Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Tenoning Machine Operation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Tenoning Machine Operation Interview

Q 1. What are the common types of tenoning machines?

Tenoning machines come in various types, each designed for specific applications and workpiece sizes. Common types include:

- Single-end tenoners: These machines process one end of a workpiece at a time, typically performing operations like cutting tenons, shoulders, and shaping the end. They are versatile and suitable for smaller workshops and various wood types.

- Double-end tenoners: These machines process both ends of a workpiece simultaneously, significantly increasing efficiency. They’re ideal for high-volume production lines and often feature more advanced capabilities, like automated feeding systems.

- Through-feed tenoners: Designed for continuous operation, these machines feed the workpiece through the cutting heads for repetitive tenon creation. They are exceptionally efficient for high-volume production, particularly with standardized components.

- Gang rip tenoners: These specialized machines are used for cutting multiple tenons simultaneously on a single board, maximizing material yield. They are often found in larger-scale operations producing furniture or flooring.

The choice of tenoning machine depends heavily on production volume, workpiece dimensions, and the complexity of the tenons required.

Q 2. Explain the difference between a vertical and horizontal tenoning machine.

The key difference between vertical and horizontal tenoning machines lies in the orientation of the workpiece during processing.

- Vertical tenoners: The workpiece is held vertically during the cutting process. This is beneficial for taller, narrower pieces, often used in window frame or door construction. The machine’s design allows for precise cuts and efficient operation within a smaller footprint.

- Horizontal tenoners: The workpiece is positioned horizontally as it’s fed through the cutting heads. This configuration is generally preferred for longer pieces and higher production volumes. They are often seen in larger production facilities working with longer timbers.

Imagine cutting a long plank of wood for a table leg versus a shorter piece for a chair rung – the orientation of the wood would influence the choice of machine.

Q 3. Describe the safety procedures you follow when operating a tenoning machine.

Safety is paramount when operating any tenoning machine. My routine includes:

- Pre-operation checks: Thoroughly inspect the machine for any loose parts, damage, or obstructions. Ensure all guards are securely in place and functioning correctly.

- Proper PPE: Wearing safety glasses, hearing protection, and work gloves is non-negotiable. Depending on the operation, a dust mask might also be necessary.

- Machine Lockout/Tagout: Before any maintenance or adjustment, the power must be completely disconnected and locked out. This prevents accidental start-ups and injuries.

- Clear work area: Keep the area around the machine free from clutter and obstructions to minimize trip hazards.

- Feed stock safely: Never attempt to force wood through the machine. Ensure the wood is properly aligned and securely held to prevent kickback.

- Awareness of moving parts: Maintain a safe distance from moving parts and avoid reaching into the cutting area while the machine is running.

A commitment to these safety procedures is critical for preventing accidents and ensuring a safe work environment.

Q 4. How do you adjust the cutting depth and length on a tenoning machine?

Adjusting cutting depth and length varies slightly depending on the machine’s specific model but generally involves these steps:

- Cutting Depth: Most machines have adjustment knobs or levers that control the distance the cutting head descends into the workpiece. These adjustments are usually calibrated in millimeters or inches. I would always test on a scrap piece before adjusting to the final setting for the project to avoid mistakes.

- Cutting Length: This is usually controlled through adjustable stops or fences that determine how far the workpiece travels through the cutting head. Precise adjustment of the stops ensures consistent tenon length on each piece. Again, testing is crucial for accuracy.

Precise adjustments are crucial for achieving the desired tenon dimensions. Incorrect adjustments can lead to poorly fitting joints or damaged workpieces.

Q 5. How do you maintain and clean a tenoning machine?

Regular maintenance and cleaning are essential for maintaining the machine’s performance and longevity.

- Daily cleaning: Remove sawdust and wood chips from the machine’s various components using a brush or compressed air. Ensure the cutting heads are free from debris.

- Regular lubrication: Apply lubricating oil to moving parts as recommended in the machine’s manual. This reduces friction, prevents wear, and extends the machine’s lifespan.

- Blade sharpening/replacement: Dull blades will cause poor cuts and increased risk of kickback. Sharpen or replace blades as needed. This can be a time-consuming task, but sharp blades are a cornerstone of successful tenoning.

- Periodic inspection: Conduct regular inspections of all components to identify any wear or damage. Address issues promptly to prevent larger problems.

Preventative maintenance is significantly more efficient and cost-effective than dealing with costly repairs later.

Q 6. What are the common causes of jams or malfunctions in a tenoning machine?

Jams and malfunctions are often caused by:

- Dull or damaged blades: Dull blades can cause the wood to bind and jam. Damaged blades can lead to inconsistent cuts and potentially cause further damage to the machine.

- Improper workpiece alignment: Incorrectly aligned wood can lead to binding and jamming, particularly when using multiple cutting heads.

- Excessive sawdust build-up: An accumulation of sawdust can interfere with the machine’s moving parts, causing jams and malfunctions.

- Component wear: Wear on the machine’s various parts, such as bearings or gears, can cause reduced performance and increased risk of failures. Regular inspections are paramount here.

- Electrical issues: Problems with the machine’s electrical system, such as loose wiring or a faulty motor, can result in malfunctions or sudden stops.

Preventing these issues often requires careful attention to detail and routine maintenance.

Q 7. How do you troubleshoot common tenoning machine problems?

Troubleshooting tenoning machine problems requires a systematic approach:

- Safety first: Turn off and lock out the power supply before attempting any troubleshooting.

- Identify the problem: Observe the machine carefully to pinpoint the exact nature of the malfunction. Is the problem related to the cutting operation, the feed system, or the electrical system?

- Check the obvious: Start with the simpler checks, such as clearing sawdust build-up, ensuring proper lubrication, and verifying the blades’ condition.

- Consult the manual: The machine’s manual is an invaluable resource for troubleshooting common problems and finding solutions.

- Seek expert help: If the problem persists or you are unsure how to proceed, seek assistance from a qualified technician or the machine’s manufacturer.

A methodical approach, combined with attention to detail, allows for efficient problem resolution. Remember to always prioritize safety during troubleshooting.

Q 8. How do you identify and address blade wear or damage?

Identifying blade wear or damage on a tenoning machine is crucial for safety and precision. Think of the blades as the heart of the machine; a worn blade compromises the entire process. I always begin by visually inspecting the blades for any obvious signs of damage such as chipping, cracks, or significant dulling. A chipped blade is immediately dangerous and needs replacing. Dullness is more subtle, but equally important.

Dull blades lead to inaccurate cuts, splintering, and increased friction, resulting in heat buildup and potential machine damage. I often check for uneven wear patterns, which may indicate a problem with machine alignment. A magnifying glass can be helpful for detailed inspection. To quantify dullness, I sometimes use a blade sharpness gauge; this provides a numerical value that indicates when a blade needs sharpening or replacing.

Addressing blade issues is straightforward. Chipped or severely damaged blades must be replaced immediately; safety is paramount. Dull blades can often be sharpened using specialized equipment and techniques. This requires experience and precise measurements to maintain the blade’s profile and ensure continued accuracy. The blade must be correctly reset and re-aligned after sharpening. Regular blade inspection and maintenance, including careful cleaning and lubrication, is key to extending blade life.

Q 9. Describe your experience setting up and changing tooling on a tenoning machine.

Setting up and changing tooling on a tenoning machine requires precision and attention to detail. It’s like assembling a complex puzzle, where each piece – the blade, fence, and stops – plays a crucial role in achieving the desired cut. My experience spans various tenoning machine models, and I’m comfortable working with a range of tooling, from different blade profiles to various stop systems.

The process typically starts with ensuring the machine is powered down and locked out. Safety is my top priority. Then I carefully remove the old tooling, paying attention to any special procedures for my specific machine model. This often includes removing holding bolts and ensuring smooth disengagement from the machine’s spindles. Next, I meticulously clean the tooling area, removing any debris that could affect the alignment or performance of the new tooling. The new tooling is then installed, following the manufacturer’s guidelines precisely. Alignment is critical, using precision measuring tools to ensure the blade’s position, fence angles, and stops are perfectly set. After installation, a test cut on scrap material is essential to verify the accuracy before starting the actual work.

Q 10. How do you ensure the accuracy and precision of cuts on a tenoning machine?

Accuracy and precision in tenoning are paramount; a slight error can affect the entire joinery project. I achieve this through a multi-faceted approach. First, precise machine setup, as discussed previously, forms the foundation. Second, meticulous attention is paid to material handling. This includes ensuring the workpiece is securely held and properly aligned before the cut. Third, regular checks on machine calibration are performed. This might involve using precision gauges to verify the accuracy of the stops and fences. Fourth, consistent feed rates are maintained throughout the tenoning process.

For example, if I’m producing tenons for a specific type of joint, I’ll use a digital caliper to accurately measure each tenon, comparing it to my specifications. Small adjustments can be made to the fence or stops as needed. If inconsistencies persist, I’ll investigate potential causes like blade wear, machine misalignment, or even inconsistencies in the wood itself (e.g., warping or knots).

Q 11. What are the different types of tenons you can create using a tenoning machine?

Tenoning machines offer versatility in creating different tenon types. The choice depends on the type of joint and the specific application.

- Through Tenons: These extend completely through the workpiece and offer a strong connection. Common in chairs and tables.

- Shouldered Tenons: These have a shoulder that sits flush against the workpiece, offering a cleaner appearance. Often used in fine furniture.

- Stub Tenons: Shorter than through tenons, they are often hidden within the joint.

- Haunched Tenons: These have a reduction in thickness on one side, commonly seen in mortise and tenon joints to aid assembly.

- Double Tenons: These feature two tenons on the same workpiece, enhancing strength and stability.

The specific tenon profile – the shape and dimensions – is determined by the tooling and machine settings. I adjust these parameters to create the appropriate tenon for the given application, carefully considering factors such as wood species and desired joint strength.

Q 12. Explain the importance of proper material handling in tenoning machine operation.

Proper material handling is fundamental to safe and efficient tenoning machine operation. It’s about treating each piece of wood with care and ensuring that it’s properly positioned and secured before, during, and after the cutting process. Think of it as a choreography where each move is precise and deliberate.

Improper handling can lead to kickback (the workpiece being violently thrown back toward the operator), inaccurate cuts, damaged material, and ultimately, accidents. My process always starts with sorting the wood, ensuring similar pieces are grouped to maintain consistency. I inspect each piece for defects like knots or cracks that might compromise the tenoning process. Before loading material onto the machine, I double-check that it is firmly clamped or held in place, preventing movement during the cutting operation. After tenoning, I carefully stack the pieces to prevent warping or damage.

Q 13. How do you ensure the quality of the finished product?

Ensuring the quality of the finished product involves a holistic approach. It starts with careful selection and preparation of the materials and ends with a thorough inspection of the finished tenons. Throughout the process, quality control is integrated, starting from properly setting the machine, accurately measuring the tenons to ensure they meet the required dimensions and tolerances, and finally, checking for any imperfections such as splintering or tear-out.

I routinely check dimensions using precision measuring tools such as calipers and squares. I also examine the surface finish of the tenons, looking for imperfections that could affect the final joint. Any tenons that fail to meet my quality standards are rejected and either reworked or discarded. In my experience, consistent quality control procedures not only ensure product quality but also improve efficiency, reducing waste and rework.

Q 14. What is your experience with different types of wood and their impact on tenoning?

Different types of wood impact tenoning in significant ways. Hardwoods like oak and maple, while offering strength and durability, are more challenging to cut cleanly than softwoods like pine or fir. They can be prone to tear-out if not handled correctly. The grain pattern also plays a critical role. Working with wood having irregular grain requires adjusting feed rates and possibly blade angles to prevent damage.

For example, when tenoning oak, I might use a sharper blade with a finer tooth profile and a slower feed rate to minimize tear-out. With pine, I can often use a slightly coarser blade and faster feed rates. Moisture content is another important factor; wet wood is more likely to splinter or warp during the cutting process. I always consider the properties of the specific wood species and adjust my technique accordingly, ensuring a clean, precise, and safe tenoning operation.

Q 15. How do you work with different types of tenon profiles?

Tenon profiles dictate the shape and size of the tenon cut on the workpiece, influencing the strength and aesthetics of the final joint. Working with diverse profiles requires understanding the machine’s capabilities and making appropriate adjustments. Common profiles include:

- Through Tenons: These extend completely through the workpiece, offering exceptional strength. Setting the appropriate depth on the tenoning machine is crucial.

- Shoulder Tenons: The tenon only extends partially through, creating a shoulder on the end of the workpiece. Machine setup involves precisely controlling the cutting depth.

- Haunched Tenons: These have a reduced width near the shoulder, allowing for better fit and potentially greater strength. This requires precise setup and potentially additional tooling.

- Double Tenons: Two tenons are cut on a single piece, requiring careful attention to spacing and alignment within the machine.

Adapting to different profiles involves careful study of the design, selection of the right cutters, and precise adjustments to the machine’s settings such as fence position, stop blocks and depth of cut. For example, a haunched tenon might require a special shaping cutter in addition to the main tenoning cutter. Each profile requires meticulous attention to detail to ensure accuracy and joint strength.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with CNC tenoning machines?

My experience with CNC tenoning machines is extensive. I’ve operated and programmed various models, from smaller shop-based machines to larger, high-production systems. This includes experience with both stand-alone CNC tenoners and those integrated into larger automated production lines.

CNC tenoners offer unparalleled precision and repeatability. My skills encompass:

- Programming: I’m proficient in creating and modifying CNC programs using CAM software, optimizing cutting parameters for different wood species and tenon profiles.

- Setup and Operation: I can efficiently set up CNC tenoning machines, including tool changes, workpiece clamping, and program loading and execution. This also includes checking the machine’s zero points and reference planes for accurate cutting.

- Troubleshooting: I’m adept at diagnosing and resolving mechanical and software issues, maximizing machine uptime.

- Maintenance: I understand the importance of regular maintenance to optimize machine performance and prevent costly breakdowns.

For example, I once optimized the CNC program for a complex tenon-and-mortise joint in an automated line, significantly reducing cycle time while maintaining precision. This involved analyzing the cutting path, optimizing tool speeds and feeds, and fine-tuning the program for minimal material waste.

Q 17. How familiar are you with different types of feed systems?

Tenoning machines utilize various feed systems to move the workpiece through the cutting tools. Understanding these systems is crucial for optimal performance and safety. I’m familiar with several types:

- Manual Feed: The operator manually pushes the workpiece through the cutters. This method is suitable for small-scale operations or individual pieces, but is less efficient for high-volume work.

- Powered Roll Feed: Powered rollers pull the workpiece through the machine at a consistent speed. This system is more efficient than manual feed and offers better consistency.

- Chain Feed: Chains engage with the workpiece, precisely moving it through the cutting heads. This provides exceptional precision and repeatability, especially beneficial for complex tenons.

- Infeed/Outfeed Conveyors: These automated systems are commonly found in high-production environments to continuously feed and remove workpieces. This increases efficiency and reduces manual handling.

My experience includes troubleshooting issues with various feed systems. For instance, I once resolved a problem with a chain feed system by adjusting chain tension and cleaning accumulated sawdust, ensuring smooth and consistent workpiece movement.

Q 18. Describe your experience working with different types of cutting tools (e.g., blades, cutters)?

My experience encompasses a wide range of cutting tools used in tenoning machines. The choice of tool depends on the material, tenon profile, and desired finish.

- High-Speed Steel (HSS) Cutters: These are commonly used for softer woods. They are relatively affordable, but require more frequent sharpening.

- Carbide-Tipped Cutters: These offer superior durability and cutting life, ideal for hardwoods and high-volume production. They are more expensive but ultimately more cost-effective due to extended lifespan.

- Shaping Cutters: These create intricate profiles beyond simple rectangular tenons, allowing for complex joint designs.

- Profile Cutters: These are designed to produce specific tenon shapes, often used for decorative joints.

Proper cutter selection and maintenance are key to achieving high-quality cuts. Dull or damaged cutters can lead to poor finish, inaccurate cuts, and even machine damage. I’m skilled in sharpening and maintaining various cutter types, ensuring optimal performance and safety.

Q 19. What is your experience with preventative maintenance schedules for tenoning machines?

Preventative maintenance is crucial for ensuring the longevity and safety of tenoning machines. My experience includes developing and implementing comprehensive maintenance schedules, ensuring machines operate optimally and minimizing downtime. A typical schedule would include:

- Daily Checks: Inspecting for loose bolts, checking cutting tool sharpness and alignment, and cleaning sawdust buildup.

- Weekly Checks: Lubricating moving parts, checking feed system functionality, and inspecting drive belts.

- Monthly Checks: More thorough inspection of electrical components, testing safety mechanisms, and conducting more detailed lubrication.

- Annual Checks: Complete machine inspection, including blade balancing and alignment, and potentially replacing worn parts.

Maintaining detailed records of all maintenance activities is essential for tracking machine performance and identifying potential issues early on. Proactive maintenance significantly reduces the risk of unexpected breakdowns and costly repairs.

Q 20. Describe a time you had to troubleshoot a complex problem with a tenoning machine.

During a high-volume production run, a tenoning machine experienced inconsistent cutting depths. Initial checks revealed no obvious problems with the cutting tools or feed system. After systematically investigating each component, we discovered minute variations in the thickness of the incoming workpieces.

The solution involved a two-pronged approach:

- Improved Infeed System: We adjusted the infeed rollers to better accommodate the slight variations in workpiece thickness. This ensured a more consistent feed rate into the cutting heads.

- Program Adjustment (if applicable): In a CNC setting, the CNC program may need to be modified to adjust for the workpiece thickness variability with the help of sensors and feedback controls.

By implementing these adjustments, we restored consistent cutting depths, minimizing waste and ensuring high-quality output. This experience highlighted the importance of methodical troubleshooting and the need to consider all potential factors contributing to a problem.

Q 21. What is your understanding of the relationship between feed rate, blade speed, and cut quality?

The relationship between feed rate, blade speed, and cut quality is fundamental to tenoning machine operation. These three factors are intrinsically linked, and achieving optimal results requires careful balancing.

- Feed Rate: This refers to the speed at which the workpiece moves through the cutting tool. A slower feed rate typically leads to a cleaner cut, while a faster rate can lead to burning or chipping, especially in harder woods.

- Blade Speed: This is the rotational speed of the cutting tool. Higher blade speed generally produces a cleaner, smoother cut, but can increase the risk of overheating the workpiece and the tool.

- Cut Quality: This depends on the interaction of feed rate and blade speed. A well-balanced combination will yield a precise, clean, and burr-free tenon. Improper settings can lead to poor surface finish, chipping, burning, or even tool breakage.

Finding the optimal balance often involves trial and error. Experienced operators know how to adjust these parameters based on the wood type, tenon profile, and desired finish. For instance, a harder wood might require a slower feed rate and potentially a slightly higher blade speed to prevent tearing or burning. Conversely, softer woods may tolerate higher feed rates with slightly lower blade speed. Proper experimentation and careful observation are key to mastering this delicate interplay.

Q 22. What are the key safety features of a tenoning machine and how do they work?

Safety is paramount when operating a tenoning machine. These machines are powerful and can cause serious injury if not handled correctly. Key safety features include:

- Emergency Stop Button: A large, easily accessible button that instantly stops all machine functions in case of an emergency. Think of it as your ‘panic button’.

- Blade Guard: A safety guard that covers the blade when not in use, preventing accidental contact. It’s like a shield protecting you from the sharp blade.

- Push Sticks and Feeders: These tools help keep your hands a safe distance from the blade during operation, preventing accidental cuts. Imagine them as your extra helping hands.

- Foot Pedal Control (Optional): Some machines use foot pedals for power activation, freeing up your hands to manage the workpiece securely. This allows for better control and safety.

- Proper Machine Maintenance: Regularly checking for loose parts, blade sharpness, and lubrication is critical. A well-maintained machine is a safer machine. A dull blade can be more dangerous than a sharp one because it requires more force, increasing the risk of kickback.

All these features work together to create a safer working environment. Failing to use them properly can lead to serious injury.

Q 23. How do you interpret blueprints and specifications for tenoning operations?

Interpreting blueprints and specifications for tenoning is crucial for accurate work. I start by carefully reviewing the drawings to identify the dimensions of the tenon and mortise (the hole that receives the tenon). Key elements I look for include:

- Tenon Length, Width, and Thickness: These dimensions determine the size of the tenon to be cut.

- Shoulder Dimensions: The shoulders are the ends of the tenon; their precise dimensions are vital for a tight fit.

- Mortise Dimensions: The dimensions of the mortise must be slightly larger than the tenon to allow for a snug, yet not overly tight, fit.

- Cutting Angles (if any): Some designs require angled tenons; these angles must be precisely replicated.

- Material Specifications: The type of wood significantly impacts the cutting process and the final result; hardwood requires different settings than softwood.

I use a combination of careful measurement and an understanding of woodworking principles to translate the blueprint’s abstract representations into a precise cutting plan. I always double-check my interpretations before starting the cutting process. It’s far easier to make corrections on paper than on a piece of valuable wood!

Q 24. What is your understanding of different types of wood joints and their applications?

I have extensive knowledge of various wood joints. Here are a few common types and their applications:

- Through Tenon: A simple joint where the tenon extends completely through the mortise. It’s strong and widely used in furniture construction, such as chair legs and table frames.

- Blind Tenon: The tenon doesn’t fully extend through the mortise, leaving a portion hidden. This creates a cleaner look, often used in finer joinery.

- Haunched Tenon: A tenon with a reduced thickness at the shoulder for improved strength and easier assembly, especially for thicker stock.

- Mitre Tenon: A tenon cut at an angle, commonly used in frame-and-panel construction for mitered corners.

- Double Tenon: Two tenons are used for added strength and stability, particularly useful for load-bearing applications.

The choice of joint depends on the project’s specific requirements, considering factors like strength, aesthetics, and ease of assembly.

Q 25. How do you handle discrepancies between the blueprint and the actual dimensions?

Discrepancies between blueprints and actual dimensions require careful attention. My approach is:

- Verify the Blueprint: Double-check the blueprint for any errors or ambiguities. Sometimes, a simple oversight can explain the difference.

- Re-measure the Workpiece: Accurately measure the workpiece to confirm the discrepancy. Multiple measurements using different tools are crucial to eliminate measurement error.

- Analyze the Cause: Determine if the discrepancy is due to blueprint error, material inconsistencies, or a cutting error during a previous process.

- Consult Supervisor: If the discrepancy is significant or I’m unsure about the best course of action, I consult with my supervisor for guidance. Safety and quality are paramount.

- Document Findings: All discrepancies, corrective actions, and decisions are meticulously documented to maintain clear records and to prevent the recurrence of similar issues.

The goal is to identify the root cause and implement the appropriate correction to ensure the final product meets the specifications.

Q 26. What is your experience using measuring instruments to ensure accuracy in tenoning?

Accuracy is essential in tenoning. I regularly use various measuring instruments to ensure precise results, including:

- Steel Rules and Tape Measures: For overall dimensions and checking the workpiece.

- Calipers: For precise measurements of tenon thickness and width. Vernier calipers offer even greater accuracy.

- Squares: To verify the squareness of the tenon shoulders and the mortise.

- Digital Measuring Tools: These tools provide highly accurate readings, minimizing human error.

The choice of instrument depends on the required level of accuracy and the specific measurement being taken. I always calibrate my instruments regularly and employ best practices to ensure accurate readings. A small mistake in measurement can create a big problem in the final assembly.

Q 27. What is your understanding of the impact of different cutting angles on the tenon’s strength?

Cutting angles significantly impact a tenon’s strength. A perfectly square tenon (90-degree angle) provides maximum strength in the joint. However, angled tenons can be necessary for specific designs.

- Increased Strength (within reason): Slight angles may increase strength in some cases, depending on the design and wood grain orientation. This can optimize the fit and enhance the joint’s structural integrity.

- Weakened Joint: Steeper angles or poorly executed cuts will weaken the joint, increasing the risk of failure.

- Aesthetic Considerations: Angles are often used for stylistic purposes. The trade-off between aesthetics and structural strength must be carefully considered.

Understanding wood grain direction is critical. Cutting along the grain usually results in a stronger tenon than cutting across it.

Q 28. How do you prioritize safety and productivity while operating a tenoning machine?

Prioritizing safety and productivity requires a balanced approach. I always adhere to the following:

- Safety First: I never compromise safety for speed. Following all safety procedures and using appropriate safety equipment is my top priority.

- Efficient Workflows: I optimize my workflow to minimize wasted time and maximize output without sacrificing accuracy or safety. Careful planning and setup are crucial here.

- Regular Maintenance: Well-maintained equipment operates more efficiently and safely, reducing downtime and the risk of accidents. I perform regular checks and cleaning.

- Continuous Improvement: I consistently look for ways to improve my techniques and processes to enhance both safety and productivity. Learning from mistakes and seeking feedback from colleagues helps improve efficiency.

The most efficient operator is the one who goes home safely each day, having completed high-quality work.

Key Topics to Learn for Tenoning Machine Operation Interview

- Machine Setup and Calibration: Understanding the various settings and adjustments required for different wood types and tenon sizes. This includes blade alignment, feed rate adjustments, and depth of cut settings.

- Safe Operating Procedures: Demonstrating knowledge of safety protocols, including lockout/tagout procedures, proper personal protective equipment (PPE) usage, and emergency shutdown procedures. Practical application includes describing your experience following these protocols.

- Material Handling and Wood Selection: Understanding the properties of different wood types and their impact on tenoning. This includes knowing how to handle lumber safely and efficiently, and selecting appropriate material for the project.

- Troubleshooting and Maintenance: Ability to identify common malfunctions, perform basic maintenance tasks (e.g., blade changes, lubrication), and describe your problem-solving approaches when faced with machine errors. This includes preventative maintenance strategies.

- Quality Control and Inspection: Understanding the importance of producing high-quality tenons that meet specifications. This includes inspection techniques to ensure accuracy and identify defects.

- Production Efficiency and Optimization: Demonstrating an understanding of how to maximize production while maintaining quality. This could include knowledge of different cutting techniques and strategies to minimize waste.

- Understanding Tenon Joint Types and Applications: Demonstrate familiarity with various tenon joint types (e.g., through tenons, stub tenons) and their appropriate applications in different woodworking projects.

Next Steps

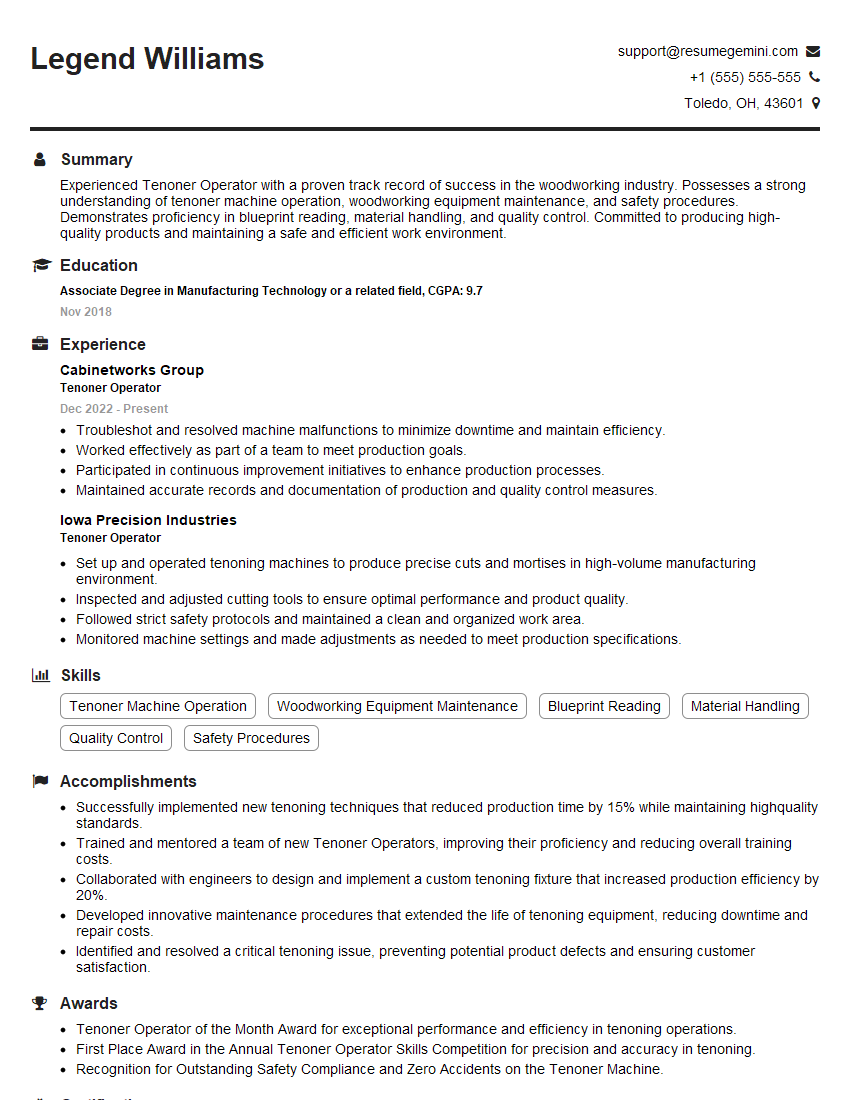

Mastering Tenoning Machine Operation opens doors to exciting career opportunities in woodworking, manufacturing, and construction, offering competitive salaries and potential for advancement. A strong resume is crucial to landing your dream job. Crafting an ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of getting noticed by potential employers. Use ResumeGemini to build a professional and impactful resume that showcases your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Tenoning Machine Operation, helping you present yourself as the ideal candidate.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO