The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Shifter adjustment interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Shifter adjustment Interview

Q 1. Explain the process of adjusting a manual transmission shifter.

Adjusting a manual transmission shifter involves fine-tuning the linkage between the shifter lever and the transmission itself to ensure smooth, precise gear selection. This process often involves adjusting the length of linkage rods or cables, or repositioning linkage components to achieve the optimal throw and engagement for each gear. The exact procedure varies greatly depending on the vehicle’s make, model, and year, but generally involves accessing the linkage mechanism, typically underneath the car or within the center console, and then making adjustments using nuts, bolts, or adjustment screws. Think of it like fine-tuning a guitar – you need to make small, precise adjustments to get everything in perfect harmony.

For instance, a loose shifter could cause difficulty getting into gear, requiring more effort and potentially damaging the transmission. Conversely, a shifter with too little travel might prevent the gear from fully engaging. The goal is to achieve a smooth, positive engagement in each gear without excessive force.

Q 2. How do you diagnose a shifter linkage problem?

Diagnosing a shifter linkage problem starts with a visual inspection for any obvious signs of damage or wear, such as broken or bent linkages, worn bushings, or loose fasteners. Next, you would operate the shifter lever, carefully observing the movement of the linkage components. Look for any binding, sticking, or excessive play. If everything looks visually sound, test the shifting action; the shifting effort needed, the precision of each gear selection and the ease of returning to neutral are all key observations. A common diagnostic technique involves disconnecting the shifter linkage at the transmission end and then moving the lever to check for smoothness. This isolates the issue to either the linkage or the transmission itself.

For example, if you observe excessive play, it usually points to worn bushings or loose linkages. If the shift lever feels stiff or binds in certain positions, a bent or damaged linkage might be the culprit.

Q 3. Describe the common causes of imprecise shifting.

Imprecise shifting, that is, difficulty in selecting gears or feeling that the gears aren’t fully engaging, can stem from several common issues. Worn linkage components, such as bushings or ball joints, introduce slop into the system, leading to imprecise movements. Bent or misaligned linkage rods can also cause inaccurate gear selection. Likewise, worn or stretched shifter cables can allow for too much play and imprecise action. Internal transmission problems like worn synchronizers can also *manifest* as imprecise shifting, although this is usually accompanied by other symptoms like grinding or difficulty selecting gears under load. Finally, improper adjustment of the shifter linkage itself is often the main contributor.

Consider this analogy: Imagine trying to steer a car with excessive play in the steering column; the result would be a lack of precision and control, just like with a poorly adjusted shifter.

Q 4. What tools are necessary for shifter adjustment?

The tools needed for shifter adjustment vary depending on the vehicle, but a basic set typically includes:

- Jack and jack stands (for safe vehicle lifting)

- Wheel chocks (for safety)

- Socket set and wrenches (various sizes)

- Screwdrivers (Phillips and flathead)

- Pliers

- A flashlight or work light

- Shifter adjustment tools (specific to vehicle model; may include special wrenches or adjustment tools)

- Shop rags or paper towels

- Pen and paper for noting adjustments

Always consult your vehicle’s repair manual for specific tools and procedures. Safety is paramount!

Q 5. How do you adjust a shifter cable?

Adjusting a shifter cable typically involves locating the cable’s adjustment mechanism, often a nut or bolt at the transmission or lever end. Turning this adjustment mechanism changes the cable’s effective length. Common procedures involve loosening the locking nut or bolt, then rotating the adjustment screw to increase or decrease cable tension. After adjustment, test the shifting action and re-tighten the locking nut. It’s crucial to refer to your vehicle’s service manual because some cable adjustment mechanisms are far more complex. They might incorporate specific clamps, brackets or even require specialized tools.

Remember: small adjustments make a big difference. Make incremental changes, testing the shift after each adjustment.

Q 6. How do you check for proper shifter travel?

Checking for proper shifter travel involves verifying that the shifter lever moves through the correct range of motion for each gear. This typically requires visual inspection of the linkage movement while shifting, combined with careful testing of gear engagement. You’ll need to check if each gear engages fully and smoothly without excessive force or binding. Improper travel indicates a problem with the linkage, potentially including worn bushings, bent rods, or a misadjusted cable. The service manual will usually provide specifications for the correct amount of play in the linkage as well as the exact travel distance for each gear.

An example would be noting if the lever only goes halfway to third gear, revealing a problem in the linkage. You would then proceed to trace the linkage’s movement to identify the exact point of failure.

Q 7. What are the safety precautions when working on a shifter mechanism?

Safety is paramount when working on a shifter mechanism. Always support the vehicle securely with jack stands, never rely on a jack alone. Disconnect the negative battery terminal to prevent accidental short circuits. Use wheel chocks to prevent the vehicle from rolling. Wear safety glasses to protect your eyes from debris. Work in a well-ventilated area. Never reach under a vehicle supported only by a jack; it’s extremely dangerous. Use appropriate tools for the job and consult the repair manual before beginning any work. Take detailed notes or photos of the linkage arrangement before disassembling anything, to ensure proper reassembly. Remember that if unsure at any stage of the procedure, it is always best to seek professional help.

Ignoring these precautions can lead to serious injury or damage to the vehicle.

Q 8. Explain the difference between adjusting a cable-operated and rod-operated shifter.

Adjusting cable-operated and rod-operated shifters differs significantly in their mechanisms. Cable-operated shifters use a Bowden cable to transmit movement from the shifter lever to the transmission, much like the cable on bicycle brakes. Adjustments involve tightening or loosening cable tension at the transmission end or the shifter lever itself, usually with an adjuster barrel or clamp. This affects the shift feel and precision. Rod-operated shifters, conversely, use a linkage system of rods and pivots to mechanically connect the shifter lever to the transmission. Adjustment often involves manipulating linkage lengths, pivot points, or adjusting the position of the rods themselves using shims or other mechanisms to achieve accurate shifting. Think of it like adjusting the linkage on a bicycle derailleur, where each component’s position needs fine-tuning for optimal shifting.

For example, on a cable-operated shifter, a loose shift might require tightening the cable at the transmission, while a sluggish shift might indicate a worn cable needing replacement. In a rod-operated system, a sloppy shift could indicate worn bushings at the pivot points or a bent connecting rod, necessitating replacement or realignment.

Q 9. How do you identify a worn or damaged shifter bushing?

Worn or damaged shifter bushings are usually identified through visual inspection and by assessing the feel of the shifter. Visually, you’ll look for cracks, excessive wear, or deformation of the bushing material, often rubber or plastic. The bushing’s role is to provide a smooth, low-friction pivot point for the shift linkage, so a worn bushing will often manifest as a sloppy, imprecise shift, excessive play, or even a binding/sticking feel. Sometimes, you might even hear a clicking or knocking noise as the worn bushing allows for excessive movement within the linkage. If you suspect a worn bushing, removing the shifter linkage will allow for a direct examination of the bushing’s condition for confirmation. Always replace the bushing with an identical replacement part to maintain proper alignment and function.

Q 10. How do you troubleshoot a shifter that feels loose or sloppy?

Troubleshooting a loose or sloppy shifter involves a systematic approach. Begin with a visual inspection of the entire shifter linkage and its connections to the transmission. Check for any loose bolts or nuts. Then, carefully examine each component for wear and tear, focusing on the shifter bushings (as discussed earlier), linkage rods for bends or damage, and the shifter lever itself for excessive play. Next, check the cable tension if it’s a cable-operated system. If the looseness persists, carefully look for worn or damaged components, such as a bent shift lever, or excessive slop in the linkage. Replacement of damaged or worn components is often necessary to restore proper shifting. In more complex systems, consulting a workshop manual is crucial to understand the complete linkage and appropriate adjustment methods.

Q 11. What are the potential consequences of improperly adjusted shifters?

Improperly adjusted shifters can lead to a range of issues, impacting both drivability and vehicle longevity. The most immediate consequence is difficulty in engaging the correct gear, causing missed shifts, grinding gears, and premature wear of the transmission components. This can result in reduced fuel efficiency and unpleasant driving experience. More seriously, misadjusted shifters can eventually cause damage to the synchronizers or other internal components of the transmission, leading to costly repairs or even transmission failure. In some cases, an improperly adjusted shifter could even lead to a loss of control of the vehicle under certain circumstances, particularly with manual transmissions.

Q 12. How do you adjust a shifter on a vehicle with an overdrive transmission?

Adjusting a shifter on a vehicle with an overdrive transmission is similar to adjusting shifters on other transmissions but requires careful attention to the overdrive engagement. The procedures largely depend on the specific vehicle and transmission type. However, the fundamental principles remain the same: ensuring smooth, precise shifting across all gears, including the overdrive. This often involves adjustments to the shift linkage or cable tension to ensure accurate engagement and disengagement of the overdrive. For cable-operated systems, the cable adjustment typically involves fine-tuning at the transmission end. Consult your vehicle’s service manual for detailed instructions on how to adjust the shifter for optimal overdrive operation, as some systems have additional mechanisms specifically for the overdrive control. Incorrect adjustment might manifest as problems shifting into or out of overdrive or slipping in that gear.

Q 13. Describe the procedure for bleeding a hydraulic shifter.

Bleeding a hydraulic shifter is crucial to remove any air bubbles that might hinder its smooth operation. Air bubbles can cause sluggish shifting, inconsistent engagement, or even complete failure. The procedure typically involves using a special bleeding tool or syringe to introduce fresh hydraulic fluid while purging the air. This is often done by opening a bleed screw at the shifter mechanism while actuating the shifter multiple times. Fresh fluid should be pumped through until no more air bubbles are visible. Always consult your vehicle’s service manual for the exact location of the bleed screw and the specific steps involved. It is also important to use the correct type of hydraulic fluid specified by the manufacturer. Failure to bleed the system correctly can result in poor shifting, damage to the internal components, or even failure of the hydraulic system.

Q 14. How do you determine if a shifter problem is mechanical or electrical?

Determining whether a shifter problem is mechanical or electrical depends on the type of vehicle and transmission. In older, mechanical systems, issues are generally mechanical, involving worn linkages, bushings, or cables. These manifest as sloppy shifting, missed shifts, or binding. In contrast, more modern vehicles might use electronic shift control, with solenoids or actuators controlling gear selection. Problems in these systems often relate to electrical components like faulty sensors, switches, or control modules, which can result in erratic shifting, incorrect gear selection, or complete failure to shift. Diagnostic tools, such as an OBD-II scanner, can be invaluable in diagnosing electrical problems. Analyzing shift patterns, listening for abnormal noises, and conducting a visual inspection of the mechanical components can help identify if the problem is indeed mechanical. If the fault is not readily apparent, consultation with a qualified mechanic who has a diagnostic tool to fully assess the vehicle’s systems will be needed.

Q 15. What are some common causes of shifter binding?

Shifter binding, that frustrating feeling of a gear refusing to engage smoothly, usually stems from a few key culprits. Think of it like trying to force a rusty door – something’s preventing smooth operation.

- Worn or damaged shifter cables: These are the critical links between your shifter and the transmission. Over time, the cables can fray, kink, or become stiff, leading to binding. Imagine a frayed rope – it won’t pull smoothly.

- Bent or damaged shifter linkage: The linkage is the mechanical system connecting the shifter to the transmission. A bent rod or damaged bushing can restrict movement, creating binding. This is like having a wobbly hinge on a door.

- Insufficient lubrication: Moving parts need lubrication! Lack of grease or lubricant in the shifter mechanism can cause friction and binding, especially in older vehicles. It’s like trying to move a dry hinge.

- Transmission problems: Sometimes, the issue isn’t the shifter itself, but the transmission. Internal problems within the transmission can cause resistance, making the shifter feel stiff or bind. This is like trying to shift a jammed gear.

- Incorrect adjustment: The shifter linkage may be improperly adjusted, causing it to bind. Think of it as a misaligned door latch.

Identifying the exact cause requires careful inspection and testing, often involving visual examination and checking for free movement throughout the linkage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you inspect a shifter for damage?

Inspecting a shifter for damage requires a systematic approach. We’re looking for signs of wear, misalignment, or breakage. Start with a visual inspection:

- Check the cables: Look for fraying, kinking, or rust. Feel the cable for stiffness; a stiff cable is a likely culprit.

- Examine the linkage: Look for bent rods, worn bushings (the little rubber or metal parts that reduce friction), or loose bolts. Pay attention to where the linkage connects to the transmission.

- Inspect the shifter housing: Look for cracks, damage, or any obstructions that might interfere with movement.

- Check for proper alignment: Make sure all components are correctly aligned and that nothing is binding against another part. It should all move freely and smoothly.

You might need specialized tools for a thorough inspection, especially when dealing with internal components of the transmission, but a careful visual check will often point to the problem area. Remember safety first – always disconnect the battery before working on electrical components.

Q 17. Explain the function of a shifter detent.

A shifter detent is like a little ‘catch’ that holds the shifter in each gear position. Think of it as the satisfying click you feel when you shift into gear. It’s crucial for preventing accidental gear changes and ensuring smooth shifting.

The detent mechanism uses springs, balls, or other small components to create resistance and hold the shifter in place. When you shift, you overcome the detent’s resistance, and the shifter moves to the next gear. Without a functional detent, the shifter would be sloppy and unreliable, potentially allowing accidental shifting out of gear.

A faulty detent can lead to vague shifting or the inability to stay in a specific gear. You’d feel it as a lack of positive engagement or the shifter moving around loosely.

Q 18. How do you replace a worn shifter cable?

Replacing a worn shifter cable is a common repair. The steps will vary depending on the vehicle, but the general process involves these steps:

- Disconnect the battery: Safety first!

- Locate and disconnect the cable ends: This usually involves releasing clamps or disconnecting from the transmission and shifter lever.

- Route the new cable: Carefully follow the path of the old cable, ensuring the new one runs smoothly and doesn’t rub against anything.

- Connect the new cable: Secure the ends of the new cable to the transmission and shifter lever using the appropriate clamps or connectors.

- Adjust the cable tension: This is crucial to ensure proper gear shifting. There’s usually an adjustment mechanism (a barrel adjuster or similar) that allows you to fine-tune the cable’s tension.

- Test the shift mechanism: Try shifting through all gears, checking for smooth, positive engagement.

This job often requires some mechanical aptitude and the right tools. A repair manual specific to your vehicle is highly recommended.

Q 19. What are some common problems with automatic transmission shifters?

Automatic transmission shifters, while generally more convenient, are not immune to problems. Common issues include:

- Shifting delays or sluggishness: This often points to issues with the transmission fluid, valve body, or solenoids.

- Inconsistent shifting: The transmission might shift harshly or skip gears, indicating problems with the transmission’s internal components or control system.

- Failure to shift into a specific gear: This could be caused by a faulty solenoid, electrical problem, or mechanical issue within the transmission.

- Shift interlock problems: The shifter might not allow you to move out of park without pressing the brake pedal, or it might not allow shifting at all.

- Electronic issues: Modern automatic transmissions rely heavily on electronics. Faulty sensors or control modules can cause a wide range of shifting problems.

Diagnosing these problems typically requires more advanced tools and diagnostic equipment and may necessitate professional assistance.

Q 20. How do you troubleshoot a delayed shifting in an automatic transmission?

Troubleshooting delayed shifting in an automatic transmission requires a systematic approach. It’s like detective work!

- Check the transmission fluid: Low fluid level, dirty or contaminated fluid, or the wrong type of fluid can cause shifting problems. Check the fluid level and condition; it should be clean and the correct color.

- Inspect the transmission filter: A clogged filter restricts fluid flow, leading to shifting delays. Consider replacing the filter as part of fluid service.

- Check for error codes: Many modern vehicles have onboard diagnostic (OBD) systems that can identify fault codes related to the transmission. A code reader can provide valuable clues.

- Inspect electrical components: Check the wiring and connectors associated with the transmission solenoids and sensors for any damage or corrosion.

- Consider internal transmission problems: Delayed shifting could indicate more serious problems within the transmission itself. This may necessitate a professional inspection.

Remember, working on automatic transmissions can be complex. If you’re not comfortable with it, consult a qualified technician to avoid further damage.

Q 21. Describe the different types of shifter mechanisms.

Shifter mechanisms vary widely, depending on the vehicle and the type of transmission (manual or automatic).

- Cable-actuated shifters: These use cables to connect the shifter to the transmission. They’re common in many vehicles and are relatively simple to repair, although adjusting cable tension is important.

- Linkage-actuated shifters: These use a system of rods and levers to connect the shifter to the transmission. They are more common in older vehicles. Problems can be pinpointed by visually inspecting the linkage for binding, bent parts, or loose joints.

- Electronic shifters (automatic): Modern automatic transmissions often use electronic controls. The shifter itself might be entirely electronic, with no direct mechanical connection to the transmission. Diagnosing problems in electronic shifters often requires specialized diagnostic equipment.

- Push-button or rotary shifters: These are becoming more common in modern vehicles. They use electronic controls and offer different user interfaces. Diagnostic and repair procedures for these types of shifters can be challenging and often require specialized tools and knowledge.

Understanding the specific type of shifter mechanism in your vehicle is essential for effective diagnosis and repair.

Q 22. How do you adjust the shift points on an electronically controlled transmission?

Adjusting shift points on an electronically controlled transmission isn’t a matter of physical linkage adjustment like in older vehicles. It’s done through the vehicle’s computer system, often using specialized diagnostic software. Think of it like fine-tuning a computer program rather than adjusting a mechanical lever. You’ll need a scan tool capable of communicating with the transmission control module (TCM). This tool allows access to parameters that define shift points, such as engine speed (RPM) and throttle position. The process generally involves accessing the TCM’s calibration data, modifying the shift schedules within the allowable parameters (manufacturer-set limits exist for safety and drivability), and then writing the new calibration back to the TCM. This requires a deep understanding of the transmission’s operating characteristics and the potential consequences of altering shift points. Improper adjustment can lead to poor fuel economy, rough shifting, or even transmission damage. For example, you might adjust shift points to improve fuel efficiency by raising the shift points at lighter throttle inputs. However, you must ensure these changes don’t negatively impact performance or cause excessive wear.

Q 23. How do you identify and address a problem with the shifter linkage?

Identifying shifter linkage problems usually starts with a visual inspection. Look for bent, broken, or loose linkage components. Pay close attention to the connection points between the shifter lever, the transmission, and any intermediate linkages. A common issue is worn bushings or pivot points. These can cause sloppy shifting, imprecise selection of gears, or even the inability to select certain gears. To address these problems, you might replace worn bushings, adjust linkage rod lengths to ensure proper alignment (usually involving the use of adjustment nuts or bolts), or replace broken or damaged components. A good test is to move the shifter through all its ranges while observing the linkage movement. Any binding, excessive play, or misalignment indicates a problem. For instance, I once worked on a vehicle where the linkage was severely bent after a minor collision, causing the shifter to feel extremely vague and making it nearly impossible to select reverse gear.

Q 24. Explain how to test a shifter switch.

Testing a shifter switch, which often signals the transmission control unit (TCM) about the selected gear, usually involves a multimeter and some basic electrical knowledge. First, you need to locate the switch and its wiring harness. With the ignition on (engine off is usually sufficient for this type of test), use the multimeter in continuity test mode. Test each switch contact (usually there’s one for each gear position) to ensure proper electrical continuity when the shifter is in that particular position. No continuity when the shifter is in a certain position, or continuity when it shouldn’t be, points towards a faulty switch. Additionally, ensure there are no shorts or open circuits in the wiring. For example, if the ‘Reverse’ switch is malfunctioning, the backup lights might not work, and the TCM may not recognize the reverse gear. You would replace the faulty switch once the problem is pinpointed.

Q 25. Describe how you would perform a road test to evaluate shifter performance.

A road test is essential for evaluating shifter performance holistically. Start by checking for smooth shifts at various engine speeds and throttle inputs. Pay attention to the feel of the shifts; are they crisp, or are they delayed or hesitant? Listen for any unusual noises during shifts (grinding, clunking, etc.). Test all gear selections, including reverse and park. Specifically, accelerate and decelerate progressively under various conditions to assess whether the downshifts occur smoothly and correctly. Observe if the automatic transmission shifts into the correct gear under varying driving scenarios. On steep inclines, for instance, evaluate if the transmission maintains the appropriate gear for optimal performance and preventing excessive engine stress. Any issues found on the road test will provide clues regarding the problem’s nature – is it mechanical (linkage), electrical (sensors, switches), or a software-related (TCM calibration) issue? This holistic evaluation helps determine the extent of the repair needed.

Q 26. What are the differences in adjusting shifters in different vehicle makes and models?

Shifter adjustments vary significantly between vehicle makes and models. Some use simple cable-actuated systems, while others employ complex electronic systems with multiple sensors and actuators. For cable-shifters, adjustments usually involve adjusting cable tension using specialized tools or adjusting linkage rods. Electronic shifters, however, require diagnostic tools to access and modify parameters within the TCM. Even within the same make and model, differences exist depending on the transmission type (automatic, manual, CVT), the year of manufacture, and specific options. For example, adjusting a shifter on a classic American muscle car with a floor-mounted manual transmission involves very different techniques than adjusting a modern Japanese vehicle with a push-button electronic shifter. It’s crucial to consult the manufacturer’s service information to avoid mistakes, as working on the wrong thing could be very damaging.

Q 27. How do you diagnose a problem with the shift selector?

Diagnosing a shift selector problem (the physical part the driver interacts with) involves a methodical approach. Begin with a thorough visual inspection of the selector itself; check for any visible damage, cracks, or broken parts. Test its movement – is it smooth and precise, or is there excessive play or binding? If the selector feels loose or sloppy, it could be due to worn bushings or internal linkage. A faulty shift interlock (the mechanism preventing gear changes while the car is moving) could also be the issue. This is often related to a faulty switch or wiring. The next step is checking the linkage that connects the selector to the transmission. Inspect for bent, broken, or loose components. If you suspect electronic issues, use a scan tool to check for diagnostic trouble codes (DTCs) related to the transmission or selector. Once DTCs are identified and the cause is pinpointed, you can determine whether repair, adjustment, or replacement is necessary.

Q 28. Describe your experience with different types of transmission shifters (e.g., column, floor, etc.)

My experience spans various shifter types. Column shifters (common in older vehicles) typically utilize a series of levers and linkages that extend from the steering column to the transmission. Floor shifters offer a more direct connection, and can be either mechanical (linked directly to the transmission via rods and linkages) or electronic (connected to the transmission via sensors and actuators). Electronic shifters, which often incorporate buttons, rotary dials, or even paddle shifters, utilize complex control systems that require advanced diagnostic equipment for accurate diagnosis and repair. I’ve also worked with shifters in various vehicle types, including cars, trucks, and even specialized equipment, which presented unique challenges and considerations in each case. For instance, the shifter mechanism in a heavy-duty truck requires different expertise and maintenance considerations than one in a typical passenger vehicle. Experience has taught me that understanding the specific design and operation of each shifter type is crucial to effectively troubleshooting and resolving issues. Each system requires a unique approach based on its specific functionality and complexity.

Key Topics to Learn for Shifter Adjustment Interview

- Fundamentals of Shifter Mechanisms: Understanding the different types of shifters (manual, automatic, automated manual), their internal components, and how they operate. This includes exploring the linkages, cables, and hydraulic systems involved.

- Troubleshooting Common Shifter Issues: Gaining practical experience in diagnosing problems such as imprecise shifting, gear slippage, or complete shifter failure. Learn to identify the root cause through systematic analysis and testing.

- Calibration and Adjustment Procedures: Mastering the techniques for calibrating and adjusting shifters to ensure smooth and precise gear changes. This includes understanding the specifications and tolerances involved.

- Safety Procedures and Best Practices: Prioritizing safety while working on shifter systems. This includes understanding potential hazards and implementing appropriate safety precautions.

- Diagnostic Tools and Techniques: Familiarizing yourself with the various diagnostic tools and techniques used to assess shifter functionality and identify potential problems. This could involve using specialized software or equipment.

- Maintenance and Repair: Understanding preventative maintenance and repair procedures for various shifter types. This includes tasks like lubrication, component replacement, and system cleaning.

- Shifter System Integration: Understanding how the shifter system interacts with other components of the vehicle, such as the transmission, engine control unit (ECU), and other related systems.

Next Steps

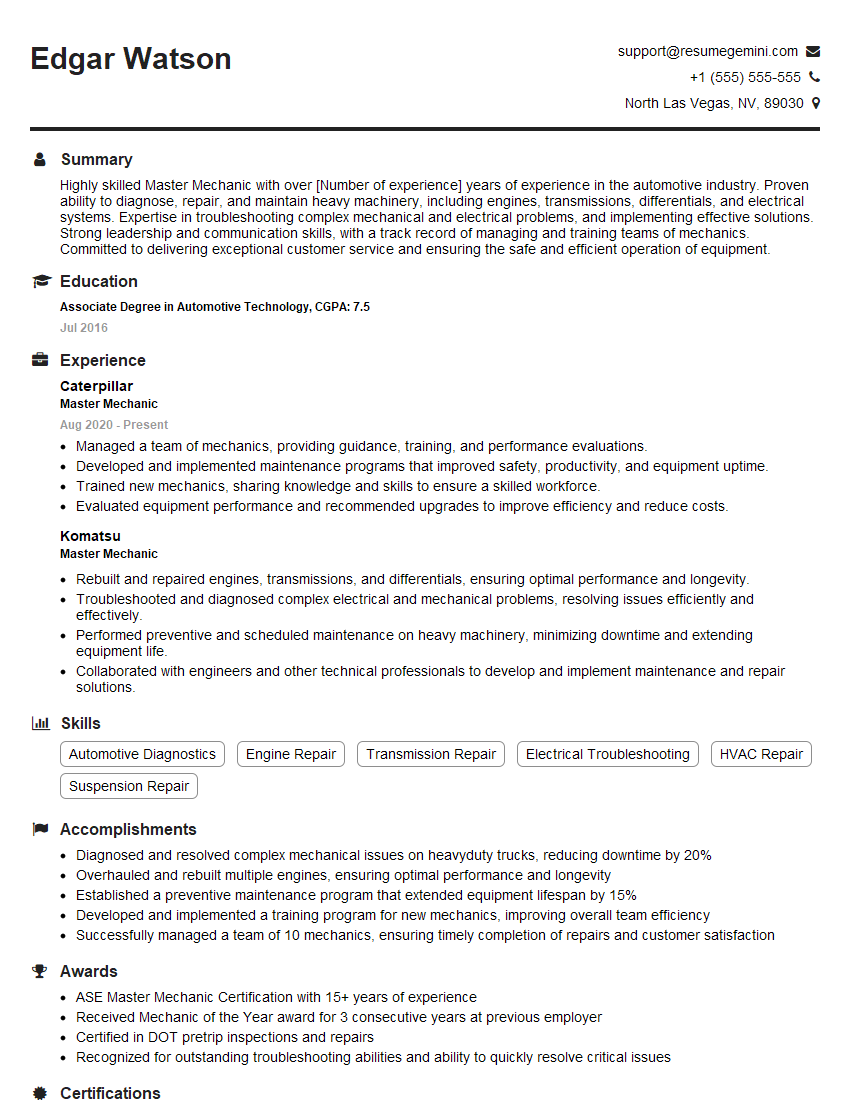

Mastering shifter adjustment is crucial for career advancement in automotive repair and maintenance. A strong understanding of these systems demonstrates valuable technical skills and problem-solving abilities, making you a highly sought-after candidate. To significantly boost your job prospects, create an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications shine. Examples of resumes tailored to Shifter adjustment are available to help guide you in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO