Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Surface Finishing and Treatment interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Surface Finishing and Treatment Interview

Q 1. Explain the difference between electroplating and electroless plating.

The key difference between electroplating and electroless plating lies in the need for an external power source. Electroplating, as the name suggests, uses an electric current to drive the deposition of metal ions onto a substrate. Think of it like charging a battery – we force metal ions to adhere to the surface. Electroless plating, on the other hand, is an autocatalytic process; it doesn’t require an external electrical current. Instead, a chemical reducing agent in the plating solution reduces the metal ions, causing them to deposit onto the substrate. This is more like a chemical reaction where the metal ions are spontaneously plating onto the surface.

Electroplating is widely used for applications requiring uniform coatings and precise thickness control, such as chrome plating on car parts or gold plating on jewelry. The process allows for highly controlled deposition, resulting in consistent and aesthetically pleasing finishes. Electroless plating is often preferred when uniform coating is needed on complex shapes with recesses, where electroplating might have difficulty reaching. For instance, electroless nickel plating is frequently employed in the electronics industry for its corrosion resistance and uniform coating on intricate circuit boards.

Q 2. Describe the process of powder coating, including pre-treatment steps.

Powder coating is a durable, decorative finish applied as a free-flowing, dry powder. Unlike liquid paints, it doesn’t require solvents. The powder is electrostatically charged and sprayed onto the substrate, adhering to it. Then, the coated part is cured in an oven, melting the powder and forming a continuous, tough coating.

Pre-treatment is absolutely crucial for successful powder coating. It ensures proper adhesion and prevents defects. A typical pre-treatment process involves:

- Cleaning: Removing any dirt, grease, or oil from the substrate using solvents, detergents, or alkaline cleaners. Think of this as washing your car before waxing it.

- Surface Preparation: This could involve different methods depending on the substrate. For metals, abrasive blasting (sandblasting) or chemical etching might be used to create a rougher surface for better adhesion. This is like creating a grip for the coating to hold onto.

- Conversion Coating: This step applies a thin chemical layer to the substrate, often a phosphate or chromate coating, that enhances adhesion and corrosion resistance. It’s the primer that prepares the surface for paint.

After pre-treatment, the powder is applied, cured, and then the finished product is ready. The entire process delivers a thick, long-lasting, and aesthetically pleasing finish often seen on appliances, furniture, and automotive parts.

Q 3. What are the common anodizing processes and their applications?

Anodizing is an electrochemical process that creates a thicker, more durable oxide layer on the surface of metals, particularly aluminum. It enhances corrosion resistance, wear resistance, and provides a base for dyeing or painting. The common anodizing processes include:

- Sulfuric Acid Anodizing: The most common type, offering good corrosion resistance and a relatively smooth finish. Widely used in architectural applications, transportation, and consumer products.

- Chromic Acid Anodizing: Produces a thinner, harder, and more corrosion-resistant coating than sulfuric acid anodizing, but it’s less commonly used due to environmental concerns related to chromium.

- Hard Anodizing: A thicker, more wear-resistant coating than standard anodizing, achieved by using higher voltages and lower temperatures during the process. Used in aerospace, defense, and automotive industries for wear-resistant parts.

Applications vary widely based on the type of anodizing. For instance, sulfuric acid anodizing is used on architectural aluminum for its durability and aesthetic appeal, while hard anodizing protects the components in harsh environments like aerospace applications.

Q 4. How do you control the thickness of a plated layer?

Controlling the thickness of a plated layer is crucial for ensuring the desired properties and performance of the finished product. Several techniques can be used:

- Time Control: The simplest method, where plating time is directly proportional to the thickness. However, this method is less accurate and susceptible to variations in current density and solution concentration.

- Current Density Control: Precisely controlling the current density applied to the substrate provides more consistent results. Higher current densities generally lead to faster plating rates, but excessive current can lead to defects.

- Thickness Measurement: Using instruments like magnetic thickness gauges, eddy current testers, or cross-section microscopy allows for real-time monitoring and adjustment of the plating process to achieve the desired thickness. This method provides the most accurate control.

In practice, a combination of these methods is often employed to ensure optimal results. For instance, a process might start with a target plating time and current density, with regular thickness checks to fine-tune the process and maintain the desired thickness within specific tolerances.

Q 5. What are the different types of surface defects you might encounter and how would you address them?

Surface defects in surface finishing are common and can significantly impact the quality and performance of the finished product. Some common defects include:

- Pitting: Small holes or depressions on the surface. Often caused by contaminants or irregularities in the plating solution.

- Blistering: Bubbles or raised areas formed due to trapped gases or poor adhesion.

- Burning: Localized areas of excessive plating, usually caused by high current density.

- Roughness: An uneven surface finish, which can be due to poor pre-treatment or plating conditions.

Addressing these defects requires a systematic approach: Firstly, identify the root cause. This often involves examining the process parameters, the quality of the plating solution, and the pre-treatment stages. Once the cause is identified, corrective actions can be implemented. For example, pitting can be minimized by thorough cleaning of the substrate and careful control of the plating solution. Blistering might require adjusting the plating bath’s chemistry or changing pre-treatment procedures.

Q 6. Explain the importance of pre-treatment in surface finishing.

Pre-treatment is not just a preliminary step; it’s the foundation for a successful surface finish. It significantly impacts the adhesion, corrosion resistance, and overall quality of the final coating. Think of it as preparing a canvas before painting. A poorly prepared surface will lead to peeling, flaking, and a shorter lifespan of the coating.

The importance of pre-treatment lies in:

- Enhanced Adhesion: Cleaning and surface preparation create a clean, well-defined surface for the coating to adhere to. This minimizes the risk of delamination and peeling.

- Improved Corrosion Resistance: Conversion coatings provide an additional layer of protection against corrosion, particularly important in outdoor or harsh environments.

- Uniform Coating: Pre-treatment helps to create a uniform substrate surface, leading to a more even and aesthetically pleasing finish.

- Reduced Defects: By removing contaminants and smoothing out the surface, pre-treatment reduces the likelihood of defects such as pitting, blistering, and poor adhesion.

Neglecting pre-treatment can lead to premature coating failure, impacting the product’s lifespan and overall quality. It’s a critical process that shouldn’t be overlooked.

Q 7. What are the environmental concerns related to surface finishing processes?

Surface finishing processes, while crucial for many industries, pose significant environmental concerns. Many traditional processes use hazardous chemicals and generate waste, impacting air and water quality. Specific concerns include:

- Wastewater: Plating solutions and cleaning agents often contain heavy metals like chromium, nickel, and cadmium, which are highly toxic and can pollute water sources if not properly treated.

- Air Emissions: Some processes release volatile organic compounds (VOCs) and other harmful gases into the atmosphere. These can contribute to air pollution and respiratory problems.

- Hazardous Waste: Spent plating solutions, sludge, and other byproducts require careful disposal to prevent environmental contamination. Improper disposal can lead to soil and water pollution.

- Energy Consumption: Processes like anodizing and powder coating require significant energy for heating and curing, contributing to greenhouse gas emissions.

The industry is moving towards more environmentally friendly processes, such as using less hazardous chemicals, implementing stricter waste management practices, and adopting cleaner production technologies. Regulations are also increasingly stringent, pushing companies to adopt sustainable practices.

Q 8. How do you determine the appropriate surface finish for a given application?

Selecting the right surface finish is crucial; it’s like choosing the right outfit for a specific occasion. The process involves considering several factors: the material’s properties, the intended application’s functional requirements (e.g., corrosion resistance, wear resistance, aesthetics), and the manufacturing process’s limitations.

For instance, a surgical instrument needs a biocompatible, highly polished finish to prevent bacterial growth and ease cleaning, while a car bumper requires a durable, scratch-resistant finish that can withstand daily wear and tear. We assess factors like required surface roughness (measured in Ra or Rz), the desired appearance (matte, glossy, textured), and the specific performance characteristics needed. A detailed analysis of the application’s operating environment (temperature, humidity, exposure to chemicals) further refines the selection. A systematic approach, using material selection charts and consulting industry standards, often plays a key role. Sometimes, prototyping with different finishes is necessary to make the final determination.

Q 9. Describe the different types of plating solutions and their applications.

Plating solutions are diverse, each offering unique properties. They are typically categorized by the metal deposited.

- Nickel plating: Offers excellent corrosion resistance and hardness, widely used in automotive parts and electronics.

- Chrome plating: Provides exceptional hardness, corrosion resistance, and a highly reflective finish. Commonly used in decorative applications and tools.

- Zinc plating: Sacrificial plating, protecting the underlying metal from corrosion by oxidizing first. Cost-effective and suitable for fasteners and hardware.

- Gold plating: Used in electronics for its excellent conductivity and corrosion resistance; often preferred in high-reliability applications.

- Silver plating: Offers high conductivity and reflectivity, often applied to electrical contacts and decorative items.

The selection of the plating solution depends on factors like the base metal, the desired properties of the coating, and the cost. The chemistry of the plating bath is also crucial, and it must be precisely controlled (pH, temperature, current density) to ensure consistent, high-quality plating.

Q 10. What are the key parameters to control in a powder coating process?

Powder coating involves applying a dry powder coating to a surface, which is then cured by heat. Precise control of several parameters is vital for a successful outcome.

- Pre-treatment: Proper cleaning and surface preparation are crucial for adhesion. This often includes degreasing, chemical etching, or sandblasting.

- Powder application: The method (electrostatic spraying, fluidized bed) and the powder gun settings (voltage, air pressure) directly influence the coating thickness and uniformity.

- Curing temperature and time: The oven’s temperature and dwell time must be precisely controlled to ensure proper fusion and cross-linking of the powder particles. Incorrect curing can lead to poor adhesion, blistering, or inadequate film hardness.

- Powder type and formulation: The choice of powder depends on the required properties (e.g., gloss level, color, chemical resistance). Specific formulations are available to meet various application needs.

Monitoring these parameters is done using instruments like thickness gauges, temperature sensors, and visual inspection. Failure to control these parameters can result in defects like orange peel, pinholes, or poor adhesion.

Q 11. How do you ensure quality control in a surface finishing operation?

Quality control in surface finishing is paramount. It’s a multi-faceted process that starts before the process begins and continues even after the job is finished.

It involves:

- Incoming material inspection: Checking the cleanliness and condition of the parts before surface treatment.

- Process monitoring: Regularly checking the plating bath composition, temperature, and current density for plating; oven temperature and curing time for powder coating.

- In-process inspection: Visual inspection during the process and using techniques like thickness measurements to ensure coating uniformity.

- Final inspection: Thorough examination of the finished parts, often using techniques like salt spray testing, adhesion tests, and gloss measurements to verify compliance with specifications. Statistical process control (SPC) charts are used to track and analyze process data and identify trends that might indicate issues. This allows for preventative measures before defects arise.

Documentation is also crucial. Maintaining detailed records of all stages provides traceability and allows for continuous improvement.

Q 12. What are the safety precautions necessary when working with surface finishing chemicals?

Surface finishing chemicals can be hazardous, posing risks of skin irritation, respiratory problems, and even long-term health issues. Safety is paramount.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, respirators, and protective clothing as per the specific chemical’s safety data sheet (SDS).

- Ventilation: Ensure adequate ventilation in the work area to prevent inhalation of harmful fumes and mists.

- Waste disposal: Follow proper procedures for the disposal of spent chemicals and wastewater, complying with local environmental regulations.

- Emergency procedures: Establish clear emergency procedures, including eyewash stations and safety showers, and ensure all personnel are trained in their proper use.

- SDS Review: Before working with any chemical, review the SDS to understand the potential hazards and necessary safety precautions.

Regular training and awareness programs are essential to reinforce safe practices and ensure employee safety. The investment in safety is an investment in protecting the workforce and the environment.

Q 13. Explain the principles of passivation.

Passivation is a surface treatment that enhances the corrosion resistance of a metal, usually stainless steel, by forming a protective oxide layer. It’s like giving the metal a thin, invisible shield. This is achieved by exposing the metal to an oxidizing agent, often nitric acid. The process selectively oxidizes the surface, creating a thin, stable passive film that protects the underlying metal from further corrosion. The film’s composition and thickness depend on the metal, the oxidizing agent, and the process parameters. This thin oxide layer acts as a barrier, preventing the penetration of corrosive substances. The quality of the passivation layer can be measured using techniques like electrochemical testing.

Q 14. What is the difference between hard anodizing and soft anodizing?

Both hard and soft anodizing are electrochemical processes used to create a thicker oxide layer on aluminum, enhancing its corrosion resistance and wear resistance. The key difference lies in the thickness and hardness of the resulting oxide layer.

- Hard anodizing: Produces a thicker, harder oxide layer (typically 25-75 microns). This offers superior wear resistance, abrasion resistance, and dielectric strength. It’s often used in applications demanding high durability, such as aerospace components, firearm parts, and tools.

- Soft anodizing: Produces a thinner, less hard oxide layer (typically 5-25 microns). While still providing corrosion protection, it lacks the exceptional hardness of hard anodizing. It’s often preferred in applications where good corrosion resistance is needed but extreme hardness isn’t critical, for example, decorative applications where a smooth surface finish is desired.

In summary, hard anodizing prioritizes durability and wear resistance, while soft anodizing focuses on corrosion protection and aesthetics.

Q 15. How do you troubleshoot issues with adhesion in a coated component?

Troubleshooting adhesion issues in coated components requires a systematic approach. Poor adhesion often manifests as peeling, blistering, or flaking of the coating. The first step is to identify the root cause, which can stem from problems with the substrate, the pretreatment process, or the coating application itself.

Substrate Issues: Examine the substrate for contamination (oil, grease, oxides), insufficient surface roughness (lack of mechanical interlocking), or residual stresses. Cleaning methods may need to be reviewed or improved. For instance, inadequate degreasing can leave behind residues preventing proper adhesion. A simple visual inspection may reveal surface defects.

Pretreatment Problems: The pretreatment stage is crucial. Insufficient surface preparation, like inadequate etching or passivation, weakens the bond between the substrate and coating. For example, insufficient chromate conversion coating on aluminum can severely impact adhesion. Analyzing the pretreatment process parameters – time, temperature, chemical concentration – is essential.

Coating Application Issues: Problems in the coating application process itself, such as incorrect viscosity, improper curing temperature, or contamination of the coating material, can hinder adhesion. For example, air bubbles trapped within the coating can create weak points. Review the coating application parameters – spray pressure, nozzle distance, film thickness.

Troubleshooting Steps:

- Visual Inspection: Carefully examine the coated component for signs of poor adhesion.

- Substrate Analysis: Analyze the substrate for cleanliness, roughness, and surface composition using techniques like SEM or surface energy measurements.

- Pretreatment Evaluation: Verify that the pretreatment process parameters are correct and consistent.

- Coating Analysis: Analyze the coating for defects and composition. Techniques like cross-sectional microscopy can reveal adhesion weaknesses.

- Adhesion Testing: Conduct adhesion tests such as tape tests, pull-off tests, or scratch tests to quantify the adhesion strength.

By systematically investigating these areas, the specific cause of poor adhesion can be identified and corrected.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of surface tension and its relevance in surface finishing.

Surface tension is the tendency of liquid surfaces to shrink into the minimum surface area possible. Imagine a water droplet – its spherical shape minimizes the surface area. This is due to the cohesive forces between liquid molecules. Molecules within the liquid are surrounded by others, experiencing balanced attractive forces. However, molecules at the surface are only attracted inwards, creating a net inward force that causes the surface to contract.

In surface finishing, surface tension is critical because it dictates how a liquid coating will wet a substrate. High surface tension means the liquid will bead up and not spread easily, leading to poor wetting and inadequate coverage. Low surface tension promotes better wetting and coating uniformity. Think of trying to paint a surface that’s covered in grease: the paint beads up because the surface tension of the paint is higher than the adhesion force between the paint and the greasy surface.

Relevance in Surface Finishing: To achieve good coating adhesion and uniformity, it’s essential to match the surface tension of the coating and the substrate. Surface treatments, like cleaning and surface activation, are often employed to reduce the surface tension of the substrate, promoting better wettability. Surfactants, or wetting agents, can be added to the coating to lower its surface tension and improve its spreadability.

Q 17. What are the different types of surface testing methods you are familiar with?

Numerous surface testing methods are used to characterize surface properties relevant to finishing. These methods help to ensure quality and predict the performance of the finished product. The choice of method depends on the specific properties of interest.

Visual Inspection: A simple yet crucial first step. This checks for surface defects like scratches, cracks, or pitting.

Microscopy (Optical, SEM, AFM): Provides high-resolution images of the surface topography, allowing for detailed analysis of surface roughness, texture, and the presence of contaminants or defects.

Profilometry: Measures surface roughness quantitatively, providing numerical data for consistency and quality control.

Contact Angle Measurement: Determines the wettability of the surface by measuring the angle formed by a liquid droplet on the surface. This gives insight into surface energy and its suitability for coating.

Surface Energy Measurement: Quantifies the energy associated with the surface, indicating its ability to interact with other materials, crucial for adhesion prediction.

Adhesion Testing (Tape Test, Pull-off Test, Scratch Test): Evaluates the strength of the bond between the coating and the substrate.

Thickness Measurement (Electroplating thickness): Determines the thickness of the applied coating.

Corrosion Testing (Salt Spray Test, Electrochemical Impedance Spectroscopy): Assesses the corrosion resistance of the finished surface.

Hardness Testing: Measures the hardness of the coating, indicating its durability and resistance to wear.

Q 18. Describe the process of zinc plating.

Zinc plating is an electroplating process used to deposit a layer of zinc onto a metal substrate, typically steel or iron. This process provides corrosion protection, improved appearance, and enhanced lubricity. It’s a cost-effective method widely used in various industries.

The process typically involves the following steps:

Cleaning: The substrate is thoroughly cleaned to remove oil, grease, oxides, and other contaminants. This usually involves alkaline cleaning, followed by rinsing and sometimes acid pickling.

Surface Preparation: The substrate is further prepared to enhance adhesion. This may involve processes like etching or mechanical treatments to increase surface roughness.

Electroplating: The cleaned and prepared substrate is immersed in an electrolyte solution containing zinc salts. An electric current is passed through the solution, causing zinc ions to deposit onto the substrate as a metallic layer. The substrate acts as the cathode, while an anode (often a zinc bar) supplies the zinc ions.

Rinsing: After plating, the workpiece is rinsed thoroughly to remove residual electrolyte.

Post-Treatment (Optional): Depending on the application, additional treatments may be performed, such as passivation (to enhance corrosion resistance) or chromating (historically used for enhanced corrosion resistance but being phased out due to environmental concerns).

Types of Zinc Plating: Different types of zinc plating exist, offering varying properties. These include cyanide-based, chloride-based, and alkaline zinc plating, each having its own advantages and disadvantages related to cost, speed, and environmental impact. Modern processes increasingly favor chloride and alkaline alternatives, owing to the toxicity of cyanide.

Q 19. What are the advantages and disadvantages of different surface finishing methods?

The advantages and disadvantages of surface finishing methods vary significantly depending on the specific method, the substrate material, and the desired properties. Let’s consider some examples:

Electroplating (e.g., Zinc, Chrome, Nickel):

- Advantages: Good corrosion resistance, uniform coating, relatively low cost.

- Disadvantages: Can be environmentally unfriendly (depending on the plating solution), potential for hydrogen embrittlement (depending on the substrate and process).

Powder Coating:

- Advantages: Durable, wide range of colors and finishes, good corrosion resistance.

- Disadvantages: Requires specialized equipment, can be less uniform than electroplating.

Anodizing (for Aluminum):

- Advantages: Excellent corrosion resistance, hard wear-resistant surface, decorative.

- Disadvantages: Only applicable to aluminum and its alloys, can be more expensive than some other methods.

Painting:

- Advantages: Versatile, wide range of colors and finishes, relatively inexpensive.

- Disadvantages: Can be susceptible to chipping and scratching, requires careful surface preparation.

The selection of an appropriate method involves careful consideration of factors such as cost, desired properties (corrosion resistance, hardness, appearance), environmental impact, and the compatibility of the finishing method with the substrate material.

Q 20. How do you select the appropriate surface pretreatment for a specific substrate?

Selecting the appropriate surface pretreatment depends heavily on the substrate material and the chosen coating. The goal is to create a clean, compatible surface that promotes adhesion and prevents coating failure. Consider the following factors:

Substrate Material: Different materials require different pretreatments. For example, steel may require alkaline cleaning, acid pickling, and possibly phosphating to remove rust and scale and create a suitable surface for painting. Aluminum might require an alkaline etch to remove surface oxides before anodizing.

Coating Type: The type of coating also dictates the necessary pretreatment. For instance, powder coating often benefits from a chemical conversion coating to enhance adhesion, while electroplating requires meticulous cleaning and surface activation.

Desired Properties: The final desired properties of the finished component influence the choice of pretreatment. If corrosion resistance is paramount, a conversion coating might be necessary. If improved adhesion is the primary concern, surface roughening techniques might be used.

Examples of Pretreatment Methods:

Cleaning: Solvents, detergents, or ultrasonic cleaning to remove grease, oils, and other contaminants.

Acid Pickling: Removes oxides and scale from ferrous metals.

Alkaline Cleaning: Removes oils and grease.

Etching: Creates a rougher surface for improved mechanical bonding.

Chemical Conversion Coatings: Form a thin, protective layer on the substrate (e.g., phosphating, chromating).

The selection process often involves testing different pretreatments to determine the optimal approach for achieving the desired adhesion, corrosion resistance, and other performance characteristics.

Q 21. Explain the concept of corrosion resistance and its relation to surface finishing.

Corrosion resistance refers to a material’s ability to withstand degradation due to environmental factors, primarily oxidation (reaction with oxygen) or chemical reactions with other substances. Surface finishing plays a vital role in enhancing corrosion resistance. A protective layer, applied via various techniques, acts as a barrier between the substrate and the corrosive environment.

The Relation to Surface Finishing: Surface finishing methods create a protective layer or modify the surface properties of the substrate to improve its resistance to corrosion. For instance:

Electroplating: Deposits a layer of a corrosion-resistant metal (like zinc, nickel, or chromium) onto the substrate, acting as a sacrificial layer (in the case of zinc) or a barrier layer (in the case of nickel or chromium).

Anodizing: Forms a hard, protective oxide layer on the aluminum surface, significantly improving its resistance to corrosion.

Powder Coating: Provides a robust barrier layer that prevents moisture and corrosive substances from reaching the substrate.

Painting: Applies a protective film to isolate the substrate from the environment, though the effectiveness depends on the type of paint and its application.

The choice of surface finishing method should consider the specific corrosive environment (e.g., salt spray, humidity, industrial chemicals). For example, a zinc coating might suffice for mild outdoor exposure, while a more robust coating like nickel or stainless steel might be necessary in harsh industrial settings. The selection of appropriate surface finishing techniques to enhance corrosion resistance is crucial for extending the lifespan and reliability of components.

Q 22. What are the different types of coatings and their properties?

Coatings are applied to surfaces to enhance their properties, such as wear resistance, corrosion protection, aesthetics, or thermal insulation. The choice of coating depends heavily on the application and desired outcome. There’s a vast array, but some common types include:

- Electroplating: This involves depositing a thin layer of metal (like chromium, nickel, or zinc) onto a substrate using an electric current. It’s excellent for corrosion resistance and improved appearance. Think of the shiny chrome on a car bumper – that’s electroplating.

- Powder Coating: A dry powder is applied electrostatically and then cured in an oven. It’s durable, chip-resistant, and offers a wide range of colors and textures. You’ll find it on appliances, furniture, and even some automotive parts.

- Painting: A broad category encompassing various types of paints (e.g., acrylic, epoxy, polyurethane) applied by spraying, brushing, or dipping. Offers excellent aesthetic customization, but durability varies depending on the type of paint and the substrate.

- Anodizing: An electrochemical process used primarily on aluminum to create a thicker, more corrosion-resistant oxide layer. It’s known for its durability and is often seen on architectural aluminum and electronic components.

- Physical Vapor Deposition (PVD): A vacuum-based process that deposits thin films of materials onto substrates. This results in extremely hard, wear-resistant coatings, often used in tools and high-performance components. Think of the scratch-resistant coatings on some eyeglasses or watches.

- Chemical Vapor Deposition (CVD): Similar to PVD, but uses chemical reactions in a gas phase to deposit films. Offers high purity and precise control over film thickness and properties. Commonly used for creating protective layers on semiconductors.

The properties of each coating type vary significantly – some prioritize hardness, others corrosion resistance, while others emphasize aesthetics or specific functional properties. Selecting the right coating requires a thorough understanding of the application requirements and the properties of each coating type.

Q 23. Describe your experience with different surface finishing equipment.

My experience encompasses a wide range of surface finishing equipment, including:

- Electroplating systems: I’ve worked extensively with various electroplating tanks, rectifiers, and automated plating lines. This includes experience troubleshooting issues related to current density, solution chemistry, and anode/cathode configuration. For example, I once identified a problem with uneven plating caused by a faulty rectifier, resulting in a significant improvement in product quality.

- Powder coating equipment: I’m familiar with powder coating booths, spray guns, curing ovens, and pre-treatment systems. A particular challenge I overcame involved optimizing the oven temperature profile to ensure consistent curing across different part geometries, resulting in improved coating adhesion and durability.

- Painting systems: I’ve used various spray painting systems, including airless and electrostatic sprayers. My experience includes selecting appropriate paint types, optimizing spray parameters (e.g., air pressure, fluid viscosity), and maintaining the painting equipment to ensure consistent film thickness and finish quality.

- Anodizing equipment: I’m proficient in operating anodizing tanks, rectifiers, and sealing systems. I have a deep understanding of the chemical processes involved and the factors that influence the quality of the anodized layer. I once managed a project which included upgrading our anodizing line resulting in a 20% increase in efficiency.

- PVD and CVD systems: While my direct hands-on experience with these high-vacuum systems is limited, I possess a strong theoretical understanding of their operation and the parameters that control film properties. I’ve been involved in selecting and overseeing the use of external PVD/CVD service providers for specific projects.

My expertise isn’t limited to operation; I also have a strong background in equipment maintenance, troubleshooting, and process optimization.

Q 24. How would you manage a situation where a batch of parts fails quality control?

A batch failure in quality control is a serious issue, requiring a systematic approach to identify the root cause and implement corrective actions. My approach would involve the following steps:

- Immediate Containment: Isolate the failed batch to prevent further processing or shipment.

- Root Cause Analysis: A thorough investigation, potentially involving a cross-functional team, is needed. We would analyze the process parameters (temperature, time, chemical concentrations), equipment performance, raw materials, and operator procedures. Data analysis (statistical process control charts, etc.) would play a critical role here.

- Corrective Actions: Based on the root cause analysis, we would implement appropriate corrective actions. This could involve recalibrating equipment, adjusting process parameters, replacing faulty components, retraining operators, or changing raw material suppliers. We will always focus on a permanent fix, not just a temporary workaround.

- Verification: Before releasing a new batch, we’d run a series of verification tests to confirm that the corrective actions were effective and that the process is consistently producing parts that meet the quality specifications.

- Preventive Measures: To prevent future occurrences, we’d implement preventive measures. This could include enhanced monitoring, more frequent quality checks, and improved operator training. We would also document everything, learning from mistakes and improving our processes.

Throughout this process, clear communication with stakeholders (management, customers, etc.) is crucial to maintain transparency and build trust.

Q 25. Explain the importance of maintaining consistent process parameters.

Maintaining consistent process parameters is paramount in surface finishing to ensure consistent product quality. Inconsistencies lead to variations in coating thickness, appearance, adhesion, and overall performance. Think of it like baking a cake: if you don’t maintain the correct temperature and baking time, you won’t get a consistent result.

Consistent parameters ensure:

- Predictable Results: Meeting customer specifications consistently.

- Reduced Defects: Fewer rejects and rework, saving time and resources.

- Improved Efficiency: Optimized process flow and reduced downtime.

- Enhanced Reproducibility: Ability to consistently replicate results across different batches and production runs.

To maintain consistency, we rely on robust process control measures, including regular equipment calibration, precise monitoring of process variables (temperature, pressure, current, time), use of statistical process control (SPC) techniques, and rigorous quality checks at each stage of the process.

Q 26. How do you interpret surface finish specifications?

Surface finish specifications typically define the desired surface characteristics, such as roughness, texture, and appearance. These specifications are crucial for ensuring that the finished part meets the required functional and aesthetic requirements. They’re usually expressed using various standards and measurement techniques.

Interpreting these specifications involves understanding the terminology and units used. For example:

- Roughness (Ra): Often expressed in micrometers (µm) or microinches (µin), Ra represents the average roughness of the surface. A lower Ra value indicates a smoother surface.

- Surface texture: Describes the overall pattern and characteristics of the surface, including waviness, lay, and flaws. Visual inspection and profilometry are often used for evaluation.

- Appearance: Can be subjective but is often defined using visual standards or gloss measurements. The specification might specify a particular color, shine, or freedom from defects.

Understanding the implications of different surface finishes is critical. For instance, a very smooth surface might be required for reducing friction in a bearing, while a slightly rougher surface could be beneficial for improving adhesion of a subsequent coating. Misinterpreting the specifications can lead to production of non-conforming parts which could affect functionality and potentially lead to costly rework or failure of the end product.

Q 27. Describe your experience with different surface finishing standards (e.g., ASTM, ISO).

My experience encompasses several surface finishing standards, primarily ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards. These standards provide guidelines and specifications for various aspects of surface finishing, ensuring consistency and quality across different industries and geographical locations.

Examples of standards I frequently use include:

- ASTM B117 (Salt Spray Test): Used to evaluate the corrosion resistance of metallic coatings.

- ASTM D714 (Adhesion Test): Assesses the adhesion strength of coatings to the substrate.

- ISO 4287 (Surface Roughness): Defines parameters for measuring and specifying surface roughness.

- ISO 2896 (Salt Spray Test): Similar to ASTM B117, but with slightly different procedures and reporting requirements.

Understanding these standards is crucial for ensuring compliance, communicating effectively with clients and suppliers, and establishing consistent quality control procedures. The specific standard to use will be driven by the industry, material, and application involved.

Q 28. How do you stay updated with the latest advancements in surface finishing technologies?

Staying current in the rapidly evolving field of surface finishing technologies requires a multifaceted approach:

- Professional Organizations: Active membership in organizations like the Surface Finishing Society (SFS) or similar provides access to publications, conferences, and networking opportunities. These events offer valuable insights into the latest advancements and industry trends.

- Trade Publications and Journals: Regularly reading trade publications and journals keeps me updated on new materials, processes, and equipment. I typically subscribe to several industry-specific publications and search for relevant research papers online.

- Conferences and Workshops: Attending industry conferences and workshops allows me to directly engage with experts, learn about cutting-edge technologies, and network with peers.

- Online Resources: I actively utilize online resources such as webinars, technical articles, and manufacturer websites to learn about new technologies and advancements.

- Continuing Education: Participating in short courses and workshops helps to expand my knowledge and improve my skills in specific areas.

This combined approach ensures I stay informed about the newest materials, processes, and equipment to ensure I can select optimal techniques to deliver the required functionality and quality for any project.

Key Topics to Learn for Surface Finishing and Treatment Interview

- Electroplating: Understanding various electroplating processes (e.g., chrome, nickel, zinc), their applications, and the factors affecting plating quality. Consider the environmental impact and regulatory compliance aspects.

- Anodizing: Learn the principles of anodizing aluminum and other metals, including process parameters, surface characteristics achieved, and their applications in diverse industries (aerospace, automotive, architecture).

- Powder Coating: Explore the different types of powder coatings, application methods (electrostatic, fluidized bed), curing processes, and the advantages and limitations compared to other surface treatments.

- Surface Preparation: Master the importance of proper surface preparation techniques (cleaning, degreasing, pre-treatments) and their impact on the adhesion and durability of the final finish. Understand different cleaning methods and their suitability for various materials.

- Quality Control and Testing: Familiarize yourself with common testing methods used to assess the quality of surface finishes (e.g., adhesion testing, corrosion resistance testing, thickness measurement). Understand the importance of quality control in ensuring product performance and longevity.

- Surface Treatments for Specific Materials: Develop expertise in surface finishing techniques specific to different materials like plastics, ceramics, and composites. Understand the challenges and solutions related to each material.

- Environmental Considerations and Regulations: Be prepared to discuss environmentally friendly surface finishing practices and adherence to relevant regulations (e.g., waste management, emissions control). This demonstrates responsible and sustainable practices.

- Troubleshooting and Problem-Solving: Practice identifying and resolving common problems encountered in surface finishing processes (e.g., poor adhesion, pitting, discoloration). This showcases your practical skills and analytical abilities.

Next Steps

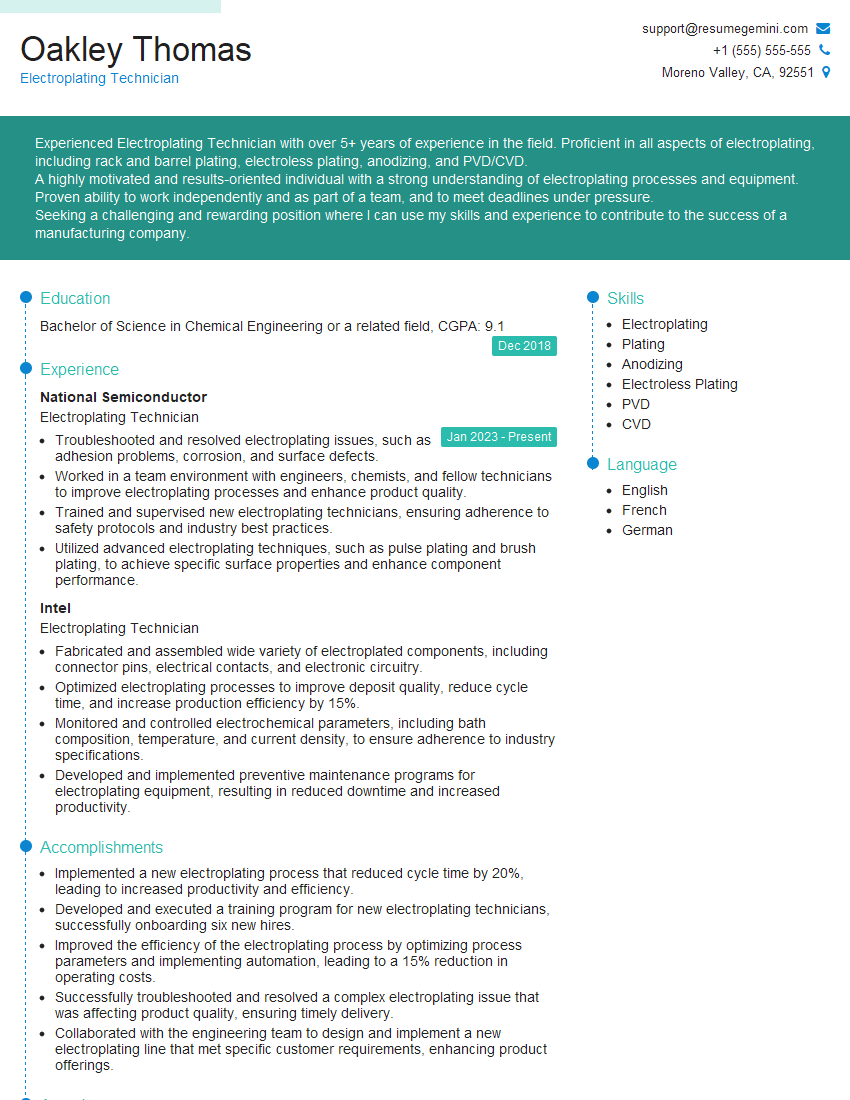

Mastering Surface Finishing and Treatment opens doors to exciting career opportunities in diverse industries. A strong understanding of these processes is highly sought after, leading to increased earning potential and career advancement. To significantly improve your job prospects, it’s crucial to create an Applicant Tracking System (ATS)-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the specific requirements of the Surface Finishing and Treatment field. Examples of resumes tailored to this industry are provided to guide you through the process. Invest time in crafting a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

There are no reviews yet. Be the first one to write one.