The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Switchlist Management interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Switchlist Management Interview

Q 1. Explain the process of creating a switchlist.

Creating a switchlist involves meticulously planning the movement of railcars within a yard. It’s like choreographing a complex dance for dozens of railcars, ensuring they end up in the right place at the right time. The process starts with understanding the inbound and outbound requirements. We receive information about incoming trains, specifying the type and number of cars, and the destinations or tracks they need to go to. Simultaneously, we know the outgoing trains and their required car types. We then use this information to build a sequence of movements, assigning specific cars to specific tracks and ensuring efficient flow within the yard. This process often involves using specialized software, where we input the train information and the system helps optimize the switchlist to minimize conflict and maximize efficiency. For example, we might prioritize cars needing immediate dispatch or those bound for connecting trains departing soon.

- Gather Information: Collect data on incoming and outgoing trains, including car type, number, and destination.

- Sequence Movements: Create a step-by-step sequence for moving cars to designated tracks.

- Utilize Software: Employ switchlist software to optimize movements and minimize conflicts.

- Review and Verify: Double-check the switchlist for accuracy and consistency before distributing it.

Q 2. How do you prioritize tasks within a switchlist?

Prioritizing tasks in a switchlist is crucial for efficient yard operations. Think of it as managing a very busy airport; planes (trains) need to land (arrive), depart (leave), and be serviced (cars sorted). We prioritize based on several factors:

- Time Sensitivity: Cars bound for connecting trains with imminent departures take precedence. Delays here have cascading effects.

- Car Type/Destination: Perishable goods or high-value shipments often get priority to avoid spoilage or delays.

- Track Availability: If a specific track is needed for a larger train, cars destined for other tracks might be moved first to free up space.

- Blocking Instructions: Certain cars might need to be grouped together, prioritizing movements that enable this.

We use a combination of scheduling software and experience to determine the best sequencing. Sometimes, unforeseen circumstances, like a mechanical issue with a railcar, necessitate real-time adjustments to the priority list.

Q 3. What are the key metrics you use to evaluate switchlist efficiency?

Evaluating switchlist efficiency involves tracking several key metrics. These act as our scorecard for assessing performance and identifying areas for improvement. Imagine a factory production line; you constantly monitor output and efficiency to improve the flow.

- Switch Time: The total time taken to complete all movements specified in the switchlist.

- Car Movement Efficiency: The ratio of cars moved successfully versus total cars on the switchlist.

- On-Time Performance: The percentage of trains that depart according to schedule, directly related to switchlist execution.

- Yard Congestion: Measuring the average occupancy rate of tracks and the frequency of blockages or delays due to inefficient switchlist planning.

- Safety Incidents: Tracking near misses and accidents helps us identify weak points in our procedures and improve safety protocols.

By monitoring these metrics regularly, we can pinpoint bottlenecks and make data-driven adjustments to our processes.

Q 4. Describe your experience with switchlist software or systems.

My experience with switchlist software includes extensive use of both proprietary and commercial systems. I’ve worked with systems ranging from simple, spreadsheet-based tools to sophisticated, integrated yard management systems. These systems often integrate with train scheduling, track occupancy monitoring, and even maintenance scheduling. For example, I’ve used systems that generate switchlists automatically based on train manifests, optimizing for shortest routes and minimum conflicts. These systems offer features like real-time tracking, allowing for immediate responses to delays or unexpected events, and reporting dashboards to track key performance indicators. I’m comfortable with a range of software, from customizing basic systems to troubleshooting complex functionalities.

Q 5. How do you handle unexpected delays or changes to the switchlist?

Handling unexpected delays or changes requires adaptability and quick thinking. Imagine a traffic jam on a highway – you need to reroute efficiently. The first step involves identifying the cause of the delay – a mechanical issue, a signal malfunction, or even an unexpected increase in inbound traffic. Then we use real-time data from the yard management system to assess the impact on the switchlist. This might involve re-prioritizing tasks, re-routing cars, or even creating a completely revised switchlist. Effective communication is paramount during such events, coordinating with train crews, yardmasters, and dispatchers. In some situations, we might use the software’s simulation capabilities to test different scenarios before implementing changes.

Q 6. What is the significance of accuracy in switchlist creation?

Accuracy in switchlist creation is paramount; it’s the foundation of safe and efficient yard operations. An inaccurate switchlist can lead to several issues. Think of it like following a map to reach a destination. An error on the map can lead you to a completely different place!

- Collisions and Derailments: Incorrect car assignments can lead to collisions if two trains are directed to the same track. Misplaced cars can also lead to derailments.

- Delays and Bottlenecks: Incorrect car sequencing can create bottlenecks in the yard and cause delays in train departures.

- Lost or Misdirected Cargo: Mistakes can lead to cars being sent to incorrect destinations, resulting in delays, additional handling, and potentially damage or loss of goods.

- Increased Costs: Inefficiencies resulting from inaccurate switchlists increase labor costs and downtime.

Therefore, we employ rigorous verification and validation steps at every stage of switchlist creation to prevent errors.

Q 7. How do you ensure compliance with safety regulations when managing switchlists?

Ensuring compliance with safety regulations is non-negotiable. We strictly adhere to all relevant Federal Railroad Administration (FRA) and company safety regulations. This is our top priority – safety is paramount.

- Following Procedures: We strictly follow established procedures for creating and executing switchlists, including regular safety briefings and training.

- Employee Training: All personnel involved in switchlist creation and execution receive comprehensive training on safety procedures and regulations.

- Risk Assessments: We regularly conduct risk assessments to identify potential hazards and implement mitigation strategies.

- Regular Audits: We are subject to regular internal and external audits to ensure that our safety protocols are effective and up-to-date.

- Data Integrity: Maintaining accurate and up-to-date information is fundamental to safety, minimizing the risk of errors that could compromise safety.

Our commitment to safety goes beyond compliance; we strive for a culture of safety where every employee is empowered to report concerns and contribute to a safe working environment.

Q 8. Explain your experience with different types of railcars and their handling requirements.

My experience encompasses a wide range of railcars, from standard boxcars and gondolas to specialized units like tank cars, refrigerated cars (reefers), and intermodal containers. Handling each requires a nuanced understanding of their specific characteristics. For instance, tank cars carrying hazardous materials necessitate stringent safety protocols, including careful placement to avoid potential spills or impacts. Refrigerated cars need to be positioned near power sources to maintain their temperature controls. Intermodal containers, while generally robust, demand consideration of their weight distribution and secure fastening to prevent shifting during transit. I’m proficient in utilizing switchlist software that incorporates these unique characteristics, ensuring efficient and safe handling of diverse railcar types.

For example, I once managed a switchlist involving a shipment of highly sensitive electronics in reefer containers. Proper placement was crucial to maintain a stable temperature and avoid potential damage during the shunting process. I coordinated with the yardmaster and the train crew to ensure that these cars were positioned in a designated, secure area away from heavy machinery and other potentially damaging elements.

Q 9. How do you manage communication between different teams involved in switchlist execution?

Effective communication is paramount in switchlist execution. I leverage a multi-pronged approach involving regular meetings, digital communication tools, and clear documentation. Pre-execution meetings with the yardmaster, train crews, and other relevant personnel are essential to review the switchlist, address any potential issues, and establish clear roles and responsibilities. During execution, real-time communication via two-way radios ensures prompt resolution of unforeseen events. Post-execution debriefs serve to identify areas of improvement and refine future processes. I also utilize a centralized digital platform for switchlist distribution and tracking, providing all stakeholders with instant access to relevant information and updates.

Imagine a scenario where a critical car is misplaced. Immediate notification through radio communication, followed by prompt re-evaluation and adjustment of the switchlist, minimizes delays and potential safety hazards. The digital platform allows us to document the issue and its resolution efficiently, creating a comprehensive record for future analysis and improvement.

Q 10. How do you identify and resolve conflicts between different switchlists?

Conflicts between switchlists, often stemming from scheduling discrepancies or conflicting priorities, are addressed through a prioritized approach. First, I thoroughly analyze each switchlist, identifying the points of conflict. This involves examining arrival and departure times, car destinations, and resource allocation (e.g., track availability, locomotives). Then, based on urgency and operational constraints, I prioritize the switchlists. This often entails close collaboration with dispatchers, yardmasters, and train crews to negotiate a solution that minimizes delays and operational disruptions. The updated switchlist is then disseminated to all concerned parties through the previously mentioned digital communication platform, ensuring everyone operates with the most current information.

For example, if two switchlists require the same track at the same time, I might prioritize the one with a tighter deadline or involving time-sensitive cargo, potentially adjusting the other’s schedule with the collaboration of relevant stakeholders. This ensures smooth operations while mitigating the risk of delays and conflicts.

Q 11. Describe a time you had to optimize a switchlist under pressure.

During a severe winter storm, a significant backlog developed at our yard, creating a major bottleneck. Multiple switchlists were delayed, impacting several outbound trains. Under immense pressure to maintain the schedule and prevent further delays, I used my knowledge of the yard layout to identify alternative routes and strategies. I re-sequenced the cars, prioritizing the most time-sensitive shipments and utilizing less congested tracks. This involved close communication with the yard crew, utilizing their on-the-ground knowledge to adapt to changing conditions. By optimizing the sequence and utilizing available resources effectively, we managed to clear the backlog within a few hours, minimizing the overall impact of the storm.

This situation emphasized the importance of adaptability, strong communication, and a deep understanding of the yard’s operational capacity under pressure. By thinking strategically and collaboratively, we successfully mitigated a potential crisis.

Q 12. What are the potential consequences of errors in switchlist management?

Errors in switchlist management can have severe consequences, ranging from operational inefficiencies to significant safety risks. An inaccurate switchlist can lead to misplaced cars, causing delays and impacting schedules. This can disrupt supply chains, leading to financial losses for involved companies. More critically, incorrect switchlists can lead to unsafe track configurations, increasing the risk of derailments, collisions, or other accidents that can cause damage to property, injury, or even fatalities. Furthermore, inaccurate information can cause a loss of confidence amongst stakeholders which could hamper long term cooperation.

For example, a missing car in a switchlist might result in its unexpected presence on a main track, potentially leading to a collision with an oncoming train. These repercussions highlight the critical need for accurate and meticulous switchlist management.

Q 13. How do you handle a situation where a switchlist is incomplete or inaccurate?

Upon discovering an incomplete or inaccurate switchlist, I immediately initiate a verification process. This involves cross-referencing the switchlist with available data, including train manifests, tracking information, and communication with the originating source. If inconsistencies are found, I investigate the cause of the error, attempting to locate the missing information or correct the inaccurate data. If the problem can’t be quickly resolved, I escalate the issue to the relevant supervisors, clearly outlining the discrepancy and its potential impact. In the meantime, a temporary workaround or adjusted switchlist might be implemented, ensuring the continued movement of trains with safety as the priority. A thorough investigation is always carried out to prevent similar issues from occurring in the future.

For example, if a car’s destination is missing, I would immediately contact the originating yard or shipping company to clarify the intended destination, ensuring that the car is correctly routed. This prevents the car from being placed on an incorrect track or causing a delay in the shipment.

Q 14. How familiar are you with various track layouts and their impact on switchlist creation?

I possess a strong understanding of various track layouts and their impact on switchlist creation. My experience spans different yard configurations, including hump yards, flat yards, and other specialized facilities. Each layout presents unique operational challenges and influences the optimal switchlist design. For example, a hump yard’s gravity-based sorting system requires careful consideration of car type and weight distribution to ensure smooth and efficient movement. Flat yards, on the other hand, rely on locomotive power for switching, requiring a different approach to sequencing and resource allocation. I utilize specialized software that incorporates track layouts and constraints into the switchlist generation process, helping to optimize efficiency and minimize switching movements.

Understanding the nuances of each yard layout is crucial for creating efficient and safe switchlists. For instance, knowledge of track gradients and curvature is essential for avoiding potential derailments, especially when handling heavier or longer railcars. This ensures that the switchlist is optimized not only for efficiency but also for safety.

Q 15. Explain your understanding of train classification and its relation to switchlists.

Train classification is the process of grouping railcars with similar destinations or characteristics into specific trains. This is crucial for efficient yard operations and directly impacts switchlists. A switchlist is essentially a detailed instruction manual created based on this classification. It dictates the precise movements needed to assemble the correctly classified cars into their respective outbound trains.

For example, imagine a yard receiving cars destined for Chicago, New York, and Los Angeles. The classification process would sort these cars into three separate groups. The switchlist then specifies which cars need to be moved from which tracks to which other tracks to form the Chicago-bound, New York-bound, and Los Angeles-bound trains. Without accurate classification, the switchlist would be chaotic and inefficient, leading to delays and potential errors.

Career Expert Tips:

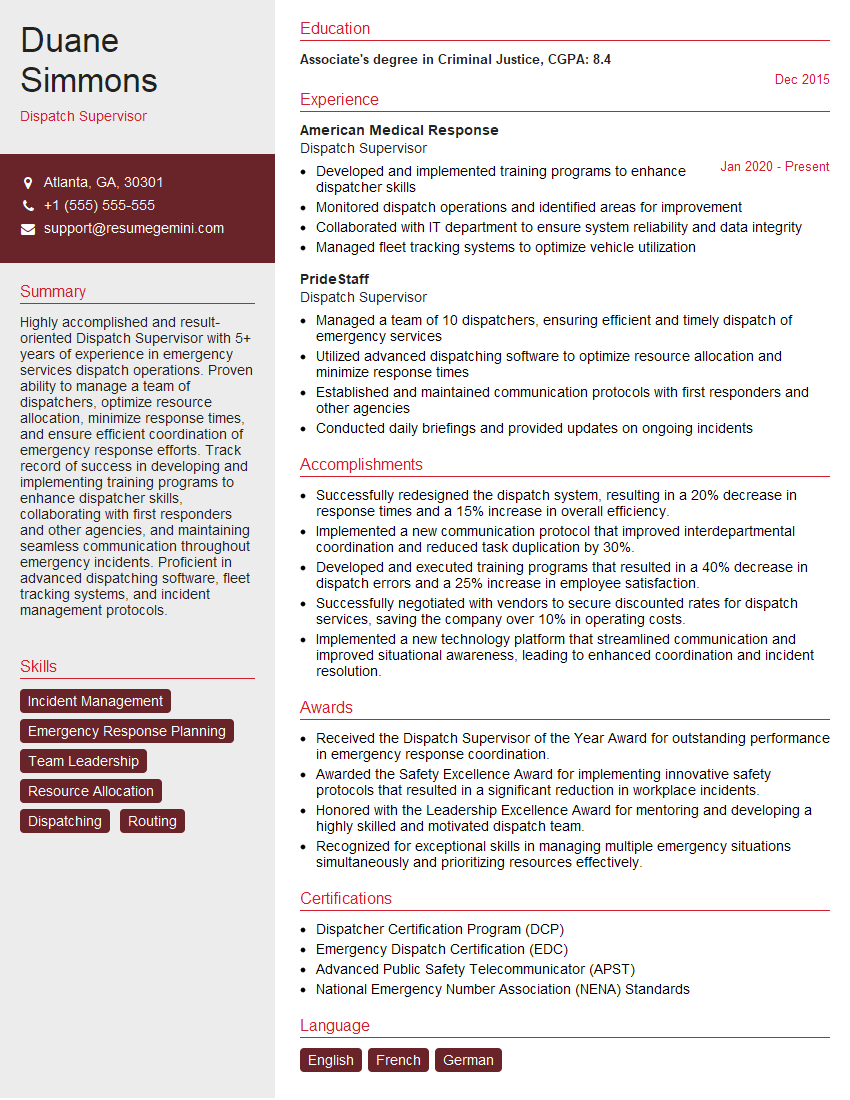

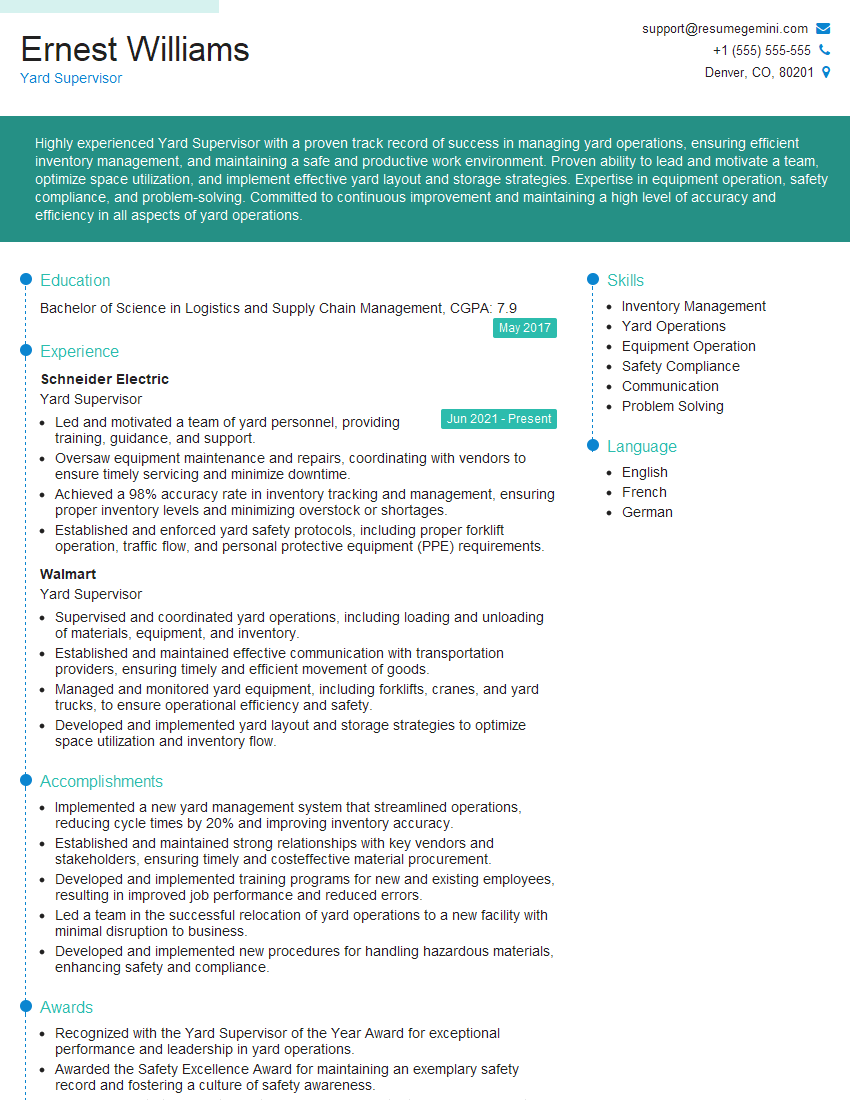

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you incorporate real-time data into switchlist management?

Real-time data integration is fundamental to modern switchlist management. This involves leveraging data feeds from various sources, such as train tracking systems (providing arrival and departure times), yard sensors (monitoring track occupancy), and inbound/outbound manifest data (providing details about the cars themselves). This information is fed into the switchlist creation and optimization process.

For instance, if a sensor detects an unexpected delay on a specific track, the system can automatically adjust the switchlist to minimize disruption. Similarly, if an inbound train arrives earlier than expected, the system can adjust the schedule and optimize the sequence of switching operations to accommodate the early arrival. This dynamic adjustment dramatically reduces waiting times and improves overall yard efficiency.

Q 17. What strategies do you use to minimize idle time in the yard?

Minimizing idle time requires a multi-pronged approach. Firstly, accurate forecasting of arrival and departure times is essential. Secondly, efficient switchlist design is critical, sequencing operations to minimize conflicts and unnecessary movements. Finally, effective communication and coordination between yard personnel are vital.

- Optimized Switchlist Sequencing: We use algorithms to sequence switchlist tasks to minimize conflicts and ensure that locomotives and crews are used efficiently.

- Predictive Maintenance: Proactive maintenance of yard equipment reduces downtime caused by unexpected breakdowns.

- Real-time Monitoring and Adjustment: Constant monitoring allows for quick responses to unexpected delays, minimizing their impact on the overall schedule.

- Crew Scheduling and Management: Proper crew scheduling ensures that personnel are available when needed, avoiding delays due to staffing shortages.

For example, by strategically grouping cars with similar destinations, we minimize the number of times a locomotive needs to travel across the yard, significantly reducing idle time.

Q 18. Describe your approach to training new personnel on switchlist procedures.

Training new personnel involves a combination of classroom instruction, on-the-job training, and simulated exercises. We begin with a thorough overview of yard operations, including safety procedures and the importance of accurate switchlist execution.

- Classroom Instruction: Covers switchlist interpretation, yard terminology, and safety regulations.

- On-the-Job Training: Mentorship from experienced switchers allows for hands-on learning and real-world application of knowledge.

- Simulated Exercises: Using software or physical models, we simulate various scenarios, allowing trainees to practice decision-making under pressure.

We emphasize the importance of attention to detail, problem-solving skills, and effective communication. We also use scenario-based training to prepare them for unusual situations or emergencies.

Q 19. How do you contribute to continuous improvement in switchlist processes?

Continuous improvement is an ongoing process. We regularly review switchlist performance data, identifying bottlenecks and areas for optimization. We also actively seek feedback from yard personnel, as they often identify inefficiencies that are not immediately apparent from data analysis.

- Data Analysis: Regular review of key performance indicators (KPIs), such as dwell time, switching efficiency, and on-time performance, allows us to identify areas for improvement.

- Process Mapping: Visualizing the entire switchlist process helps identify redundancies and opportunities for simplification.

- Technology Upgrades: Staying current with the latest technologies in train management systems and yard automation is crucial for continuous improvement.

- Feedback Mechanisms: Regularly soliciting feedback from yard crews provides valuable insights into practical challenges and potential solutions.

For example, analyzing dwell time data might reveal a specific track consistently experiencing congestion. This insight could lead to changes in the switchlist or yard layout to improve flow.

Q 20. What are your skills in using relevant software and technology (e.g., TMS)?

I am proficient in several Transportation Management Systems (TMS) including [mention specific systems, e.g., SAP TM, Oracle Transportation Management]. My skills encompass switchlist generation, scheduling optimization, real-time monitoring, and reporting. I’m also experienced with yard management systems that integrate with TMS to provide a holistic view of yard operations. Beyond TMS, I’m adept at using data analytics tools to extract insights from operational data and create visualizations that aid decision-making.

For example, I can use a TMS to generate optimized switchlists based on real-time data, then analyze the results to identify opportunities for further efficiency gains. This involves using both the built-in reporting functionality of the TMS and external data analysis tools to gain a deeper understanding of operational performance.

Q 21. How do you manage the flow of information related to the switchlist?

Managing switchlist information flow requires a structured and transparent approach. This involves using a combination of digital and physical methods to ensure timely and accurate communication to all relevant parties.

- Digital Platforms: Using a central TMS or yard management system ensures that all switchlists are readily accessible to authorized personnel.

- Automated Notifications: Automated alerts notify relevant parties of any changes or delays to the switchlist.

- Clear Communication Protocols: Establish clear communication channels to address any discrepancies or questions promptly.

- Version Control: Implement a version control system to track changes and ensure everyone is working with the latest version of the switchlist.

For example, using a TMS with automated notifications ensures that the train crew receives updated switchlists in real-time, reducing the potential for errors and delays. A robust digital system minimizes ambiguity and ensures everyone is on the same page.

Q 22. Describe your experience using various communication methods during switchlist operations.

Effective communication is the backbone of successful switchlist management. My experience encompasses a variety of methods, tailored to the specific situation and individuals involved. This includes:

Radio communication: Essential for real-time updates during yard operations. I’m proficient in using railroad radios to relay information quickly and accurately to locomotive engineers and yard crews, confirming car placements and addressing any immediate issues. For example, I might use the radio to inform the engineer about a slight adjustment needed to couple cars properly.

Computer-based systems: I’m highly experienced with various switchlist management software, using them to generate, distribute, and track switchlists electronically. This allows for seamless communication and record-keeping. The software often provides features for instant messaging or notifications to key personnel about changes or delays.

Phone calls: Phone calls are crucial for coordinating with supervisors, other departments (like train dispatch), and external stakeholders involved in the transportation process. For instance, if there’s a delay due to a mechanical issue, I use the phone to inform relevant parties and coordinate a solution.

Written communication: Formal documentation, including switchlist reports and incident reports, is essential for maintaining a clear audit trail. This helps in identifying trends, improving processes, and providing evidence for investigations if needed.

Choosing the right communication method ensures clear, timely, and effective information flow, minimizing errors and maximizing safety.

Q 23. How do you handle discrepancies between the planned switchlist and actual yard activities?

Discrepancies between the planned switchlist and actual yard activities are inevitable. My approach involves a systematic process to identify, investigate, and resolve these differences:

Immediate identification: Through real-time monitoring of yard operations (using software tracking, radio communication, and on-site observation), I promptly identify any deviations from the planned switchlist.

Root cause analysis: Once a discrepancy is identified, I investigate the root cause. This could involve factors like incorrect car identification, equipment malfunctions, unexpected delays, or human error. For instance, a discrepancy might be due to a car being misidentified in the yard or a delay caused by unexpected congestion.

Corrective actions: Based on the root cause analysis, I implement corrective actions, which could involve re-sequencing the switchlist, adjusting the yard plan, or providing additional instructions to the yard crew. It might require me to manually update the switchlist in the system to reflect the actual yard situation.

Documentation: All discrepancies, investigations, and corrective actions are meticulously documented. This documentation serves as a valuable resource for future reference and continuous improvement.

Communication: I communicate the discrepancy and resolution to all relevant parties to ensure everyone is informed and synchronized. This avoids confusion and ensures the smooth continuation of operations.

By proactively addressing discrepancies, I maintain the accuracy of the switchlist and prevent further complications.

Q 24. What are some common challenges in switchlist management and how do you address them?

Switchlist management presents various challenges. Some common ones include:

Inaccurate or incomplete data: This can lead to delays, misplacements, and safety risks. To mitigate this, I implement robust data validation checks and utilize data cleansing techniques before creating switchlists.

Unexpected delays or disruptions: These can be caused by equipment malfunctions, weather conditions, or unforeseen track issues. I manage these by having contingency plans and effective communication strategies with relevant personnel.

Communication breakdowns: Misunderstandings or lack of clarity can lead to errors. I use multiple communication channels, regularly verify information, and maintain clear, concise communication protocols.

Limited resources: Sometimes, yard space, equipment, or personnel might be limited. I prioritize tasks, optimize yard operations, and collaborate with other departments to find efficient solutions. This may include creative re-sequencing of the switchlist based on available resources.

Safety concerns: Ensuring the safe handling of cars is paramount. I enforce strict safety protocols, provide clear instructions, and monitor yard activities closely.

Addressing these challenges requires a proactive and adaptable approach, combining careful planning, robust systems, and effective communication.

Q 25. How do you ensure the integrity and security of switchlist data?

Data integrity and security are critical in switchlist management. My strategies involve:

Access control: Restricting access to switchlist data based on roles and responsibilities using user authentication and authorization mechanisms within the software. Only authorized personnel should have access to create, modify, or delete switchlists.

Data validation: Implementing strict data validation rules to prevent entry of incorrect or inconsistent data. This might include checks for valid car numbers, destination codes, and other critical information.

Regular backups: Creating regular backups of switchlist data to protect against data loss due to system failures or accidental deletions. A robust backup and recovery plan is a necessity.

Data encryption: Using encryption to protect switchlist data during transmission and storage, safeguarding sensitive information from unauthorized access.

Audit trails: Maintaining detailed audit trails of all switchlist creation, modification, and access activities to track changes and identify any potential security breaches.

Software updates: Keeping switchlist management software up to date with the latest security patches to protect against vulnerabilities.

By implementing these measures, I ensure the confidentiality, integrity, and availability of switchlist data.

Q 26. How do you balance efficiency with safety in switchlist management?

Balancing efficiency and safety is paramount. This is achieved through a multi-faceted approach:

Optimized switchlist creation: Designing switchlists that minimize car movements and maximize efficiency while adhering to safety regulations. For example, grouping cars destined for the same location reduces unnecessary switching.

Clear communication and instructions: Providing clear, concise, and unambiguous instructions to yard crews, emphasizing safety protocols. Visual aids such as maps and diagrams can enhance understanding.

Regular safety checks and training: Conducting regular safety checks and providing ongoing training to yard crews on safe switching procedures and risk management. This ensures they understand safety procedures and best practices.

Technological advancements: Leveraging technology such as automated switch machines and real-time tracking systems to improve efficiency while enhancing safety. This can increase the speed of operations while reducing the chances of human error.

Continuous improvement: Regularly reviewing switchlist processes and identifying areas for improvement to enhance both efficiency and safety. Regular audits and feedback sessions can identify problem areas.

Safety is never compromised for the sake of efficiency. Both are equally important and must be integrated into every aspect of switchlist management.

Q 27. What is your experience with different switchlist formats and their pros and cons?

I have experience with various switchlist formats, including:

Printed switchlists: Traditional paper-based format. Pros: readily available offline, simple to understand. Cons: prone to errors, difficult to update, inefficient for large yards.

Spreadsheet-based switchlists: Using software like Excel or Google Sheets. Pros: easy to create and share, some basic data manipulation possible. Cons: lacks advanced features, prone to data inconsistencies, difficult to track revisions.

Dedicated switchlist management software: Specialized software designed for switchlist creation, distribution, and tracking. Pros: robust features, advanced data validation, improved accuracy, real-time tracking, better collaboration. Cons: requires training, higher initial cost.

The choice of format depends on the size and complexity of the yard, available resources, and technological capabilities. Modern dedicated software provides the most efficient and accurate approach, although a transition to this requires initial investment in software and training.

Q 28. How do you prioritize tasks when dealing with multiple concurrent switchlists?

Prioritizing tasks with multiple concurrent switchlists requires a structured approach:

Categorization: I categorize switchlists based on urgency, priority, and due dates. This might involve separating time-sensitive deliveries from less critical movements.

Resource allocation: I assess available resources (locomotives, crews, tracks) and allocate them efficiently to handle multiple switchlists concurrently. This requires careful planning to avoid conflicts and bottlenecks.

Communication: I maintain clear communication with all involved parties to keep them informed of priorities and any potential delays or conflicts. This helps avoid any confusion or misunderstandings.

Dynamic adjustment: I continuously monitor progress and adapt the prioritization as needed based on real-time events, such as unexpected delays or changes in resource availability. Flexibility is key in handling dynamic situations.

Software support: I use the scheduling features within the switchlist management software to aid in prioritizing and tracking progress across multiple switchlists.

Effective prioritization ensures that all switchlists are processed efficiently and on time, minimizing delays and maximizing resource utilization.

Key Topics to Learn for Switchlist Management Interview

- Understanding Switchlist Fundamentals: Grasp the core concepts of switchlists, their purpose within railway operations, and the different types of switchlists used.

- Practical Application: Creating and Interpreting Switchlists: Learn how to create accurate and efficient switchlists based on various scenarios, including train schedules, track layouts, and car assignments. Practice interpreting existing switchlists to identify potential problems or inefficiencies.

- Safety Procedures and Regulations: Familiarize yourself with safety protocols and regulatory compliance related to switchlist management. Understand how to avoid errors that could compromise safety.

- Technology and Switchlist Management Systems: Explore the role of technology in modern switchlist management, including software applications and automated systems. Understand their benefits and limitations.

- Problem-Solving and Troubleshooting: Develop your ability to identify and resolve issues related to switchlist discrepancies, delays, and conflicts. Practice using logical thinking and analytical skills to find efficient solutions.

- Communication and Teamwork: Understand the importance of clear and effective communication with various stakeholders, including train crews, dispatchers, and yardmasters. Practice collaborating effectively in a team environment.

- Optimization Techniques: Explore strategies for optimizing switchlist creation to minimize delays, improve efficiency, and reduce operational costs.

Next Steps

Mastering Switchlist Management opens doors to exciting career opportunities within the railway industry, offering a path towards increased responsibility and higher earning potential. An ATS-friendly resume is crucial for showcasing your skills and experience effectively to potential employers. To enhance your job prospects, we strongly encourage you to leverage the power of ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides you with the tools and templates necessary to craft a compelling resume that highlights your expertise in Switchlist Management. Examples of resumes tailored to Switchlist Management are available to guide your process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO