Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Tooling Corrective Action interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Tooling Corrective Action Interview

Q 1. Describe your experience with implementing corrective actions for tooling failures.

Implementing corrective actions for tooling failures involves a systematic approach focusing on identifying the root cause, implementing effective solutions, and verifying their success. My experience spans various manufacturing environments, including automotive and aerospace, where I’ve managed corrective actions for a wide range of tooling issues, from minor adjustments to major overhauls. This has involved collaborating with engineers, technicians, and shop floor personnel to analyze failures, develop solutions, and implement them safely and efficiently. A crucial aspect of my approach is ensuring that corrective actions not only address the immediate problem but also prevent recurrence. For example, I once addressed a recurring issue with a stamping die fracturing by implementing a new lubrication system and modifying the die’s material composition. The result was a significant reduction in failure rates and associated downtime.

Q 2. Explain the 5 Whys technique and how you’ve applied it to tooling issues.

The 5 Whys technique is a powerful root cause analysis tool used to drill down into the underlying reasons for a problem by repeatedly asking ‘Why?’ It’s particularly effective for tooling issues where seemingly simple failures might have complex root causes. I’ve used it extensively. For example, consider a press tool breaking. The initial problem is ‘The press tool broke.’

- Why? Because it fractured under load.

- Why? Because the material was fatigued.

- Why? Because of excessive vibration during operation.

- Why? Because the machine’s foundation was insufficiently dampened.

- Why? Because the machine was improperly installed.

This sequence helps pinpoint the root cause – improper machine installation – allowing us to implement a permanent solution rather than just replacing the broken tool. The 5 Whys is simple but effective in getting to the heart of a problem, ensuring a lasting solution, unlike superficial fixes that lead to recurrences.

Q 3. How do you prioritize corrective actions based on urgency and impact?

Prioritizing corrective actions is crucial in a fast-paced manufacturing environment. I use a risk matrix that considers both the urgency (how quickly the problem needs fixing) and the impact (the potential consequences of not fixing it). Urgency factors include immediate safety hazards, significant production downtime, or critical customer deadlines. Impact factors include financial losses, quality issues, and reputational damage. I then plot each corrective action on a matrix, allowing for a clear prioritization. High-urgency, high-impact issues get immediate attention, while lower-priority issues are addressed systematically according to their risk score. This prioritization ensures efficient resource allocation and minimizes overall risk.

Q 4. What tools and techniques do you use for root cause analysis in tooling?

My toolbox for root cause analysis includes several methods. The 5 Whys, as mentioned, is a key tool for simpler issues. For more complex problems, I often employ Failure Mode and Effects Analysis (FMEA), a systematic approach to identify potential failure modes in a system and their effects. I also use fault tree analysis, which diagrams the various events that can lead to a failure, helping to uncover multiple contributing factors. Data analysis plays a vital role; I leverage statistical process control (SPC) charts and historical data to identify trends and patterns in tool failures, often uncovering hidden clues.

Furthermore, physical inspection, microscopic analysis, and material testing are crucial components. Finally, collaborating with the team provides invaluable insights, leveraging collective experience and observations to build a comprehensive understanding of the problem. For instance, a pattern of tool breakage at a specific point could be revealed through SPC charts, and a subsequent microscopic analysis could uncover microscopic cracks, revealing the underlying material weakness.

Q 5. How do you validate the effectiveness of implemented corrective actions?

Validating the effectiveness of corrective actions is critical to ensure that the root cause has truly been addressed and future failures are prevented. This involves monitoring key metrics after implementing the corrective action. For example, if a corrective action aimed to reduce tool breakage, we would monitor the failure rate after the implementation. We’d use control charts to track the effectiveness of the implemented solution over time and establish statistical significance. Regular inspections and audits are also conducted to assess the ongoing performance of the tooling and the implemented solution. If the corrective action is not effective in mitigating the problem, it demonstrates a need for further root cause analysis and a revised corrective action plan.

Q 6. Describe a situation where a corrective action failed to resolve the root cause. What did you do?

In one instance, a series of injection molding failures were attributed to mold wear. We implemented a corrective action focusing on more frequent mold maintenance and polishing. However, the failures continued. Further investigation revealed that the problem wasn’t solely mold wear but also inconsistent material feed causing excessive pressure on the mold. This uncovered a deeper issue – a malfunctioning material handling system. Once we addressed the material handling issue, the mold failures ceased. This highlights the importance of thorough root cause analysis and the need for iterative problem-solving if initial solutions prove ineffective. In situations like this, I prioritize further investigation and retesting, involving a cross-functional team, to uncover the hidden cause.

Q 7. How do you document and track corrective actions for tooling?

Documentation and tracking of corrective actions is essential for continuous improvement and compliance. We use a dedicated system, a combination of a Computerized Maintenance Management System (CMMS) and shared document management platform, to record all corrective actions. Each record includes details like the initial problem, root cause analysis findings, implemented solutions, responsible parties, and validation data. The system allows for tracking the effectiveness of each action, the time taken for implementation, and any associated costs. This data is regularly reviewed to identify trends and areas for improvement in our tooling management processes. Regular audits are conducted to ensure consistency and accuracy of records.

Q 8. What are your preferred methods for communicating corrective action plans and results?

Effective communication is crucial for successful corrective actions. My preferred methods involve a multi-pronged approach, ensuring transparency and accountability. I begin with a concise, clearly written corrective action request (CAR) detailing the problem, root cause, proposed solution, and responsible parties. This is typically distributed via email to all relevant stakeholders.

For larger or more complex issues, I schedule a kickoff meeting to discuss the CAR in detail, allowing for questions and collaborative brainstorming. I utilize project management software (like Jira or Asana) to track progress, deadlines, and assign tasks. Regular updates are then shared through the same platform, and I might also use email for brief updates or quick questions.

Finally, upon completion of the corrective action, I prepare a comprehensive report outlining the implemented solution, its effectiveness (including data-driven evidence like improved production yield or reduced defect rates), and any lessons learned. This report is formally circulated to all involved parties, ensuring everyone is aware of the outcome and potential future implications.

Q 9. How do you ensure compliance with relevant standards and regulations in your corrective actions?

Compliance is paramount. My approach involves a thorough understanding of all relevant standards and regulations impacting our tooling. This includes industry standards (like ISO 9001 or TS 16949 for automotive), regulatory requirements (OSHA, EPA, etc.), and internal company policies. I ensure all corrective actions are planned and executed in strict adherence to these guidelines.

Before initiating any corrective action, I conduct a thorough risk assessment to identify potential non-compliance issues. This process includes reviewing existing documentation, checking for regulatory changes, and consulting with relevant internal experts (e.g., quality control, legal). The corrective action plan itself explicitly addresses compliance requirements, detailing how the proposed solution meets all relevant standards. Documentation of the entire process, including approvals, implementation steps, and verification results, is meticulously maintained to demonstrate compliance during any audits.

For example, if a tooling malfunction poses a safety hazard, our corrective action will strictly adhere to OSHA guidelines, including implementing appropriate safety measures and retraining personnel. Regular audits and internal reviews are crucial to ensure sustained compliance.

Q 10. Explain your experience with FMEA (Failure Mode and Effects Analysis) related to tooling.

FMEA (Failure Mode and Effects Analysis) is a vital tool for proactive risk management in tooling. My experience involves conducting FMEAs for new tooling designs, as well as for existing tools exhibiting recurring problems. I follow a structured approach, working collaboratively with design engineers, manufacturing personnel, and quality control.

We systematically identify potential failure modes for each component of the tooling, analyze their effects on the overall process and product quality, and assess the severity, occurrence, and detection of each failure. The resulting Severity, Occurrence, Detection (SOD) matrix helps prioritize corrective actions. A high SOD value indicates a high-risk failure mode that needs immediate attention.

For instance, in analyzing a stamping die, we might identify a potential failure mode as ‘die cracking’ due to excessive force. We would assess the severity (e.g., potential for production downtime, product defects, injury), occurrence (how often this might happen), and detectability (how easily we can detect the crack before it leads to failure). This would guide us in implementing preventive measures, such as modifying the die design, improving lubrication, or implementing a more frequent inspection schedule.

Q 11. Describe your experience with Pareto analysis in identifying tooling problems.

Pareto analysis, also known as the 80/20 rule, is extremely helpful in identifying the vital few tooling problems responsible for the majority of issues. My experience involves using Pareto charts to visualize the frequency and impact of different tooling-related problems.

We collect data on tooling failures, downtime, and defects over a specific period. Then, we categorize these issues and tally their occurrences. The Pareto chart clearly displays the issues in descending order of frequency, highlighting the ‘vital few’ that account for a significant percentage (typically 80%) of the total problems. This analysis allows us to focus our corrective action efforts on these key issues, achieving significant improvements with minimal resource expenditure.

For example, a Pareto chart might reveal that 80% of our downtime is caused by just two tooling problems: a worn-out punch and a recurring malfunction in a specific clamping mechanism. This directs our attention towards addressing these two problems effectively, delivering a large impact for the resources invested.

Q 12. How do you balance the cost of corrective action with the risk of failure?

Balancing cost and risk requires a structured approach. I use a risk-based prioritization method that considers both the cost of implementing corrective actions and the potential consequences of tool failure. This involves quantifying both factors.

We estimate the cost of implementing each potential corrective action, including material costs, labor, and downtime. Simultaneously, we assess the potential cost of failure, including lost production, scrap, warranty claims, and potential safety hazards. We then compare the cost of correction against the potential cost of inaction (failure). Corrective actions that prevent high-risk, high-cost failures are prioritized, even if their implementation cost is higher.

For instance, replacing a critical tooling component might be expensive, but failing to do so might lead to significant production losses and safety risks. A cost-benefit analysis clearly demonstrates that the cost of replacement is less than the potential costs associated with failure, justifying the expense.

Q 13. How do you involve different teams and stakeholders in the corrective action process?

Involving different teams and stakeholders is essential for effective corrective actions. I utilize a collaborative approach that leverages the expertise of various departments. This includes engineers, production supervisors, quality control personnel, maintenance technicians, and even operators who directly interact with the tools.

I use regular meetings, email communication, and project management software to facilitate this collaboration. A cross-functional team is often formed to tackle complex issues. Each member contributes their expertise, enhancing the problem-solving process and creating buy-in for the implemented solution. Clearly defined roles and responsibilities within the team prevent confusion and ensure accountability.

For example, when addressing a tooling problem related to part dimensional accuracy, the team would include design engineers (to review specifications), production supervisors (to assess process impacts), quality control (to provide measurement data), and maintenance technicians (to implement the solution). This multidisciplinary approach leads to comprehensive and lasting solutions.

Q 14. Describe your experience using a CMMS (Computerized Maintenance Management System).

My experience with CMMS (Computerized Maintenance Management System) involves using it to track, schedule, and manage tooling maintenance and corrective actions. I utilize the system to record all relevant data, including tool specifications, maintenance history, failure reports, and corrective actions taken.

The CMMS helps schedule preventive maintenance, reducing the likelihood of failures. It streamlines the entire corrective action process by automating tasks such as work order generation, parts ordering, and technician assignments. Real-time data allows for monitoring of the effectiveness of corrective actions and identification of recurring problems. Detailed reporting capabilities provide valuable insights into tooling performance and maintenance needs.

For example, the CMMS allows us to track the maintenance history of a specific press die, alerting us when it’s due for preventive maintenance (e.g., lubrication, inspection). If a failure occurs, we can quickly log it in the system, generating a work order for repair and tracking its resolution. The system also provides historical data that can help identify trends and predict future maintenance requirements, enabling proactive interventions.

Q 15. How do you measure the effectiveness of your corrective action program?

Measuring the effectiveness of a corrective action program is crucial for continuous improvement. We don’t just fix problems; we ensure they stay fixed and prevent recurrence. I use a multi-pronged approach, focusing on both leading and lagging indicators.

Lagging Indicators (outcomes): These measure the *results* of our actions. For example, we track the reduction in the number of tooling-related failures after implementing corrective actions. A significant decrease in scrap rate or downtime directly attributable to a specific corrective action is a strong indicator of success. We might also look at customer returns related to tooling defects, aiming for a consistent downward trend.

Leading Indicators (processes): These measure the *effectiveness* of our processes. We track metrics like the time it takes to complete a corrective action, the percentage of actions completed within a defined timeframe, and the effectiveness of root cause analysis. A shorter completion time and higher percentage of effective root cause analyses suggest improvements in our processes. For instance, if we consistently resolve issues within 48 hours, that’s a positive leading indicator.

Qualitative Feedback: We also gather feedback from the teams involved in the corrective action process—operators, maintenance personnel, engineers. Their insights are invaluable in identifying areas for improvement and confirming the lasting impact of our actions. Regular meetings and surveys help us understand the effectiveness from a practical standpoint.

By combining lagging and leading indicators with qualitative feedback, we get a holistic picture of our corrective action program’s effectiveness. We regularly review these metrics and adjust our processes as needed to continuously improve.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What metrics do you use to track tooling performance and identify potential issues?

Tracking tooling performance is essential for proactive maintenance and preventing costly downtime. We employ a range of metrics, categorized for clarity:

Performance Metrics: These directly assess the tooling’s functionality. For stamping dies, this includes the number of parts produced between sharpening or repairs, and the dimensional accuracy of the parts. For molds, we track cycle time, defect rate, and the number of acceptable parts produced. For jigs, it’s the accuracy of the parts produced and the frequency of adjustments needed.

Maintenance Metrics: These focus on the maintenance schedule and its effectiveness. We monitor the time spent on preventative maintenance, the frequency of repairs, and the overall cost of maintenance per part produced. High maintenance frequency might indicate a problem with the tooling or the maintenance process itself.

Downtime Metrics: This is a crucial KPI. We track the total downtime caused by tooling failures, the frequency of such failures, and the duration of each downtime event. A sudden spike in downtime warrants immediate investigation.

Defect Rate: The percentage of defective parts produced due to tooling issues is a vital measure. A rise in this rate signals a problem that needs immediate attention.

We use a combination of manual data collection and automated data acquisition systems where feasible. This data feeds into our preventative maintenance schedules and helps us identify patterns that could predict potential failures. For example, a gradual decrease in the number of parts produced between sharpening sessions for a stamping die could warn us of impending failure.

Q 17. How do you handle situations where multiple corrective actions are required?

Handling multiple required corrective actions demands a structured approach. Simply addressing each issue in isolation can be inefficient and lead to overlooked dependencies. I utilize a prioritization matrix and a phased approach:

Prioritization Matrix: We assess each corrective action based on factors like severity (impact on production, safety, quality), urgency (time to implement), and cost. A simple matrix with severity and urgency can quickly identify critical actions. For example, a high-severity, high-urgency issue (e.g., a safety hazard) takes precedence over a low-severity, low-urgency issue (e.g., minor cosmetic flaw).

Phased Approach: Once prioritized, we break down complex corrective actions into smaller, manageable phases. This allows for parallel processing of multiple actions and makes progress tracking easier. For example, repairing a large mold might involve phase 1 (cleaning and inspection), phase 2 (part replacement), and phase 3 (testing and verification). This modular approach allows for efficient resource allocation and minimizes disruption.

Dependency Mapping: We carefully examine the interdependencies between corrective actions. Addressing one issue might influence another; for instance, fixing a worn jig might require adjustments to the associated stamping die. This mapping ensures we resolve issues in the correct order to avoid rework or cascading failures.

This combined approach enables us to efficiently manage complex scenarios while ensuring that critical issues receive immediate attention.

Q 18. How do you identify and mitigate potential risks associated with corrective actions?

Identifying and mitigating risks associated with corrective actions is critical to avoiding unintended consequences. We employ a risk assessment framework that considers the potential impact and likelihood of various risks:

Risk Identification: We systematically identify potential risks during the root cause analysis phase. This could include risks associated with the chosen corrective action (e.g., downtime, cost overruns, unintended damage to other equipment), or risks related to the implementation process (e.g., human error, insufficient training). We brainstorm potential risks and document them.

Risk Assessment: We use a matrix to assess the likelihood and impact of each identified risk. This helps prioritize mitigation efforts. A risk with high likelihood and high impact needs immediate attention.

Risk Mitigation: For each identified risk, we develop strategies to reduce its likelihood or impact. This might include using specialized tools, providing extra training, implementing safety protocols, or creating contingency plans.

Risk Monitoring: We monitor the effectiveness of our mitigation strategies throughout the corrective action process. We regularly check for any new emerging risks during the implementation of corrective actions.

This structured approach allows us to proactively manage risks, ensuring that corrective actions are implemented safely and effectively, minimizing disruptions and potential damage.

Q 19. What is your experience with preventative maintenance for tooling?

Preventative maintenance is the cornerstone of a successful tooling program. It’s far more cost-effective to prevent failures than to react to them. My experience involves establishing and overseeing comprehensive preventative maintenance schedules customized for different tooling types.

Scheduled Maintenance: We develop detailed schedules outlining routine inspections, cleaning, lubrication, and minor adjustments. These schedules are based on factors like usage frequency, tooling complexity, and manufacturer recommendations. For instance, stamping dies might require more frequent lubrication than molds.

Condition-Based Monitoring: We incorporate condition-based maintenance techniques, using sensors or regular inspections to assess the tooling’s condition and predict potential problems. For example, monitoring vibration levels in a CNC machine can help us identify potential bearing failures before they cause major downtime.

Data Analysis: We track preventative maintenance data to identify trends and improve our maintenance strategies. We monitor the effectiveness of our maintenance tasks and adjust schedules or procedures if necessary. For instance, if a specific maintenance task consistently fails to prevent failures, we’ll revisit the process.

Training and Documentation: Comprehensive training programs ensure that maintenance personnel have the skills and knowledge to perform tasks effectively. Detailed documentation, including procedures, checklists, and maintenance histories, is essential for maintaining consistency and traceability.

By combining scheduled, condition-based, and data-driven approaches, we optimize our preventative maintenance program to maximize tooling lifespan, reduce downtime, and improve overall productivity.

Q 20. Describe your experience with different types of tooling (e.g., stamping dies, molds, jigs).

My experience encompasses a wide range of tooling, including stamping dies, molds, and jigs, each requiring a specialized approach to maintenance and corrective action.

Stamping Dies: I’ve worked extensively with progressive dies, compound dies, and single-stage dies. My focus has been on maintaining dimensional accuracy, optimizing die life through proper lubrication and sharpening techniques, and troubleshooting issues like breakage, wear, and misalignment. We use sophisticated measuring equipment to ensure the quality and consistency of the produced parts.

Molds: Experience includes working with injection molds, blow molds, and compression molds. The emphasis here is on maintaining surface finish, ensuring consistent part ejection, and managing issues like wear, erosion, and cracking. Regular preventative maintenance, including cleaning and lubrication, is crucial for maintaining mold quality and extending its lifespan. We use specialized software for mold design and analysis.

Jigs and Fixtures: My experience with jigs involves maintaining their dimensional accuracy and ensuring proper clamping forces. We pay special attention to wear points to prevent misalignment or part defects.

This diverse experience has provided me with a solid understanding of the unique challenges associated with each tooling type and the best practices for their maintenance and repair.

Q 21. How do you manage and prioritize multiple concurrent tooling corrective actions?

Managing multiple concurrent tooling corrective actions effectively requires a robust system for prioritization, resource allocation, and communication. I use a combination of techniques:

Prioritization Matrix (as described in Q3): This ensures that the most critical issues are addressed first, minimizing disruption and potential losses.

Resource Allocation: We assign personnel and resources based on the complexity and urgency of each action. Skilled technicians might be allocated to critical tasks, while less complex actions could be handled by less experienced personnel. We also ensure that the necessary tools, equipment, and materials are available.

Project Management Software: We utilize project management tools to track progress, manage deadlines, and facilitate communication between teams. These tools enable us to visualize the entire process, identify potential bottlenecks, and adjust plans as needed. It helps us monitor resource allocation and deadlines effectively.

Regular Status Meetings: Frequent communication is key. Regular meetings with all involved parties ensure transparency, identify and resolve roadblocks, and keep everyone informed of the progress. These meetings promote teamwork and facilitate proactive problem-solving.

By combining these techniques, we can effectively manage multiple concurrent corrective actions, minimizing downtime and ensuring the timely resolution of all issues.

Q 22. Explain how you ensure corrective actions are implemented consistently across shifts.

Consistency in corrective action implementation across different shifts is paramount for maintaining operational efficiency and product quality. To achieve this, we utilize a standardized, documented process that’s readily accessible to all personnel, regardless of shift. This includes clear, step-by-step instructions for each corrective action, coupled with visual aids like checklists and flowcharts.

Furthermore, we implement regular shift handovers, where outgoing shift personnel brief the incoming team on ongoing issues, planned actions, and any relevant updates. This ensures a seamless transition and continuity of effort. We also leverage a centralized system, such as a digital work order management system, to track and document all corrective actions, providing real-time visibility to all shifts and management.

For instance, if a specific milling machine consistently malfunctions, the corrective action procedure, detailing the troubleshooting steps and necessary adjustments, is readily available to the day, evening, and night shifts. This avoids any ambiguity and ensures uniform handling of the issue across the entire operation.

Q 23. How do you ensure the proper training of personnel on new tooling and corrective action procedures?

Effective training is crucial for successful tooling corrective action implementation. Our approach involves a multi-faceted strategy encompassing both initial and ongoing training programs. New tooling is introduced through a combination of classroom instruction, hands-on demonstrations, and practical exercises. This includes detailed explanations of the tooling’s functionality, safety protocols, and specific troubleshooting guidelines. For instance, training on a new CNC milling machine will cover machine operation, maintenance, error codes, and corrective action steps for common issues.

Regarding corrective action procedures, we employ interactive training modules, simulations, and shadowing opportunities with experienced technicians. We use a blended learning approach to cater to different learning styles. This allows technicians to not only understand the procedures but also practice applying them in a controlled environment, reinforcing their retention. Regular refresher courses and updates ensure knowledge remains current and relevant to evolving technologies and best practices. This minimizes the risk of mistakes and ensures efficient problem-solving.

Q 24. What is your experience with using data analysis to identify trends in tooling failures?

Data analysis plays a vital role in identifying trends and patterns in tooling failures, allowing us to implement proactive measures. We collect data on tooling failures, including type of failure, frequency, location, and associated downtime. This data is then analyzed using statistical methods and data visualization tools to pinpoint recurring problems.

For example, we might use Pareto charts to identify the ‘vital few’ causes of tooling failures, contributing to the majority of downtime. Control charts help track changes in failure rates over time, revealing potential issues before they escalate. We might find that a specific type of drill bit consistently fails after a certain number of uses, leading us to investigate factors such as material selection, sharpening techniques, or operating parameters. Root cause analysis techniques, such as the 5 Whys, help us delve deeper into the underlying causes of these failures.

This data-driven approach allows us to make informed decisions about preventative maintenance schedules, tooling upgrades, and operator training, ultimately reducing overall tooling costs and maximizing operational efficiency.

Q 25. How do you handle situations where corrective actions require significant capital investment?

When corrective actions require significant capital investment, a structured approach is essential. This involves a thorough cost-benefit analysis to justify the expenditure. We carefully assess the potential return on investment (ROI) by considering factors such as reduced downtime, improved product quality, and increased productivity. This analysis is documented and presented to senior management for approval.

We also explore alternative solutions and evaluate their cost-effectiveness. This might involve exploring leasing options, phased implementation, or seeking external funding. For instance, instead of immediately purchasing a new, expensive machine, we might opt for a cost-effective repair solution in the short-term while planning for a long-term upgrade in the next budget cycle. Transparency and clear communication with management throughout the process are vital for securing support and ensuring the project’s success.

Q 26. Describe your approach to escalating complex tooling issues to senior management.

Escalating complex tooling issues requires a well-defined protocol. We start by documenting the problem thoroughly, including all relevant data, attempted solutions, and their results. This comprehensive report becomes the foundation for our communication with senior management.

We present the issue concisely, highlighting its impact on production, potential risks, and proposed solutions. We also provide a timeline for resolution and clearly articulate the resources required. For instance, if a critical machine is down and all internal attempts at repair have failed, we would immediately escalate this, highlighting production losses and potential customer delivery delays. This enables management to quickly understand the situation and prioritize the necessary resources for resolution.

Regular updates are crucial throughout the escalation process to keep management informed of progress and any changes in the situation.

Q 27. How do you balance short-term solutions with long-term preventative measures for tooling?

Balancing short-term solutions with long-term preventative measures is a crucial aspect of effective tooling management. Short-term solutions address immediate problems and minimize downtime. For instance, if a tool breaks during production, a quick repair or replacement is the short-term solution. However, we simultaneously analyze the root cause of the failure to prevent recurrence.

Long-term preventative measures focus on eliminating the underlying causes of failures. This might involve implementing improved maintenance schedules, investing in higher-quality tooling, improving operator training, or redesigning processes to reduce stress on the tools. Think of it as fixing a flat tire (short-term) while also rotating your tires regularly and ensuring proper inflation to prevent future flats (long-term). A balanced approach ensures both immediate operational efficiency and long-term cost savings.

Q 28. Describe your experience with implementing continuous improvement initiatives related to tooling.

I have extensive experience implementing continuous improvement initiatives related to tooling, primarily utilizing Lean methodologies and Six Sigma principles. We’ve successfully implemented several projects focusing on reducing tooling downtime, improving tooling lifespan, and optimizing tooling costs.

One example involves implementing a 5S system in our tooling storage area, leading to improved organization, easier tool retrieval, and reduced tool damage. Another initiative utilized Value Stream Mapping to identify and eliminate non-value-added steps in the tooling maintenance process, streamlining the workflow and reducing lead times. Data-driven decision making, including statistical process control (SPC), is central to our continuous improvement efforts, allowing us to monitor performance, identify trends, and implement effective changes.

These initiatives have resulted in significant improvements in overall equipment effectiveness (OEE), reduced tooling costs, and enhanced product quality. Regular reviews and assessments ensure that the implemented changes remain effective and adaptable to evolving needs.

Key Topics to Learn for Tooling Corrective Action Interview

- Root Cause Analysis Techniques: Understanding and applying methodologies like 5 Whys, Fishbone diagrams, and fault tree analysis to identify the underlying causes of tooling failures.

- Corrective Action Implementation: Developing and executing effective solutions to prevent recurrence of tooling issues, including implementing preventative maintenance schedules and operator training programs.

- Documentation and Reporting: Mastering the creation of clear, concise, and compliant documentation for corrective actions, including reports, work instructions, and change control records.

- Tooling Design and Manufacturing Processes: A foundational understanding of how tooling is designed, manufactured, and used within the production environment. This includes familiarity with materials, tolerances, and common failure modes.

- Statistical Process Control (SPC): Applying SPC principles to monitor tooling performance, identify trends, and proactively address potential issues before they escalate.

- Quality Management Systems (QMS): Understanding how tooling corrective actions integrate with overall quality management systems, such as ISO 9001 or IATF 16949. This includes knowledge of auditing procedures and compliance requirements.

- Problem-Solving Methodologies: Applying structured problem-solving approaches like DMAIC (Define, Measure, Analyze, Improve, Control) to systematically address tooling issues.

- Communication and Collaboration: Effectively communicating technical information to various stakeholders, including engineers, technicians, and management.

Next Steps

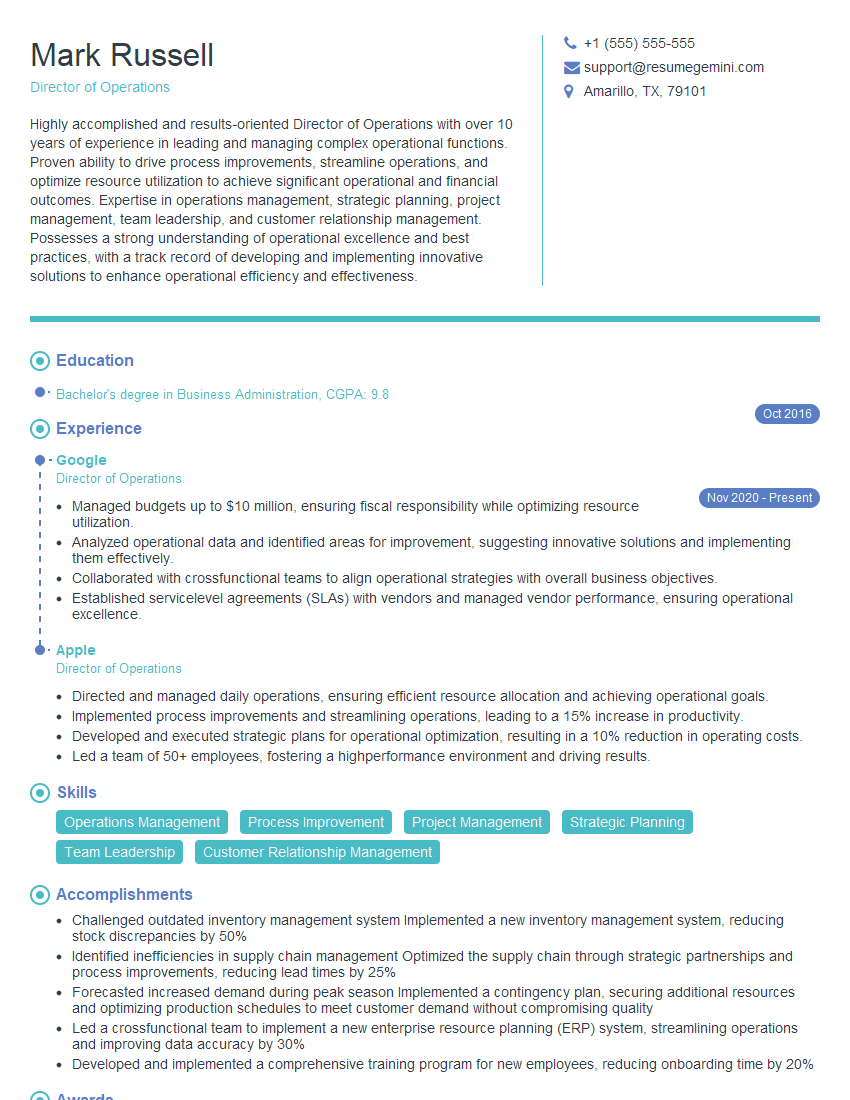

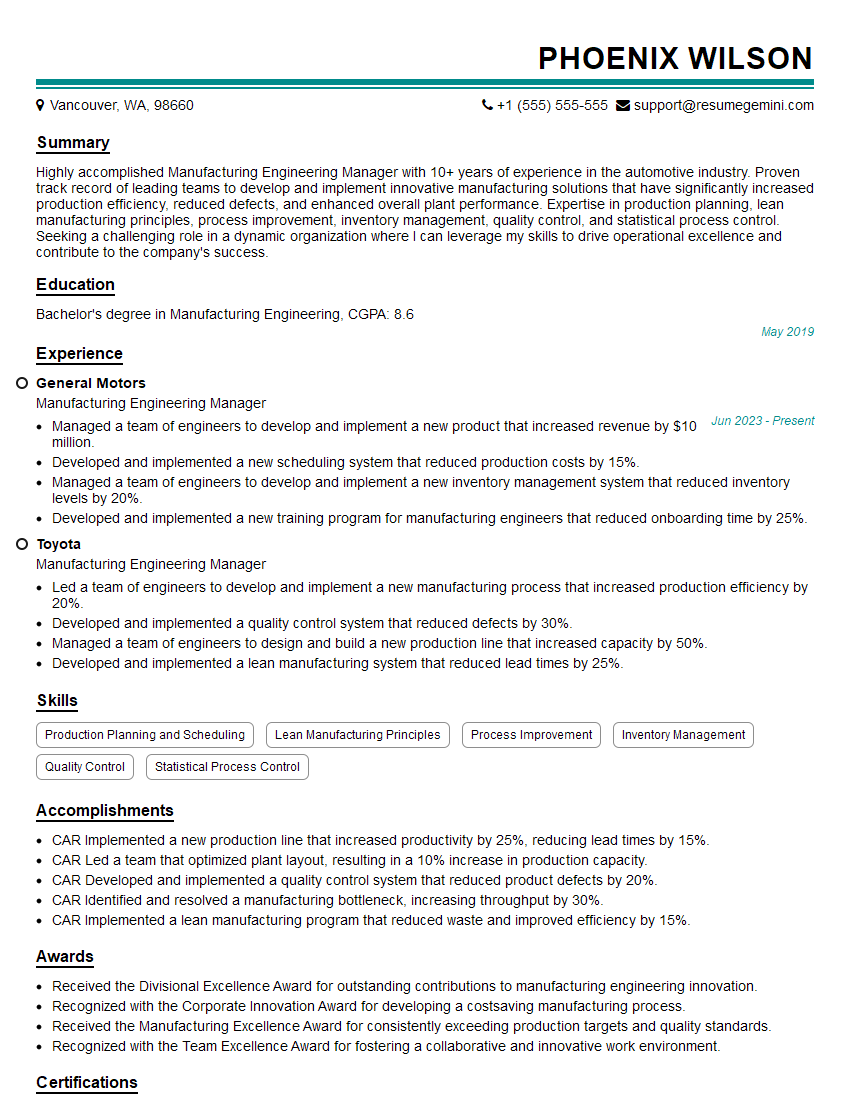

Mastering Tooling Corrective Action is crucial for career advancement in manufacturing and engineering. It demonstrates your ability to solve complex problems, improve efficiency, and ensure product quality. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes that get noticed. Use ResumeGemini to craft a compelling narrative that showcases your expertise in Tooling Corrective Action. Examples of resumes tailored to this field are available within ResumeGemini to guide your creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO