The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Using Measuring Tools interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Using Measuring Tools Interview

Q 1. What are the different types of calipers and their applications?

Calipers are precision instruments used for measuring the dimensions of objects. Several types exist, each suited to different applications.

- Vernier Calipers: These are widely used for measuring both internal and external dimensions, depths, and steps. They offer relatively high accuracy (typically to 0.01mm or 0.001 inches). Imagine measuring the diameter of a cylindrical component for a machine – vernier calipers are perfect for that.

- Digital Calipers: These operate similarly to vernier calipers but provide a digital readout, eliminating the need for interpretation of the vernier scale. This improves speed and reduces the risk of human error. Think of a quality control inspection on a manufacturing line – digital calipers streamline the process.

- Inside Calipers: These are specifically designed for measuring internal dimensions, such as the diameter of a hole. Their design ensures accurate measurement of concave surfaces. An example is checking the inside diameter of a pipe before installing a fitting.

- Outside Calipers: As the name suggests, these measure external dimensions. They’re simple yet effective for quick measurements of objects with regular shapes. Consider quickly checking the width of a block of wood before cutting.

The choice of caliper depends heavily on the required accuracy, the type of measurement, and the specific application. For instance, a digital caliper might be preferred for mass production quality control due to its speed, while a vernier caliper might suffice for less critical measurements.

Q 2. Explain the principle of operation of a micrometer.

A micrometer, or micrometer caliper, works on the principle of precise screw threads. A precisely machined screw with a known pitch (distance between threads) is rotated to move a spindle against the object being measured.

The distance the screw moves is directly proportional to the number of rotations. A thimble, graduated in smaller units than the main barrel, allows for highly accurate readings. Imagine the screw as a very fine measuring tape, rolled up tightly. Each rotation advances the spindle a specific amount; then the thimble lets you finely adjust the measurement to fractions of a rotation. The combination of the barrel and thimble readings gives the total measurement.

Example: A micrometer with a 0.5mm pitch, with the barrel reading 5mm and the thimble reading 0.25mm, would indicate a total measurement of 5.25mm.This simple yet precise mechanism allows for measurements accurate to hundredths or even thousandths of a millimeter, far beyond the capabilities of ordinary rulers or calipers.

Q 3. How do you ensure accurate readings when using a dial indicator?

Accurate readings from a dial indicator require careful attention to detail and technique.

- Proper Mounting: Ensure the dial indicator is securely mounted to a stable base and aligned correctly with the object being measured. Any wobble or movement will introduce error.

- Zeroing: Always zero the dial indicator before each measurement against a known reference point. This sets the baseline for comparison.

- Consistent Contact Force: Apply a consistent, light pressure to avoid deflection of the indicator or the object being measured. Too much pressure can distort the readings.

- Avoid Parallax Error: Observe the indicator needle from directly in front to prevent misreading due to parallax (apparent shift in position due to viewing angle).

- Environmental Conditions: Be aware of temperature fluctuations, which can affect the indicator’s accuracy. Calibration might be needed if conditions are far outside the operating range.

A simple analogy: Imagine measuring the height of a plant with a ruler. If the ruler isn’t straight or you don’t look directly at the plant’s top, your measurement will be inaccurate. Similar care is needed with a dial indicator to ensure consistent, accurate results.

Q 4. Describe the process of calibrating a measuring instrument.

Calibrating a measuring instrument involves comparing its readings to a known standard of higher accuracy. The process varies depending on the instrument but typically involves the following steps:

- Gather Equipment: You’ll need the instrument to be calibrated, a standard (e.g., a calibrated gauge block for calipers), and any necessary accessories (e.g., a micrometer).

- Prepare the Instrument: Clean the instrument thoroughly to remove any debris that might affect the measurement.

- Compare Readings: Take several measurements using both the instrument to be calibrated and the known standard. Make sure to record each reading precisely.

- Analyze Differences: Compare the readings of the instrument being calibrated against those of the standard. Calculate the difference and determine if it falls within acceptable tolerances.

- Adjust (if Necessary): If the differences are outside of acceptable tolerances, the instrument may need to be adjusted by a qualified technician. Some instruments might allow for minor adjustments through calibration screws.

- Document: Maintain a record of the calibration procedure, including dates, readings, and any adjustments made.

Calibration ensures accuracy and traceability of measurement throughout the production or process.

Q 5. What are common sources of measurement error?

Measurement errors can creep in from numerous sources. Here are some common culprits:

- Instrument Error: Wear, damage, or improper calibration of the measuring instrument itself. For example, a worn-out caliper might produce consistently inaccurate measurements.

- Environmental Factors: Temperature changes, humidity, vibration, or even magnetic fields can influence readings. Imagine using a steel measuring tape in a hot environment; thermal expansion will cause errors.

- Operator Error: Parallax error, improper handling, inconsistent application of force, or misreading scales. Human error is often a major source of inaccuracy.

- Method Error: Faulty measurement techniques or improper setup of the equipment can lead to systematic errors. For instance, using a worn-out measuring surface to check dimensions.

- Tool Wear: The tips or jaws of calipers or micrometers can become worn or damaged over time, introducing bias in measurements.

Understanding these sources helps you take proactive steps to minimize their impact.

Q 6. How do you handle measurement uncertainties?

Measurement uncertainties are inevitable. To handle them effectively:

- Repeat Measurements: Taking multiple readings and calculating an average helps reduce random errors. This is particularly important when human error might be a factor.

- Statistical Analysis: Employ statistical methods (e.g., standard deviation) to quantify uncertainty and estimate confidence intervals. This provides a clearer picture of the reliability of the data.

- Calibration and Maintenance: Regular calibration and proper maintenance of measuring instruments are crucial in reducing systematic errors.

- Error Propagation: Consider how uncertainties in individual measurements might propagate through calculations and affect the final result. This is vital when a measurement feeds into a more complex calculation.

- Uncertainty Budget: Create an uncertainty budget that identifies all potential sources of error and estimates their contribution to the overall uncertainty.

By carefully accounting for uncertainties, we can provide a more realistic assessment of the reliability and precision of our measurements.

Q 7. Explain the difference between accuracy and precision.

Accuracy and precision are often confused, but they represent distinct concepts related to measurement quality.

Accuracy refers to how close a measurement is to the true value. Think of it like hitting the bullseye on a dartboard. A highly accurate measurement has minimal systematic error.

Precision refers to how close repeated measurements are to each other. It’s about the reproducibility of the measurement. Think of this as how tightly clustered your darts are on the board. High precision implies low random error.

It’s possible to be precise but inaccurate (all darts clustered in one area, but far from the bullseye), or accurate but imprecise (darts scattered around the bullseye). Ideally, measurements should be both accurate and precise. This means consistently getting close to the true value.

Q 8. What are the limitations of different measuring tools?

Every measuring tool has inherent limitations. Accuracy is always a key consideration, and this is affected by factors like the tool’s resolution (the smallest increment it can measure), its material and construction (leading to potential warping or wear), and the skill of the user. For example, a ruler might only be accurate to the nearest millimeter, making it unsuitable for precise micro-measurements. A digital caliper, while more precise, can be affected by battery life or calibration errors. Tape measures can stretch or kink, leading to inaccurate readings. The environment also plays a role – temperature fluctuations can affect the length of some measuring tools.

- Resolution Limitations: A simple ruler’s limited resolution is a prime example. You can’t measure a fraction of a millimeter with it.

- Material Limitations: Wooden rulers can warp over time due to changes in humidity. Steel tape measures can be affected by corrosion.

- User Error: Parallax error, where the measurement is read from an angle, is a common limitation affecting many tools. Incorrect zeroing of digital tools is another.

Q 9. How do you select the appropriate measuring tool for a specific task?

Selecting the right measuring tool is crucial for obtaining accurate and reliable results. The process starts by understanding the task. Consider the required precision, the size and shape of the object being measured, and the material the object is made from.

- Precision: If you need very precise measurements (e.g., for machining a part), you’ll use a micrometer or digital caliper. For less precise tasks like measuring a room, a tape measure suffices.

- Size and Shape: A flexible tape measure is ideal for curved surfaces, while a rigid ruler is better for straight lines. For measuring the internal diameter of a pipe, a special internal caliper is needed.

- Material: The material of the object being measured may influence the choice. Measuring hot metal requires a non-contact measuring tool like a laser distance meter to prevent burns.

For instance, when building a bookshelf, I would use a tape measure for overall dimensions and a level to ensure shelves are straight and parallel. For woodworking, I might employ a combination square to check angles and a caliper for precise measurements of joinery.

Q 10. How do you interpret measurement data?

Interpreting measurement data involves more than just reading the numbers. It requires understanding the units, the tool’s precision, and potential sources of error. Always double-check measurements to minimise errors. Look for consistency in your readings and consider potential sources of error like parallax or tool calibration.

For example, if a measurement reads 10.5 cm using a ruler with 1 mm resolution, it means the actual length lies somewhere between 10.45 cm and 10.55 cm. Understanding the inherent uncertainty is key to proper data interpretation. Documenting your measurements, including the tool used and any observations about potential errors, is important for reproducibility and traceability.

Q 11. Describe your experience using different types of measuring tapes.

My experience with measuring tapes spans various types, each with its own strengths and weaknesses. I’ve extensively used standard retractable steel tape measures for construction and general measurements. Their durability and relatively low cost make them ideal for many tasks. I’ve also worked with fiberglass tape measures, which are lighter and less prone to kinking than steel tapes, making them handy for overhead work. Finally, I’ve used specialized tape measures with features like locking mechanisms, improved ergonomics, and even digital readouts. The digital ones are more expensive but significantly speed up the measurement process and reduce human errors, particularly when recording large amounts of data.

I’ve learned to handle each type with care, ensuring the tape is retracted smoothly to avoid damage or jamming, especially with the retractable steel ones. With fiberglass tapes, being mindful of avoiding sharp edges is key to avoid fraying the end. Properly zeroing digital models before each use and regularly checking their calibration is essential for accuracy.

Q 12. How do you measure angles accurately?

Accurately measuring angles depends on the precision required and the type of angle. For simple angles, a protractor is usually sufficient. For more precise measurements or in complex scenarios, a digital inclinometer or angle finder is often preferred. These provide readings in degrees and sometimes even in gradients or radians.

When using a protractor, ensure the baseline of the protractor is aligned precisely with one side of the angle. Then, read the angle where the other side of the angle intersects the protractor’s arc. Avoiding parallax errors by viewing the intersection point directly overhead is essential. In construction, a speed square or combination square is frequently used to check and create angles accurately.

Q 13. What are the safety precautions when using measuring tools?

Safety when using measuring tools is paramount. Sharp edges on rulers or calipers can cause cuts. Retractable tape measures can pinch fingers if not handled carefully. Laser measuring devices should not be pointed at eyes. Always wear appropriate safety glasses or eye protection, especially when working with sharp tools or lasers.

- Sharp edges: Handle tools carefully to avoid cuts.

- Retracting tapes: Avoid sudden retractions to prevent finger injuries.

- Laser safety: Never point laser measuring devices at eyes or skin.

- Working at Heights: Use appropriate fall protection when measuring at heights.

- Electrical Safety: Never use measuring tools near exposed electrical wires or equipment.

In my experience, maintaining situational awareness and a focused approach significantly reduces risks. I always inspect tools before use and ensure they are in good working condition.

Q 14. How do you maintain and care for measuring instruments?

Proper maintenance is crucial for prolonging the life and ensuring the accuracy of measuring instruments. Cleaning is important. For example, wiping down steel tape measures with a cloth to remove dirt and debris prevents corrosion. Regularly checking for damage, such as bends, cracks, or loose parts, is essential. For digital tools, checking and replacing batteries when needed and periodically calibrating against a known standard are key to accuracy.

- Cleaning: Regularly clean the tools to remove dirt and debris.

- Storage: Store tools in a dry and safe place to prevent damage and corrosion.

- Calibration: Periodically calibrate digital tools and check for accuracy.

- Inspection: Regularly inspect for damage and wear and tear.

For instance, I regularly oil the moving parts of my calipers to ensure smooth operation. I store my tape measures in a protective case to keep them from being bent or damaged.

Q 15. Describe your experience with laser measurement devices.

My experience with laser measurement devices spans several years and diverse applications. I’ve extensively used laser distance meters (LDMs) for tasks ranging from precise room dimensioning in construction projects to accurate distance measurements in surveying. I’m proficient in operating various models, understanding their limitations, and interpreting the data they provide. For instance, I’ve used LDMs with different accuracy levels, selecting the appropriate device based on the project’s requirements. In one project, the extremely high precision of a Leica Disto required for precise architectural modelling, was critical to the project’s success. Understanding the impact of environmental factors, such as temperature and reflectivity of the target surface, on the accuracy of laser measurements is crucial, and I have practical experience mitigating these potential sources of error. I’m also familiar with laser scanners, understanding their applications in creating 3D models of large-scale structures, something which I’ve used to great effect when mapping out the interior of a large warehouse for optimal space utilization.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of tolerance and its importance in measurement.

Tolerance in measurement represents the permissible variation from a specified dimension or value. Think of it like a target: the bullseye is the ideal measurement, and the tolerance defines the acceptable range around the bullseye where the actual measurement can fall without being considered faulty. Its importance stems from ensuring that components or products meet the required specifications for proper functioning and interchangeability. For example, if you’re manufacturing a bolt that needs to fit precisely into a nut, both the bolt and nut dimensions will have a tolerance range. If the actual dimensions fall outside this tolerance, the bolt might not fit correctly, leading to malfunction. Tolerance is specified using plus/minus values. For example, a dimension of 10mm ± 0.1mm means the acceptable range is 9.9mm to 10.1mm. Ignoring tolerance can result in costly errors and production issues, therefore, it’s paramount in any precision-based manufacturing or engineering discipline.

Q 17. How do you deal with a malfunctioning measuring tool?

My approach to a malfunctioning measuring tool is systematic and prioritizes safety. First, I’d identify the specific problem: is it displaying incorrect readings, not powering on, or showing other signs of malfunction? Then, I’d check for obvious issues: is the battery dead or incorrectly installed? Is the measuring tool dirty or damaged? I’d consult the manufacturer’s instructions for troubleshooting steps and calibration procedures. For digital instruments, I’d check if there’s a self-diagnostic function. If the problem persists, I would attempt to recalibrate the instrument following established procedures, always referring to the manufacturer’s guidelines to avoid damaging the instrument or obtaining inaccurate data. If the tool remains unserviceable, I’d report the fault, and if possible, replace it with a verified and calibrated tool to ensure accuracy and avoid delays in my workflow. Safety is a primary concern – I would never use a malfunctioning instrument that could compromise accuracy or safety.

Q 18. What are the different units of measurement and their conversions?

The most common units of measurement are based on the International System of Units (SI). These include:

- Length: Meter (m), centimeter (cm), millimeter (mm), kilometer (km), inch (in), foot (ft)

- Mass: Kilogram (kg), gram (g), pound (lb), ounce (oz)

- Volume: Cubic meter (m³), liter (L), gallon (gal)

Conversions between these units are essential. For example: 1 meter = 100 centimeters = 1000 millimeters; 1 inch = 25.4 millimeters; 1 kilogram = 1000 grams. I’m highly proficient in performing these conversions quickly and accurately, using both mental calculations and conversion tools when necessary. Many measuring devices offer the ability to change units of measurement, streamlining the workflow. Accurate unit conversions are pivotal to preventing errors and ensuring the reliability of project data.

Q 19. Describe your experience with digital measuring devices.

I have extensive experience using a wide range of digital measuring devices, including digital calipers, micrometers, and multi-meters. I’m comfortable interpreting digital readouts, understanding their resolution and accuracy limitations, and using their various functionalities, such as zeroing, data logging, and different measurement modes. For example, I’ve used digital calipers to measure the dimensions of small components with high precision, and digital multimeters to verify the voltage and current in various circuits. Digital measuring devices offer advantages such as increased speed, improved readability, and often the ability to store measured data for later analysis. However, I also know that their accuracy is dependent on proper calibration and maintenance. I regularly check the calibration of these instruments to ensure consistent and reliable measurements. Understanding the error margins of each device is critical to obtaining meaningful results. In one project, this involved meticulous calibration of a digital micrometer, ensuring consistency and repeatability of measurements when producing tiny components in a precision setting.

Q 20. How do you ensure the traceability of your measurements?

Traceability of measurements ensures that the results can be linked back to internationally recognized standards. This is critical for verifying accuracy and reliability. I achieve this by using calibrated instruments that have traceable certificates linking them to national or international standards organizations. Regular calibration at accredited laboratories is essential. Calibration certificates provide documented evidence of the instrument’s accuracy at a specific point in time. Furthermore, meticulous record-keeping of all measurements, including the instrument used, date, time, and environmental conditions, is crucial. This comprehensive documentation forms an audit trail, supporting the traceability and reliability of my measurements. Any deviations from standard procedures are carefully documented, explaining the rationale behind them. In short, I ensure my measurements can be verified and validated through this comprehensive system of calibration, records, and documentation.

Q 21. Explain the significance of proper measurement techniques.

Proper measurement techniques are paramount for obtaining accurate and reliable results. Incorrect techniques can lead to significant errors. These techniques include:

- Selecting the right tool: Using a caliper to measure a large object is impractical; the right tool for the job ensures accuracy.

- Proper handling and positioning: Avoiding parallax errors (errors due to incorrect eye position) is crucial. For instance, when using a ruler, ensuring your eye is directly above the measurement point minimizes error.

- Environmental considerations: Temperature and humidity can affect measurements, especially with precision instruments. Controlling these factors ensures accuracy.

- Calibration: Regular calibration guarantees the instrument’s accuracy. Uncalibrated instruments lead to inaccurate and unreliable measurements.

In a real-world example, I once had to measure the precise diameter of a cylindrical part for an aerospace application. Using a micrometer with proper technique, ensuring it was calibrated and paying attention to parallax error, I obtained reliable and precise measurements vital for the component’s correct functioning. Ignoring any of these steps could have resulted in serious consequences.

Q 22. Describe your experience with statistical process control (SPC) in relation to measurement.

Statistical Process Control (SPC) is crucial for ensuring consistent and reliable measurements. It involves using statistical methods to monitor and control a process, identifying variations and preventing defects. In the context of measurement, SPC helps us understand the inherent variability in our measuring tools and the processes they are used in. This allows us to determine if our measurements are truly reflecting the actual values or if there’s an underlying issue affecting accuracy and precision.

For example, I’ve used control charts, like X-bar and R charts, extensively. These charts plot the average and range of measurements taken over time. By analyzing the data plotted on these charts, we can identify trends, shifts, or outliers that indicate potential problems with the measuring instrument itself, the measurement process, or the material being measured. If a data point falls outside the control limits, it flags a potential issue that requires investigation. This proactive approach prevents errors from propagating through the manufacturing process or research study.

Another example is using capability analysis to assess whether a measuring instrument is capable of meeting the required specifications. This helps to determine if the tool’s variability is within acceptable limits for the application.

Q 23. How do you document your measurements?

Thorough documentation is paramount for traceability and repeatability. I typically use a combination of methods to document my measurements. Firstly, I always use a calibrated instrument and record its identification number along with the date of calibration. This ensures that if there are any issues later on, the instrument can be checked for accuracy.

Secondly, I create detailed data sheets for each measurement, recording all relevant information including: the date and time, the instrument used, the specific procedure followed, the measured values, units, and any observations made during the process. I also record environmental conditions like temperature and humidity if they could potentially impact the measurements.

Finally, all data is entered into a digital database or spreadsheet for easy access, analysis, and reporting. This organized approach provides an auditable trail and aids in quality control.

Q 24. What are some common problems encountered when using measuring tools?

Several common problems can arise when using measuring tools. One frequent issue is improper calibration. A tool that hasn’t been calibrated properly can lead to systematic errors, consistently producing inaccurate results. For instance, a micrometer that’s out of calibration might always read a value slightly higher or lower than the actual dimension.

- Operator error: Incorrect handling or reading of the instrument can cause significant measurement inaccuracies. For example, parallax error when reading a scale, or applying incorrect pressure with a caliper.

- Tool wear: Over time, tools can wear down or become damaged, leading to inaccuracies. This is particularly true for tools with mechanical components like calipers or micrometers.

- Environmental factors: Temperature, humidity, and even vibrations can influence the accuracy of certain instruments.

- Poorly defined measurement methods: Vague or ambiguous measurement procedures can lead to inconsistencies in results among different operators.

Q 25. How would you troubleshoot a discrepancy in measurements?

Troubleshooting measurement discrepancies involves a systematic approach. First, I’d carefully review my documentation to ensure that the measurement procedures were followed correctly. This includes checking the calibration status of the instrument, verifying that environmental factors were considered, and comparing my results to those obtained by other reliable measuring methods.

Next, I’d check the measuring instrument itself to look for signs of damage or wear. If the instrument is suspected to be faulty, I’d use a known standard (like a gauge block for length measurements) to verify its calibration. If discrepancies persist, it’s important to repeat the measurement multiple times to assess the variability and rule out random errors.

If the discrepancies cannot be attributed to the instrument or the procedure, it’s important to re-examine the object being measured. If multiple measurements from different instruments consistently show a discrepancy, it might indicate an issue with the object itself.

Finally, if none of the above steps resolve the discrepancy, it might be necessary to consult with a metrology expert for further investigation and analysis.

Q 26. Describe a situation where precise measurement was critical to the success of a project.

In a recent project involving the development of a microfluidic device, precise measurements were absolutely critical. We were designing channels with dimensions on the order of micrometers, and even small errors could have significantly impacted the device’s functionality. Incorrect dimensions could have led to problems with fluid flow, mixing efficiency, and the overall performance of the device.

We utilized high-precision optical microscopy and interferometry techniques to measure the dimensions of the channels and features on the device. Detailed documentation was essential, not only to ensure the accuracy of our measurements but also to provide traceability to regulatory bodies for compliance. Any deviation from the target dimensions could have rendered the device ineffective, resulting in a costly project failure.

Q 27. What software or tools are you familiar with for data analysis from measuring instruments?

I’m proficient in using several software packages for data analysis from measuring instruments. Microsoft Excel is widely used for basic analysis, including calculating statistics like mean, standard deviation, and plotting data to create control charts.

For more advanced analysis, I’ve used statistical software packages such as Minitab and JMP. These allow for more sophisticated statistical modeling and analysis techniques, such as ANOVA, regression analysis, and capability analysis. I have also worked with specialized software for data acquisition and analysis associated with specific measuring instruments.

Moreover, I’m familiar with LabVIEW, which provides a powerful platform for controlling instruments, collecting data, and performing real-time analysis. The choice of software depends on the complexity of the data, the types of analysis required, and the specific measuring instruments being used.

Q 28. Explain your understanding of different measurement scales (e.g., nominal, ordinal, interval, ratio).

Understanding measurement scales is essential for proper data analysis and interpretation. There are four main types:

- Nominal Scale: This scale categorizes data into distinct groups without any inherent order. For example, classifying objects by color (red, blue, green) or material type (metal, plastic, wood).

- Ordinal Scale: This scale categorizes data into ordered groups. The intervals between categories aren’t necessarily equal. A classic example is a customer satisfaction survey using ratings like “Excellent, Good, Fair, Poor.”

- Interval Scale: This scale has equal intervals between values, but lacks a true zero point. Temperature measured in Celsius or Fahrenheit is a good example. 0°C doesn’t mean the absence of temperature.

- Ratio Scale: This scale has equal intervals between values and a true zero point, indicating the absence of the measured quantity. Weight, length, and time are classic examples; 0 kg indicates no weight.

The type of scale used influences the statistical analyses that are appropriate. For example, you can calculate the mean for ratio and interval scales, but not for nominal or ordinal scales.

Key Topics to Learn for Using Measuring Tools Interview

- Understanding Measurement Systems: Mastering both metric (SI) and imperial systems, including unit conversions and their practical implications in different industries.

- Precision and Accuracy: Differentiating between precision and accuracy in measurement, understanding sources of error, and applying appropriate techniques to minimize them.

- Selecting Appropriate Tools: Knowing the strengths and limitations of various measuring tools (e.g., calipers, micrometers, rulers, tape measures, levels) and selecting the most appropriate tool for a given task.

- Proper Tool Usage: Demonstrating proficiency in the correct handling and operation of each measuring tool, including proper calibration techniques.

- Reading and Interpreting Measurements: Accurately reading and interpreting measurements from various tools, understanding significant figures, and expressing measurements with appropriate units and precision.

- Practical Applications: Discussing real-world applications of measuring tools across diverse fields such as manufacturing, construction, engineering, and quality control.

- Troubleshooting Measurement Issues: Identifying and addressing common problems encountered during measurement processes, such as tool malfunction, environmental factors, and human error.

- Safety Procedures: Understanding and adhering to relevant safety procedures when using measuring tools, including proper handling and storage.

- Data Recording and Analysis: Effectively recording measurement data, performing basic data analysis, and presenting results in a clear and concise manner.

- Advanced Techniques (if applicable): Exploring more advanced techniques such as using digital measuring tools, statistical process control (SPC), or specific industry-standard measuring protocols.

Next Steps

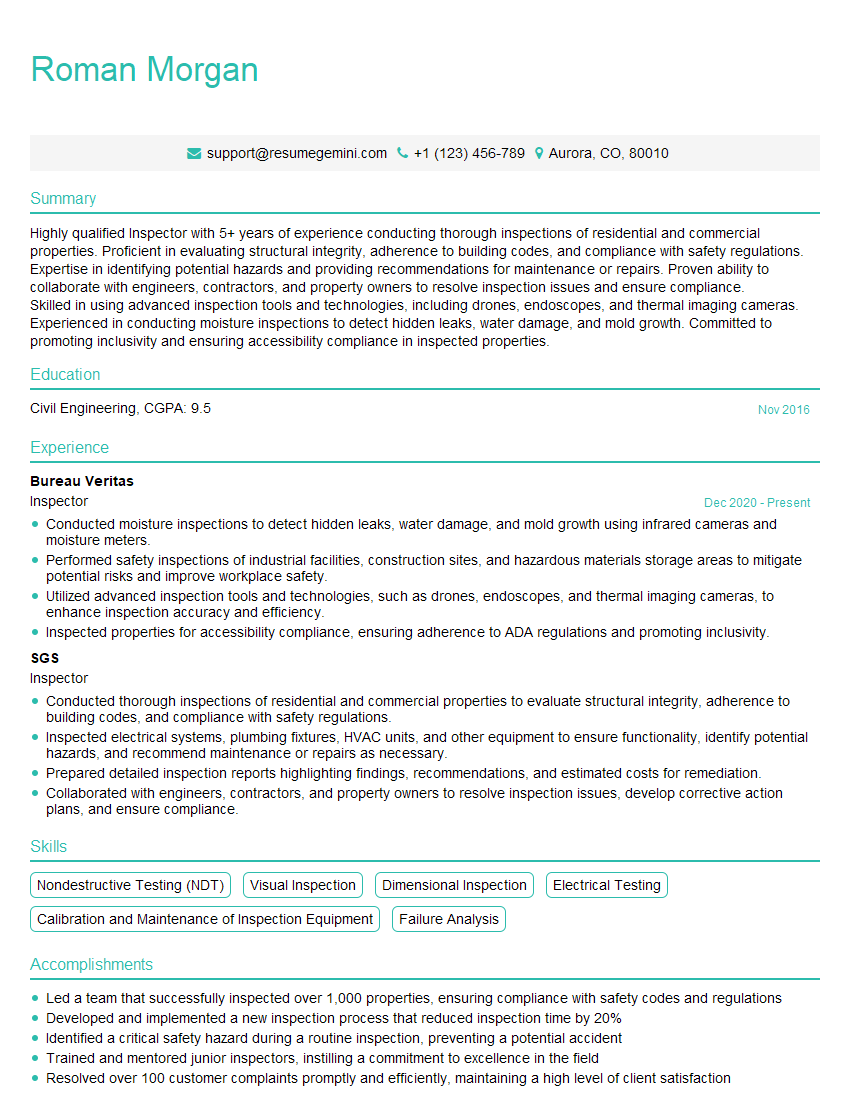

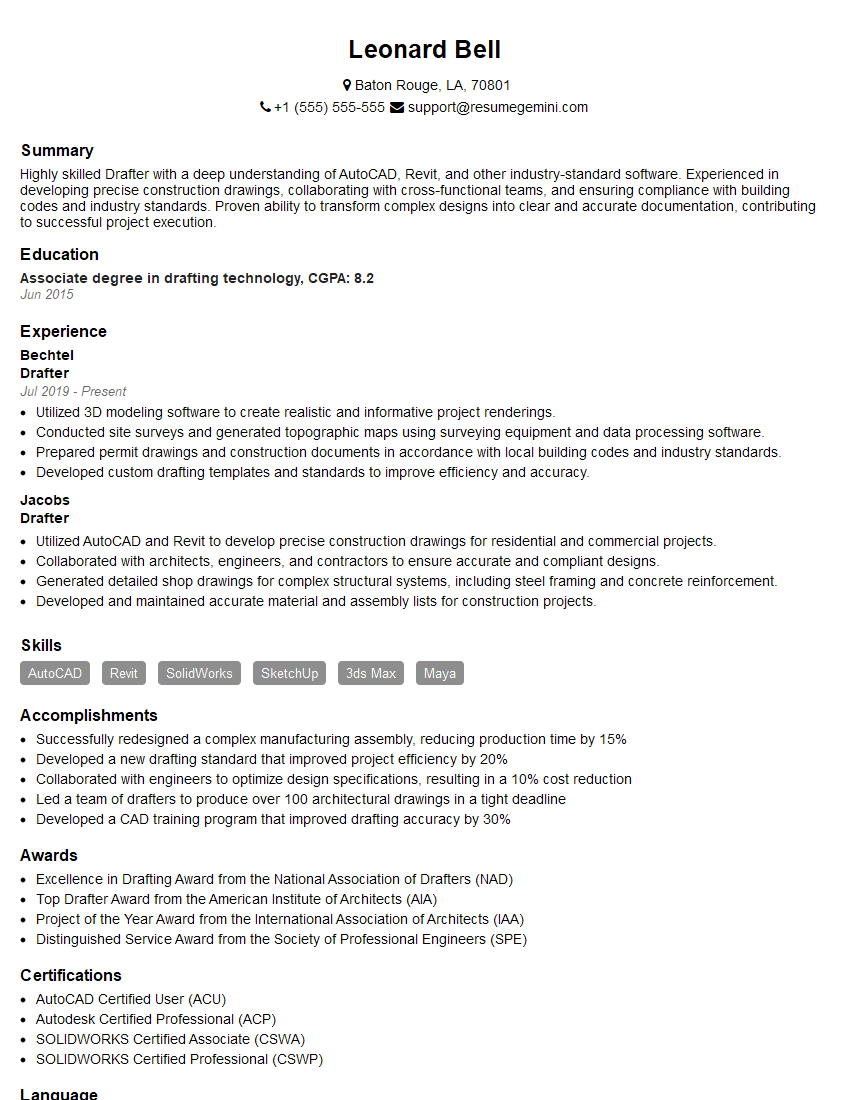

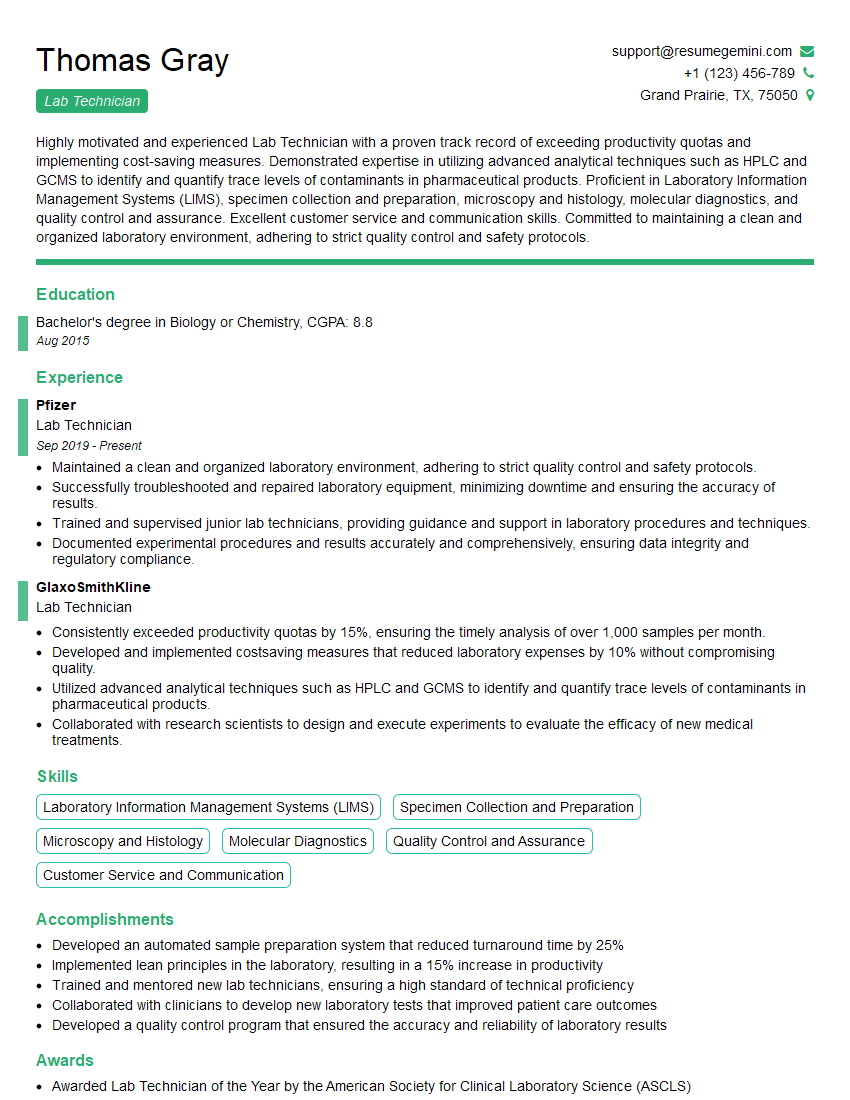

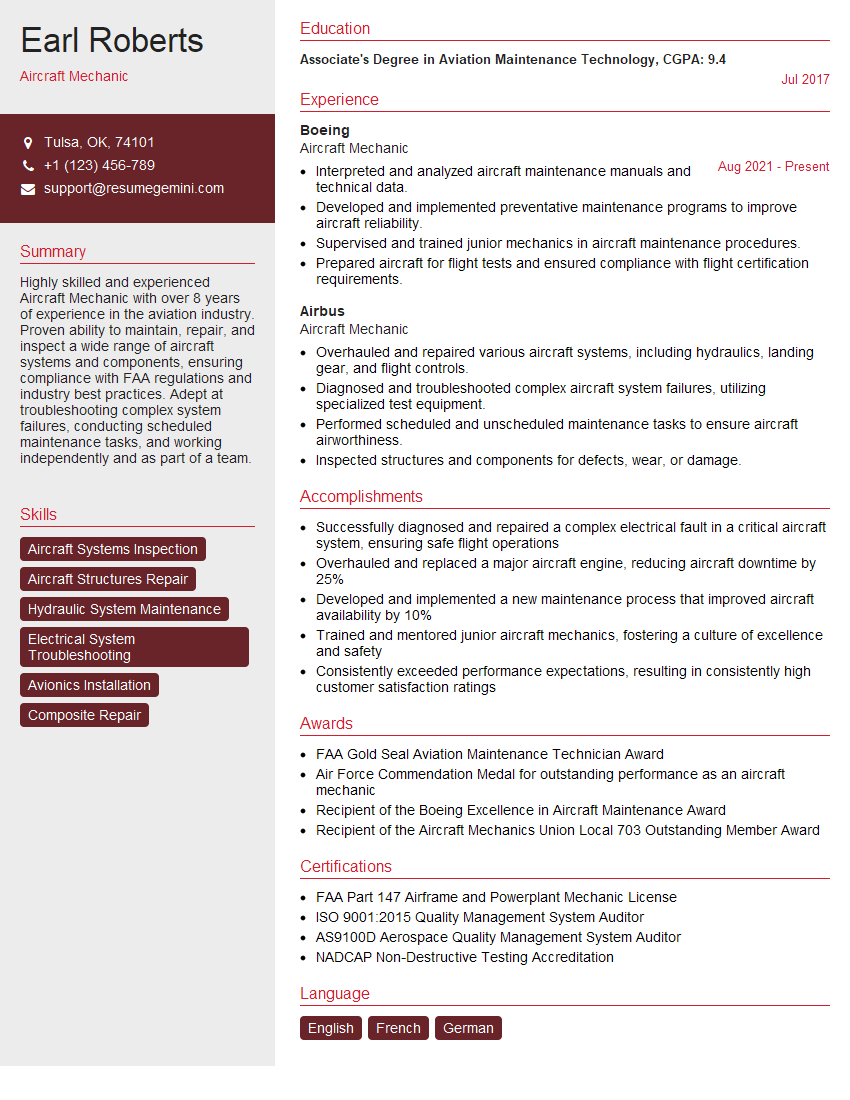

Mastering the use of measuring tools is crucial for success in many technical fields, opening doors to rewarding careers with excellent growth potential. A strong resume is your key to unlocking these opportunities. Building an ATS-friendly resume is essential for getting your application noticed by recruiters. To help you create a compelling and effective resume, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to roles involving Using Measuring Tools, ensuring your qualifications shine through.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO