Cracking a skill-specific interview, like one for Tank Truck Driving Experience, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Tank Truck Driving Experience Interview

Q 1. Describe your experience with pre-trip inspections of tank trailers.

Pre-trip inspections of tank trailers are crucial for safety and legal compliance. They’re essentially a thorough check of the vehicle before I even start the engine. Think of it like a doctor giving you a check-up before a marathon – you want to ensure everything is in optimal condition.

- Exterior Check: I start with a visual inspection of the tires, wheels, brakes, lights, and reflectors, checking for any damage, leaks, or wear. I look for cracks or damage to the tank itself, paying close attention to welds and seams. I also check the condition of the valves and fittings, ensuring they’re secure and not leaking.

- Interior Check: Next, I’ll check the tank’s interior for any signs of contamination or residue from previous loads. This is especially critical when dealing with hazardous materials. I also inspect the tank’s gauges, ensuring they’re functioning correctly to monitor pressure and levels.

- Documentation: Finally, I meticulously document all my findings in the pre-trip inspection report, noting any issues or repairs needed. This documentation is vital for legal and safety reasons. If I find something amiss, I won’t proceed until it’s addressed.

For instance, once I found a small crack in a weld during a pre-trip. I immediately reported it and the trailer was taken out of service for repair. This prevented a potential accident and leak of hazardous material.

Q 2. Explain the proper procedures for loading and unloading hazardous materials.

Loading and unloading hazardous materials requires strict adherence to safety protocols and regulations. It’s not just about moving the product; it’s about doing so safely and responsibly. Think of it like handling explosives – careful planning and execution are paramount.

- Proper PPE: First, I always don appropriate personal protective equipment (PPE), including respirators, gloves, and safety glasses, based on the specific hazard class of the material.

- Grounding and Bonding: Before loading or unloading, I ensure the tank trailer and the loading/unloading facility are properly grounded and bonded to prevent static electricity buildup, which could lead to ignition in flammable material transport.

- Placarding and Documentation: I meticulously verify that the correct placards are displayed on the trailer, reflecting the hazardous materials being transported. All paperwork, including shipping papers, manifests, and emergency response plans, must be in order and readily accessible.

- Slow and Steady Procedures: I use slow and controlled movements when loading or unloading to avoid spills or leaks. I’m always conscious of pressure levels and ensure they’re within safe operating parameters.

- Post-Transfer Inspection: After completion, I perform a post-transfer inspection, checking for leaks, spills, or any other issues.

For example, when loading flammable liquids, I’ll always use a vapor recovery system to minimize the risk of vapor release. My attention to detail has prevented numerous potential accidents.

Q 3. How do you ensure compliance with DOT regulations during your routes?

DOT compliance is non-negotiable in this profession. It’s not just a set of rules; it’s a commitment to safety. To ensure compliance, I follow a multi-pronged approach.

- Hours of Service (HOS): I meticulously track my hours of service, ensuring I don’t exceed the legally allowed limits. I use electronic logging devices (ELDs) to accurately record my driving time, which significantly reduces the risk of violations.

- Vehicle Maintenance: Regular vehicle maintenance is crucial. I ensure that all pre-trip inspections are completed accurately and that any necessary repairs are promptly done. Ignoring maintenance can lead to breakdowns and violations.

- Cargo Securement: Proper cargo securement is vital. I make sure the cargo is properly secured within the tank to prevent shifting during transit. This is especially crucial for liquid cargo to prevent sloshing.

- Driver Qualification Files: I maintain all my driver qualification files, including my medical certificate, driving record, and training records, ensuring they are up to date and easily accessible for DOT inspections.

- Knowledge of Regulations: I stay abreast of current DOT regulations and updates. Industry publications and training courses keep me informed about any changes.

A regular review of the Federal Motor Carrier Safety Administration (FMCSA) website helps me stay on top of all changes.

Q 4. What are the different types of tank trailers and their applications?

Tank trailers come in various designs, each optimized for specific types of cargo. Each type has its own unique characteristics and is built for specific applications. Think of them like specialized tools—each designed for a particular job.

- Liquid Tanks: These are commonly used for transporting liquids such as petroleum products, chemicals, and food-grade liquids. They come in different materials like stainless steel, aluminum, or carbon steel, depending on the cargo.

- Pressure Tanks: Used for transporting gases under pressure, these tanks are built to withstand high pressures. They often involve specific safety mechanisms and are used for substances like propane and compressed air.

- Vacuum Tanks: These tanks create a vacuum to transport sensitive or viscous materials that need careful handling. The vacuum prevents the product from being damaged during transportation.

- Dry Bulk Tanks: These are used for transporting dry bulk materials like powders, pellets, and grains. They often feature pneumatic unloading systems.

For example, I’ve hauled gasoline in liquid tanks, propane in pressure tanks, and food-grade ingredients in stainless-steel liquid tanks. The differences in tank type, material and safety procedures for each type are significant. This underscores the importance of understanding the characteristics of each tank and cargo.

Q 5. How do you handle unexpected mechanical issues on the road?

Unexpected mechanical issues are a reality in long-haul trucking. My approach is methodical and prioritizes safety.

- Assess the Situation: The first step is to assess the situation, identifying the problem and its severity. If it’s safe to do so, I pull over to the side of the road, away from traffic.

- Safety First: I prioritize safety, ensuring warning lights and triangles are deployed appropriately. If necessary, I call for roadside assistance.

- Contact Dispatch: I immediately contact my dispatch team to inform them of the issue and my location. They can coordinate repairs and provide any necessary support.

- Documentation: I document the issue, including the time, location, and nature of the problem. This information will be crucial in any claims or reports.

- Repair or Replacement: Once the issue is resolved, either through roadside repairs or replacement parts, I’ll confirm the vehicle’s safety before resuming my route.

I once experienced a tire blowout on a remote highway. I safely pulled over, contacted dispatch, and waited for roadside assistance. Thankfully, I had followed all safety protocols and no one was injured. The quick response and well-documented process minimized the disruption.

Q 6. Describe your experience with different types of cargo (e.g., liquids, gases, powders).

My experience encompasses a wide range of cargo types, each requiring unique handling procedures. Knowing the specific properties of the material is critical for safe transport.

- Liquids: I’ve hauled various liquids, from petroleum products (requiring strict fire safety measures) to food-grade liquids (requiring sanitary procedures to prevent contamination).

- Gases: Transporting gases demands a keen awareness of pressure and temperature. Leaks could be hazardous, requiring extra caution.

- Powders: Powders can be prone to settling or clumping, potentially affecting the accuracy of delivery. Proper loading and unloading techniques are crucial.

One time, I hauled a sensitive chemical liquid that required constant temperature monitoring. I used a temperature monitoring device linked to dispatch that alerted me to any significant temperature fluctuations, ensuring the product arrived at its destination in perfect condition.

Q 7. How do you manage your time effectively on long hauls?

Effective time management on long hauls is vital for efficiency and compliance with HOS regulations. It’s about more than just sticking to a schedule; it’s about smart planning and execution.

- Trip Planning: I meticulously plan my routes, considering traffic patterns, rest stops, and potential delays. Using route planning software helps optimize travel time.

- Rest Breaks: I adhere to HOS regulations, taking regular breaks to avoid fatigue. I plan my breaks strategically, choosing safe and convenient rest areas.

- Communication: Maintaining open communication with dispatch keeps things running smoothly. Reporting delays or unexpected issues helps them adjust schedules accordingly.

- Vehicle Maintenance: Scheduling maintenance during planned downtime prevents unexpected delays.

- Document Everything: Meticulous record keeping of arrival and departure times, fuel purchases, and other logistical details ensures everything is compliant.

For example, on a recent cross-country trip, I used a route planning app to identify rest stops along my route with convenient amenities, reducing downtime and improving my overall experience.

Q 8. What safety measures do you take to prevent accidents?

Preventing accidents is paramount in tank truck driving. My approach is multifaceted, focusing on proactive measures and diligent adherence to safety protocols. It starts with a thorough pre-trip inspection, meticulously checking everything from tire pressure and fluid levels to lights, brakes, and the securement of the cargo. I treat this inspection not just as a checklist, but as a critical safety assessment, ensuring the vehicle is roadworthy.

Beyond the pre-trip, safe driving is key. This involves maintaining a safe following distance, especially when hauling heavy loads, and anticipating potential hazards like inclement weather or congested traffic. I prioritize defensive driving techniques, constantly scanning the road and surroundings, and adjusting my speed accordingly. I also avoid distractions – no cell phone use, and a strict focus on the road at all times. Regular breaks are crucial to prevent driver fatigue, a major contributor to accidents. Finally, I actively participate in company safety training programs to stay updated on best practices and new regulations.

For instance, I once noticed a loose lug nut during a pre-trip inspection. This seemingly minor issue could have resulted in a catastrophic tire failure. By addressing it immediately, I prevented a potential accident.

Q 9. Explain your understanding of Hazmat placards and their significance.

Hazmat placards are diamond-shaped signs displayed on the outside of vehicles transporting hazardous materials. They communicate the type of hazardous material being carried and the associated risks to emergency responders and the public. Understanding them is crucial for safe handling and emergency response. Each placard has a unique identification number and color-coding system indicating the hazard class (e.g., flammable, explosive, corrosive). This information is critical for emergency personnel to understand the nature of the hazard and take appropriate precautions.

The significance of Hazmat placards cannot be overstated. They provide crucial first-responder information in the event of an accident, allowing them to quickly assess the situation and take the necessary safety measures. Incorrect placarding or a lack of placards can lead to serious consequences, including injury, property damage, and environmental harm. My training emphasizes the precise application of placards according to the specific hazardous material being transported and the regulations governing their use.

For example, a truck carrying flammable liquids would display a red placard indicating its flammability. This allows firefighters to approach the situation with the appropriate extinguishing agents and safety gear.

Q 10. How do you maintain accurate logs and documentation?

Maintaining accurate logs and documentation is non-negotiable in tank truck driving. It’s a legal requirement and essential for safety and efficiency. I use both electronic and paper logs (depending on the requirements) to meticulously record my driving hours, duty status (driving, on-duty, off-duty, sleeper berth), and vehicle location. I ensure every entry is accurate and complete, adhering strictly to regulations. Any discrepancies are immediately addressed and corrected.

For paper logs, I use a legible handwriting and follow the specific format and rules. For electronic logging devices (ELDs), I regularly check for errors and ensure the system is functioning correctly. I back up my electronic logs regularly and maintain both physical and electronic copies for record-keeping. I understand that falsifying records is illegal and dangerous and would never compromise the accuracy of my logs.

Maintaining these records isn’t just about compliance; it’s also about accountability and operational efficiency. It helps to track my performance, identify areas for improvement in terms of route planning and efficiency, and helps the company manage operations better.

Q 11. Describe your experience with electronic logging devices (ELDs).

My experience with Electronic Logging Devices (ELDs) has been overwhelmingly positive. ELDs have significantly improved the accuracy and efficiency of logbook maintenance. They automate many aspects of the process, eliminating the potential for human error and ensuring compliance with Hours of Service (HOS) regulations. I’m proficient in using the ELD system, understanding its functionalities like automatically recording driving time, creating duty status records, and generating reports.

Furthermore, ELDs provide a detailed record of my driving behavior, which is helpful for analyzing driving patterns and identifying areas for improvement in fuel efficiency and safety. I use the data generated by the ELD to optimize my routes, minimize idle time, and make sure I’m adhering to the regulations set by the Department of Transportation. Regularly reviewing the ELD data also allows me to catch potential issues early on, such as exceeding my hours of service or potential maintenance needs.

The transition to ELDs was initially a learning curve, but I quickly adapted. I understand the importance of regular system checks, battery life management, and troubleshooting common issues. This technology is pivotal for enhancing safety and compliance in the trucking industry.

Q 12. How do you handle emergency situations involving spills or accidents?

Handling emergency situations like spills or accidents requires immediate action and a calm, systematic approach. My training emphasizes the importance of prioritizing safety and following established emergency procedures. In case of a spill, my first step is to secure the area, ensuring the safety of myself and others. This includes activating emergency lights, setting up warning devices (cones, flares), and contacting emergency services and my company immediately.

Depending on the nature of the spill (hazardous or non-hazardous material), I follow specific containment and cleanup procedures. I am trained in the use of spill kits and know how to properly handle different types of materials. Communication is vital during such emergencies, so keeping emergency personnel, company representatives, and regulatory bodies informed is crucial. I’ll follow all instructions given by emergency services, providing them with the relevant information like the type of material spilled and its quantity.

I remember one instance where I experienced a minor fuel leak. By quickly activating the emergency lights, contacting dispatch, and following the prescribed spill response plan, we were able to contain the leak and prevent any further damage or environmental harm.

Q 13. What are your strategies for fuel efficiency?

Fuel efficiency is a crucial aspect of tank truck driving, impacting both cost and environmental impact. My strategies focus on several key areas. Firstly, I maintain a consistent speed, avoiding sudden acceleration and braking. These actions waste fuel and put extra strain on the engine. I also anticipate traffic conditions and adjust my speed appropriately, minimizing unnecessary idling or hard braking. Proper tire inflation is essential; under-inflated tires increase rolling resistance and fuel consumption.

I also optimize my routes to avoid unnecessary detours or congested areas. Understanding the route and planning it efficiently helps to reduce overall mileage and fuel consumption. Regular vehicle maintenance, including engine tune-ups and preventative checks, plays a significant role in fuel efficiency. A well-maintained engine runs more smoothly and consumes less fuel. Finally, I avoid unnecessary idling, shutting off the engine whenever possible during stops, especially during longer periods.

For instance, I routinely check my tire pressure before each trip and follow pre-determined routes that avoid heavy traffic congestion. These small changes cumulatively impact fuel efficiency significantly.

Q 14. How do you manage your driving hours to comply with regulations?

Managing driving hours to comply with regulations is a cornerstone of safe and responsible tank truck driving. I meticulously track my hours using ELDs and adhere strictly to the Hours of Service (HOS) regulations. This involves carefully planning my trips, accounting for driving time, breaks, and rest periods. I understand the limitations on driving time within a 24-hour period and over a 7/8-day period, and I never compromise my rest to meet deadlines. If I anticipate reaching my driving limit, I make appropriate arrangements to ensure I comply with the rules.

Planning ahead is crucial. I use route-planning tools to estimate drive times and ensure sufficient rest periods are incorporated into my schedule. The safety and wellbeing of myself and others are paramount. I prioritize adequate sleep, knowing that fatigue significantly impairs driving ability and increases the risk of accidents. I also ensure I’m well-hydrated and take regular breaks during the journey to prevent fatigue.

For instance, If I have a long haul, I will plan my route with overnight stops that enable me to get at least 10 hours of rest before resuming my drive.

Q 15. Describe your experience with different types of tank trailer valves and connections.

My experience encompasses a wide range of tank trailer valves and connections, crucial for safe and efficient product transfer. I’m proficient with both bottom-loading and top-loading systems, understanding the nuances of each. Bottom loading, for instance, often utilizes specific cam and groove couplings, demanding precision to avoid spills. Top loading, conversely, might involve various types of valves, including butterfly valves, ball valves, and gate valves, each with its own operational procedures and safety protocols. I’m familiar with different connection types like API (American Petroleum Institute) flanges and Storz couplings, understanding their respective strengths and weaknesses in terms of pressure resistance and ease of connection. I’ve worked with numerous product-specific valves and fittings, always ensuring compatibility and adhering strictly to safety regulations to prevent cross-contamination and leaks.

For example, when transferring highly volatile chemicals, I’m meticulous in checking the compatibility of the valve seals and gaskets with the chemical being transported. I also understand the importance of pressure relief valves and their function in preventing over-pressurization within the tank.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of weight distribution and its importance in tank trucking.

Weight distribution in tank trucking is paramount for safety and legal compliance. An improperly loaded tank can lead to instability, reduced fuel efficiency, and even accidents. It’s all about achieving a balanced load, distributing the weight evenly across the axles to remain within legal weight limits and maintain optimal handling characteristics. Think of it like balancing a seesaw – you need to find the perfect point to prevent tipping.

We achieve this through careful planning. Before loading, I always check the weight capacity of each axle and the gross vehicle weight rating (GVWR). I then work with the loading personnel to ensure the weight is distributed correctly, often using load charts and software to model different weight scenarios. I also account for the weight of the tank itself, the cargo, and any additional equipment. An uneven load can stress the tires, suspension, and even the frame of the truck, significantly increasing the risk of mechanical failure and accidents. Maintaining proper weight distribution reduces wear and tear, improves fuel economy, and greatly enhances safety.

Q 17. How do you calculate the appropriate payload for different cargo types?

Calculating the appropriate payload depends heavily on the cargo’s density, the tank’s capacity, and legal weight restrictions. I start by referring to the tank’s specifications, which provide the maximum capacity in gallons or liters. I then consult the relevant shipping documents or the shipper’s instructions to find the product’s density (weight per unit volume) – this is usually given in pounds per gallon (lbs/gal) or kilograms per liter (kg/L). Using these, I calculate the maximum weight the tank can safely hold:

Maximum weight = Tank capacity (in gallons/liters) x Product density (lbs/gal or kg/L)

Once I have this figure, I compare it against the legal weight limits for my truck and trailer combination. This involves considering axle weight limits, gross vehicle weight rating (GVWR), and any state-specific regulations. The lower of the two values (calculated maximum weight or legal weight limit) determines the appropriate payload. For example, if my tank has a capacity of 8,000 gallons and the product density is 7 lbs/gal, my maximum weight is 56,000 lbs (8,000 gallons x 7 lbs/gal). If the legal limit is 50,000 lbs, then 50,000 lbs is the appropriate payload.

For hazardous materials, I must consult additional regulations and shipping papers to ensure compliance with specific handling and loading requirements.

Q 18. Describe your experience with route planning and optimization.

Route planning and optimization are critical to efficiency and on-time delivery in tank trucking. I utilize various tools, including GPS navigation systems and specialized routing software, considering factors such as distance, traffic conditions, road restrictions (weight limits, hazardous material routes), and delivery deadlines. I’m skilled in identifying alternative routes to avoid congestion or road closures, minimizing delays and fuel consumption. I also factor in rest stops and other necessary breaks to comply with hours-of-service regulations.

For instance, I might use a route optimization software to compare multiple routes, weighing distance against potential traffic delays. This helps me select the most efficient route, which often saves time and fuel. I also regularly review my routes for potential improvements, learning from past experiences and adjusting my approach based on changing conditions. Pre-trip route planning allows for a smoother, more predictable journey, contributing to overall operational efficiency and safety.

Q 19. What are your strategies for maintaining the cleanliness and sanitation of your tank trailer?

Maintaining cleanliness and sanitation is essential in tank trucking, especially when transporting food-grade products or hazardous materials. My strategies involve a multi-step approach, starting with thorough cleaning after each delivery. I use appropriate cleaning agents specific to the previous cargo, meticulously removing any residue. I pay close attention to valves, fittings, and all internal surfaces to prevent cross-contamination. I also conduct regular inspections for any signs of damage or corrosion that might compromise cleanliness. Documentation of cleaning procedures is critical, ensuring traceability and compliance with regulations.

For example, after transporting milk, I’ll use a food-grade cleaning agent and high-pressure washer to remove any remaining dairy residue. Following this, I’ll thoroughly rinse the tank, ensuring no traces of the cleaning agent remain. This process is carefully documented, including the cleaning agent used, the date, and the driver’s signature.

Q 20. How do you communicate effectively with dispatchers and clients?

Effective communication is crucial in tank trucking. I maintain clear and concise communication with dispatchers and clients, using a combination of phone calls, radio, and messaging apps. I provide regular updates on my location, estimated time of arrival (ETA), and any unforeseen challenges, such as traffic delays or mechanical issues. Active listening is equally important; I ensure I understand all instructions clearly and ask clarifying questions if needed. I also maintain professional and courteous communication, keeping both dispatchers and clients informed of my progress and any potential delays.

For example, if I encounter an unexpected road closure, I immediately inform both the dispatcher and the client, providing alternative routes and an updated ETA. This proactive communication helps prevent delays and maintains trust.

Q 21. Explain your experience with different types of cargo securing methods.

Secure cargo transport is paramount. My experience includes various cargo securing methods, tailored to the specific cargo type and tank configuration. I’m familiar with using straps, chains, and other restraining devices to prevent shifting during transit. The method selected depends on the product’s weight, viscosity, and any potential hazards. For liquids, ensuring the tank is properly filled and the valves are securely closed is critical. I always double-check the tightness of all connections and securing devices before starting the journey, to minimize risk.

For example, when hauling a load of potentially hazardous chemicals, I might use specialized chains and tie-downs to secure the tank to the trailer, exceeding the minimum safety requirements. I also use load indicators to monitor the tension on the securing devices, ensuring they maintain adequate restraint throughout the journey.

Q 22. How do you handle difficult or demanding customers?

Handling demanding customers in tank truck driving requires a calm, professional approach focused on de-escalation and problem-solving. I always start by actively listening to their concerns, acknowledging their frustrations, and validating their feelings. This shows empathy and creates a space for productive communication. Then, I clearly explain the situation from my perspective, outlining any constraints or limitations, while remaining respectful and factual. For example, if a customer is upset about a late delivery due to unexpected traffic, I wouldn’t make excuses, but explain the situation, offer a revised ETA, and potentially suggest alternative solutions, such as partial delivery if feasible. If the issue stems from a mistake on my part, I take full responsibility and outline the steps I’m taking to rectify the situation. My goal is always to find a mutually acceptable resolution that preserves the professional relationship.

In one instance, a customer was extremely agitated because their delivery was delayed due to an unforeseen road closure. Instead of arguing, I calmly explained the situation, provided alternative delivery options, and even contacted their production manager directly to provide an update. This proactive approach diffused the tension and salvaged the relationship.

Q 23. Describe your experience working with various types of shipping documents.

My experience encompasses a wide range of shipping documents, including Bills of Lading (BOLs), delivery receipts, hazardous materials manifests, and proof of delivery (POD) forms. Understanding the specifics of each document is crucial for ensuring legal compliance and accurate record-keeping. The BOL, for instance, acts as a contract between the shipper and the carrier, detailing the goods being transported, the origin and destination, and the agreed-upon terms. Hazardous materials manifests require meticulous attention to detail, as they contain critical information about the transported chemicals and the necessary safety precautions. I’m proficient in completing each document accurately and efficiently, ensuring all relevant information is included and all signatures are obtained. Furthermore, I understand the importance of maintaining organized records, both physical and digital, for easy retrieval and audit purposes.

I regularly review and double-check all shipping documents before, during, and after each delivery to guarantee accuracy and prevent potential discrepancies. For example, I always verify that the product description, quantity, and destination on the BOL match the load I’m carrying and the delivery address. This meticulous approach has prevented potential issues and ensured seamless operations throughout my career.

Q 24. What are your strategies for preventing cargo damage or contamination?

Preventing cargo damage and contamination is paramount in tank truck driving. My strategies focus on pre-trip inspections, safe handling practices, and adherence to all relevant regulations. Before each trip, I perform a thorough inspection of the tanker, checking for leaks, damage, and ensuring the cleanliness of the compartment. During loading and unloading, I follow strict procedures to minimize the risk of spills or cross-contamination, including proper grounding techniques to prevent static electricity buildup and careful monitoring of flow rates. I also meticulously inspect the tanker after each delivery to confirm its condition and ensure complete unloading. For hazardous materials, I adhere strictly to all regulations, including proper labeling, placarding, and emergency response procedures.

For example, when transporting food-grade liquids, I ensure the tanker is thoroughly cleaned and sanitized before loading to prevent contamination. Likewise, when handling hazardous chemicals, I wear the appropriate personal protective equipment (PPE) and follow all safety protocols to mitigate the risk of accidents or spills. By diligently adhering to these safety measures, I’ve consistently maintained a spotless record of cargo integrity.

Q 25. Explain your experience with different types of weather conditions and their impact on driving.

Weather significantly impacts tank truck driving. Extreme heat can affect the viscosity of certain liquids, requiring adjustments to pumping procedures. Cold weather can lead to fuel gelling and reduced tire traction. Heavy rain and snow reduce visibility and traction, demanding slower speeds and increased caution. Strong winds can affect the vehicle’s stability, particularly when hauling tall loads. I adjust my driving techniques based on weather conditions, employing defensive driving practices like increasing following distances, reducing speed, and allowing for extra travel time. I always check weather forecasts before a trip and plan accordingly, potentially adjusting routes to avoid areas with severe weather.

I once experienced a sudden snowstorm during a long haul. I immediately pulled over to a safe location, contacted dispatch to inform them of the situation, and waited for the storm to subside before continuing my journey. This cautious approach ensured my safety and prevented a potential accident.

Q 26. How do you maintain your physical fitness and stamina for long hauls?

Maintaining physical fitness and stamina is crucial for long-haul tank truck driving. My routine includes regular exercise, a healthy diet, and sufficient sleep. I prioritize cardiovascular health through activities such as running, swimming, or cycling. Strength training helps maintain muscle strength and endurance, reducing fatigue during physically demanding tasks like securing loads. A balanced diet rich in fruits, vegetables, and whole grains provides the necessary energy and nutrients. Getting adequate sleep is vital for alertness and concentration, which are essential for safe driving. I also stay hydrated throughout the day by drinking plenty of water.

I incorporate regular stretching and light exercises during breaks to prevent stiffness and improve circulation. Regular checkups with my physician help monitor my overall health and address any potential concerns proactively.

Q 27. Describe your experience with using GPS navigation systems.

GPS navigation systems are essential tools for efficient and safe route planning in tank truck driving. I’m proficient in using various GPS devices and applications, utilizing features such as route optimization, real-time traffic updates, and avoidance of low-clearance areas or weight restrictions. I regularly update the maps and software on my devices to ensure accuracy and reliability. I understand the limitations of GPS technology, such as signal loss in certain areas, and always have backup maps and route planning resources. I also incorporate local knowledge and road conditions into my route decisions, using the GPS as a guide rather than relying solely on its directions.

On one occasion, my GPS directed me down a road with unexpectedly low clearance for my tanker. Luckily, I was aware of the potential for inaccuracies and checked a physical map beforehand, avoiding a potentially damaging situation. This highlights the importance of using GPS strategically and not solely relying on its guidance.

Q 28. How do you stay up-to-date with changes in regulations and industry best practices?

Staying updated on regulations and industry best practices is vital for a tank truck driver. I regularly attend industry conferences and webinars, participate in professional development courses, and actively follow relevant publications and websites. I also maintain contact with fellow drivers and industry professionals to share information and best practices. The Department of Transportation (DOT) website and other relevant government agencies provide vital information on regulations related to hazardous materials, hours of service, and vehicle maintenance. I consistently check for updates to these regulations and ensure my practices align with the latest standards. Keeping up-to-date with these aspects ensures compliance, safety, and efficiency in my operations.

For example, recent changes in hours-of-service regulations required me to adjust my scheduling and break planning. By staying informed, I adjusted my operation smoothly and avoided any violations.

Key Topics to Learn for Your Tank Truck Driving Experience Interview

- Safety Regulations and Procedures: Understanding and adhering to all relevant federal, state, and company safety regulations. This includes pre-trip inspections, hazardous materials handling, and emergency response protocols.

- Load Securement and Handling: Mastering the techniques for safely securing various types of liquid cargo, understanding the impact of weight distribution, and recognizing potential hazards during loading and unloading.

- Vehicle Maintenance and Troubleshooting: Familiarity with basic vehicle maintenance, recognizing signs of potential mechanical issues, and knowing when to report problems to the appropriate personnel. This includes understanding the unique aspects of maintaining tank trucks.

- Route Planning and Navigation: Efficiently planning routes, considering factors like weight restrictions, hazardous material routes, and delivery deadlines. Utilizing GPS and other navigation tools effectively.

- Logbooks and Documentation: Accurately maintaining electronic and/or paper logbooks, complying with Hours of Service regulations, and ensuring all required documentation is complete and accurate.

- Communication and Customer Service: Effectively communicating with dispatchers, customers, and other stakeholders. Providing excellent customer service and representing the company professionally.

- Hazardous Materials (HazMat) Transportation: If applicable, thorough understanding of HazMat regulations, including proper handling, placarding, and emergency response procedures for specific hazardous materials.

- Problem-Solving and Decision-Making: Demonstrate your ability to assess situations quickly, make sound decisions under pressure, and effectively troubleshoot unexpected issues on the road.

Next Steps

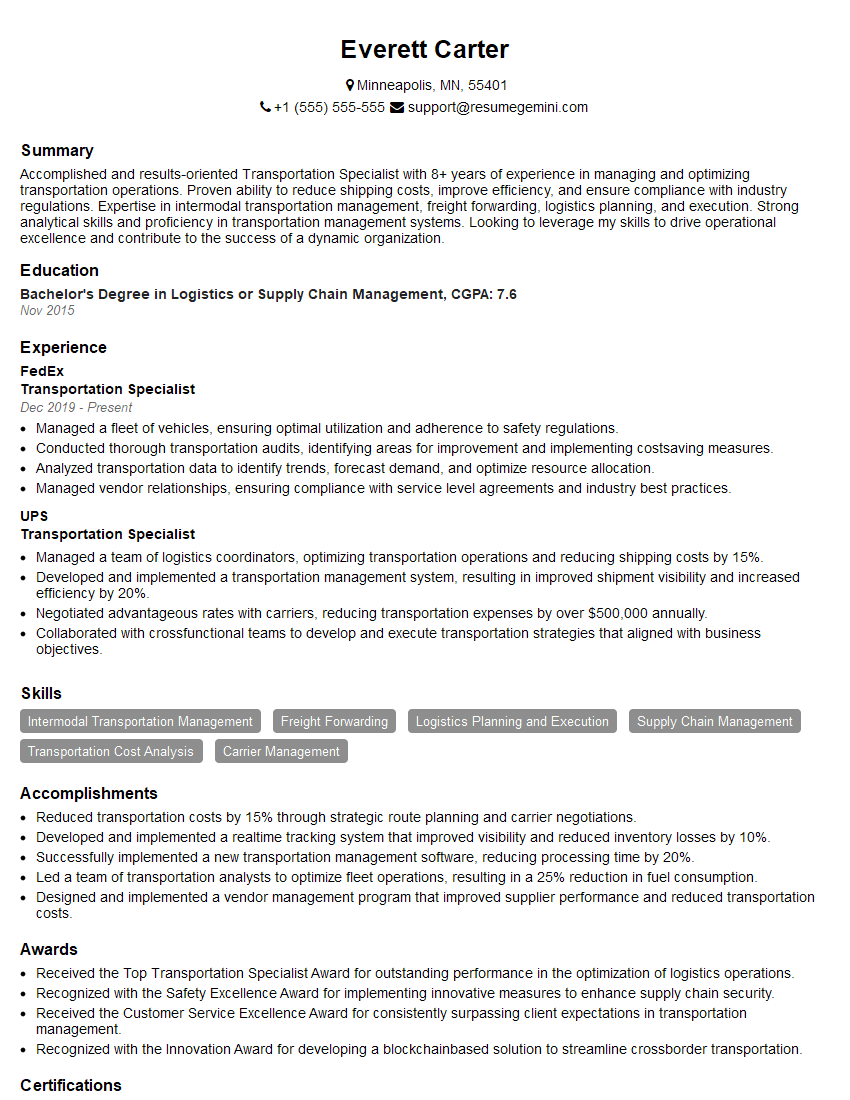

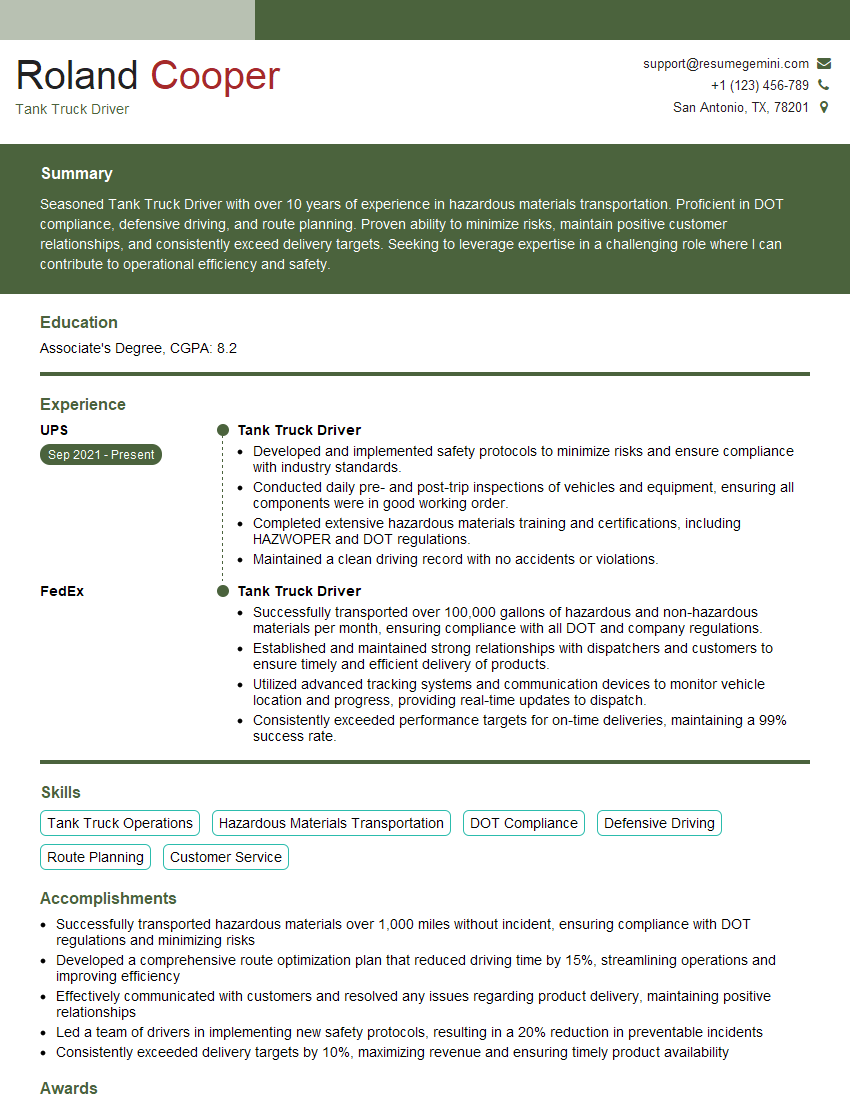

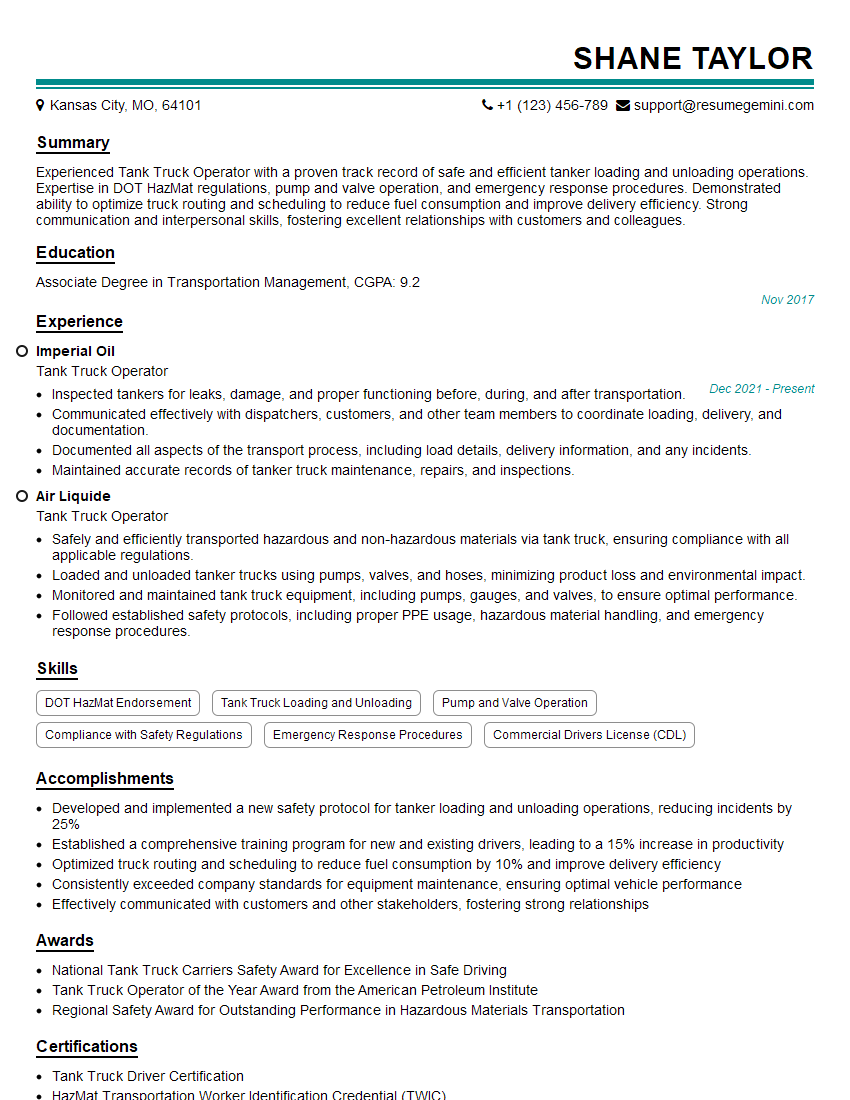

Mastering tank truck driving experience is crucial for career advancement in this specialized field. A strong understanding of safety procedures, regulations, and efficient operations will set you apart. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to tank truck driving experience are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO