation. I documented the event and the solution, preventing similar incidents in the future.

Q 26. How familiar are you with the different phases of a drilling operation?

I’m very familiar with the different phases of a drilling operation. Understanding these phases is crucial for efficient and safe roustabout operations. The main phases are:

- Spudding: The initial stage of drilling, where the bit penetrates the ground and the wellbore is begun.

- Drilling: The process of advancing the wellbore to the target depth, involving various drilling techniques and procedures.

- Casing and cementing: Installing steel casing (pipe) and cementing it to stabilize the wellbore and prevent collapse or contamination.

- Formation testing: Testing the formations encountered to assess their properties and potential for hydrocarbon production.

- Completion: Preparing the well for production by installing various downhole equipment.

- Workover: Operations performed on a producing well to maintain or enhance its production.

My experience covers assisting in all these phases. I know what to expect during each stage and the safety protocols associated with each. For instance, during the casing and cementing phase, I’m aware of the hazards related to handling heavy casing and cementing equipment and adhere strictly to safety procedures.

Q 27. Explain your experience with preventative maintenance procedures.

Preventative maintenance is crucial for avoiding costly breakdowns and ensuring the safety of the rig. Our focus is on proactive maintenance rather than reactive repairs. This includes:

- Daily inspections: We perform routine inspections of equipment and tools, checking for wear and tear, leaks, or other potential problems.

- Scheduled maintenance: We follow a rigorous schedule for preventative maintenance, conducting regular servicing, lubrication, and replacements of parts as per manufacturer’s recommendations.

- Record keeping: All maintenance activities are carefully documented, including dates, performed work, and any findings. This allows us to track equipment performance and anticipate potential problems.

- Equipment familiarity: As roustabouts, we are trained to identify potential issues with various equipment types and are familiar with their maintenance procedures.

- Collaboration: We collaborate with rig mechanics and engineers to ensure the efficiency and effectiveness of preventative maintenance tasks.

For example, we regularly inspect the crown block and travelling block, checking for wear and tear on sheaves and ensuring proper lubrication. This preventative maintenance reduces the risk of catastrophic failure during lifting operations.

Q 28. How do you ensure compliance with all safety regulations and company policies?

Compliance with safety regulations and company policies is non-negotiable. It’s not just about following rules; it’s about creating a culture of safety. My approach involves:

- Familiarization with regulations: I thoroughly understand all relevant safety regulations, including OSHA, industry best practices, and company-specific policies.

- Training and certifications: I maintain all necessary certifications and actively participate in safety training programs.

- Reporting hazards: I promptly report any unsafe conditions or practices to my supervisor. No matter how small, it could be a significant safety hazard.

- Active participation in safety meetings: I actively participate in safety meetings and contribute to discussions about improving safety practices.

- Personal protective equipment (PPE): I consistently wear the appropriate PPE, such as hard hats, safety glasses, gloves, and steel-toed boots.

- Following procedures: I meticulously follow all established safety procedures and ensure that others on the crew do the same.

One example is my commitment to wearing my PPE at all times, even for seemingly minor tasks. I believe that consistent adherence to safety protocols fosters a safe environment for everyone on the rig.

Key Topics to Learn for Roustabout Operations Interview

- Wellsite Safety Procedures: Understanding and applying safety regulations, including emergency response protocols and hazard identification. Practical application: Describe your experience with lockout/tagout procedures or confined space entry protocols.

- Equipment Handling and Maintenance: Knowledge of various equipment used in roustabout operations (e.g., pumps, valves, pressure gauges). Practical application: Explain your experience with preventative maintenance or troubleshooting common equipment malfunctions.

- Drilling and Completion Operations: Familiarity with the different stages of drilling and well completion, including casing, cementing, and well testing. Practical application: Describe your understanding of the role of a roustabout in supporting these operations.

- Fluid Handling and Management: Understanding the properties of drilling fluids and their handling procedures. Practical application: Explain how you would respond to a mud leak or other fluid-related incident.

- Pressure Control: Knowledge of pressure control equipment and procedures, including blowout preventers (BOPs). Practical application: Describe your experience working under pressure or in high-risk environments.

- Communication and Teamwork: Effective communication and collaboration with the drilling crew. Practical application: Share an example of how you successfully communicated a critical safety issue or collaborated to solve a problem on a team.

- Environmental Awareness: Understanding and adhering to environmental regulations and best practices related to waste management and pollution prevention. Practical application: Describe your experience with spill response or environmental cleanup procedures.

Next Steps

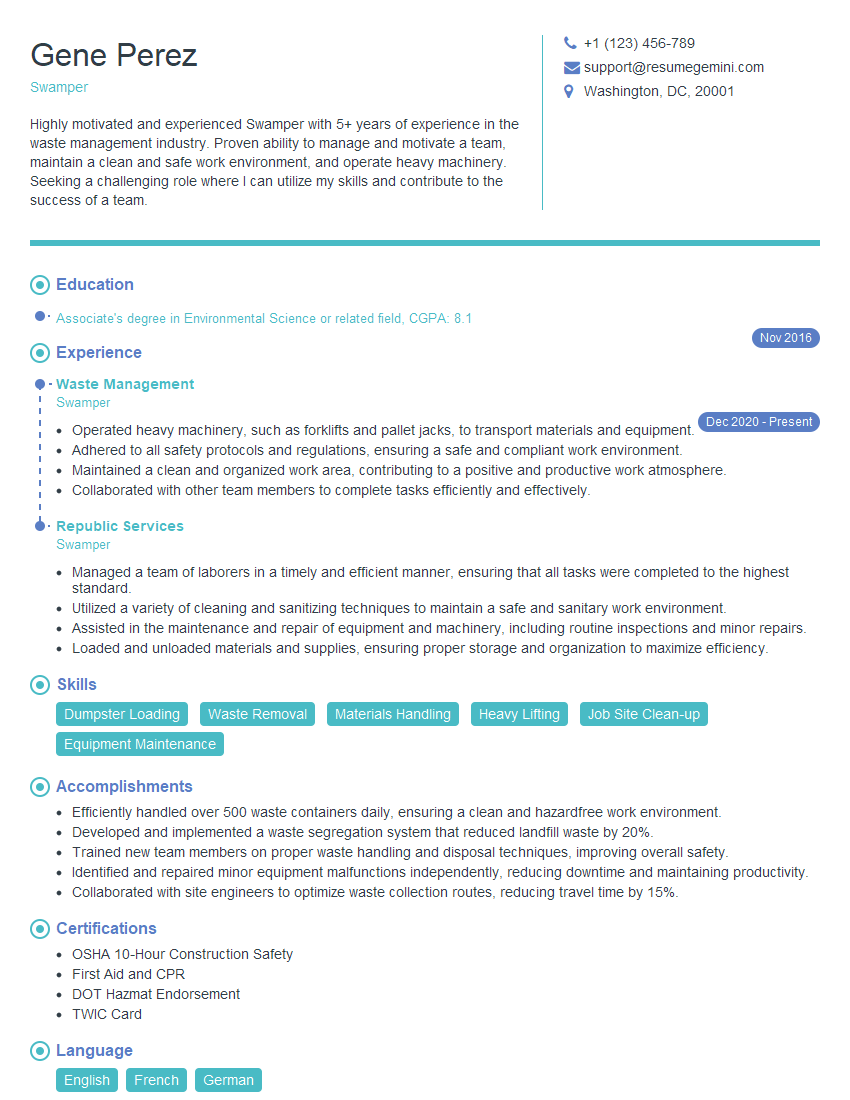

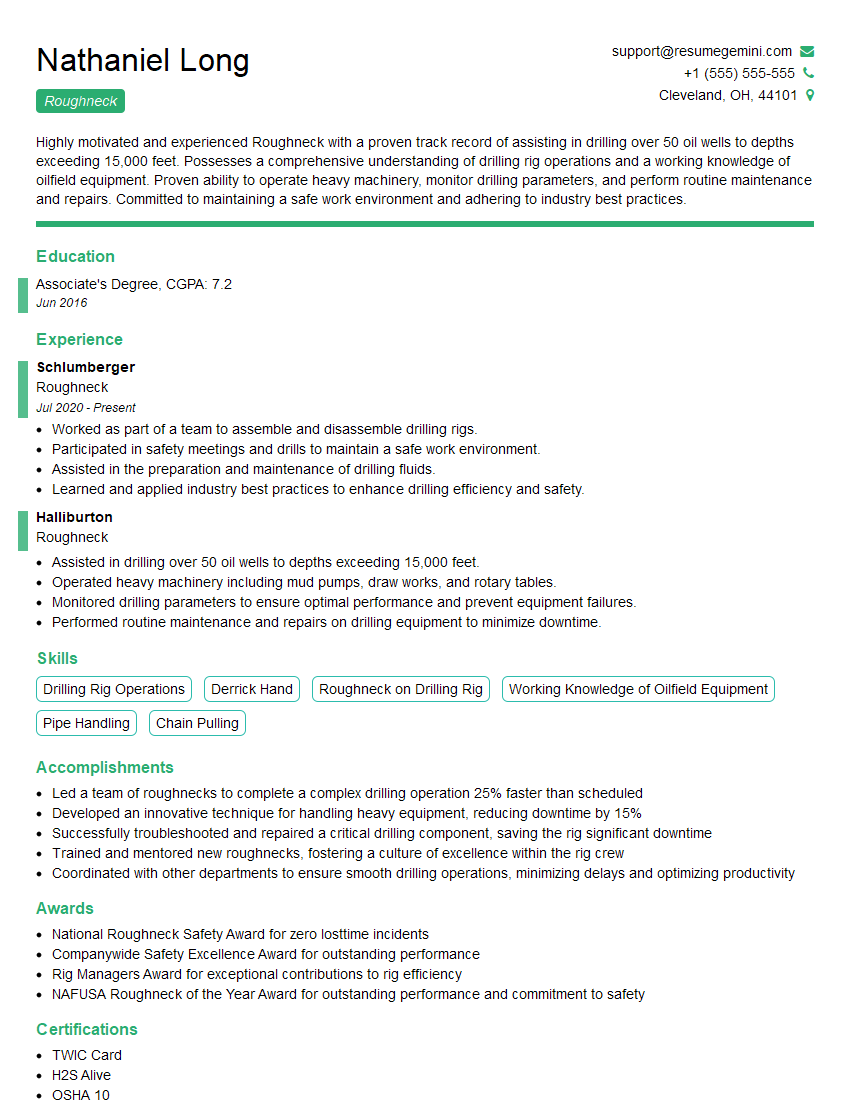

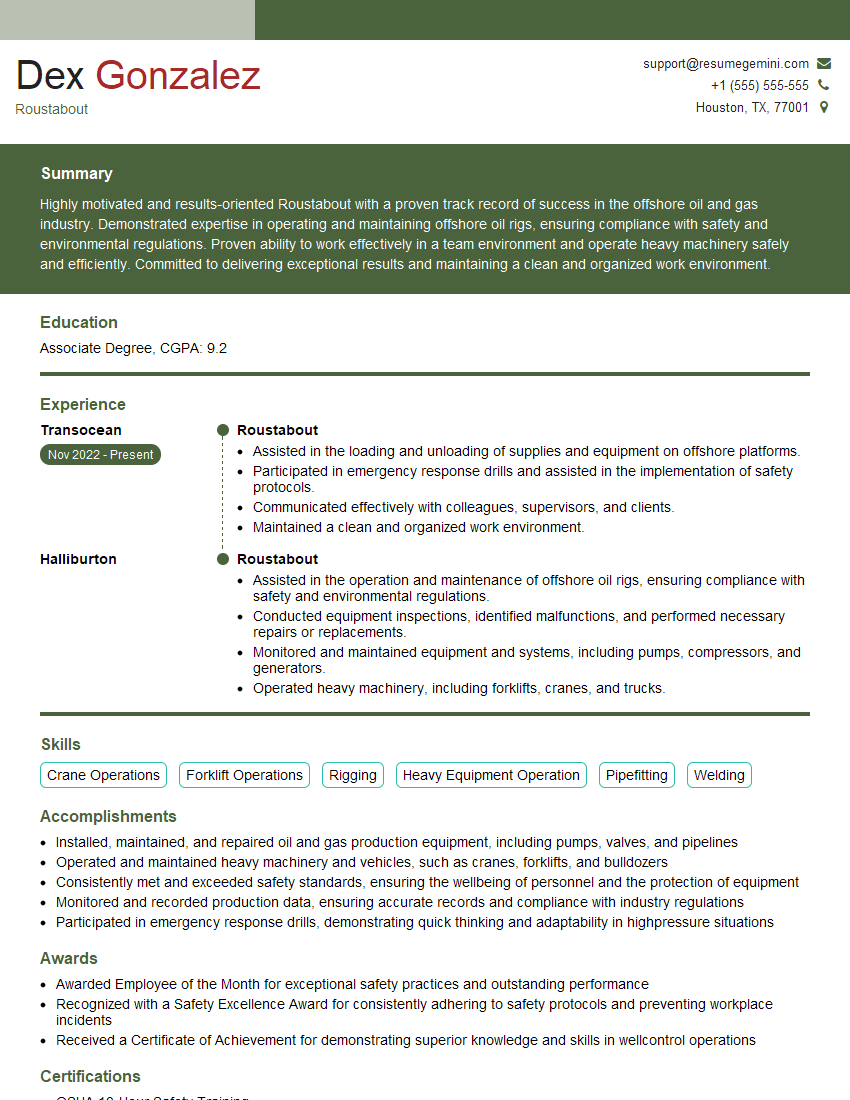

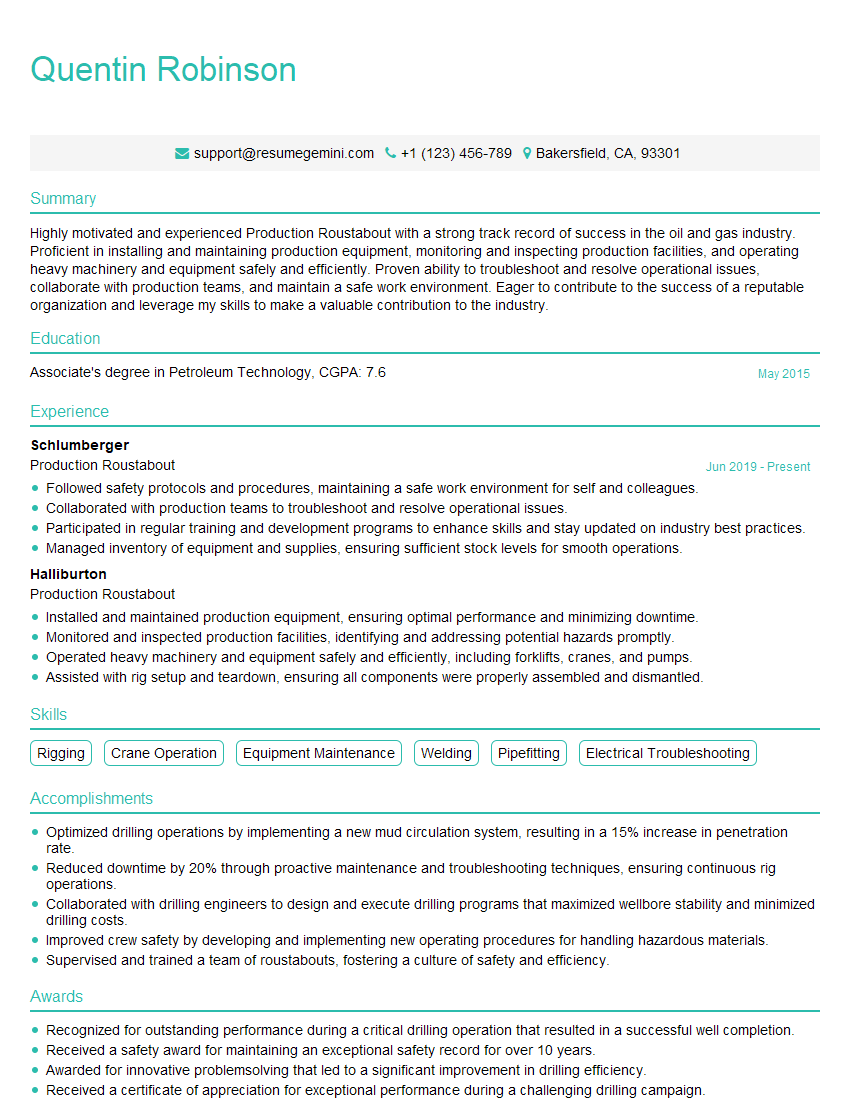

Mastering Roustabout Operations opens doors to a rewarding career with excellent growth potential within the oil and gas industry. Your expertise in safety, equipment handling, and teamwork is highly valuable. To maximize your job prospects, create an ATS-friendly resume that clearly highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that grabs recruiters’ attention. Examples of resumes tailored specifically for Roustabout Operations are available to help guide you. Take the next step toward your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO