Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Safety Equipment and Personal Protective Gear (PPE) Usage interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Safety Equipment and Personal Protective Gear (PPE) Usage Interview

Q 1. What are the key components of a comprehensive PPE program?

A comprehensive PPE program isn’t just about providing equipment; it’s a holistic system ensuring worker safety. It comprises several key components working in synergy:

- Hazard Assessment: A thorough identification of all workplace hazards, assessing the risks to workers. For example, a construction site needs to assess risks from falling objects, heavy machinery, and chemical exposure.

- PPE Selection: Choosing the right PPE for each identified hazard. This isn’t a one-size-fits-all approach; it’s tailored to specific risks. For instance, welders require specialized eye protection, while electricians need insulated gloves.

- Training and Education: Workers must understand the hazards they face, the purpose of each PPE item, how to properly use it, and when it’s necessary. This isn’t a single training session; it should be ongoing and reinforce best practices.

- PPE Provision and Maintenance: The program must ensure readily available, correctly sized, and well-maintained PPE for all employees. Regular inspections and timely replacements are critical. Think of it like maintaining a safety net; a torn net is useless.

- Inspection and Enforcement: Regular checks ensure PPE is used correctly and remains functional. This involves observation, feedback, and enforcement of safety policies. Managers should be actively involved in promoting safety.

- Record Keeping: Detailed records of hazard assessments, PPE selection, training, and inspections are essential for compliance and continuous improvement. This provides a detailed history and helps identify areas for improvement.

Q 2. Explain the hierarchy of hazard controls.

The hierarchy of hazard controls prioritizes eliminating hazards entirely over relying solely on PPE. It’s a pyramid of control measures, starting with the most effective and progressing to less effective options:

- Elimination: Removing the hazard completely. For example, replacing a dangerous chemical with a safer alternative.

- Substitution: Replacing the hazard with a less hazardous alternative. Instead of using a high-pressure cleaning system, using a low-pressure one reduces the risk of injury.

- Engineering Controls: Modifying the workplace to reduce or eliminate the hazard. This could involve installing guards on machinery or improving ventilation.

- Administrative Controls: Changing work practices or procedures to minimize exposure to hazards. Implementing strict work permits for high-risk tasks is an example.

- Personal Protective Equipment (PPE): Protecting workers from remaining hazards when other controls are insufficient. This is the last line of defense, always used in conjunction with other controls.

Think of it as building a strong foundation. Elimination and substitution are the foundation; engineering and administrative controls build on that, and PPE is the final layer of protection.

Q 3. Describe the selection criteria for choosing appropriate PPE.

Choosing the right PPE depends heavily on the specific hazard. The selection process involves:

- Hazard Identification: Clearly defining the type and severity of the hazard (e.g., chemical splash, impact, electrical shock).

- Risk Assessment: Determining the probability and severity of harm. A higher risk requires more robust PPE.

- PPE Standard Compliance: Selecting PPE that meets relevant industry standards and regulations (e.g., ANSI, OSHA).

- Worker Comfort and Fit: PPE must be comfortable to wear for extended periods to encourage consistent use. A poorly fitting respirator won’t protect effectively.

- Environmental Compatibility: Considering the working environment’s conditions (e.g., temperature, humidity). Heat stress can be a major concern with some types of PPE.

- User Training and Competence: Ensuring workers understand how to use and maintain the PPE properly.

For example, selecting a respirator involves considering the specific respiratory hazard (e.g., dust, fumes, gases) and choosing a respirator with the appropriate filter type and fit.

Q 4. How do you ensure PPE is properly fitted and used?

Proper fit and use are crucial for PPE effectiveness. This involves:

- Proper Size and Fit: PPE should be correctly sized and adjusted to ensure a snug but comfortable fit. This often requires individual fitting procedures, especially for respirators and hearing protection.

- Training on Use and Donning/Doffing: Workers need training on how to correctly put on (don) and take off (doff) the PPE to avoid contamination and ensure proper protection.

- Regular Inspection: Workers should inspect their PPE before each use to identify any damage or defects.

- Compliance Enforcement: Supervisors must regularly observe workers to ensure correct PPE use and address any non-compliance issues immediately.

Think of it like wearing a seatbelt – if it’s not fastened correctly, it won’t offer the protection it’s designed for.

Q 5. What are the limitations of different types of PPE (e.g., respirators, gloves)?

All PPE has limitations. Understanding these is critical:

- Respirators: Can be uncomfortable, restrict breathing, and require proper fit testing. They don’t protect against all airborne hazards, and failure to follow proper procedures can compromise their effectiveness.

- Gloves: Offer varying levels of protection depending on material and design. They can be easily punctured or degraded by certain chemicals, and may not protect against all types of hazards (e.g., cuts from sharp objects).

- Eye Protection: May not offer full protection against all types of impacts or chemical splashes, especially in extreme conditions.

- Hearing Protection: Can be uncomfortable and ineffective if not properly fitted or maintained. They don’t completely eliminate noise exposure, and some designs can affect communication.

It’s vital to choose PPE that addresses the specific hazard and to be aware of its limitations. Using multiple layers of PPE to address different potential hazards might be necessary.

Q 6. How do you inspect and maintain PPE to ensure its effectiveness?

Regular inspection and maintenance are essential to ensure PPE effectiveness and longevity:

- Visual Inspection: Regularly checking for any signs of damage, wear, tears, cracks, or contamination. This should be done before each use and at regular intervals.

- Cleaning and Sanitization: Cleaning PPE according to manufacturer instructions after each use to remove contaminants. Some PPE requires specific cleaning and sanitization methods.

- Storage: Proper storage protects PPE from damage and contamination. PPE should be stored in a clean, dry environment away from extreme temperatures.

- Repair or Replacement: Damaged or worn-out PPE should be repaired (if possible) or replaced immediately. Don’t compromise safety by using damaged equipment.

- Scheduled Maintenance: Some PPE (e.g., respirators) requires regular maintenance or testing (e.g., fit testing) by qualified personnel.

Think of it like regularly servicing a car; preventative maintenance helps extend its lifespan and ensures optimal performance.

Q 7. What are the legal requirements for PPE usage in your industry?

Legal requirements for PPE vary depending on the specific industry, location, and regulatory body (e.g., OSHA in the US, WHS in Australia). However, common legal requirements include:

- Hazard Assessment and Risk Management: Employers are legally required to conduct thorough hazard assessments to identify risks and implement appropriate control measures, including PPE where necessary.

- PPE Provision: Employers must provide appropriate PPE free of charge to employees who are exposed to hazards. This includes providing properly fitted and sized equipment.

- Training and Competence: Employers must provide adequate training to workers on the hazards they face, the correct use and maintenance of PPE, and the importance of compliance.

- Inspection and Maintenance: Employers are responsible for ensuring the regular inspection and maintenance of PPE to maintain its effectiveness.

- Record Keeping: Accurate records must be kept of hazard assessments, PPE provision, training, and inspections to demonstrate compliance.

- Compliance with Standards: PPE must meet relevant national and international standards.

Failure to comply with these legal requirements can lead to significant penalties and legal action. It is crucial to understand and adhere to all relevant regulations in your industry and location.

Q 8. How do you communicate PPE requirements to employees?

Communicating PPE requirements effectively involves a multi-pronged approach. It’s not enough to simply post a sign; you need to ensure understanding and compliance.

- Initial Training: All new employees receive comprehensive training on the specific hazards present in their work area and the correct PPE needed to mitigate those risks. This includes hands-on demonstrations and practice sessions.

- Regular Refresher Training: Annual or more frequent refresher training is crucial to reinforce proper usage, address any changes in procedures or equipment, and address any emerging safety concerns. This keeps the information fresh and relevant.

- Job-Specific Instructions: Detailed, job-specific instructions, possibly in the form of checklists or standard operating procedures (SOPs), should be provided. This ensures that employees know exactly which PPE is required for each task.

- Visual Aids and Signage: Clear, concise signage and visual aids (pictures, diagrams) are highly effective, especially for multilingual workplaces or those with employees who may have limited literacy. These should be strategically placed throughout the work area.

- Open Communication Channels: Establish an open communication channel where employees feel comfortable asking questions and reporting any concerns regarding PPE. Regular safety meetings, toolbox talks, and employee feedback mechanisms are vital.

- Leading by Example: Management and supervisors must consistently model the correct use of PPE. This shows employees that safety is a priority, not an afterthought.

For example, in a construction setting, we’d provide detailed training on the use of hard hats, safety glasses, and high-visibility vests, emphasizing proper fit and wear.

Q 9. Describe a time you had to address a PPE-related incident. What was your approach?

During a recent roofing project, an employee sustained a minor eye injury from a flying debris while not wearing safety glasses, despite prior training. My approach was systematic:

- Immediate Action: First aid was administered immediately, and the employee was sent for medical evaluation. The incident was thoroughly documented.

- Investigation: A thorough investigation was conducted to determine the root cause. This involved interviewing the employee and witnesses to understand what happened and why the safety glasses weren’t worn.

- Corrective Action: Based on the investigation, we identified that the training on the specific hazards of flying debris was inadequate. We revised the training program to include more realistic scenarios and reinforced the importance of consistently wearing safety glasses.

- Reinforcement: We held a safety meeting to review the incident with all employees, reiterating the importance of PPE usage and the potential consequences of non-compliance. The updated training was delivered, and additional signage emphasizing eye protection was installed.

- Follow-up: We followed up with the injured employee to ensure their recovery and addressed any lingering concerns or anxieties about returning to work.

This incident highlighted the need for continuous improvement in our safety program. By systematically addressing the incident, we improved our training and reinforced the critical importance of PPE compliance.

Q 10. What are the common hazards associated with failure to use appropriate PPE?

Failure to use appropriate PPE exposes employees to a wide range of hazards, leading to serious consequences. These can include:

- Eye Injuries: Flying debris, chemicals, and intense light can cause blindness or severe visual impairment without safety glasses or face shields.

- Hearing Loss: Prolonged exposure to loud noises in industrial settings can lead to irreversible hearing damage without proper hearing protection.

- Respiratory Illnesses: Inhaling dust, fumes, gases, or vapors can cause respiratory problems, including asthma, lung cancer, and silicosis without respirators.

- Skin Damage: Exposure to chemicals, irritants, or extreme temperatures can cause burns, rashes, and other skin problems without gloves or protective clothing.

- Head Injuries: Falls, impacts, or falling objects can cause traumatic brain injuries or skull fractures without hard hats.

- Foot Injuries: Heavy objects, sharp materials, and punctures can cause severe foot injuries without safety footwear.

These are just some examples; the specific hazards depend on the work environment. The consequences can range from minor discomfort to permanent disability or even death.

Q 11. How do you manage the disposal of contaminated PPE?

Disposal of contaminated PPE is critical for preventing the spread of infection or hazardous materials. The process varies depending on the type of contamination:

- Biohazards (blood, bodily fluids): Contaminated PPE must be handled and disposed of according to OSHA and local regulations. This typically involves placing the items in clearly labeled, leak-proof biohazard bags or containers before disposal in designated medical waste streams.

- Hazardous Chemicals: PPE contaminated with hazardous chemicals must be handled according to the chemical’s Safety Data Sheet (SDS). This may involve specialized cleaning procedures, neutralization, or specific disposal methods.

- Other Contaminated PPE: Even if not visibly contaminated, PPE used in potentially hazardous environments (e.g., asbestos abatement) should be disposed of according to specific guidelines to prevent accidental exposure.

Proper labeling, segregation, and documentation are essential throughout the disposal process. We use a color-coded system for waste bags and containers to easily identify and manage different types of contaminated PPE.

Q 12. What training is required for employees using specific types of PPE?

Training requirements vary depending on the specific type of PPE. However, some common elements include:

- Proper Selection and Fit: Employees must be trained to select the correct PPE for the task and to ensure a proper fit. An ill-fitting respirator, for example, is ineffective.

- Donning and Doffing Procedures: Correct procedures for putting on (donning) and taking off (doffing) PPE are crucial to prevent contamination or injury. This is especially important for respirators and chemical protective suits.

- Inspection and Maintenance: Employees should know how to inspect their PPE for damage or defects before each use. They also need to know how to properly maintain and store the equipment.

- Limitations and Capabilities: Training must cover the limitations of the PPE and when it is not appropriate to use. For instance, a respirator might not be effective against all types of airborne hazards.

- Emergency Procedures: Employees need to know what to do in case of an emergency, including how to remove PPE quickly and safely.

For respirators, this often involves medical evaluations to ensure the employee is physically capable of using the device and fit testing to ensure a proper seal. Formal certifications are sometimes required for specialized PPE, such as SCBA (Self-Contained Breathing Apparatus).

Q 13. How do you ensure PPE is readily available to employees?

Ensuring readily available PPE involves a combination of strategies:

- Centralized Storage: We maintain a central storage area for PPE, organized and clearly labeled. This ensures easy access for employees.

- Designated Dispensing Locations: In large facilities, we may have designated dispensing locations within each work area to improve accessibility.

- Regular Inspections and Replenishment: Regular inspections of PPE supplies are performed to ensure sufficient stock levels and to identify any damaged or expired items. We have a system for automatically reordering supplies when stocks fall below a certain threshold.

- Employee Responsibility: Employees are responsible for reporting any shortages or damaged PPE. This is reinforced through regular safety meetings and feedback mechanisms.

- Accessibility for all employees: The storage and access points are designed to be accessible for all employees, regardless of their physical capabilities.

This ensures that employees always have the correct PPE readily available when they need it, reducing the chance of working without proper protection.

Q 14. What are the different classes of respirators and their applications?

Respirators are classified based on their ability to filter or supply clean air. The classes and their applications are complex, but here’s a simplified overview:

- NIOSH (National Institute for Occupational Safety and Health) Classifications: NIOSH is a key organization involved in setting standards for respirators in the US. They classify respirators based on their assigned protection factor (APF).

- Air-Purifying Respirators (APRs): These respirators filter the air the wearer breathes. They are appropriate for environments with known contaminants at levels below the Immediately Dangerous to Life or Health (IDLH) concentration. They come in various classes based on the type of filter (e.g., N, R, P for different particulate matter; A, O for various gases and vapors).

N95respirators are a common example, filtering at least 95% of airborne particles. - Supplied-Air Respirators (SARs): These respirators provide a continuous supply of clean air from an external source, offering a higher level of protection. They are used in environments with higher concentrations of contaminants or where the air-purifying capabilities of an APR are insufficient. This includes airline respirators and self-contained breathing apparatus (SCBA).

- Self-Contained Breathing Apparatus (SCBA): SCBAs provide a complete and independent supply of breathable air, essential for environments with immediately dangerous to life and health (IDLH) conditions. They are used in situations like confined space entry or firefighting.

The choice of respirator depends entirely on the specific hazards present. A proper hazard assessment is crucial to selecting the appropriate type and ensuring the user receives adequate training and medical clearance.

Q 15. Explain the difference between hearing protection and eye protection.

Hearing protection and eye protection, while both crucial components of Personal Protective Equipment (PPE), safeguard different sensory organs from distinct hazards. Hearing protection, such as earplugs or earmuffs, is designed to reduce exposure to loud noises that can cause hearing loss or tinnitus. Eye protection, including safety glasses, goggles, or face shields, protects the eyes from flying debris, chemical splashes, impacts, and intense light sources that can lead to injuries ranging from minor irritation to blindness. The key difference lies in the specific hazard they address and the organ they protect.

Think of it this way: hearing protection is like a sound buffer, reducing the intensity of noise reaching your inner ear, while eye protection is a shield, creating a physical barrier between your eyes and potential dangers.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you assess the effectiveness of a PPE program?

Assessing the effectiveness of a PPE program is a multi-faceted process that goes beyond simply providing equipment. It requires a systematic approach incorporating several key metrics.

- Incident Rate: A significant decrease in workplace accidents involving eye or hearing injuries, cuts, burns, or chemical exposure directly demonstrates the program’s impact. A trend analysis is vital here.

- Compliance Rate: Regular observation and audits measure the consistent and correct use of PPE by employees. Low compliance often highlights training gaps or equipment issues.

- Employee Feedback: Surveys and regular meetings gauge employee satisfaction with the PPE provided and training received. Addressing complaints and concerns ensures comfort and proper use.

- Hazard Assessments: Ongoing reviews of workplace hazards ensure the PPE program adapts to evolving risks. New machinery, chemicals, or processes may necessitate adjustments.

- Record Keeping: Meticulous maintenance of records, including incident reports, training completion, and equipment inspections, provides crucial data for program evaluation and improvement.

For example, a successful program might show a 50% reduction in eye injuries after implementing mandatory safety glasses use and comprehensive training. Conversely, high incident rates and low compliance rates point towards weaknesses within the program needing immediate attention.

Q 17. What are some common PPE-related injuries and how can they be prevented?

Common PPE-related injuries often stem from improper use, inadequate selection, or a lack of training. Examples include:

- Eye Injuries: Chemical burns, scratches, abrasions, and even blindness from projectiles striking unprotected eyes.

- Hearing Loss: Permanent damage due to prolonged exposure to excessive noise without adequate hearing protection.

- Skin Injuries: Burns, cuts, and chemical reactions due to insufficient protection from heat, sharp objects, or corrosive substances.

- Respiratory Problems: Inhalation of harmful dust, fumes, or gases when using inadequate respirators.

Prevention hinges on a robust PPE program that includes:

- Proper Hazard Assessment: Identifying and classifying all potential risks.

- Appropriate PPE Selection: Choosing the right type and fit of PPE for each hazard.

- Comprehensive Training: Educating employees on the correct use, maintenance, and limitations of their PPE.

- Enforcement and Monitoring: Ensuring consistent use and addressing any non-compliance.

- Regular Inspection and Maintenance: Checking PPE for damage or wear and replacing as needed.

For instance, a construction worker not wearing safety glasses could suffer serious eye injury from flying debris. Proper training and enforcement ensure the worker understands the risk and utilizes the provided protection.

Q 18. How do you stay updated on changes in PPE standards and regulations?

Staying current with PPE standards and regulations is paramount for maintaining a safe work environment. I utilize a multi-pronged approach:

- Subscription to Professional Organizations: Membership in organizations like the American Society of Safety Professionals (ASSP) or the National Safety Council (NSC) provides access to updates, publications, and webinars on the latest standards.

- Government Agency Websites: Regularly reviewing websites of relevant government agencies like OSHA (Occupational Safety and Health Administration) for changes in regulations and guidelines.

- Industry Publications and Journals: Staying informed through industry-specific journals and publications offers insights into emerging technologies and best practices.

- Manufacturer Information: Checking manufacturers’ websites for updates on product certifications and compliance with new standards.

- Professional Development Courses: Participating in continuing education programs and workshops ensures I am updated on new techniques and regulatory changes.

This proactive approach ensures that our company’s PPE program remains compliant and utilizes the most effective and up-to-date protective measures.

Q 19. Describe your experience with conducting PPE fit testing.

My experience with PPE fit testing encompasses various types of equipment, including respirators and hearing protection. Fit testing is crucial to ensure the selected PPE provides adequate protection for the individual user. For respirators, I’ve conducted both qualitative and quantitative fit tests. Qualitative tests, like the user seal check, are simpler and involve the wearer performing various maneuvers while the respirator is in place to detect leaks. Quantitative tests use sophisticated equipment to measure the leakage rate precisely. For hearing protection, proper fit is equally important, and I assess the correct placement and seal of earplugs and earmuffs. I emphasize user comfort, as discomfort often leads to improper use.

A recent example involved fitting a new line of respirators for employees working with hazardous chemicals. We performed quantitative fit tests to verify the seal for each individual, ensuring the right respirator size was selected and the wearer was properly trained on its use.

Q 20. How do you handle employee resistance to wearing PPE?

Employee resistance to wearing PPE is a common challenge, and addressing it requires a combination of strategies. It’s rarely about willful disobedience; often, it stems from discomfort, inconvenience, or a lack of understanding. My approach is to:

- Open Communication: Conducting one-on-one conversations to understand the reasons behind the resistance. This allows addressing specific concerns.

- Education and Training: Reinforcing the importance of PPE through clear explanations of the potential hazards and how the equipment protects them.

- Involving Employees in the Selection Process: When feasible, allow input on the choice of PPE to increase acceptance and improve comfort.

- Providing High-Quality, Comfortable PPE: Supplying well-fitting, comfortable PPE minimizes discomfort and improves compliance.

- Incentivizing Compliance: Positive reinforcement programs, like rewards for consistent PPE use, can encourage compliance.

- Addressing Underlying Issues: In cases where resistance is persistent, it’s essential to look for underlying issues, such as inadequate training or poor workplace conditions.

For example, if employees find hard hats uncomfortable, providing adjustable headbands or lighter-weight alternatives might solve the problem. Addressing concerns proactively increases acceptance and improves safety.

Q 21. What are the key elements of a successful PPE training program?

A successful PPE training program is comprehensive, engaging, and regularly updated. Key elements include:

- Hazard Identification and Risk Assessment: Begin with clearly identifying the hazards employees face and the specific PPE required to mitigate those risks.

- PPE Selection and Use: Training should cover the proper selection of PPE based on the hazard, correct donning and doffing procedures, inspection for damage, and limitations of the equipment.

- Practical Application: Hands-on training is essential. Employees should have the opportunity to practice using the equipment correctly.

- Maintenance and Storage: Training must include proper cleaning, storage, and disposal of PPE to ensure its effectiveness and longevity.

- Emergency Procedures: Employees should know what to do in the event of an accident or equipment failure.

- Regular Review and Updates: The training program should be regularly reviewed and updated to reflect changes in standards, regulations, or workplace hazards.

- Documentation and Record Keeping: Maintaining detailed records of training sessions, including attendance and evaluation of understanding, is vital.

By combining theoretical knowledge with practical exercises and reinforcement, a successful training program empowers employees to use PPE effectively and confidently, ensuring a safer work environment.

Q 22. How do you ensure compliance with OSHA regulations regarding PPE?

Ensuring OSHA compliance regarding PPE involves a multi-faceted approach. It starts with a thorough hazard assessment to identify all potential workplace risks. This assessment dictates the types of PPE required. Next, we establish a comprehensive PPE program, which includes selecting appropriate PPE, providing training on its proper use, maintenance, and limitations, and implementing a system for regular inspection and replacement. We must also ensure that employees understand the importance of using PPE correctly and the consequences of not doing so. Crucially, we maintain detailed records of training, inspections, and any incidents involving PPE. This documentation is critical for demonstrating compliance during OSHA audits. For instance, if we’re working with chemicals, we wouldn’t just provide gloves; we’d ensure the gloves are chemically resistant to the specific substance, and employees are trained on proper donning and doffing procedures, including handwashing afterward. We also need to ensure the program adapts to changing conditions and new hazards.

Q 23. Explain the importance of regular PPE inspections.

Regular PPE inspections are vital for ensuring worker safety and preventing accidents. Damaged or improperly functioning PPE can significantly increase the risk of injury. Think of a hard hat with a crack – it’s no longer offering the protection it’s designed for. Regular inspections allow us to identify and replace such items before they compromise safety. We typically inspect PPE before each use, looking for signs of wear and tear, damage, or contamination. This process includes checking for holes, tears, cracks, or any other physical damage that could affect its protective capabilities. We also need to check for proper fit. For instance, a poorly fitting respirator may not effectively filter airborne contaminants. A systematic inspection program, often including checklists and documented findings, is key. This helps track maintenance and replacement schedules and provides a valuable record for accountability and safety audits.

Q 24. What are the different types of gloves and their applications?

Gloves are a critical piece of PPE, and the type needed depends entirely on the task. We have several categories:

- Cut-resistant gloves: Made from materials like Kevlar or steel mesh, offering protection from sharp objects in industries like manufacturing or construction.

- Chemical-resistant gloves: These protect against various chemicals, and the material choice (nitrile, neoprene, etc.) depends on the specific chemical being handled. Incorrect selection here is incredibly dangerous.

- Heat-resistant gloves: Used for handling hot materials or surfaces in settings like welding or working with ovens. Different materials offer varied levels of heat resistance.

- Insulated gloves: Protect hands from cold temperatures in environments like freezers or cold storage facilities.

- General-purpose gloves: Offer basic protection against abrasions and minor impacts and are often used for tasks that don’t require specialized protection.

Choosing the wrong glove can have severe consequences. Using general-purpose gloves when handling chemicals, for example, could lead to chemical burns or exposure. Proper selection always begins with a thorough hazard assessment.

Q 25. How do you ensure the correct selection of safety footwear?

Correct safety footwear selection hinges on the workplace hazards. We start by identifying the potential risks. Are there risks of punctures, slips, electrical hazards, or crushing injuries? The material, sole type, and features of the footwear need to address these specifically. Steel-toe boots are standard for construction, protecting against dropped objects. Slip-resistant soles are crucial in environments with wet or oily surfaces. Electrical hazard footwear is critical in environments with electrical risks. Beyond hazard assessment, we also consider fit and comfort; uncomfortable footwear can lead to fatigue and poor work practices. Proper fit ensures protection and minimizes the risk of foot injuries. We always ensure footwear meets relevant safety standards.

Q 26. Describe your experience with fall protection equipment.

My experience with fall protection equipment is extensive. I’ve worked with a range of systems, including full-body harnesses, lanyards, lifelines, and anchor points. I’m proficient in the inspection and maintenance of these systems, ensuring they meet safety standards and are appropriately rated for the specific application. I understand the importance of proper anchor point selection, the different types of fall arrest systems (e.g., self-retracting lifelines, shock-absorbing lanyards), and the importance of regular training for workers on safe usage. For example, I’ve overseen the implementation of a comprehensive fall protection program at a construction site, involving training employees on harness fitting, rescue procedures, and the proper selection of anchor points based on the task. This involved ensuring compliance with all relevant safety regulations and performing regular inspections of equipment.

Q 27. What are the key factors to consider when selecting respiratory protection?

Selecting respiratory protection requires careful consideration of the specific hazards. We must first identify the type of contaminant (e.g., dust, fumes, gases, vapors) and its concentration. This determines the appropriate respirator type – N95 masks for particulate matter, for instance, versus more specialized respirators for gases and vapors. The respirator must also fit properly to ensure an effective seal. A poorly fitting respirator, even one with the correct filter, won’t protect the wearer. We must account for the user’s physical capabilities and any pre-existing health conditions. Regular fit testing is crucial to ensure continued effectiveness. Training on proper use, maintenance, and limitations of the chosen respirator is paramount. Ignoring this could lead to serious health consequences from exposure to hazardous substances.

Q 28. How do you manage the procurement and inventory of PPE?

Managing PPE procurement and inventory requires a structured approach. We begin with an accurate assessment of PPE needs based on our hazard assessments and employee headcount. This drives our purchasing decisions and ensures we have adequate stock. We use a computerized inventory management system to track stock levels, order dates, expiration dates, and usage patterns, allowing us to anticipate demand and prevent shortages. For PPE with expiration dates, such as respirators, we establish a clear rotation system, using a FIFO (First-In, First-Out) approach to prevent expired items from being used. We also incorporate quality control measures throughout the procurement and storage processes, ensuring that only certified and approved PPE makes it into our inventory. This integrated system optimizes cost-effectiveness, minimizes waste, and maximizes worker safety.

Key Topics to Learn for Safety Equipment and Personal Protective Gear (PPE) Usage Interview

- Understanding PPE Types: Learn the different categories of PPE (e.g., respiratory protection, eye protection, hearing protection, hand protection, head protection, fall protection) and their specific applications.

- Selecting Appropriate PPE: Master the process of choosing the right PPE for various hazards and work environments. This includes understanding hazard assessments and risk mitigation strategies.

- Proper PPE Use and Donning/Doffing Procedures: Familiarize yourself with the correct methods for putting on, using, and removing PPE, emphasizing safe and effective practices to prevent contamination and injury.

- PPE Maintenance and Inspection: Understand the importance of regular inspection, cleaning, and storage of PPE to ensure its effectiveness and longevity. Know how to identify damaged or compromised equipment.

- Legal and Regulatory Compliance: Be aware of relevant safety regulations and standards concerning PPE usage in your industry. This includes understanding OSHA or equivalent regulations.

- Communicating Safety Procedures: Practice explaining safety protocols and PPE usage to coworkers effectively and clearly, demonstrating leadership in workplace safety.

- Problem-solving with PPE: Prepare to discuss scenarios where PPE malfunctions or is inadequate, and how you would address such situations to maintain safety.

- Emerging Technologies in PPE: Research advancements in PPE materials, design, and technology. Showing awareness of industry trends demonstrates proactive learning.

Next Steps

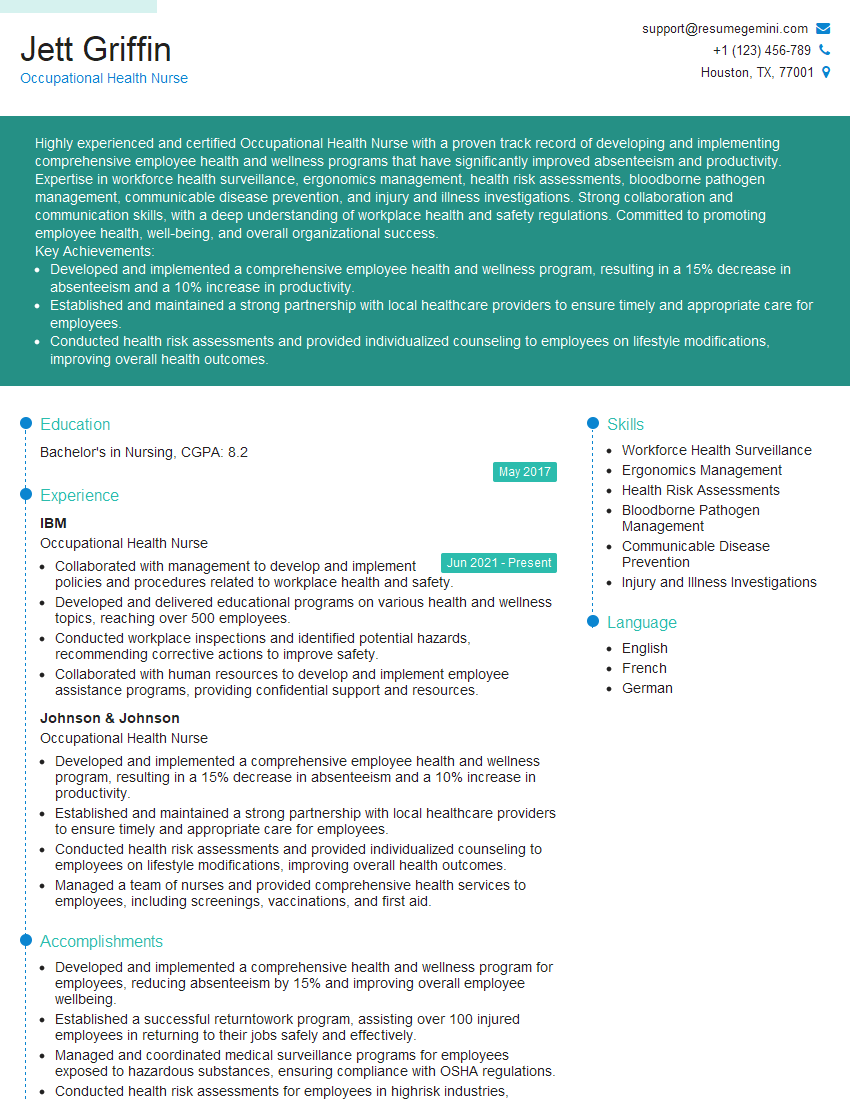

Mastering Safety Equipment and Personal Protective Gear (PPE) usage is crucial for career advancement in many safety-critical industries. Demonstrating a thorough understanding of PPE ensures workplace safety and minimizes risks, making you a valuable asset to any team. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored specifically to Safety Equipment and Personal Protective Gear (PPE) Usage roles to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO