Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Tooling Six Sigma interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Tooling Six Sigma Interview

Q 1. Explain the DMAIC methodology in the context of tooling.

DMAIC, which stands for Define, Measure, Analyze, Improve, and Control, is a structured problem-solving methodology widely used in Six Sigma. In the context of tooling, it provides a systematic approach to enhance tooling processes, reduce defects, and improve overall efficiency. Let’s break down each phase:

- Define: Clearly define the problem, the project goals, and the scope. For example, reducing the number of broken tooling components during production runs or decreasing the setup time for a specific tooling fixture.

- Measure: Collect data to quantify the current state of the process. This might involve tracking defect rates, cycle times, or downtime. Key metrics need to be defined and data collection methods established.

- Analyze: Identify the root causes of the problems defined in the first phase using statistical tools like Pareto charts, fishbone diagrams, or regression analysis. For instance, analyzing whether tool wear, improper handling, or material defects are contributing to the breakage of components.

- Improve: Develop and implement solutions to address the root causes identified during the analysis phase. This might include implementing new training protocols, upgrading equipment, modifying tooling designs, or improving material handling procedures.

- Control: Establish a system to sustain the improvements made. This often involves implementing control charts for ongoing monitoring, establishing standardized work instructions, and regularly reviewing performance metrics. For example, implementing a preventative maintenance schedule for the tooling and training operators on best practices for proper handling.

By following the DMAIC cycle, tooling engineers can systematically address and eliminate defects in the manufacturing process, leading to improved quality, reduced costs, and increased productivity.

Q 2. Describe your experience with Statistical Process Control (SPC) charts in tooling applications.

Statistical Process Control (SPC) charts are crucial for monitoring tooling processes and ensuring stability. I have extensive experience using various SPC charts, such as X-bar and R charts, p-charts, and c-charts, depending on the type of data being collected.

For example, in a project involving injection molding tools, we used X-bar and R charts to monitor the dimensions of the molded parts. By tracking the average dimension (X-bar) and the range of variation (R) over time, we could identify any shifts or trends indicating process instability. This allowed for timely intervention, preventing the production of defective parts and minimizing tool wear.

Another project involved using p-charts to track the defect rate of a stamping die. By plotting the proportion of defective parts over time, we could quickly detect any increases in the defect rate, signaling potential problems with the die’s wear, alignment, or material handling.

Implementing SPC charts is not just about detecting problems; it also helps in demonstrating the effectiveness of implemented improvements. By showing a shift towards stability and a reduction in variability after implementing changes, we can build confidence in the effectiveness of our interventions.

Q 3. How do you identify and prioritize improvement opportunities in a tooling process?

Identifying and prioritizing improvement opportunities in tooling processes requires a structured approach. I typically start by employing a combination of methods:

- Data Analysis: Analyzing process data to pinpoint areas with high defect rates, long cycle times, or excessive downtime. Tools such as Pareto charts and histograms help visualize the most significant issues.

- Voice of the Customer (VOC): Gathering feedback from operators, maintenance personnel, and even customers to understand their pain points and unmet needs regarding the tooling process. This can reveal hidden problems that data analysis alone may miss.

- Failure Analysis: Investigating failures in the tooling process to identify root causes using tools like 5 Whys, fishbone diagrams, and Fault Tree Analysis (FTA). This helps to understand the underlying reasons for defects and inefficiencies.

- Benchmarking: Comparing the current tooling process to best-in-class practices to identify potential areas for improvement and identify gaps that need to be closed.

Once potential improvement opportunities are identified, I prioritize them based on their potential impact and feasibility. This often involves using a Prioritization Matrix that considers factors such as the impact on quality, cost, and delivery, as well as the ease and cost of implementation. Opportunities with high impact and low implementation costs are given the highest priority.

Q 4. What are the key metrics you use to measure the effectiveness of tooling Six Sigma projects?

The key metrics I use to measure the effectiveness of tooling Six Sigma projects depend on the specific goals of the project, but commonly include:

- Defect Rate: A reduction in the number of defective parts or products produced, often expressed as defects per million opportunities (DPMO).

- Cycle Time: A decrease in the time required to complete a tooling process, such as setup time, machining time, or maintenance time.

- Downtime: A reduction in the time the tooling is out of service due to failures or maintenance. This is often measured as downtime per unit of production.

- Cost Savings: A reduction in tooling costs, including material costs, labor costs, and repair costs.

- Tool Life: An increase in the useful life of tooling components before replacement is needed.

- Customer Satisfaction: Improved customer satisfaction as a result of higher product quality and on-time delivery.

These metrics are tracked before, during, and after the implementation of Six Sigma improvements to demonstrate the project’s effectiveness and provide a quantifiable return on investment.

Q 5. Explain how you would apply Gage R&R studies to a tooling process.

Gage R&R studies are essential to assess the measurement system used for a tooling process. This ensures that the data collected is reliable and reflects actual process variation, not measurement error. The study determines the variation caused by the measurement system itself (gage repeatability and reproducibility) compared to the total variation in the process.

For example, if we are measuring the diameter of a machined part using a caliper, a Gage R&R study would evaluate the variation in measurements taken by different operators using the same caliper (reproducibility) and the variation in repeated measurements taken by the same operator using the same caliper (repeatability). We’d use ANOVA (Analysis of Variance) to partition the total variation.

The results are typically presented as a percentage of total variation attributable to the gage (measurement system) and the process. An acceptable Gage R&R is typically less than 10% of the total variation. If the percentage is higher, it indicates a problem with the measurement system, and adjustments – such as improved calibration procedures, operator training, or upgrading the measuring instrument – are necessary before proceeding with process improvement efforts.

Q 6. Describe your experience with Failure Mode and Effects Analysis (FMEA) in tooling.

Failure Mode and Effects Analysis (FMEA) is a proactive risk assessment tool that I frequently use in tooling. It helps identify potential failure modes in the tooling process, assess their severity, occurrence, and detection, and develop preventative actions to mitigate the risks.

In a recent project involving a complex stamping die, we performed an FMEA to identify potential failure modes, such as die cracking, tool breakage, or misalignment. For each failure mode, we assessed its severity, occurrence (likelihood of happening), and detection (ease of detection). The severity, occurrence, and detection scores were multiplied to create a Risk Priority Number (RPN). This RPN helped prioritize the failure modes and focus our improvement efforts on the most critical ones.

Based on the FMEA, we implemented several preventative actions, including improved material selection, enhanced lubrication, more frequent inspections, and improved operator training. This proactive approach significantly reduced the risk of costly tooling failures and downtime.

Q 7. How do you handle resistance to change when implementing Six Sigma improvements in tooling?

Resistance to change is a common challenge when implementing Six Sigma improvements. To handle it effectively, I employ a multi-pronged approach:

- Communication and Education: Clearly communicate the reasons for change, the expected benefits, and the impact on the team. This includes explaining the data-driven approach and demonstrating the potential improvements to productivity, quality, and safety.

- Involvement and Participation: Engage the team in the process improvement effort by actively seeking their input, feedback, and suggestions. This fosters a sense of ownership and reduces resistance to the changes being implemented.

- Pilot Projects: Implementing small-scale pilot projects allows testing and refining the proposed improvements before a large-scale rollout. This demonstrates the effectiveness of the changes and increases confidence in the overall implementation.

- Addressing Concerns: Proactively identify and address any concerns or apprehensions raised by the team. This includes providing clear answers to their questions and addressing any anxieties they may have about job security or workload.

- Incentives and Recognition: Acknowledging and rewarding the team’s contributions and successes strengthens their buy-in and motivates continued engagement with the process improvement effort.

By addressing resistance to change proactively and building a collaborative environment, I’ve successfully implemented numerous Six Sigma projects that have resulted in significant improvements in tooling processes.

Q 8. What tools and techniques do you use for root cause analysis in tooling issues?

Root cause analysis is crucial in tooling Six Sigma to pinpoint the underlying issues driving defects or inefficiencies. I employ a multi-pronged approach, combining several powerful tools. One of my favorites is the 5 Whys, a simple yet effective technique where we repeatedly ask ‘why’ to drill down to the root cause. For example, if a tool is breaking frequently, we might ask:

- Why is the tool breaking? (Answer: Excessive vibration)

- Why is there excessive vibration? (Answer: Loose mounting)

- Why is the mounting loose? (Answer: Inadequate tightening procedure)

- Why is the tightening procedure inadequate? (Answer: Lack of clear instructions)

- Why is there a lack of clear instructions? (Answer: Insufficient training for operators)

Beyond the 5 Whys, I also leverage fishbone diagrams (Ishikawa diagrams) to brainstorm potential causes categorized by factors like manpower, materials, machinery, methods, measurement, and environment. Fault tree analysis (FTA) is particularly useful for complex systems where multiple factors can contribute to a failure. This method visually maps out potential failure modes and their causes, helping to identify critical points of failure. Finally, data analysis plays a vital role. By carefully examining process data, we can identify trends and patterns that point toward underlying root causes.

Q 9. How do you measure the cost savings achieved through tooling Six Sigma projects?

Measuring cost savings in tooling Six Sigma projects requires a systematic approach. We start by defining baseline costs before the project begins. This includes direct costs like material waste, rework, scrap, and downtime, as well as indirect costs such as labor associated with problem-solving and customer complaints. After implementing improvements, we meticulously track these costs again. The difference represents the direct cost savings. We also quantify indirect cost reductions; for example, reducing downtime leads to increased production and higher revenues.

To illustrate, consider a project where we reduced the defect rate from 10% to 1%. If the cost of each defective part is $10, and we produce 10,000 parts per month, the initial monthly cost of defects was $10,000 (10% * 10,000 * $10). After the improvement, the cost drops to $1,000 (1% * 10,000 * $10). This represents a cost savings of $9,000 per month. We document all these calculations and present a comprehensive cost-benefit analysis to justify the project’s success.

Q 10. Describe your experience with design of experiments (DOE) in tooling.

Design of Experiments (DOE) is a powerful statistical tool I frequently use to optimize tooling processes. It allows us to systematically manipulate input variables (factors) to determine their effect on output variables (responses), such as tool lifespan, dimensional accuracy, or surface finish. I’ve employed both full factorial and fractional factorial designs depending on the complexity and the number of factors involved. A full factorial design examines all possible combinations of factor levels, providing comprehensive data but becoming computationally intensive with many factors. Fractional factorial designs are more efficient when dealing with numerous factors, allowing us to identify significant effects with fewer experiments.

For instance, in optimizing a stamping die, I might use DOE to study the impact of factors like punch speed, die temperature, and lubrication on the resulting part’s dimensional accuracy. The results would guide modifications to the process parameters to optimize the output within the desired specifications. Software packages like Minitab or JMP greatly assist in designing, conducting, and analyzing DOE experiments.

Q 11. How do you ensure the sustainability of Six Sigma improvements in tooling after project completion?

Sustaining Six Sigma improvements after project completion requires proactive measures. Simply handing over the improved process isn’t enough. We actively involve the shop floor personnel in all phases of the project, fostering ownership and buy-in. This includes thorough training on new procedures and standardized work instructions. We also establish robust monitoring systems, utilizing control charts to track key process parameters and detect any deviations early. Standard operating procedures (SOPs) are crucial, clearly outlining the improved processes to ensure consistency.

Furthermore, we implement regular process audits to verify adherence to the new standards and address any emerging issues promptly. A crucial element is creating a culture of continuous improvement, encouraging employees to report problems and suggest further enhancements. Finally, we integrate the improvements into the company’s overall quality management system to ensure long-term sustainability. We often establish a post-implementation review period to ensure the project is performing as intended.

Q 12. Explain your understanding of Cp and Cpk in tooling processes.

Cp and Cpk are process capability indices that measure how well a process performs relative to its specifications. Cp (process capability) assesses the inherent variability of a process compared to the specification tolerance, assuming the process is centered. A Cp of 1 indicates the process is just capable of meeting specifications, while a Cp greater than 1 signifies increasing capability. Cpk (process capability index) considers both the process variability and its centering relative to the specification limits. It provides a more realistic assessment, as most processes aren’t perfectly centered.

In tooling, a high Cp and Cpk are essential. For example, if we’re manufacturing a precision part with tight tolerances, a low Cpk would indicate a high risk of producing defective parts, leading to scrap and rework. We strive to achieve Cpk values greater than 1.33 or even 1.5 for robust processes. This indicates that only a small percentage of parts will likely fall outside the specifications. We might use control charts and gauge R&R studies to assess Cp and Cpk and identify areas for improvement. A Cp of 1.5 indicates that only 0.00066% of products will fall outside the specification limits.

Q 13. How do you utilize control charts to monitor tooling performance?

Control charts are fundamental in monitoring tooling performance, helping to identify trends, shifts in the process mean, or increases in variability before they lead to significant defects. I commonly use various control charts like X-bar and R charts to track the average and range of critical process parameters such as tool wear, dimensional accuracy of parts produced, or cycle time. Individuals and moving range (I-MR) charts are useful when we’re monitoring a single value per sample, such as the diameter of a hole produced by a specific tool. I also use p-charts for attribute data, monitoring the percentage of defective parts produced or the proportion of tools that fail within a given time frame. The choice of chart depends on the type of data collected. These charts provide visual cues helping us quickly detect shifts in the process and enable proactive intervention.

For example, a control chart showing an upward trend in tool wear allows us to schedule preventive maintenance before the tool fails, preventing costly downtime. Out-of-control points signal that a special cause of variation may exist and should trigger investigation to correct the root cause and maintain consistent performance.

Q 14. Describe a time you improved a tooling process using Six Sigma methodologies. What was the result?

In a recent project involving a plastic injection molding process, we were experiencing a high rate of rejects due to inconsistent part dimensions. The initial defect rate was around 15%. After implementing DMAIC (Define, Measure, Analyze, Improve, Control) methodology, we first defined the problem – excessive dimensional variation in molded parts. We measured the process capability, identifying the key variables such as injection pressure, mold temperature, and cooling time. Analysis involved using DOE to determine the significant effects of each variable. We discovered that fluctuations in mold temperature were the primary driver of dimensional variation.

In the improvement phase, we implemented a closed-loop temperature control system, along with better operator training for monitoring and adjustment. After these improvements, we measured the defect rate again, finding that it had dropped to less than 2%. This translated to significant cost savings due to reduced scrap and rework and improved customer satisfaction. The project culminated in the control phase where we set up control charts to continuously monitor mold temperature and other key process variables, ensuring the process remains stable and within specified limits.

Q 15. What are the key characteristics of a well-designed tooling process?

A well-designed tooling process is characterized by its efficiency, repeatability, and robustness. It minimizes waste, maximizes output, and consistently produces parts that meet specifications. Key characteristics include:

- Robust Design: The tooling is designed to withstand the rigors of production, minimizing wear and tear and ensuring consistent performance over time. This involves careful consideration of material selection, geometry, and tolerances.

- Process Capability: The process is capable of consistently producing parts within specified tolerances. This is assessed through process capability studies (Cp, Cpk).

- Ease of Use and Maintenance: The tooling is designed for easy setup, operation, and maintenance, minimizing downtime and operator errors. This might involve modular design or quick-change features.

- Error-Proofing: Measures are in place to prevent common errors, such as misalignment or incorrect part placement. This often involves poka-yoke (mistake-proofing) techniques.

- Traceability and Documentation: Detailed documentation is maintained, including design specifications, manufacturing records, and maintenance logs, ensuring traceability throughout the tooling lifecycle.

For example, a well-designed injection mold will have precise cavity dimensions, robust ejection mechanisms, and cooling channels optimized for efficient part production and minimal deformation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy and precision of tooling?

Ensuring accuracy and precision in tooling involves a multi-faceted approach that begins even before manufacturing. It hinges on meticulous design, rigorous manufacturing processes, and thorough inspection and verification. Key steps include:

- Precise Design and CAD/CAM: Using advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to create precise 3D models and generate CNC programs for tool manufacture.

- High-Precision Manufacturing: Employing state-of-the-art manufacturing techniques like CNC machining, EDM (Electrical Discharge Machining), or laser cutting with precise tooling and well-maintained equipment.

- Regular Calibration and Verification: Regular calibration of measuring instruments (e.g., CMM – Coordinate Measuring Machine) and periodic verification of the tooling against design specifications using statistical process control (SPC) charts.

- Material Selection: Choosing materials with appropriate strength, hardness, wear resistance, and thermal properties to withstand the process demands.

- Proper Handling and Storage: Protecting tooling from damage during handling, transportation, and storage through appropriate packaging and storage facilities.

Imagine making a precise gear. Using a poorly calibrated CMM to inspect the final product would propagate the error throughout the process. Instead, we verify the CMM regularly and ensure the manufacturing process itself is accurate and controlled.

Q 17. What are the common sources of variation in tooling processes?

Variations in tooling processes stem from numerous sources, broadly categorized as:

- Material Variation: Differences in the raw materials used for tooling manufacturing (e.g., inconsistencies in hardness or composition of steel). This can impact the tool’s lifespan and accuracy.

- Machine Variation: Variations in machine performance due to wear, tear, or improper maintenance (e.g., inconsistencies in CNC machine feed rates or temperatures). This translates into inconsistencies in the final tool’s dimensions.

- Environmental Variation: Fluctuations in temperature, humidity, or other environmental factors can affect the tooling’s performance and dimensional stability.

- Operator Variation: Differences in operator skill, experience, or adherence to procedures. Incorrect setup or operation can lead to significant variations in the output.

- Tool Wear: Progressive wear and tear of the tooling over time, resulting in gradual changes in dimensions or performance.

- Process Parameter Variation: Inconsistencies in process parameters like pressure, temperature, or speed in processes like injection molding or stamping.

For instance, inconsistent cooling in an injection mold can lead to variations in part shrinkage and dimensional accuracy.

Q 18. How do you validate a new tooling process?

Validating a new tooling process is crucial to ensure it meets all requirements before full-scale production. This involves a phased approach, typically including:

- Design Verification: Thorough review of the tooling design to ensure it meets all specifications and requirements.

- Trial Runs and Testing: Conducting trial runs using representative materials and process parameters to assess the process’s capability and identify potential issues.

- Process Capability Analysis: Performing a process capability study (Cp, Cpk) to determine if the process is capable of consistently producing parts within specified tolerances. A Cp/Cpk of 1.33 or higher is generally considered acceptable, but this depends on the application.

- Dimensional Inspection: Precise measurement of manufactured parts using instruments like CMMs to verify that dimensions conform to specifications. This typically employs statistical methods.

- Functional Testing: Testing the functionality of the tooling and manufactured parts to ensure they perform as intended. This might involve strength testing, fatigue testing, or other relevant tests.

- Failure Mode and Effects Analysis (FMEA): Identifying potential failure modes and their effects, and implementing mitigation strategies to prevent issues.

A successful validation ensures consistent production of high-quality parts, minimizing scrap and rework.

Q 19. How do you manage tooling change control?

Tooling change control is essential for maintaining consistency and traceability throughout the tooling lifecycle. A robust system ensures that any changes to the tooling are documented, approved, and implemented in a controlled manner. This typically involves:

- Change Request System: A formal system for proposing, reviewing, and approving changes to the tooling.

- Change Impact Assessment: Evaluating the potential impact of any proposed changes on the manufacturing process and product quality.

- Documentation and Approval: Maintaining detailed records of all changes, including the rationale, approval process, and implementation details.

- Version Control: Tracking different versions of the tooling and associated documentation.

- Verification and Validation: Verifying that the implemented changes meet requirements and validating the impact on the process capability.

Consider a scenario where a small change in the tooling geometry is made without proper documentation. If problems arise, tracing the cause becomes difficult, leading to lost time and potential quality issues. A proper change control system prevents such scenarios.

Q 20. What is your experience with different types of tooling (e.g., stamping, injection molding)?

I have extensive experience with various tooling types, including stamping and injection molding, as well as experience with other processes like die casting and extrusion tooling.

Stamping Tooling: I’m familiar with progressive dies, blanking dies, and forming dies, understanding the intricacies of die design, material selection (considering wear resistance and springback), and precise tolerance control crucial for high-volume production. I’ve worked on projects involving optimizing die life through material selection and process optimization, reducing downtime and scrap rates.

Injection Molding Tooling: My expertise includes designing and managing the production of molds for various thermoplastics. I’m adept at optimizing gate locations, runner systems, cooling channels, and ejection mechanisms to achieve optimal part quality and cycle times. This includes selecting appropriate steel grades for mold components and anticipating potential issues like sink marks or weld lines.

In both domains, I have a thorough understanding of tool design principles, manufacturing processes, and quality control measures, leveraging my expertise in Six Sigma methodologies to minimize variation and maximize process capability.

Q 21. Explain your understanding of process capability analysis.

Process capability analysis is a statistical method used to assess whether a process is capable of consistently producing output that meets predefined specifications. It helps determine if the natural variation inherent in the process is within acceptable limits. Key aspects include:

- Cp and Cpk Indices: Cp (Process Capability Index) measures the potential capability of a process, while Cpk (Process Capability Index) considers both the potential capability and the process centering relative to the specification limits. A higher Cp/Cpk value indicates better process capability.

- Control Charts: Used to monitor the process performance over time and identify any shifts or trends that might indicate process instability. Common control charts include X-bar and R charts.

- Histogram and Data Analysis: Visual representation of the process output distribution to assess its normality and identify potential outliers or unusual patterns.

- Specification Limits: The upper and lower limits of acceptable variation defined by the product design or customer requirements.

For example, if a process produces parts with a target dimension of 10mm and a tolerance of ±0.1mm, a process capability study would determine if the process variation is within this tolerance range consistently. A low Cp/Cpk value would suggest that process improvements are necessary. This could involve adjustments to machine parameters, operator training, or even tooling improvements.

Q 22. How do you use data to drive decision-making in tooling projects?

Data is the lifeblood of effective tooling Six Sigma projects. We leverage data to identify areas for improvement, validate solutions, and track progress. This isn’t just about collecting numbers; it’s about understanding what those numbers *mean*. For example, in a die-casting project, we might collect data on cycle time, scrap rate, and tool wear. Instead of simply observing high scrap rates, we’d analyze the data to pinpoint the root cause—is it due to material inconsistencies, machine vibration, or operator error? We then use statistical tools like control charts (e.g., X-bar and R charts) to monitor process stability and identify shifts that signal potential problems. This data-driven approach allows us to make informed decisions, prioritize efforts, and ultimately improve process efficiency and product quality.

Imagine a situation where we’re experiencing high rejection rates in a stamping process. Instead of reacting with gut feelings, we’d meticulously collect data on factors such as material thickness variations, die wear, press tonnage, and operator technique. By using statistical software like Minitab, we can analyze the correlations between these variables and the rejection rate. This analysis might reveal that variations in material thickness are the primary driver of defects, leading us to focus improvements on material sourcing or pre-processing. Without data-driven decision-making, we might waste resources chasing less significant factors.

Q 23. Describe your experience with different types of sampling methods.

Sampling is crucial for efficient data collection in tooling projects, as it’s often impractical to inspect every single part or process cycle. My experience encompasses various methods, each with its strengths and weaknesses. I’ve utilized:

- Simple Random Sampling: Every part has an equal chance of being selected, providing unbiased estimates. This is useful for initial assessments of process capability but can be less efficient if the process is highly variable.

- Stratified Random Sampling: The population is divided into strata (e.g., different shifts, machines) and then random samples are taken from each stratum. This ensures representation from all important subgroups and improves precision, especially if variability exists between strata.

- Systematic Sampling: Parts are selected at fixed intervals (e.g., every 10th part). While simple, it can be susceptible to bias if there’s a periodic pattern in the process.

- Acceptance Sampling: This focuses on determining if a batch meets a predefined quality level. We use techniques like attribute sampling (e.g., counting defects) or variables sampling (measuring a continuous quality characteristic) to make acceptance/rejection decisions.

The choice of sampling method depends heavily on the project’s specific context and objectives. In one project involving injection molding, stratified sampling helped us identify that tool wear was significantly more pronounced on one particular machine, prompting targeted maintenance efforts.

Q 24. How do you communicate complex technical information to non-technical audiences?

Communicating complex technical information to non-technical audiences requires a shift in perspective. The key is to translate technical jargon into plain language, using relatable analogies and visual aids. I avoid using acronyms or highly technical terms without explanation. I often start by outlining the problem in simple terms, emphasizing the impact on the business. Then, I use visuals like graphs, charts, and even simple drawings to illustrate key findings and proposed solutions. Storytelling is also powerful; I weave narratives around data, making the information more engaging and memorable. For instance, instead of saying ‘We observed a 20% increase in process capability index (Cpk)’, I’d say, ‘We’ve made significant improvements: the chances of producing a defective part have dropped by 20%, saving us X dollars in scrap and rework’. This approach helps ensure everyone understands the situation and the implications of the proposed actions.

Q 25. What software are you proficient in for Six Sigma and tooling analysis?

My proficiency in Six Sigma and tooling analysis software includes Minitab (for statistical analysis, design of experiments, and control charts), JMP (for advanced statistical modeling and visualization), and AutoCAD (for reviewing and understanding tooling designs). I also have experience with MS Excel for data manipulation and presentation, and specialized software like Moldflow for simulation of plastic injection molding processes.

Q 26. How do you balance cost and quality considerations in tooling decisions?

Balancing cost and quality is a continuous challenge in tooling decisions. It’s not a simple trade-off; it’s about finding the optimal balance that maximizes value. This often involves a cost-benefit analysis. We carefully consider the initial investment cost of a tool, its expected lifespan, maintenance costs, and the potential cost of defects produced if the tool isn’t of high quality. We also evaluate the potential impact of improved quality on downstream processes and customer satisfaction. For instance, using a more expensive, high-precision tool might reduce scrap rates significantly, offsetting the higher initial cost through reduced material waste and rework. This necessitates a robust understanding of the cost drivers for each element, including materials, labor, and potential downtime. Using Design of Experiments (DOE) can help optimize tool design to achieve desired quality at a minimum cost. For instance, we might experiment with different material combinations to identify the most cost-effective option that still meets the required strength and durability.

Q 27. Describe a situation where you had to troubleshoot a complex tooling problem. What was your approach?

In a previous project involving the production of precision injection molded components, we encountered a recurring problem of sink marks on the finished parts. Initial assumptions pointed towards insufficient injection pressure. My approach was systematic and followed the DMAIC (Define, Measure, Analyze, Improve, Control) methodology.

- Define: We clearly defined the problem: unacceptable sink marks affecting cosmetic appearance and potentially functionality.

- Measure: We collected data on various process parameters, including injection pressure, melt temperature, mold temperature, and cycle time, and correlated them with the occurrence of sink marks. We also measured the dimensions of the sink marks to quantify the severity.

- Analyze: Through data analysis (using Minitab), we discovered that the correlation between injection pressure and sink mark severity was not as strong as initially expected. Instead, the analysis highlighted a strong correlation between mold temperature inconsistencies and sink mark formation.

- Improve: Based on the analysis, we implemented improvements to the mold temperature control system, ensuring more consistent temperature distribution across the mold cavity. We also conducted a Design of Experiments (DOE) to fine-tune mold temperature settings for optimal results.

- Control: We implemented a robust monitoring system to track mold temperature and ensure the improvements were sustained. We created a control chart to monitor the process and detect any potential deviations from the optimized settings.

This methodical approach, driven by data and a structured problem-solving framework, successfully resolved the sink mark issue and significantly improved product quality.

Key Topics to Learn for Tooling Six Sigma Interview

- DMAIC Methodology: Understand the Define, Measure, Analyze, Improve, and Control phases and their application in tooling processes. Be prepared to discuss practical examples of how you’ve used this methodology to solve problems.

- Process Capability Analysis (Cp, Cpk): Know how to interpret Cp and Cpk indices, and explain their significance in assessing process performance and identifying areas for improvement in tooling. Be ready to discuss real-world scenarios where you used this analysis.

- Gauge R&R Studies: Understand the importance of accurate measurement systems in Six Sigma. Be familiar with different Gauge R&R techniques and their application in evaluating measurement variability in tooling processes.

- Statistical Process Control (SPC): Know how to interpret control charts (X-bar and R charts, etc.) and use them to monitor process stability and identify out-of-control situations in tooling applications. Prepare to discuss how you’ve used SPC to prevent defects.

- Failure Modes and Effects Analysis (FMEA): Be able to explain the FMEA process and how it’s used to proactively identify potential failure modes in tooling and implement preventive measures. Illustrate your understanding with examples from your experience.

- Design of Experiments (DOE): Understand the basics of DOE and its application in optimizing tooling processes. Be able to discuss different experimental designs and their uses. Highlight your ability to analyze experimental data and draw meaningful conclusions.

- Root Cause Analysis Techniques: Familiarity with various root cause analysis tools like 5 Whys, Fishbone diagrams, and Pareto charts is essential. Be prepared to discuss how you’ve used these techniques to identify and resolve problems in tooling.

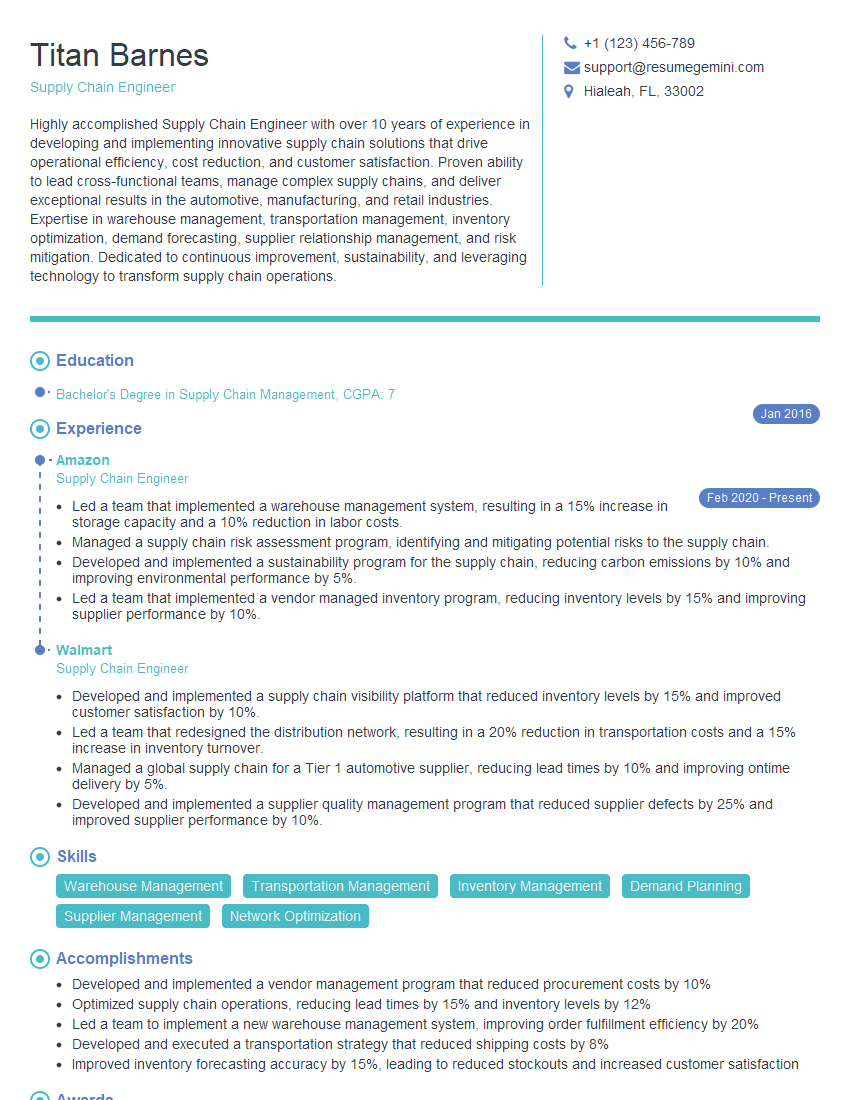

Next Steps

Mastering Tooling Six Sigma principles significantly enhances your problem-solving skills and demonstrates your commitment to process improvement – highly valued attributes in many manufacturing and engineering roles. This expertise opens doors to advanced positions and higher earning potential. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a compelling resume that showcases your skills effectively. We provide examples of resumes tailored to Tooling Six Sigma to give you a head start. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO