Unlock your full potential by mastering the most common TIG Welding of Semiconductor Components interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in TIG Welding of Semiconductor Components Interview

Q 1. Explain the principles of Gas Tungsten Arc Welding (GTAW/TIG).

Gas Tungsten Arc Welding (GTAW), or TIG welding, is a highly precise arc welding process that uses a non-consumable tungsten electrode to produce the weld. The process relies on a precisely controlled arc to melt the base materials, which are then fused together. A shielding gas, typically argon or a mixture of argon and helium, protects the weld pool from atmospheric contamination, ensuring high-quality welds. Unlike other arc welding processes, filler metal is often added separately, giving the welder fine control over the weld bead.

Think of it like this: the tungsten electrode acts like a tiny, incredibly hot pencil that creates the heat, the shielding gas is a protective bubble preventing oxygen and nitrogen from spoiling the weld, and the filler metal (if used) is like carefully adding paint to complete the picture. The entire process is very precise, requiring skill and control to achieve good results.

Q 2. Describe the differences between AC and DC TIG welding.

The key difference between AC and DC TIG welding lies in the type of electrical current used. DC (Direct Current) provides a constant polarity, either electrode-positive (DC+) or electrode-negative (DC-). DC+ results in better penetration and is generally preferred for thicker materials. DC- produces a cleaner weld puddle and is better for thin materials and aluminum.

AC (Alternating Current) welding, on the other hand, switches polarity continuously. This is particularly useful for welding aluminum because the alternating polarity helps to clean the surface of the aluminum oxide layer, enabling better weld penetration. The frequency of the current switching can be adjusted to optimize the cleaning effect. However, AC welding generally offers slightly less penetration compared to DC welding.

In semiconductor applications, the choice often leans toward AC for aluminum components and DC for other materials depending on their thickness and the specific application requirements. The choice hinges on achieving the optimal balance between penetration and weld bead quality.

Q 3. What are the critical factors influencing weld quality in semiconductor applications?

In semiconductor applications, weld quality is paramount because even minor defects can lead to component failure or malfunction. Critical factors influencing this include:

- Heat Input: Too much heat can cause distortion and damage to sensitive components; too little heat results in incomplete fusion. Precise control is essential.

- Weld Penetration: The weld needs to fully penetrate the base material to ensure proper strength and reliability. Insufficient penetration is a significant concern.

- Contamination: The presence of even microscopic contaminants (dust, oxide layers) can drastically weaken the weld and compromise its integrity. This is why cleanroom environments are critical.

- Porosity: Pores, or small voids, within the weld indicate a problem with gas entrapment during the welding process. These weaken the weld and increase the risk of failure.

- Intermetallic Compounds: In multi-material welds, the formation of brittle intermetallic compounds can severely impact weld quality. Material selection and welding parameters are vital to prevent this.

Each of these factors needs meticulous control and monitoring to guarantee that semiconductor welds are strong, reliable, and defect-free. A single flaw can mean the difference between a functional device and a costly failure.

Q 4. What filler metals are commonly used in TIG welding of semiconductor components?

The filler metals used in TIG welding semiconductor components must be highly pure and precisely matched to the base materials. Common choices include:

- High-purity Aluminum (various alloys): For aluminum components, ensuring the purity and alloy composition match is crucial to avoid intermetallic compound formation.

- High-purity Gold (Au): Frequently employed for bonding gold wires and other gold-containing components. The purity ensures excellent electrical conductivity.

- High-purity Copper (Cu): Occasionally used for copper wire bonding or connecting copper components. The high thermal and electrical conductivity is key.

- Nickel-based alloys: In certain specialized semiconductor packaging applications where specific high-temperature properties are needed.

The selection of filler metal is driven by the specific materials being joined and the application’s functional requirements. The cleanliness and the precise composition of the filler metal are paramount to ensure a reliable and high-quality weld.

Q 5. How do you select the appropriate shielding gas for semiconductor TIG welding?

Shielding gas selection is crucial for preventing contamination and ensuring weld quality. For most semiconductor applications, argon (Ar) is the preferred shielding gas due to its inert nature and ability to create a stable arc. However, a mixture of argon and helium (Ar/He) can be used to increase penetration and improve arc stability, depending on material thickness and welding parameters.

The purity of the shielding gas is paramount. High-purity argon (99.998% or higher) is essential to minimize the risk of impurities compromising the weld. Any contaminant can severely compromise the weld’s strength and reliability.

The selection of the gas mixture and the purity level are determined based on the specifics of the materials involved and the desired weld characteristics. For instance, a higher helium content might be chosen for thicker materials to improve penetration.

Q 6. Explain the importance of cleanroom practices in semiconductor TIG welding.

Cleanroom practices are absolutely indispensable in semiconductor TIG welding. Even tiny particles of dust or other contaminants can wreak havoc on the weld quality, resulting in porosity, weakness, and ultimately, component failure. These particles can be introduced from the air, the welder’s clothing, or the surrounding environment.

Strict adherence to cleanroom protocols, including the use of cleanroom garments, filtered air, regular cleaning procedures, and meticulous preparation of the welding area, is essential to minimize contamination risk. The welder’s technique, equipment cleanliness, and the surrounding environment all play a role in maintaining the purity needed for a successful and reliable weld. A seemingly small speck of dust can have a disproportionately large negative impact.

Q 7. Describe the process of setting up a TIG welding machine for semiconductor applications.

Setting up a TIG welding machine for semiconductor applications requires precision and attention to detail. The steps generally include:

- Selecting the appropriate welding machine: A high-frequency TIG welder with precise current and voltage control is essential. The unit should allow for adjustments in pulse frequency and waveform, particularly if welding aluminum.

- Choosing the correct electrode: A tungsten electrode of the appropriate size and purity is crucial. The electrode should be sharpened to a fine point to ensure a stable and focused arc. The type of tungsten (e.g., pure tungsten, thoriated tungsten) should be selected based on the material being welded.

- Setting the shielding gas flow rate: A sufficient flow rate is necessary to create a protective blanket around the weld pool. The specific flow rate will depend on the nozzle size, the welding current, and the shielding gas used.

- Selecting and setting the welding parameters: Current, voltage, pulse frequency, and pulse width must be precisely set according to the materials being welded and the desired weld penetration. These parameters require careful optimization based on experiments or existing procedures.

- Preparing the workpiece: The components to be welded must be thoroughly cleaned and degreased to remove any contaminants. The weld area should be precisely positioned to achieve proper alignment and penetration.

- Calibrating the machine: Before welding critical components, a calibration weld should be performed on a similar material to ensure the parameters are correctly set and to check for defects.

Once these steps are completed, the welder can start the process, ensuring strict adherence to cleanroom procedures throughout the entire welding operation.

Q 8. How do you control weld penetration and bead shape in micro TIG welding?

Controlling weld penetration and bead shape in micro TIG welding is crucial for the integrity of semiconductor components. It’s a delicate balance achieved through precise manipulation of several parameters. Think of it like drawing a fine line with a very precise pen – too much pressure, and you’ll break through; too little, and the line is faint.

Current (Amperage): Lower amperage results in shallower penetration and a narrower bead. Increasing amperage increases both. We usually work with extremely low amperages, often in the single-digit range, for semiconductor work.

Voltage: Higher voltage increases arc length, leading to a wider and potentially deeper weld pool. Lower voltage concentrates the arc, resulting in better control and a narrower weld bead. Voltage adjustments are subtle and critical in micro TIG.

Travel Speed: Slower travel speeds allow for deeper penetration as more heat is applied to a smaller area. Faster speeds produce shallower welds and narrower beads. Maintaining consistent speed is paramount for even bead formation.

Tungsten Electrode Angle and Distance: The angle of the tungsten electrode relative to the workpiece significantly affects the weld pool shape. A steeper angle focuses the heat, resulting in deeper penetration. The distance between the electrode and the workpiece (arc length) must be carefully maintained for consistent arc stability and bead width. A longer arc is wider, shorter more concentrated.

Shielding Gas Flow Rate: Proper shielding gas flow protects the weld from atmospheric contamination. Too little gas can lead to oxidation, while too much can disrupt the arc and hinder bead formation. We often use argon, or a mixture with helium for increased penetration control.

In practice, we often use a combination of these parameters to achieve the desired outcome. For example, to create a very shallow, narrow weld, we might use a low amperage, low voltage, and a relatively fast travel speed, combined with a focused tungsten angle. For deeper welds, we increase amperage and slow the travel speed while adjusting other parameters accordingly.

Q 9. What are the common defects found in TIG welds of semiconductor components, and how are they prevented?

Common defects in TIG welds of semiconductor components often stem from the extremely small scale and the sensitivity of the materials. They can severely impact functionality and reliability. Prevention is key, and requires meticulous attention to detail.

Porosity: Small holes in the weld, caused by trapped gas. Prevention: Ensuring proper shielding gas coverage, using clean materials, and optimizing welding parameters.

Incomplete Fusion: Areas where the weld metal doesn’t fully fuse with the base metal. Prevention: Proper joint preparation, adequate heat input, and proper control of the arc.

Undercutting: A groove melted into the base metal adjacent to the weld. Prevention: Careful control of amperage, travel speed, and tungsten angle. Avoid excessive heat input.

Cracking: Fractures in the weld metal due to residual stresses or material incompatibility. Prevention: Preheating the workpiece (if necessary), selecting appropriate filler material, and employing post-weld heat treatments.

Excess spatter: Small molten metal droplets scattered around the weld. Prevention: Optimizing welding parameters, maintaining a clean workspace, and using a suitable filler material.

Regular inspection using optical microscopy or even SEM (Scanning Electron Microscopy) is crucial to catch defects early and make adjustments to the process as needed. Careful documentation and adherence to stringent quality control protocols are indispensable. A single flawed weld on a microchip can lead to significant failure in the final product.

Q 10. What safety precautions are essential when performing TIG welding in a semiconductor environment?

Safety is paramount in a semiconductor environment, where even small amounts of contamination can be damaging. TIG welding introduces specific hazards that must be mitigated carefully.

Eye and Skin Protection: Always wear a welding helmet with appropriate shade filters and protective clothing, including gloves, to shield from UV radiation and molten metal spatter.

Respiratory Protection: Welding fumes contain harmful particles and gases. A properly fitted respirator should be used, especially when welding certain materials or in enclosed areas.

Fire Prevention: Flammable materials should be kept well away from the welding area. The environment should be free of combustible materials, and appropriate fire extinguishers should be readily available.

Electrocution Prevention: Ensure proper grounding and insulation to prevent electrical shocks. Avoid touching the workpiece or electrode while the power is on.

Cleanliness: Maintaining a clean and organized workspace is crucial to prevent contamination of the sensitive semiconductor components. The use of clean room practices is highly important here.

Shielding Gas Safety: Argon is an inert gas, but working in a confined space can lead to oxygen displacement and asphyxiation. Ensure proper ventilation and monitor gas concentrations. Helium is also commonly used and potentially flammable.

Regular safety training and adherence to established safety protocols are vital. We conduct rigorous pre-weld inspections and regularly review safety procedures to ensure the well-being of all personnel involved.

Q 11. Explain the importance of maintaining consistent amperage and voltage during the welding process.

Maintaining consistent amperage and voltage during TIG welding is crucial for producing high-quality, repeatable welds. Inconsistent power supply leads to inconsistent heat input, creating defects and affecting the overall quality.

Think of it like baking a cake: if the oven temperature fluctuates, the cake will be unevenly cooked. Similarly, inconsistent amperage and voltage cause the weld pool to vary in size and temperature, leading to issues like porosity, incomplete fusion, and irregular bead shape. In micro-TIG, this is amplified due to the smaller weld pool and the delicate nature of the materials.

Constant monitoring of amperage and voltage is achieved through the use of precise power sources with digital displays and feedback systems. Advanced TIG welders have integrated controls which allow presetting of the weld parameters, thus enabling efficient, repeatable work. Furthermore, proper calibration and regular maintenance of the welding equipment are essential to ensuring consistent power delivery.

Q 12. How do you ensure proper joint preparation for optimal weld quality?

Proper joint preparation is fundamental to achieving optimal weld quality in micro TIG welding of semiconductor components. This involves creating a clean, precisely aligned joint that facilitates good heat transfer and penetration.

Cleanliness: The surfaces to be welded must be meticulously cleaned to remove any oxides, contaminants, or grease. This often involves using specialized cleaning agents and techniques to maintain a cleanroom level of cleanliness.

Joint Design: The joint design should provide sufficient weld area and ensure proper alignment. Common joint designs for semiconductor applications include butt joints and lap joints, often requiring the use of jigs and fixtures to maintain precision.

Fixturing: Accurate fixturing is critical for holding the components in precise alignment during welding. The fixtures themselves must be non-contaminating and capable of withstanding the heat generated during welding.

Gap Control: The gap between the parts to be welded is extremely important. A small, consistent gap ensures proper penetration without creating excessive weld metal buildup. Even small inconsistencies can lead to defects.

The level of precision required in semiconductor welding means that joint preparation is often a time-consuming and critical step. Using specialized equipment and techniques like precision grinding and laser cleaning is frequently required to achieve the necessary accuracy and cleanliness.

Q 13. What techniques are employed to minimize weld distortion in sensitive components?

Minimizing weld distortion in sensitive semiconductor components is a major challenge due to the high thermal gradients involved in the welding process. Techniques employed aim to distribute the heat and minimize localized stresses.

Low Heat Input Welding: Using lower amperage and faster travel speeds reduces the overall heat input, minimizing distortion.

Pulse Welding: Pulse TIG welding delivers current in short pulses, reducing the peak heat input and enabling better control over the weld pool. This is commonly used in micro-TIG.

Preheating/Post-heating: Preheating the workpiece can reduce thermal shock during welding and reduce the tendency for distortion. Controlled post-weld cooling can also help to minimize residual stresses.

Backing Strips/Shims: Using backing strips or shims behind the weld joint can provide support and reduce distortion by restricting metal flow during the welding process.

Fixture Design: Carefully designed fixtures offer mechanical support and constrain the movement of the components during welding.

Welding Sequence: The sequence in which welds are applied can significantly affect distortion. Planning the weld sequence carefully to minimize cumulative effects is critical.

In practice, we often use a combination of these techniques. For instance, a complex assembly might utilize preheating, a carefully planned welding sequence with pulse TIG welding, and supportive fixturing to minimize distortion to an acceptable level. Finite Element Analysis (FEA) is sometimes used to model and predict the effects of welding on the component’s structural integrity.

Q 14. Describe the different types of TIG welding torches and their applications.

TIG welding torches come in various designs to suit different applications, especially crucial in micro-TIG where precision and accessibility are paramount.

Air-Cooled Torches: These are simple and relatively inexpensive. They are suitable for lower amperage applications and are commonly used for micro-TIG work where extreme heat isn’t required. Their simplicity contributes to better control in delicate operations. Cooling is provided by the ambient air.

Water-Cooled Torches: These are used for higher amperage applications requiring greater heat dissipation. The water cooling allows for higher current without overheating the torch, providing more power for bigger welds, although this is rarely necessary for micro-TIG.

Flex Neck Torches: These offer greater maneuverability and allow access to tight spaces, ideal for welding complex semiconductor components. The flexible neck allows for precise positioning of the electrode, enabling superior control over the weld pool.

Micro-TIG Torches: Specifically designed for micro-welding applications, these torches feature smaller bodies and electrodes, enabling precise control over small weld pools. They are highly specialized and are crucial for the fine control needed in semiconductor work.

Gas Lens Torches: These incorporate a gas lens system that improves the quality and stability of the arc. The lens focuses the shielding gas, providing enhanced arc shielding and reducing weld spatter.

The choice of torch depends on the specific application. For micro-TIG welding of semiconductor components, we primarily utilize air-cooled or gas lens micro-TIG torches with a flexible neck to gain the necessary precision and access.

Q 15. What are the advantages and limitations of using TIG welding compared to other welding methods for semiconductors?

TIG welding, or Gas Tungsten Arc Welding (GTAW), offers several advantages over other methods for joining semiconductor components due to its precision and control. Its primary benefit is the ability to produce high-quality welds with minimal heat input, crucial for delicate semiconductor materials which are highly sensitive to thermal damage. This minimizes the risk of warping, cracking, or altering the electrical properties of the components.

- Advantages: Excellent control over weld bead shape and size, minimal heat-affected zone (HAZ), high weld quality, suitability for a variety of metals, and ease of automation for repeatable processes.

- Limitations: Relatively slower welding speed compared to methods like resistance welding, requires a skilled operator, and the process can be more complex to set up.

For instance, in contrast to resistance welding, which can cause significant heating and potential damage to the semiconductor material, TIG welding’s precise control allows for joining of dissimilar metals and extremely fine wires often encountered in semiconductor packaging with minimal risk of component degradation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you perform post-weld inspection and verification?

Post-weld inspection is critical to ensure the integrity of the weld and the overall functionality of the semiconductor device. It typically involves a multi-faceted approach:

- Visual Inspection: This is the first step, checking for any obvious defects like cracks, undercuts, or excessive spatter. Magnification is often employed to detect very fine imperfections.

- Microscopic Examination: A more detailed examination using a microscope to assess the weld’s microstructure, identifying potential porosity, inclusions, or incomplete penetration. This helps to determine the weld’s metallurgical quality.

- Dye Penetrant Testing (PT): This non-destructive test uses a dye to reveal surface-breaking defects like cracks that might not be visible to the naked eye. It’s particularly useful in identifying tiny cracks which could compromise the weld’s strength and hermeticity.

- Electrical Testing: This is crucial for semiconductor applications, verifying the electrical continuity and integrity of the weld joint. It checks for any short circuits or increased resistance that might result from a poorly formed weld.

- Radiographic Testing (RT) or X-ray inspection: For critical applications, X-ray inspection can detect internal defects like porosity or incomplete fusion that are not visible on the surface. This is especially important in hermetic sealing applications where leakage cannot be tolerated.

The specific techniques used will depend on the application’s criticality and the requirements specified in the design documentation.

Q 17. What are the common causes of porosity in TIG welds, and how are they addressed?

Porosity, the presence of small holes or voids in the weld, is a common defect in TIG welding, particularly with semiconductors. Several factors contribute to its formation:

- Contamination: The presence of oxides, grease, or other contaminants on the base metal or filler material can become trapped in the weld pool, forming pores. Thorough cleaning before welding is therefore essential.

- Improper Shielding Gas Coverage: Inadequate shielding gas flow or turbulence can allow atmospheric gases (like oxygen or nitrogen) to enter the weld pool, creating porosity. Maintaining a consistent and sufficient flow of the shielding gas is vital.

- Excessive Moisture: Moisture in the base metal, filler wire, or surrounding environment can produce hydrogen gas during the welding process, leading to the formation of small pores. Proper drying of materials and environmental control is crucial.

- Incorrect Welding Parameters: Parameters such as amperage, voltage, and welding speed can impact the weld pool’s fluidity and can trap gases, leading to porosity. Optimization of parameters is paramount for a defect-free weld.

Addressing porosity involves a multifaceted approach including meticulous cleaning of the base materials, employing appropriate shielding gas flow and purity, ensuring materials are dry, and optimizing welding parameters based on the specific materials and application. Trial welds are often conducted to refine the parameters and mitigate porosity before proceeding with critical welds.

Q 18. Explain your experience with different types of filler metals (e.g., gold, silver, aluminum).

My experience encompasses working with various filler metals, each possessing unique properties suitable for specific applications in semiconductor welding. The choice of filler metal greatly influences the weld’s mechanical, thermal, and electrical properties.

- Gold (Au): Commonly used for its excellent electrical conductivity and corrosion resistance. It’s frequently used in high-reliability applications where electrical performance is paramount, such as in wire bonding or interconnections.

- Silver (Ag): Also boasts high electrical conductivity and good thermal conductivity, making it a viable alternative to gold in some applications, offering a cost-effective solution.

- Aluminum (Al): Offers advantages in applications requiring high thermal conductivity and lightweight constructions. However, its susceptibility to oxidation necessitates careful cleaning procedures and specialized filler materials to ensure a clean weld.

In one project, we used gold wire for bonding very fine wires to delicate semiconductor chips. The low heat input of TIG welding, coupled with gold’s properties, ensured a reliable and robust connection without damaging the surrounding components. In another instance, we employed a silver-based filler to join aluminum heat sinks to a semiconductor package to enhance heat dissipation. Selecting the appropriate filler metal requires careful consideration of the base metal, the intended application, and the desired weld properties.

Q 19. How do you handle different base metal thicknesses during TIG welding?

Handling varying base metal thicknesses requires adjustments to the welding parameters to ensure complete penetration and a sound weld. Thicker materials require higher current and potentially a slower welding speed to allow sufficient heat to penetrate the entire joint. Conversely, thinner materials necessitate a lower current and potentially a higher welding speed to prevent excessive melting and burn-through. This is often approached by employing specialized techniques like using a smaller diameter electrode and changing the angle of the electrode.

In addition to current and speed adjustments, the use of backing materials (e.g., copper backing plates) can be crucial for preventing burn-through in thin materials. The backing material conducts heat away from the weld zone, promoting a more uniform weld bead.

For example, when welding a very thin gold wire to a thicker substrate, we would start with a low amperage and ensure the arc is precisely focused to ensure adequate fusion without causing burn-through. Experience and careful control of the welding process are crucial for success in these situations.

Q 20. Describe your experience with different types of joint designs in semiconductor welding.

My experience spans various joint designs critical for semiconductor welding, each chosen based on the application’s mechanical and electrical requirements.

- Butt Joints: Used when joining two parts end to end, requiring precise alignment and proper preparation of the joint surfaces for optimal penetration.

- Lap Joints: Two overlapping parts are welded together, offering a simpler design but potentially a less structurally robust connection. Often used with thin components where alignment is a concern.

- T-Joints: One part joins perpendicularly to another, needing careful manipulation of the welding torch to ensure proper fusion and penetration.

- Edge Joints: This involves welding the edges of two overlapping components, offering a good combination of strength and aesthetics.

The selection of the joint design often takes into account factors such as the materials being joined, the required strength, the size of the components, and overall device design constraints. For example, a lap joint might be preferred when welding thin gold wires to avoid damaging the wire during clamping preparation for a butt joint.

Q 21. How do you maintain and clean your TIG welding equipment?

Maintaining and cleaning TIG welding equipment is crucial for ensuring consistent weld quality and the longevity of the equipment. Regular maintenance prevents defects and extends the lifespan of components. My routine includes:

- Daily Cleaning: After each use, cleaning the tungsten electrode by grinding it to a fine point to remove contamination and maintaining optimal arc characteristics. Cleaning the torch body to remove spatter and ensure gas flow. Cleaning the work area and removing any spatter or debris.

- Regular Inspection: Regularly inspect all gas lines, ensuring connections are tight and free of leaks. Checking gas regulators and pressure gauges. Periodic inspection of the welding power source to ensure proper function.

- Preventative Maintenance: Following the manufacturer’s recommendations for preventative maintenance, which may include changing filters or lubricating moving parts.

- Electrode Storage: Storing the tungsten electrodes properly to protect them from damage or contamination.

Neglecting these routines can lead to poor weld quality, equipment damage, and even safety hazards. Regular maintenance is crucial, ensuring reliable and high-quality welds in the demanding semiconductor industry.

Q 22. What is the importance of using a calibrated welding machine?

A calibrated welding machine is crucial in semiconductor TIG welding for ensuring consistent and repeatable weld quality. Calibration verifies the accuracy of the machine’s parameters – current, voltage, pulse frequency, etc. – against established standards. Without calibration, you risk inconsistencies in weld penetration, bead shape, and overall integrity, leading to potential defects that can compromise the performance and reliability of the semiconductor component. Think of it like using a precise scale in a pharmacy; a slight inaccuracy can have significant consequences. A calibrated machine ensures that every weld meets the stringent specifications required in semiconductor manufacturing, minimizing rework and maximizing yield.

Q 23. Describe your experience with troubleshooting TIG welding issues.

Troubleshooting TIG welding issues in semiconductor work requires a systematic approach. I typically start by visually inspecting the weld for defects such as porosity, undercutting, or lack of fusion. This gives initial clues about the potential root cause. Then, I analyze the welding parameters – current, voltage, gas flow, and travel speed – to identify any deviations from the established process parameters. For example, insufficient gas flow might lead to oxidation, while incorrect current settings can result in poor penetration. I also check for contamination on the workpiece or the tungsten electrode, as even tiny particles can affect the weld quality. If the problem persists, I might investigate the power source itself, ensuring it’s functioning correctly. Documenting each step and the adjustments made is crucial for continuous improvement and future problem solving. One memorable instance involved persistent porosity in a series of welds. After systematically checking all parameters, I found a tiny leak in the argon gas line. Replacing the line immediately resolved the issue.

Q 24. What are your preferred methods for cleaning weld spatter?

Cleaning weld spatter in a cleanroom environment requires meticulous care to avoid contaminating the surrounding area and the components. My preferred methods involve using specialized tools such as a small wire brush or a stainless steel scraper designed for delicate work. These tools allow me to carefully remove spatter without damaging the surrounding material. For more stubborn spatter, I might use a low-pressure air gun, ensuring the air is filtered to prevent particulate contamination. Afterwards, I always thoroughly clean the area with a cleanroom-approved solvent and lint-free wipes. The key is to choose cleaning methods that are both effective and compatible with the cleanroom environment’s strict cleanliness requirements.

Q 25. How do you ensure traceability and documentation in a cleanroom welding environment?

Traceability and documentation are paramount in a cleanroom welding environment. Every weld must be meticulously documented, including the date, time, operator, welding parameters (current, voltage, gas flow, pulse frequency etc.), part number, and any relevant observations. This information is typically entered into a database or a specialized software system. We use unique identification numbers or barcodes for tracking individual parts throughout the entire process, from receiving to final inspection. This ensures complete traceability, allowing us to identify and analyze any issues that might arise. Furthermore, regular calibration records of the welding equipment are maintained, demonstrating that the equipment is operating within specified tolerances. This comprehensive documentation helps us maintain high quality standards and meet stringent regulatory requirements.

Q 26. Explain your understanding of different welding parameters (e.g., pulse frequency, pulse width).

Understanding welding parameters is crucial for optimal weld quality.

- Pulse Frequency: This refers to the number of pulses per second. Higher frequency typically results in a smoother weld bead with better control of heat input, useful for thinner materials or intricate joints. Lower frequency is usually employed for deeper penetration in thicker materials.

- Pulse Width: This determines the duration of each pulse. A wider pulse width delivers higher heat input per pulse, leading to better penetration. A narrower pulse width reduces heat input, promoting better control and reducing the risk of burn-through in delicate components.

Q 27. Describe a situation where you had to overcome a challenging TIG welding problem. (Focus on technical aspects).

I once faced a challenge welding extremely fine gold wires (less than 50 microns in diameter) onto delicate silicon wafers. The challenge was maintaining consistent weld penetration without causing damage to the silicon. The gold’s low melting point made it prone to burn-through, and the fine wire diameter made precise control of the heat input paramount. After experimenting with different pulse frequency and width settings, we discovered that a very high pulse frequency with a relatively narrow pulse width provided the optimal balance between sufficient penetration and minimizing heat distortion. We also implemented a precise pre-flow and post-flow gas purge to protect the weld zone from oxidation during the process. This required significant adjustments to the standard parameters and a meticulous approach to each weld, but ultimately allowed us to successfully and reliably complete the project without compromising the integrity of the wafers. This experience highlighted the importance of adapting and optimizing the welding parameters to accommodate specific material properties and geometrical constraints.

Key Topics to Learn for TIG Welding of Semiconductor Components Interview

- Understanding the TIG Welding Process: Explore the principles of Gas Tungsten Arc Welding (GTAW), focusing on its suitability for delicate semiconductor components. This includes understanding the role of shielding gas, electrode selection, and current control.

- Material Science & Metallurgy: Gain a strong understanding of the materials used in semiconductor manufacturing (e.g., silicon, various metals and alloys) and how their properties influence the welding process. Focus on material compatibility and potential issues like thermal stress and cracking.

- Joint Design & Preparation: Master the techniques for preparing joints for TIG welding, including cleaning, fitting, and fixturing, specific to the small scale and precision required in semiconductor work. Learn different joint types and their applications.

- Weld Parameter Optimization: Learn how to adjust welding parameters (current, voltage, gas flow, travel speed) to achieve high-quality welds with minimal heat input to prevent damage to sensitive components.

- Defect Identification & Prevention: Develop the ability to identify common weld defects (porosity, cracks, lack of fusion) and understand the root causes. Learn preventative measures and troubleshooting strategies.

- Safety Procedures & Regulations: Demonstrate familiarity with safety protocols for TIG welding, including personal protective equipment (PPE), handling of gases, and proper waste disposal.

- Quality Control & Inspection: Understand different inspection techniques used to ensure the integrity of welds, such as visual inspection, non-destructive testing (NDT) methods, and the importance of documentation.

- Advanced Techniques (as applicable): Explore advanced techniques like pulsed TIG welding or specialized fixturing as needed for specific applications in semiconductor manufacturing.

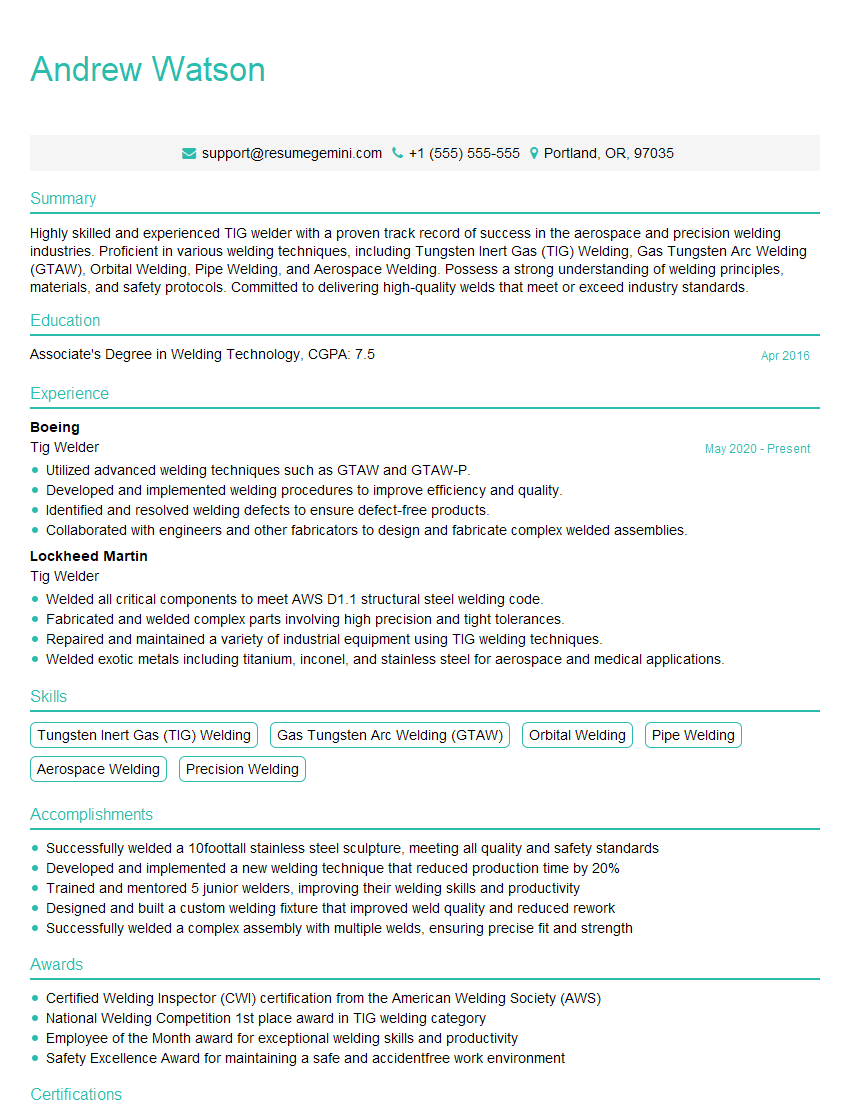

Next Steps

Mastering TIG welding of semiconductor components opens doors to a rewarding career in a high-tech industry demanding precision and expertise. Your skills will be highly sought after by leading semiconductor manufacturers, ensuring strong job security and excellent career progression. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to TIG Welding of Semiconductor Components are available to help guide you. Take the next step in your career journey today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO