Preparation is the key to success in any interview. In this post, we’ll explore crucial Tool Setup interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Tool Setup Interview

Q 1. Describe your experience with different types of tooling.

My experience spans a wide range of tooling, from simple hand tools like wrenches and calipers to complex CNC tooling such as end mills, drills, and specialized cutting inserts. I’m proficient with tooling used in various machining processes including milling, turning, drilling, and grinding. For example, I’ve extensively used carbide end mills for high-speed machining of aluminum and steel, and high-speed steel (HSS) drills for various materials. My experience also includes setting up and using tooling for specialized processes like wire EDM and laser cutting. I understand the importance of selecting the correct tool based on material properties, desired surface finish, and machining parameters. This includes considering aspects like tool geometry, coatings, and material composition. I’m also familiar with tool pre-setters and their impact on setup efficiency and accuracy.

Q 2. Explain the process of setting up a CNC machine.

Setting up a CNC machine is a multi-step process that requires precision and attention to detail. It begins with verifying the machine’s operational readiness, including checking coolant levels, lubrication, and overall machine health. Then, the specific program for the part needs to be loaded and verified. Next comes the crucial tool setup phase. This involves installing the correct cutting tool into the spindle, and using a tool setter (often a probe) to precisely measure the tool length and diameter. This data is then input into the machine’s control system. This ensures the tool is positioned correctly relative to the workpiece. We also perform a tool offset compensation in the CNC program to account for the tool’s physical dimensions. Finally, a test run (often with a scrap piece of material) is used to confirm the setup and make any necessary adjustments before machining the actual part. Think of it like preparing a complex recipe: each step needs to be executed correctly to achieve the desired outcome. The slightest error can result in a flawed final product.

Q 3. How do you ensure the accuracy of tool setup?

Accuracy in tool setup is paramount to producing high-quality parts. We employ several techniques to ensure this accuracy. Firstly, using a calibrated tool pre-setter eliminates manual measurement errors. These devices provide extremely precise measurements of tool length and diameter. Secondly, we frequently use touch probes or other measurement devices to verify the tool’s position relative to the workpiece coordinate system. This process is referred to as tool length and diameter compensation (TLC). Thirdly, we conduct test cuts on scrap material to assess the machining process and make minor adjustments as needed before starting production on actual components. Regular calibration and maintenance of all measuring instruments is also crucial. One example of ensuring accuracy is using a digital caliper to measure a tool’s diameter, comparing this to the nominal diameter specified in the tool’s documentation. Any discrepancy would highlight a potential problem and require investigation.

Q 4. What are the common problems encountered during tool setup, and how do you troubleshoot them?

Common problems during tool setup include incorrect tool length offset, tool breakage or wear, incorrect spindle speed or feed rate, and collisions between the tool and the workpiece or fixture. Troubleshooting involves a systematic approach. For incorrect tool length offset, I would re-measure the tool using a pre-setter and adjust the offset in the CNC program. Tool breakage might indicate improper tool selection or excessive cutting parameters, requiring a review of the machining process and a possible tool change. Collisions often result from improper part programming or incorrect work coordinate system setup; careful review of the program and machine coordinates is necessary. A systematic approach, combined with the use of diagnostic tools provided by the CNC machine, allows for efficient troubleshooting. For instance, if I encountered chatter during machining, I’d analyze the cutting parameters, tool condition, and workpiece stability to identify the cause – it could be anything from worn tooling to an insufficient clamping force.

Q 5. What safety precautions do you follow during tool setup?

Safety is my top priority. Before any tool setup, I always ensure that the machine is properly locked out and tagged out to prevent accidental startup. I wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and cut-resistant gloves. I carefully handle cutting tools, avoiding sharp edges and ensuring tools are properly stored when not in use. I regularly inspect the machine and tooling for any signs of damage or wear before commencing any operation. Before any test runs or production runs, I carefully review the CNC program to avoid potential collisions. Following established safety protocols, including machine guarding, is crucial. Think of it like preparing for a challenging hike: proper gear and preparation can prevent accidents.

Q 6. How do you interpret engineering drawings and specifications related to tooling?

Interpreting engineering drawings and specifications is fundamental to my role. I am proficient in reading blueprints and technical documentation, extracting information about required tooling, dimensions, tolerances, and material specifications. This includes identifying specific tool types, sizes, and geometries needed for the machining process. I understand different types of annotations, including GD&T (Geometric Dimensioning and Tolerancing) which ensures consistent and precise part production. For example, when I encounter a drawing specifying a 1/4” diameter hole, I understand this indicates the requirement of a 1/4” drill bit. The tolerance specified dictates the acceptable deviation from that ideal diameter. The material specification guides the selection of the most appropriate cutting tool materials to ensure optimal cutting performance and tool life.

Q 7. Explain your experience with different types of cutting tools.

My experience encompasses a broad range of cutting tools, including high-speed steel (HSS), carbide, and ceramic cutting tools. HSS tools are versatile and cost-effective, suitable for a wide variety of materials, but they have lower cutting speeds and shorter tool life compared to more advanced materials. Carbide tools offer much higher hardness and wear resistance, enabling higher cutting speeds and improved tool life, making them ideal for machining tougher materials. Ceramic tools are even harder and offer excellent wear resistance at even higher speeds but are more brittle. I understand the trade-offs between different tool materials and select the optimal tool based on the specific application. For example, I would use carbide end mills for aluminum and steel components requiring high precision and surface finish, while opting for HSS tools for softer materials like brass or wood where the higher cost of carbide may not be justified.

Q 8. Describe your experience with tool presetting and measuring equipment.

My experience with tool presetting and measuring equipment spans over ten years, encompassing various technologies and methodologies. I’m proficient in using both traditional and advanced presetting systems, including laser-based systems, contact probes, and optical comparators. For example, I’ve extensively used Renishaw’s OMP400 and similar systems for precise tool length and geometry measurement. This involves not just the operation of the equipment itself but also a deep understanding of its limitations and potential sources of error, such as thermal drift or probe wear. I regularly perform calibrations and maintenance checks to ensure accuracy and reliability. I’m also experienced in using various measuring tools like micrometers, calipers, and dial indicators for secondary verification and quick checks in the machine shop itself. The ability to swiftly and accurately measure tools directly impacts setup time, reducing waste and boosting overall efficiency.

Q 9. How do you select the appropriate tooling for a specific machining operation?

Selecting the right tooling for a machining operation is crucial for achieving the desired surface finish, dimensional accuracy, and productivity. The process involves considering several factors. First, I determine the material being machined – the properties of the workpiece material directly influence tool material selection. For example, harder materials like titanium alloys require tools made of high-speed steel or carbide with specific coatings to withstand the increased cutting forces. Next, I consider the machining operation itself: milling, turning, drilling, etc. Each operation requires tools with specific geometries and cutting edges. A face milling operation necessitates a different cutter compared to a profile milling operation. The required tolerances and surface finish are paramount in choosing the correct tool insert and cutting parameters. A fine surface finish will often demand a tool with a sharper cutting edge and smaller chip loads. Finally, I factor in factors such as machine capacity and available tooling inventory before making a selection.

For instance, when machining a complex aluminum part with tight tolerances, I’d likely select a high-precision ball-nose end mill with a specific coating for aluminum, coupled with a CNC machine capable of precise control over feed rates and spindle speeds.

Q 10. Explain the importance of proper tool clamping and securing.

Proper tool clamping and securing is absolutely fundamental to safe and reliable machining. An improperly clamped tool is a recipe for disaster, leading to tool breakage, machine damage, and even potential injury. The clamping force must be sufficient to securely hold the tool in place, preventing vibrations and chatter during operation, but not so excessive as to damage the tool or the machine’s tool holder. This requires a solid understanding of the clamping mechanism used and its correct application. Different tool holders use various clamping systems; ER collet chucks, hydraulic chucks, and Weldon shank systems all require their specific procedure. Visual inspection after clamping is crucial – there should be no visible gaps or loose connections. I always perform a test run at low speeds after tool change to check for any vibration or unexpected noises that would signal an improper clamping. Think of it like this: a perfectly secured tool is like a well-anchored ship in a storm, weathering whatever forces are thrown at it.

Q 11. How do you manage tool wear and replacement?

Managing tool wear and replacement is an ongoing process that directly impacts productivity and part quality. I monitor tool wear through several methods: visual inspection for chipping, cracking, or excessive wear; measuring tool geometry using a tool presetter to detect changes in cutting edge dimensions; and monitoring cutting forces and surface finish of the machined parts, as increased cutting forces or a degraded surface finish can indicate tool wear. I maintain detailed records of tool usage, including cutting parameters and the number of parts machined before replacement. This helps determine optimal tool life and scheduling preventative maintenance. There are many factors to consider. Inconsistent materials or poorly maintained machines can accelerate tool wear, so proactive maintenance and training of machine operators is a key component to extending tool life. Tool wear monitoring systems and data analytics can provide advanced warnings and reduce downtime. Replacing tools promptly, even if they haven’t completely failed, avoids unexpected breakdowns and helps maintain consistent part quality.

Q 12. What are the different methods for tool compensation?

Tool compensation is critical for maintaining accuracy over the tool’s life as it wears. Several methods are used. The most common is cutter radius compensation (CRC), which the CNC controller automatically adjusts the toolpath based on the tool’s radius. This ensures that the actual cut follows the desired geometry, even as the tool’s diameter reduces from wear. G41 and G42 are commonly used G-codes for this. Tool length offset (TLO) compensates for variations in tool length. The machine’s controller remembers the length of each tool, allowing for the exact positioning of the tool tip. Wear compensation is a more advanced method, where the CNC system dynamically adjusts the toolpath to account for changes in cutting edge dimensions during operation, this often requires more sophisticated CAM software and tool monitoring systems. Regular calibration of these systems and thorough understanding of the applied compensation strategies are crucial to the success of the process.

Q 13. Describe your experience with automated tool changing systems.

I have extensive experience with automated tool changing (ATC) systems, both in Fanuc and Siemens controlled machines. These systems significantly improve productivity by automating the tool changing process. My experience extends from understanding the mechanics of the ATC system, including the tool magazine design and operation, to programming and troubleshooting issues. I’m familiar with different ATC configurations: turret-type systems, chain-type systems, and robotic systems. A common issue is dealing with tool recognition and tool breakage issues within the ATC system. Proper maintenance, including regular lubrication and cleaning of the tool changer mechanism and the accurate identification and placement of tools in the magazine are essential. Proficiency in diagnosing ATC related problems, such as misalignment, mechanical failures, or software glitches, is paramount for minimal downtime. An automated system significantly improves efficiency compared to manual tool changing, reducing idle time and enabling higher overall production.

Q 14. How do you ensure the longevity of your tooling?

Ensuring the longevity of tooling requires a multifaceted approach. Proper storage is crucial; tools should be stored in a clean, dry environment, away from excessive heat or humidity. Using the correct cutting parameters, avoiding excessive cutting speeds and feeds, is critical to minimizing wear. Regular inspection for wear and damage, coupled with proactive replacement based on monitoring data, prevents catastrophic failures. Employing appropriate coolants and lubricants significantly impacts tool life by reducing heat generation and friction. Furthermore, operator training on correct machining techniques, such as proper tool handling and avoidance of collisions, contributes significantly to tool longevity. By optimizing cutting parameters and employing preventive maintenance, a company can effectively reduce tool costs and ensure consistent output.

Q 15. Explain your experience with tool maintenance and storage procedures.

Tool maintenance and storage are critical for ensuring tool longevity, operational safety, and efficient workflow. My approach involves a multi-faceted strategy encompassing regular cleaning, lubrication, inspection, and organized storage.

- Regular Cleaning: Tools are cleaned after each use, removing debris and preventing corrosion. Compressed air is used for delicate tools, while brushes and solvents are employed for heavier duty cleaning, depending on the material. For instance, cutting tools used on aluminum require a different cleaning process compared to those used on steel to prevent cross-contamination.

- Lubrication: Moving parts of tools, such as hinges, spindles, and bearings, receive regular lubrication with appropriate lubricants to reduce friction and wear. The type of lubricant depends on the tool and the operating environment. For example, high-temperature grease is essential for tools used in high-heat applications.

- Inspection: A thorough inspection for damage, wear, or any signs of malfunction is conducted before and after each use. This includes checking for cracks, chips, or loose parts. A simple visual inspection often suffices, however, some tools necessitate more detailed checks using measuring instruments. For example, checking the precise diameter of a drill bit is paramount.

- Organized Storage: Tools are stored in designated areas, using labelled containers, cabinets, or racks to prevent damage, loss, and facilitate quick retrieval. Tools are categorized by type, size, and frequency of use for easy access and inventory management. Sharpened tools are stored separately to prevent accidental damage.

This systematic approach ensures that tools remain in optimal condition, minimizing downtime and maximizing operational efficiency. I’ve successfully implemented this system in previous roles, leading to a significant reduction in tool-related incidents and maintenance costs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you document tool setup procedures?

Documenting tool setup procedures is essential for consistency, training, and troubleshooting. My preferred method involves a combination of visual aids and written instructions.

- Visual Aids: I create detailed photographs and videos demonstrating each step of the tool setup process. This approach makes the procedure easily understandable, regardless of language barriers or technical literacy levels. For example, a video showing the proper alignment of a milling machine’s cutting head is far more effective than a written description alone.

- Written Instructions: I complement the visual aids with comprehensive written instructions, including specific torque values, alignment specifications, and safety precautions. These instructions are organized in a clear and concise manner, using numbered steps and headings. The language is simple and avoids technical jargon whenever possible. For example, instead of ‘establish orthogonal trajectory’, I’d state ‘ensure the cutting tool moves at a right angle to the workpiece’.

- Software Utilization: I utilize software like Microsoft Word or specialized CMMS (Computerized Maintenance Management System) platforms to create and manage the documentation. This ensures easy access, version control, and efficient distribution of the updated procedures.

By combining visual and written documentation, I ensure that the tool setup procedures are easily understood, followed, and maintained, minimizing errors and maximizing productivity.

Q 17. Describe your experience working with different types of materials.

My experience encompasses working with a wide range of materials, including metals (steel, aluminum, titanium), plastics (polycarbonate, ABS), composites (carbon fiber, fiberglass), and wood. Understanding material properties is crucial for selecting the appropriate tools and adjusting setup parameters.

- Metals: I’m proficient in working with various metals, understanding the differences in machinability and the impact on tool selection and setup. For example, working with hardened steel requires specialized tooling and significantly different cutting parameters compared to soft aluminum.

- Plastics: I have experience setting up tools for plastic molding, extrusion, and machining. The key here is understanding the temperature sensitivity and potential for material deformation. This necessitates careful control of tool temperatures and feed rates.

- Composites: Working with composites requires careful consideration of the layered structure and the potential for fiber damage. Specialized tooling and techniques are often required to prevent delamination or fiber pull-out during cutting or forming operations.

- Wood: I am experienced in wood working, setting up tools for various woodworking operations such as cutting, shaping, and joinery. This involves an understanding of wood grain orientation and different cutting techniques to prevent tear-out.

My broad experience ensures that I can effectively adapt to different material requirements, optimizing tool setup for maximum efficiency and quality.

Q 18. How do you handle tool breakage or malfunction during operation?

Tool breakage or malfunction during operation requires a swift and methodical response to minimize downtime and ensure safety. My approach involves the following steps:

- Immediate Stoppage: The operation is immediately stopped to prevent further damage and potential injury. Safety is always the top priority.

- Assessment: A thorough assessment of the damage is conducted, identifying the cause of the breakage or malfunction. This might involve inspecting the tool itself, the workpiece, and the machine settings.

- Documentation: The incident is thoroughly documented, including the type of tool, the material being processed, the operating parameters, and the cause of failure. This information is critical for future preventative measures.

- Repair or Replacement: If repairable, the tool is repaired according to established procedures. Otherwise, the tool is replaced with a new one. This step also involves verifying the replacement tool is correctly set up.

- Root Cause Analysis: A root cause analysis is conducted to determine the underlying reasons for the failure. This could involve reviewing the operational procedures, the quality of the tool, or the material properties. Corrective actions are implemented to prevent recurrence.

This systematic approach ensures that tool failures are handled efficiently and effectively, minimizing their impact on production and promoting continuous improvement.

Q 19. What software or systems are you proficient in for tool setup and management?

I’m proficient in several software and systems for tool setup and management. This includes:

- Computerized Maintenance Management Systems (CMMS): I have experience using CMMS software like (mention specific software, e.g., UpKeep, Fiix, or similar) for tracking tool inventory, scheduling maintenance, and managing repair records. These systems provide a centralized platform for managing all aspects of tool lifecycle.

- CAD/CAM Software: I’m familiar with CAD/CAM software (mention specific software, e.g., SolidWorks, AutoCAD, Mastercam), allowing me to design and simulate tool paths, optimizing tool setup for complex parts and ensuring accurate machining parameters.

- Spreadsheet Software (e.g., Microsoft Excel): I use spreadsheets to track tool performance data, including tool life, cycle times, and maintenance records. This data is crucial for identifying trends and improving tool management processes. For instance, tracking the number of parts produced before tool wear necessitates replacement allows for optimized tool replacement schedules.

- ERP Systems: Familiarity with ERP systems (mention specific examples, e.g., SAP, Oracle) allows for seamless integration of tool management data with broader production planning and inventory control systems.

My proficiency in these software and systems enables me to efficiently manage tools, track their performance, and optimize tool setup processes.

Q 20. Describe your experience with statistical process control (SPC) in relation to tooling.

Statistical Process Control (SPC) plays a crucial role in ensuring consistent tool performance and product quality. I utilize SPC techniques to monitor key tool parameters and identify potential problems before they affect production.

- Control Charts: I use control charts to track parameters like tool wear, dimensional accuracy, and process capability. These charts help to identify trends and deviations from established control limits, allowing for timely intervention to prevent defects.

- Data Analysis: I analyze SPC data to identify sources of variation and implement corrective actions. For example, if a control chart shows increasing tool wear rates, I’d investigate factors such as cutting speed, feed rate, or tool material.

- Process Capability Studies: I conduct process capability studies to assess the capability of the tool setup and the process to meet specified tolerances. This analysis helps to identify areas for improvement and ensure consistent production of high-quality parts.

By applying SPC techniques, I can proactively identify and address potential problems in tool setup, leading to increased efficiency, improved product quality, and reduced waste. This proactive approach is more effective than reacting to problems after they arise.

Q 21. How do you contribute to continuous improvement in tool setup processes?

Continuous improvement is central to my approach to tool setup. I actively contribute to process optimization by:

- Data-Driven Decision Making: I utilize data collected from tool performance monitoring and SPC analysis to identify areas for improvement. This could involve changing tool materials, adjusting cutting parameters, or modifying setup procedures.

- Lean Principles: I apply lean principles to eliminate waste in the tool setup process. This includes reducing setup times, minimizing tool changes, and optimizing tool storage and retrieval. For example, implementing a 5S system in the tool storage area improves workflow and reduces search time.

- Kaizen Events: I participate in Kaizen events (continuous improvement workshops) to collaboratively identify and solve problems related to tool setup. This is a highly effective method to brainstorm solutions and implement improvements rapidly.

- Implementing Automation: Where feasible, I explore opportunities to automate aspects of tool setup to increase efficiency and reduce human error. This could involve using automated tool changers, robotic systems, or other automation technologies.

My commitment to continuous improvement ensures that tool setup processes remain efficient, reliable, and adaptable to changing production requirements. This proactive approach leads to significant cost savings and enhanced productivity.

Q 22. How do you ensure the quality of the tools used in the setup process?

Ensuring tool quality is paramount for efficient and accurate machining. My approach involves a multi-layered strategy. First, I meticulously inspect tools upon arrival, checking for any damage, wear, or inconsistencies. This includes visual inspection with magnification as needed, checking for proper coatings and sharpness (for cutting tools), and verifying dimensions with precision measuring instruments like micrometers and calipers.

Secondly, I utilize a robust tool management system. This system tracks tool usage, maintenance history, and performance data. This allows me to identify patterns of wear and tear, enabling proactive replacement before tools become a potential source of defects or machine damage. For example, if a certain type of drill bit consistently fails after 50 holes, I’ll know to replace it before it reaches that threshold.

Finally, I regularly calibrate measuring equipment and adhere to strict cleaning and storage procedures for tools. This minimizes the risk of contamination or damage. Imagine a chef meticulously cleaning and storing their knives – the same principle applies to ensuring tool quality in a machining environment. Proper maintenance and handling are crucial.

Q 23. What is your experience with different types of machine tools?

My experience encompasses a broad range of machine tools, including CNC milling machines (both 3-axis and 5-axis), CNC lathes (including Swiss-type lathes for high-precision work), and EDM (Electrical Discharge Machining) equipment. I’m proficient in setting up and operating tools for various materials, from aluminum and steel to plastics and composites.

For example, I’ve worked extensively with end mills, drills, reamers, taps, and various turning tools on CNC milling and lathe machines. My experience with EDM involves setting up and maintaining wire EDM and sinker EDM machines for precise cutting of intricate shapes in conductive materials. This breadth of experience allows me to adapt quickly to new machining challenges.

Q 24. How do you manage multiple tool setups concurrently?

Managing multiple tool setups concurrently requires careful planning and organization. I utilize a combination of techniques, including a detailed tool list for each setup, a clear scheduling system, and efficient use of available resources. I prioritize setups based on urgency and dependencies.

For example, if one setup requires a specific tooling fixture that another needs later, I would schedule those setups accordingly. I leverage digital tools like CNC machine simulation software to optimize toolpaths and minimize setup time. Furthermore, efficient communication with operators and other team members is crucial to keep the workflow running smoothly. I always aim for a smooth handover between setups to minimize downtime.

Q 25. Describe your experience with setting up and maintaining tooling for high-speed machining operations.

High-speed machining demands extremely precise tooling and setups. My experience includes setting up tooling for operations involving speeds exceeding 20,000 RPM. This necessitates the use of high-precision tooling, optimized toolpaths, and stringent quality control measures.

Key considerations for high-speed machining include selecting tools with appropriate geometry and coatings to minimize vibrations and heat generation. Balancing the cutting forces is vital to prevent tool breakage and maintain surface quality. Regular tool monitoring and adjustments are also crucial, often involving in-process measurement techniques to ensure accuracy and maintain part quality. For instance, using a probe to check tool length offsets frequently is an important part of maintaining consistency during high-speed operations.

Q 26. What are your preferred methods for verifying tool setup accuracy?

Verifying tool setup accuracy is critical. I employ several methods, including pre-machining simulations to predict potential issues, using a tool presetter to accurately measure and set tool lengths, and conducting trial cuts on scrap material before machining the actual workpiece.

After the initial setup, I use various verification techniques, such as performing a touch-off procedure and measuring the machined part against the design specifications using coordinate measuring machines (CMMs) or other precision measuring instruments. Any discrepancies are carefully analyzed, and adjustments are made as needed, until acceptable tolerances are achieved. This iterative approach guarantees a high degree of accuracy.

Q 27. Explain your experience with preventative maintenance of tooling.

Preventative maintenance is vital for extending tool life and maintaining machining accuracy. My approach includes regular cleaning of tools to remove chips and debris, ensuring proper lubrication where applicable, and adhering to recommended storage procedures.

I also conduct regular inspections for signs of wear, damage, or potential issues. This involves examining tools under magnification to detect subtle wear patterns. A well-defined preventative maintenance schedule is followed, with tasks like tool sharpening or recoating performed at specific intervals. This proactive approach minimizes unexpected downtime and ensures machining accuracy.

Q 28. How do you adapt to changes in tooling requirements or specifications?

Adapting to changes in tooling requirements is a regular part of my work. I stay abreast of industry advancements and new tooling technologies through professional development activities, trade publications, and vendor interactions.

When faced with a change, I thoroughly review the new specifications and requirements, identify any potential challenges, and develop a plan for implementing the change efficiently and safely. This includes evaluating the impact on existing processes, training personnel on new tools or techniques, and updating documentation. I consider it crucial to stay flexible and embrace changes, recognizing they often lead to improved efficiency and quality.

Key Topics to Learn for Tool Setup Interview

- Understanding Tooling Requirements: Analyze project specifications to determine the appropriate tools and equipment needed for efficient and safe operation.

- Safe Tool Handling and Operation: Demonstrate proficiency in the safe and correct use of various tools, adhering to all safety regulations and best practices. Include practical experience with preventative maintenance.

- Calibration and Maintenance: Explain the importance of regular tool calibration and maintenance procedures, and how to identify and address potential issues.

- Troubleshooting and Problem Solving: Describe your approach to identifying and resolving common tool malfunctions, including preventative measures and effective troubleshooting techniques.

- Setup Optimization and Efficiency: Discuss strategies for optimizing tool setup processes to improve efficiency, reduce downtime, and enhance overall productivity. This includes understanding different setup methodologies and their applications.

- Documentation and Record Keeping: Explain the importance of maintaining accurate records of tool usage, maintenance, and calibration, emphasizing best practices for clear and organized documentation.

- Working with Different Tool Types: Demonstrate familiarity with a range of tools relevant to the specific job description (e.g., hand tools, power tools, specialized equipment). Highlight adaptability to new technologies.

- Teamwork and Communication: Explain how you effectively communicate with colleagues and supervisors regarding tool setup processes, potential issues, and safety concerns.

Next Steps

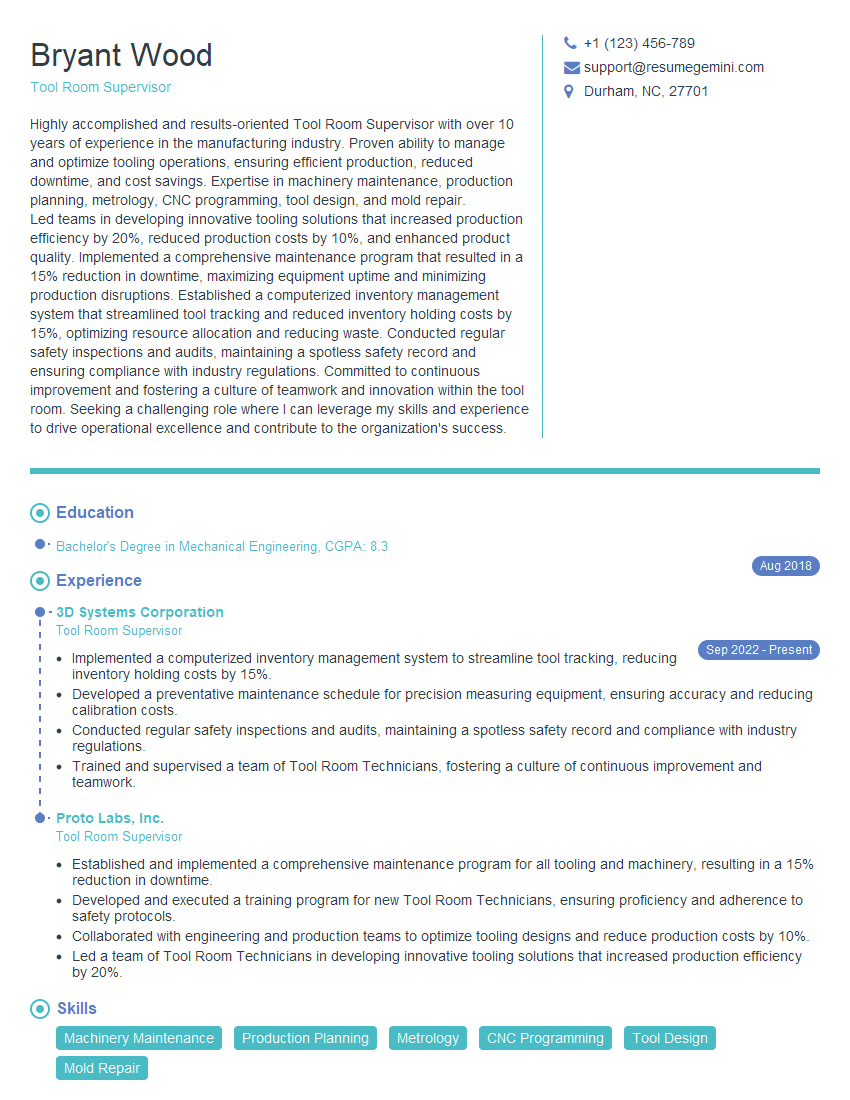

Mastering Tool Setup skills opens doors to exciting career opportunities and higher earning potential within manufacturing, construction, and many other technical fields. A strong foundation in these skills showcases your practical abilities and dedication to safety and efficiency. To maximize your job prospects, invest time in crafting an ATS-friendly resume that effectively highlights your qualifications. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Tool Setup are available to guide you through the process, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO