Preparation is the key to success in any interview. In this post, we’ll explore crucial Use cylindrical grinders interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Use cylindrical grinders Interview

Q 1. Explain the difference between internal and external cylindrical grinding.

The core difference between internal and external cylindrical grinding lies in the location of the workpiece relative to the grinding wheel. In external cylindrical grinding, the outside diameter of a workpiece (like a shaft or rod) is ground. The workpiece rotates on its axis, while the grinding wheel feeds against it, removing material to achieve the desired diameter and surface finish. Think of it like sharpening a pencil – you’re working on the outer surface.

Internal cylindrical grinding, on the other hand, works on the inside diameter of a workpiece (like a bore or hole). Here, a smaller grinding wheel is used, often mounted on a slender shaft, which rotates inside the workpiece. The wheel’s traverse and infeed remove material to achieve the specified internal diameter and surface quality. Imagine honing the inside of a pipe – that’s internal cylindrical grinding.

Q 2. Describe the various types of cylindrical grinding wheels and their applications.

Cylindrical grinding wheels are categorized by several factors, primarily their abrasive type, grain size, and bond type. Common abrasive types include aluminum oxide (Al2O3) for ferrous metals and silicon carbide (SiC) for non-ferrous materials like cast iron and non-metals. Grain size dictates the surface finish – coarser grains for faster material removal, finer grains for superior surface quality. The bond type, which holds the abrasive grains together, can be vitrified (ceramic), resinoid (organic), or metallic, each exhibiting different characteristics regarding strength, durability, and suitability for specific applications.

- Vitrified wheels are widely used due to their hardness and resistance to heat, suitable for a wide range of materials and operations.

- Resinoid wheels offer flexibility and are frequently used for grinding intricate shapes or softer materials.

- Metallic wheels are robust and ideal for heavy-duty grinding where rapid material removal is crucial.

Specific applications, such as plunge grinding, traverse grinding, or creep feed grinding, require appropriately chosen wheel types. For example, a resinoid wheel might be preferred for grinding a delicate component, whereas a vitrified wheel with a coarser grain size might be chosen for roughing out a large shaft.

Q 3. How do you select the appropriate grinding wheel for a specific material and application?

Selecting the right grinding wheel is paramount for optimal results and efficiency. It involves understanding the material properties and the desired outcome. You need to consider:

- Material hardness: A harder wheel is needed for harder materials. A softer wheel is suitable for softer materials to avoid damage to the workpiece.

- Workpiece material: Different materials respond differently to specific abrasive types. Aluminum oxide is generally effective for steel, while silicon carbide is preferred for cast iron.

- Desired surface finish: Finer grain size yields a smoother finish, while coarser grains are better for faster material removal.

- Grinding operation: The type of operation (e.g., roughing, finishing, internal, external) influences the choice of wheel type and bond.

For instance, grinding hardened steel requires a harder wheel with aluminum oxide abrasive and a vitrified bond. Conversely, grinding aluminum might use a softer wheel with silicon carbide abrasive and a resinoid bond. Consulting grinding wheel manufacturers’ charts and guidelines, alongside practical experience, is essential for successful wheel selection.

Q 4. What are the key parameters to set up a cylindrical grinding machine?

Setting up a cylindrical grinding machine involves meticulous attention to several key parameters, all of which influence the accuracy and quality of the final product. These include:

- Workhead speed: This determines the workpiece’s rotational speed, influencing the rate of material removal and surface finish. The speed is usually set based on the material and diameter of the workpiece.

- Wheel speed: The grinding wheel’s speed affects its cutting action, also influencing material removal and surface finish. This speed is generally recommended by the wheel manufacturer.

- Workpiece centering: Accurate centering is vital to prevent eccentricity and ensure a cylindrical workpiece. This involves using precision collets, centers, or chucks.

- Wheel dressing and truing: Before each grinding operation, it’s crucial to dress and true the wheel to remove glaze, restore its shape and ensure optimal cutting performance.

- Infeed and traverse rates: These define how the wheel interacts with the workpiece; the infeed depth dictates material removal per pass, while the traverse rate influences the surface finish.

- Coolant application: Adequate coolant application is essential to prevent overheating, maintain the wheel’s sharpness, and improve surface finish. The type of coolant depends on the material being ground.

Precise adjustments to these parameters are critical for producing high-quality parts. Incorrect settings can lead to inaccuracies, surface imperfections, and potentially damage to the workpiece or the machine.

Q 5. How do you ensure dimensional accuracy during cylindrical grinding?

Dimensional accuracy in cylindrical grinding relies on a combination of factors, starting from proper machine setup and extending to meticulous process control. Key aspects include:

- Precise machine calibration: Regular calibration of the machine’s measuring systems (e.g., dial indicators, electronic gauges) is crucial to ensure accurate measurements.

- Accurate workpiece setup: Careful centering and clamping of the workpiece in the workhead is paramount to avoid eccentricity errors.

- Controlled grinding parameters: Precise control over infeed depth, traverse rate, and wheel speed is essential to achieve the desired dimensions.

- Regular wheel dressing and truing: This maintains the wheel’s profile and sharpness, ensuring consistent material removal and minimizing dimensional variations.

- Appropriate coolant usage: Proper coolant application prevents wheel glazing and ensures consistent material removal.

- Regular inspection: Frequent measurement of the workpiece during and after grinding is vital for detecting any deviations from the required dimensions.

- Use of measuring equipment: High-precision measuring instruments (micrometers, calipers, optical comparators) are indispensable for verifying dimensional accuracy.

The use of automatic gauging systems linked directly to the grinding machine can significantly enhance accuracy and reduce the chances of errors.

Q 6. Explain the concept of infeed and traverse grinding.

Infeed and traverse grinding are two fundamental grinding modes used in cylindrical grinding, each achieving material removal in different ways. Imagine a wheel grinding a shaft.

Infeed grinding involves advancing the grinding wheel into the workpiece in a series of small steps, or infeed. Each step removes a small amount of material. This method is suited for removing larger amounts of stock or achieving precise diameter control. Think of it as making several shallow cuts in one place to reach the desired depth.

Traverse grinding involves moving the wheel back and forth across the workpiece while simultaneously feeding the wheel into the workpiece. This allows for the grinding of a longer length in a more continuous fashion. This is common for producing long, straight, cylindrical parts. Imagine it as a wheel cutting across the shaft continuously, removing material at each pass.

Often, a combination of infeed and traverse grinding is employed for optimal efficiency and surface finish – several infeed passes may be used to reach the final diameter, with each infeed pass involving traverse grinding to cover the entire length of the workpiece.

Q 7. Describe the process of dressing and truing a grinding wheel.

Dressing and truing a grinding wheel are essential maintenance procedures that restore its shape and cutting ability. A dull or improperly shaped wheel can lead to poor surface finish, dimensional inaccuracies, and even damage to the workpiece.

Dressing is the process of removing surface irregularities and glaze from the wheel to expose sharp abrasive grains. This is done using a dressing tool, which can be a diamond dressing stick, a silicon carbide stick, or a diamond roller. The dressing tool wears away the wheel’s surface and removes any dull or clogged grains.

Truing is the process of restoring the grinding wheel’s precise shape and dimensions. Truing ensures that the wheel’s profile matches the desired workpiece shape. This is usually accomplished using a diamond truing tool, often a diamond roll, which accurately shapes the wheel’s surface. Truing is particularly critical for accurate cylindrical grinding to ensure consistency and avoid taper.

Both dressing and truing are typically performed before each grinding operation to ensure optimal cutting performance and part quality. The frequency depends on factors like the type of wheel, material being ground, and the amount of material being removed.

Q 8. How do you troubleshoot common cylindrical grinding problems such as chatter or burning?

Troubleshooting chatter and burning in cylindrical grinding involves a systematic approach. Chatter, the rhythmic vibration causing surface imperfections, often stems from excessive workpiece overhang, insufficient rigidity in the machine setup, or improper wheel dressing. Burning, characterized by discoloration and surface damage, usually indicates insufficient coolant flow, too high a feed rate, or a dull grinding wheel.

- Chatter Troubleshooting: First, check for workpiece deflection. Reduce the overhang, use a more rigid setup (e.g., steadies, stronger chuck), or employ a higher-frequency wheel. Second, inspect the wheel and machine for any imbalance or looseness. Finally, optimize the grinding parameters: reduce the depth of cut and/or feed rate. If the problem persists, consider dynamic balancing of the workpiece or the grinding wheel.

- Burning Troubleshooting: Ensure adequate coolant flow and concentration – a clogged nozzle or a low coolant level is a common culprit. Check the coolant’s properties as well. Increase the coolant flow rate and ensure it directly contacts the grinding zone. Reduce the depth of cut and feed rate. Make sure your grinding wheel is sharp and correctly dressed. Overly aggressive grinding parameters lead to localized heat build-up.

For example, I once encountered severe chatter on a long, slender shaft. By adding a steady rest to support the workpiece midway, the problem was immediately resolved. Similarly, I diagnosed burning on a particular job to be caused by a dull wheel; after dressing, the burning ceased.

Q 9. How do you measure roundness and cylindricity?

Roundness and cylindricity are crucial parameters in cylindrical grinding. Roundness refers to the deviation of a cross-section from a perfect circle, while cylindricity encompasses the deviation of the entire workpiece from a perfect cylinder (both roundness and straightness). These are measured using precision instruments.

- Roundness Measurement: A roundness tester employs a highly sensitive probe that measures the radial distance from a center point. It generates a polar graph showing deviations from perfect roundness. Common measurement units include micrometers (µm).

- Cylindricity Measurement: Cylindricity measurement often involves combining roundness measurements at multiple axial positions along the workpiece. This helps determine not only the roundness at each section but also the straightness of the axis. Advanced CNC cylindrical grinders often have built-in probes for in-process measurement.

Imagine making a piston. Consistent roundness is vital for sealing and proper movement in the cylinder. A roundness gauge, combined with a dial indicator to assess straightness, ensures it meets tolerance.

Q 10. Explain the importance of coolant in cylindrical grinding.

Coolant plays a vital role in cylindrical grinding. It acts as a lubricant, a heat sink, and a chip remover, improving process efficiency and workpiece quality.

- Lubrication: Coolant reduces friction between the grinding wheel and workpiece, minimizing wear on both and improving surface finish.

- Heat Dissipation: Grinding generates significant heat. Coolant absorbs this heat, preventing workpiece distortion, burning, and wheel glazing (loss of cutting ability).

- Chip Removal: The coolant carries away grinding swarf (chips) keeping the grinding zone clear.

Without coolant, the grinding process would generate excessive heat, potentially damaging the workpiece and significantly shortening the life of the grinding wheel.

Q 11. What are the safety precautions you take while operating a cylindrical grinder?

Safety is paramount when operating cylindrical grinders. Several precautions are essential:

- Proper training and authorization: Operators must receive comprehensive training before operating the machine.

- Personal Protective Equipment (PPE): Eye protection, hearing protection, and work gloves are mandatory. Depending on the material being ground, additional PPE may be needed (e.g., a respirator for grinding certain metals).

- Machine guards: Ensure all safety guards are in place and functioning correctly. Never operate a machine with guards removed or malfunctioning.

- Workpiece securing: Securely clamp the workpiece to prevent it from rotating unexpectedly during the grinding operation.

- Emergency stop: Know the location and operation of the emergency stop button and regularly check its functionality.

- Regular maintenance: Ensure the machine receives routine maintenance to prevent potential hazards. This includes regular inspections of electrical systems and mechanical components.

I always emphasize the importance of a thorough pre-operation inspection of the grinder and workplace to avoid unexpected incidents.

Q 12. How do you interpret engineering drawings and specifications for cylindrical grinding?

Interpreting engineering drawings and specifications is crucial for accurate cylindrical grinding. This involves understanding the various dimensions, tolerances, and surface finish requirements. A typical drawing will specify:

- Dimensions: Diameter, length, and other critical dimensions of the workpiece.

- Tolerances: Acceptable deviations from the specified dimensions, often expressed using plus/minus values (±) or geometric dimensioning and tolerancing (GD&T) symbols.

- Surface finish: The desired roughness of the workpiece surface, often indicated by Ra (average roughness) values or symbols.

- Material: The material the workpiece is made of, influencing the grinding process parameters.

For example, a drawing might specify a shaft diameter of 25.000 mm ±0.005 mm with a surface finish of Ra 0.4 µm. This indicates the diameter must be between 24.995 and 25.005 mm, and the surface roughness must not exceed 0.4 µm.

Q 13. Describe your experience with different types of grinding fluids.

My experience encompasses various grinding fluids, each with its own advantages and disadvantages:

- Water-based fluids: These are commonly used due to their cost-effectiveness and environmental friendliness. However, they may not provide the same level of lubrication and cooling as oil-based fluids.

- Oil-based fluids: Offer superior lubrication and cooling capabilities, improving surface finish and reducing wheel wear. However, they pose disposal challenges due to their environmental impact.

- Synthetic fluids: Designed to combine the advantages of both water-based and oil-based fluids, offering good lubrication, cooling, and environmental compatibility. They usually have a higher upfront cost.

The choice of grinding fluid depends on the material being ground, the desired surface finish, and environmental considerations. For example, I might use a water-soluble fluid for a stainless steel part requiring a fine finish, while an oil-based fluid might be better suited for grinding hardened steel where extreme cooling is required.

Q 14. What are the advantages and disadvantages of using CNC cylindrical grinders?

CNC cylindrical grinders offer significant advantages over conventional machines, but also have some disadvantages:

- Advantages:

- Increased precision and accuracy: CNC control ensures higher dimensional accuracy and surface finish.

- Improved efficiency: Automated operation and optimized grinding parameters lead to faster cycle times and higher productivity.

- Reduced labor costs: Less operator intervention is required compared to manual operation.

- Complex part capability: CNC grinders can handle intricate shapes and complex geometries difficult for manual machines.

- Disadvantages:

- Higher initial cost: CNC machines have a significantly higher purchase price than conventional machines.

- Maintenance cost: CNC machines require specialized maintenance, leading to higher maintenance costs.

- Operator skill requirements: Operators need specific training and skills to program and operate CNC machines effectively.

In my experience, the advantages of CNC cylindrical grinders in terms of precision, speed, and repeatability generally outweigh the higher initial investment, particularly for high-volume production or parts with tight tolerances.

Q 15. Explain the process of setting up and operating a CNC cylindrical grinder.

Setting up and operating a CNC cylindrical grinder involves several crucial steps. Think of it like baking a cake – you need the right ingredients and precise measurements for a perfect outcome. First, you need to securely mount the workpiece on the machine’s chuck, ensuring concentricity is perfect to avoid runout. This is akin to properly prepping your cake pans. Then, you select the appropriate grinding wheel based on the material being ground and the desired surface finish. The wheel selection is like choosing the right flour for your cake. Next, you input the CNC program, which dictates the grinding parameters such as depth of cut, feed rate, and wheel speed. This is where the recipe comes in! Finally, you initiate the grinding process, monitoring the machine’s performance, and making any necessary adjustments. Once the process is complete, the part is carefully removed. Regularly checking for things like vibration, wheel wear, and coolant flow during operation is key to preventing damage and maintaining accuracy.

- Workpiece Mounting: Crucial for accuracy; improper mounting leads to errors.

- Wheel Selection: Determines surface finish and grinding efficiency.

- CNC Program Input: Specifies the cutting parameters.

- Process Monitoring: Essential to ensure consistent quality and prevent damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you program a CNC cylindrical grinder?

Programming a CNC cylindrical grinder involves using specialized software, often CAM (Computer-Aided Manufacturing) software. Think of it as writing a detailed recipe for the machine. This software allows you to create a program that defines the precise movements of the grinding wheel and workpiece. The program typically includes information on the geometry of the part, the desired tolerances, and the grinding parameters (depth of cut, feed rate, speed, etc.). We often use G-code, a standardized programming language, to communicate these instructions to the machine. A simple example would involve defining the starting and ending points of a cut and the precise path the wheel will take, including compensation for wheel wear. The complexity increases significantly when dealing with complex profiles.

G00 X10.0 Y0.0 ; Rapid traverse to starting point

G01 X10.0 Y5.0 F100 ; Linear interpolation, feed rate of 100 mm/min

G01 X0.0 Y5.0 F100 ; ...and so onThis code snippet shows a simple linear cut. Real-world programs are much more intricate and often involve multiple cuts and compensation strategies.

Q 17. How do you perform regular maintenance on a cylindrical grinding machine?

Regular maintenance of a cylindrical grinder is paramount for ensuring accuracy, prolonging its lifespan, and maintaining safety. It’s like regular servicing of your car – preventative measures avoid expensive repairs. This involves several key steps: daily checks of coolant levels and cleanliness, weekly inspection of the grinding wheel for wear and damage, and monthly lubrication of moving parts. More substantial tasks, such as checking for bearing play and alignment, should be done at scheduled intervals. Regular cleaning of the machine to remove metal chips and dust is also extremely important for safety and preventing damage. Documenting all maintenance tasks is critical for tracking performance and identifying potential issues before they escalate. Proper maintenance not only keeps the machine running smoothly but also contributes to the overall quality of the finished products.

Q 18. What are the different types of surface finishes achievable through cylindrical grinding?

Cylindrical grinding offers a wide range of surface finishes, depending on the grinding wheel used, the grinding parameters, and the material being ground. Think of it as choosing the right sandpaper for your project – you can achieve a coarse finish or a fine polish. Surface finishes are often specified using parameters like Ra (average roughness) or surface texture. A coarse finish might be suitable for a functional part where precision isn’t paramount, while a highly polished finish is essential for applications requiring low friction or excellent reflectivity. We can achieve finishes ranging from rough ground surfaces (high Ra values), suitable for certain applications, to mirror-like finishes (very low Ra values), where smoothness and precision are critical. The selection of the grinding wheel, in terms of its grit size and bond type, plays a huge role in achieving the desired finish.

Q 19. How do you inspect the finished parts for quality and conformance to specifications?

Inspecting finished parts for quality and conformance to specifications is a crucial step that requires precision and attention to detail. We use a variety of methods, depending on the required level of accuracy and the specific part features. Common tools and techniques include: using precision measuring instruments like micrometers and calipers to verify dimensions, surface roughness measurements using profilometers, and visual inspection with magnifying glasses to check for defects such as scratches or pitting. For complex geometries, coordinate measuring machines (CMMs) are utilized to provide comprehensive dimensional inspection. Statistical Process Control (SPC) is often employed to track the consistency of the finished parts and identify any trends that may indicate potential problems with the grinding process. This rigorous inspection process ensures that only parts meeting the required specifications are released.

Q 20. Explain your experience with different types of grinding wheel bonds.

Grinding wheel bonds are the material that holds the abrasive grains together. Different bonds are used for different applications, similar to how different glues work best for different materials. Vitrified bonds are the most common, offering good strength and thermal stability. They are ideal for a wide range of grinding operations. Resinoid bonds offer flexibility and are often preferred for grinding softer materials or complex shapes. Metallic bonds provide high strength and are suited for applications requiring aggressive grinding. Silicate bonds offer a balance of strength and thermal stability. The choice of bond depends heavily on the material being ground, the desired finish, and the grinding conditions. For instance, a vitrified bond might be suitable for grinding hardened steel, while a resinoid bond may be preferred for grinding aluminum or softer materials. Selecting the correct bond is crucial for ensuring optimal grinding performance and wheel life.

Q 21. How do you handle different materials during cylindrical grinding (e.g., hardened steel, aluminum)?

Grinding different materials requires careful consideration and adjustments to the grinding process. Hardened steel requires a different approach than aluminum due to differences in material properties like hardness and toughness. Hardened steel, for example, demands robust grinding wheels and careful control of parameters to avoid burning or cracking. We might use harder grinding wheels with higher concentrations of abrasive grains and modify the feed rates and cutting speeds to optimize the grinding operation. Aluminum, on the other hand, is softer and requires gentler grinding parameters to avoid excessive wear on the grinding wheel or creating heat-related damage to the workpiece. This might involve using softer wheels with less aggressive cutting parameters and increased coolant flow. The selection of the right coolant is also crucial for effective lubrication and heat dissipation, helping to minimize damage and improve surface finish.

Q 22. Describe your experience with different types of grinding machine setups (e.g., centerless, through-feed).

My experience encompasses a wide range of cylindrical grinding setups, including centerless and through-feed methods. Centerless grinding, where the workpiece isn’t held between centers, is ideal for high-volume production of parts with simple geometries. I’ve extensively worked with both infeed and through-feed centerless grinders, mastering the adjustments of regulating wheels and work rests to achieve precise tolerances. For example, I optimized a through-feed centerless grinding process for a client manufacturing small diameter shafts, resulting in a 20% increase in production efficiency while maintaining tight dimensional accuracy.

Through-feed grinding, where the workpiece passes continuously through the grinding wheel, is equally familiar to me. I’ve used this method for longer parts, requiring careful control of in-feed rates and wheel dressing to maintain consistent surface finish and roundness. A challenging project involved grinding long, slender rods to extremely tight tolerances using a through-feed setup; I managed this by implementing a sophisticated vibration dampening system and precise control of the coolant flow.

In addition to these two primary methods, I also have experience with internal cylindrical grinding, where the grinding wheel is internal to the workpiece, and external cylindrical grinding, typically with workpieces mounted between centers.

Q 23. How do you deal with unexpected issues or malfunctions during the grinding process?

Unexpected issues are part and parcel of grinding. My approach involves a systematic troubleshooting process. First, I carefully analyze the problem. Is it a dimensional issue, a surface finish problem, or a machine malfunction? I’ll start by checking the obvious: wheel dressing, coolant flow, work holding, and machine settings. A common issue I’ve encountered is wheel loading (the clogging of the wheel with workpiece material), usually addressed by dressing the wheel or adjusting the coolant. If the problem is more complex, I systematically check components, starting with the most likely causes. For instance, if the workpiece isn’t round, I’d examine the work-holding fixture, then the alignment of the machine components. I keep detailed logs of all parameters and adjustments made during the troubleshooting process for future reference.

Documentation is key. I always refer to maintenance logs and the machine’s operational manual. If the problem persists despite my efforts, I don’t hesitate to seek the help of experienced colleagues or consult relevant technical resources. The safety of both the equipment and the operator is paramount, and I’ll shut down the machine if I’m unsure about a particular problem.

Q 24. What are the common causes of grinding wheel wear?

Grinding wheel wear is inevitable but controllable. Common causes include improper wheel selection, incorrect grinding parameters, and poor wheel maintenance. Using a wheel with incorrect grain size or bond type for the material being ground will accelerate wear. Too aggressive a feed rate or insufficient coolant can also cause rapid wear. I always carefully select the wheel based on the material properties and required surface finish.

Furthermore, inconsistent wheel dressing contributes to uneven wear, leading to premature failure and dimensional inaccuracies. I use a variety of dressing techniques, from single-point diamond tools to truing rolls, and maintain detailed records of the dressing process to ensure consistency. Dull wheels are another significant factor, and I strictly adhere to a regular dressing schedule. Ultimately, understanding the material properties, machine settings, and diligently following dressing protocols are crucial in prolonging wheel life.

Q 25. How do you calculate the grinding wheel speed and feed rate?

Calculating grinding wheel speed and feed rate is crucial for achieving desired results and preventing damage. Wheel speed is typically determined using the surface speed formula: Surface Speed (SFM) = (π x Diameter x RPM) / 12 where diameter is in inches and RPM is revolutions per minute. The optimal surface speed depends on the wheel material and the workpiece material. For example, grinding steel might require a surface speed of 6000 SFM, while grinding aluminum might be lower. The machine usually displays this information and can be adjusted using the controls.

Feed rate refers to how quickly the workpiece moves across the grinding wheel. It’s expressed in inches per minute (IPM) or millimeters per minute (mm/min). Too high a feed rate can lead to wheel glazing, while too low a rate will slow down the process. The optimal feed rate is dependent on factors like the material, wheel type, and desired surface finish and is often determined through experimentation and based on machine specifications and engineering best practices. I generally start with conservative settings and gradually increase them until the desired finish and tolerances are met.

Q 26. Explain your experience using various measuring instruments (e.g., micrometers, calipers).

I’m proficient in using a wide array of measuring instruments, including micrometers, vernier calipers, dial indicators, and optical comparators. Micrometers and calipers are indispensable for precise measurements of workpiece dimensions and tolerances. I regularly use micrometers to measure shaft diameters to thousandths of an inch, ensuring that parts meet specifications.

Dial indicators are vital for checking roundness and concentricity, while optical comparators provide a visual inspection of surface finish and complex geometries. I am also well-versed in using coordinate measuring machines (CMMs) for precise three-dimensional measurements.

Accuracy is critical. I always calibrate my instruments regularly and maintain meticulous records of calibration results. Proper instrument handling is essential to avoid damage or inaccurate readings. I ensure that I use the correct instrument for the measurement task and consider factors like temperature and ambient conditions.

Q 27. How do you ensure the accuracy and repeatability of your grinding operations?

Ensuring accuracy and repeatability in grinding involves a multi-faceted approach. Firstly, meticulous machine setup and calibration are paramount. This includes carefully aligning the workpieces, ensuring correct wheel dressing, and setting up the optimal grinding parameters (speed and feed).

Secondly, consistent work holding is critical. I use appropriate fixtures to ensure the workpiece is securely and consistently held during the grinding process. Thirdly, regular maintenance of the machine and tools is essential. This includes cleaning, lubricating, and inspecting the machine parts and replacing worn components as needed. Finally, continuous monitoring and adjustment are key to maintaining accuracy. During the grinding process, I regularly monitor the dimensions and surface finish of the workpiece, making adjustments to maintain consistency.

Statistical Process Control (SPC) techniques are also used to monitor and control the process. Tracking key parameters like dimensions, surface roughness, and wheel wear allows for early detection of deviations from target values, leading to timely interventions and process adjustments.

Q 28. Describe your experience working with different types of work holding devices (e.g., chucks, collets).

My experience with work holding devices is extensive, ranging from simple collets and chucks to more complex fixtures designed for specific applications. Collets are ideal for holding cylindrical parts of uniform diameter, offering excellent concentricity and repeatability. I’ve often used them when grinding small, precision parts. Chucks provide more versatility, allowing me to hold parts of varying diameters and shapes.

For more intricate or complex shapes, I’ve designed and utilized custom fixtures to maintain the required accuracy and stability during the grinding process. One project involved grinding a series of intricate camshafts. We designed a custom fixture that enabled us to accurately position and secure each camshaft, guaranteeing consistent results across the entire batch. The selection of the work holding device is always dependent on the part geometry, material, and the desired accuracy and repeatability of the grinding operation. Careful consideration is given to avoid workpiece deformation and damage during clamping.

Key Topics to Learn for Cylindrical Grinder Operation Interviews

- Machine Setup and Operation: Understanding the different types of cylindrical grinders (centerless, center-type, etc.), proper workpiece mounting, wheel selection and dressing, coolant application, and safe operating procedures.

- Grinding Parameters and Processes: Knowledge of infeed rate, crossfeed rate, speed, depth of cut, and their impact on surface finish, accuracy, and workpiece integrity. Understanding various grinding processes like plunge grinding, traverse grinding, and cylindrical internal grinding.

- Measurement and Quality Control: Proficiency in using measuring instruments (micrometers, calipers, dial indicators) to ensure dimensional accuracy and surface finish quality. Understanding tolerance specifications and quality control procedures.

- Troubleshooting and Maintenance: Identifying and resolving common issues such as wheel wear, chatter, workpiece deflection, and understanding preventative maintenance procedures for optimal machine performance and longevity.

- Safety Procedures: Comprehensive understanding and adherence to all safety regulations related to operating cylindrical grinders, including proper use of personal protective equipment (PPE).

- Material Science Basics: Fundamental knowledge of different workpiece materials (steel, aluminum, etc.) and their machinability characteristics, relating this to appropriate grinding strategies.

- CNC Programming (if applicable): If the role involves CNC cylindrical grinders, familiarity with CNC programming, G-code, and machine control systems is crucial.

Next Steps

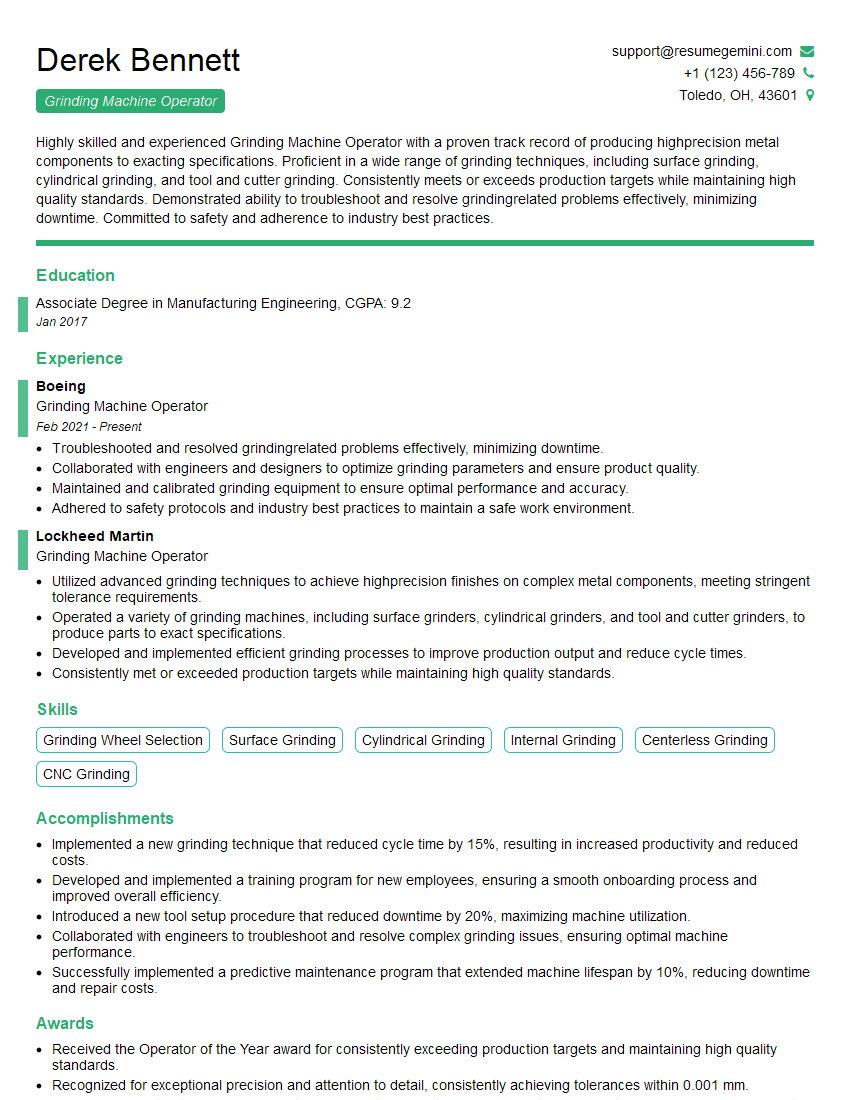

Mastering cylindrical grinder operation opens doors to rewarding careers in manufacturing, offering opportunities for specialized skill development and advancement. To maximize your job prospects, it’s essential to create a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you craft a compelling resume tailored to the specific requirements of cylindrical grinder operator positions. Examples of resumes optimized for these roles are available through ResumeGemini, providing valuable templates and guidance to help you stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO