Are you ready to stand out in your next interview? Understanding and preparing for Standards interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Standards Interview

Q 1. Explain the importance of standardization in your field.

Standardization is the cornerstone of efficiency and interoperability across various industries. Imagine a world where every electrical plug was different – chaos! Standards ensure compatibility, safety, and quality. In my field, consistent standards allow for seamless integration of systems, efficient processes, and reduced risks. They provide a common language and framework, facilitating communication and collaboration among different stakeholders – from engineers and developers to clients and regulators. This leads to cost savings, increased productivity, and improved product quality.

For example, in software development, adhering to coding standards ensures maintainability, readability, and reduces errors. In manufacturing, standards dictate safety protocols, leading to fewer workplace accidents. The benefits are widespread and crucial for a functioning, productive, and safe environment.

Q 2. Describe your experience with ISO 9001.

My experience with ISO 9001 spans over five years, encompassing both internal auditing and implementation within a manufacturing company. We underwent a comprehensive assessment to achieve certification, focusing on all aspects of the standard, including quality management system (QMS) documentation, process mapping, internal audits, management reviews, and corrective actions. My role involved documenting processes, conducting gap analyses against the ISO 9001 requirements, and training employees on the QMS. The certification process significantly improved our operational efficiency, reduced waste, and enhanced customer satisfaction. We consistently monitored key performance indicators (KPIs) to ensure continual improvement in line with the standard’s requirements. This included tracking defect rates, customer complaints, and lead times. The results were demonstrably positive – a significant decrease in production errors and a marked improvement in customer feedback.

Q 3. How familiar are you with ISO 27001 and its key principles?

I’m very familiar with ISO 27001, the international standard for information security management systems (ISMS). Its key principles revolve around risk assessment and management. The standard requires organizations to identify, analyze, and treat information security risks, establishing appropriate controls to mitigate them. This includes aspects like access control, encryption, incident management, and business continuity planning. Understanding the Annex A controls is critical for effective implementation. These controls provide a detailed framework for implementing security measures across various areas of an organization. My understanding includes practical experience in conducting risk assessments, developing security policies, and implementing technical controls to align with ISO 27001 requirements. I’ve also participated in several ISMS audits, both internal and external, ensuring conformity with the standard’s guidelines. For instance, I helped a client implement multi-factor authentication and data loss prevention measures, significantly strengthening their security posture.

Q 4. What is your experience with implementing and maintaining standards?

I have extensive experience implementing and maintaining various standards, including ISO 9001, ISO 14001 (Environmental Management Systems), and ISO 27001. My approach involves a phased implementation, starting with a gap analysis to identify the current state against the desired standard. This is followed by developing an implementation plan, including timelines, responsibilities, and resource allocation. Training is a critical component, ensuring all relevant personnel understand their roles and responsibilities within the new system. Regular internal audits monitor compliance, and management reviews track progress and address any deviations. Maintaining the standards requires continuous monitoring, improvement, and adaptation to changes in the business environment and regulatory landscape. This ongoing process involves regular updates to documentation, processes, and employee training. I use a data-driven approach, tracking key performance indicators (KPIs) to measure effectiveness and identify areas for improvement.

Q 5. Describe a situation where you had to resolve a conflict related to standards.

In one project, a conflict arose between the engineering team and the manufacturing team regarding the implementation of a new standard for product testing. The engineering team favored a more rigorous, time-consuming testing procedure, while the manufacturing team prioritized speed and efficiency. This threatened project timelines and budgets. To resolve this, I facilitated a series of meetings involving both teams, using a collaborative approach focused on finding common ground. We analyzed the risks associated with both approaches, and through open discussion, identified a compromise that satisfied both teams. This involved adopting a phased approach where initially a quicker, simplified testing procedure was implemented. Later, as the production process stabilized, the more rigorous tests were gradually integrated. This solution preserved both quality and timeliness, demonstrating the importance of open communication and a collaborative spirit in resolving standards-related conflicts.

Q 6. How do you stay updated on the latest industry standards?

Staying updated on the latest industry standards requires a multifaceted approach. I actively subscribe to industry publications and journals, attend conferences and workshops, and participate in professional organizations. Networking with other professionals within my field is crucial; it provides insights into best practices and emerging trends. I also leverage online resources, such as standard bodies’ websites, to access the latest versions of standards and related guidance documents. Regularly reviewing and updating our internal standards and procedures based on this information is critical to maintain relevance and competitiveness.

Q 7. Explain the difference between a standard and a guideline.

The difference between a standard and a guideline lies primarily in their enforceability. A standard is a formally documented specification that is often mandatory for compliance, frequently enforced by regulatory bodies or industry organizations. Non-compliance can lead to penalties or sanctions. Guidelines, on the other hand, offer recommendations or best practices but are not mandatory. They provide suggestions for achieving optimal results but don’t carry the same level of legal or regulatory weight as a standard. Think of it this way: a standard is like a law, while a guideline is like advice. Both aim to improve processes and outcomes, but standards possess legal teeth, whereas guidelines are more flexible and adaptable to individual circumstances. For example, ISO 9001 is a standard, while a company’s internal document outlining best practices for email communication could be considered a guideline.

Q 8. How would you handle a non-compliance issue?

Handling a non-compliance issue requires a systematic approach. First, I’d identify the specific deviation from the standard, documenting the nature, extent, and potential impact. This involves gathering evidence, interviewing relevant personnel, and reviewing related documentation. Next, I’d initiate a root cause analysis to understand why the non-compliance occurred. Was it due to a lack of training, inadequate resources, a process failure, or something else? Once the root cause is identified, we can develop a corrective action plan to address the issue and prevent recurrence. This plan must include immediate corrective actions to resolve the current non-compliance and preventive actions to stop future occurrences. For example, if a non-compliance is found during a safety audit, immediate corrective action might involve halting the operation until the hazard is mitigated. Preventive action might involve enhanced training or the implementation of a new safety procedure. Finally, I’d monitor the effectiveness of the corrective and preventive actions, documenting the results and making any necessary adjustments. Regular follow-up ensures long-term compliance.

Imagine a scenario where a food processing plant fails to maintain proper temperature records, violating a critical safety standard. The corrective action might involve immediate rectification of the temperature, disposal of potentially contaminated products, and retraining of staff. Preventive action could be implementing automated temperature monitoring systems and improved record-keeping processes.

Q 9. What are some common challenges in maintaining standards compliance?

Maintaining standards compliance presents several challenges. One common challenge is keeping up with evolving standards. Standards are often updated to reflect technological advancements or address new risks. Staying current requires continuous professional development and access to the latest versions of relevant standards documents. Another major challenge is resource constraints. Implementing and maintaining compliance can be costly, requiring investments in training, equipment, and software. Budgetary limitations can hinder effective compliance efforts. Resistance to change is also common. People may resist adopting new standards or processes due to familiarity with existing methods, perceived inconvenience, or lack of understanding. Effective communication and training are key to overcoming this resistance. Finally, measuring effectiveness can be tricky. Determining the precise impact of implemented standards often necessitates the development of appropriate metrics and data collection mechanisms.

Q 10. Describe your experience with auditing standards compliance.

My experience in auditing standards compliance encompasses a wide range of industries. I’ve conducted both internal and external audits, employing various methodologies including checklists, interviews, document review, and observations. In one particular project for a healthcare facility, I audited compliance with HIPAA regulations related to patient data privacy and security. This involved reviewing access controls, data encryption protocols, and employee training records. I identified several areas of non-compliance, including insufficient password security and a lack of employee awareness regarding data breaches. My recommendations led to improvements in their security protocols and significantly enhanced their compliance posture. In another instance, I audited a manufacturing company’s compliance with ISO 9001 quality management standards. This involved verifying the effectiveness of their quality management system, examining product quality records, and assessing their processes for continuous improvement. My findings were instrumental in helping the company achieve ISO 9001 certification.

Q 11. How do you ensure that standards are implemented effectively?

Effective standards implementation relies on a multi-faceted strategy. First, clear communication is paramount. Stakeholders must understand the purpose, scope, and requirements of the standards. This involves providing training, creating accessible documentation, and holding regular communication sessions. Next, strong leadership commitment is essential. Leaders must actively promote compliance and allocate the necessary resources. Regular monitoring and evaluation are critical. A system for tracking progress, identifying gaps, and taking corrective actions should be implemented. This might involve regular audits, performance reviews, and data analysis. Furthermore, integrating standards into existing processes streamlines compliance efforts. Instead of treating standards as an add-on, they should be woven into daily operations. Finally, fostering a culture of continuous improvement encourages proactive compliance. Regularly reviewing and updating standards and procedures ensures they remain effective and relevant.

Q 12. Explain the process for developing a new standard.

Developing a new standard is a rigorous process. It often starts with identifying a need or gap in existing standards. This might be driven by technological advancements, changing industry practices, or emerging risks. Next, a group of experts, usually from different organizations and backgrounds, is formed to develop the standard. This group typically follows a consensus-based approach, ensuring that the standard meets the needs of all stakeholders. The process involves several stages, including drafting, review, feedback collection, revisions, and final approval. Throughout the process, transparency and openness are critical. Once finalized, the standard is often published and made available to the public. Maintaining and updating the standard is an ongoing process, involving periodic review and revision to ensure its continued relevance and effectiveness. For instance, a new standard for cybersecurity in the healthcare sector would be developed by bringing together IT experts, healthcare professionals, and legal advisors.

Q 13. What metrics do you use to measure the effectiveness of implemented standards?

Measuring the effectiveness of implemented standards requires a combination of quantitative and qualitative metrics. Quantitative metrics might include the number of non-compliance incidents, the frequency of audits, the cost of compliance, or the number of successful certifications. These metrics provide a numerical measure of compliance performance. Qualitative metrics focus on the impact of standards on broader organizational goals. For example, the improvement in product quality, increased customer satisfaction, reduced risks, or enhanced employee safety could be assessed through surveys, interviews, or other qualitative methods. Choosing the right metrics depends on the specific standards and the organization’s goals. For example, in a manufacturing setting, the number of defects per million units produced can be a key quantitative metric. Simultaneously, the impact on employee safety and morale (qualitative) would be important for measuring the success of health and safety standards.

Q 14. How do you communicate standards to different stakeholders?

Communicating standards effectively to diverse stakeholders requires a tailored approach. Different groups have different needs and levels of understanding. For management, communication should emphasize the business benefits of compliance such as reduced risk, increased efficiency, or improved reputation. For employees, communication should focus on their roles and responsibilities in maintaining compliance, including practical training and clear instructions. For customers, communication might emphasize the quality, safety, or reliability of products or services that result from adherence to standards. The best method for communication may vary from formal training programs and written documentation to informal discussions and interactive workshops. Using multiple channels, such as emails, intranet sites, presentations, and training videos, ensures a wider reach and caters to diverse learning styles. Regular feedback mechanisms allow stakeholders to provide input and address any misunderstandings.

Q 15. Explain the concept of a standard operating procedure (SOP).

A Standard Operating Procedure (SOP) is a set of step-by-step instructions compiled by an organization to help workers carry out complex routine operations. Think of it as a recipe for consistent and successful outcomes. SOPs are crucial for maintaining quality, ensuring safety, and minimizing errors. They’re not just for complex tasks; even seemingly simple processes benefit from standardization. For example, a simple SOP might detail the steps for handling customer inquiries, ensuring everyone follows the same process, leading to consistent and efficient service. A more complex one might outline the procedure for a critical manufacturing process, ensuring product quality and safety.

A well-written SOP typically includes:

- Purpose: Clearly states the goal of the procedure.

- Scope: Defines what the SOP covers and doesn’t cover.

- Step-by-step instructions: Detailed, clear, and unambiguous steps with visuals where appropriate.

- Safety precautions: Addresses any potential hazards and safety measures.

- Record-keeping: Specifies what data needs to be recorded and how.

- References: Links to related documents or standards.

In my experience, effectively implemented SOPs significantly reduce errors, improve efficiency, and ensure consistent performance, ultimately benefiting the entire organization.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage conflicting standards?

Managing conflicting standards requires a structured approach. It’s a common challenge, especially in organizations that work with multiple external regulations or internal departments with their own preferred methods. My approach involves these key steps:

- Identification: Thoroughly identify and document all conflicting standards. This often involves meetings with stakeholders from relevant departments or reviewing existing documentation.

- Prioritization: Determine the relative importance of each standard. This usually involves considering legal requirements, safety regulations, and business impact. For example, a safety standard would typically override a less critical internal guideline.

- Resolution: This stage involves several options:

- Negotiation: Discuss the conflict with relevant stakeholders to find a mutually acceptable compromise.

- Exception Management: Document exceptions where compliance with one standard necessitates deviation from another, ensuring appropriate justification and control.

- Adaptation: Modify existing procedures or standards to resolve the conflict, ensuring all stakeholders are informed and agree upon the changes.

- Prioritization (again):If a compromise cannot be reached, prioritize one standard over the other, clearly documenting the reasons and any associated risks.

- Communication: Communicate the chosen resolution to all affected parties. This ensures everyone is aware of the changes and how to implement them.

- Monitoring and Review: Regularly monitor the effectiveness of the chosen resolution and review the situation periodically to assess whether adjustments are needed.

For example, I once had to resolve a conflict between an ISO 9001 requirement for detailed documentation and a lean manufacturing initiative that emphasized minimizing paperwork. We resolved this by focusing on effective digital documentation systems and ensuring that all necessary data was still tracked, but not in overly cumbersome ways.

Q 17. Describe your experience with risk management related to standards.

Risk management concerning standards is integral to my work. It involves proactively identifying, analyzing, and mitigating potential negative consequences related to the implementation, application, or non-compliance of standards. I use a structured risk assessment process, often based on a framework like FMEA (Failure Mode and Effects Analysis), to evaluate potential risks.

This involves:

- Identifying potential risks: This could include inadequate training, insufficient resources, outdated standards, or lack of awareness among employees.

- Assessing the likelihood and impact of each risk: Assigning probabilities and severity levels to each identified risk helps to prioritize mitigation efforts.

- Developing mitigation strategies: This could involve providing additional training, allocating more resources, implementing monitoring mechanisms, or updating standards.

- Monitoring and reviewing: Regularly monitor the effectiveness of implemented mitigation strategies and adjust them as necessary. This is a continuous process, not a one-time activity.

For instance, during a project involving the implementation of a new safety standard, we identified the risk of inadequate employee training leading to accidents. We mitigated this by developing a comprehensive training program, providing hands-on practice, and implementing regular competency assessments.

Q 18. How do you handle resistance to implementing standards?

Resistance to implementing standards is a common challenge, but it can be effectively managed with a proactive and collaborative approach. I avoid a top-down, dictatorial approach; instead, I focus on building consensus and understanding.

My strategy includes:

- Communication: Clearly explain the benefits of implementing the standards, addressing concerns and answering questions openly and honestly. Show how the standards improve efficiency, reduce risks, or enhance overall quality.

- Engagement: Involve stakeholders in the development and implementation process. This can include seeking feedback, incorporating suggestions, and even assigning ownership of specific aspects of the implementation.

- Training and Support: Provide thorough training to ensure that everyone understands how to use the new standards and has the necessary resources and support. Address any knowledge gaps early.

- Incentivization: Recognize and reward employees who successfully implement and adhere to the new standards. Positive reinforcement fosters a culture of compliance.

- Addressing Concerns: Listen actively to concerns and address them constructively. If legitimate issues exist, find solutions collaboratively rather than imposing directives.

For example, I once encountered resistance to a new documentation standard from a team concerned about the increased workload. By working with them to streamline the process and provide appropriate training, we addressed their concerns and successfully implemented the standard.

Q 19. What is your experience with developing and using standard templates and documentation?

I have extensive experience developing and using standard templates and documentation. Consistent templates are critical for efficient communication, easy data retrieval, and reducing ambiguity. They ensure uniformity across different projects and teams.

My experience includes:

- Creating templates for various document types: This includes SOPs, reports, presentations, risk assessments, and meeting minutes. I always strive for clarity, consistency, and ease of use.

- Implementing version control systems: This ensures that everyone is working with the most up-to-date version of the templates and avoids confusion.

- Developing naming conventions: Using clear and consistent naming conventions makes it easy to locate and manage documents. This often involves a combination of project codes, revision numbers, and dates.

- Training users on the use of templates: Ensuring that everyone understands how to use the templates correctly is crucial for successful implementation.

- Regularly reviewing and updating templates: To keep them relevant, current, and efficient.

I often use tools like Microsoft Word with tracked changes and version history, or specialized document management systems, to maintain version control and ensure consistency.

Q 20. Explain your understanding of version control and its relevance to standards.

Version control is essential for managing standards, especially in dynamic environments where standards are updated regularly. It’s a system that tracks changes to documents, allowing you to revert to previous versions if needed, track who made what changes, and ensure everyone is using the most current, approved version.

Without version control, there’s a high risk of confusion, inconsistencies, and using outdated information. Imagine trying to manage multiple versions of a safety standard floating around; the risk of accidents increases dramatically. Using a version control system, such as Git (commonly used for software development but adaptable to other document types), ensures that only approved versions are used.

My experience with version control in the context of standards involves:

- Choosing the appropriate version control system: The choice depends on the complexity of the standards and the number of users.

- Establishing a clear branching and merging strategy: This helps to manage different versions and incorporate changes without disrupting ongoing work.

- Implementing a review and approval process: This ensures that all changes are reviewed and approved before being incorporated into the main version.

- Training users on using the version control system: Effective training ensures all users understand the system’s capabilities and how to use it correctly.

For example, in a previous role, we used a shared document repository with version control to manage our ISO 14001 environmental management system documentation. This ensured that all changes were tracked, reviewed, and approved before becoming the official version, preventing confusion and potential non-compliance.

Q 21. How do you ensure consistency in the application of standards across different teams or locations?

Ensuring consistent application of standards across different teams and locations requires a multifaceted approach focusing on communication, training, and monitoring. The key is to foster a common understanding and commitment to the standards.

My strategies include:

- Centralized repository: Store all standards in a single, accessible location, using a version control system to manage changes and ensure everyone has access to the most current version.

- Standardized training programs: Implement consistent training programs for all teams and locations to ensure everyone understands and can apply the standards correctly. This often includes hands-on training and regular refresher courses.

- Regular audits and inspections: Conduct regular audits and inspections to monitor compliance and identify areas needing improvement. This helps to identify inconsistencies and address them proactively.

- Feedback mechanisms: Establish clear channels for feedback, allowing teams to report challenges or suggest improvements to the standards or their application.

- Communication tools: Use a combination of communication tools, such as intranet sites, newsletters, and team meetings, to keep everyone informed of updates, changes, and best practices.

- Consistent metrics: Track key metrics related to standard compliance to measure the effectiveness of implemented processes and identify areas for improvement.

For instance, in a global organization, we used a combination of online training modules, regular virtual meetings, and on-site audits to ensure consistent application of quality standards across all manufacturing facilities worldwide. We also established a centralized knowledge base for easy access to documents and best practices.

Q 22. What tools or software do you use to manage and track standards compliance?

Managing and tracking standards compliance requires a robust system. I typically leverage a combination of tools, depending on the specific standards and organizational needs. This often includes a dedicated Standards Management System (SMS), which could be a software solution or a carefully designed internal process. These systems often feature features like:

- Centralized repository: Storing all relevant standards documents, updates, and related documentation in a single, easily accessible location.

- Version control: Tracking changes to standards over time, ensuring everyone is working with the latest version.

- Audit trails: Recording all actions related to standards compliance, such as approvals, reviews, and training completion, for traceability and accountability.

- Reporting and analytics: Generating reports on compliance status, identifying gaps, and monitoring progress towards objectives.

Examples of software I’ve used include ISOTools, Enablon, and SharePoint configured for standards management. In smaller organizations, a well-structured file management system coupled with regular internal audits can be sufficient, but proper version control and documentation remain crucial.

Q 23. Describe your experience with Six Sigma and its relation to standards.

Six Sigma is a data-driven methodology focused on process improvement and minimizing defects. Its relationship to standards is deeply intertwined, as both aim for consistent, high-quality outcomes. Six Sigma provides a framework for achieving and maintaining compliance with standards.

In my experience, I’ve used Six Sigma tools like DMAIC (Define, Measure, Analyze, Improve, Control) to identify and address inconsistencies within processes that impact compliance. For example, when implementing a new ISO 9001 quality management system, I used DMAIC to analyze the current workflow, measure its effectiveness against the standard’s requirements, and implement improvements to ensure consistent compliance. This involved using statistical process control techniques to monitor key process indicators (KPIs) and ensure they remained within acceptable limits, as defined by the standard.

The rigorous data analysis inherent in Six Sigma helps pinpoint areas of non-compliance proactively, leading to more efficient and effective compliance efforts. It turns standards from abstract requirements into concrete, measurable targets.

Q 24. How familiar are you with NIST standards?

I am very familiar with NIST (National Institute of Standards and Technology) standards. My experience encompasses a range of NIST publications, particularly those focused on cybersecurity, data management, and cloud computing. I’ve worked extensively with frameworks such as NIST Cybersecurity Framework (CSF), NIST Special Publication 800-53 (Security and Privacy Controls for Federal Information Systems and Organizations), and NIST SP 800-61 (Computer Security Incident Handling Guide).

For instance, I helped an organization implement NIST CSF to improve its cybersecurity posture by aligning its security activities with the framework’s five functions: Identify, Protect, Detect, Respond, and Recover. This involved mapping the organization’s existing security controls to the CSF and identifying gaps requiring remediation.

Understanding NIST standards is critical for ensuring interoperability, security, and reliability in various technological domains. My knowledge extends to understanding the nuances of specific publications and their practical application in diverse contexts.

Q 25. Explain your experience with regulatory compliance and relevant standards.

Regulatory compliance is a core aspect of my work, and I have extensive experience navigating the complexities of various regulations and associated standards. My experience covers areas like data privacy (GDPR, CCPA), HIPAA (healthcare), and industry-specific regulations within the financial services sector. I approach regulatory compliance by first thoroughly understanding the specific requirements of each relevant regulation.

For example, when assisting a healthcare provider with HIPAA compliance, I ensured their systems and processes adhered to all requirements for protecting Protected Health Information (PHI). This included implementing appropriate security measures, conducting regular risk assessments, and developing comprehensive breach notification plans. I’ve also helped organizations develop and implement comprehensive compliance programs, integrating regulatory requirements into their existing operational frameworks and providing ongoing monitoring and reporting.

A key element of my approach involves staying up-to-date with evolving regulations and adapting compliance strategies accordingly. This requires a combination of ongoing professional development and close monitoring of regulatory changes.

Q 26. How do you measure the impact of implemented standards on business outcomes?

Measuring the impact of implemented standards on business outcomes requires a multi-faceted approach. It’s not enough to simply state that standards are in place; you need to demonstrate their value. This involves:

- Defining Key Performance Indicators (KPIs): Before implementing standards, I define specific, measurable KPIs that directly reflect the intended impact. For example, if implementing a quality management standard, KPIs might include defect rates, customer satisfaction scores, and cycle times.

- Baseline measurements: Gathering baseline data before implementation provides a benchmark against which to compare post-implementation results. This allows for quantifying the improvement achieved.

- Data collection and analysis: Continuously collecting and analyzing relevant data to track progress towards the defined KPIs. This might involve using data analytics tools or statistical methods.

- Return on Investment (ROI) analysis: Quantifying the financial benefits of compliance, such as reduced costs from fewer defects, improved operational efficiency, or enhanced customer loyalty.

For example, after implementing ISO 14001 (environmental management), we measured the reduction in waste generated, the improvement in energy efficiency, and the overall reduction in environmental impact. This demonstrably showcased the ROI of the environmental management system.

Q 27. Describe a time you identified a gap in existing standards and proposed a solution.

During a project involving the development of a new software product, I identified a gap in the existing software security standards related to handling sensitive user data. The existing standards were adequate for general security, but lacked specific guidance on the encryption and secure storage of highly sensitive personal information. My proposed solution involved augmenting the existing standards with a supplementary document that outlined:

- Specific encryption algorithms: Defining the minimum acceptable level of encryption for different data categories.

- Key management practices: Establishing secure procedures for generating, storing, and rotating encryption keys.

- Data loss prevention (DLP) measures: Implementing controls to prevent unauthorized access, disclosure, use, modification, or destruction of sensitive data.

This supplementary document was reviewed and approved by relevant stakeholders, and it was subsequently integrated into the overall software development lifecycle, enhancing the security and compliance posture of the software.

Q 28. What are your preferred methods for training staff on standards compliance?

Effective training on standards compliance is crucial for maintaining a compliant organization. My preferred methods involve a blended learning approach that combines different techniques to cater to various learning styles.

- Interactive online modules: Using e-learning platforms to deliver engaging and interactive training materials. This allows for self-paced learning and convenient access.

- Instructor-led workshops: Conducting interactive workshops to facilitate group discussions, practical exercises, and Q&A sessions. This allows for more in-depth understanding and personalized guidance.

- On-the-job training and mentoring: Providing hands-on support and guidance to staff while they apply their knowledge in real-world scenarios. This ensures practical application and immediate feedback.

- Gamification: Incorporating game-like elements into training modules to make learning more fun and engaging.

- Regular refresher training: Providing regular updates to keep staff informed of any changes or updates to relevant standards.

The key is to make the training relevant, engaging, and accessible, ensuring staff understand the “why” behind compliance, not just the “what”.

Key Topics to Learn for Standards Interview

- Defining and Classifying Standards: Understand the different types of standards (e.g., industry, national, international) and their hierarchical relationships. Consider the processes involved in developing and maintaining standards.

- Practical Application of Standards: Explore real-world examples of how standards impact various industries (e.g., safety regulations, interoperability in technology, quality control). Be prepared to discuss specific standards relevant to your field of interest.

- Compliance and Auditing: Understand the implications of non-compliance with standards and the role of audits in ensuring adherence. Consider the ethical considerations related to standard implementation.

- Standards Development Lifecycle: Familiarize yourself with the stages involved in creating and updating standards, from initial proposal to final approval and ongoing maintenance.

- Impact of Standards on Innovation: Discuss how standards can both encourage and constrain innovation. Consider the balance between standardization and the need for flexibility and adaptability.

- Technological Standards and Interoperability: If relevant to your target role, delve into the specific challenges and solutions related to technological standards and ensuring seamless interoperability between systems.

- Problem-Solving with Standards: Practice analyzing scenarios where standards are relevant, identifying potential conflicts or gaps, and proposing solutions that align with best practices and regulatory requirements.

Next Steps

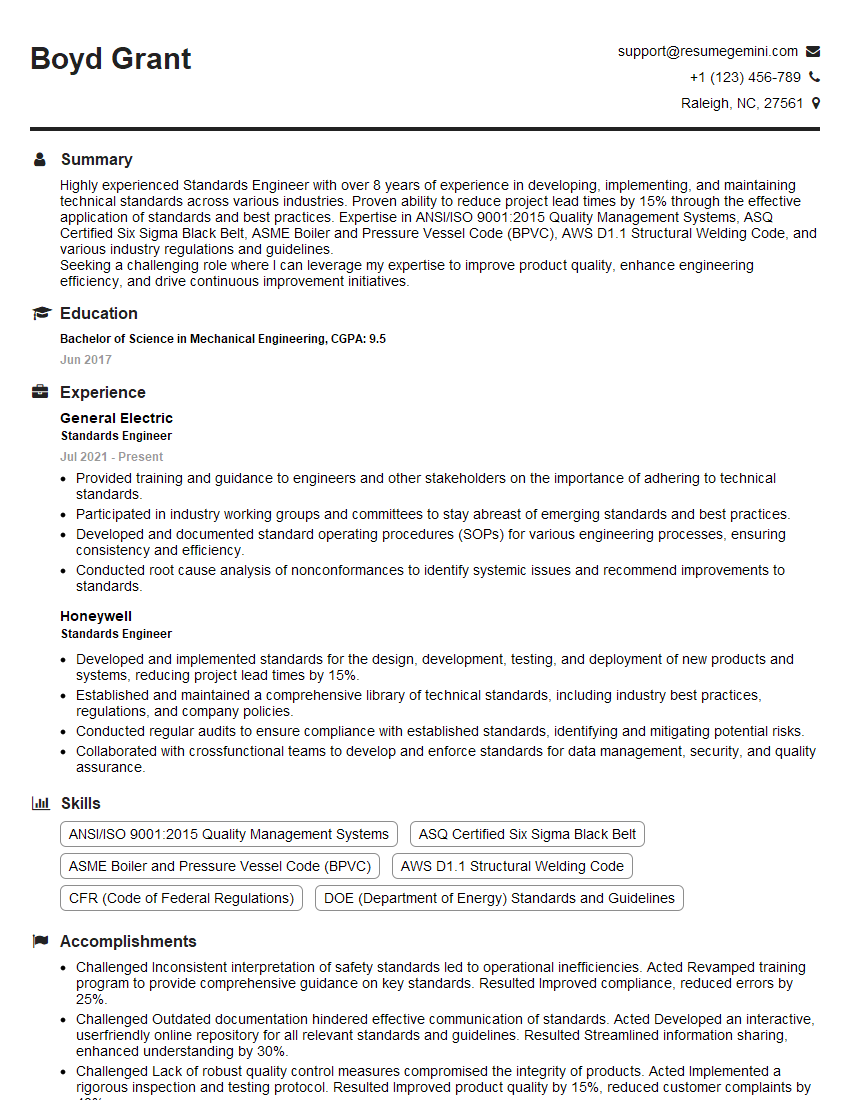

Mastering Standards is crucial for career advancement in today’s competitive landscape. A deep understanding of standards demonstrates your commitment to quality, safety, and ethical practices, making you a highly valuable asset to any organization. To maximize your job prospects, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific career goals. Examples of resumes tailored to Standards are available within ResumeGemini to guide your process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO