The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Survey Instrument Operation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Survey Instrument Operation Interview

Q 1. Describe your experience with different types of survey instruments (e.g., total stations, GPS receivers, levels).

My experience encompasses a wide range of survey instruments. I’m proficient with total stations, using them for precise distance and angle measurements in various terrains. I’m equally comfortable with GPS receivers, understanding their reliance on satellite signals for positioning and the importance of differential GPS for enhanced accuracy. Finally, my experience extends to levels, which are crucial for establishing elevations and creating level benchmarks. Each instrument has its strengths and weaknesses; for example, total stations excel in detailed site surveys, while GPS is better suited for large-scale mapping projects where quick positioning is essential, and levels are indispensable for precise elevation control. I’ve utilized all three in numerous projects, often integrating their data for a comprehensive survey.

Q 2. Explain the process of setting up and calibrating a total station.

Setting up and calibrating a total station is a meticulous process crucial for accurate measurements. It begins with proper centering over a known point, using a plumb bob or optical plummet. Leveling the instrument is the next step, typically using the built-in circular level and then the more precise leveling screws. This ensures the horizontal axis is truly horizontal. After leveling, the instrument is oriented using a known direction (e.g., from a previous benchmark), often by setting a backsight. Finally, calibration involves checking the internal parameters of the total station, such as the distance measurement system and the angle encoder. This may involve using a known distance or comparing measurements with a known angle. Regular calibration ensures consistent accuracy. I always follow manufacturer’s recommendations and document all steps carefully in my field notes. For example, if I’m working on a construction site, I’ll ensure my initial setup and calibration are rigorous as any inaccuracies here will compound through the entire survey.

Q 3. How do you ensure the accuracy of your survey measurements?

Accuracy in surveying is paramount. I ensure accuracy through several methods. First, I use properly calibrated instruments, regularly checked and maintained. Second, I employ rigorous field procedures, meticulously documenting all measurements and checks. This includes double-checking measurements, using multiple setups when appropriate, and performing redundant observations to identify potential errors. Third, I utilize appropriate surveying techniques for the task at hand. For example, choosing traversing over triangulation if the terrain is more suitable. Lastly, post-processing of data plays a vital role. I use appropriate software to analyze and adjust the raw data, accounting for systematic errors such as instrument limitations and atmospheric conditions. In essence, a multi-layered approach, from careful fieldwork to rigorous data processing, guarantees the highest accuracy.

Q 4. What are the common sources of error in survey measurements, and how do you mitigate them?

Survey measurements are susceptible to various errors. Instrumental errors, such as miscalibration or malfunctioning equipment, are mitigated through regular calibration and maintenance. Systematic errors, caused by factors like temperature or atmospheric refraction, are reduced through careful observation planning and data adjustments. Random errors, unpredictable variations in measurements, are minimized by taking multiple measurements and applying statistical methods. Human errors, such as misreading instruments or recording data incorrectly, are reduced by meticulous procedures, double-checking, and teamwork. For example, improper leveling of a total station can introduce a systematic error in all subsequent measurements, which careful leveling eliminates. I always create a checklist for every survey to help minimize the risk of common mistakes.

Q 5. Describe your experience with different types of surveying techniques (e.g., traversing, triangulation, leveling).

My experience includes various surveying techniques. Traversing involves establishing a network of connected points by measuring angles and distances. Triangulation uses angles measured from known points to determine the positions of other points, ideal for large areas. Leveling determines elevations by establishing a series of benchmark points along a level line. Each technique has its application; traversing is useful for establishing control networks, triangulation is suited for areas with limited access, and leveling is essential for construction and engineering projects. I’ve used all three extensively, often combining them in a single project to leverage their individual strengths and achieve a holistic survey result. For instance, a large construction site might need a control network established through traversing, with details refined using total station measurements, and elevations obtained through leveling.

Q 6. Explain the concept of coordinate systems and datums in surveying.

Coordinate systems and datums are fundamental in surveying. A coordinate system defines the location of points on the Earth’s surface using coordinates (e.g., latitude and longitude). A datum is a reference surface used for calculating those coordinates. Different datums exist because the Earth is not a perfect sphere. Using the wrong datum can lead to significant errors. For example, the North American Datum of 1983 (NAD83) and the World Geodetic System 1984 (WGS84) are common datums. Understanding and correctly specifying the coordinate system and datum used is crucial for ensuring that survey data is compatible and accurately represents the Earth’s surface. The importance of proper datum selection is often underestimated, but any error here ripples through all calculations. Mismatched datums lead to significant positional inaccuracies when merging data from different sources.

Q 7. How do you handle data processing and quality control in survey projects?

Data processing and quality control are crucial for ensuring the reliability of survey results. My process involves importing raw data into specialized software, editing and cleaning the data to remove outliers or obvious errors. Next, I perform data adjustments using appropriate methods (e.g., least squares adjustment) to account for systematic errors and improve overall accuracy. I then analyze the adjusted data to identify any remaining discrepancies or unexpected patterns. Finally, I generate reports and maps visualizing the data, thoroughly documenting the entire processing workflow. Throughout this process, quality control is integrated at every stage, checking for consistency, plausibility, and adhering to established accuracy standards. A well-documented processing workflow allows for traceability and enables others to audit my findings, boosting the overall confidence in the survey’s results. For instance, I regularly compare field measurements to my processed data and investigate any discrepancies immediately.

Q 8. What software are you proficient in for processing survey data (e.g., AutoCAD Civil 3D, ArcGIS)?

For processing survey data, I’m highly proficient in several software packages. My primary tools are GeoDa for spatial statistical analysis, crucial for identifying patterns and anomalies in survey data. I’m also adept at using R and its statistical packages (like ggplot2 for visualization and dplyr for data manipulation) for advanced statistical modeling and analysis. Finally, I frequently use QGIS, a powerful open-source GIS software, for spatial data visualization and manipulation, especially when integrating survey data with geographical information. AutoCAD Civil 3D and ArcGIS are less frequently used for my work unless dealing with specific infrastructure projects where CAD-based design is a significant element of the survey data analysis workflow.

Q 9. Describe your experience working with GPS receivers and post-processing techniques.

My experience with GPS receivers and post-processing techniques is extensive. I’ve worked extensively with various GPS receiver models, from single-frequency to high-precision dual-frequency receivers. My fieldwork has involved collecting data using both static and kinematic methods (I’ll detail the differences later). Post-processing involves using specialized software like RTKLIB or commercial packages like Trimble Business Center to process raw GPS data. This process corrects for atmospheric delays, satellite clock errors, and other sources of error, resulting in highly accurate coordinate positions. I routinely conduct quality checks on the processed data, verifying the accuracy and consistency of the results by examining the statistics generated during the post-processing workflow. For instance, I’ll check for cycle slips and outliers, and re-process data if necessary to improve accuracy. I’ve had success in using advanced techniques such as precise point positioning (PPP) for projects demanding centimeter-level accuracy.

Q 10. How do you deal with signal obstructions or multipath errors during GPS surveying?

Signal obstructions and multipath errors are common challenges in GPS surveying. Multipath occurs when the GPS signal reflects off surfaces like buildings or water before reaching the receiver, leading to inaccurate measurements. To mitigate these issues, I employ several strategies. First, I carefully select antenna locations to minimize obstructions. This involves physically scouting the area and assessing potential sources of interference. Second, I utilize techniques such as receiver averaging and cycle slip detection during post-processing to filter out erroneous data points. Third, for highly accurate work, I might employ techniques like using a choke ring antenna which minimizes the impact of multipath. For instance, when surveying in a dense urban environment, I may need to take multiple observations at slightly different locations to reduce the effect of signal reflections. Advanced receivers with advanced signal processing capabilities are utilized to further alleviate the problem. Additionally, proper data validation and quality control are indispensable in identifying and excluding data points affected by these issues.

Q 11. Explain the difference between static and kinematic GPS surveying.

The key difference between static and kinematic GPS surveying lies in how long the receiver occupies a single point. Static surveying involves setting up the receiver at a point for an extended period (typically several hours) to collect numerous measurements. This allows for the precise determination of position by averaging out many of the errors associated with GPS signal reception. Think of it like taking many pictures of the same object from slightly different angles, thereby improving the quality of the final image. This approach provides centimeter-level accuracy, crucial for base station establishment. Kinematic surveying, on the other hand, involves continuously moving the receiver while collecting data. The position is determined by comparing its measurements to a known reference point (base station), enabling real-time positioning. This is ideal for tasks such as mapping roads or pipelines, where speed is essential. The processing time for kinematic data is faster compared to static data. This method delivers higher accuracy compared to real-time kinematic methods which involve rapid data processing.

Q 12. Describe your experience with different types of leveling techniques (e.g., differential leveling, trigonometric leveling).

I have extensive experience in various leveling techniques. Differential leveling is a precise method for determining elevation differences between points. It involves setting up a level instrument between two points and taking readings to determine the height difference. It’s extremely accurate and commonly used for establishing benchmarks and creating highly accurate topographic surveys. This is like measuring the height of a building step-by-step using a ruler. Trigonometric leveling, however, uses angles and distances to determine elevation differences. This method is more suited for larger areas or inaccessible locations, where a direct leveling setup might be impractical. It’s less accurate but faster for large-scale projects. This is akin to using trigonometry to calculate the height of a mountain by measuring distances and angles from a known point. I also use methods like GPS leveling, particularly for extensive projects where speed and efficiency are prioritized. The choice of technique depends heavily on the project requirements, available resources, and desired accuracy.

Q 13. How do you ensure the proper maintenance and care of survey equipment?

Proper maintenance and care of survey equipment are paramount to ensure accuracy and longevity. This involves several key steps. Before and after each use, I conduct a thorough inspection of all equipment for any physical damage or signs of malfunction. This includes checking for water ingress and making sure the equipment is clean. I also diligently follow the manufacturer’s recommended procedures for calibration and maintenance; this often includes regular checks and adjustments. Storing equipment correctly, in a clean, dry environment, is crucial to prevent damage. For electronic equipment, maintaining proper battery storage and handling is critical. I regularly test the equipment against known standards and use reference points to ensure that the equipment’s measurements remain reliable. This proactive approach minimizes downtime and maintains the integrity of survey data.

Q 14. What are the safety procedures you follow while operating survey instruments in the field?

Safety is my top priority in fieldwork. I always follow established safety protocols and consider potential hazards. This includes conducting thorough site assessments before commencing work to identify potential risks such as uneven terrain, traffic hazards, and environmental conditions (like extreme weather). Wearing appropriate personal protective equipment (PPE) such as high-visibility clothing, safety footwear, and hard hats is mandatory. When working near roads or other traffic areas, I ensure appropriate traffic control measures are in place. If working near powerlines, I never proceed without verifying power is shut off. Using three-person teams when setting up instruments for large operations ensures additional safety and improves efficiency. These are more than rules: they’re fundamental for ensuring everyone’s well-being and completing projects safely.

Q 15. Describe your experience with working in various terrains and weather conditions.

My experience spans diverse environments, from dense urban areas with challenging accessibility to rugged mountainous terrains and remote locations. I’ve conducted surveys in extreme weather conditions, including heavy rain, snow, and high winds. For instance, during a recent project mapping a pipeline route through the Appalachian Mountains, we faced unexpectedly heavy snowfall, forcing us to adjust our schedule and employ additional safety measures like using specialized snowshoes and employing a weather monitoring system. This required careful planning and adaptation of our techniques to ensure both the safety of the team and the accuracy of the data collected. In coastal regions, I’ve accounted for tidal changes affecting benchmark stability. This adaptability is crucial for reliable survey outcomes in any condition.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected problems or equipment malfunctions during a survey?

Unexpected problems are inevitable in surveying. My approach is systematic and proactive. First, I prioritize safety. If equipment malfunctions or a hazardous situation arises, work stops immediately until the issue is resolved or the danger is mitigated. Troubleshooting involves a combination of practical skills and methodical checks. For example, if a total station malfunctions, I’ll first check battery levels, power connections, and ensure the instrument is correctly leveled and oriented. If the problem persists, I systematically investigate potential internal errors. If the malfunction is beyond my immediate expertise, I’ll contact the equipment manufacturer’s support. In the case of sudden weather changes, I always have contingency plans involving shelter, communication backup, and alternate survey strategies. Detailed field notes are critical for documenting these events and ensuring data integrity. For example, if I have to temporarily cease operations due to a downpour, I would record the time, location, and the state of the instrument in the field notes for later reference.

Q 17. Describe your experience with data collection and field note-taking procedures.

Data collection and field note-taking are fundamental to accurate surveying. My procedures follow a rigorous system emphasizing precision and clarity. I employ established protocols for recording data, including using standardized units, precise measurements, and clear descriptions. Field notes always include the date, time, location, weather conditions, instrument used, and any relevant observations. I’m adept at employing various data collection methods, including digital data loggers, paper field books, and utilizing the data recording capabilities of modern surveying equipment such as robotic total stations. For example, I meticulously record instrument settings, control point information, and any deviations from the planned survey route. My digital data is always backed up regularly to prevent loss. Data is meticulously checked for inconsistencies and errors during and after the collection phase. A robust system of checks and balances ensure the data is consistent and reliable.

Q 18. How familiar are you with surveying standards and regulations (e.g., ASTM, ACSM)?

I am thoroughly familiar with surveying standards and regulations, including those set by ASTM (American Society for Testing and Materials) and ACSM (American Congress on Surveying and Mapping). This familiarity informs my work on all aspects of a project, from planning and execution to data processing and final report generation. I understand the importance of adhering to standards regarding accuracy, precision, and data presentation. For example, I am well-versed in the standards for horizontal and vertical control surveys, coordinate systems, and data formats. I am also knowledgeable in relevant health and safety regulations that pertain to survey work. Understanding these standards ensures the quality and legal compliance of my work.

Q 19. How do you manage and organize large datasets from survey projects?

Managing large datasets is a crucial aspect of modern surveying. I use a combination of software and organizational skills to effectively manage and organize this data. My workflow typically involves importing data into GIS (Geographic Information System) software such as ArcGIS or QGIS. I use database management techniques to structure and organize the data systematically. This includes assigning unique identifiers to each data point and creating clear and consistent naming conventions for files and folders. Data is meticulously checked for outliers and errors before analysis. Regular backups and version control are critical to prevent data loss. I also utilize cloud-based storage solutions for secure storage and collaboration. In addition to software, I maintain detailed documentation outlining the data’s structure, format, and source, ensuring data integrity and traceability.

Q 20. What is your experience with using robotic total stations?

I have extensive experience operating robotic total stations. I’m proficient in setting up, calibrating, and using these instruments for various surveying tasks, including traversing, detail surveying, and construction staking. I am familiar with various brands and models, and I understand their functionalities, including automated target recognition, remote operation, and data processing capabilities. For example, I’ve used robotic total stations to perform high-accuracy topographic surveys in challenging environments. My skills extend to troubleshooting and maintaining these sophisticated instruments, maximizing their efficiency and accuracy in the field.

Q 21. Describe your experience with using RTK (Real-Time Kinematic) GPS technology.

My experience with RTK (Real-Time Kinematic) GPS technology is substantial. I’m proficient in setting up and operating RTK GPS receivers for high-precision positioning. I understand the principles of differential GPS corrections and their impact on accuracy. I’m familiar with different types of base station configurations and network RTK systems. I’ve utilized RTK GPS for various applications, including control surveys, topographic mapping, and construction staking. I know how to assess the quality of RTK data by examining the precision values (e.g., standard deviation of coordinate measurements) and assessing the impact of atmospheric conditions on signal quality. My expertise ensures precise and efficient data collection using this technology.

Q 22. How do you ensure the accuracy and reliability of your data collection process?

Ensuring accurate and reliable data collection in surveying is paramount. It involves a multi-pronged approach focusing on meticulous planning, precise execution, and thorough quality control.

- Pre-survey Planning: This includes defining clear objectives, selecting appropriate equipment, developing a detailed survey strategy (including control point selection and measurement techniques), and thorough crew training. A poorly planned survey is a recipe for disaster.

- Calibration and Maintenance: Regularly calibrating all equipment, such as total stations, GPS receivers, and levels, is crucial. This minimizes systematic errors. Maintaining a detailed equipment log with calibration dates and results is essential for traceability. I personally use a checklist to ensure nothing is overlooked.

- Redundancy and Cross-Checking: Employing multiple measurement techniques and comparing results is a powerful way to detect and correct errors. For example, using both GPS and total station measurements for critical points provides a valuable cross-check.

- Data Processing and Validation: Rigorous data processing using appropriate software (e.g., AutoCAD Civil 3D, Leica GeoMos) is critical. This involves identifying and correcting outliers and blunders. Automated quality control checks within the software are a must.

- Field Notes and Documentation: Maintaining meticulous field notes is essential. These notes should clearly describe the procedures, observations, and any potential issues encountered. Digital photography of key points and setup can provide valuable documentation as well.

For instance, in a recent project involving a large-scale land survey, we implemented a double-checking system where two surveyors independently measured critical points. This helped to catch a minor discrepancy in elevation measurements early on, preventing potential errors in the final deliverables.

Q 23. What is your experience in interpreting survey data and creating maps/plans?

Interpreting survey data and creating maps/plans is a core part of my expertise. My process typically involves several steps:

- Data Processing and Adjustment: This stage focuses on cleaning and adjusting the raw survey data to account for systematic and random errors. This often involves least-squares adjustment techniques to obtain the most probable values.

- Data Analysis: This involves evaluating the data to identify trends, patterns, and anomalies. For example, analyzing elevation data to identify potential drainage issues or analyzing boundary data to resolve potential conflicts.

- Map/Plan Creation: I utilize various software packages like AutoCAD Civil 3D, ArcGIS, and QGIS to create accurate and visually appealing maps and plans. This includes incorporating various data layers such as topography, boundaries, utilities, and other relevant features.

- Presentation and Reporting: Finally, I prepare clear and concise reports to communicate the findings of the survey, including graphical representations (maps, cross-sections, profiles) and detailed descriptions.

In a recent project for a new road construction, I used the survey data to create a detailed DTM, which was then used to design the road alignment, calculate earthworks volumes, and optimize drainage design. The resulting maps and plans significantly reduced construction time and costs.

Q 24. How familiar are you with different types of survey control points?

Survey control points are fundamental to any accurate survey. They provide a framework of known coordinates to which other measurements are referenced. Different types of control points exist, each suitable for different applications and accuracies:

- Geodetic Control Points: These are highly accurate points established using sophisticated techniques like GPS or precise traversing. They form the basis for large-scale mapping and engineering projects and are often established by government agencies.

- Local Control Points: These are points established within a smaller area, using techniques like traversing or resection. They are less precise than geodetic points but are sufficient for many projects.

- Control Points established by photogrammetry: these points are determined through image processing techniques using aerial or terrestrial photographs.

- Monumentation: The physical marker indicating the location of a control point (e.g., a concrete pillar, a marked stake). The quality and permanence of monumentation is critical for long-term accuracy.

Understanding the different types of control points and their accuracies is crucial for choosing the appropriate method for a given survey project. For example, a high-precision land surveying project might require geodetic control, while a smaller construction site survey might only require local control.

Q 25. What is your experience with the use of digital terrain models (DTMs)?

Digital Terrain Models (DTMs) are invaluable tools in modern surveying. My experience includes generating, processing, and analyzing DTMs for various applications.

- DTM Generation: I’m proficient in generating DTMs from various data sources, including LiDAR point clouds, contour lines, and ground survey data. Software such as ArcGIS, AutoCAD Civil 3D, and specialized point cloud processing software is used.

- DTM Analysis: I can extract various information from DTMs, including elevation, slope, aspect, and viewsheds. This information is used for things like drainage analysis, volume calculations, and site planning.

- DTM Applications: I’ve applied DTMs in various projects, including road design, flood modeling, and environmental impact assessments. In one case, I utilized a DTM to model the potential impact of a proposed development on local hydrology.

DTMs are not simply elevation models; they are powerful tools that can significantly improve the accuracy and efficiency of various design and analysis tasks. Understanding their capabilities and limitations is critical for effective application.

Q 26. Describe your experience with using different mapping software and techniques.

Proficiency in various mapping software and techniques is essential in my field. I’m experienced with a range of tools, including:

- AutoCAD Civil 3D: My expertise extends to utilizing this software for CAD drafting, surface modeling, and the creation of detailed design plans for engineering projects.

- ArcGIS: I’m skilled in using ArcGIS for geospatial data management, analysis, and cartography, including creating thematic maps, spatial analyses, and integrating various data layers.

- QGIS: I leverage QGIS for open-source GIS solutions, particularly when dealing with large datasets or when working on projects with limited software budgets.

- Other Software: I also have experience with Leica GeoMos, Carlson Survey, and other specialized survey processing software.

Choosing the appropriate software depends on the specific project needs. For example, AutoCAD Civil 3D is ideal for engineering design, while ArcGIS is better suited for spatial analysis and data management. The ability to adapt to different software and techniques is crucial for efficient project completion.

Q 27. How do you manage and maintain survey equipment inventory?

Managing and maintaining survey equipment inventory is crucial for ensuring the accuracy and efficiency of surveys. My approach involves:

- Regular Calibration and Maintenance: I implement a rigorous calibration and maintenance schedule for all equipment. This ensures accuracy and reduces the risk of equipment failure during surveys.

- Inventory Management System: I use a digital inventory management system (either a dedicated software or a spreadsheet) to track all equipment, including its location, condition, calibration dates, and repair history. This allows for easy tracking and identification of equipment.

- Preventive Maintenance: Regular cleaning and preventative maintenance checks are performed to prolong the life and improve the performance of equipment.

- Secure Storage: Equipment is stored securely to prevent theft, damage, and environmental degradation. This also includes proper storage of batteries and other sensitive components.

For example, I recently implemented a barcode system for tracking equipment, which significantly improved the efficiency of inventory management and reduced the risk of lost or misplaced equipment. A well-maintained inventory saves both time and money in the long run.

Q 28. What are your skills in using and interpreting survey drawings and plans?

Interpreting survey drawings and plans is a fundamental skill for any surveyor. My expertise includes:

- Understanding Symbols and Conventions: I’m proficient in interpreting various symbols, conventions, and annotations commonly used in survey drawings, including those specified in relevant standards (e.g., ANSI, ISO).

- Spatial Reasoning: I possess strong spatial reasoning abilities, allowing me to quickly understand the relationships between different features and elements on the drawings.

- Data Extraction: I can efficiently extract relevant information from survey drawings, such as coordinates, elevations, dimensions, and other critical data points. This information is used for various calculations and analyses.

- Plan Review and Identification of Errors: I can effectively review survey plans for completeness, accuracy, and compliance with relevant standards, identifying any potential discrepancies or errors.

In a recent project involving a property boundary dispute, my ability to interpret old survey drawings and identify inconsistencies helped to resolve the conflict and provide a clear and accurate boundary definition. A thorough understanding of survey plans saves time and prevents costly mistakes.

Key Topics to Learn for Survey Instrument Operation Interview

- Instrument Calibration and Maintenance: Understanding procedures for calibrating various survey instruments (e.g., total stations, GPS receivers, levels) to ensure accuracy and performing routine maintenance to prolong instrument lifespan. Practical application includes troubleshooting common malfunctions and performing preventative maintenance.

- Data Acquisition Techniques: Mastering efficient and accurate data collection methods using different survey instruments. This includes understanding the principles of various surveying techniques (e.g., traversing, leveling, GPS surveying) and their appropriate applications in different field conditions.

- Data Processing and Analysis: Familiarity with software used for processing survey data (e.g., AutoCAD Civil 3D, ArcGIS) and performing basic data analysis to identify and correct errors. This also includes understanding coordinate systems and projections.

- Health and Safety Procedures: Knowledge of relevant safety regulations and procedures for operating survey equipment in various environments. This includes understanding risk assessment and mitigation strategies.

- Survey Project Planning and Execution: Understanding the stages involved in a typical survey project, from planning and design to fieldwork and reporting. This includes familiarity with survey specifications and deliverables.

- Understanding Survey Errors and their Mitigation: Knowing the various sources of error in surveying (e.g., instrumental, human, environmental) and employing appropriate techniques to minimize their impact on the accuracy of survey results.

Next Steps

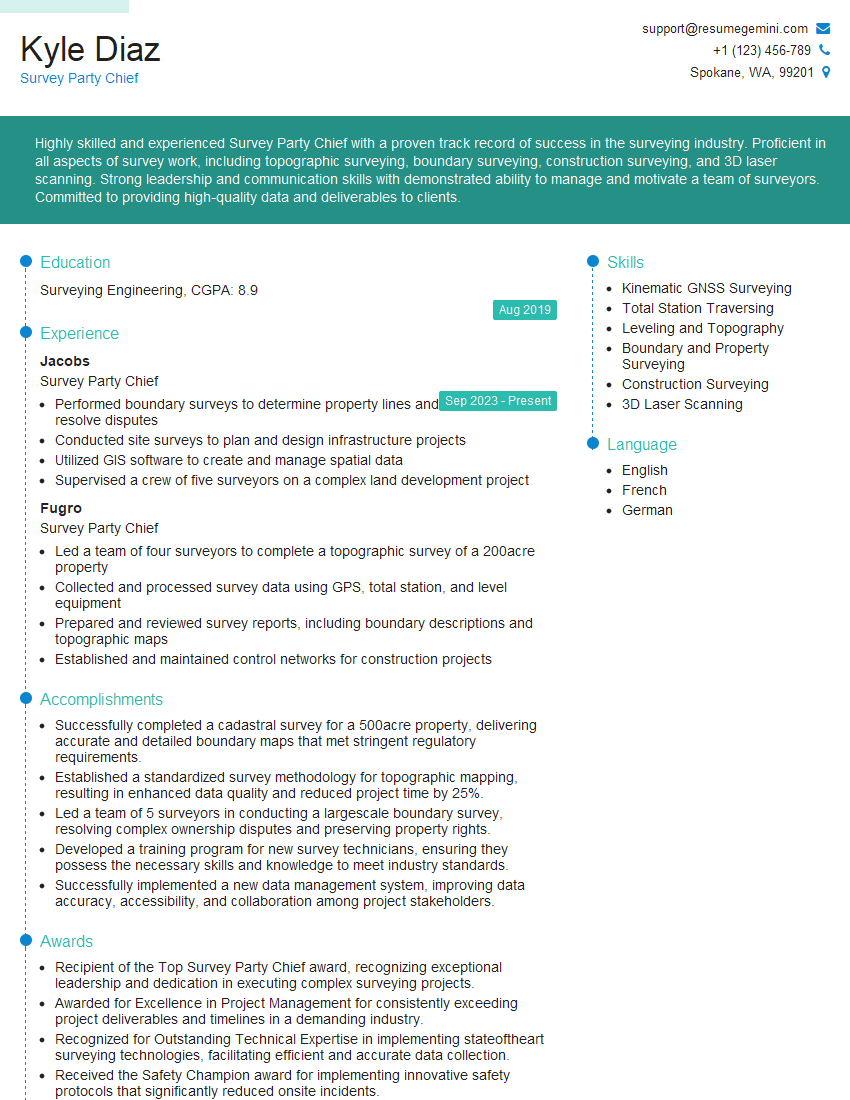

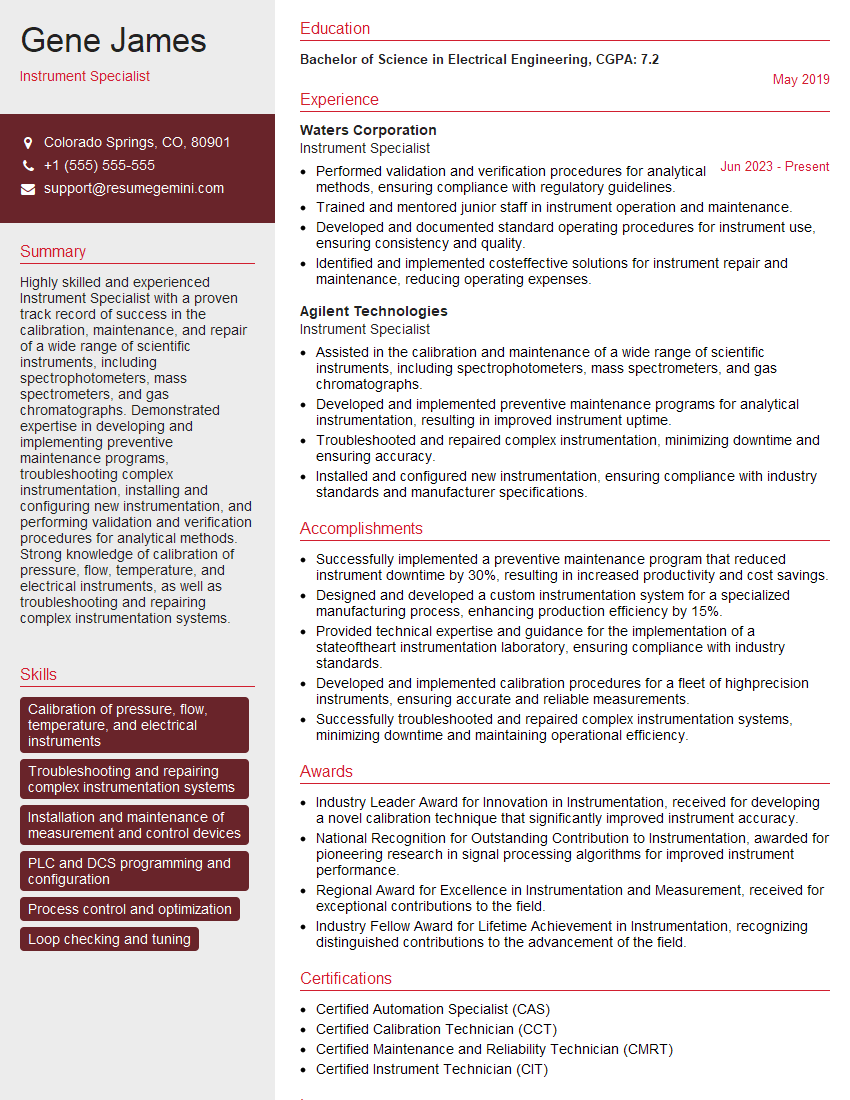

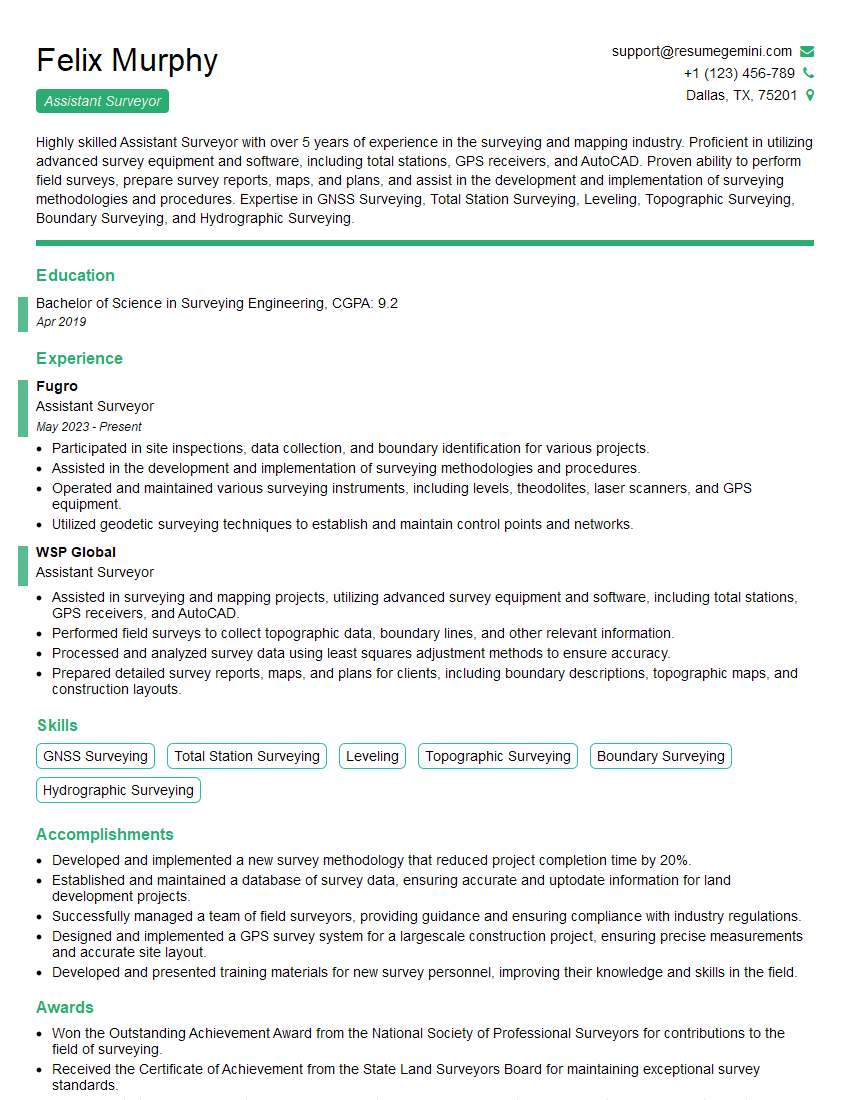

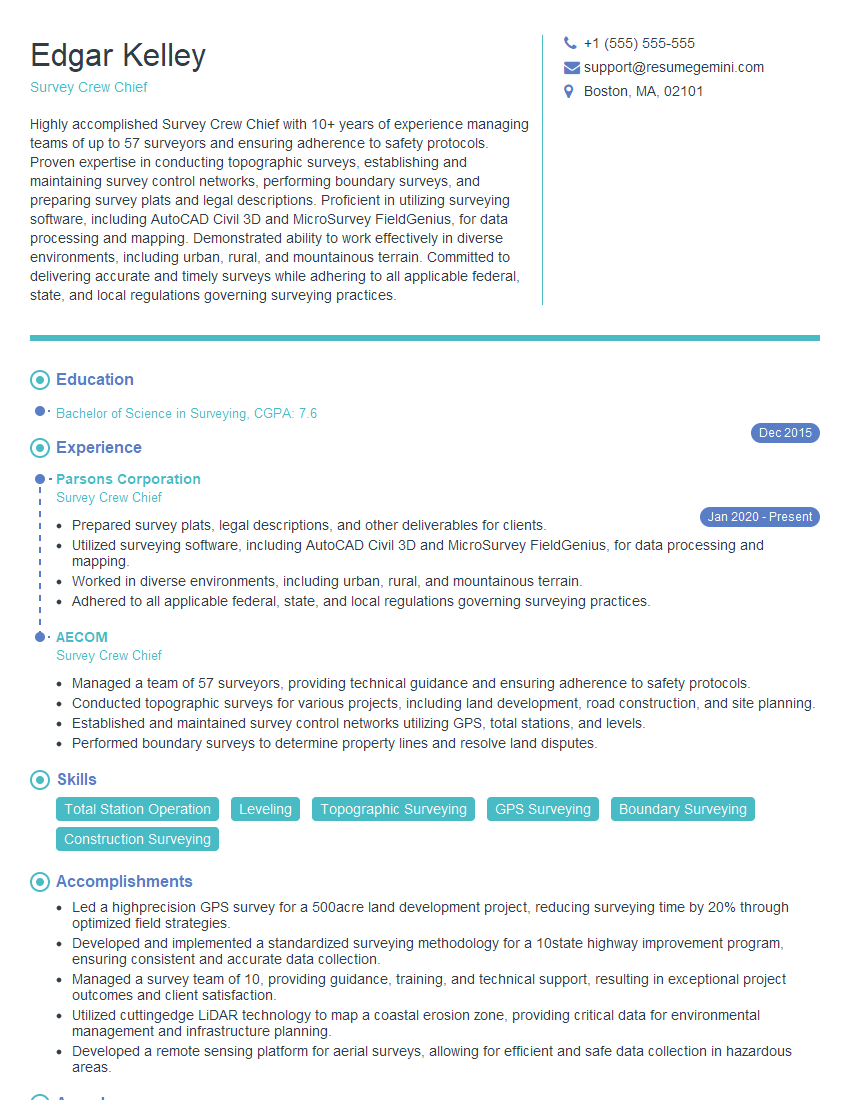

Mastering Survey Instrument Operation opens doors to exciting career opportunities in construction, engineering, land surveying, and more. A strong foundation in these skills significantly enhances your employability and opens paths to higher-paying roles and increased responsibility. To maximize your job prospects, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to Survey Instrument Operation to guide you in crafting a winning application. This will significantly improve your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO