Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Sanding and Finishing Techniques interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Sanding and Finishing Techniques Interview

Q 1. What types of sandpaper grits are commonly used and when?

Sandpaper grits are measured by their coarseness, indicated by a number: the lower the number, the coarser the grit. Choosing the right grit is crucial for achieving a smooth, even finish. Different grits are used at various stages of the sanding process.

- Coarse grits (24-80): Used for initial shaping, removing significant imperfections, and leveling out rough surfaces. Imagine smoothing out a very rough piece of wood; you’d start with a very coarse grit.

- Medium grits (100-180): Used to refine the surface after coarse sanding, reducing scratches left by coarser grits. Think of it as refining the rough shape into something more precise.

- Fine grits (220-400): Used for final smoothing before finishing, removing very fine scratches. This is your polishing stage, ensuring a flawless surface for the finish to adhere to.

- Ultra-fine grits (600 and above): Used for extremely smooth surfaces or specialized finishes where the highest level of smoothness is needed. These are often used for polishing certain types of wood or preparing for high-gloss finishes.

For example, when sanding a tabletop, I might start with 80-grit, move to 120, then 220, and finally 320 before applying the finish. The choice depends on the wood, the desired finish, and the initial condition of the surface.

Q 2. Explain the difference between open-pore and closed-pore woods.

The terms “open-pore” and “closed-pore” refer to the size and visibility of wood pores. This significantly impacts how the wood accepts and displays a finish.

- Open-pore woods: These woods have large, readily visible pores, such as oak, ash, and walnut. The pores are easily noticeable, often creating a textured surface. Finishes need to fill these pores to achieve a smooth surface, especially with high-gloss finishes.

- Closed-pore woods: These woods have smaller, less visible pores, like maple, birch, and cherry. Their surfaces are generally smoother, requiring less pore filling before finishing. They may accept finishes more readily.

Imagine a sponge (open-pore) versus a smooth ceramic tile (closed-pore). The finish needs to penetrate and fill the holes in the sponge, whereas it sits on top of the smooth tile. This understanding dictates your finishing approach. For open-pore woods, a wood filler might be necessary before the topcoat, while it’s often unnecessary for closed-pore woods.

Q 3. Describe the process of preparing a surface for finishing.

Surface preparation is the most critical step in achieving a beautiful and durable finish. A poorly prepared surface will result in a poor-looking finish, regardless of the quality of the finish itself. It’s like trying to paint a house with peeling paint – no matter how good the new paint is, it will still show imperfections.

- Sanding: This involves progressively using finer grits of sandpaper to remove imperfections and create a smooth surface. This is done in the direction of the wood grain to avoid scratches.

- Cleaning: After sanding, the surface must be thoroughly cleaned to remove all dust particles. A tack cloth is ideal for this, as it picks up fine dust without leaving residue. A shop vacuum is also beneficial in removing the coarser dust particles.

- Filling (if necessary): Open-pore woods often benefit from wood filler to fill the pores and create a smoother surface before the finish is applied. The filler should be applied sparingly and sanded smooth.

- Final cleaning: Before applying the finish, the surface needs another thorough cleaning to remove any remaining dust or filler residue.

Careful surface preparation is a time-consuming but essential process that yields significantly better results.

Q 4. What are the different types of wood finishes and their properties?

Various wood finishes offer different properties and aesthetics. The choice depends on the desired look, durability, and the type of wood being finished.

- Oil finishes: Penetrate the wood, enhancing its natural beauty and providing some protection. They are relatively easy to apply and repair but offer less durability than other finishes. Linseed oil, tung oil, and Danish oil are popular examples. These are great for highlighting wood grain.

- Varnish: Forms a hard, protective layer on the wood’s surface, offering excellent durability and water resistance. It comes in various gloss levels, from high gloss to satin. It offers a good balance of protection and aesthetics.

- Lacquer: Dries quickly, forming a hard and durable surface. It’s often used for furniture and other applications where quick drying is advantageous. Its hard finish is durable and protective.

- Shellac: A natural resin finish that provides a warm, amber tone. It’s easy to apply but is less durable than varnish or lacquer. It has a classic feel and is easy to repair.

- Polyurethane: A synthetic finish that is extremely durable and water-resistant. It is available in different gloss levels and is often used for floors and other high-traffic areas. It’s ideal for heavy use furniture and surfaces.

Each finish has its strengths and weaknesses, and selecting the appropriate one depends heavily on the project’s requirements.

Q 5. How do you determine the correct amount of finish to apply?

Applying too much finish can lead to runs and drips, while too little may leave the wood unprotected. The key is thin, even coats, allowing each to dry completely before applying the next.

For oil finishes, apply a small amount at a time, working it into the wood grain. Wipe off any excess after a few minutes. For film-forming finishes (varnish, lacquer, polyurethane), apply a thin, even coat, allowing the finish to self-level. Avoid heavy applications, which tend to run and sag. Many finishes recommend several thin coats rather than one thick coat.

Practice makes perfect, and it’s better to err on the side of thin coats. It’s easier to add more coats than to remove excess finish.

Q 6. What are the signs of improper sanding?

Improper sanding is readily apparent in the finished product. Here are some key signs:

- Scratches: Visible scratches indicate sanding in the wrong direction (across the grain), using too coarse a grit, or applying too much pressure.

- Uneven surface: A bumpy or uneven surface indicates inconsistent sanding pressure or the failure to use progressively finer grits.

- Sanding marks: These are fine, visible marks left by the sandpaper. They suggest the need for more sanding with a finer grit.

- Burn marks: These dark streaks are caused by excessive sanding pressure, generating heat that discolors the wood.

Addressing these issues requires resanding with appropriate grits and techniques. Prevention is key. Always sand with the grain, use appropriate pressure, and proceed progressively through finer grits.

Q 7. Explain the importance of proper ventilation when using finishes.

Many wood finishes release volatile organic compounds (VOCs) that are harmful if inhaled. Proper ventilation is crucial to minimize health risks. Always work in a well-ventilated area, preferably outdoors or in a space with good air circulation.

Consider using respirators or masks designed to filter out VOCs, especially when working with strong-smelling finishes like lacquer or polyurethane. Open windows, use exhaust fans, or consider a dedicated spray booth for larger projects. Never underestimate the importance of safety when working with potentially hazardous materials. Your health is paramount.

Q 8. How do you address sanding marks or imperfections in a finished surface?

Addressing sanding marks or imperfections in a finished surface requires a systematic approach, starting with identifying the type and severity of the imperfection. Light scratches can often be addressed with progressively finer grits of sandpaper, working your way up from coarser to finer. Deeper scratches or imperfections may require more aggressive methods, such as filling with wood filler, followed by sanding and refinishing.

Think of it like baking a cake: if you have a minor imperfection, a quick touch-up fixes it. But a major flaw might require starting over. Similarly, for minor scratches, we might start with 220-grit sandpaper, then move to 320, and finally 400-grit to achieve a smooth surface. For deeper imperfections, filling with wood filler and then sanding becomes necessary.

- Light scratches: Use progressively finer grits of sandpaper (e.g., 220, 320, 400).

- Deeper scratches/imperfections: Fill with wood filler, let it dry completely, sand smooth, and reapply the finish.

- Major damage: Repair or replacement might be required.

Q 9. Describe the process of applying a lacquer finish.

Applying a lacquer finish involves several key steps to ensure a professional-looking result. First, prepare the surface by sanding it smooth with fine-grit sandpaper (e.g., 320-grit). Then, apply a thin, even coat of lacquer using a spray gun, brush, or pad, ensuring that no runs or sags form. Allow the coat to dry completely before applying subsequent coats, usually several coats are needed for a durable finish. Light sanding between coats (with very fine sandpaper like 400-600 grit) helps improve adhesion and creates a smoother surface. After the final coat dries, you can carefully rub out any imperfections with rubbing compound and polishing compound for a truly professional shine.

Imagine painting a wall – you wouldn’t just slap on one thick coat. You’d apply thin coats to avoid drips and ensure even coverage. Lacquer application is similar. It’s all about patience and controlled application.

- Surface Preparation: Sanding to a smooth finish.

- Application: Thin, even coats with adequate drying time between coats.

- Sanding Between Coats (optional): Light sanding with very fine grit sandpaper.

- Finishing: Rubbing out with compound for maximum shine.

Q 10. What are the advantages and disadvantages of using oil-based finishes?

Oil-based finishes offer several advantages, including excellent depth and richness of color, durability, and water resistance. They are often preferred for outdoor furniture or applications requiring high durability. However, they have significant drawbacks. Oil-based finishes have a strong odor, take a longer time to dry, require mineral spirits or solvents for cleanup, and are less environmentally friendly than water-based options. The longer drying time also means the project takes more time to complete, impacting your efficiency.

Think of it as a trade-off between quality and convenience. Oil-based finishes offer superior protection, but they are less convenient to work with.

- Advantages: Durability, water resistance, depth of color.

- Disadvantages: Strong odor, long drying time, solvent cleanup, environmental impact.

Q 11. How do you achieve a smooth, even finish on curved surfaces?

Achieving a smooth, even finish on curved surfaces requires careful technique and often specialized tools. Flexible sanding pads or blocks conform to the curves, allowing for even sanding. For tight curves, specialized sanding tools or even hand sanding with a piece of fine sandpaper wrapped around a suitably shaped object is necessary. The key is to use light pressure and avoid excessive sanding in one area, which can create inconsistencies or damage the surface. Multiple coats of finish, applied thinly and evenly, will also help to enhance the smoothness of the final product.

Imagine trying to sand a ball. You can’t use a flat sanding block; you need something that can follow the curve. The same logic applies to all curved surfaces.

- Flexible Sanding Tools: Use flexible sanding pads or blocks.

- Hand Sanding: For tight curves, hand sand with sandpaper wrapped around a suitable object.

- Multiple Thin Coats: Apply several thin coats of finish.

Q 12. Explain the process of applying a stain and sealant.

Applying a stain and sealant involves a process of preparing the wood, applying the stain, and then applying a sealant to protect the stain and wood. First, sand the wood surface smooth. Then apply the stain evenly, according to the manufacturer’s instructions. Allow the stain to penetrate the wood for the recommended time before wiping away any excess. Once the stain is dry, apply the sealant following the manufacturer’s instructions. Several coats of sealant are usually needed to provide sufficient protection. The order is crucial; stain is applied first and the sealant acts as the protective topcoat.

Think of it as dressing up your wood – the stain is the makeup, the sealant is the sunscreen. The sealant protects your stain and keeps it looking beautiful for longer.

- Surface Preparation: Sand the wood smooth.

- Stain Application: Apply evenly, allow sufficient penetration time.

- Sealant Application: Apply several coats after the stain dries completely.

Q 13. What safety precautions are necessary when working with sanding and finishing materials?

Safety is paramount when working with sanding and finishing materials. Always wear appropriate personal protective equipment (PPE), including a dust mask or respirator to prevent inhalation of sanding dust, safety glasses to protect your eyes, and gloves to protect your skin from chemicals. Work in a well-ventilated area, preferably outdoors or in a space with proper ventilation systems. Dispose of sanding dust and finishing materials according to local regulations. Keep flammable materials away from any ignition sources, especially when using oil-based products or spray finishes.

Think of it like working in a science lab – careful preparation and protection is key.

- PPE: Dust mask/respirator, safety glasses, gloves.

- Ventilation: Work in a well-ventilated area.

- Waste Disposal: Dispose of materials properly.

- Fire Safety: Avoid ignition sources near flammable materials.

Q 14. How do you clean and maintain your sanding and finishing equipment?

Cleaning and maintaining your sanding and finishing equipment is crucial for its longevity and performance. After each use, remove any excess material from sanding blocks and pads. Clean spray guns thoroughly with the appropriate solvent recommended by the manufacturer. Store equipment in a clean, dry place to prevent rust or damage. Regularly inspect tools for wear and tear and replace them as necessary. A well-maintained tool ensures a clean and efficient work process.

Just like you maintain your car, your tools need regular care.

- Cleaning: Remove excess material, clean spray guns with solvent.

- Storage: Store in a clean, dry place.

- Inspection: Regular checks for wear and tear.

Q 15. Describe your experience with different types of spray equipment.

My experience with spray equipment spans a wide range, from basic HVLP (High Volume Low Pressure) systems to more advanced airless sprayers and even electrostatic sprayers. HVLP systems are great for fine finishes and offer excellent control, minimizing overspray, but they can be slower. I’ve found them ideal for applying lacquer and shellac on delicate furniture pieces. Airless sprayers, on the other hand, are much faster and provide a heavier coat, perfect for covering large surfaces quickly, like a deck or fence, with stains or paints. However, they require more skill to avoid runs and drips. Electrostatic sprayers are amazing for efficiency and minimizing waste, as the charged particles attract to the workpiece, reducing overspray significantly. I’ve used these extensively in larger projects where minimizing waste and maximizing coverage is crucial. Each system requires a different level of technique and understanding of fluid viscosity, air pressure, and nozzle selection. For example, adjusting the fluid tip on an airless sprayer significantly impacts the finish quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the proper method for handling and disposing of finish waste?

Proper handling and disposal of finish waste is paramount for both environmental safety and personal health. Firstly, all rags and materials used with oil-based finishes should be stored in a sealed, metal container to prevent spontaneous combustion. Never leave them in a pile – this is a significant fire hazard. Water-based finishes are less hazardous in this regard, but still should be contained appropriately. I always follow local regulations regarding waste disposal. In many areas, oil-based finish waste requires special handling and disposal at designated hazardous waste facilities. Water-based finishes may be disposed of differently, depending on local regulations, often via the regular waste stream, but sometimes they need separate disposal based on solvent composition. It’s vital to thoroughly clean all spray equipment according to the manufacturer’s instructions to prevent curing of the finish and clogging. The cleaning solvents also need proper disposal, often following the same guidelines as the finish itself. Always refer to the Safety Data Sheets (SDS) provided by the finish manufacturer for specific instructions.

Q 17. How do you troubleshoot common finishing problems, such as runs or drips?

Troubleshooting runs and drips in finishing is a common issue, and often involves a combination of factors. Runs typically occur due to excessive material application, too high a viscosity, or improper spraying technique. The solution often involves adjusting the spray pattern, reducing the material flow rate, or increasing the distance from the surface. Drips can be caused by an overly thick finish, excessive pressure, or inadequate surface preparation. Sometimes, simply allowing the surface to dry more slowly in a dust free area will reduce dripping. If the problem persists, consider thinning the finish according to the manufacturer’s recommendations. For example, if you’re using lacquer and experiencing runs, try reducing the amount of reducer or slowing down your application speed. Surface preparation is critical. Proper sanding and application of a quality primer can minimize these issues. In some cases, a defective sprayer nozzle might be the culprit; cleaning or replacing it is then necessary. I’ve found that meticulous preparation and consistent application technique are the keys to preventing these issues.

Q 18. Explain your experience with different wood species and their finishing requirements.

My experience with different wood species and their finishing requirements is extensive. Each species has unique properties that affect how it accepts and displays a finish. For instance, hardwoods like cherry and mahogany are relatively dense and often require less preparation but may show more grain variation, requiring careful selection of finish and application technique to highlight these variations. Softwoods such as pine and fir are more porous and require more attention to sanding and potentially the use of wood filler to achieve a smooth finish. These woods also absorb more stain and finish, potentially requiring multiple coats. The open grain structure of oak, for example, demands a careful approach, potentially requiring a grain filler to achieve a perfectly smooth surface before top coats are applied. I adapt my technique based on the specific wood’s properties. For example, I might use a sanding sealer on porous woods to level the surface before applying a stain or top coat. Working with exotic woods requires special consideration of their properties and the best finishing methods to highlight their unique features. The final selection of a finish can be heavily impacted by the wood and the desired look.

Q 19. How do you determine the appropriate drying time for a finish?

Determining the appropriate drying time for a finish depends on several crucial factors: the type of finish (lacquer dries much faster than oil-based polyurethane), the ambient temperature and humidity (higher humidity slows drying), the thickness of the applied coat, and the desired level of cure. Always consult the manufacturer’s instructions for the specific finish being used, as this is the most reliable source of information. Overly rapid drying can lead to cracking or other finish defects, while insufficient drying time can result in a soft, easily damaged finish. While waiting the recommended time as indicated on the datasheet is often best, if the specific conditions are unusually hot and dry, the surface may dry faster. In these cases, a light touch test with your fingertip can indicate if the finish is dry enough to sand or apply the next coat. Remember, though, you should avoid any pressure when doing this light touch test.

Q 20. Describe your experience with color matching techniques.

Color matching is a complex skill that requires a keen eye for detail and a thorough understanding of color theory. I typically use a combination of techniques, starting with analyzing the target color using a color matching system. This may involve using a spectrophotometer to obtain precise color readings. Then, I create samples using various stains and tints, adjusting their proportions to get as close as possible to the desired color. This iterative process involves testing on scrap wood of the same species as the project to account for color absorption. Often, multiple coats and the strategic use of glazing techniques might be needed to achieve a perfect match. For instance, to match a particular antique piece, I might layer multiple translucent stains of slightly different hues to build up the depth and complexity of the original color. The goal isn’t just to match the color visually, but also to replicate its subtle variations and depth.

Q 21. How do you achieve a high-gloss finish?

Achieving a high-gloss finish requires meticulous attention to detail throughout the entire process, starting with meticulous surface preparation. This includes careful sanding through progressively finer grits to create a perfectly smooth surface. Next, applying multiple thin coats of a high-gloss finish, ensuring each coat is completely dry before applying the next is crucial. Between each coat, light sanding with super fine grit is necessary to remove any imperfections or dust particles before application. I always use a high-quality sanding block to ensure evenness. The application of each coat should be consistent, avoiding heavy buildup in one area, and ensuring full coverage of the surface. Lastly, a final polishing step, often involving rubbing compound and progressively finer polishing compounds, is necessary to eliminate minor imperfections and maximize the gloss level. This stage can require significant effort to reach a mirror-like finish. The choice of finish itself matters; certain polyurethane finishes are formulated specifically for achieving a high-gloss sheen.

Q 22. What is your experience with different types of sanding blocks?

My experience with sanding blocks spans a wide range, from basic hand-held blocks to more specialized options. I’m proficient with various grits and materials. For example, I frequently use cork sanding blocks for fine finishing, as their flexibility allows for a smoother, more even finish, especially on curved surfaces. For larger, flatter areas, I prefer hard rubber or wooden blocks for greater durability and efficiency. I also utilize sanding sponges, which are excellent for reaching intricate details and contours, and even specialized foam blocks for achieving super-fine finishes. The choice of sanding block always depends on the project’s specific demands—the material’s hardness, the desired level of smoothness, and the shape of the workpiece.

I find that the quality of the block material directly impacts the final finish. A low-quality block can leave scratches or an uneven surface, negating hours of careful work. For instance, a worn-out cork block can leave a slightly textured surface that would be difficult to address without further sanding, causing extra labor and material costs.

Q 23. Explain your understanding of grain raising and how to address it.

Grain raising is the phenomenon where wood fibers swell and stand up when exposed to moisture, either from the finishing process itself or from humidity. This results in a rough surface that needs addressing before applying subsequent coats. Think of it like the nap of a carpet raising after being wet. To address grain raising, I always begin with a thorough sanding once the initial coat has dried, typically using 180-grit sandpaper to level the raised fibers. This is followed by finer grits (220, 320, and sometimes even higher, depending on the wood and desired finish) to progressively refine the surface.

Sometimes, even after thorough sanding, subtle grain raising can still be visible. In those cases, I might employ a light sanding between coats, or carefully employ a very fine steel wool to level the surface gently without removing excessive finish. The key is to be patient and methodical to ensure a smooth, flawless final product. Neglecting grain raising can lead to an uneven surface, impacting the final look and feel of the finished piece.

Q 24. Describe your experience with repairing minor damage to finished surfaces.

Repairing minor damage on finished surfaces requires a careful approach and a good understanding of the finish. For small scratches, I often start with a very fine grit sandpaper (400 or higher) to gently feather the edges of the scratch, smoothing it out without removing too much of the surrounding finish. This is followed by applying a touch-up of the original finish, carefully blending it into the surrounding area. A soft cloth or a tiny brush is employed here to ensure a smooth, seamless repair.

For minor dents or chips, I might use a wood filler, carefully matching the color of the surrounding wood. Once dried, the filler is sanded smooth and the finish is retouched. For more significant damage, a professional restoration may be necessary. The key to successful repair lies in patience and attention to detail; a well-executed repair should be virtually invisible.

Q 25. What is your process for testing a new finish on a small sample?

Testing a new finish on a small sample is crucial before applying it to the entire piece. I always prepare a scrap piece of the same wood species and cut it to a size that allows for proper testing (at least a 4×4 inch square). I then apply the finish following the manufacturer’s instructions, observing the drying time, color development, and overall appearance. This allows me to assess if the finish is compatible with the wood, if the color matches expectations, and if there are any unexpected reactions, like excessive grain raising or uneven drying. This small-scale trial prevents costly mistakes on the main project and allows for adjustments before the full application.

Q 26. How do you ensure the consistent quality of your finishes?

Consistent finish quality relies on a combination of factors: consistent application techniques, environmentally controlled conditions (temperature and humidity), and using high-quality products. I maintain meticulous control over these factors. For example, I always apply thin, even coats, allowing ample drying time between them. I carefully monitor the environment during application and drying to avoid problems caused by rapid drying or excessively humid conditions. I also use calibrated equipment like spray guns when appropriate, and clean my equipment thoroughly between uses to prevent contamination.

Furthermore, thorough preparation of the wood surface is paramount. Proper sanding and the use of appropriate sealers or primers create a consistent base for the finish. This commitment to quality and attention to detail across all steps ensures consistent, high-quality results, every time.

Q 27. What are your preferred brands of sanding and finishing products?

My preferred brands for sanding products often include Mirka (for abrasives) and 3M (for various sanding tools and accessories). For finishes, my go-to brands are often Sherwin-Williams and General Finishes, known for their high-quality products and wide range of colors and finishes. However, the best brand for a specific project often depends on the type of wood, the desired look, and the project’s budget. My selection is always informed by the specific needs of the project and what will yield the best results.

Q 28. Describe a challenging finishing project you completed and how you overcame the challenges.

One challenging project involved finishing a highly figured, highly figured mahogany table with a high-gloss finish. The wood’s intricate grain patterns presented numerous challenges in achieving an even application. The open grain of the mahogany required multiple coats of a sanding sealer to properly fill the pores and prevent the finish from settling unevenly. Additionally, I had to carefully manage the drying time to prevent dust nibs (small particles of dust embedding into the wet finish) in the high-gloss finish. The solution was to create a controlled environment with minimal dust, using slow-drying finishes, and employing meticulous sanding between coats to ensure a flawlessly smooth surface. The final product was a stunning piece showcasing the wood’s beauty through a mirror-like, even finish, a testament to the dedication and technical skill required to overcome such challenges.

Key Topics to Learn for Sanding and Finishing Techniques Interview

- Wood Grain Understanding: Identifying different wood types and their impact on sanding and finishing techniques. Understanding how grain direction affects the final finish.

- Abrasive Selection: Choosing the right sandpaper grit for various stages of sanding (e.g., roughing, smoothing, finishing). Understanding the differences between open and closed coats.

- Sanding Techniques: Mastering proper sanding techniques to avoid swirl marks, scratches, and other imperfections. This includes hand sanding, machine sanding (belt sanders, random orbital sanders), and understanding the appropriate pressure and speed for each.

- Finishing Materials: Knowledge of various finishing materials (e.g., stains, sealers, lacquers, varnishes, polyurethane) and their properties. Understanding how to apply each material effectively and troubleshoot common issues.

- Surface Preparation: Preparing surfaces for finishing, including cleaning, repairing imperfections, and applying primers or sealers as needed. This involves understanding wood filler and putty applications.

- Finishing Application Techniques: Different application methods for various finishes (e.g., brushing, spraying, wiping). Understanding the importance of even application, avoiding runs and drips, and achieving a smooth, uniform finish.

- Troubleshooting Common Issues: Identifying and resolving common problems encountered during sanding and finishing, such as uneven finishes, dust nibs, and other imperfections. This includes understanding the importance of proper drying times.

- Safety Procedures: Understanding and adhering to safety procedures related to sanding and finishing, including proper ventilation, dust collection, and the use of personal protective equipment (PPE).

- Tools and Equipment: Familiarity with various sanding and finishing tools and equipment, understanding their functionalities and limitations. This includes maintenance and proper usage.

- Environmental Considerations: Understanding the environmental impact of finishing materials and choosing eco-friendly options where possible.

Next Steps

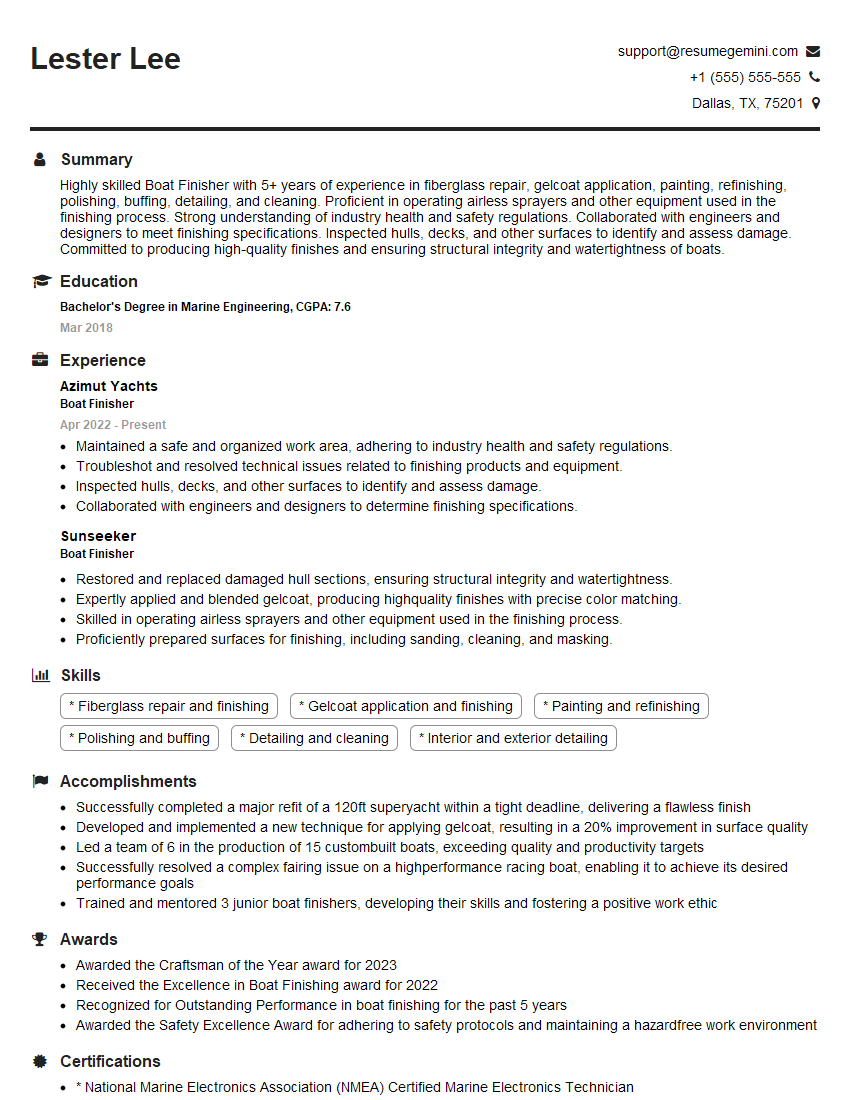

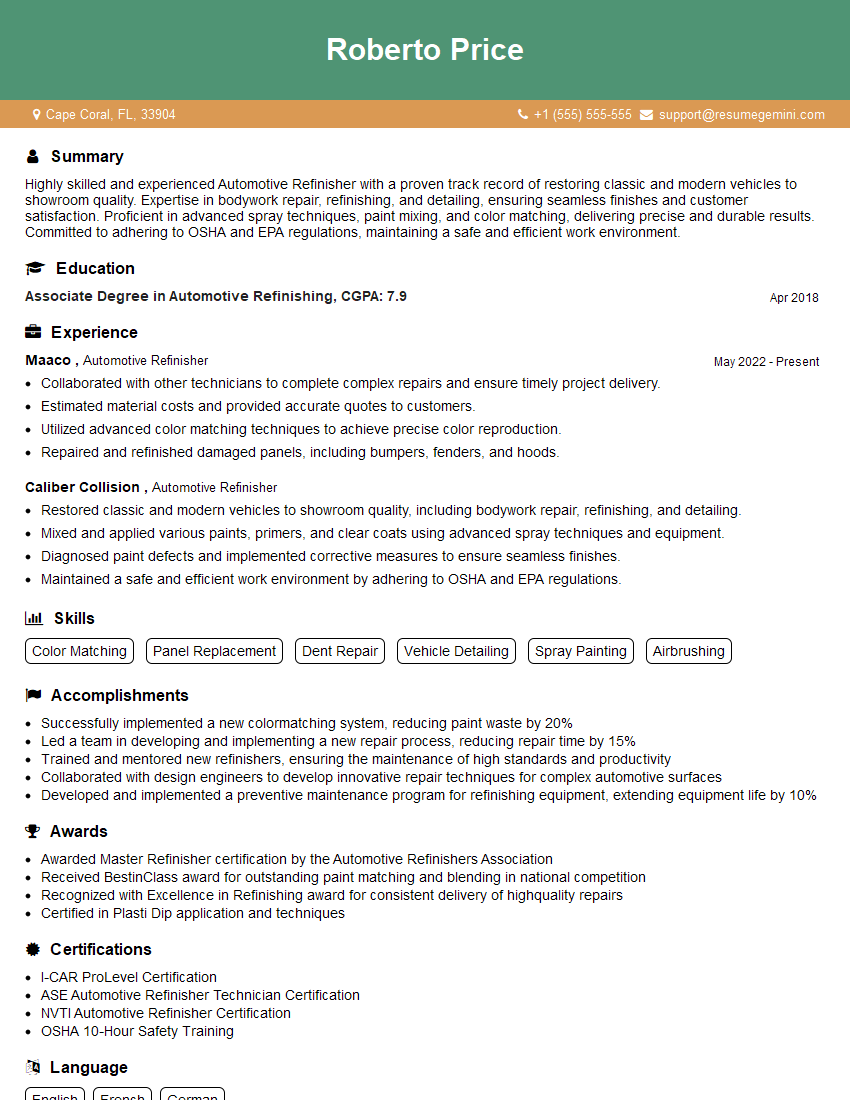

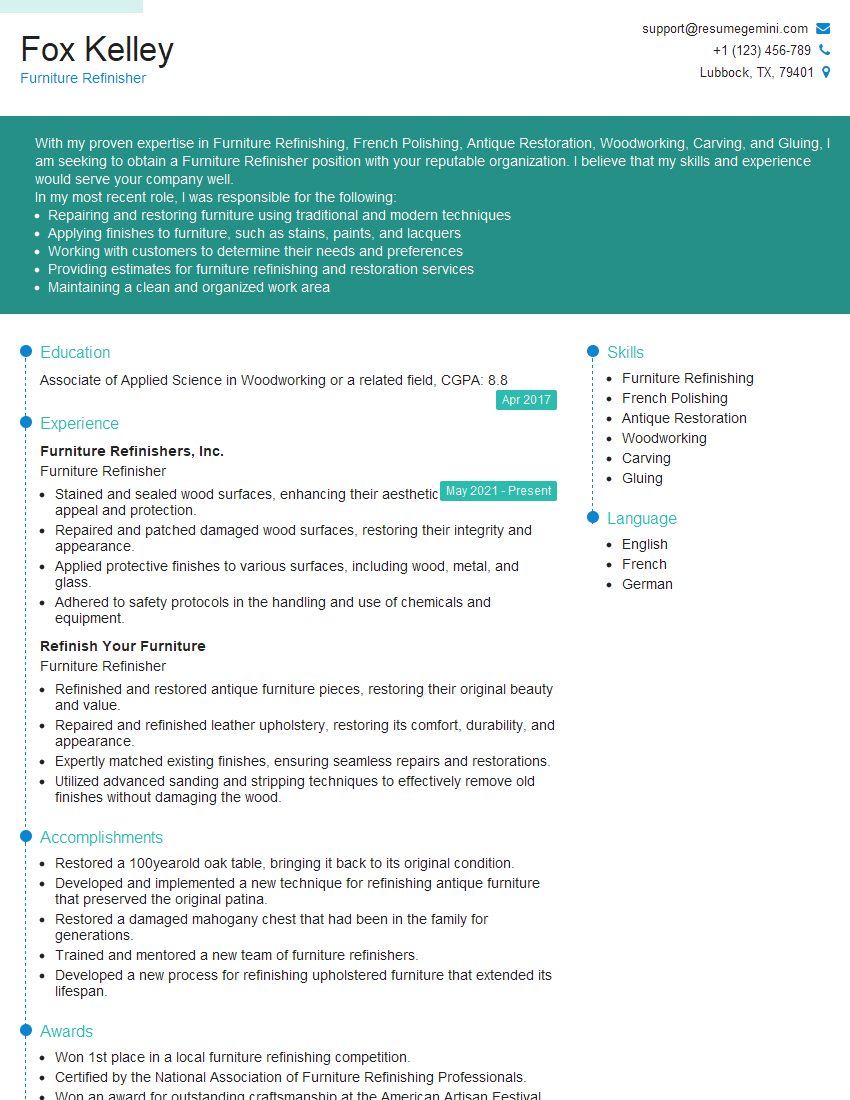

Mastering sanding and finishing techniques is crucial for career advancement in many industries, showcasing your precision, attention to detail, and problem-solving abilities. An ATS-friendly resume is key to getting your application noticed. To maximize your job prospects, craft a compelling resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Sanding and Finishing Techniques to guide you through the process. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO