Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Tool Inspection and Verification interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Tool Inspection and Verification Interview

Q 1. Explain the process of verifying the accuracy of a micrometer.

Verifying a micrometer’s accuracy involves comparing its readings to a known standard. This is crucial because even slight inaccuracies can lead to significant errors in manufacturing. Think of it like calibrating a kitchen scale – you wouldn’t want to bake a cake using an inaccurate scale!

The process typically involves:

- Using a traceable standard: We use gauge blocks (precision-machined blocks of known dimensions) or a master micrometer that has been recently calibrated by a certified lab. These standards have certificates tracing their accuracy back to national or international standards.

- Measuring the gauge blocks: We carefully measure several gauge blocks of different thicknesses with the micrometer, noting the readings.

- Comparing readings: We then compare the micrometer’s readings to the known dimensions of the gauge blocks. Any deviation indicates an error.

- Calibration adjustment (if needed): Some micrometers have an adjustment mechanism; if the error is within an acceptable range, it might be corrected. Otherwise, the micrometer needs to be sent for recalibration.

- Documentation: All readings and comparisons are meticulously documented, including the date, gauge block serial numbers, and any adjustments made.

For example, if a 10mm gauge block reads 10.002mm on the micrometer, it indicates a small positive error. This error needs to be considered for future measurements with that specific micrometer.

Q 2. Describe your experience with different types of measuring instruments (e.g., calipers, CMMs).

My experience encompasses a wide range of measuring instruments, from basic tools to sophisticated technologies. I’ve extensively used:

- Vernier Calipers: These are versatile for quick measurements of length, depth, and inside/outside diameters. I’ve used them daily for checking dimensions of various parts in manufacturing settings, from small electronic components to larger mechanical assemblies.

- Dial Calipers: Similar to vernier calipers but with a dial indicator for more precise readings, especially useful for repetitive measurements. I find them particularly efficient when rapid and consistent readings are crucial.

- Micrometers: For extremely precise measurements, micrometers are essential. I have experience using both outside and inside micrometers, for instance, when checking the diameter of a shaft or the bore of a hole. Understanding their proper usage and zero setting is crucial for accuracy.

- Coordinate Measuring Machines (CMMs): CMMs are invaluable for three-dimensional measurements and inspection of complex parts. I’m proficient in operating different types of CMMs (e.g., bridge-type, gantry-type) and employing various probing techniques for high precision, including touch-trigger and laser scanning probing. I can also program CMMs and interpret measurement data effectively.

Each instrument has its strengths and limitations; selecting the right tool for the job is critical for ensuring accurate measurements and efficient inspection.

Q 3. How do you identify and document non-conforming tools?

Identifying non-conforming tools involves a systematic approach. It starts with a thorough inspection against the tool’s specifications and tolerances. If any deviation exceeds these limits, the tool is considered non-conforming.

The documentation process involves:

- Clear Identification: The tool is uniquely identified (e.g., using a serial number, tag, or other identifier).

- Detailed Description: The nature of the non-conformity is precisely described. For example, ‘Micrometer #1234, reading consistently 0.005mm high’. Supporting images or videos may be used.

- Measurement Data: The actual measurements taken during the inspection, compared to the specified dimensions, are recorded.

- Cause Analysis (if possible): An attempt is made to determine the root cause of the non-conformity (e.g., damage, wear, or incorrect calibration).

- Disposition: The disposition of the non-conforming tool is documented; this might include repair, rejection, or quarantine until further investigation.

- Record Keeping: All information is documented in a controlled manner, often using a non-conformance report (NCR) that adheres to ISO 9001 or similar standards. This provides traceability and allows us to monitor trends.

We maintain a dedicated database for non-conforming tools, tracking their status and history, which is crucial for corrective and preventive actions. This prevents the same problem from recurring.

Q 4. What are the common causes of tool wear and how can they be prevented?

Tool wear is a common problem in manufacturing, leading to inaccurate measurements and potentially defective products. Several factors contribute to it:

- Abrasion: The friction between the tool and the workpiece causes gradual material removal. Think of a knife blade becoming dull with frequent use.

- Impact: Impacts, especially during forceful measurements or accidental drops, can damage the measuring surfaces or internal mechanisms.

- Corrosion: Exposure to moisture or chemicals can corrode the tool’s surfaces, affecting accuracy.

- Improper Handling: Incorrect use, such as applying excessive force, dropping the tool, or failing to clean it properly, can accelerate wear.

Prevention strategies include:

- Regular Calibration: Calibrating the tool at specified intervals helps detect and compensate for gradual wear.

- Proper Cleaning and Storage: Regularly cleaning the tool to remove debris and storing it in a protective case reduces wear and corrosion.

- Appropriate Use: Training personnel on correct usage and handling procedures minimizes damage and premature wear.

- Preventive Maintenance: Implementing scheduled maintenance programs (such as lubrication) extends the lifespan and accuracy of the tool.

- Protective coatings: Some tools utilize coatings to help increase resistance to wear and corrosion.

By implementing these prevention methods, we can significantly extend the life of our tools and maintain measurement accuracy.

Q 5. Explain your understanding of tolerance and its importance in tool inspection.

Tolerance represents the permissible variation in a dimension or characteristic. In simple terms, it defines the acceptable range of error for a given measurement. Imagine manufacturing a bolt – it needs to fit snugly into a nut. Tolerance defines how much variation is allowed in the bolt’s diameter to ensure it still fits.

Tolerance is critical in tool inspection because it defines the acceptable limits for the tool’s accuracy. If a micrometer consistently produces measurements outside its specified tolerance, it’s considered inaccurate and needs recalibration or replacement. This is directly linked to the quality of the parts being produced; a tool that is outside tolerance may result in parts that are also outside tolerance and thus may not function correctly.

For example, a dimension might be specified as 10mm ± 0.01mm. This means the acceptable range is between 9.99mm and 10.01mm. Measurements outside this range indicate a problem.

Tool inspection verifies that the measuring tools themselves are within their specified tolerances, ensuring that the resulting measurements are reliable and meet the requirements of the manufactured parts.

Q 6. How do you ensure the traceability of your measurement equipment?

Traceability in measurement equipment is essential for ensuring the accuracy and reliability of all measurements. It ensures that our measurements can be linked back to a known standard. Think of it like a chain of custody – we need to be able to track the history of each piece of equipment to guarantee its accuracy.

We maintain traceability through:

- Calibration Certificates: All measurement equipment undergoes regular calibration by accredited laboratories. These labs provide certificates that document the calibration results and trace the equipment’s accuracy back to national or international standards.

- Calibration Records: We keep detailed records of all calibration events, including the date, calibration results, and any necessary adjustments.

- Unique Identification: Each piece of equipment is uniquely identified using a serial number or other identifier, facilitating tracking throughout its lifespan.

- Calibration Schedule: We maintain a strict calibration schedule, ensuring that all equipment is calibrated at appropriate intervals according to manufacturer’s specifications and our own internal quality procedures.

- Calibration Software: We often utilize calibration management software to streamline the process, ensuring timely calibration and easy access to records.

By maintaining rigorous traceability, we can ensure the reliability and validity of our measurements, guaranteeing the quality of our work and meeting regulatory requirements.

Q 7. Describe your experience with statistical process control (SPC) in tool inspection.

Statistical Process Control (SPC) is a powerful tool for monitoring and controlling the variation in manufacturing processes. In tool inspection, SPC helps us detect potential problems early and maintain the accuracy of our measurements. Think of it as a way to proactively identify trends and prevent problems from escalating.

My experience with SPC in tool inspection involves:

- Control Charts: We use control charts (e.g., X-bar and R charts) to monitor the variation in measurement readings over time. This allows us to identify trends and patterns, indicating potential issues such as tool wear or drift.

- Capability Analysis: We perform capability studies to assess the ability of our measurement equipment to meet the required tolerances. This helps determine if the equipment is suitable for the intended application.

- Process Improvement: By using data from SPC, we can identify areas for improvement in our inspection process. For example, if a control chart shows an upward trend in variation, we might investigate the cause (e.g., tool wear) and implement corrective actions.

- Data Analysis: I am proficient in interpreting control charts and other SPC data, using statistical software to analyze trends and identify outliers. The aim is not merely to measure and record, but to utilize the data for process improvement and proactive error detection.

Implementing SPC in tool inspection allows for proactive detection of inconsistencies and the implementation of corrective actions, helping ensure the quality and reliability of our measurements and ultimately the products manufactured.

Q 8. What are your preferred methods for documenting inspection results?

Documenting inspection results meticulously is crucial for traceability and accountability. My preferred methods involve a combination of digital and physical records. I utilize a comprehensive, customized digital database that tracks all inspection data, including date, time, instrument used, inspector’s name, and detailed results with images and potentially video where appropriate. This data is securely stored and easily accessible. For physical records, I maintain hard copies of inspection reports, signed and dated, which are stored in a secure, organized filing system. This dual approach ensures redundancy and safeguards against data loss. For instance, during an inspection of a complex injection mold, I would record detailed measurements of critical features, including cavity dimensions and parting line alignment, both digitally and on a hard copy report, noting any deviations from specifications. This redundancy ensures that all data is available, even if one system fails.

Q 9. How do you handle discrepancies between measurement readings from different instruments?

Discrepancies between measurement readings from different instruments require a systematic approach. First, I verify the calibration status of each instrument involved; ensuring that all instruments have undergone recent calibration and that their certifications are up to date. Second, I analyze the readings for patterns or trends. If a particular instrument consistently shows a deviation from others, it may indicate a problem with that instrument’s accuracy or calibration. I then investigate potential sources of error, such as incorrect instrument setup, environmental factors (temperature, humidity), or operator error. Finally, I document the discrepancies and perform further measurements if necessary, perhaps using a third, independent instrument as a check. The final documented result reflects a consensus, with the justifications for any chosen reading clearly articulated and referenced. For example, if one caliper reads a dimension as 10.02mm while another reads 10.00mm, I will check the calibration certifications, re-measure using a micrometer and possibly a CMM if the discrepancy is significant, documenting all measurements and the reasons for choosing a final value based on the available evidence.

Q 10. Describe your experience with different types of tool inspection reports.

My experience encompasses various tool inspection reports, each tailored to specific needs. I’m proficient with First Article Inspection Reports (FAIRs), which are critical for verifying the conformance of the first manufactured part to the design specifications. I also have extensive experience with Calibration Reports, documenting the accuracy and traceability of measurement instruments. Tooling Inspection Reports cover the overall condition and functionality of tools, including wear and tear assessment. Finally, I’m familiar with reports for Non-Conforming Material Reports (NCRs), which detail deviations from standards and recommend corrective actions. Each report type requires specific data points and formats to ensure clarity and compliance with relevant industry standards. I’ve worked with various software systems and templates to optimize report generation and ensure consistent formatting across different projects. For example, I’ve used customized spreadsheets for simpler tooling inspections and specialized software for complex FAIRs requiring detailed GD&T analysis.

Q 11. How familiar are you with various types of gage blocks and their use in calibration?

I have extensive experience with various types of gage blocks, including steel, carbide, and ceramic, and their use in instrument calibration. I understand the importance of handling them carefully to avoid damage and maintain their accuracy. I’m familiar with different grades of gage blocks based on their tolerances (e.g., AA, A, B). I know how to use them in conjunction with other measuring instruments like dial indicators and CMMs for calibration purposes. I also understand the importance of maintaining a clean and controlled environment for gage block use. For example, during the calibration of a micrometer, I would use a set of appropriately graded gage blocks to establish a known reference point, ensuring the micrometer’s readings align with the known dimensions of the gage blocks. This process is meticulously documented and forms part of the overall calibration report.

Q 12. Explain your understanding of GD&T (Geometric Dimensioning and Tolerancing).

GD&T, or Geometric Dimensioning and Tolerancing, is a system for defining and communicating engineering tolerances. It uses symbols to specify the permissible variations in a part’s geometry. My understanding extends to all aspects of GD&T, including form tolerances (straightness, flatness, circularity, cylindricity), orientation tolerances (parallelism, perpendicularity, angularity), location tolerances (position, concentricity, symmetry), and runout tolerances. I am adept at interpreting GD&T specifications on drawings and using appropriate measuring instruments and techniques to verify whether a part conforms to these specifications. I understand the use of Maximum Material Condition (MMC) and Least Material Condition (LMC) and their implications for part acceptance criteria. For example, interpreting a position tolerance symbol on a drawing requires understanding the associated tolerance zone and MMC/LMC values, which is key for accurate measurement and inspection.

Q 13. How do you ensure the safety of yourself and others during tool inspection?

Safety is paramount during tool inspection. I always follow established safety protocols, including the use of appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection when operating machinery. I’m mindful of potential hazards like sharp edges, moving parts, and hazardous materials. Before commencing any inspection, I carefully inspect the tooling for visible damage, and the workplace for tripping hazards and other safety risks. I make sure the work area is clean, well-lit, and has adequate ventilation. I adhere strictly to all company safety regulations and participate actively in safety training programs. I report any unsafe conditions or equipment malfunctions immediately to the appropriate personnel. Safe work practices are integrated into every aspect of my inspection process. I consider safety not just a set of rules to follow, but a critical component of effective and responsible inspection.

Q 14. Describe your experience with CMM programming and operation.

I have significant experience with CMM programming and operation. I am proficient in creating and modifying CMM programs using various software packages, including PCDMIS and Calypso. This includes developing measurement routines, selecting appropriate probes and probe configurations, defining measurement points, and setting up the CMM for accurate and efficient measurement. I understand the importance of proper probe calibration and the impact of environmental factors on measurement accuracy. I’m capable of troubleshooting issues that may arise during CMM operation and making necessary adjustments to optimize measurement performance. I’m experienced in generating inspection reports from the CMM data, ensuring accurate and comprehensive documentation of inspection results. For example, I recently programmed a CMM to inspect the intricate features of a turbine blade, ensuring accurate measurement of all critical dimensions and surface finishes, generating a comprehensive report for review and analysis.

Q 15. How do you prioritize tasks when faced with multiple urgent inspection requests?

Prioritizing urgent inspection requests involves a systematic approach. I begin by assessing the criticality of each request, considering factors like potential safety hazards, production downtime costs, and the urgency expressed by the requesting department. I use a matrix system, weighing the severity of the potential consequences against the time required for inspection. For instance, a request concerning a critical tool showing signs of significant wear would take precedence over a routine inspection of a less critical tool. I then create a prioritized list, ensuring that the most critical inspections are completed first, while still aiming for efficient allocation of resources. This might involve delegating less critical tasks if feasible, or working longer hours in high-demand periods. Clear communication with stakeholders about timelines is vital throughout this process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with root cause analysis of tool failures?

Root cause analysis of tool failures is crucial for preventing future incidents. My approach follows a structured methodology, often employing the 5 Whys technique. This involves repeatedly asking “Why?” to drill down to the underlying cause. For example, if a cutting tool fractured, the initial answer might be “due to excessive force.” Then, we ask, “Why was excessive force applied?” Perhaps the machine settings were incorrect. Further questioning might reveal the operator lacked proper training or the machine lacked a safety interlock. Beyond the 5 Whys, I leverage data analysis, examining tool usage logs, maintenance records, and even environmental factors. I also consider material degradation, improper storage, or defects in manufacturing. Once the root cause is identified, I recommend corrective actions that might range from improved training programs, equipment upgrades, changes to operational procedures, or tighter quality control measures during tool procurement.

Q 17. Explain your experience with different types of tool materials and their properties.

My experience encompasses a wide range of tool materials, each with unique properties influencing their suitability for specific applications. For example, high-speed steel (HSS) tools are known for their hardness and wear resistance, making them ideal for demanding cutting operations. However, they lack the toughness of carbide tools, which are better suited to resisting shock loads. I’m also familiar with ceramic tools, which exhibit exceptional hardness and wear resistance at high temperatures, but can be brittle. Understanding the properties – hardness, toughness, wear resistance, thermal stability, and corrosion resistance – of each material is crucial in selecting the appropriate tool for a given task. Furthermore, I understand the impact of coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) on improving tool performance. These coatings enhance properties like lubricity, reducing friction and wear, thus extending tool life.

Q 18. How do you manage your workload effectively to meet deadlines?

Effective workload management is essential for meeting deadlines in tool inspection. I utilize several strategies including task prioritization (as discussed earlier), time blocking, and regular progress tracking. I allocate specific time slots for different tasks based on their complexity and urgency. This helps avoid multitasking, which can reduce efficiency. I also maintain a detailed log of tasks, their status, and deadlines, using both digital tools and physical task lists. Regular reviews allow me to identify potential bottlenecks and adjust my schedule accordingly. Proactive communication with stakeholders about potential delays is crucial for preventing disruptions. Finally, I strive for a balance between work and personal life, recognizing that burnout reduces productivity. Regular breaks and time off can improve focus and prevent errors.

Q 19. Describe your experience with using a microscope for tool inspection.

Microscope use is a routine part of my tool inspection process, particularly for detecting subtle defects. I’m proficient with both optical and digital microscopes, understanding the principles of magnification, resolution, and depth of field. For example, I use optical microscopes for visual inspection of surface finish, detecting minute cracks or chips that are otherwise invisible to the naked eye. Digital microscopes offer the advantage of image capture and analysis, allowing for detailed documentation and comparison over time. I understand the importance of proper lighting techniques to avoid glare and shadows, ensuring accurate observation. Furthermore, I am familiar with various measurement techniques using microscope stages and calibrated software. This enables precise quantification of defects and ensures accurate reporting.

Q 20. What are your strengths and weaknesses in the context of tool inspection?

My strengths lie in my meticulous attention to detail, my systematic approach to problem-solving, and my strong understanding of various tool materials and inspection techniques. I’m adept at using diverse inspection equipment and am comfortable working independently and as part of a team. A weakness I’m working on is delegating tasks. I often find myself wanting to handle every inspection personally to ensure high standards, but I recognize the importance of efficient team management and am actively developing skills in this area. I’m addressing this by participating in team-building activities and seeking opportunities to mentor junior inspectors.

Q 21. How do you stay updated on the latest technologies and standards in tool inspection?

Staying updated in the field of tool inspection involves continuous professional development. I regularly attend industry conferences and workshops, subscribe to relevant journals and online resources, and participate in professional organizations. I also actively seek out training opportunities on new technologies and inspection techniques. For example, I’ve recently completed a course on advanced microscopy techniques, including confocal microscopy, which offers enhanced imaging capabilities for complex tool structures. Keeping abreast of updated standards, such as those from ISO, is critical to ensure that my inspection methods are compliant and reliable. I also network with other professionals in the field, exchanging insights and learning about best practices.

Q 22. Describe a time when you identified a critical tool failure that prevented a significant problem.

During a critical production run for a major automotive client, we were using a high-precision CNC milling machine. Routine pre-shift inspection revealed unusual wear on the spindle bearing. While initially dismissed as minor, my experience with similar machines prompted a more thorough investigation. Using a calibrated micrometer, I measured the runout, which was significantly exceeding the acceptable tolerance. Had we ignored this, the subsequent milling operations would have produced parts outside specification, leading to costly rework, potential product recalls, and reputational damage for the company. Flagging this early allowed us to replace the spindle bearing proactively, preventing production delays and ensuring the quality of the final parts. This highlights the importance of meticulous inspection and trusting one’s intuition when something seems amiss, even if the initial assessment appears minor.

Q 23. What is your understanding of the different types of inspection methods (e.g., visual, dimensional, functional)?

Tool inspection methods are categorized to ensure all aspects of tool integrity are assessed. Think of it like a medical checkup; you need various tests to get a complete picture of health.

- Visual Inspection: This is the first and often most important step. It involves a thorough visual examination of the tool for signs of wear, damage (chips, cracks, deformation), contamination (oil, dirt), or any unusual characteristics. Think of carefully checking a screwdriver for bending or a hammer for cracks. It’s a quick, cost-effective method that often identifies problems early.

- Dimensional Inspection: This uses precision measuring tools such as calipers, micrometers, and CMMs (Coordinate Measuring Machines) to verify the tool’s dimensions against specifications. For instance, checking the diameter of a drill bit or the length of a cutting tool to ensure they are within acceptable tolerances. This ensures the tool will perform as intended.

- Functional Inspection: This goes beyond measuring dimensions to assess the tool’s performance. It could involve checking the cutting ability of a blade, the clamping force of a vise, or the accuracy of a gauge. This often involves testing the tool under simulated work conditions.

Each method complements the others, and the specific methods used depend on the tool’s complexity and criticality in the manufacturing process.

Q 24. Describe your experience with creating and maintaining tool inspection procedures.

My experience includes developing and implementing detailed inspection procedures for a variety of tools, ranging from simple hand tools to complex CNC cutting heads. The process involves:

- Defining Scope: Clearly identifying the tools to be inspected, the frequency of inspections, and the personnel responsible.

- Choosing Methods: Selecting appropriate inspection methods (visual, dimensional, functional) based on the tool’s characteristics and criticality.

- Developing Checklists: Creating step-by-step checklists with clear acceptance criteria for each inspection point. These checklists are critical for consistency and traceability.

- Documentation: Detailed documentation of the procedures, including diagrams, photos, and reference standards.

- Training: Training personnel on the proper use of inspection equipment and procedures.

- Review and Update: Regularly reviewing and updating the procedures based on new tools, technological advances, or lessons learned from previous inspections.

For example, I created a comprehensive inspection procedure for our laser cutting heads, incorporating visual checks for mirror alignment, dimensional checks of the focal point using a laser beam profiler, and functional checks by cutting sample materials and evaluating the resulting cut quality.

Q 25. How do you ensure the integrity of the inspection process?

Ensuring inspection process integrity is paramount. This is achieved through several key measures:

- Calibration: All measuring instruments must be regularly calibrated against traceable standards to ensure accuracy. Calibration certificates are essential to document this.

- Standard Operating Procedures (SOPs): Clear, documented SOPs for every inspection task eliminate ambiguity and ensure consistent application.

- Operator Training: Properly trained inspectors are crucial for correct interpretation of results and consistent application of procedures.

- Audits: Regular internal audits of the inspection process ensure compliance with standards and identify areas for improvement.

- Record Keeping: Meticulous record keeping, including inspection reports and calibration certificates, provides complete traceability and allows for trend analysis.

- Statistical Process Control (SPC): Implementing SPC helps identify trends and patterns in inspection data, allowing for proactive identification of potential issues before they impact production.

Think of it like building a house; you need a strong foundation (calibration), detailed blueprints (SOPs), skilled builders (trained inspectors), regular inspections during construction (audits), and meticulous documentation (record keeping) to ensure a quality structure.

Q 26. Explain your understanding of calibration certificates and their significance.

Calibration certificates are essential documents that verify the accuracy of measuring instruments. They confirm that the instrument has been tested and meets specific performance standards at a particular point in time. Think of it as a passport for your measuring equipment, proving its validity. The certificate includes details such as the instrument’s identification, calibration date, measured values, tolerances, and the accredited laboratory that performed the calibration.

Their significance lies in several key areas:

- Ensuring Accuracy: They ensure that the measuring instruments are providing accurate and reliable data, which is crucial for the integrity of the inspection process.

- Compliance: Many quality management systems (e.g., ISO 9001) require calibration certificates as proof of compliance with regulatory standards.

- Traceability: Calibration certificates provide traceability to national or international standards, guaranteeing the accuracy and reliability of the measurements.

- Legal and Liability: In case of disputes or legal issues related to product quality, calibration certificates serve as irrefutable evidence of the instrument’s accuracy.

Outdated or missing calibration certificates invalidate the inspection results and can lead to serious consequences.

Q 27. How would you handle a situation where a tool fails inspection but is urgently needed for production?

This is a critical situation requiring a risk-based approach. A failed inspection implies the tool may not perform as expected, potentially causing defects or damage. However, production urgency demands a solution.

- Assess the Risk: Determine the potential consequences of using the tool despite its failed inspection. What is the severity and probability of product defects or damage?

- Investigate the Failure: Identify the specific cause of the failure. Is it minor and easily rectified (e.g., cleaning), or is it a significant issue (e.g., major damage)?

- Consider Alternatives: Are there alternative tools available that can perform the same function? Can the production task be temporarily postponed or rescheduled?

- Implement Corrective Action: If the failure is minor and the risk is acceptable, implement corrective actions immediately and re-inspect the tool. Document all actions thoroughly.

- Limited Use with Monitoring: If no alternative is available, use the tool for a limited time with close monitoring of the output and increased scrutiny of the produced parts. This should only be done after thorough risk assessment and with approval from relevant management personnel.

- Documentation: The entire process must be thoroughly documented, including the reasons for the decision, the corrective actions taken, and the monitoring performed.

Remember, using a failed tool is a risk and should only be considered as a last resort after a careful assessment of the situation and after exhausting all other options.

Q 28. What software or systems are you proficient in for managing inspection data?

I am proficient in several software and systems for managing inspection data. These include:

- CMM Software: Experience with various CMM software packages (e.g., PC-DMIS, Calypso) for data acquisition, analysis, and reporting from Coordinate Measuring Machines.

- LIMS (Laboratory Information Management Systems): Proficient in using LIMS for managing calibration data, inspection results, and generating reports.

- Spreadsheet Software (Excel): Experienced in using Excel for data entry, analysis, charting, and generating reports. I frequently create custom spreadsheets for tracking inspection results and identifying trends.

- ERP/MRP Systems: Familiar with integrating inspection data into enterprise resource planning (ERP) or material requirements planning (MRP) systems to provide real-time visibility into tool status and potential production issues.

- Database Management Systems (SQL): Proficient in creating and managing databases for storing and retrieving inspection data. This allows for sophisticated data analysis and trend identification.

The choice of software depends on the complexity of the inspection process, the volume of data, and the organization’s IT infrastructure. I am adept at selecting and implementing the most appropriate system for the given context.

Key Topics to Learn for Tool Inspection and Verification Interview

- Tool Calibration and Measurement Techniques: Understanding various calibration methods, precision instruments, and error analysis. Practical application includes performing calibrations and documenting results accurately.

- Inspection Procedures and Standards: Familiarity with industry standards (e.g., ISO 9001) and company-specific procedures for inspecting tools. Practical application involves following these procedures meticulously and identifying deviations.

- Types of Tool Defects and their Detection: Knowledge of common tool defects (wear, damage, misalignment) and methods for their detection (visual inspection, dimensional checks, functional testing). Practical application includes using appropriate tools and techniques to identify and document defects.

- Documentation and Reporting: Understanding the importance of accurate and complete documentation, including inspection reports, calibration records, and non-conformance reports. Practical application involves maintaining clear and organized records.

- Safety Procedures and Regulations: Knowledge of relevant safety regulations and procedures related to tool handling, inspection, and maintenance. Practical application includes following all safety protocols diligently.

- Problem-Solving and Troubleshooting: Ability to identify and troubleshoot issues related to tool performance and inspection processes. Practical application includes developing solutions to resolve inspection-related challenges and prevent future occurrences.

- Statistical Process Control (SPC): Understanding basic SPC principles and their application in tool inspection to monitor process capability and identify trends. Practical application includes interpreting control charts and taking corrective actions.

Next Steps

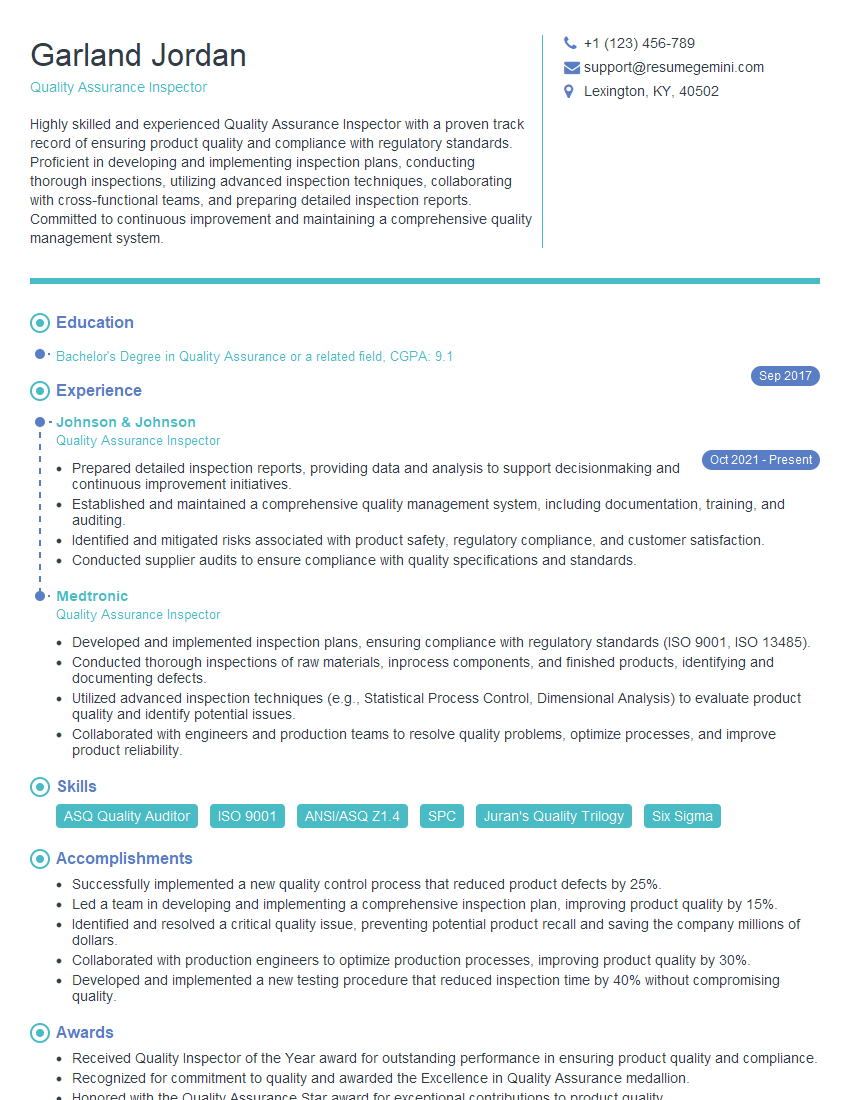

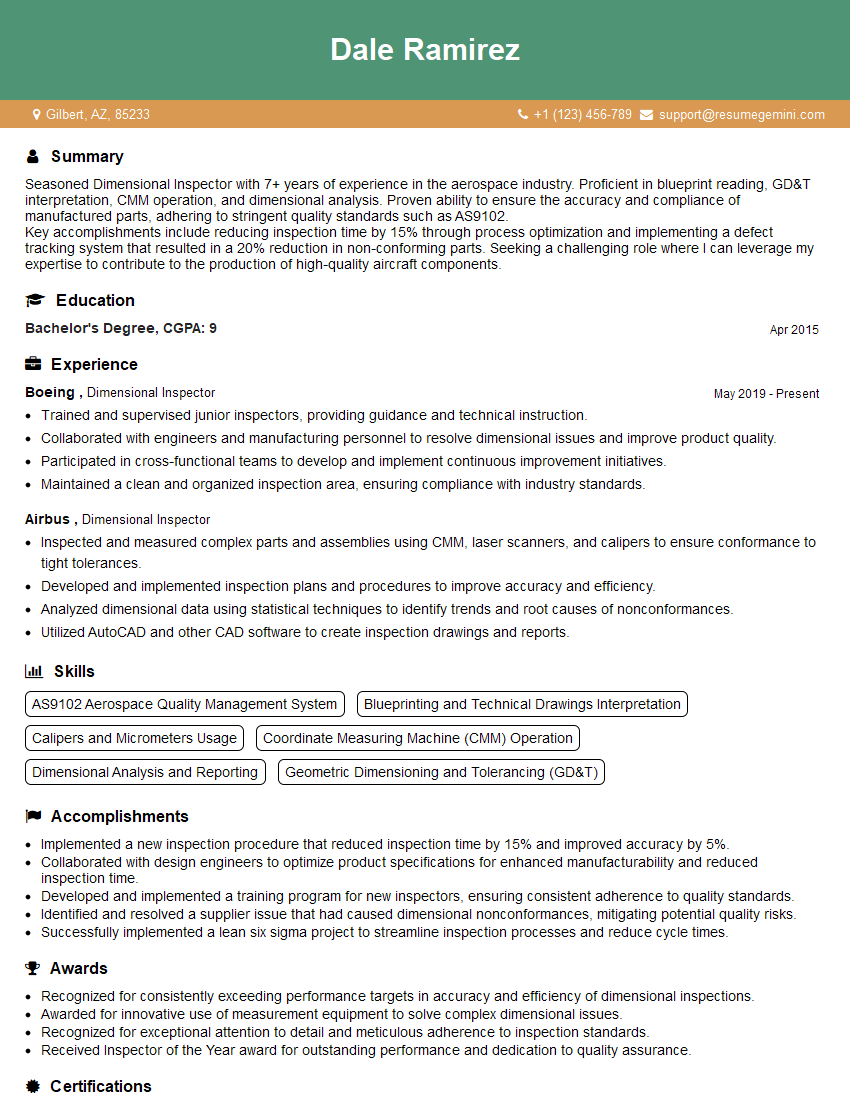

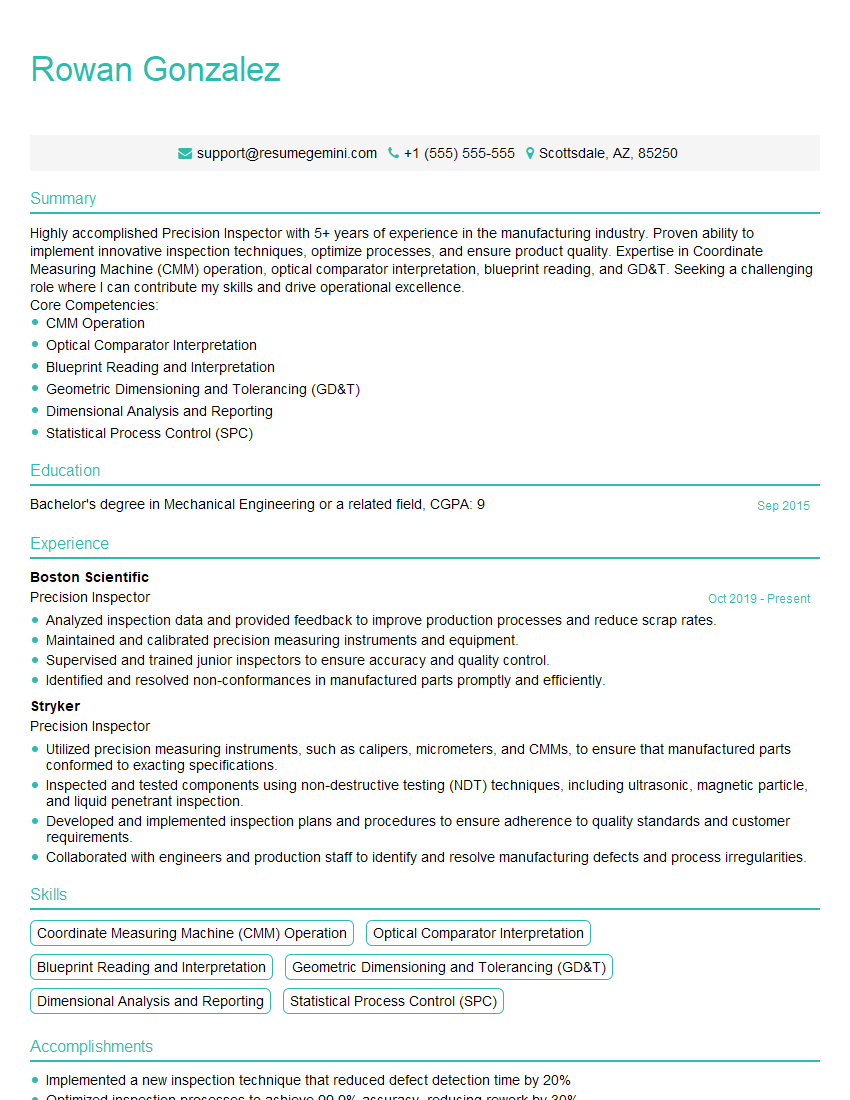

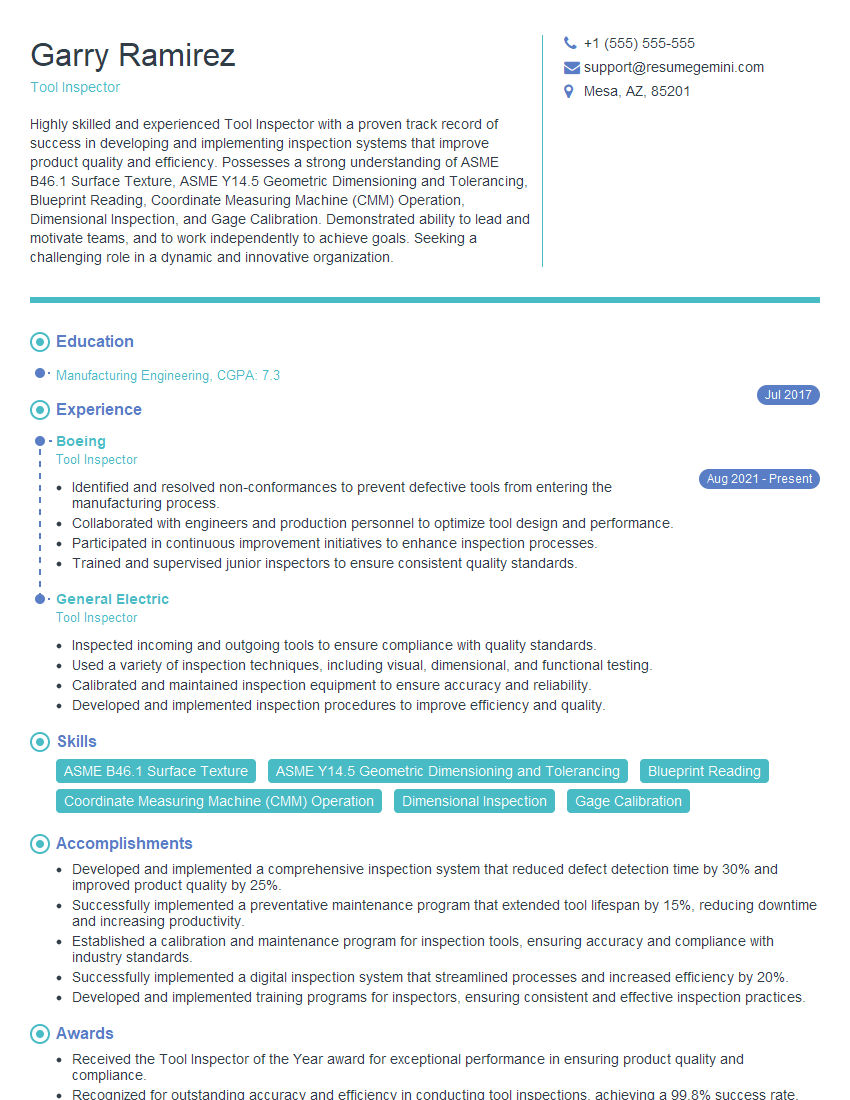

Mastering Tool Inspection and Verification opens doors to exciting career opportunities in manufacturing, quality control, and engineering. A strong understanding of these principles demonstrates a commitment to precision, safety, and quality – highly valued attributes in any industry. To significantly enhance your job prospects, it’s crucial to create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Tool Inspection and Verification to guide you in crafting a document that highlights your qualifications and increases your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO