Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Spring Forming and Heat Treatment interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Spring Forming and Heat Treatment Interview

Q 1. Explain the different types of spring forming processes.

Spring forming encompasses several processes, each tailored to the spring’s geometry and material properties. The choice depends on factors like spring size, material ductility, and desired precision. Here are some key methods:

Coiling: This is the most common method, where wire is wound around a mandrel to form helical springs (like those in a pen). Variations include close-coiled and open-coiled springs, impacting spring characteristics. The mandrel size and coiling speed determine the spring’s dimensions and stresses.

Bending: Used for leaf springs and other non-helical forms, this involves shaping a flat strip or wire into a desired curve. Bending can be achieved using press brakes, roll forming, or other specialized tooling. Careful control of bending radius and force prevents cracking or deformation.

Punching and Stamping: Suitable for smaller springs with simpler geometries, these methods use dies to cut and form springs from sheet metal. This is efficient for high-volume production, but design complexity is limited.

Imagine making a paperclip; coiling is akin to twisting the wire, bending to create the loop, and punching/stamping would be like using a hole punch for a tiny spring.

Q 2. Describe the various heat treatment methods used for springs.

Heat treatment is crucial for achieving the desired mechanical properties in springs, primarily strength and fatigue resistance. Key methods include:

Stress Relieving: A low-temperature heat treatment that reduces internal stresses introduced during forming. This prevents warping or cracking during subsequent operations.

Hardening: This increases the spring’s hardness and strength by heating the material to a critical temperature, followed by rapid cooling (quenching). The specific temperature and quench medium (oil, water, brine) dictate the final hardness and microstructure.

Tempering: A low-temperature heat treatment after hardening. It relieves brittleness introduced during hardening and adjusts the balance between strength and ductility. The tempering temperature significantly affects the final properties.

Austempering/Martempering: These are specialized techniques aimed at obtaining specific microstructure and enhanced mechanical properties. Austempering involves isothermal transformation, while martempering utilizes a controlled cooling rate to minimize distortion.

Think of it like baking bread; hardening is like baking at a high temperature to create structure, and tempering is like cooling it gently to achieve the right texture and prevent it from being too hard or brittle.

Q 3. What are the key factors affecting spring fatigue life?

Spring fatigue life, or the number of cycles a spring can withstand before failure, is influenced by several critical factors:

Material Properties: The inherent fatigue strength of the spring material is paramount. Higher-strength materials like spring steel alloys generally exhibit better fatigue resistance.

Residual Stresses: Stresses remaining after forming and heat treatment can significantly reduce fatigue life. Careful process control minimizes these stresses.

Surface Finish: A smoother surface reduces stress concentration at imperfections, improving fatigue life. Shot peening is often used to improve the surface finish and induce compressive stresses.

Spring Design: The geometry of the spring, including wire diameter, coil diameter, and number of coils, impacts fatigue life. Proper design minimizes stress concentration points.

Operating Conditions: The amplitude of loading, operating temperature, and corrosive environment influence fatigue life. High stress amplitudes, elevated temperatures, and corrosive environments accelerate fatigue.

Consider a paperclip repeatedly bending; imperfections on the wire or sharp bends would quickly lead to fatigue and failure.

Q 4. How do you determine the appropriate heat treatment for a specific spring material?

Choosing the right heat treatment depends on several factors, all intertwined. It’s a multi-step process:

Material Selection: Identify the spring material (e.g., music wire, oil-hardening steel) based on strength, fatigue resistance, and cost requirements. Each material has a specific heat treatment window.

Desired Properties: Define the target properties like ultimate tensile strength, yield strength, and hardness. These properties will dictate the required heat treatment parameters.

Testing & Analysis: After heat treatment, conduct mechanical testing (e.g., tensile testing, hardness testing) to verify that the target properties have been achieved. Microscopic analysis can reveal the microstructure and confirm the effectiveness of the heat treatment.

Refinement: Based on testing results, fine-tune the heat treatment parameters to achieve optimal properties. This often involves iterative adjustments to temperature, time, and cooling rate.

It is important to note that there’s no one-size-fits-all answer. Consulting material datasheets and collaborating with metallurgists is crucial for complex spring applications.

Q 5. Explain the relationship between spring material properties and its forming process.

The material properties dictate the feasibility and outcome of the forming process. For instance:

Ductility: Highly ductile materials are easier to form into complex shapes without fracturing. However, they may not possess the same strength as less ductile materials.

Yield Strength: A higher yield strength indicates greater resistance to permanent deformation during forming, but may require more force and potentially lead to cracking.

Springback: This refers to the elastic recovery of a material after forming. Springback must be accounted for in the forming process, otherwise, the spring may not meet its target dimensions.

Imagine trying to bend a plastic straw versus a steel rod; the plastic straw is easier to bend (higher ductility), but also more likely to deform permanently (lower yield strength).

Q 6. What are the common defects encountered in spring forming and how are they prevented?

Several defects can occur during spring forming:

Fractures: Caused by excessive stress during forming or heat treatment. Proper control of forming forces, adequate lubrication, and careful heat treatment can mitigate these defects.

Set: A permanent deformation of the spring after loading. This can be due to inadequate heat treatment or excessive stress during service.

Surface imperfections: Scratches, pitting, and other surface flaws can act as stress concentrators, reducing fatigue life. Improved surface finishing techniques and careful handling can minimize these defects.

Dimensional inaccuracies: Inconsistent spring dimensions can arise from inaccuracies in tooling or forming process parameters. Precise tooling and process control are essential.

Preventing these defects often requires a multifaceted approach combining proper material selection, careful process control, and rigorous quality inspection.

Q 7. Describe the process of spring design and selection.

Spring design and selection involve a systematic approach:

Define Requirements: Specify the spring’s function, load requirements, space constraints, and operating environment.

Material Selection: Choose a spring material based on strength, fatigue resistance, cost, and corrosion resistance.

Preliminary Design: Use spring design equations or software to determine preliminary dimensions (wire diameter, coil diameter, number of coils).

Analysis & Optimization: Analyze the design for stress, fatigue, and other relevant factors. Iteratively modify the design to optimize performance and manufacturability.

Prototyping & Testing: Create prototypes and conduct testing to validate the design and identify potential issues.

Finalization & Manufacturing: Finalize the design and select an appropriate manufacturing process.

This iterative process ensures that the selected spring meets all performance and reliability requirements.

Q 8. Explain the importance of stress relieving in spring forming.

Stress relieving in spring forming is crucial because the forming process introduces internal stresses within the spring material. These stresses, if left unaddressed, can lead to dimensional instability, reduced fatigue life, and even premature spring failure. Imagine bending a paperclip – you can see how the metal is strained. Similarly, forming a spring introduces similar, albeit more complex, stresses. Stress relieving is a heat treatment process that reduces these internal stresses by heating the spring to a specific temperature, holding it there for a period, and then slowly cooling it. This allows the material to relax, minimizing distortion and improving the spring’s overall performance and reliability.

For example, a compression spring formed without stress relieving might exhibit spring-back or settle over time as the internal stresses gradually relax. Stress relieving ensures the spring maintains its desired shape and dimensions under load, critical for its intended application.

Q 9. How do you measure the spring rate and its tolerance?

The spring rate, also known as the spring constant (k), represents the force required to deflect the spring by a unit length. It’s typically measured using a spring testing machine. This machine applies a known force to the spring and measures the resulting deflection. The spring rate is then calculated using Hooke’s Law: k = F/δ, where F is the applied force and δ is the deflection.

Tolerance in spring rate is crucial for ensuring the spring functions within its design parameters. Tolerances are specified as a percentage or a range around the target spring rate. For instance, a spring with a target rate of 10 N/mm might have a tolerance of ±5%, meaning the acceptable range is 9.5 N/mm to 10.5 N/mm. This tolerance is controlled through precise material selection, accurate forming processes, and careful heat treatment.

Q 10. What are the different types of spring materials and their applications?

Spring materials are selected based on the application’s requirements for strength, fatigue life, corrosion resistance, and temperature range. Common materials include:

- High-carbon steel: Offers high strength and fatigue resistance, commonly used in automotive and general-purpose springs. Examples include music wire and valve spring wire.

- Stainless steel: Provides excellent corrosion resistance, suitable for applications in harsh environments or where cleanliness is paramount. Different grades offer varying strength and fatigue properties.

- Phosphor bronze: Exhibits good conductivity and corrosion resistance, often used in electrical contact springs.

- Beryllium copper: Offers high strength, conductivity, and fatigue resistance, utilized in demanding applications such as aerospace components.

- Titanium alloys: Provide high strength-to-weight ratio and excellent corrosion resistance, ideal for aerospace and medical applications.

The choice depends heavily on factors like the working environment, required load, desired fatigue life, and cost considerations. A high-performance race car might use expensive, high-strength titanium springs, while a simple door spring might use less-expensive high-carbon steel.

Q 11. Explain the concept of residual stress in springs.

Residual stress refers to the internal stresses present in a spring even when it’s unloaded. These stresses are a consequence of the forming process. During spring forming, certain areas are subjected to more deformation than others, leading to an uneven distribution of stresses. Think of bending a metal rod – the outside experiences tension, while the inside experiences compression. These stresses are ‘locked in’ after forming and can significantly influence spring properties.

High residual stresses can negatively impact fatigue life, causing premature failure. They can also contribute to dimensional instability, leading to changes in the spring’s shape or dimensions over time or under load. Controlled heat treatments can help manage residual stresses, improving overall spring performance and reliability.

Q 12. How do you ensure the dimensional accuracy of formed springs?

Ensuring dimensional accuracy in formed springs requires a multi-faceted approach, starting with precise design and material selection. Accurate tooling is crucial; dies must be manufactured to tight tolerances, and the forming process itself needs careful control. This includes monitoring and controlling parameters like forming pressure, speed, and temperature.

Measuring equipment, such as coordinate measuring machines (CMMs) or optical comparators, are used to inspect the dimensions of the finished springs. Statistical process control (SPC) methods help monitor the production process and identify any deviations from the desired dimensions, allowing for timely adjustments to maintain quality. In-process inspection is also key to catching potential defects before they become problematic.

Q 13. What are the effects of different heating and cooling rates on spring properties?

Heating and cooling rates significantly influence the microstructure and properties of spring materials. Rapid heating and cooling (quenching) can trap the atoms in a high-energy state, resulting in a hard and brittle microstructure. Conversely, slow cooling (annealing) allows atoms to rearrange into a lower energy state, leading to a softer, more ductile microstructure.

For example, rapid quenching might increase the spring’s strength but reduce its ductility and toughness, making it more susceptible to fracture. Slow cooling might improve ductility and toughness, but reduce strength. The optimal heating and cooling rates depend on the material and the desired spring properties. The heat treatment process is carefully designed to achieve the required balance of strength, toughness, and fatigue resistance.

Q 14. Describe the role of quenching and tempering in heat treatment.

Quenching and tempering are two crucial steps in the heat treatment of springs. Quenching involves rapidly cooling the spring from a high temperature, typically using a quenching medium like oil or water. This rapid cooling transforms the microstructure, increasing hardness and strength. However, quenching alone often leads to brittleness. This is where tempering comes in.

Tempering is a lower-temperature heat treatment that follows quenching. It involves reheating the spring to a lower temperature and then slowly cooling it. Tempering reduces the internal stresses introduced during quenching, relieving brittleness and improving ductility. The combination of quenching and tempering allows for precise control over the final properties of the spring, balancing hardness, strength, and toughness to meet the application requirements.

Q 15. How do you troubleshoot issues related to spring breakage or deformation?

Troubleshooting spring breakage or deformation involves a systematic approach, starting with identifying the root cause. This often requires a combination of visual inspection, material analysis, and understanding the spring’s operating conditions.

- Visual Inspection: Examine the broken spring carefully. Look for signs of fatigue cracks (often starting at stress concentrations like bends or sharp edges), corrosion, or evidence of overloading. Note the location of the break and any unusual deformations.

- Material Analysis: Testing the spring’s material properties (hardness, tensile strength, yield strength) can reveal if the material itself was faulty or if the heat treatment process was suboptimal. This might involve hardness testing (Rockwell, Brinell), tensile testing, or microstructural analysis.

- Operating Conditions: Analyze the environment where the spring operates. Excessive vibration, corrosive substances, or operating beyond the spring’s design limits can all contribute to failure. Consider factors such as temperature variations and cyclical loading.

- Design Review: Review the spring design. Incorrect spring geometry, inadequate material selection, or flaws in the manufacturing process (such as improper coiling or insufficient stress relieving) can lead to premature failure. Finite element analysis (FEA) can be useful here.

Example: I once investigated a series of spring failures in a high-vibration application. Visual inspection showed fatigue cracks originating at the inner diameter. Material analysis confirmed the material met specifications. However, a more detailed analysis of the operating conditions revealed that the vibration frequency was resonant with the spring’s natural frequency, leading to significantly amplified stress. Redesigning the spring with a different geometry that shifted its resonant frequency resolved the issue.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the significance of grain size in spring material?

Grain size is crucial in spring material because it significantly impacts mechanical properties like strength, ductility, and fatigue resistance. Smaller grain sizes generally lead to stronger and more fatigue-resistant springs.

- Increased Strength: Smaller grains impede dislocation movement, making the material harder to deform, thus increasing yield strength and ultimate tensile strength.

- Enhanced Fatigue Resistance: Fine-grained materials have more grain boundaries, which act as barriers to crack propagation, improving fatigue life.

- Improved Ductility (to a point): While smaller grains generally increase strength, excessively small grains can lead to reduced ductility, making the material more brittle. An optimal grain size is needed for a balance of strength and ductility.

Practical Application: Spring manufacturers carefully control the heat treatment process to achieve the desired grain size. For instance, a spring requiring high fatigue resistance might be given a heat treatment leading to a smaller grain size, whereas one requiring high ductility might have a coarser grain size.

Q 17. Explain the principles of spring design optimization.

Spring design optimization aims to achieve the best balance between performance, cost, and reliability. It involves careful consideration of several factors.

- Material Selection: Choosing the right material based on required strength, fatigue life, and corrosion resistance.

- Geometry Optimization: Adjusting parameters like wire diameter, coil diameter, number of active coils, and free length to meet the target spring rate and deflection, minimizing stress concentrations and maximizing fatigue life.

- Stress Analysis: Employing tools like FEA to analyze stress distribution under various loading conditions and identify potential stress concentration points.

- Manufacturing Considerations: Taking into account the manufacturability of the design and the limitations of the forming process. This includes ensuring the design is feasible with available equipment and tooling.

Example: Optimizing a compression spring for a vehicle suspension might involve using a high-strength steel with a smaller grain size to improve fatigue life. FEA would be used to ensure the spring doesn’t experience excessive stress at the ends or during compression. The final design would balance strength, fatigue resistance, manufacturing cost, and available space within the vehicle.

Q 18. How do you verify the hardness and other mechanical properties of heat-treated springs?

Verifying the hardness and mechanical properties of heat-treated springs is critical to ensuring they meet design specifications and are safe for operation. This typically involves a combination of destructive and non-destructive testing methods.

- Hardness Testing: Rockwell, Brinell, or Vickers hardness tests are commonly used to determine the hardness of the spring material. This provides an indication of the strength and wear resistance. Hardness is often correlated to tensile strength using empirical relationships specific to the material.

- Tensile Testing: A tensile test determines the ultimate tensile strength, yield strength, and elongation of the spring material. This provides a comprehensive measure of the material’s strength and ductility.

- Fatigue Testing: This involves subjecting the spring to cyclic loading to determine its fatigue life – the number of cycles it can withstand before failure. This is especially important for springs subjected to repetitive loading.

- Microstructural Analysis: Techniques like optical microscopy or electron microscopy can be used to examine the microstructure of the spring material, providing insights into the grain size and the effectiveness of the heat treatment process.

Example: For a critical application such as an aerospace component, I would specify a comprehensive testing program, including hardness testing, tensile testing, fatigue testing, and possibly even fracture toughness testing to ensure the spring’s structural integrity.

Q 19. What are the safety precautions involved in spring forming and heat treatment operations?

Safety precautions in spring forming and heat treatment are paramount to prevent injuries and damage to equipment. These include:

- Personal Protective Equipment (PPE): This is essential and includes safety glasses, gloves, hearing protection (especially near forming machines), and appropriate clothing to prevent burns from hot materials in heat treatment.

- Machine Guarding: All machinery should have appropriate guards in place to prevent contact with moving parts.

- Lockout/Tagout Procedures: These procedures are essential before performing any maintenance or repair work on machinery to prevent accidental start-up.

- Heat Treatment Safety: Proper ventilation is necessary during heat treating to remove harmful fumes. Protective clothing and handling procedures are crucial for working with extremely hot materials.

- Material Handling: Use of appropriate lifting equipment for heavier springs to prevent back injuries.

- Emergency Procedures: Clearly defined emergency procedures and readily available first-aid equipment are critical.

Example: In my experience, we had a near-miss incident involving a spring coiling machine. A worker’s glove became entangled in the machine, but thankfully the machine’s emergency stop button was readily accessible. This reinforced the importance of regular machine inspections, employee training, and strict adherence to safety procedures.

Q 20. Describe your experience with different types of spring forming machinery.

My experience encompasses a variety of spring forming machinery, ranging from simple hand-operated machines to highly automated CNC-controlled systems.

- Hand-Operated Machines: I’ve worked with machines like hand coilers for smaller springs, providing valuable hands-on understanding of the fundamental forming processes. This experience highlights the importance of precision and control in manual spring forming.

- Automatic Coiling Machines: These machines offer significant advantages in terms of speed and consistency. I’ve worked extensively with CNC-controlled machines, which allow for the production of highly precise springs with complex geometries.

- Spring Forming Presses: These machines are capable of forming a wide range of spring designs, including those requiring substantial force. Understanding their capabilities and limitations is important for selecting the appropriate machinery for a specific job.

- Secondary Operations Machinery: Equipment used for secondary operations such as end forming, shot peening, or surface finishing plays a critical role in achieving the desired spring characteristics. I am familiar with the operation and maintenance of such equipment.

Example: For a high-volume production run of a precision compression spring, a CNC-controlled automatic coiling machine with integrated quality control sensors was the optimal choice. This ensured consistency in spring dimensions and properties, improving yield and reducing scrap.

Q 21. Explain your experience with quality control methods used in spring manufacturing.

Quality control in spring manufacturing is crucial for ensuring product reliability and meeting customer specifications. My experience incorporates various methods:

- In-Process Inspection: Regular checks throughout the manufacturing process, including visual inspection of coil geometry and dimensions, are carried out to identify and correct defects early on.

- Dimensional Measurement: Precise measurement of spring dimensions (free length, outside diameter, inside diameter, and coil pitch) using calibrated measuring instruments (micrometers, calipers) is essential to ensure conformance to drawings.

- Hardness Testing: Regular hardness testing verifies that the heat treatment has achieved the desired hardness level.

- Visual Inspection of Finished Springs: A final visual inspection before packaging helps to identify any surface imperfections or other defects that may not have been detected earlier.

Example: We implemented an SPC system to monitor the spring rate of a particular spring design. This enabled us to identify a subtle drift in the process, leading to a timely adjustment in the manufacturing parameters, preventing a large batch of non-conforming springs.

Q 22. How do you interpret material data sheets and specifications for spring materials?

Interpreting material data sheets for spring materials is crucial for successful spring design and manufacturing. These sheets provide vital information about the material’s mechanical properties, chemical composition, and heat treatment characteristics. I begin by carefully reviewing the tensile strength, yield strength, fatigue strength, and elastic modulus. These properties directly impact the spring’s load-carrying capacity, deflection, and fatigue life. For example, a higher tensile strength indicates a material’s ability to withstand greater stress before yielding, which is essential for springs designed to carry heavy loads. Similarly, the fatigue strength determines the spring’s lifespan under cyclic loading.

Next, I examine the material’s chemical composition to understand its suitability for the application. Certain elements affect the material’s hardenability and corrosion resistance. For instance, the presence of carbon in steel significantly influences its hardness and strength after heat treatment. Finally, I pay close attention to the recommended heat treatment processes, ensuring compatibility with the chosen manufacturing method. Understanding the material’s response to heat treatment – such as tempering, stress relieving, or precipitation hardening – is critical to achieving the desired spring properties. Failure to do so can lead to spring failure or significantly reduced lifespan. I often cross-reference multiple data sheets and specifications to ensure accuracy and consistency before proceeding with the design and production.

Q 23. How do you select appropriate tooling for different spring forming operations?

Tooling selection for spring forming is vital for producing springs that meet specifications and minimize defects. The choice depends heavily on the spring’s geometry, material properties, and production volume. For example, simple compression springs might be formed using a simple coiling machine with appropriate dies, while more complex springs, such as torsion or wire-form springs, might require more sophisticated tools like progressive dies or CNC-controlled wire bending machines.

When selecting tooling, I consider factors such as die material (tool steel, carbide, etc.), die geometry (radius, pitch, etc.), and the machine’s capacity. I also evaluate the tooling’s durability and wear resistance, especially when dealing with high-strength or abrasive materials. A well-designed tool will minimize spring defects like set, cracks, or inconsistencies in dimensions. Further, I consider the tooling’s cost and maintenance requirements; balancing the initial investment with long-term operational expenses and production efficiency. For large-scale production, automated tooling with integrated quality control systems is favored for consistency and efficiency.

Q 24. Describe the process of designing a spring for a specific application.

Designing a spring for a specific application is an iterative process requiring a deep understanding of spring mechanics and the application’s requirements. It typically starts with defining the spring’s function and the forces and displacements it must endure. I begin by identifying the spring type (compression, extension, torsion, etc.) best suited for the application. Then, I establish key design parameters: the required spring rate (force vs. deflection), the load capacity, the allowable deflection, and the space constraints. Using relevant equations and software, I perform calculations to determine the optimal spring dimensions, including wire diameter, coil diameter, number of coils, and free length.

For instance, for a compression spring, I use formulas to calculate the spring rate (k) based on the material’s properties (shear modulus, wire diameter, coil diameter, and number of coils). I then iterate the design, adjusting parameters to optimize for performance, manufacturability, and cost. Finite Element Analysis (FEA) software can be utilized to simulate the spring’s behavior under load and identify potential stress concentrations or failure points, enabling refinements to the design. Finally, detailed drawings and specifications are created, outlining all critical dimensions and tolerances for manufacturing. Throughout the process, material selection plays a critical role, considering factors such as fatigue resistance, corrosion resistance, and cost-effectiveness.

Q 25. What are the challenges associated with automating spring forming processes?

Automating spring forming processes presents several challenges, mainly centered around the complexity of the forming operations and the need for precise control. The inherent variability in wire properties, such as diameter and material consistency, can affect the forming process and make precise automation difficult. Maintaining consistent wire feeding and accurate positioning are crucial for producing high-quality springs. Robots and automation systems must be programmed to handle these variations and ensure consistent spring dimensions and quality.

Another challenge is the detection and rejection of defective springs. Automated vision systems and sensors are needed to identify defects such as cracks, kinks, or dimensional inconsistencies. These systems must be sophisticated enough to detect subtle defects that might affect the spring’s performance. Furthermore, the integration of different automated processes, such as wire feeding, forming, and quality control, presents logistical and programming complexities. The initial investment in automation equipment can be substantial, requiring careful cost-benefit analysis. Finally, ensuring operator safety around high-speed automated machinery is paramount and requires stringent safety protocols.

Q 26. How do you manage and reduce waste in spring forming operations?

Waste reduction in spring forming is crucial for both environmental and economic reasons. Strategies involve optimizing the design for minimum material usage and minimizing scrap generation. This includes selecting appropriate wire diameters and coil geometries to minimize material waste. Improved nesting techniques for cutting wire from coils can reduce scrap significantly. Implementing efficient coil handling and feeding systems, that minimize wire breakage and waste during the process, reduces material loss.

Process optimization is key, with techniques like precise die design and machine parameter optimization to minimize defects and rejections. Regular maintenance of equipment reduces downtime and prevents material loss due to malfunction. Implementing a robust quality control system to identify and rectify defects early on reduces the number of rejected springs. Finally, efficient scrap management practices, such as recycling of scrap material, are critical for minimizing waste’s environmental impact and potentially recovering some of the material cost.

Q 27. How do you ensure compliance with industry standards and regulations in spring manufacturing?

Compliance with industry standards and regulations is paramount in spring manufacturing. This involves adhering to relevant safety standards, quality control procedures, and environmental regulations. I ensure compliance by staying updated on the latest standards, such as those from ISO (International Organization for Standardization), ASTM (American Society for Testing and Materials), and industry-specific guidelines. These standards cover aspects like material specifications, dimensional tolerances, performance requirements, and testing procedures.

We maintain detailed records of all manufacturing processes, including material certifications, process parameters, and quality inspection results. Regular audits ensure our procedures meet the standards, and any non-conformances are addressed promptly through corrective and preventive actions. We also prioritize worker safety, implementing safety protocols, providing proper training, and regularly inspecting equipment to ensure safe operation. Environmental compliance is maintained through proper waste management, recycling programs, and adherence to emission standards.

Q 28. Describe your experience with different types of furnaces used in heat treatment.

My experience encompasses various furnace types used in heat treatment for springs, each with its strengths and limitations. I’ve worked extensively with batch furnaces, which are suitable for smaller production runs and offer good control over the heating and cooling cycles. These furnaces typically use resistive heating elements or gas-fired burners. Their simplicity and lower initial cost make them attractive for smaller operations.

I’m also familiar with continuous furnaces, ideal for high-volume production due to their continuous throughput. These furnaces often use conveyor systems to move parts through different temperature zones, allowing for precise control of the heating and cooling rates. They are more efficient than batch furnaces for large-scale operations but have higher initial investment costs. Finally, I’ve used vacuum furnaces, especially for applications demanding precise control over the atmosphere and minimizing oxidation or decarburization of the springs. Vacuum furnaces are especially valuable for processing high-value, complex spring designs.

Key Topics to Learn for Spring Forming and Heat Treatment Interviews

- Spring Forming Processes: Understanding various spring forming methods (coiling, bending, winding), their respective advantages and limitations, and the selection criteria based on spring design and material properties.

- Material Selection: Knowledge of suitable materials for spring manufacturing (e.g., steel alloys, non-ferrous metals), their mechanical properties (tensile strength, yield strength, fatigue resistance), and the impact of material selection on spring performance and lifespan.

- Heat Treatment Fundamentals: Grasping the principles of heat treatment processes like annealing, normalizing, hardening, and tempering, and their effects on the microstructure and mechanical properties of spring materials.

- Stress and Strain Analysis: Ability to analyze stress and strain distributions in springs under various loading conditions, including static and dynamic loads, using appropriate engineering principles and possibly FEA software.

- Spring Design and Calculations: Proficiency in calculating spring dimensions, spring rate, and deflection, considering factors like material properties, load requirements, and desired spring characteristics.

- Quality Control and Inspection: Familiarity with quality control techniques used in spring manufacturing, including dimensional inspection, material testing, and performance testing, to ensure the quality and reliability of springs.

- Troubleshooting and Problem Solving: Ability to identify and troubleshoot common issues encountered in spring forming and heat treatment processes, such as spring breakage, deformation, or inconsistencies in material properties.

- Safety Procedures and Regulations: Understanding and adhering to relevant safety protocols and industry regulations related to spring manufacturing and heat treatment operations.

- Automation and Advanced Manufacturing Techniques: Familiarity with automated spring forming and heat treatment processes, including robotic systems and advanced manufacturing technologies.

Next Steps

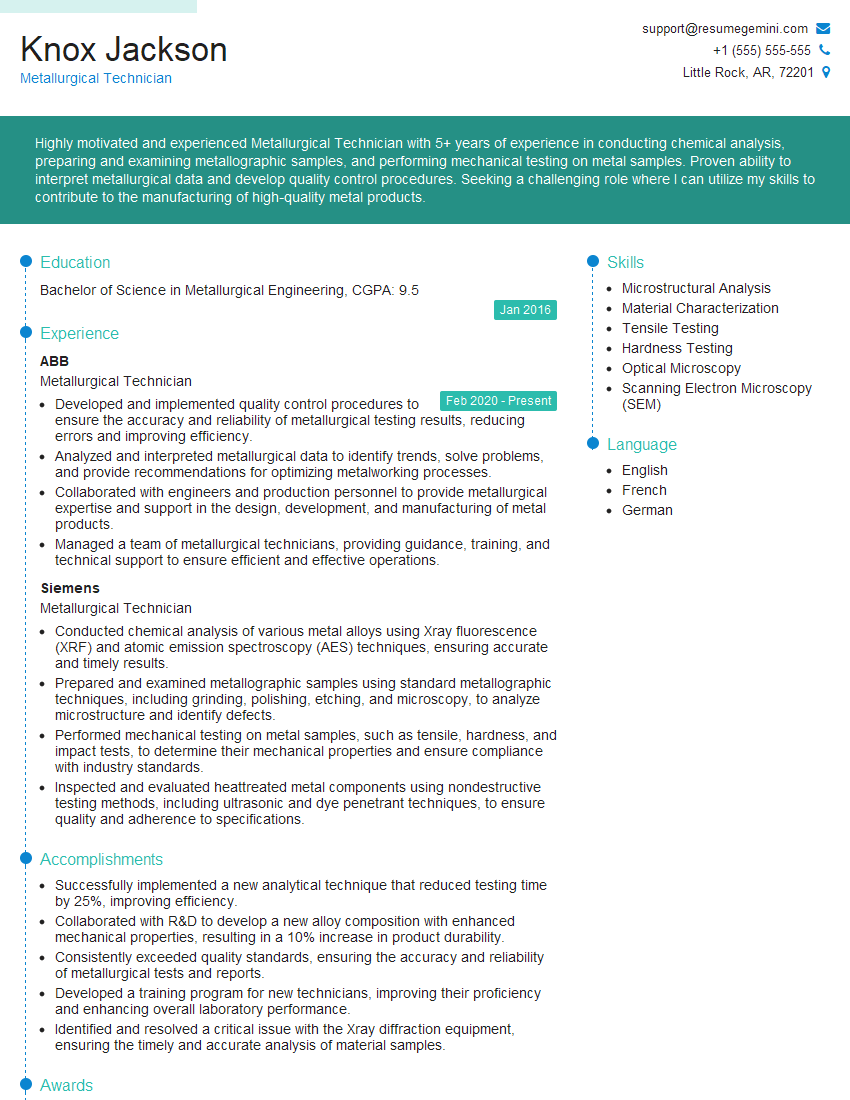

Mastering Spring Forming and Heat Treatment opens doors to exciting career opportunities in manufacturing, automotive, aerospace, and other high-tech industries. A strong understanding of these processes is highly valued by employers and will significantly boost your career prospects. To make a great first impression, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that showcases your skills and experience effectively. They provide examples of resumes tailored to Spring Forming and Heat Treatment, allowing you to craft a document that highlights your unique qualifications and gets you noticed. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO