Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Use quality control procedures interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Use quality control procedures Interview

Q 1. Describe your experience implementing a quality control system.

Implementing a quality control system involves a systematic approach to ensure products or services meet predefined standards. In my previous role at Acme Manufacturing, we overhauled our quality control process. This involved first defining clear quality metrics for our key products – in our case, widget dimensions and functionality. We then implemented a multi-stage inspection process, including in-process checks at various manufacturing stages and final inspection before shipment. We utilized statistical process control (SPC) charts to monitor key parameters and identify trends. Crucially, we also established a robust system for documenting findings, corrective actions, and preventative measures, all tracked via a centralized database. This system drastically reduced our defect rate by 25% within six months, improving customer satisfaction and reducing waste.

Q 2. Explain the different types of quality control charts and when to use each.

Several types of quality control charts exist, each designed for a specific purpose.

- Control Charts for Variables: These charts track continuous data, such as weight, length, or temperature. Common types include:

- X-bar and R charts: Monitor the average (X-bar) and range (R) of a sample. Useful for identifying shifts in the average or variability of a process.

- X-bar and s charts: Similar to X-bar and R, but use the standard deviation (s) instead of the range. Better for larger sample sizes.

- Control Charts for Attributes: These charts track discrete data, such as the number of defects or the percentage of non-conforming units. Examples include:

- p-charts: Track the proportion of defective units in a sample. Ideal for monitoring the percentage of defects in a large batch.

- c-charts: Track the number of defects per unit. Useful when the number of defects per unit is important.

- u-charts: Similar to c-charts, but track the average number of defects per unit. Ideal when the number of units varies.

The choice of chart depends on the type of data being collected and the specific quality characteristic being monitored. For instance, if we were tracking the weight of a product, we’d use an X-bar and R chart; if we were tracking the number of scratches on a surface, we’d use a c-chart.

Q 3. How do you identify and analyze root causes of quality issues?

Identifying root causes of quality issues requires a systematic approach. I typically use the 5 Whys technique and fishbone diagrams (Ishikawa diagrams). The 5 Whys involves repeatedly asking “Why?” to drill down to the root cause. For example, if a product is defective, we might ask: Why is it defective? (Faulty component). Why was the faulty component used? (Supplier issue). Why did we use this supplier? (Lower cost). Why did we prioritize cost over quality? (Pressure to meet budget). The fishbone diagram visually organizes potential causes, categorized into categories like manpower, machinery, materials, methods, measurement, and environment. This helps to identify contributing factors and prioritize corrective actions.

Beyond these, tools like Pareto analysis (identifying the vital few causes) and fault tree analysis (mapping out the failure modes) are also valuable. Data analysis of defect reports and process parameters often reveals recurring patterns pointing to systemic problems.

Q 4. What are some common quality control metrics you use?

Common quality control metrics I use include:

- Defect Rate: The percentage of defective units produced.

- Yield: The percentage of conforming units produced.

- Customer Returns: The number of products returned due to quality issues.

- Process Capability (Cp, Cpk): Measures the ability of a process to meet specifications.

- Mean Time Between Failures (MTBF): Measures the reliability of a product.

- Customer Satisfaction (CSAT): Measures customer perception of quality.

The selection of metrics depends on the specific context and industry. For example, in a manufacturing environment, defect rate and yield are crucial; in a service industry, customer satisfaction might be paramount.

Q 5. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is fundamental to effective quality control. My experience involves using SPC methods to monitor and improve manufacturing processes. This includes using control charts (as described earlier) to detect process shifts and variations. I’ve used SPC to identify assignable causes of variation (special causes) from common causes. For example, identifying a machine malfunction that led to increased product defects was solved through scheduled maintenance. The use of SPC allows for proactive identification of problems before they impact large volumes of production, thus avoiding significant waste and rework. I’m proficient in using software packages to analyze SPC data and generate reports to track process performance over time.

Q 6. How do you ensure compliance with relevant quality standards (e.g., ISO 9001)?

Ensuring compliance with quality standards like ISO 9001 requires a comprehensive approach. This involves establishing a robust Quality Management System (QMS) that conforms to the standard’s requirements. This includes documenting all processes, establishing clear responsibilities, conducting regular internal audits, and maintaining records of corrective and preventative actions. It’s critical to regularly review and update the QMS to reflect changes in the organization and industry best practices. At my previous company, we achieved ISO 9001 certification by implementing a systematic process, starting with gap analysis against ISO 9001 requirements, followed by document creation, training, and implementation of the QMS. We then underwent a third-party audit to verify our compliance, addressing any identified non-conformances before certification.

Q 7. Explain your experience with quality audits and inspections.

I have extensive experience with quality audits and inspections. My role has often involved both conducting and participating in internal and external audits. Internal audits ensure our processes align with our QMS and standards like ISO 9001. External audits are conducted by third-party certification bodies to verify our compliance with these standards. Inspections involve the examination of products or processes to assess conformity to specifications. These inspections can be done at various stages of production, from raw materials to finished goods. I’m adept at developing audit checklists, conducting thorough assessments, and documenting findings. My experience includes identifying root causes of non-conformances and working with teams to implement corrective and preventative actions to prevent recurrence.

Q 8. How do you handle discrepancies or non-conformances found during quality control checks?

When discrepancies or non-conformances arise during quality control checks, my approach is systematic and prioritizes immediate action while minimizing disruption. First, I meticulously document the finding, including precise details such as the location, nature, and extent of the non-conformance. I then use a standardized form for consistency and traceability. This form typically includes fields for date, time, product ID, and a detailed description. A photograph or video is frequently added for visual evidence.

Next, I assess the severity of the non-conformance using a pre-defined risk assessment matrix. This matrix classifies non-conformances based on their potential impact on safety, functionality, and regulatory compliance. This categorization guides the urgency of the corrective action. For minor issues, a simple rework or adjustment might suffice. For critical non-conformances, a thorough investigation is necessary, involving root cause analysis and immediate containment to prevent further defects. All actions are documented and reviewed for efficacy.

For example, if we find inconsistencies in the weight of a packaged product, the immediate action would be to isolate the affected batch. Then, we would launch a root cause analysis, possibly involving equipment calibration checks, review of the weighing process and operator training. Following the investigation, a corrective action, such as recalibration or retraining, will be implemented and verified. A preventative action, such as implementing a more robust automated weighing system, might also be put in place to prevent recurrence.

Q 9. What is your experience with corrective and preventive actions (CAPA)?

Corrective and Preventive Actions (CAPA) are fundamental to continuous improvement in quality control. My experience encompasses the entire CAPA lifecycle, from initial identification of a non-conformance through investigation, root cause analysis, corrective action implementation, verification of effectiveness, and preventive action implementation. I’m proficient in using various root cause analysis tools, such as the 5 Whys, fishbone diagrams (Ishikawa diagrams), and fault tree analysis.

In a previous role, we implemented a CAPA system using a dedicated software platform. This system allowed for centralized tracking of all CAPA activities, providing an auditable record of the process. We utilized a structured approach, clearly defining roles and responsibilities, and setting deadlines for each stage of the CAPA process. Regular reviews of open CAPAs helped maintain focus and ensure timely resolution. For example, we once investigated a spike in customer complaints about product defects. Through a thorough investigation, we uncovered a problem with a newly implemented component supplier. By switching suppliers, we resolved the issue, implemented stricter incoming inspection procedures and added a quality check at the start and end of the production line.

Q 10. Describe your experience with process improvement initiatives related to quality control.

I have extensive experience leading and participating in process improvement initiatives focused on enhancing quality control. My approach combines data-driven analysis with lean manufacturing principles. I’ve successfully implemented Six Sigma methodologies, such as DMAIC (Define, Measure, Analyze, Improve, Control) to systematically identify and eliminate process variations. I am also experienced in using control charts to monitor process stability and identify trends that might indicate potential problems.

In one project, we reduced the defect rate by 40% by implementing a visual management system on the factory floor. This involved implementing clear visual indicators of performance, targets, and potential problems. We also introduced standardized work instructions and improved operator training, leading to a more consistent and efficient production process. This was a collaborative effort, involving cross-functional teams including engineers, operators, and quality control personnel. The outcome was not only a reduction in defects but also a significant improvement in employee morale and engagement.

Q 11. How do you prioritize quality control tasks when faced with competing demands?

Prioritizing quality control tasks involves a multi-faceted approach balancing urgency and impact. I use a risk-based prioritization framework, considering factors such as the potential impact of a failure, the likelihood of failure, and the urgency of the task. Tasks with high impact and high likelihood of failure are prioritized first. I also consider the regulatory requirements and customer expectations, giving precedence to tasks crucial for compliance and customer satisfaction.

For example, if a critical regulatory audit is impending, tasks directly related to audit preparedness would be prioritized. Similarly, if a major customer complaint involves a potential safety hazard, addressing the issue becomes paramount. While I utilize project management tools like Gantt charts to visualize task dependencies, I also keep a flexible approach, adapting priorities as new information arises or unexpected issues occur. Regular communication with stakeholders ensures alignment and transparency.

Q 12. Describe a situation where you had to make a difficult decision related to quality control.

In a previous role, we faced a situation where a significant batch of products showed subtle, yet potentially serious, defects that were only detectable through advanced testing. The initial inclination was to release the batch since the defects were not immediately apparent and the cost of discarding was substantial. However, a thorough investigation, including external expert consultation, raised concerns about long-term safety implications. This presented a difficult choice between immediate financial losses and potential future liabilities.

After careful consideration of all aspects, including regulatory compliance, reputational risks, and ethical considerations, we decided to recall the affected batch. This decision was communicated transparently to all stakeholders, and we proactively launched an extensive investigation to understand the root cause and prevent future recurrences. While financially challenging, the decision was ultimately the correct one as it prioritized ethical conduct and long-term sustainability over short-term profit. This experience reinforced the importance of making principled decisions, even in the face of significant pressure.

Q 13. How do you effectively communicate quality control findings to stakeholders?

Effective communication of quality control findings is crucial for successful collaboration and continuous improvement. I tailor my communication style to suit the audience, using clear, concise language that avoids technical jargon whenever possible. For technical audiences, I use detailed reports and data visualizations. For senior management, I focus on the key findings, impacts, and proposed actions. I use a multi-channel communication strategy, combining regular meetings, email updates, and presentations to ensure transparency and prompt feedback.

For example, when reporting significant findings to executive leadership, I focus on the business impact using key performance indicators (KPIs). I use visuals, like charts and graphs, to highlight trends and patterns. When addressing shop-floor personnel, I focus on practical solutions and how they can contribute to resolving the issue. Open dialogue and active listening are essential in creating a shared understanding and encouraging collaboration.

Q 14. What are your preferred methods for documenting quality control procedures?

My preferred methods for documenting quality control procedures involve a combination of electronic and paper-based systems. Electronic documentation systems, such as a Quality Management System (QMS) software, offer centralized storage, version control, and ease of access. These systems facilitate the creation and revision of Standard Operating Procedures (SOPs), work instructions, and quality records. They also allow for automated reporting and analysis.

However, I also find value in maintaining paper-based records for specific critical processes or those requiring immediate access in less technologically advanced environments. These records are meticulously maintained with clear labeling, versioning, and storage. Regardless of whether a paper or electronic method is used, meticulous detail, accuracy, and traceability are key principles. All documentation adheres to the principles of Good Documentation Practices (GDP), ensuring clarity, completeness, and integrity.

Q 15. What software or tools are you proficient in for quality control management?

My proficiency in quality control software spans a range of tools, each suited for different aspects of the process. For instance, I’m highly experienced with Minitab for statistical process control (SPC), using its capabilities for creating control charts (like X-bar and R charts, p-charts, etc.) to monitor process variation and identify potential issues. I also utilize JMP for more in-depth statistical analysis, including design of experiments (DOE) to optimize processes. For managing quality data and tracking metrics, I’m proficient with Microsoft Excel, employing advanced features like pivot tables and macros for efficient data analysis and reporting. Finally, I have experience using cloud-based solutions such as Jira and Azure DevOps for project management and tracking quality-related tasks and bugs across the product lifecycle.

The choice of software depends heavily on the specific needs of the project and the data involved. For example, a simple process might only need Excel for tracking, while a complex manufacturing process might require Minitab and JMP for detailed statistical analysis and process optimization.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you stay current with evolving quality control best practices?

Staying current in the dynamic field of quality control requires a multi-pronged approach. I actively participate in professional organizations like the American Society for Quality (ASQ), attending webinars and conferences to learn about the latest methodologies and best practices. I also regularly read industry publications like Quality Progress and peer-reviewed journals to stay informed about cutting-edge research and advancements. Furthermore, I participate in online forums and communities dedicated to quality control, engaging in discussions and sharing knowledge with other professionals. Finally, I actively seek opportunities for professional development, such as taking online courses or workshops on emerging techniques in quality management, like AI-driven quality assurance solutions.

This commitment ensures I remain at the forefront of the field, adapting my techniques and knowledge base to meet the evolving needs of the industry.

Q 17. Describe your experience working with cross-functional teams on quality initiatives.

My experience working with cross-functional teams on quality initiatives has been extensive. I’ve consistently found that successful quality improvement requires a collaborative environment where different perspectives are valued and integrated. In one project involving the launch of a new software product, I worked closely with engineers, developers, marketing, and customer support teams. I facilitated workshops to identify key quality attributes, established common metrics for tracking quality, and designed a testing process that integrated feedback from all team members. This collaborative approach allowed us to identify and address potential issues early in the development cycle, resulting in a higher quality product and reduced launch-related problems. A key element of this success was clearly defined roles and responsibilities, ensuring that quality was not siloed but was a shared accountability across the entire team.

Q 18. Explain your understanding of Six Sigma methodologies.

Six Sigma is a data-driven methodology focused on process improvement and minimizing defects. It employs statistical methods to identify and eliminate variations in processes that lead to errors or inefficiencies. The core principles revolve around DMAIC (Define, Measure, Analyze, Improve, Control), a five-phase process that provides a structured approach to problem-solving.

- Define: Clearly define the problem, the project goals, and the scope of work.

- Measure: Collect data to understand the current process performance, identifying key metrics.

- Analyze: Analyze the data to pinpoint the root causes of defects or variations.

- Improve: Implement solutions to address the root causes and improve the process.

- Control: Establish monitoring systems to ensure the improvements are sustained over time.

I have utilized Six Sigma techniques in various projects, such as reducing customer complaints by analyzing call center data to identify areas needing improvement in customer service processes. The application of DMAIC methodologies helped us to pinpoint specific communication failures, implement training programs, and ultimately decrease customer complaints significantly.

Q 19. What is your experience with failure mode and effects analysis (FMEA)?

Failure Mode and Effects Analysis (FMEA) is a systematic approach to identifying potential failure modes in a system or process and assessing their potential effects. It’s a proactive risk assessment tool used to prevent problems before they occur. The process involves creating a table listing potential failure modes, their causes, their effects, severity, occurrence, and detection ratings. A risk priority number (RPN) is calculated (Severity x Occurrence x Detection) to prioritize the failure modes that require the most immediate attention.

In a past project involving the design of a new medical device, we used FMEA to identify potential risks across the entire product lifecycle, from design to manufacturing to usage. This allowed us to proactively address critical issues, minimizing the risks of defects and ensuring patient safety. The FMEA process helped us identify potential hazards, such as malfunctioning sensors, and implement design changes and testing protocols to mitigate these risks.

Q 20. Describe your experience with quality control in a specific industry (mention your industry).

My experience in quality control is primarily within the pharmaceutical industry. Here, quality is paramount due to the critical impact on patient safety and health. I’ve been involved in various aspects of quality assurance, from raw material inspection and testing to finished product quality control and regulatory compliance. I have extensive experience working with Good Manufacturing Practices (GMP) regulations and ensuring adherence to stringent quality standards. For example, I’ve implemented and managed quality systems to ensure compliance with regulatory requirements such as the FDA’s Current Good Manufacturing Practice (cGMP). This involved developing and implementing standard operating procedures (SOPs), conducting audits, and investigating deviations to maintain compliance.

Specifically, I’ve led teams in conducting stability testing to evaluate the quality of products over time, and in managing deviations, conducting root cause analysis, and implementing corrective and preventative actions (CAPA) to prevent future occurrences.

Q 21. How do you balance the speed of production with the maintenance of high quality?

Balancing the speed of production with the maintenance of high quality is a constant challenge, often described as a delicate act of balancing quality and efficiency. The key is to establish a culture that prioritizes both, rather than viewing them as opposing forces. This is achieved through a combination of strategies.

- Proactive Quality Management: Implementing robust quality control measures early in the production process, such as using statistical process control (SPC) and other preventative measures to identify and address potential issues before they lead to major defects.

- Automation and Technology: Leveraging technology such as automated inspection systems and robotic process automation (RPA) to improve efficiency and consistency, freeing up human resources to focus on higher-value tasks.

- Continuous Improvement: Regularly reviewing and improving processes through methods like Kaizen or Lean manufacturing to streamline operations while maintaining quality standards. This includes data-driven analysis to understand bottlenecks and waste.

- Employee Empowerment: Empowering employees to identify and report quality issues, fostering a culture where quality is everyone’s responsibility. This includes training employees on quality control procedures and encouraging them to actively participate in continuous improvement initiatives.

By implementing these strategies, organizations can achieve both high production speeds and high-quality output.

Q 22. Explain your understanding of the PDCA cycle (Plan-Do-Check-Act).

The PDCA cycle, also known as the Deming cycle or Shewhart cycle, is a four-step iterative process for continuous improvement. It’s a cornerstone of quality control, helping organizations systematically identify problems, implement solutions, and track their effectiveness. Think of it as a continuous feedback loop.

- Plan: This involves defining the problem, establishing goals, and developing a plan of action to address the issue. This might include identifying root causes through tools like fishbone diagrams or 5 Whys.

- Do: This is the implementation phase. The plan is executed on a small scale, perhaps as a pilot program, to test its feasibility and effectiveness.

- Check: Here, you analyze the results of the implemented plan. Data is collected and compared to the original goals. This often involves using control charts or other statistical methods to monitor performance.

- Act: Based on the ‘Check’ phase, you decide whether to standardize the improvement, abandon it, or revise and repeat the cycle. This might involve documenting the changes made, training staff, or implementing new procedures.

Example: Imagine a manufacturing plant experiencing a high defect rate in a particular product. The PDCA cycle would be used to address this. In the ‘Plan’ phase, they might identify the potential root causes through data analysis and brainstorming. ‘Do’ would involve implementing a new process change. ‘Check’ would entail tracking the defect rate after the change. And ‘Act’ would finalize the new process or initiate another PDCA cycle if the defect rate remains high.

Q 23. How do you measure the effectiveness of your quality control efforts?

Measuring the effectiveness of quality control efforts requires a multi-faceted approach. We can’t just rely on one metric; we need a combination to get a holistic view.

- Key Performance Indicators (KPIs): These are quantifiable measures directly related to quality. Examples include defect rates, customer complaints, process yield, cycle time, and customer satisfaction scores. We’d set targets for these KPIs and track progress regularly.

- Audits and Inspections: Regular audits of processes and products are crucial to identify potential issues before they become major problems. These can range from simple visual inspections to more thorough audits using checklists and standardized procedures.

- Customer Feedback: Directly gathering feedback from customers through surveys, focus groups, or reviews is vital. This offers invaluable insights into the effectiveness of quality control measures from the end-user perspective.

- Continuous Improvement Projects: Tracking the success of improvement projects initiated as a result of quality control efforts is another key indicator. Documenting the cost savings or efficiency gains achieved provides tangible evidence of effectiveness.

Example: If we aim to reduce customer complaints by 20%, we’d track the number of complaints before and after implementing new quality control procedures. A reduction below the target would indicate a successful implementation and a strong QC system.

Q 24. Describe your experience in developing and implementing quality control training programs.

I have extensive experience in designing and delivering quality control training programs. My approach focuses on a blend of theoretical knowledge and practical application, ensuring trainees develop both understanding and skill.

- Needs Assessment: I begin by analyzing the specific needs of the target audience. This includes identifying knowledge gaps, skill deficiencies, and the unique challenges faced in their roles.

- Curriculum Development: Based on the needs assessment, I develop a customized curriculum. This typically includes modules covering relevant quality standards (like ISO 9001), statistical process control (SPC), root cause analysis, and problem-solving techniques.

- Training Delivery: I employ a variety of instructional methods to cater to different learning styles, including lectures, group discussions, case studies, hands-on exercises, and role-playing simulations. I leverage visual aids, interactive tools, and real-world examples to make the training engaging and relevant.

- Assessment and Feedback: The effectiveness of the training is evaluated through quizzes, tests, practical assessments, and post-training surveys. Constructive feedback is provided to trainees to reinforce learning and encourage continuous improvement.

Example: In a previous role, I developed a training program for production line workers focusing on SPC. The program included interactive modules on control charts, process capability analysis, and the interpretation of data, leading to a significant reduction in defects and improved process efficiency.

Q 25. How do you handle pressure and tight deadlines in a quality control role?

Handling pressure and tight deadlines in quality control is a crucial skill. My approach centers around prioritization, efficient resource allocation, and proactive communication.

- Prioritization: I assess tasks based on their criticality and urgency, ensuring that the most important quality control checks are performed first. This involves utilizing tools like Eisenhower Matrix (Urgent/Important).

- Efficient Resource Allocation: I effectively delegate tasks where appropriate, leveraging the skills of my team to ensure workload balance and timely completion. This also involves identifying and optimizing workflows to enhance efficiency.

- Proactive Communication: I keep stakeholders informed of progress, potential delays, and any risks to quality. Open communication prevents misunderstandings and allows for timely adjustments to plans.

- Problem-Solving: I utilize data-driven problem-solving techniques to quickly identify and address bottlenecks, enabling us to stay on track despite time constraints.

Example: Faced with a tight deadline for product launch, I prioritized critical quality checks, delegated less critical tasks, and communicated transparently with the development team, leading to a successful on-time launch without compromising product quality.

Q 26. What are your salary expectations for this quality control position?

My salary expectations are in line with the market rate for a quality control professional with my experience and skills in this region. I’m open to discussing this further once I have a better understanding of the full scope of the role and the company’s compensation package.

Q 27. What are your long-term career goals related to quality control?

My long-term career goals involve becoming a recognized leader in the quality control field. I aspire to take on increasing responsibility, potentially leading quality control teams or departments. I’m particularly interested in developing and implementing innovative quality management systems and contributing to the development of industry best practices. My goal is to continually refine my skills and expertise, consistently delivering exceptional results and driving organizational success through superior quality control.

Q 28. Why are you interested in this specific quality control position?

I’m highly interested in this specific quality control position due to several factors. Firstly, [Company Name]’s reputation for excellence and commitment to quality aligns perfectly with my own professional values. Secondly, the opportunity to work on [mention specific projects or aspects of the role that interest you] is incredibly appealing. Finally, the collaborative team environment and the opportunity for professional growth within the organization are highly attractive prospects.

Key Topics to Learn for Use Quality Control Procedures Interview

- Understanding Quality Standards: Learn about various quality standards (e.g., ISO 9001, Six Sigma) and their practical implementation in different industries. Understand the importance of defining clear quality metrics and objectives.

- Quality Control Methodologies: Explore different quality control methodologies such as Statistical Process Control (SPC), Total Quality Management (TQM), and root cause analysis. Be prepared to discuss your experience with these methods or your understanding of their application.

- Inspection and Testing Procedures: Familiarize yourself with various inspection and testing methods used to ensure product or service quality. This includes understanding different sampling techniques and the interpretation of test results.

- Data Analysis and Interpretation: Master the skills needed to analyze quality control data, identify trends, and draw meaningful conclusions. Practice interpreting control charts and other statistical tools.

- Corrective and Preventive Actions (CAPA): Understand the process of identifying and resolving quality issues. Learn how to implement effective CAPA plans to prevent future occurrences.

- Documentation and Record Keeping: Discuss the importance of maintaining accurate and complete quality control records. This includes understanding various documentation practices and regulatory requirements.

- Continuous Improvement: Demonstrate your understanding of continuous improvement principles and how they relate to quality control. Be ready to discuss examples of how you’ve contributed to improving quality processes in the past.

- Problem-Solving Approaches: Practice applying problem-solving methodologies like the 5 Whys or fishbone diagrams to analyze quality issues and develop effective solutions. Be prepared to discuss your problem-solving approach in a practical scenario.

Next Steps

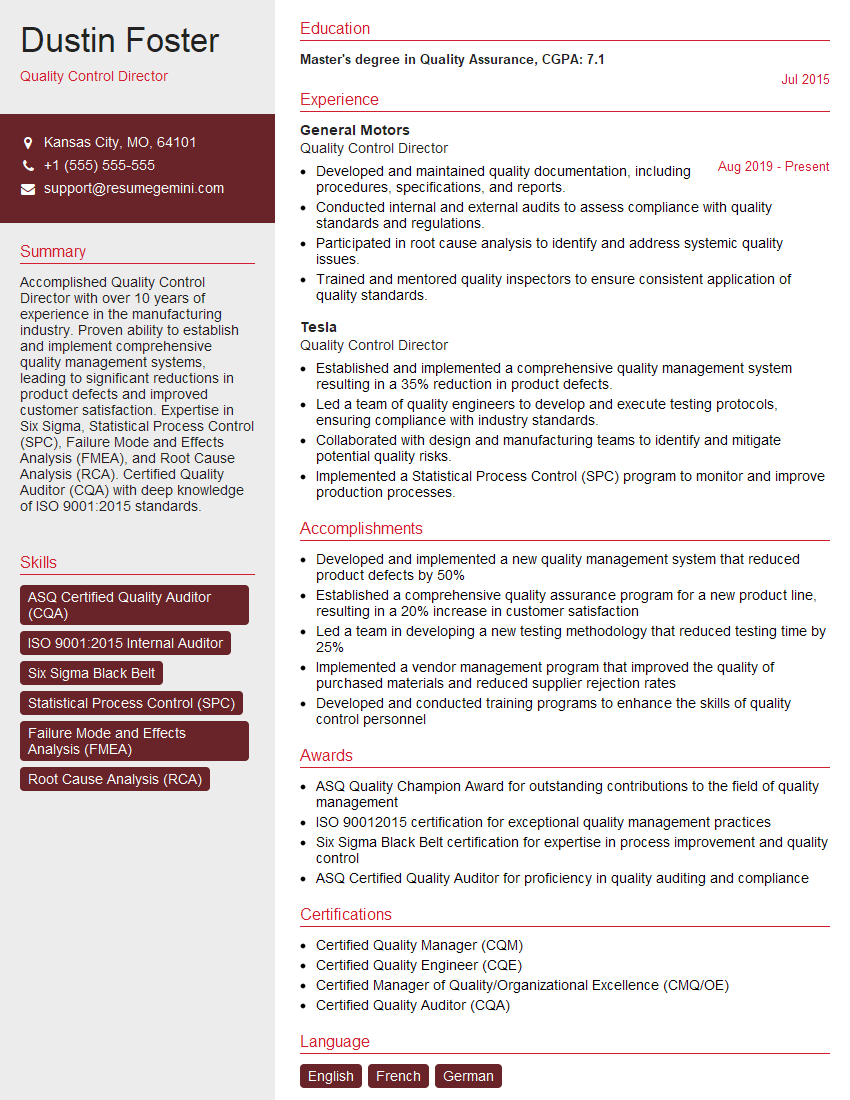

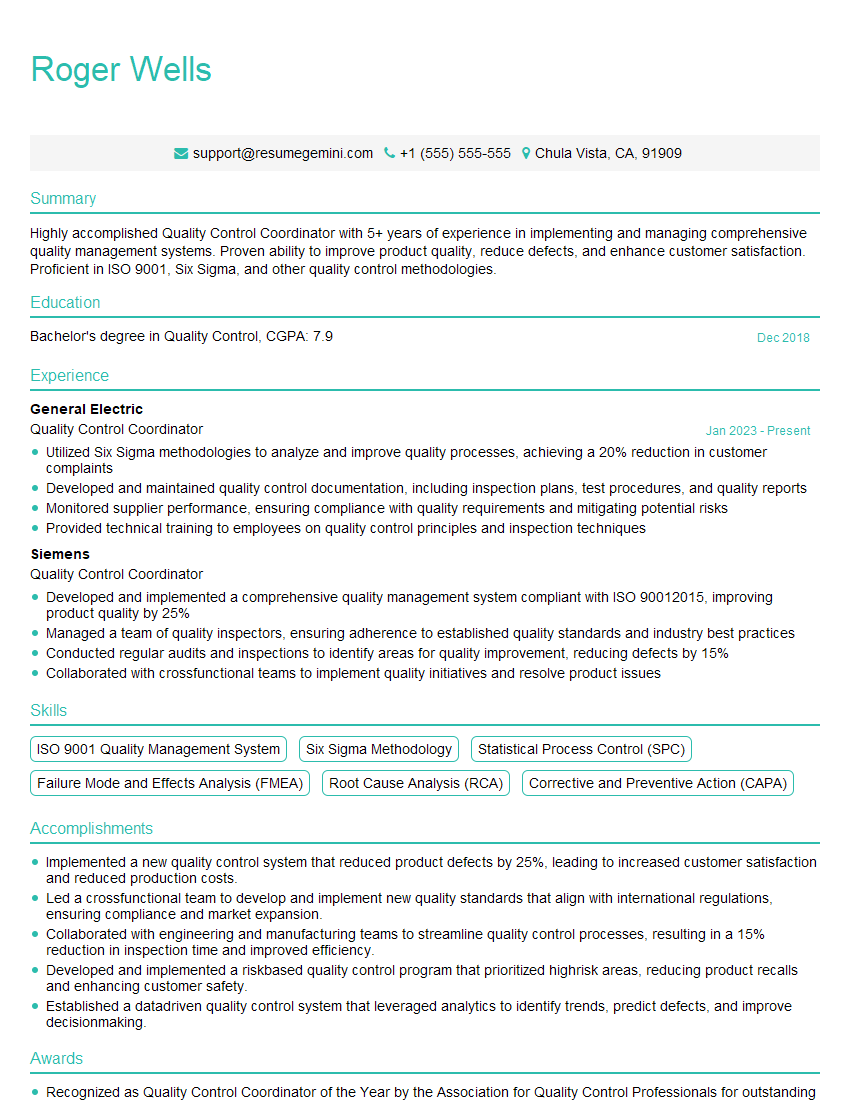

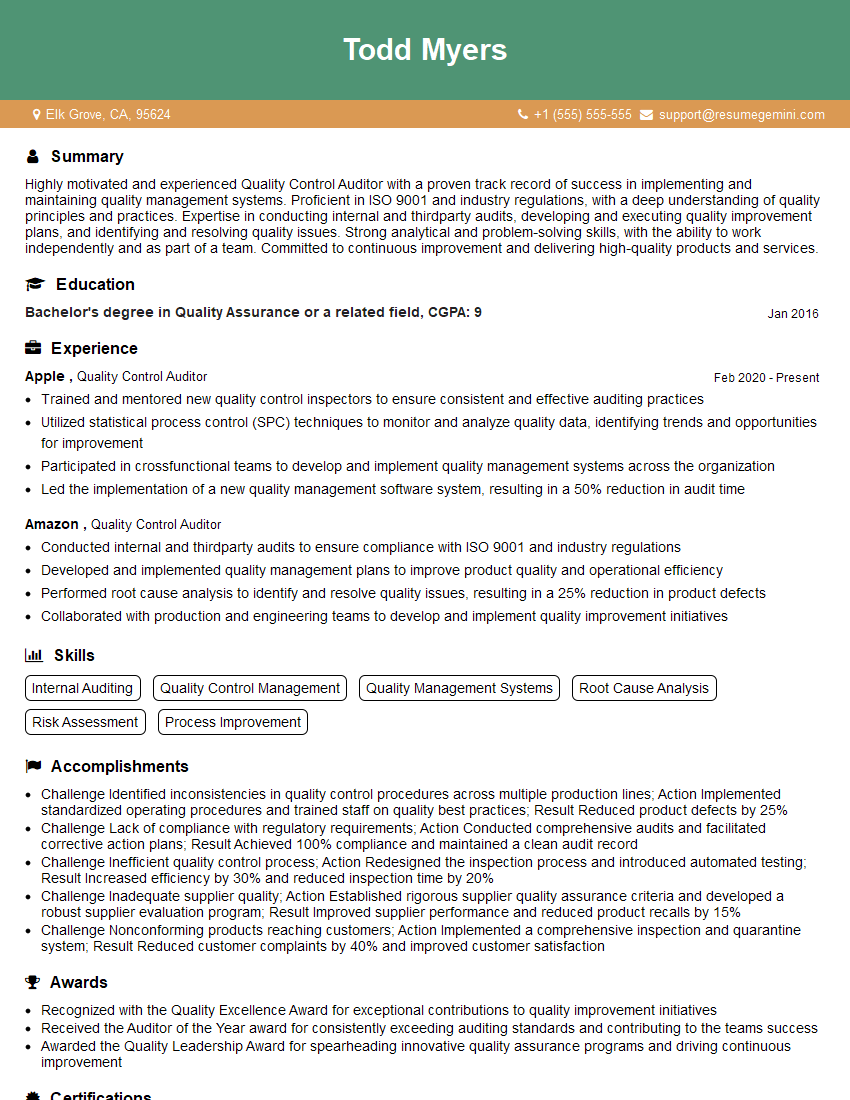

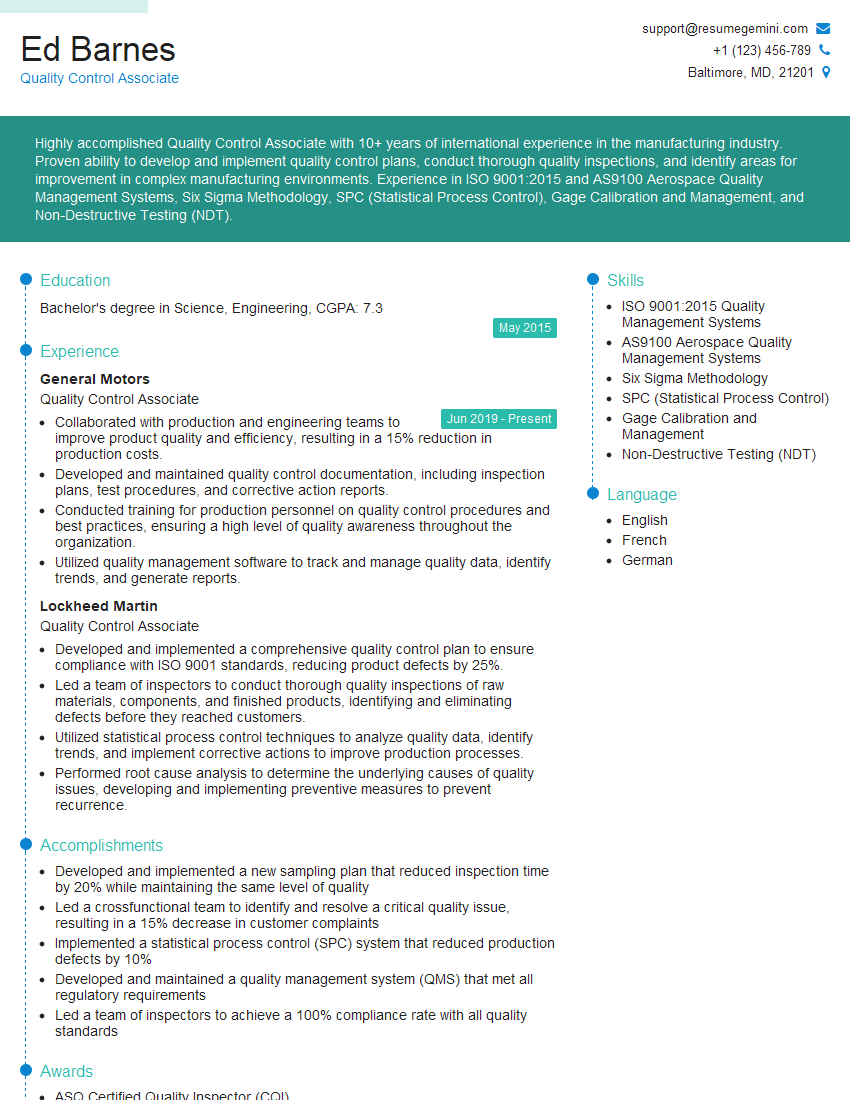

Mastering quality control procedures is crucial for career advancement in many industries. A strong understanding of these principles demonstrates your commitment to excellence and your ability to contribute to efficient and effective operations. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience in this area. ResumeGemini is a trusted resource to help you build a professional resume that showcases your qualifications effectively. Examples of resumes tailored to quality control procedures are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO