The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Skilled in Engine Diagnostics and Repair interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Skilled in Engine Diagnostics and Repair Interview

Q 1. Explain the diagnostic process you follow when troubleshooting a malfunctioning engine.

Diagnosing a malfunctioning engine is a systematic process. I always begin by gathering information from the driver, noting any symptoms like unusual noises, warning lights, or performance issues. Then, I perform a visual inspection, checking for obvious signs of damage, leaks, or loose connections. Next, I use a scan tool to retrieve Diagnostic Trouble Codes (DTCs) from the engine control unit (ECU). These codes provide clues about potential problems. Based on the initial findings and DTCs, I’ll conduct further tests, which might include checking fuel pressure, compression, and sensor readings using a multimeter. If needed, I’ll utilize more specialized tools like an oscilloscope to analyze sensor signals in detail. Finally, I systematically address the identified issues, retesting after each repair to ensure the problem is resolved and doesn’t trigger other issues. This iterative approach guarantees a thorough and effective fix.

Q 2. Describe your experience with various diagnostic tools, such as scan tools, multimeters, and oscilloscopes.

I’m proficient with a wide range of diagnostic tools. Scan tools, like those from Snap-on and Autel, are essential for retrieving DTCs and accessing live data streams from the ECU. This data provides real-time information on engine parameters such as RPM, fuel trim, and oxygen sensor readings. Multimeters are invaluable for checking voltage, current, and resistance in various circuits, ensuring proper operation of sensors and actuators. I frequently use them to test ignition coils, fuel injectors, and ground connections. Finally, oscilloscopes are particularly helpful for examining sensor waveforms, allowing me to detect subtle irregularities that might be missed by other tools. For instance, I’ve used an oscilloscope to diagnose a faulty crankshaft position sensor by analyzing the shape and timing of its signal. My experience encompasses a wide array of tools and their applications, allowing me to choose the right instrument for any situation.

Q 3. How do you interpret diagnostic trouble codes (DTCs)?

Interpreting DTCs requires understanding their structure. A typical DTC consists of a manufacturer-specific code followed by a numerical code. For example, a P0171 code indicates a lean condition in bank 1 of the engine. I use repair manuals and online databases, such as ALLDATA, to decipher these codes and understand their potential causes. It’s important to remember that a DTC often points to a system or component rather than a specific part. For instance, a P0300 (random misfire) requires further investigation to pinpoint the source. Therefore, I always consider the DTCs alongside other diagnostic tests and symptoms, rather than relying solely on the code.

Q 4. What are the common causes of engine misfires?

Engine misfires occur when a cylinder fails to ignite properly, resulting in incomplete combustion. Common causes are faulty spark plugs, damaged ignition wires, low fuel pressure, insufficient air supply, and problems with the fuel injectors. Worn valve seals can also lead to misfires due to oil contamination in the combustion chamber. A failing crankshaft position sensor can also cause erratic misfires by disrupting the ignition timing. Sometimes, a vacuum leak might deprive the engine of sufficient air, resulting in a misfire. Diagnosing the root cause requires a systematic approach, beginning with the simplest and most likely factors before moving towards more complex issues.

Q 5. How would you diagnose a loss of power in a vehicle?

Diagnosing a loss of power requires a methodical approach. First, I’d determine if the loss of power is gradual or sudden. A gradual loss might indicate issues like clogged air filters, failing fuel pumps, or worn-out spark plugs. A sudden loss could be caused by a broken timing belt, a failed catalytic converter, or a major electrical fault. I would then use a scan tool to check for DTCs, focusing on codes related to fuel delivery, ignition, and air intake. I’d also check for boost leaks in turbocharged vehicles and inspect the air filter for excessive dirt. A compression test will quickly identify any mechanical issues in the cylinders. Ultimately, the diagnostic strategy would depend on the specific vehicle and the nature of the power loss, but the starting point is always a systematic evaluation of potential problem areas.

Q 6. Explain the different types of engine sensors and their functions.

Engine sensors are crucial for providing the ECU with essential information. The Mass Air Flow (MAF) sensor measures the amount of air entering the engine. The Throttle Position Sensor (TPS) monitors the throttle plate’s position. The Crankshaft Position Sensor (CKP) determines the engine’s rotational speed. The Oxygen (O2) sensor measures the amount of oxygen in the exhaust, helping regulate the air-fuel mixture. The Manifold Absolute Pressure (MAP) sensor indicates the pressure in the intake manifold. Each sensor plays a critical role in ensuring efficient and clean engine operation. A faulty sensor can lead to various problems, from poor fuel economy to engine misfires and emission issues. It’s essential to have a solid understanding of their function to correctly diagnose problems. I’ve used specific tests for each sensor, like verifying the voltage signal with a multimeter, to identify malfunctioning components.

Q 7. Describe your experience with engine performance testing.

Engine performance testing is a key part of my diagnostic process. This includes checking compression, checking fuel pressure, and analyzing exhaust gases. Compression tests determine the health of the cylinders and their ability to contain pressure. Low compression in one or more cylinders indicates a problem like worn rings, leaky valves, or a blown head gasket. Fuel pressure testing is crucial for assessing the fuel delivery system, ensuring that the fuel pump is delivering adequate fuel pressure to the injectors. Exhaust gas analysis involves measuring the levels of carbon monoxide, hydrocarbons, and oxygen in the exhaust. These readings help in diagnosing issues like misfires, incorrect air/fuel ratio, and problems with the catalytic converter. Combining these performance tests with DTCs and other diagnostic procedures provides a thorough assessment of the engine’s condition, facilitating accurate diagnosis and effective repair.

Q 8. How do you troubleshoot a vehicle with a rough idle?

A rough idle, that shaky feeling when your engine’s running at low speed, is a symptom, not a diagnosis. It indicates a problem somewhere in the combustion process, fuel delivery, or ignition system. My troubleshooting starts with a systematic approach.

- Visual Inspection: I begin by looking for any obvious issues like loose vacuum hoses, damaged wiring, or visible leaks. A quick visual check can often reveal the culprit.

- OBD-II Scan: Next, I’ll plug in an OBD-II scanner to retrieve diagnostic trouble codes (DTCs). These codes provide valuable clues, narrowing down the possibilities. For example, a misfire code (P0300) indicates a cylinder isn’t firing properly.

- Data Stream Analysis: I’ll analyze the live data stream from the OBD-II scanner. This allows me to observe real-time parameters like fuel trims, engine RPM, and oxygen sensor readings. Anomalies here point to imbalances in the air/fuel mixture or issues with sensor feedback.

- Further Diagnostic Tests: Based on the initial findings, I might perform additional tests, such as a compression test (to check for leaking valves or worn piston rings), a vacuum leak test (using a smoke machine), or a fuel pressure test (to ensure adequate fuel delivery).

- Component Testing: If necessary, individual components like ignition coils, spark plugs, mass airflow sensor (MAF), throttle position sensor (TPS) may be tested using a multimeter or dedicated testing equipment to determine faulty parts.

For example, I once worked on a vehicle with a rough idle. The OBD-II scan revealed a misfire in cylinder 3. Further investigation showed a faulty ignition coil. Replacing the coil resolved the issue immediately. A rough idle can be caused by many things, but a systematic approach ensures a quick and efficient diagnosis.

Q 9. How do you diagnose and repair an overheating engine?

An overheating engine is a serious problem that can lead to significant damage if not addressed promptly. My approach is focused on identifying the root cause, not just treating the symptom.

- Check Coolant Levels: The first step is to check the coolant level in the radiator and overflow reservoir. Low coolant indicates a leak somewhere in the system.

- Inspect Hoses and Connections: Visually inspect all coolant hoses and clamps for leaks, cracks, or damage. Look for signs of leaking coolant near the water pump, radiator, thermostat housing, and engine block.

- Thermostat Check: A faulty thermostat can prevent the engine from reaching its optimal operating temperature or cause it to overheat. I’ll often check its functionality.

- Radiator Condition: Inspect the radiator for any damage, clogs, or blockages. A clogged radiator restricts coolant flow and leads to overheating. Sometimes, it’s necessary to flush the radiator to clean out debris.

- Water Pump Function: A malfunctioning water pump will fail to circulate coolant effectively. Its operation might be checked visually or with a stethoscope.

- Fan Operation: Check the cooling fan’s operation. The fan should turn on when the engine reaches a certain temperature. Failure of the cooling fan can lead to overheating.

- Head Gasket Check: In severe cases, overheating might indicate a blown head gasket. This can be checked by testing the coolant for exhaust gases or by performing a compression test.

Remember, never open the radiator cap on a hot engine. The pressure could cause serious burns. Overheating can stem from simple things like a low coolant level to complex issues such as a warped cylinder head. Thorough inspection and testing are vital for accurate diagnosis.

Q 10. What is your experience with fuel system diagnostics?

My experience with fuel system diagnostics is extensive. I’m proficient in diagnosing and repairing various fuel system issues, from minor problems like clogged fuel injectors to major issues like fuel pump failure.

- Fuel Pressure Testing: I routinely use a fuel pressure gauge to measure fuel pressure and identify problems with the fuel pump, fuel filter, or fuel pressure regulator.

- Fuel Injector Testing: I can test fuel injectors for proper spray pattern and flow rate, identifying clogged or faulty injectors that impact engine performance.

- Fuel Leak Detection: I employ techniques like pressure testing, dye tracing, and visual inspection to pinpoint fuel leaks, ensuring the system’s integrity.

- Fuel System Cleaning: I’m experienced in using fuel system cleaners and injector cleaners to improve performance and solve issues caused by contaminated fuel.

- OBD-II Data Analysis: I use OBD-II scanners to monitor fuel system parameters like fuel trim, short-term and long-term fuel corrections to identify air/fuel ratio issues or sensor problems.

For instance, I recently diagnosed a vehicle experiencing poor acceleration and rough running. Fuel pressure testing revealed a weak fuel pump. Replacing the fuel pump solved the problem, restoring the vehicle’s performance. Understanding fuel system dynamics is key to diagnosing various drivability issues.

Q 11. How familiar are you with different engine management systems (e.g., OBD-II)?

I’m highly familiar with various engine management systems, particularly OBD-II systems, which are standard in most modern vehicles. My experience extends to interpreting diagnostic trouble codes (DTCs), analyzing live data streams, and utilizing advanced scan tools to troubleshoot complex engine problems.

- OBD-II Diagnostics: I use OBD-II scanners regularly to retrieve DTCs, which provide critical information about the nature and location of engine problems.

- Data Stream Analysis: I use the live data features of advanced scanners to monitor various engine parameters in real-time, allowing me to observe the behavior of the system and pinpoint the source of a problem.

- Bi-directional Control: I can use bi-directional control capabilities to command certain actuators, such as fuel injectors or solenoids, to test their functionality and pinpoint faulty components.

- Manufacturer-Specific Scanners: While OBD-II provides standardized data, some manufacturers use proprietary systems or enhanced protocols. I have experience with several of these, allowing me to diagnose vehicles of various makes and models.

Understanding engine management systems is crucial for modern diagnostics. They provide a wealth of information beyond simple codes, offering insights into sensor performance, fuel trims, and other critical operating parameters. It allows for a much more precise and effective diagnosis.

Q 12. What are the common causes of excessive engine oil consumption?

Excessive engine oil consumption is a common problem with several potential causes. The key is to systematically investigate the possible sources.

- Worn Piston Rings: Worn piston rings are a frequent cause. They lose their ability to seal the combustion chamber, allowing oil to leak into the combustion chamber and burn off.

- Valve Stem Seals: Similarly, worn valve stem seals can allow oil to leak past the valves into the combustion chamber.

- Worn Cylinder Walls: Excessive wear on the cylinder walls can also contribute to oil consumption. This allows oil to bypass the piston rings and enter the combustion chamber.

- PCV System Issues: A malfunctioning positive crankcase ventilation (PCV) system can result in excessive oil pressure, forcing oil past seals and into the intake manifold.

- Turbocharger Issues: In turbocharged engines, a leaking turbocharger seal can allow oil to leak into the intake system.

Diagnosing the cause requires a combination of visual inspection (checking for leaks), compression testing (to assess piston ring condition), and sometimes more advanced procedures like a leak-down test (which helps pinpoint leaks in the cylinder). For example, excessive blue smoke from the exhaust is a strong indicator of oil burning in the combustion chamber, often pointing towards worn piston rings or valve stem seals.

Q 13. Explain your process for diagnosing and repairing a leaking engine gasket.

Diagnosing and repairing a leaking engine gasket, such as a head gasket or intake manifold gasket, requires careful attention to detail and a methodical approach.

- Identify the Leak: Begin by pinpointing the location of the leak. This might involve visual inspection, looking for stains, weeping, or external evidence of fluid leakage. Pressure testing or dye testing can be helpful in locating leaks that aren’t readily apparent.

- Determine the Type of Gasket: Identify the specific gasket that’s leaking (head gasket, intake manifold gasket, etc.). This determines the scope of the repair.

- Assess the Damage: Determine the extent of the damage caused by the leak. If the leak is minor, a simple gasket replacement might suffice. Significant damage, such as warped cylinder heads or cracked engine blocks, might necessitate more extensive repairs.

- Repair Procedure: The repair process involves removing the faulty gasket, cleaning the mating surfaces thoroughly, ensuring the surfaces are properly aligned, and installing a new gasket. Specific procedures vary greatly depending on the engine and the type of gasket.

- Post-Repair Testing: After the repair, it’s critical to verify the success of the repair. This includes checking for leaks, verifying proper engine operation, and monitoring coolant and oil levels.

For instance, a leaking head gasket can be a very complex repair, sometimes requiring specialized tools and expertise. The repair usually involves removing the cylinder head, resurfacing it if necessary, replacing the gasket, and reassembling the engine. Failure to address a leaking head gasket properly can lead to catastrophic engine failure.

Q 14. Describe your experience with engine compression testing.

Engine compression testing is a fundamental diagnostic procedure that measures the pressure inside each cylinder when the piston is at top dead center. It helps identify problems with the engine’s mechanical integrity.

- Test Procedure: The test involves using a compression gauge to measure the pressure in each cylinder. The engine needs to be cranked while the gauge is connected to each cylinder. This requires specialized tools and some knowledge of engine operation.

- Interpreting Results: The readings obtained are compared against the manufacturer’s specifications. Low compression in one or more cylinders indicates potential problems.

- Identifying Problems: Low compression can indicate several problems including worn piston rings, burnt or damaged valves, leaking head gasket, or even a cracked cylinder head or block. The location of the low compression helps in pinpointing the problem area.

- Leak-Down Test: A leak-down test is a more advanced procedure. It uses compressed air to identify exactly where the compression leak is occurring (past the piston rings, valves, etc.).

I’ve used compression testing countless times to diagnose problems ranging from minor valve issues to catastrophic engine damage. A proper compression test, paired with a leak-down test when necessary, is invaluable in determining the root cause of low compression and guiding effective repair strategies.

Q 15. How do you diagnose and repair problems with the vehicle’s cooling system?

Diagnosing and repairing cooling system problems requires a systematic approach. I begin by visually inspecting all components for leaks, damage, or corrosion. This includes the radiator, hoses, water pump, thermostat, and pressure cap. I then check the coolant level and its condition, looking for signs of contamination or low concentration.

Next, I use a pressure tester to check for leaks in the system under pressure, simulating operating conditions. This helps identify even small leaks that might be missed during a visual inspection. If a leak is detected, I carefully pinpoint its source before proceeding with repairs. This might involve replacing hoses, repairing a radiator, or replacing the water pump, depending on the location of the leak.

Furthermore, I assess the thermostat’s functionality by checking its opening temperature. A malfunctioning thermostat can lead to overheating or inadequate cooling. I also test the radiator fan’s operation to ensure it engages at the correct temperature, preventing overheating. Finally, I flush and refill the cooling system with the correct coolant mixture, ensuring optimal performance and corrosion prevention.

For example, I recently diagnosed a cooling system problem on a vehicle that was overheating. My initial visual inspection revealed a cracked radiator hose. After replacing the hose and pressure testing the system, I found no further leaks. The problem was resolved by a relatively simple repair. In another case, a vehicle experienced consistent overheating despite having no visible leaks. This pointed me towards a faulty thermostat, which was easily replaced and immediately resolved the overheating issue.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with timing belt/chain replacement?

Timing belt/chain replacement is a crucial maintenance procedure, and I have extensive experience performing it on a wide range of vehicles. The process varies slightly depending on the make and model, but the general steps remain consistent. It begins with a thorough inspection of the existing belt/chain, looking for wear, cracks, or damage. I then carefully remove related components to gain access to the timing belt/chain, such as the engine covers and sometimes various pulleys or idlers.

Replacing a timing belt involves precisely aligning the crankshaft and camshaft(s) using specialized tools to ensure proper engine timing. Incorrect alignment can lead to severe engine damage. Once aligned, I install the new timing belt, ensuring it is properly tensioned. I use a tension gauge to achieve the manufacturer’s specifications. I then reinstall all removed components and verify proper operation. If replacing a timing chain, the process is similar, but involves removing chain guides and sprockets. Often new tensioners are installed as well. I prioritize careful alignment and tensioning to maintain engine health.

For example, I recently completed a timing belt replacement on a high-mileage vehicle that was showing signs of wear on the old belt. The precise alignment ensured correct engine timing and the vehicle operated without issue. It’s a high-stakes job that requires precision and attention to detail; a misplaced tooth can cause serious damage.

Q 17. Explain your experience with engine rebuild procedures.

Engine rebuild procedures are complex and require a deep understanding of internal combustion engines. I’ve been involved in numerous engine rebuilds, from minor repairs to complete overhauls. The process typically begins with a thorough disassembly of the engine, carefully documenting the removal of each component. Each part is then inspected for wear, damage, or defects. This usually includes checking piston rings, cylinder walls, bearings, crankshaft, and connecting rods.

Based on the inspection, I determine the necessary repairs or replacements. This might involve honing the cylinders, replacing worn piston rings, resurfacing the cylinder head, and replacing damaged bearings. The engine block and cylinder head often require cleaning and inspection for cracks or damage. Once all parts are cleaned, inspected, and repaired or replaced, I proceed with reassembly. This is a meticulous process requiring attention to detail, proper torque specifications, and meticulous cleaning to prevent debris from entering the engine.

After reassembly, I perform a thorough break-in procedure to ensure proper seating of new components and to avoid premature wear. This involves running the engine for a specified period under controlled conditions. A final inspection ensures everything is correctly assembled and running smoothly. This entire process demands patience, precision, and a complete understanding of engine mechanics.

Q 18. How do you handle complex engine repair situations?

Handling complex engine repair situations necessitates a systematic approach. I start by thoroughly diagnosing the problem, using diagnostic tools and my knowledge of engine operation to pinpoint the root cause. This might involve analyzing engine codes, performing compression tests, and conducting leak-down tests. I then gather information, such as repair manuals, technical bulletins, and online resources, to ensure I have the necessary information to proceed.

I meticulously plan the repair, detailing the steps involved, the tools required, and the estimated time required for completion. This ensures a smooth and efficient repair process. If specialized tools or expertise are needed, I don’t hesitate to seek assistance or consult with other experienced mechanics. I prioritize safety throughout the repair process, adhering to all safety regulations and procedures.

For instance, I once encountered a vehicle with a misfire that was difficult to diagnose. Through methodical testing, including a detailed examination of the electrical system and fuel delivery, I finally pinpointed a faulty crankshaft position sensor. Replacing it immediately solved the problem. The key to solving these complex issues is thorough diagnostics and organized execution of the repair process.

Q 19. Describe your experience with emissions testing and repair.

Emissions testing and repair are critical for ensuring vehicles meet environmental regulations. I have experience performing various emission tests, including OBD-II scans, smoke tests, and gas analyzer tests. OBD-II scans provide valuable data regarding engine performance and potential emission-related problems. Smoke tests help identify leaks in the vacuum system, while gas analyzer tests measure the concentration of various exhaust gases.

Based on the test results, I can accurately diagnose and repair emission-related issues. These repairs might involve replacing faulty oxygen sensors, catalytic converters, or other emission control system components. I am familiar with various emission control systems and their complexities, and I utilize my knowledge to repair a wide variety of problems. Proper diagnostics are critical to ensure that repairs address the root cause and not just the symptoms.

For example, I recently diagnosed a vehicle failing an emissions test due to a faulty oxygen sensor. After replacing the sensor and retesting, the vehicle passed, demonstrating the importance of accurate diagnosis and repair.

Q 20. What are your troubleshooting skills for starting problems?

Troubleshooting starting problems requires a systematic approach. I begin by checking the battery’s voltage and ensuring it has sufficient charge. I then check the battery terminals for corrosion and ensure a good connection. A simple loose connection can easily prevent a vehicle from starting.

Next, I check the starter motor’s operation. This involves listening for the starter’s engagement and checking for any unusual noises. I’ll test the starter circuit for proper voltage and continuity. I then move on to the ignition system, checking the spark plugs, ignition coil, and distributor (where applicable) for proper function. A weak spark or lack of spark will prevent the engine from starting.

Finally, I inspect the fuel system, verifying fuel pressure and delivery to the engine. Lack of fuel or low fuel pressure can also prevent the engine from starting. I also check for any fault codes using an OBD-II scanner which can provide clues about the cause of the problem. This step-by-step approach ensures I efficiently identify the root cause of the starting problem.

Q 21. What experience do you have with different types of fuel injection systems?

I have experience working with various fuel injection systems, including throttle body injection (TBI), multi-point fuel injection (MPFI), and direct injection (DI). Each system has its unique characteristics and potential failure points. TBI systems, while simpler, are prone to issues with injector clogging or throttle body malfunctions. MPFI systems, being more complex, can suffer from issues with individual injectors, fuel pressure regulators, or fuel pump failures. DI systems have their own set of challenges, often related to injector clogging or high-pressure fuel pump issues.

Diagnosing problems within these systems involves the use of diagnostic tools such as fuel pressure gauges, scan tools, and specialized testing equipment to accurately diagnose and repair the fuel system. For example, a misfire in an MPFI system might indicate a faulty injector, which can be diagnosed using an injector tester. Low fuel pressure might point to a faulty fuel pump or regulator. Understanding the unique characteristics of each system is key to accurate diagnosis and repair.

My experience spans various makes and models, and I adapt my diagnostic and repair strategies according to the specific fuel injection system in place. This allows me to efficiently troubleshoot and resolve fuel-related issues effectively.

Q 22. How do you determine if an engine needs a rebuild versus a repair?

The decision between an engine repair and a rebuild hinges on the extent of the damage and the cost-effectiveness of each option. A repair addresses specific problems like replacing a faulty sensor, fixing a leak, or repairing a damaged component. A rebuild, however, is a far more extensive process, involving disassembling the engine, inspecting every part, replacing worn or damaged components, and reassembling it. Think of it like this: a repair is like patching a hole in a tire, while a rebuild is like getting a whole new tire.

I determine the need for a rebuild by carefully assessing the engine’s condition. This involves a thorough diagnostic process, including compression tests, leak-down tests, visual inspection for cracks or damage, and analyzing engine oil for contaminants. If multiple major components are severely worn or damaged – like significantly scored cylinder walls, a cracked block, or extensive bearing wear – a rebuild is usually the most economical and reliable solution. If the problem is isolated to a few specific components and the rest of the engine is in good condition, a repair is the better choice.

For instance, a failing head gasket can be repaired, while significant internal damage from overheating often necessitates a rebuild. The cost of the repair versus the value of the vehicle also plays a crucial role in the decision-making process.

Q 23. Describe your safety procedures when working with automotive engines.

Safety is paramount in engine diagnostics and repair. My safety procedures begin before I even touch the vehicle. I always ensure the vehicle is properly secured, ideally on a lift with wheel chocks, and the parking brake is engaged. I disconnect the negative battery terminal to prevent accidental shorts or electrical shocks. Personal protective equipment (PPE) is non-negotiable: this includes safety glasses, gloves, hearing protection (especially when using power tools), and appropriate clothing to protect against grease, oil, and other fluids.

I meticulously follow manufacturer’s recommendations and repair manuals, paying close attention to warnings and cautions. When handling potentially hazardous materials like engine coolant or gasoline, I take extra precautions, using proper ventilation and disposal methods. I never rush a job. Taking my time ensures careful handling of tools and components, preventing injury and damage. Furthermore, I always work in a clean and well-lit workspace to reduce the risk of accidents. If working on a job that requires a partner, I have clearly defined roles and expectations for safety practices.

Q 24. How do you prioritize tasks in a busy repair shop environment?

In a busy repair shop, prioritizing tasks efficiently is key. I use a combination of approaches, including a first-in, first-out (FIFO) system where urgent jobs receive priority. I also consider the complexity of the repair and the required parts availability. If a job requires specific parts with extended lead times, that might be scheduled accordingly, preventing unnecessary downtime. I use a digital system for tracking jobs, managing parts, and recording labor hours for better time management.

Critical factors that influence priority include customer expectations, vehicle downtime costs (for example, a rental car cost for the customer), and potential safety hazards. For example, a vehicle with a major brake issue will always take priority over a routine oil change. Maintaining clear communication with customers is essential for managing expectations and scheduling. Regularly reviewing my workload and adjusting priorities as needed helps me to maintain a balanced and efficient workflow.

Q 25. Describe a time you had to troubleshoot a difficult engine problem.

I once encountered a vehicle that exhibited intermittent misfires, poor fuel economy, and a rough idle. Initial diagnostic scans yielded no definitive codes. I started by systematically checking the basics: spark plugs, ignition coils, fuel injectors, and air intake system. These checks were normal. The problem worsened under load and high RPM. This pointed to a more complex issue rather than a simple component failure.

I then focused on the crankcase ventilation system, checking for blockages or leaks. After careful inspection, I identified a significant amount of sludge build-up in the PCV valve and related passages, restricting airflow. Cleaning the system and replacing the PCV valve completely resolved the issue. The lesson learned here was the importance of not overlooking seemingly minor components. Thoroughness and a methodical approach were crucial in solving this challenging problem.

Q 26. How do you stay up-to-date on the latest engine technology and repair techniques?

Staying current in the rapidly evolving field of engine technology requires continuous learning. I subscribe to industry journals like Automotive Service Association’s (ASA) magazine, attend technical training seminars offered by manufacturers and industry organizations such as ASE (Automotive Service Excellence), and actively participate in online forums and communities of other mechanics.

I make it a point to read the service bulletins and technical service information (TSB) issued by vehicle manufacturers, as these often highlight common problems and solutions for particular vehicle models. Manufacturer training programs are also invaluable, providing first-hand access to the latest diagnostic equipment and repair procedures. Keeping up-to-date also includes familiarizing myself with new diagnostic tools and software, ensuring that I have access to the latest technology for effective troubleshooting.

Q 27. What is your experience with hybrid or electric vehicle engine systems?

My experience with hybrid and electric vehicle (HEV/EV) systems is growing, though it’s not as extensive as my experience with traditional internal combustion engines (ICE). I’ve completed several training courses focusing on the unique challenges and safety procedures involved in working on HEV/EV systems, including high-voltage safety protocols. I understand the complexities of the power electronics, battery systems, and regenerative braking mechanisms in these vehicles.

I’m proficient in using specialized diagnostic tools for HEV/EV systems, capable of analyzing battery health, motor performance, and inverter functionality. While I don’t claim expertise on par with a dedicated HEV/EV specialist, I possess a fundamental understanding of these systems, and I am always expanding my knowledge and skills in this developing area of automotive technology.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and expertise in engine diagnostics and repair. I’m confident that my skills and knowledge align well with the requirements of this position, and I’m open to discussing a competitive compensation package that reflects my value to the company. I’m more interested in a position that provides growth opportunities and a chance to contribute significantly to your team’s success.

Key Topics to Learn for Skilled in Engine Diagnostics and Repair Interview

- Engine Control Systems: Understanding how various engine systems (fuel injection, ignition, emission control) interact and function. This includes theoretical knowledge of sensors, actuators, and their control strategies.

- Diagnostic Tools & Procedures: Practical application of diagnostic scanners (OBD-II and specialized equipment) to identify and interpret diagnostic trouble codes (DTCs). This includes understanding data stream analysis and troubleshooting based on live data.

- Engine Mechanical Systems: Comprehensive knowledge of internal combustion engines, including components like pistons, connecting rods, crankshaft, valves, and camshafts. This should extend to practical understanding of engine timing, compression testing, and leak down tests.

- Electrical Systems Diagnostics: Troubleshooting electrical issues within the engine, including wiring harnesses, sensors, actuators, and power distribution. This includes understanding schematics and using multimeters effectively.

- Emission Control Systems: Deep understanding of catalytic converters, oxygen sensors, EGR systems, and other emission control components. This includes practical knowledge of emission testing procedures and regulations.

- Problem-Solving & Troubleshooting Methodology: Developing a systematic approach to diagnosing engine problems using a combination of diagnostic tools, technical knowledge, and logical deduction. This includes documenting findings and clearly explaining repair procedures.

- Safety Procedures: Understanding and adhering to all relevant safety regulations and procedures when working on vehicles, including proper use of personal protective equipment (PPE).

Next Steps

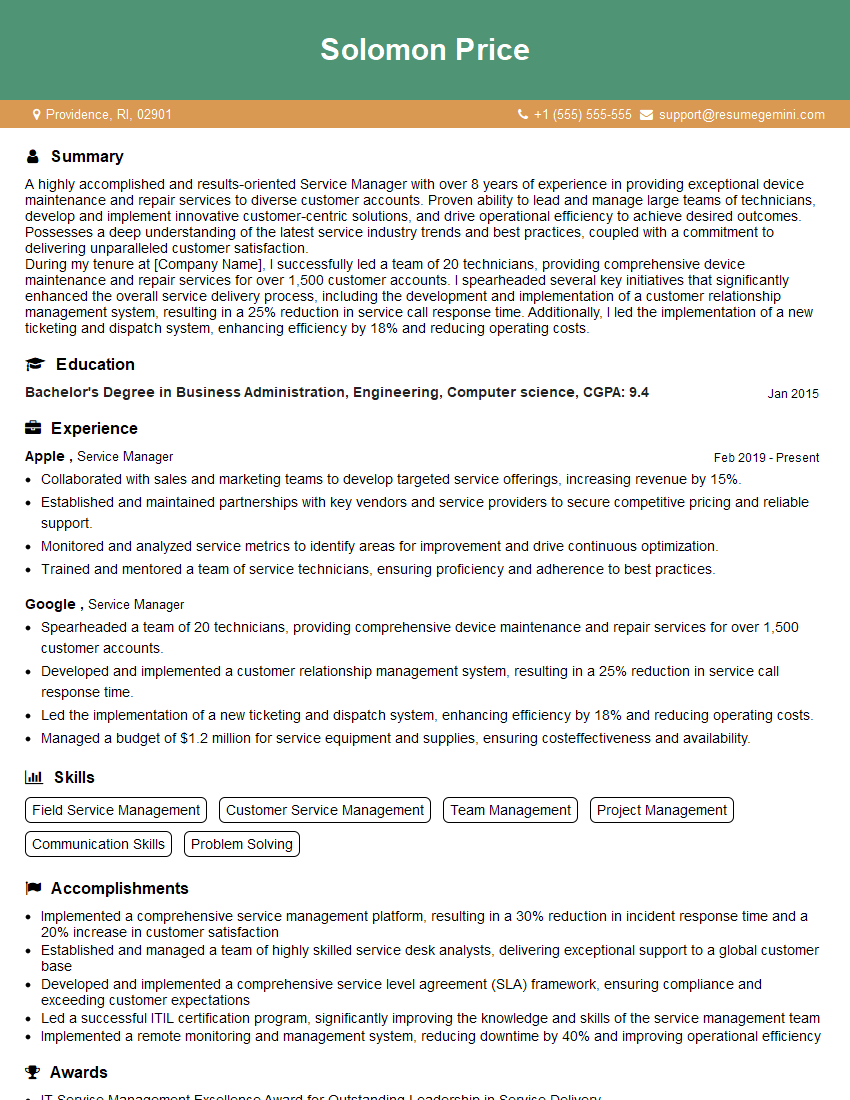

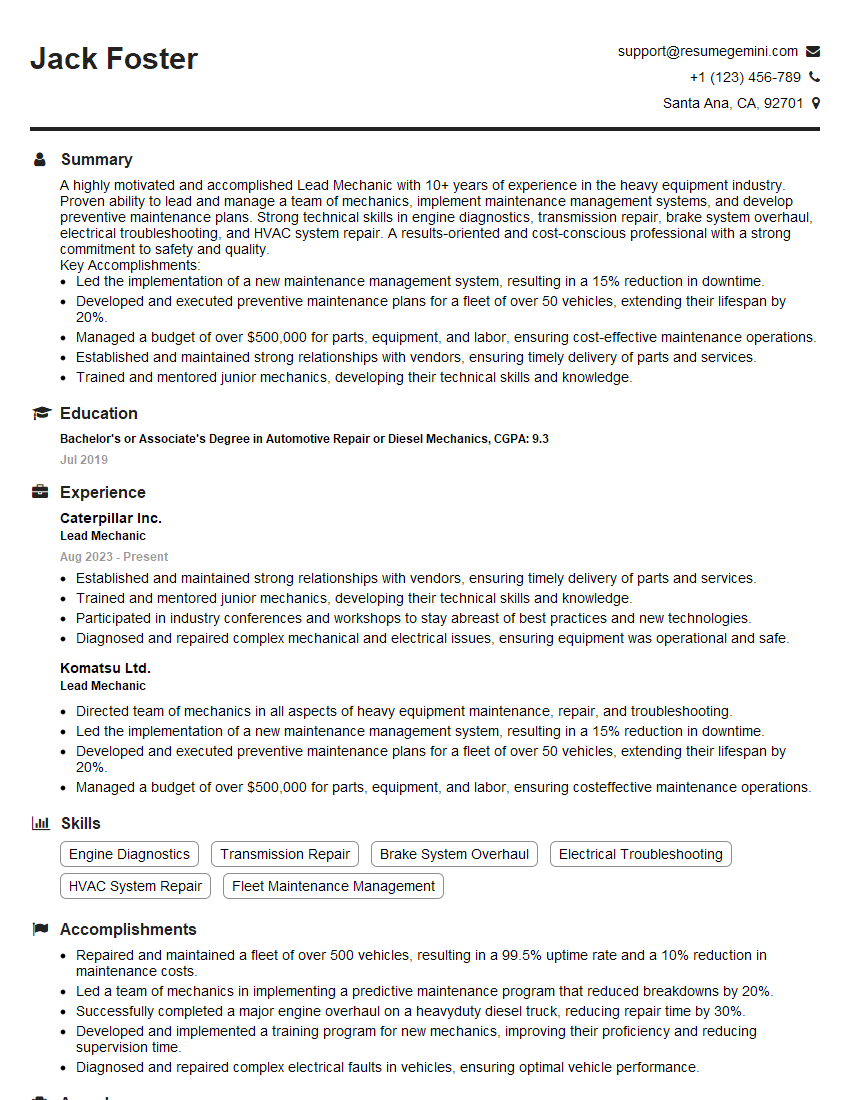

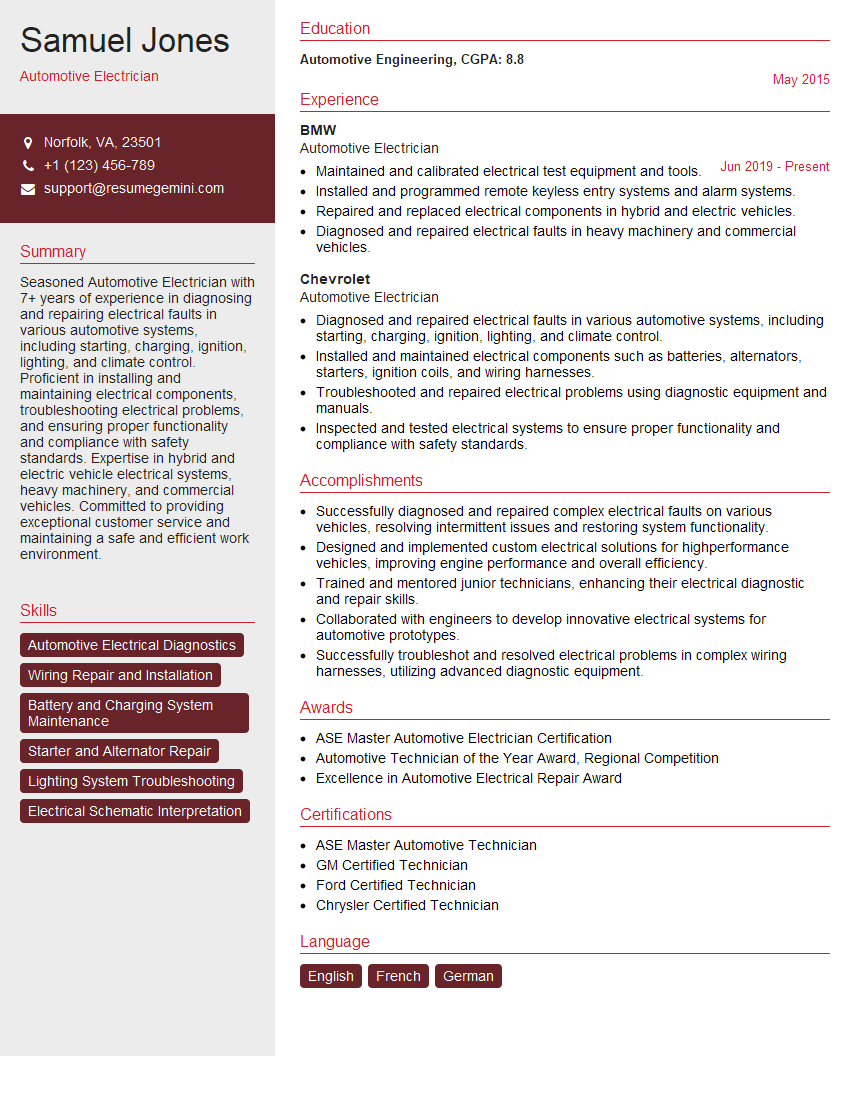

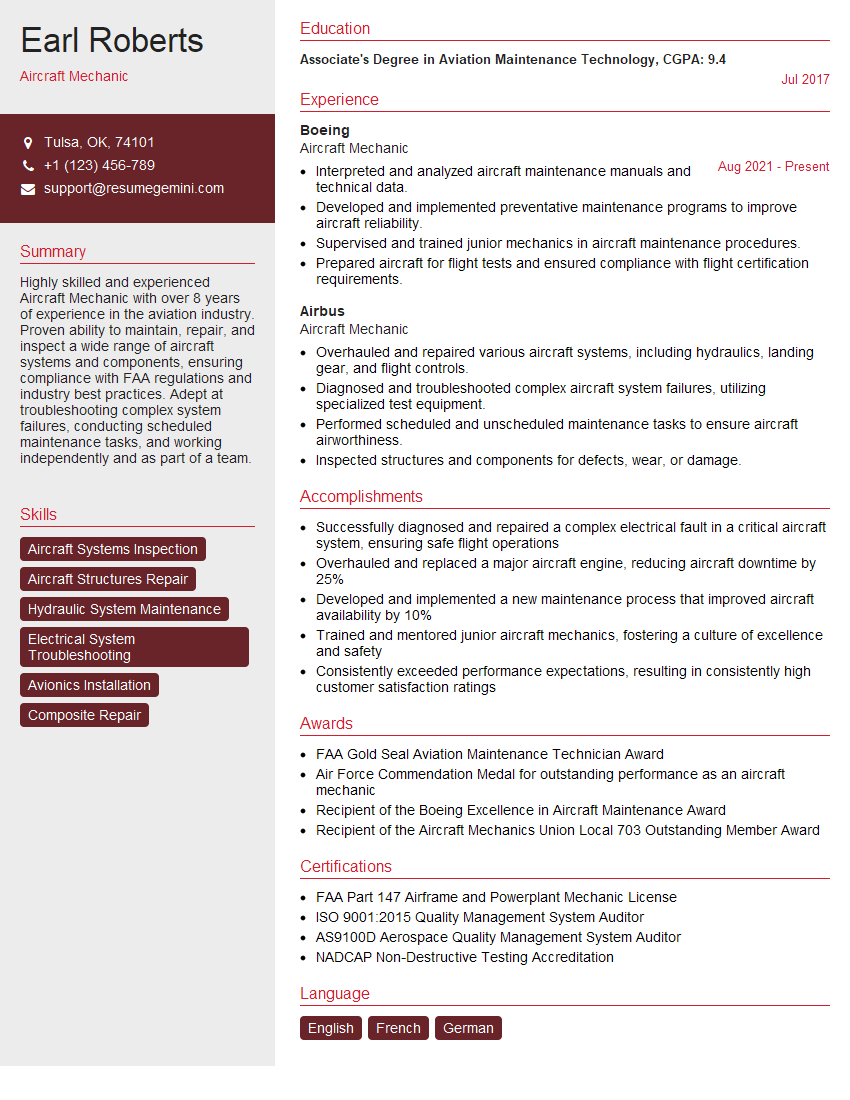

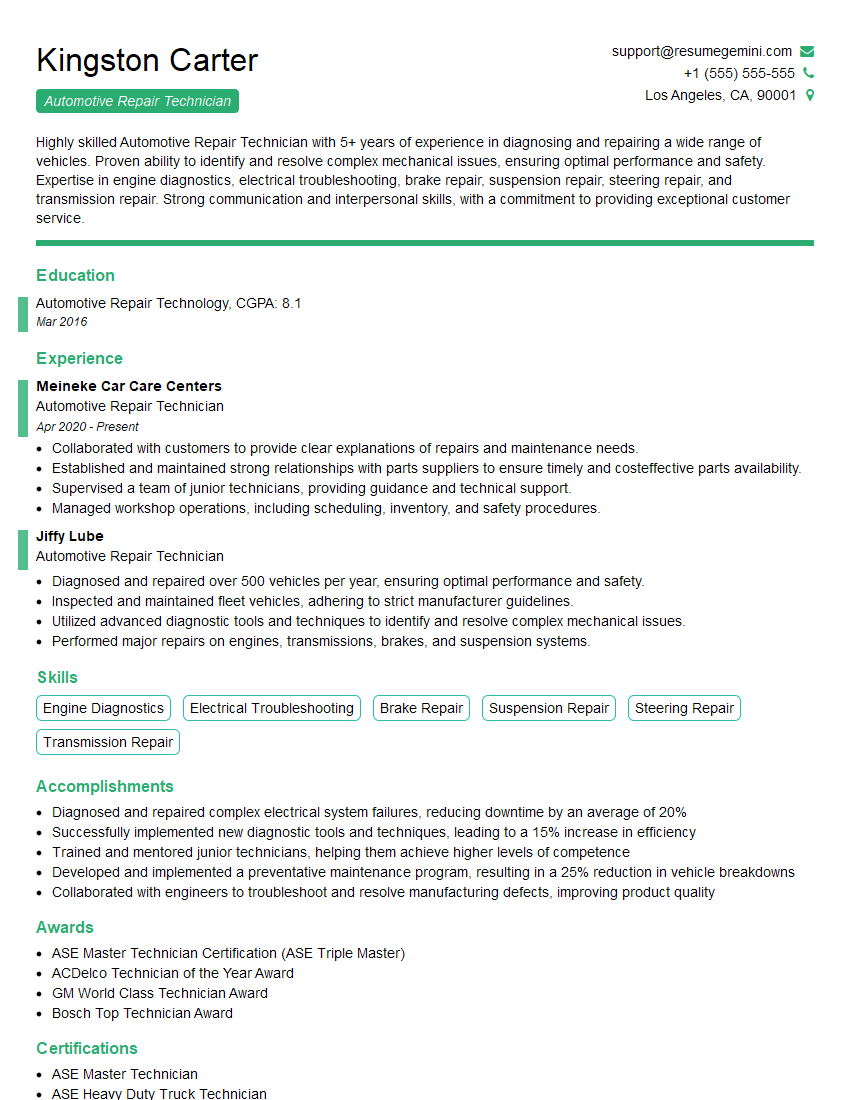

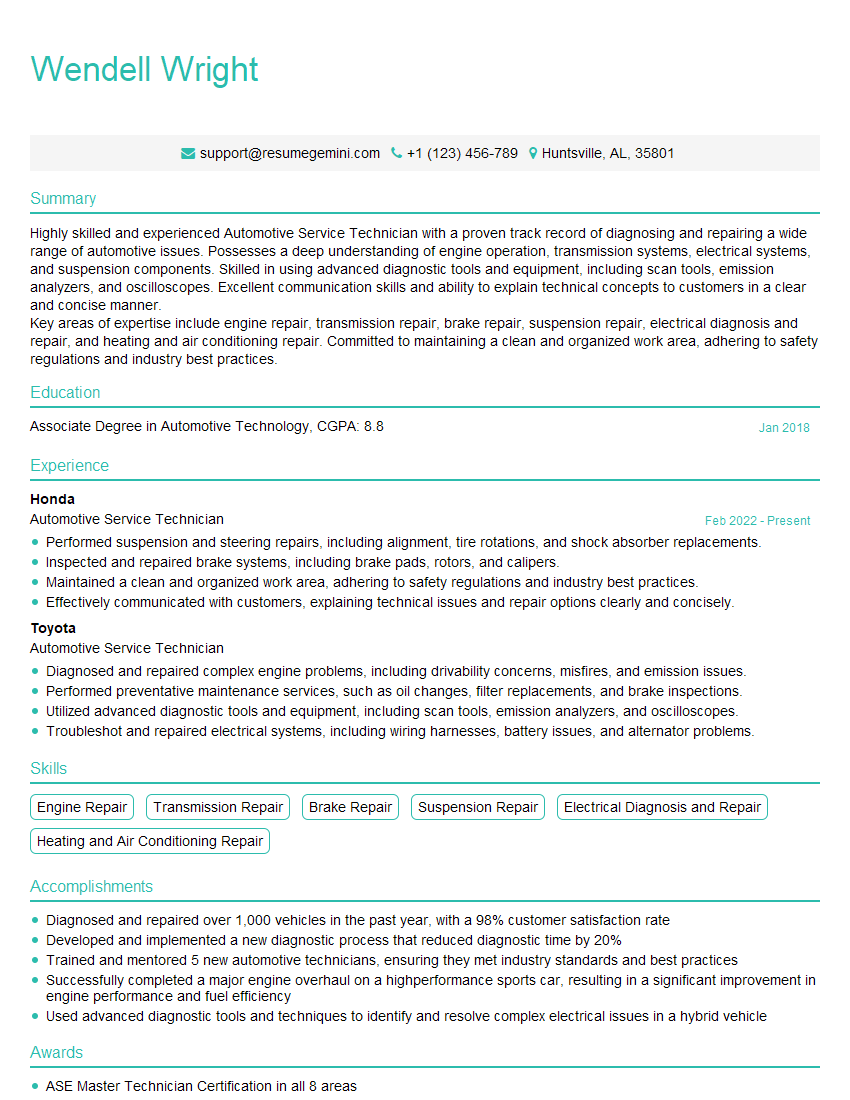

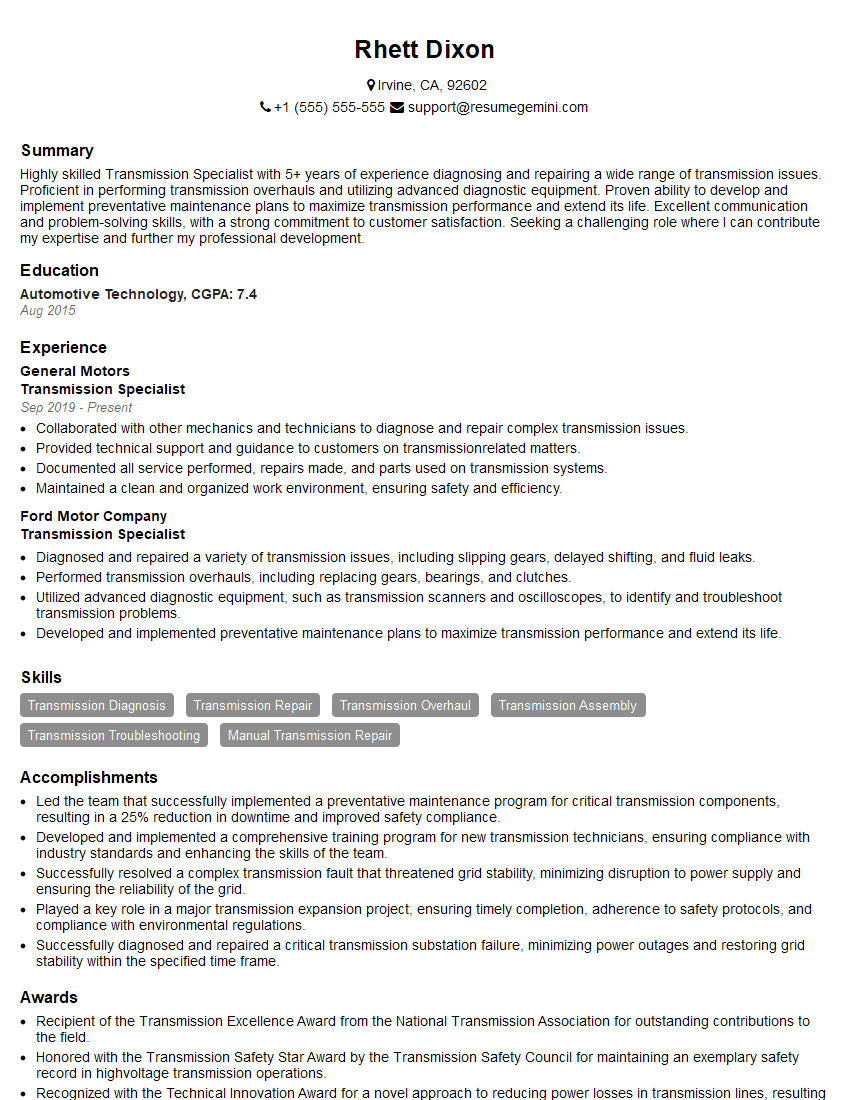

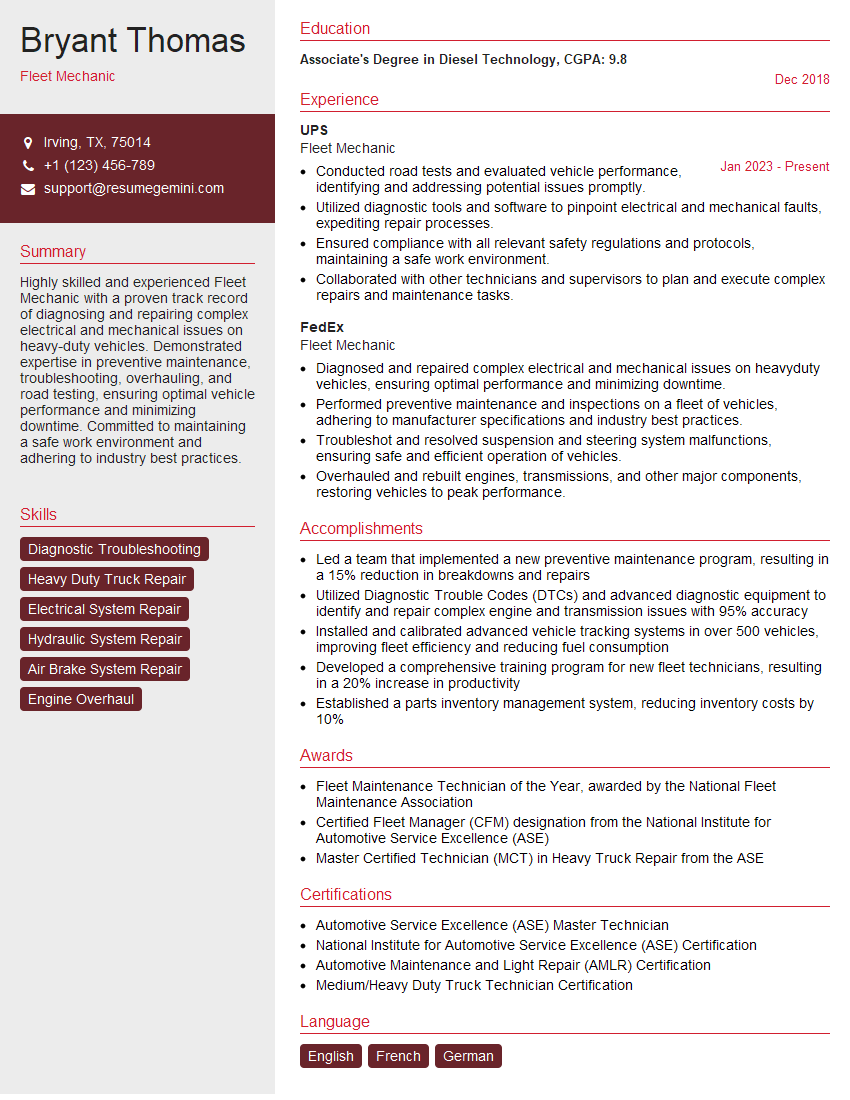

Mastering engine diagnostics and repair is crucial for career advancement in the automotive industry, opening doors to higher-paying roles and specialized areas. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume, optimized for applicant tracking systems, is essential for ensuring your application is seen by recruiters. ResumeGemini can help you build a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Skilled in Engine Diagnostics and Repair to guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO