Preparation is the key to success in any interview. In this post, we’ll explore crucial Understanding of Refrigerant Recovery and Disposal Procedures interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Understanding of Refrigerant Recovery and Disposal Procedures Interview

Q 1. Explain the process of refrigerant recovery.

Refrigerant recovery is the process of removing refrigerant from a refrigeration system and storing it in a separate container. Think of it like carefully draining the coolant from a car’s radiator – you need to do it safely and efficiently to prevent leaks and environmental harm. The goal is to capture the refrigerant in as close to its original purity as possible, minimizing any loss to the atmosphere.

The process generally involves connecting recovery equipment to the system’s service ports. The equipment creates a vacuum, pulling the refrigerant out of the system and into the recovery tank. It’s crucial to monitor the pressure and temperature throughout the process to ensure a safe and complete recovery. After recovery, the refrigerant is then prepared for either recycling or reclamation.

For example, recovering refrigerant from an old air conditioning unit involves first isolating the system, then connecting recovery hoses, establishing a vacuum, and finally, drawing out the refrigerant into a designated cylinder. Proper procedures ensure minimal refrigerant loss and prevent environmental damage.

Q 2. What are the different types of refrigerant recovery equipment?

Refrigerant recovery equipment varies in size, capacity, and features, but generally falls into a few categories:

- Self-Contained Recovery Units: These are portable units with a built-in compressor and vacuum pump. They’re commonly used for smaller systems. Think of them as all-in-one kits for smaller jobs.

- System-Dependent Recovery Units: These units rely on the refrigeration system’s compressor to pull the refrigerant. They’re often used for larger systems and require more expertise to operate.

- Stationary Recovery Units: These are larger, more powerful units typically found in shops specializing in refrigerant handling. These are the heavy-duty recovery units you’d find in a professional HVACR shop.

All units must meet EPA standards for proper operation and leak prevention. They typically include features like pressure gauges, vacuum gauges, and safety valves to monitor the process and prevent accidents.

Q 3. Describe the safety procedures involved in refrigerant recovery.

Safety is paramount during refrigerant recovery. Improper handling can lead to serious injury or environmental damage. Here are crucial safety procedures:

- Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and appropriate respiratory protection. Some refrigerants are toxic or can cause frostbite.

- Proper Ventilation: Work in a well-ventilated area to minimize exposure to refrigerant vapors. This is especially critical when dealing with older refrigerants like R-22.

- Leak Detection: Before and after recovery, use leak detection equipment (e.g., electronic leak detectors) to check for any leaks in the system or recovery equipment. Addressing leaks is critical for safety and environmental compliance.

- Follow Manufacturer’s Instructions: Carefully read and follow the instructions for the recovery equipment and the refrigerant being handled. Each refrigerant and each piece of equipment has specific requirements.

- Emergency Preparedness: Be aware of potential hazards and have emergency procedures in place. Know where the nearest safety equipment is located.

Imagine working with refrigerant like handling a pressurized container – caution and attention to detail are key to avoid accidents.

Q 4. What are the EPA regulations regarding refrigerant handling?

The EPA (Environmental Protection Agency) regulates refrigerant handling under the Clean Air Act. Key regulations focus on preventing the release of ozone-depleting substances (ODS) and high global warming potential (GWP) refrigerants into the atmosphere. These regulations cover many aspects of refrigerant handling, including:

- Recovery and Recycling Requirements: Technicians must recover refrigerant from appliances before disposal or service. Recycling and reclamation are encouraged to reduce the need for new refrigerant production.

- Technician Certification: Many areas require technicians to obtain certification to handle refrigerants, demonstrating their knowledge and ability to handle refrigerants safely and legally.

- Leak Repair and Prevention: Regulations often mandate prompt repair of leaks and encourage the use of leak detection equipment to prevent refrigerant releases.

- Record Keeping: Accurate record-keeping of refrigerant transactions is generally required to track the movement and disposal of refrigerants.

Failure to comply with EPA regulations can lead to significant fines and penalties.

Q 5. How do you identify different refrigerants?

Refrigerants are identified by various codes and labels. The most common method is through their ARI (Air-Conditioning, Heating, and Refrigeration Institute) number. This provides a unique identifier for each refrigerant type. In addition, many refrigerants have a color code associated with their cylinder or packaging. For example, R-134a is often associated with a light blue cylinder, while R-22 may be in a different color.

Additionally, refrigerant labels must include information about the refrigerant’s composition, safety precautions, and recycling instructions. Always refer to the label for accurate identification and safe handling instructions. Never rely solely on color coding – always double check the label and ARI number.

Q 6. Explain the difference between recovery, recycling, and reclamation.

These three terms represent different levels of refrigerant processing:

- Recovery: This is the process of removing refrigerant from a system and storing it in a container, as discussed earlier. It aims to capture the refrigerant with minimal loss or contamination.

- Recycling: After recovery, recycling involves cleaning the refrigerant to meet certain purity standards. This involves removing moisture, oil, and other contaminants to restore the refrigerant to a usable condition for reuse in the same system or a similar one. It’s like cleaning a reusable container before refilling it.

- Reclamation: This is the most extensive processing method. Reclamation involves purifying the refrigerant to meet the original manufacturer’s specifications. This ensures the refrigerant is suitable for use in any system requiring that specific refrigerant type. It’s akin to restoring a vintage item to its original state.

The choice of recovery, recycling, or reclamation depends on the condition of the refrigerant and the intended use.

Q 7. What are the potential environmental impacts of improper refrigerant disposal?

Improper refrigerant disposal can have severe environmental consequences. Many refrigerants are potent greenhouse gases with high global warming potentials (GWPs), contributing to climate change. Others can damage the ozone layer. For example, R-22 (HCFC-22) was known to damage the ozone layer and has been phased out.

Releases of refrigerants into the atmosphere can lead to:

- Ozone Depletion: Some refrigerants deplete the ozone layer, increasing the harmful UV radiation reaching the Earth’s surface.

- Global Warming: Many refrigerants are potent greenhouse gases contributing to climate change and global warming.

- Air and Water Pollution: Refrigerant leaks can contaminate air and water sources, posing risks to human and ecosystem health.

Proper recovery, recycling, and reclamation are essential to mitigate these environmental impacts.

Q 8. How do you ensure the proper evacuation of a refrigeration system?

Proper evacuation of a refrigeration system is crucial before servicing or disposal to remove refrigerant and air/moisture contaminants. Think of it like emptying a container before refilling it; you wouldn’t want to mix old contents with the new ones. Improper evacuation can lead to contamination and reduced system efficiency.

The process involves using a vacuum pump to lower the system’s pressure. The goal is to achieve a deep vacuum, typically below 500 microns (0.5 Torr), for a sufficient duration (often specified in the equipment’s service manual). This ensures the removal of non-condensables, like air and moisture, which can severely damage the compressor and reduce the system’s cooling capacity. You’ll also need to ensure all valves are properly closed to prevent the loss of refrigerant during the process.

Step-by-step process:

- Isolate the system: Close the service valves to isolate the system from the rest of the equipment.

- Connect the vacuum pump: Properly connect the vacuum pump to the system’s service ports.

- Start the pump: Begin the evacuation process, monitoring the vacuum gauge.

- Monitor and hold the vacuum: Once the target vacuum pressure is reached, hold it for a specified duration to ensure complete removal of non-condensables.

- Observe for leaks: After achieving and holding a vacuum, check for any pressure increase in the system. A slow pressure increase might suggest a leak.

- Disengage the vacuum pump: Once the process is complete, disconnect the vacuum pump safely.

Q 9. What are the different methods for leak detection in refrigeration systems?

Leak detection is vital for maintaining refrigeration system efficiency and environmental responsibility. A small leak, unnoticed, can result in significant refrigerant loss over time. Several methods exist, each with its strengths and weaknesses:

- Electronic Leak Detectors: These devices use sensors to detect refrigerant escaping into the atmosphere. They are relatively quick and easy to use, particularly for HFC refrigerants. Think of them like a highly sensitive sniffer.

- Dye Tracing: This involves injecting a fluorescent dye into the refrigerant system. UV light is then used to detect leaks by identifying the dye that has escaped.

- Pressure Monitoring: Regular pressure checks can detect slow leaks. A gradual pressure drop might point to a leak, especially if it occurs consistently over time. This is a good preventive maintenance method.

- Bubble Testing: Applying soapy water to suspected leak points and observing for bubbles is a simple and effective method, particularly for larger leaks. A simple, visual check.

- Halide Torch: This older method, used primarily for refrigerants containing halogens (like R-12), detects leaks by producing a green flame when refrigerant comes into contact with the flame.

The choice of method depends on factors such as the refrigerant type, the suspected leak size, and the accessibility of the system components. Often, a combination of methods is used for greater accuracy.

Q 10. What is the role of a recovery cylinder in the process?

A recovery cylinder is a crucial component in responsible refrigerant handling. It’s a specifically designed, DOT-approved container used to temporarily store refrigerant removed from a refrigeration system during servicing or disposal. Imagine it as a safe holding tank for the refrigerant.

Its role is to capture refrigerant in a controlled manner, preventing it from escaping into the atmosphere. This prevents environmental harm caused by refrigerant release, most notably ozone depletion (for ozone-depleting substances) and global warming (for high global warming potential refrigerants). The recovered refrigerant can then be recycled, reclaimed, or properly disposed of through authorized channels.

Recovery cylinders are designed to withstand the pressures of the collected refrigerant and have specific labeling requirements to ensure safe handling and transport. They are not designed for long-term storage of refrigerant, so proper disposal or transfer to a reclamation facility is important.

Q 11. How do you determine the appropriate refrigerant recovery equipment for a specific system?

Choosing the right refrigerant recovery equipment depends on several factors. You wouldn’t use a small pump for a large industrial system; it would take too long and likely be inefficient. Here’s a breakdown:

- Refrigerant Type: Different refrigerants require equipment designed to handle their specific properties, such as pressure and chemical compatibility.

- System Size: The capacity of the refrigeration system dictates the pump’s capacity. Larger systems require higher-capacity pumps for efficient recovery.

- Recovery Rate: The speed at which the refrigerant needs to be removed influences the choice of pump. Faster recovery rates require more powerful equipment.

- Compliance: Ensure that the equipment meets all applicable environmental regulations and safety standards.

For instance, a small residential air conditioning unit might only need a portable recovery unit with a relatively low capacity, while a large commercial refrigeration system will require a more substantial and powerful system with possibly a dedicated recovery unit.

Q 12. What are the legal requirements for refrigerant handling in your area?

Legal requirements for refrigerant handling vary by location (country, state, etc.), but generally involve regulations aimed at protecting the environment and human health. It’s crucial to check the specific regulations for your area. These commonly include:

- Licensing and Certification: Technicians often need specific licenses or certifications to handle refrigerants, especially those who recover or recycle them.

- Reporting Requirements: Leaks exceeding a certain threshold may need to be reported to the relevant authorities.

- Equipment Standards: Recovery equipment must meet specific standards and may require regular inspection and calibration.

- Proper Disposal Procedures: Regulations outline the correct methods for disposal and recycling of refrigerants.

- Record-keeping: Maintaining accurate records of refrigerant handling, including recovery and disposal, is often mandatory.

Failing to comply with these regulations can result in significant fines and legal consequences. It’s vital to stay up-to-date on all relevant laws and regulations.

Q 13. Describe the proper procedures for handling and storing recovered refrigerant.

Recovered refrigerant should be handled and stored with utmost care to prevent leaks and maintain its purity. This is important for both environmental reasons and the safety of those handling the refrigerant.

Handling: Always use appropriate personal protective equipment (PPE), including gloves and eye protection, when handling recovered refrigerant. Never allow the refrigerant to come into contact with open flames or sparks, as it can be highly flammable.

Storage:

- Proper containers: Store recovered refrigerant only in DOT-approved cylinders specifically designed for refrigerant storage.

- Secure location: Keep the storage area well-ventilated and away from sources of ignition.

- Labeling: Ensure cylinders are clearly labeled with the type and quantity of refrigerant.

- Temperature considerations: Store cylinders in a cool, dry place and away from direct sunlight.

- Inventory Management: Maintain accurate records of refrigerant quantities stored and track cylinder usage.

Regular inspection of storage areas and cylinders is important to detect any leaks or damage immediately.

Q 14. What are the common causes of refrigerant leaks?

Refrigerant leaks can stem from various sources. Identifying the root cause is critical for effective repair and prevention of future issues.

- Component Failure: Worn seals, cracked components (like compressor or condenser coils), and damaged tubing can lead to leaks. This is often the result of normal wear and tear, but can also be caused by corrosion or external damage.

- Improper Installation: Poorly installed connections or inadequate brazing can create weak points prone to leakage.

- Vibration and Stress: Excessive vibration from the compressor or external factors can cause fatigue and lead to cracks in system components. Improper mounting is a common culprit.

- Corrosion: Exposure to moisture or other corrosive substances can weaken system components, leading to leaks over time. This is particularly true in older systems.

- Overcharging or Undercharging: Extreme pressures within the system can stress the components, causing leaks.

Regular inspection of the refrigeration system, including visual checks and pressure testing, is crucial for early detection and prevention of leaks.

Q 15. How do you troubleshoot a refrigerant leak?

Troubleshooting a refrigerant leak involves a systematic approach combining visual inspection and specialized tools. First, we visually inspect the entire refrigeration system for any signs of leaks, such as oil stains, frost, or bubbling refrigerant. This often requires checking all connections, valves, and components carefully.

Next, we employ leak detection tools. Electronic leak detectors use sensors to identify the presence of refrigerant in the air. They’re very sensitive and can pinpoint leaks even in hard-to-reach places. Dye tracing involves adding a fluorescent dye to the system. Under UV light, any leaks will glow, making them easily visible. Pressure testing, where the system is pressurized with nitrogen, is also effective; leaks cause pressure drops, which are easily measured.

Once a leak is located, repairing it depends on its severity and location. Small leaks in accessible areas might be repaired with specialized sealant, while larger or more complex leaks require component replacement and system evacuation and recharge.

For example, I once diagnosed a leak in a supermarket’s refrigeration system. Initially, visual inspection revealed nothing. However, using an electronic leak detector, I quickly pinpointed a tiny crack in a weld near the compressor. Replacing that section resolved the issue and restored the system’s efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper record-keeping for refrigerant recovery.

Proper record-keeping is crucial for refrigerant recovery for several reasons. First, it ensures compliance with environmental regulations. Many countries have strict laws governing the handling and disposal of refrigerants, mandating detailed logs of recovery, recycling, and disposal activities. These records demonstrate responsible environmental stewardship and avoid potential legal penalties.

Second, accurate record-keeping is vital for system maintenance and troubleshooting. Knowing the type and quantity of refrigerant used, dates of recovery and recharge, and any detected leaks helps diagnose future problems and optimize system performance. This information can be invaluable for preventative maintenance.

Third, thorough records are essential for tracking inventory and minimizing waste. This is important from both a cost-saving and environmental perspective. Knowing exactly how much refrigerant is in your possession prevents overbuying and reduces the potential for refrigerant release into the atmosphere.

For instance, I’ve seen how neglecting record-keeping leads to increased maintenance costs and regulatory compliance issues. A company I consulted lacked precise records; this made it difficult to diagnose a recurring problem, ultimately delaying repairs and leading to significant refrigerant loss.

Q 17. What safety precautions should be taken when working with refrigerants?

Safety is paramount when handling refrigerants. Refrigerants can be toxic, flammable, or both, depending on the type. Therefore, appropriate personal protective equipment (PPE) is essential, including safety glasses, gloves, and respiratory protection. Furthermore, work should always be performed in a well-ventilated area to prevent the buildup of potentially hazardous gases.

Before commencing any work, technicians must become familiar with the specific hazards associated with the refrigerant being handled. Safety data sheets (SDS) provide crucial information on the refrigerant’s properties and necessary precautions. Regular training on refrigerant handling procedures, leak detection and repair techniques, and emergency response is also critical.

Always ensure proper ventilation, use leak detection equipment to monitor for leaks, and be aware of potential fire hazards, especially with flammable refrigerants. Using the correct recovery equipment and techniques is vital to preventing accidental releases. Never work alone; having a colleague nearby ensures safety in case of unexpected incidents.

Q 18. What are the signs of refrigerant overcharging?

Refrigerant overcharging can lead to several issues. One of the most common signs is a high-pressure reading on the system’s pressure gauge. The compressor might overheat, resulting in reduced efficiency and potential damage. The system might also experience liquid slugging, where liquid refrigerant enters the compressor, causing severe damage.

Other symptoms include decreased system efficiency, unusual noises emanating from the compressor (like knocking or rumbling), increased energy consumption, and potential overheating of the condenser and other system components. In extreme cases, it can cause a catastrophic system failure.

For example, an incorrectly charged system I encountered exhibited excessive compressor noise and high head pressure. Correcting the charge by removing the excess refrigerant immediately solved the problem, highlighting the importance of precise charging.

Q 19. What are the signs of refrigerant undercharging?

Undercharging a refrigeration system results in a lower-than-normal pressure reading. The most noticeable symptom is poor cooling performance, resulting in warmer temperatures within the refrigerated space. You’ll find that it takes longer to reach the desired temperature, and the system may cycle more frequently.

Other signs include frosting on the suction line (the line carrying low-pressure refrigerant), and the system may not cool effectively even with the compressor running continuously. In addition, you may notice reduced system efficiency, increased energy consumption per unit of cooling provided, and, potentially, longer compressor run times.

Imagine a walk-in freezer that’s struggling to maintain its temperature. After checking the pressure, I found it was significantly undercharged. Adding the correct amount of refrigerant restored its proper cooling function.

Q 20. What are the different types of refrigerant and their properties?

Refrigerants are classified by their chemical composition and properties. There are various types, each with unique advantages and disadvantages. Some examples include:

- HFCs (Hydrofluorocarbons): These are commonly used refrigerants like R-134a and R-410A. They have relatively low ozone depletion potential (ODP) but contribute to global warming through their Global Warming Potential (GWP).

- HFOs (Hydrofluoroolefins): Newer refrigerants such as R-1234yf and R-1234ze have very low GWPs, making them environmentally more friendly than HFCs.

- Natural Refrigerants: These include ammonia (R-717), carbon dioxide (R-744), and propane (R-290). They have zero or very low ODP and GWP, making them environmentally preferable. However, they can pose other safety concerns (flammability or toxicity) requiring specific handling procedures.

Each refrigerant’s properties, including boiling point, operating pressure, toxicity, flammability, and environmental impact, must be considered during selection and handling. The choice often involves balancing performance requirements with environmental and safety considerations.

Q 21. Explain the concept of refrigerant blends.

Refrigerant blends are mixtures of two or more refrigerants designed to enhance performance characteristics or address specific limitations of single refrigerants. These blends are often created to achieve a desirable combination of properties, such as improved efficiency, reduced operating pressures, or lower environmental impact.

Blends can be either zeotropic or azeotropic. Zeotropic blends have components with different boiling points, resulting in a temperature glide (a temperature range over which the refrigerant evaporates or condenses). This can offer advantages in certain applications. Azeotropic blends behave more like a single refrigerant, as their components have similar boiling points, thus eliminating the temperature glide.

The use of blends enables the optimization of refrigerant properties tailored to a specific refrigeration application. For example, a blend might offer superior efficiency in a particular temperature range or minimize environmental impact while maintaining adequate performance. However, understanding the behavior of blends is crucial, as leaks can alter their composition, affecting the system’s performance.

Q 22. How do you handle different types of refrigerant leaks (e.g., small vs. large)?

Handling refrigerant leaks depends heavily on the size of the leak and the type of refrigerant involved. Small leaks, often detected by pressure drops in the system, might be addressed with temporary repairs like tightening connections or replacing damaged seals. This is often followed by close monitoring of the system’s pressure. Larger leaks require immediate action to prevent significant refrigerant loss and potential environmental harm. This involves securing the area, shutting down the system, and quickly locating and repairing the leak. It’s crucial to always prioritize safety, using appropriate PPE (personal protective equipment) and following established procedures. For example, a small leak in an R-410A system might only need a sealant applied to a loose fitting, while a large leak of R-22, an ozone-depleting substance, would demand immediate shutdown, recovery of the refrigerant, and proper disposal following EPA regulations.

- Small Leaks: Monitor pressure, apply sealant (if applicable), repair minor damage.

- Large Leaks: Secure area, shut down system, recover refrigerant, repair leak, properly dispose or recycle refrigerant.

Q 23. What is the proper procedure for decommissioning a refrigeration system?

Decommissioning a refrigeration system is a crucial process designed to protect the environment and ensure worker safety. The process begins with a complete system shutdown, followed by the recovery of the refrigerant using a certified recovery machine. Once the refrigerant is recovered, the system is then depressurized and any remaining refrigerant is purged. Next, components containing oil are drained, cleaned, and often disposed of or recycled according to local regulations. Finally, the system is disassembled and the components are properly disposed of or recycled. This procedure is critical to prevent accidental release of refrigerants into the atmosphere, mitigating ozone depletion and global warming. For example, an older system using R-12 would require a more rigorous decommissioning process due to its ozone-depleting potential compared to a more modern system using R-410A or R-32.

- System Shutdown

- Refrigerant Recovery

- System Depressurization

- Oil Drainage and Cleaning

- Component Removal and Disposal

Q 24. Describe your experience with different refrigerant recovery machines.

I have extensive experience operating various refrigerant recovery machines, including those from leading manufacturers like [Manufacturer A] and [Manufacturer B]. My experience encompasses both self-contained units and those integrated into larger service vehicles. I’m proficient in using machines with different recovery capacities and functionalities, including those with electronic leak detection capabilities. The key to successful refrigerant recovery isn’t just knowing how to operate the machine but understanding its limitations, such as the refrigerant types it can handle and its recovery efficiency. For example, I’ve used small, portable units for residential systems, while larger, more powerful machines were necessary for commercial refrigeration units. My experience also extends to troubleshooting malfunctions and performing routine maintenance on these machines.

Q 25. How do you ensure compliance with all relevant safety and environmental regulations?

Ensuring compliance with safety and environmental regulations is paramount in this field. I meticulously follow all EPA guidelines, local ordinances, and industry best practices regarding refrigerant handling. This includes maintaining accurate records of refrigerant recovery and disposal, using properly certified equipment, and adhering to stringent safety protocols during each operation. I regularly check for updates to regulations and ensure that my certifications and equipment are current. For example, I strictly adhere to the Clean Air Act regulations pertaining to the recovery and recycling of ozone-depleting substances (ODS). Failure to comply with these regulations can lead to hefty fines and legal repercussions.

Q 26. Explain the importance of using proper personal protective equipment (PPE) during refrigerant recovery.

Proper PPE is critical when handling refrigerants to protect against potential hazards like exposure to harmful fumes, contact with refrigerant liquids, and potential equipment malfunctions. The type of PPE needed depends on the specific refrigerant and the task being performed. At a minimum, this includes safety glasses or goggles to protect the eyes, gloves resistant to the specific refrigerant, and a respirator to prevent inhalation of refrigerant fumes, especially when dealing with larger leaks. In some situations, full body protection may be necessary, as certain refrigerants can cause skin irritation or frostbite upon direct contact. Ignoring PPE guidelines can lead to severe health consequences and even fatalities. For instance, prolonged exposure to some refrigerants can lead to respiratory distress and irregular heartbeats.

Q 27. Describe a situation where you had to troubleshoot a refrigerant-related problem.

In one instance, I was called to a supermarket experiencing a significant temperature rise in their refrigerated cases. Initial assessment suggested a refrigerant leak. However, the leak was not immediately apparent. Using electronic leak detection tools, I systematically checked all connections and components. The leak was finally pinpointed to a hairline fracture in a hard-to-reach section of the piping. This required careful planning and precise repair techniques using specialized tools. The repair involved brazing the fracture and performing a leak test afterward. This highlighted the importance of thorough diagnostic procedures and the use of appropriate leak detection technology in addressing refrigerant-related problems.

Q 28. How do you stay updated on the latest regulations and best practices regarding refrigerant handling?

Staying updated is crucial in this rapidly evolving field. I achieve this through continuous professional development, including attending industry conferences, workshops, and training sessions. I also subscribe to industry publications, such as [Industry Publication A] and [Industry Publication B], and regularly review updates from relevant regulatory bodies like the EPA. I also actively participate in online forums and networking groups to discuss the latest trends and best practices with other professionals. This ensures that my knowledge and techniques remain current and align with the most up-to-date regulations and best practices.

Key Topics to Learn for Understanding of Refrigerant Recovery and Disposal Procedures Interview

- Refrigerant Types and Properties: Understanding the different types of refrigerants (e.g., HFCs, HFOs, natural refrigerants), their environmental impact, and their physical properties (pressure, temperature, etc.). This includes knowing the differences between ozone-depleting substances (ODS) and those with low global warming potential (GWP).

- Recovery Equipment and Procedures: Familiarize yourself with the various types of recovery equipment used, their operation, and proper safety procedures. This involves understanding the process of recovering refrigerant from various systems and ensuring proper system evacuation.

- Recycling and Reclamation: Learn the difference between recycling and reclaiming refrigerants. Understand the processes involved in cleaning and purifying refrigerants to meet specific purity standards for reuse.

- Disposal Methods: Understand environmentally sound disposal methods for refrigerants that cannot be recycled or reclaimed, including compliance with relevant regulations and best practices.

- Safety Regulations and Compliance: Thoroughly understand relevant environmental regulations (e.g., EPA regulations in the US, or equivalent international standards) and safety procedures associated with handling refrigerants. This includes understanding proper personal protective equipment (PPE) and safe handling practices.

- Troubleshooting and Problem-Solving: Be prepared to discuss common problems encountered during refrigerant recovery and disposal, and your approaches to solving them. This might include leaks, equipment malfunctions, or unexpected refrigerant behavior.

- Record Keeping and Documentation: Understand the importance of accurate and complete record keeping for all refrigerant handling activities, including compliance tracking and reporting.

Next Steps

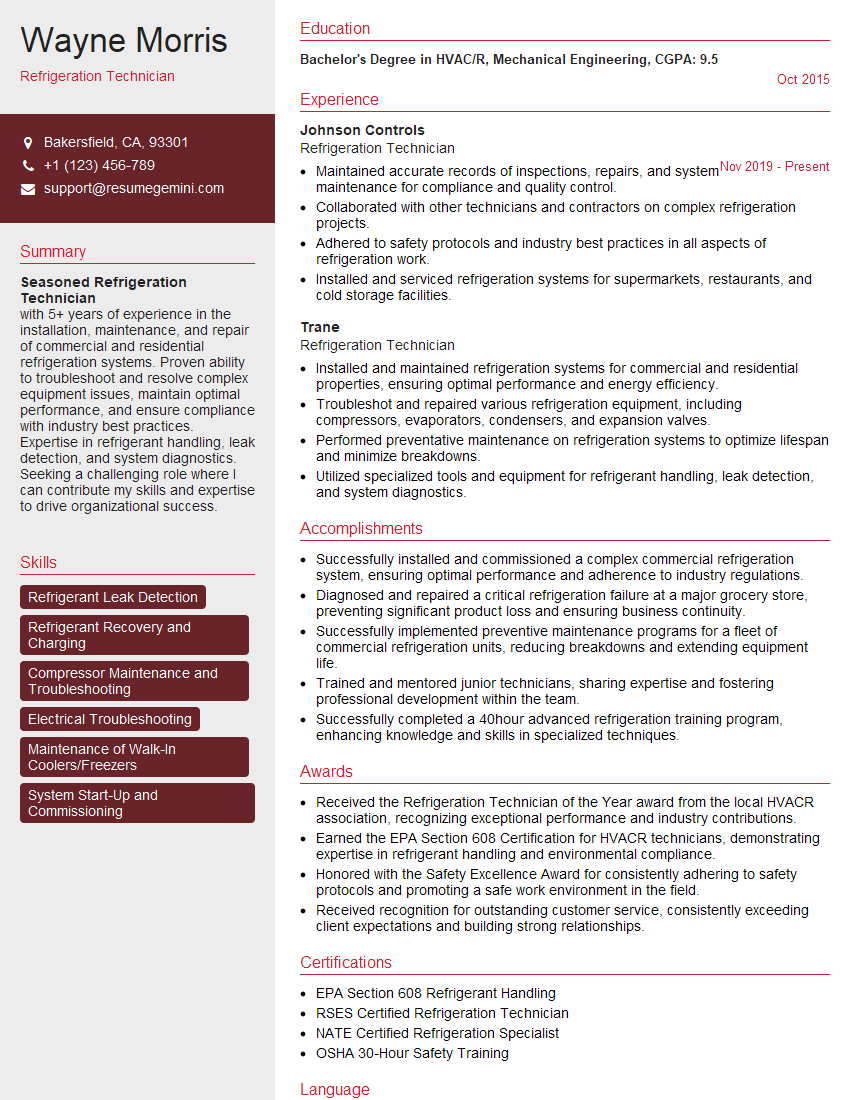

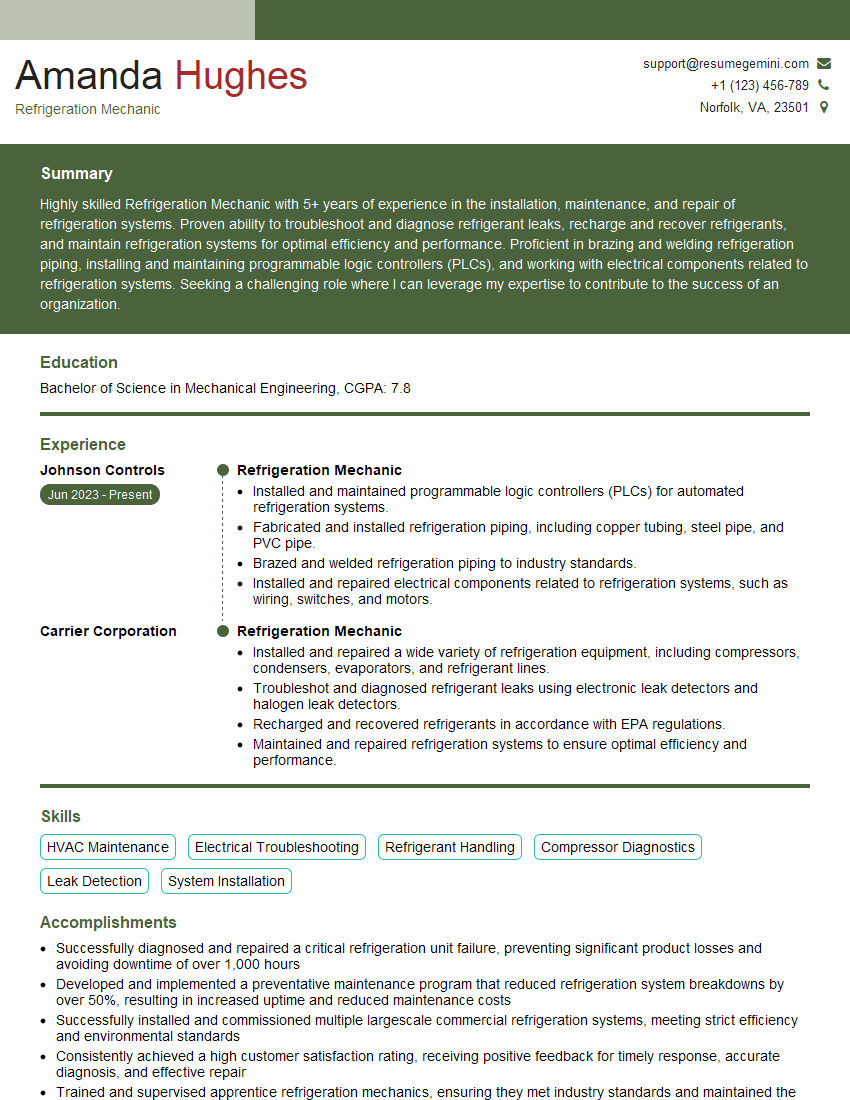

Mastering refrigerant recovery and disposal procedures is crucial for a successful career in HVACR and related fields. It demonstrates your commitment to environmental responsibility and your understanding of critical safety regulations. To stand out to potential employers, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource for building professional resumes that help you land your dream job. We provide examples of resumes tailored to highlight expertise in Understanding of Refrigerant Recovery and Disposal Procedures, giving you a head start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO