Preparation is the key to success in any interview. In this post, we’ll explore crucial Towing and Pushing Operations interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Towing and Pushing Operations Interview

Q 1. Describe your experience operating different types of tow trucks.

Throughout my career, I’ve operated a wide range of tow trucks, each suited for different vehicle types and situations. This includes wheel-lift tow trucks, ideal for smaller cars and quick tows; flatbed tow trucks, offering safer transport for damaged or low-riding vehicles; and integrated tow trucks, combining wheel-lift and flatbed capabilities for versatility. I’m also experienced with heavy-duty wreckers capable of handling large vehicles and accident recovery. For instance, I’ve used a wheel-lift to quickly remove a minorly damaged sedan from a busy intersection, and a flatbed to carefully transport a classic car with a damaged undercarriage to a restoration shop. My experience encompasses a broad spectrum of equipment, ensuring I can adapt to any towing challenge.

Q 2. Explain the proper procedure for securing a vehicle to a tow truck.

Securing a vehicle properly is paramount for safety. The process begins with a thorough assessment of the vehicle’s condition – noting any damage or pre-existing issues. Next, I choose the appropriate towing method and equipment. For a wheel-lift, I ensure the lift arms are properly positioned under the vehicle’s frame, avoiding sensitive areas like bumpers or suspension components. For a flatbed, I use wheel nets or straps to securely fasten the vehicle, distributing weight evenly. For every tow, I always use at least two securement points, and often more depending on the vehicle size and weight. Finally, I perform a thorough check before moving, confirming that the vehicle is stable and secure. Think of it like packing a suitcase – you want everything snug and in place to prevent shifting during the journey.

Q 3. How do you assess the damage to a vehicle before towing?

Before towing, I conduct a comprehensive damage assessment, documenting everything with photos and a written report. This includes checking for tire damage, body damage (dents, scratches, broken lights), undercarriage damage, and fluid leaks. I pay close attention to any pre-existing damage, documenting it clearly to avoid disputes. I also note the vehicle’s overall condition, its operability (can it be started and shifted into neutral?), and whether it needs special handling due to a mechanical fault or previous damage. This careful inspection is crucial for insurance purposes and to ensure the vehicle’s safe transport. It’s like a pre-flight checklist for an airplane, except with a car.

Q 4. What safety precautions do you take when operating a tow truck in various conditions (e.g., rain, snow, traffic)?

Safety is my top priority. In adverse weather like rain or snow, I reduce speed significantly, increase following distance, and use caution on slick surfaces. I ensure all lights are functioning correctly, and I may use additional safety lights to enhance visibility. In heavy traffic, I proceed slowly and carefully, constantly checking my mirrors and surroundings. I prioritize the safety of both myself and other drivers. I always communicate with dispatch about my location and any challenges encountered. It’s like driving defensively – anticipating potential problems and reacting appropriately.

Q 5. Describe your experience with different towing methods (e.g., wheel-lift, flatbed, integrated).

My experience spans all major towing methods. Wheel-lift towing is fast and efficient for undamaged vehicles, but not ideal for those with undercarriage damage. Flatbed towing provides the safest option for damaged vehicles, allowing for secure and level transportation. Integrated tow trucks offer flexibility, combining the speed of a wheel-lift with the security of a flatbed. The choice of method depends entirely on the vehicle’s condition and the specific circumstances. For instance, a high-end sports car might require flatbed transport due to its low profile, whereas a standard sedan can often be safely towed with a wheel-lift. The appropriate method protects both the vehicle and the operator.

Q 6. How do you handle difficult or unusual towing situations (e.g., stuck vehicles, accidents)?

Handling challenging situations requires experience, problem-solving skills, and the right equipment. For stuck vehicles, I might use winches, recovery straps, or even specialized equipment like a wrecker with a heavy-duty winch. In accident scenes, I prioritize safety, working closely with emergency responders. I secure the area, assess the vehicles involved, and choose the safest towing method, often involving specialized equipment to stabilize or lift damaged vehicles. Each situation is unique and demands a customized approach, a combination of technical skill and calm judgement.

Q 7. Explain your understanding of load distribution and weight limits during towing.

Understanding load distribution and weight limits is crucial to prevent accidents and damage. I carefully assess the weight of the vehicle being towed and ensure it’s within the tow truck’s capacity. I distribute the weight evenly on the tow truck, avoiding overloading any single point. The tow truck’s weight capacity is clearly stated, and I never exceed it. Improper weight distribution can lead to accidents, damage to the tow truck, and damage to the vehicle being towed. It’s similar to weight limits in an elevator – exceeding the limit can have serious consequences.

Q 8. What are your procedures for dealing with vehicle recovery in challenging terrains?

Recovering vehicles from challenging terrains requires a multifaceted approach prioritizing safety and efficiency. It starts with a thorough assessment of the situation: the vehicle’s condition, the terrain’s obstacles (mud, snow, steep inclines, etc.), and available recovery equipment.

My procedures involve:

- Pre-Recovery Assessment: I carefully inspect the scene, identifying potential hazards and planning the safest recovery path. This includes considering the vehicle’s weight, center of gravity, and any potential damage.

- Equipment Selection: The choice of equipment is crucial. For muddy terrain, I might opt for a winch with a high-traction rope or chains, and possibly use recovery boards to distribute the weight. On steep inclines, a snatch block and additional recovery points are often needed to improve leverage. In snowy conditions, I may need snow chains or tracks on the tow truck itself.

- Secure Attachment: Properly securing the vehicle is paramount. I use appropriate straps, chains, or shackles, ensuring they are correctly rated for the vehicle’s weight and properly attached to secure recovery points on both the vehicle and the tow truck.

- Controlled Recovery: The recovery process itself needs to be slow and deliberate. Winches should be used gradually, avoiding sudden jerks or strain. Spotters are employed whenever possible to guide the operation and identify potential issues.

- Post-Recovery Inspection: Once the vehicle is safely secured and towed, I conduct a final check of both the vehicle and the equipment, ensuring no damage has occurred during the recovery.

For instance, I once had to recover an SUV stuck deep in a muddy ditch. After assessing the situation, I used a combination of a winch, recovery boards, and a snatch block to successfully extract it without causing any further damage.

Q 9. How do you communicate with clients during the towing process?

Client communication is key to a smooth towing experience. I maintain open and consistent communication throughout the process. This usually involves:

- Initial Contact: Providing an estimated arrival time and a clear explanation of the towing process.

- Updates During Towing: Keeping the client informed about any delays or unexpected issues that may arise. I use phone calls or text messages depending on the client’s preference.

- Arrival at Destination: Confirming arrival at the destination and ensuring the client is satisfied with the service. I might take photos of the vehicle being delivered at its destination for added transparency.

- Professionalism: Maintaining a polite and respectful demeanor throughout the interaction, addressing any concerns or questions promptly and professionally.

I always strive to exceed client expectations, making the potentially stressful situation as easy as possible for them. For example, I once had a client whose car broke down late at night; I ensured they were kept updated every step of the way, even providing them with the location of the closest coffee shop while they waited for their vehicle’s arrival at the repair shop.

Q 10. How familiar are you with DOT regulations regarding towing and vehicle transport?

I am very familiar with DOT (Department of Transportation) regulations concerning towing and vehicle transport. My knowledge encompasses regulations related to:

- Vehicle Weight and Dimensions: Understanding the limitations on weight and dimensions for various classes of vehicles and ensuring compliance with permit requirements for oversized or overweight loads.

- Equipment Maintenance and Safety: Regular inspections of towing equipment to ensure it is in good working order and meets all safety standards, such as proper lighting, brakes, and signaling devices.

- Driver Qualifications: Possessing the necessary licenses and certifications required to operate towing vehicles in compliance with DOT regulations.

- Documentation and Record Keeping: Maintaining proper documentation of all towing operations, including manifests, bills of lading, and hours of service logs.

- Hazardous Materials: Proper procedures for handling hazardous materials and compliance with relevant regulations when transporting vehicles carrying such materials.

Regular updates on these regulations are vital, and I actively participate in professional development to stay current on any changes.

Q 11. Describe your experience with winches, straps, chains, and other recovery equipment.

My experience with winches, straps, chains, and other recovery equipment is extensive. I’m proficient in using different types of winches (electric, hydraulic, manual), understanding their capabilities and limitations. I am trained on safe operating procedures for each, including proper rigging techniques to minimize risk of damage or injury.

Regarding straps and chains, I know the importance of selecting the correct type and size based on the vehicle’s weight and the recovery task. This includes understanding the difference between soft shackles, which offer flexibility and reduced risk of damage, and traditional steel chains or hooks, which offer higher strength but require more care in handling. I also understand the importance of regular inspections to check for wear, tear, or damage.

Furthermore, I’m knowledgeable about the various components used in vehicle recovery, such as snatch blocks, which improve mechanical advantage, and recovery tracks, which increase traction in difficult terrain.

I always prioritize safety and employ best practices to minimize the risk of accidents during recovery operations. My experience includes numerous successful recoveries using various combinations of equipment, ranging from simple roadside assists to complex extractions.

Q 12. What is your experience with specialized towing equipment for heavy machinery or oversized loads?

I have significant experience with specialized towing equipment for heavy machinery and oversized loads. This involves working with:

- Heavy-duty tow trucks: These trucks possess higher towing capacities, specialized underlifts, and other features required for handling heavy equipment such as construction machinery or large industrial vehicles.

- Modular trailers and specialized dollies: I’m familiar with various types of trailers and dollies designed to accommodate oversized or uniquely shaped loads, ensuring secure transport without causing damage.

- Specialized rigging techniques: This includes the use of heavy-duty chains, straps, and specialized lifting equipment such as cranes or forklifts to safely secure and move heavy machinery.

- Route planning and permitting: I know the importance of planning the transportation route carefully, taking into consideration the load’s dimensions and weight, and obtaining necessary permits and escorts for safe and legal transportation.

A recent example involved towing a large industrial generator. This required a specific type of lowboy trailer, careful planning of the route to avoid low bridges, and obtaining the necessary permits. The operation was completed safely and efficiently due to my familiarity with the specialized equipment and procedures.

Q 13. Describe your knowledge of different types of pushing operations equipment.

Pushing operations equipment varies greatly depending on the task and the type of load being moved. Common types of equipment include:

- Push trucks: These are heavy-duty trucks specifically designed for pushing operations, often featuring reinforced bumpers and specialized attachments for improved pushing power and safety.

- Bulldozers: These are powerful earthmoving machines frequently employed for pushing large volumes of earth, debris, or heavy materials.

- Front-end loaders: These machines are used for pushing and loading materials, often in conjunction with other equipment like dump trucks or trailers.

- Specialized pushing beams or attachments: Various attachments can be added to trucks or other machinery to enhance their pushing capabilities in specialized applications.

Understanding the capabilities and limitations of each type of equipment is critical for safe and efficient operations. The choice of equipment is guided by factors like the weight and size of the material being pushed, the terrain, and any potential hazards present at the worksite.

Q 14. How do you ensure the safety of yourself and others during pushing operations?

Safety is paramount during pushing operations. My procedures emphasize preventative measures and risk mitigation. Key aspects include:

- Pre-operation inspection: Thoroughly checking all equipment for mechanical faults, proper functionality of lights and signals, and ensuring all safety systems are functioning correctly.

- Site assessment: Identifying and addressing potential hazards at the worksite, including uneven terrain, obstacles, and the presence of personnel or other equipment. Establishing clear communication channels and designating specific roles and responsibilities.

- Communication and signaling: Implementing clear communication protocols between the operator, spotters, and other personnel on site. Using hand signals, two-way radios, or other signaling devices to coordinate movements and ensure everyone is aware of the operation.

- Controlled maneuvers: Performing pushing operations slowly and cautiously, avoiding sudden movements or jerky actions that could lead to accidents.

- Personal protective equipment (PPE): Ensuring all personnel involved in the operation wear appropriate PPE, such as safety helmets, high-visibility clothing, and safety boots.

For instance, in a recent operation involving pushing large containers, we established a designated safety zone around the work area, used hand signals for communication, and ensured all personnel wore appropriate safety gear. By adhering to rigorous safety procedures, we successfully completed the operation without any incidents.

Q 15. What safety protocols do you follow when pushing vehicles or heavy machinery?

Safety is paramount in pushing operations. Before any push begins, a comprehensive risk assessment is conducted. This includes identifying potential hazards like obstacles, uneven terrain, and the structural integrity of the vehicle being pushed. We always ensure a clear communication plan is in place, specifying roles, hand signals, and emergency procedures.

- Pre-push Inspection: A thorough visual inspection of the vehicle and surrounding area is mandatory. This includes checking for loose parts, potential hazards and ensuring sufficient space for maneuverability.

- Spotters: At least one spotter is deployed, maintaining visual contact with the operator and the vehicle being pushed, guiding the operator and communicating any potential issues.

- Emergency Shutdown Plan: A clear emergency shutdown procedure is established, outlining how to quickly halt the operation in case of unexpected events. This includes understanding the controls of the pushing equipment and having a designated emergency shut-off switch readily accessible.

- Personal Protective Equipment (PPE): All personnel involved wear appropriate PPE including high-visibility clothing, safety glasses, and steel-toed boots. Hearing protection is used if noise levels are excessive.

- Environmental Considerations: The environment is assessed for any risks posed by pushing, such as potential damage to surrounding structures or environmental hazards.

For example, during a site-clearing operation, I always establish a safety zone around the pushing activity to protect bystanders and ensure there is a safe escape route for everyone involved.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you assess the structural integrity of a vehicle before pushing?

Assessing a vehicle’s structural integrity before pushing is crucial to prevent accidents and damage. This involves a visual inspection looking for obvious signs of damage such as cracks, bends, or missing parts, especially around critical structural areas like the frame and axles.

- Visual Inspection: Checking for rust, significant damage to the body or undercarriage. This includes evaluating the condition of the wheels, tires and suspension.

- Weight Estimation: If the weight of the vehicle is uncertain, we may need to take additional measurements or utilize specialized equipment to estimate the weight and determine whether it is within the safe pushing capacity of the equipment.

- Stability Assessment: We evaluate whether the vehicle is stable enough to be pushed without the risk of toppling over. Factors such as the vehicle’s center of gravity and the condition of the wheels are considered.

- Documentation: It’s always a good practice to document the assessment and any visible defects, taking photos if possible, for insurance or liability purposes.

For instance, if a vehicle has sustained substantial rear-end damage, I’d exercise extra caution, potentially using alternative methods such as towing instead of pushing, to avoid further damage or causing the vehicle to become unstable during the push operation.

Q 17. Explain your experience with different types of pushing operations (e.g., site clearing, demolition)?

My experience spans various pushing operations. I’ve been involved in site clearing for construction projects, where pushing is used to move debris, earth, or unwanted structures. In demolition work, controlled pushing is used to dismantle structures. Other scenarios include moving heavy machinery within industrial sites or pushing disabled vehicles to a safe location.

- Site Clearing: Requires careful planning and coordination to ensure safe and efficient movement of debris, while avoiding damage to the environment or adjacent structures.

- Demolition: This often necessitates specialized equipment and a high degree of precision to ensure the controlled collapse of structures. Safety planning is intensified here.

- Industrial Site Operations: Moving heavy machinery within a plant or factory necessitates an intimate understanding of the site layout, the weight of the machinery being moved, and the structural integrity of surrounding structures.

For example, in a recent demolition project, we used a bulldozer to push sections of a building after careful assessment of the structure’s weakened state to ensure a controlled collapse. Detailed planning, including the designated demolition pathway, debris control, and safety zones, was crucial for success.

Q 18. How do you handle unexpected situations during pushing operations?

Unexpected situations can arise during pushing operations. My approach involves maintaining constant situational awareness, immediate response, and prioritizing safety above all else.

- Equipment Malfunction: If equipment malfunctions, the immediate response is to engage the emergency stop mechanism. A thorough assessment of the malfunction is then undertaken to determine the cause and whether repairs can be conducted on-site or if external assistance is required.

- Obstacle Encountered: If an unexpected obstacle is encountered, the operation is immediately stopped. The obstacle is assessed, a safe solution is determined (e.g., removing the obstacle, rerouting, or employing different equipment), and then the operation resumes following the revised safety plan.

- Vehicle Instability: If the vehicle being pushed shows signs of instability, the pushing operation is immediately stopped, and alternative methods (e.g., towing) are considered to secure the vehicle safely.

- Weather Changes: Significant changes in weather conditions (e.g., heavy rain, strong winds) necessitate an immediate reassessment of the risks and potential need to postpone the operation.

For instance, I once encountered an underground utility line during a site-clearing operation. The operation was immediately stopped, and utility companies were contacted to ensure the line’s integrity before continuing. Safety always overrides scheduling.

Q 19. What are your communication protocols during pushing operations?

Clear and consistent communication is vital during pushing operations. We employ a combination of visual signals, radio communication, and pre-agreed hand signals.

- Pre-Operation Briefing: Before starting, all personnel receive a briefing that covers the plan, potential hazards, designated roles, communication protocols, and emergency procedures.

- Visual Signals: Spotters use clear visual signals such as hand signals or lights to guide the operator, ensuring the operation remains within the planned boundaries and avoids hazards.

- Radio Communication: Two-way radios are used for continuous communication between the operator, spotters, and any other relevant personnel. This ensures immediate updates and coordinated responses to unforeseen situations.

- Post-Operation Debrief: After the operation, a debrief is conducted to discuss any issues encountered, lessons learned, and any areas for improvement.

For example, a standardized set of hand signals is used for indicating direction, speed, and stoppage, with any deviations or ambiguities clarified during the pre-operation briefing. This reduces misunderstandings and ensures a coordinated and safe operation.

Q 20. How familiar are you with the different types of hydraulic systems used in heavy equipment?

I’m highly familiar with various hydraulic systems used in heavy equipment. Understanding hydraulic systems is crucial for safe and efficient operation. This includes knowledge of various components such as pumps, valves, cylinders, and associated safety mechanisms.

- Hydraulic Pumps: I understand the different types of hydraulic pumps (e.g., gear pumps, vane pumps, piston pumps) and their operating principles. This includes knowledge of their flow rates and pressure capabilities.

- Hydraulic Valves: I’m proficient in understanding the functions of various hydraulic valves (e.g., directional control valves, pressure control valves, flow control valves) and their roles in controlling the hydraulic fluid flow and pressure.

- Hydraulic Cylinders: I understand the construction and operation of hydraulic cylinders, their force and speed capabilities, and the safety precautions needed when working with them.

- Hydraulic System Diagnostics: I can identify and troubleshoot problems within hydraulic systems, such as leaks, blockages, and component failures.

For example, I can diagnose a hydraulic leak by identifying the source of the leak (e.g., a damaged hose, a faulty seal), determine the severity of the leak, and implement appropriate repair procedures or call for professional assistance if necessary.

Q 21. Describe your troubleshooting skills related to tow truck or pushing equipment malfunctions.

Troubleshooting tow truck or pushing equipment malfunctions requires a systematic approach, combining practical knowledge, diagnostic skills, and the ability to think critically under pressure.

- Safety First: The first step is always to ensure the safety of myself and others by deactivating the equipment and securing the area.

- Visual Inspection: I begin with a visual inspection, checking for obvious signs of damage, leaks, or loose connections.

- Systematic Check: I follow a systematic procedure, checking electrical systems, hydraulic systems, and mechanical components. This might involve checking fluid levels, inspecting belts and hoses, and testing electrical circuits.

- Diagnostic Tools: Depending on the complexity of the problem, I might utilize diagnostic tools, such as pressure gauges, multimeters, or specialized diagnostic equipment.

- Documentation: All findings and actions are documented, including the problem, diagnosis, and repair steps taken.

For example, if a tow truck’s winch isn’t functioning, I’d first check the power supply, then inspect the winch cable for damage, and then examine the hydraulic system for leaks or low fluid level. If I find a low fluid level, I would check the hydraulic reservoir and add the required hydraulic fluid. If the problem persists, further investigation is needed. I always document my findings and actions thoroughly.

Q 22. How do you perform pre-trip inspections of towing and pushing equipment?

Pre-trip inspections are crucial for safety and prevent breakdowns. Think of it like a pilot performing a pre-flight check – you wouldn’t want to take off without one! My pre-trip inspection routine is thorough and covers several key areas.

- Visual Inspection: I check for any visible damage to the truck, lights, tires, and the towing or pushing equipment itself. This includes checking for leaks, loose bolts, and worn-out parts. For example, I’d carefully examine the winch cable for any fraying or damage, as a broken cable could be catastrophic.

- Fluid Levels: Checking engine oil, coolant, transmission fluid, power steering fluid, and brake fluid is essential. Low fluid levels can lead to overheating or malfunctions. I meticulously check and top up as needed, recording the levels in my logbook.

- Lights and Signals: I test all lights – headlights, brake lights, turn signals, hazard lights – to ensure they’re functioning correctly. Clear signaling is vital for road safety, especially during night operations or in heavy traffic.

- Brakes: I thoroughly test the service and emergency brakes, confirming they are responsive and effective. This also includes examining the brake pads and lines for any wear and tear.

- Steering and Suspension: I check for any play in the steering wheel and examine the suspension for any damage or leaks. Proper steering and suspension are vital for safe and controlled operation.

- Towing/Pushing Equipment Check: This step is critical and varies depending on the equipment. For a tow truck, this includes checking the tow bar, wheel lift, and straps for damage or wear. For pushing equipment, this could involve checking the hydraulics, the pushing beam, and safety mechanisms.

I meticulously document each step of the inspection in a standardized checklist, ensuring I don’t miss any critical component. This detailed record is essential for maintenance scheduling and accident investigation if needed.

Q 23. Describe your experience maintaining and repairing tow truck or pushing equipment.

Maintaining and repairing towing and pushing equipment is a significant part of my job. I’m proficient in both preventative maintenance and handling repairs. I’ve worked on a range of equipment, from light-duty tow trucks to heavy-duty wreckers and specialized pushing vehicles.

Preventative maintenance is key. I regularly perform tasks like oil changes, lubrication, and inspections based on manufacturer recommendations. Ignoring preventative maintenance can lead to costly repairs and downtime. For example, regularly greasing the winch mechanism prevents premature wear and potential failures.

When repairs are needed, I assess the problem, identifying the faulty components. I’m comfortable working on various systems: hydraulics, electrical systems, engines, transmissions, and braking systems. I have experience replacing parts, diagnosing electrical issues using diagnostic tools, and performing welding and fabrication repairs when necessary. On several occasions, I’ve successfully repaired a malfunctioning hydraulic system, avoiding costly external repairs by tackling the issue myself. I also have a good relationship with trusted mechanics who can assist with more specialized repairs if needed.

Proper record-keeping is essential; I document all maintenance and repair activities, including parts used, labor hours, and costs, to ensure efficient tracking of equipment upkeep and budget management.

Q 24. How do you manage your time efficiently when dealing with multiple towing or pushing requests?

Managing multiple towing or pushing requests efficiently requires a structured approach. I utilize several strategies:

- Prioritization: I prioritize requests based on urgency and factors like location, vehicle type, and potential hazards. Emergencies, such as accidents involving injuries, always take precedence.

- Route Optimization: I use GPS navigation systems to optimize routes, minimizing travel time and fuel consumption. I consider traffic conditions and potential road closures when planning routes.

- Communication: Clear and prompt communication with clients and dispatch is critical. I provide estimated arrival times and keep clients updated on my progress. This transparency helps manage expectations and minimizes potential frustration.

- Time Blocking: I allocate specific time slots for different tasks. For example, I might schedule a block of time for local tows and another block for longer-distance recovery operations. This helps ensure that I am consistently on schedule and reduces the risk of conflicts.

- Delegation (if applicable): In a team setting, I effectively delegate tasks to ensure that all requests are handled efficiently. Clear communication and role assignment is crucial in these situations.

By strategically implementing these methods, I consistently manage to complete my tasks effectively and professionally even with multiple requests.

Q 25. What is your experience with GPS tracking systems for towing and pushing operations?

GPS tracking systems are indispensable in modern towing and pushing operations. They significantly improve efficiency, safety, and accountability. My experience includes working with various GPS tracking systems, both in-vehicle units and mobile apps.

Key benefits I’ve observed:

- Real-time Tracking: I can track the location of the tow truck in real-time, allowing dispatch to optimize routes and provide accurate ETAs to clients.

- Route History: The system records the route taken, providing valuable data for route optimization, fuel consumption analysis, and billing purposes.

- Improved Safety: GPS tracking enhances safety by allowing monitoring of driver behavior and providing immediate response in emergencies.

- Enhanced Communication: The GPS data can be integrated into communication systems, allowing seamless updates and coordination with clients and dispatch.

- Billing Accuracy: Accurate mileage tracking ensures precise billing based on actual distance traveled.

For example, during a recent challenging recovery operation in a remote area, the GPS tracking system proved crucial. It allowed dispatch to monitor our progress, relaying information about the terrain and alerting emergency services if needed.

Q 26. Describe a time you had to deal with a challenging towing or pushing situation.

One challenging situation involved recovering a high-value classic car involved in a minor accident on a steep, winding mountain road. The car was damaged and couldn’t be driven, and the road was narrow with limited visibility. Rain added another layer of complexity.

The challenge was maneuvering the tow truck and the damaged car safely down the mountain without causing further damage. I meticulously assessed the situation, choosing the safest route and employing specialized equipment, including additional straps and supports. I also communicated closely with dispatch to ensure emergency personnel were on standby if needed. The entire operation required a high level of skill, precision, and patience, but through careful planning and execution, we successfully recovered the vehicle without incident.

This experience reinforced the importance of thorough pre-trip inspections, route planning, and careful communication in handling complex towing situations.

Q 27. How do you maintain accurate records of towing and pushing operations?

Maintaining accurate records is crucial for compliance, billing, and operational efficiency. I employ a multifaceted approach:

- Dispatch Software: I utilize dispatch software to log all towing and pushing requests, recording details such as client information, location, vehicle type, and services rendered.

- GPS Tracking Data: Data from the GPS tracking system automatically records mileage, route, and timestamps, ensuring accurate billing and operational analysis.

- Physical Documentation: I maintain physical copies of invoices, receipts for parts, and repair orders. This creates a comprehensive audit trail.

- Digital Logbooks: I use digital logbooks to track daily activities, including vehicle inspections, maintenance performed, and details of each job completed. This provides an easily searchable record.

By using a combination of these methods, I ensure that my records are accurate, complete, and readily accessible, facilitating easy reconciliation and reporting. This is crucial for both my own performance review and for the company’s financial statements. Regular data backups are also a key part of my procedure to prevent data loss.

Q 28. Describe your experience working as part of a team in a towing or pushing operation.

Teamwork is essential in towing and pushing operations, particularly for complex or large-scale recovery jobs. I’ve worked effectively in teams of varying sizes, coordinating actions and responsibilities to achieve common goals. My experience involves collaborating with:

- Dispatch: I maintain clear communication with dispatch, providing updates, confirming arrival times, and clarifying instructions.

- Other Tow Truck Operators: In situations requiring multiple trucks, I coordinate with other operators to efficiently handle the situation, ensuring safe and effective recovery.

- Law Enforcement: I effectively collaborate with law enforcement officials at accident scenes, ensuring safety and following protocols.

- Mechanics: I work closely with mechanics, relaying information about vehicle damage and coordinating repairs.

I value open communication, mutual respect, and clear role definition when working in a team. Effective teamwork reduces the time required for jobs and ensures safety for both the team and the public. For example, during a multi-vehicle accident cleanup, a team effort using clear communication and coordinated actions allowed us to clear the scene and safely tow the vehicles within a very tight timeframe.

Key Topics to Learn for Towing and Pushing Operations Interview

- Vehicle Dynamics and Stability: Understanding how different vehicle types react to towing and pushing forces, including weight distribution, center of gravity, and potential instability factors. Practical application: Assessing risks before undertaking a tow or push operation.

- Equipment Operation and Maintenance: Safe and proficient use of towing and pushing equipment, including winches, dollies, and specialized recovery vehicles. Practical application: Performing pre-trip inspections and troubleshooting minor equipment malfunctions.

- Safety Procedures and Regulations: Adherence to all relevant safety regulations, including traffic laws, load securing techniques, and emergency response protocols. Practical application: Implementing safe towing and pushing procedures in diverse environments (e.g., highways, off-road).

- Damage Assessment and Prevention: Identifying potential damage to vehicles during towing or pushing operations and implementing preventative measures. Practical application: Using appropriate equipment and techniques to minimize risk of scratches, dents, or other damage.

- Recovery Techniques: Mastering various recovery techniques for different situations, including stuck vehicles, accidents, and challenging terrains. Practical application: Selecting the appropriate recovery method based on the specific circumstances.

- Communication and Teamwork: Effective communication with colleagues, supervisors, and clients during operations. Practical application: Coordinating with other personnel during complex recovery situations.

- Legal and Insurance Aspects: Understanding the legal and insurance implications of towing and pushing operations. Practical application: Proper documentation and reporting procedures.

Next Steps

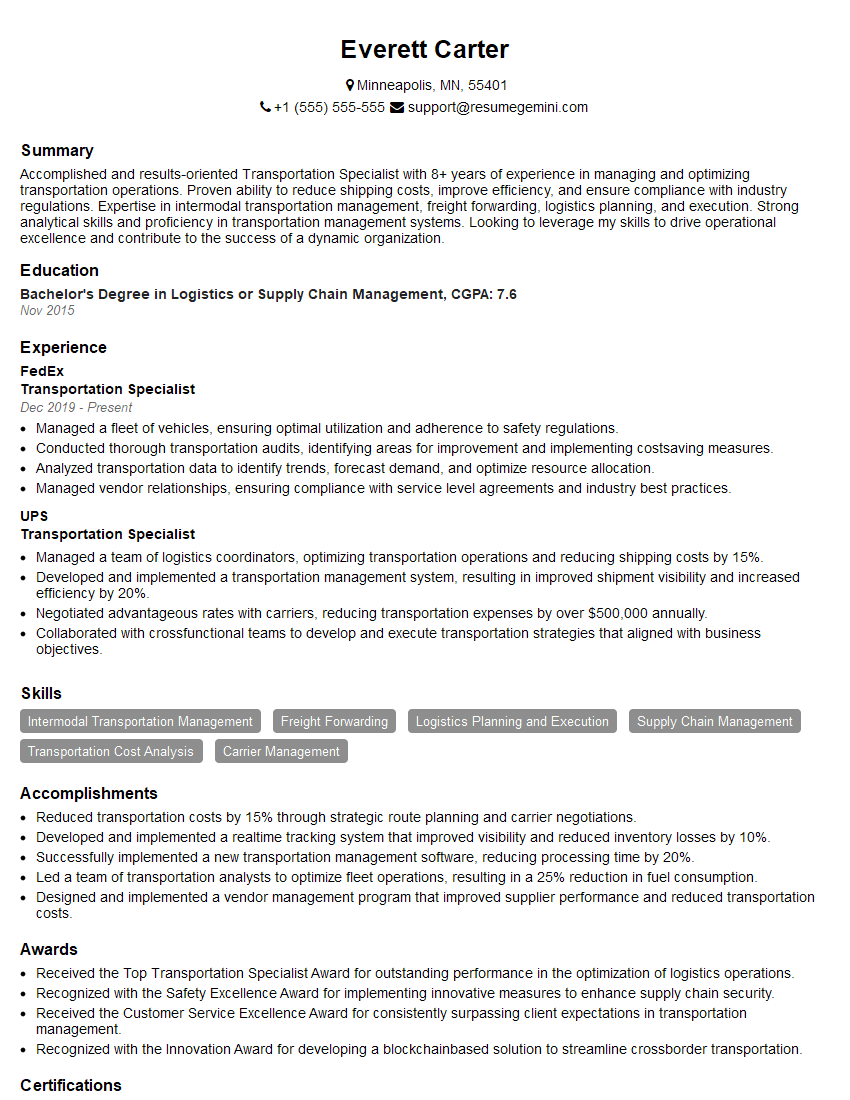

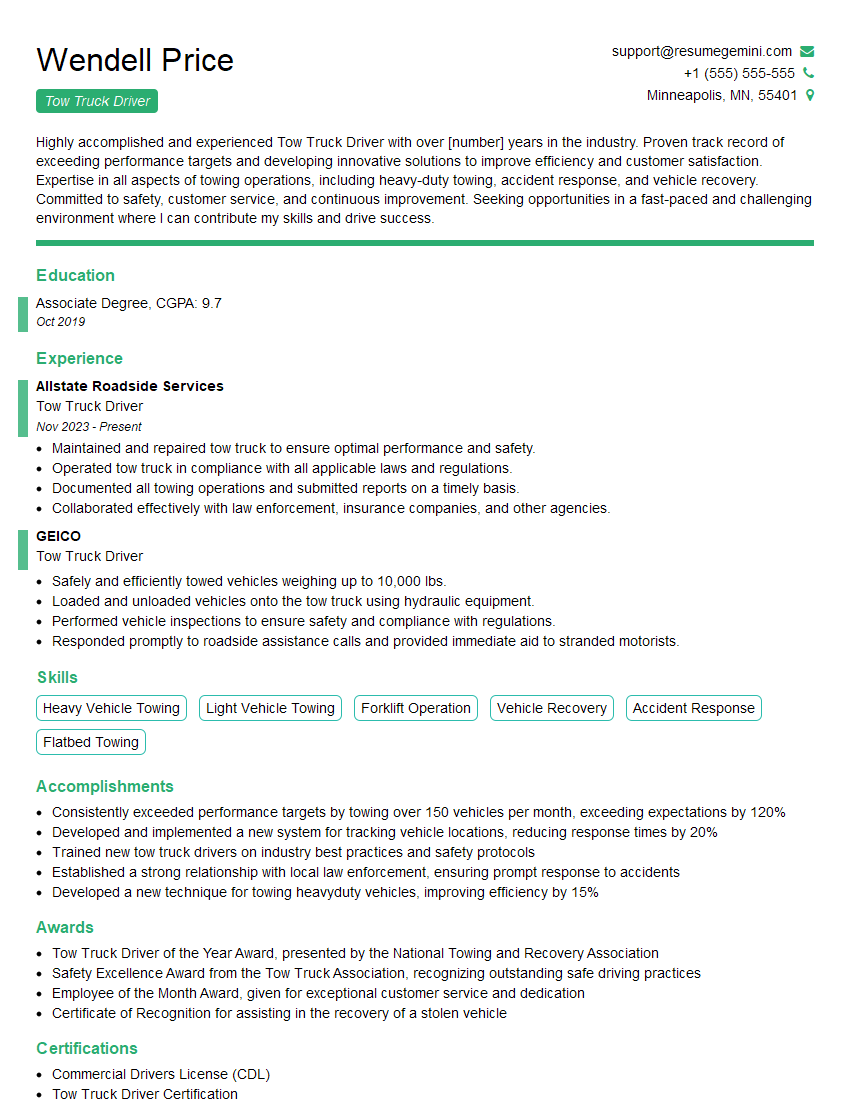

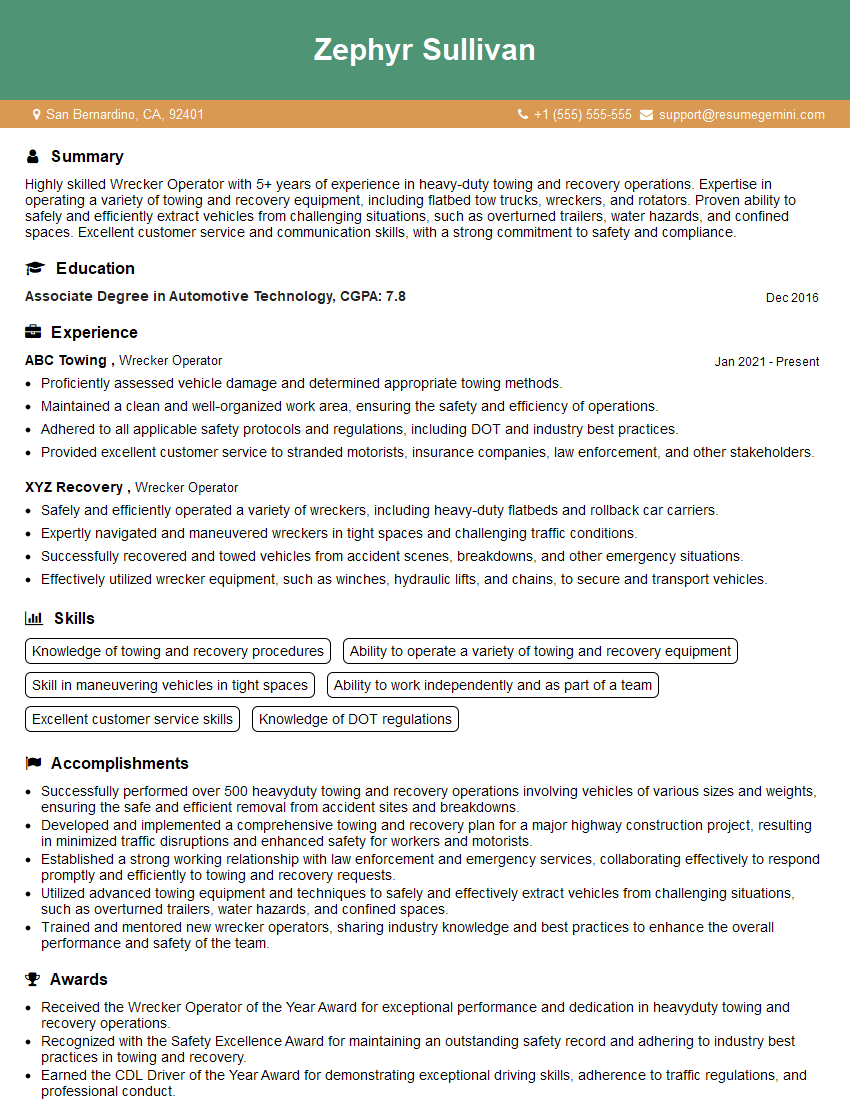

Mastering Towing and Pushing Operations opens doors to a rewarding career with excellent growth potential. From entry-level positions to specialized roles, your skills will be highly sought after in a growing industry. To maximize your job prospects, create an ATS-friendly resume that highlights your abilities and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. Take advantage of our examples of resumes tailored to Towing and Pushing Operations to craft a compelling application that showcases your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO