Cracking a skill-specific interview, like one for Vehicle Inspection and Reporting, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Vehicle Inspection and Reporting Interview

Q 1. Explain the process of a standard vehicle safety inspection.

A standard vehicle safety inspection is a systematic examination of a vehicle’s components to ensure they meet safety regulations and are roadworthy. It’s like a thorough health check for your car. The process typically involves a visual inspection of numerous parts, followed by functional tests where applicable.

- Visual Inspection: This covers checking the condition of tires, brakes, lights, wipers, steering, suspension, exhaust system, and body for damage. Think of it like walking around the car, carefully examining everything from the ground up.

- Functional Tests: These tests verify the proper operation of critical safety systems. For instance, we’ll test the brake lights, turn signals, and horn to ensure they function correctly. We might also check the brake pedal for proper feel and the steering for responsiveness.

- Undercarriage Inspection: We’ll get under the vehicle to examine the exhaust system for leaks, check the condition of the suspension components and look for any signs of rust or damage.

- Documentation: All findings, both positive and negative, are meticulously documented on an inspection report. This report details the inspected components, their condition, and any necessary repairs.

For example, during a recent inspection, I noticed a significant leak in the exhaust system of a truck. This was immediately documented and the owner was advised of the potential safety hazard and the need for immediate repair.

Q 2. Describe the different types of vehicle inspections you are familiar with.

I’m experienced with several types of vehicle inspections, each serving a distinct purpose:

- Safety Inspections (Annual/Periodic): These are routine checks mandated by law to ensure vehicles meet minimum safety standards, aiming to prevent accidents. I conduct these regularly, following the guidelines of the relevant authority.

- Pre-Purchase Inspections: These inspections are requested by prospective buyers before purchasing a used vehicle. The goal is to identify potential mechanical issues or hidden damage that may impact the vehicle’s value or safety.

- Post-Accident Inspections: Following a collision, these inspections determine the extent of vehicle damage and help assess liability. This involves detailed examination of the damage and reporting of the findings to insurance companies.

- Emissions Inspections: These focus on the vehicle’s exhaust emissions to ensure they meet environmental regulations, typically checking for pollutants like carbon monoxide and hydrocarbons.

The procedures and the depth of each inspection type are significantly different, and I adapt my approach accordingly. A pre-purchase inspection is much more detailed regarding potential issues buyers might face compared to a simple annual safety check.

Q 3. What are the key components checked during a pre-purchase vehicle inspection?

A pre-purchase vehicle inspection is crucial to avoid costly surprises after buying a used car. Think of it as a vital due diligence step. Key components checked include:

- Engine and Transmission: We assess the engine’s performance, listen for unusual noises, check fluid levels and examine the transmission for smooth shifting.

- Brakes: Brake pad thickness, rotor condition, and brake fluid level are carefully examined for efficiency and safety.

- Steering and Suspension: We check for responsiveness in steering, play, and proper alignment. We also assess suspension components for wear and tear.

- Tires: We check tread depth, tire pressure, and the overall condition of the tires, noting any potential issues like uneven wear or damage.

- Electrical System: Lights, wipers, horn, and other electrical components are tested for functionality.

- Body and Undercarriage: We examine the vehicle’s exterior and undercarriage for rust, dents, signs of collision repair, or other damage.

- Documentation: All findings are comprehensively documented with photos and detailed descriptions.

For example, I once discovered a significant frame damage during a pre-purchase inspection that was initially masked by cosmetic repairs. This saved the buyer from purchasing a potentially unsafe and unreliable vehicle.

Q 4. How do you identify and document vehicle damage effectively?

Effective documentation of vehicle damage is paramount for insurance claims, repairs, and legal purposes. My process includes:

- Detailed Description: I use precise language to describe the location, size, and type of damage. For example, instead of ‘scratched bumper’, I’d write ’12-inch scratch on the driver’s side front bumper, extending from the edge to the headlamp assembly’.

- Photography: High-quality photographs from multiple angles are essential. These should capture the extent of damage clearly.

- Measurements: I record accurate measurements of dents, scratches, and other damage. This provides a quantitative basis for the assessment.

- Diagrams: Sketches or diagrams can be useful for complex damage situations, especially for structural damage.

- Digital Reporting: All findings are recorded in a standardized report, using digital tools which ensures clarity and organization.

I always prioritize accuracy and objectivity to ensure my report is comprehensive and reliable. This has proven invaluable in facilitating smooth insurance claims and repair processes.

Q 5. What safety regulations and standards are you familiar with?

My work adheres to several safety regulations and standards, including but not limited to:

- Local and National Vehicle Safety Codes: These codes define the minimum acceptable standards for vehicle safety, covering aspects such as braking, lighting, and structural integrity. I’m very familiar with these regulations.

- Manufacturer’s Specifications: I refer to manufacturer’s recommendations for specific vehicle models, as these provide crucial details on components and safety systems.

- Industry Best Practices: I stay updated on the latest industry best practices for vehicle inspection, ensuring my methods are efficient and comprehensive.

Compliance with these standards is crucial to ensure public safety and to provide accurate and reliable inspection results. Regular updates on these regulations and standards are important for maintaining proficiency and professional integrity.

Q 6. Explain your experience with documenting inspection findings.

I have extensive experience documenting inspection findings using various methods. My reports are detailed and objective, minimizing ambiguity and ensuring all information is easily understood.

- Standardized Forms: I utilize standardized forms to ensure consistency and capture all the essential information. This includes sections for identifying the vehicle, listing inspected components, detailing their condition, and making recommendations.

- Digital Reporting Systems: I am proficient in using digital reporting software which offers features such as photo integration, data storage, and report generation.

- Clear and Concise Language: I avoid technical jargon, using clear and concise language that’s easily understood by both technical and non-technical individuals.

- Photographic Evidence: I use high-quality photographs as a crucial part of my documentation process, supplementing the written description.

Thorough documentation protects both me and my clients by providing a clear record of the inspection process and findings. This has been particularly helpful in resolving disputes and preventing misunderstandings. A well-documented report is a valuable asset.

Q 7. Describe your experience using diagnostic equipment.

I’m proficient in using a range of diagnostic equipment to enhance the accuracy and comprehensiveness of my inspections. This allows me to go beyond visual assessments and identify potential problems that might not be readily apparent.

- OBD-II Scanners: These are used to retrieve diagnostic trouble codes (DTCs) from a vehicle’s onboard computer. This helps identify issues within the engine control system, transmission, and other electronic components.

Example DTC: P0171 (System Too Lean Bank 1) - Multimeters: Multimeters are used to test the electrical system, checking voltage, current, and resistance in various circuits.

- Brake Testers: These are used to assess the effectiveness of the braking system, measuring braking force and identifying potential problems.

- Specialized Tools: Depending on the specific inspection type, I may use other specialized tools, such as suspension testers or tire tread depth gauges.

The use of diagnostic equipment allows for proactive identification of potential problems, preventing more significant and costly repairs in the future. It transforms a visual inspection into a far more complete and informative evaluation of the vehicle’s condition.

Q 8. How do you handle discrepancies or disagreements about inspection findings?

Discrepancies in vehicle inspection findings are handled with a methodical approach prioritizing safety and accuracy. First, I meticulously re-examine the area of disagreement, using calibrated tools and referencing relevant repair manuals or standards. If the discrepancy persists, I consult with a senior inspector or team lead for a second opinion. This might involve showing them the vehicle component in question and explaining my reasoning. We then discuss the findings and agree on a final assessment based on objective evidence and established inspection protocols. Clear and thorough documentation is crucial at each step, noting any dissenting views and the rationale behind the final decision. Think of it like a medical diagnosis; multiple perspectives can improve accuracy. A final disagreement may necessitate a third-party inspection by an authorized authority for resolution.

Q 9. How do you prioritize inspections based on risk assessment?

Prioritizing vehicle inspections based on risk assessment is vital for efficient resource allocation and public safety. We employ a tiered system based on factors like vehicle age, type, reported mechanical issues, and operational history. High-risk vehicles, such as those used for public transportation or those with known safety defects, are prioritized. Vehicles used in high-risk situations like long-haul trucking or carrying hazardous materials are immediately assessed. Older vehicles, or vehicles used for frequent and demanding operations, fall into a higher priority tier as well. This systematic approach ensures prompt attention is given to those vehicles posing the greatest safety threat, minimizing the possibility of accidents and ensuring compliance with regulations. The methodology can include scoring systems, weighting factors for each risk parameter, and regular review to refine the process as needed.

Q 10. What is your experience with different types of vehicle braking systems?

My experience encompasses a wide range of vehicle braking systems, from conventional hydraulic systems to more advanced anti-lock braking systems (ABS), electronic stability control (ESC), and even regenerative braking systems found in electric and hybrid vehicles. I am proficient in diagnosing and testing each system’s functionality, including checking for proper brake fluid levels, inspecting brake lines and calipers for leaks and wear, and evaluating the effectiveness of ABS and ESC using diagnostic equipment. For instance, I’m familiar with the different ABS sensor types, their locations, and diagnostic methods. With electric vehicles, understanding the regenerative braking system’s interaction with the friction brakes is critical. Each system necessitates a unique approach to testing and evaluation to ensure compliance with safety regulations and to identify potential safety hazards.

Q 11. What is your understanding of emissions testing and regulations?

Emissions testing and regulations are crucial for environmental protection and public health. My understanding includes familiarity with various emission standards (like Euro standards or EPA standards), the use of dynamometers and emission analyzers to measure exhaust gas components such as carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter (PM). I understand the importance of verifying that vehicles meet the prescribed limits for these pollutants. Moreover, I’m knowledgeable about different emission control technologies, such as catalytic converters, diesel particulate filters (DPF), and selective catalytic reduction (SCR) systems. I know how to identify malfunctioning systems through visual inspection and diagnostic trouble codes (DTCs). Keeping up-to-date on the latest regulatory changes and technological advancements is paramount in this area.

Q 12. How do you maintain accurate and detailed inspection records?

Maintaining accurate and detailed inspection records is crucial for accountability and legal compliance. We utilize digital reporting systems with secure database storage that allow for electronic record-keeping. Each inspection generates a detailed report incorporating photographs, measurements, and specific notes on any defects discovered. The data is categorized, using standardized codes to facilitate reporting. These reports contain the vehicle’s identification number (VIN), inspection date, inspector’s identification, a detailed description of the defects (with relevant standards cited), and recommendations for repair. A unique identifier is assigned to each report, ensuring traceability and preventing duplication. Regular data backups and security protocols help prevent data loss and maintain data integrity. The entire process adheres to stringent data privacy and security regulations.

Q 13. Explain your experience with heavy vehicle inspections (if applicable).

My experience with heavy vehicle inspections includes thorough examinations of braking systems (including air brake systems and their components), steering mechanisms, suspension, and lighting. I am proficient in using specialized tools to assess components like air compressors, air tanks, and brake chambers. I am familiar with the specific regulations governing heavy vehicles, including weight limits, tire condition, and load securing procedures. This includes the use of diagnostic equipment specific to heavy-duty vehicles to identify potential problems with sophisticated electronic systems. For example, I’ve worked on identifying issues related to Anti-lock Braking Systems (ABS) and Electronic Braking Systems (EBS) in articulated lorries, ensuring the safety of larger vehicles on the road. The inspection process for these larger vehicles necessitates a far more comprehensive assessment due to the increased safety risks associated with their weight and size.

Q 14. How do you ensure the safety and security of your inspection process?

Safety and security are paramount during vehicle inspections. We implement several measures, including having a clear and defined process for handling vehicles at the inspection facility. This includes designated areas, clear signage and safe procedures for moving vehicles. Inspectors are required to follow standardized safety protocols and wear appropriate protective equipment (PPE). We employ security measures to protect vehicle and inspection data. Access to the facility and inspection data is strictly controlled, with individual user logins and password protection. Regular training and continuing education on safety and security protocols ensure inspectors remain up-to-date on best practices. The implementation of a comprehensive risk assessment identifies potential hazards and mitigation strategies, regularly reviewing the safety procedures to prevent accidents and data breaches. We ensure a clear chain of custody for evidence, preserving its integrity throughout the inspection process. This guarantees accurate and reliable data for the report while ensuring transparency and accountability.

Q 15. Describe your familiarity with different types of vehicle suspension systems.

Vehicle suspension systems are crucial for a vehicle’s safety and ride comfort. They absorb shocks and vibrations from the road, maintaining tire contact and stability. I’m familiar with several types, including:

- Independent Suspension: Each wheel is independently sprung, providing better handling and ride comfort. Think of a car where one wheel hitting a pothole doesn’t drastically affect the other wheels. Examples include MacPherson struts (common in front-wheel-drive cars) and double wishbone suspensions (often found in sports cars).

- Dependent Suspension: The wheels on an axle are linked, meaning movement of one wheel affects the other. This is simpler and often cheaper to manufacture, but compromises handling. Live axles are a classic example, often seen in older trucks and SUVs.

- Air Suspension: Uses air springs instead of traditional coils or leaf springs, providing adjustable ride height and damping. This is more common in luxury vehicles and offers a smoother ride, often self-leveling to maintain a consistent ride height regardless of the load.

- Hydro-pneumatic Suspension: Employs hydraulic fluid and pressurized nitrogen to control suspension, offering a remarkably smooth and controlled ride. Historically, Citroën is known for this type of advanced system.

During inspections, I assess the condition of all suspension components, including springs, shocks/struts, bushings, control arms, and ball joints, looking for wear, damage, or leaks, noting any unusual noises or play.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage your workload and prioritize inspections?

Managing workload and prioritizing inspections requires a structured approach. I utilize a combination of techniques:

- Scheduling: I maintain a detailed schedule, considering the type of vehicle, inspection requirements, and appointment times. This helps me allocate appropriate time slots for each inspection, ensuring efficient workflow.

- Prioritization: Urgent inspections, such as those following accidents or for vehicles suspected of significant mechanical issues, are prioritized. This ensures immediate attention to safety-critical concerns.

- Batching: I group similar inspections together whenever possible (e.g., all light vehicles on one day). This optimizes the use of specialized equipment and reduces time wasted on setup changes.

- Technology: I leverage digital tools for appointment management, data logging, and report generation, allowing for smoother workflows and better organization.

By combining these strategies, I maintain a productive pace without sacrificing the quality or thoroughness of inspections.

Q 17. What is your experience with computerized vehicle inspection systems?

I have extensive experience with computerized vehicle inspection systems. These systems automate many aspects of the inspection process, improving efficiency and accuracy. My experience includes using systems that:

- Automate data entry: Reduces manual data entry, minimizing human error and speeding up report generation.

- Provide diagnostic capabilities: Integrate with onboard diagnostics (OBD) systems to detect and report electronically stored fault codes.

- Manage inspection schedules and appointments: Streamline appointment scheduling and tracking, improving organization and reducing waiting times.

- Generate detailed reports: Produce comprehensive reports, including images and diagnostic data, making it easier to communicate findings.

These systems are crucial for maintaining data integrity, ensuring compliance with regulations, and improving the overall efficiency of the vehicle inspection process. I’m proficient in using various software and hardware components of these systems, including the diagnostic scanners and specialized testing equipment.

Q 18. How do you communicate complex technical information to non-technical audiences?

Communicating complex technical information to non-technical audiences requires clear and concise language, avoiding jargon. I use several techniques:

- Analogies and metaphors: Relate technical concepts to everyday experiences. For example, explaining brake pads using the analogy of shoe soles wearing down.

- Visual aids: Use diagrams, charts, and photos to illustrate complex concepts and make them easier to understand.

- Layman’s terms: Translate technical terms into simple language that everyone can comprehend. Instead of saying ‘axial play,’ I might say ‘loose movement’.

- Interactive communication: Encourage questions and feedback to ensure the audience understands the information.

The goal is to ensure the client understands the issues identified and the recommended repairs without being overwhelmed by technical details. I’ve found this approach significantly improves client understanding and satisfaction.

Q 19. Explain your problem-solving approach when encountering unexpected issues during inspection.

My problem-solving approach when encountering unexpected issues during inspection follows a structured methodology:

- Identify the problem: Carefully assess the situation and define the specific issue. This often involves gathering additional data through further observation and testing.

- Gather information: Research the issue, consulting manuals, online resources, or colleagues for insights. This step is crucial for understanding the underlying causes.

- Develop solutions: Based on my research, I explore different solutions, considering their feasibility, safety, and cost-effectiveness.

- Implement and test: I carefully implement the chosen solution, thoroughly testing to ensure it resolves the issue and doesn’t create new problems.

- Document findings: I meticulously document all findings, actions taken, and results in the inspection report. This helps ensure consistency and traceability.

For example, if I encounter an unusual electrical fault, I’d systematically check fuses, wiring, and components, using a multimeter to isolate the problem. Careful documentation ensures that the repair is appropriately communicated.

Q 20. How familiar are you with different types of tire wear and their implications?

I’m very familiar with different types of tire wear and their implications. Understanding tire wear patterns is crucial for identifying potential mechanical issues or driving habits that affect vehicle safety.

- Uneven Wear: This can indicate problems with wheel alignment, suspension components, or improper inflation. For example, feathering (one side of the tread worn more than the other) often points to misalignment.

- Center Wear: Over-inflation is usually the culprit, as it causes only the center of the tire to contact the road.

- Shoulder Wear: Under-inflation leads to excessive wear on the tire’s outer edges.

- Cupping: This irregular wear pattern, resembling small cups, points to issues with suspension or worn-out shock absorbers.

During inspections, I carefully examine the tires, noting wear patterns and tread depth. Abnormal wear can indicate underlying issues that require attention, enhancing vehicle safety and extending tire life.

Q 21. Describe your experience with electrical system checks in vehicles.

Electrical system checks are a critical part of vehicle inspections. My experience includes testing various components and systems, including:

- Battery: Testing voltage and ensuring proper charging.

- Alternator: Checking its output voltage to ensure proper charging of the battery.

- Starter motor: Evaluating its performance and checking for issues such as excessive cranking time or noise.

- Wiring and connections: Inspecting for damage, corrosion, or loose connections. This often involves using a multimeter to test continuity and voltage.

- Lighting systems: Testing headlights, taillights, brake lights, turn signals, and other exterior lighting to ensure they’re functioning correctly.

I utilize diagnostic tools, including OBD scanners, multimeters, and specialized test lights to identify and diagnose electrical issues accurately and efficiently. This thorough approach ensures that potentially dangerous faults are identified and reported, preventing future problems.

Q 22. How do you handle situations where a vehicle fails inspection?

When a vehicle fails inspection, my priority is to clearly and professionally communicate the reasons for failure to the vehicle owner. This involves providing a detailed report outlining each defect, referencing the specific regulation violated (if applicable), and explaining the safety implications of each issue. I use plain language, avoiding technical jargon whenever possible, ensuring the owner understands the seriousness of the problems.

Next, I explain the necessary repairs required to pass the inspection. I provide a written list, potentially including photos or diagrams to help the owner understand the issues visually. I am also available to answer any questions the owner may have and offer guidance on finding reliable repair shops. Finally, I clearly explain the re-inspection process and the associated fees. For example, if a vehicle failed due to worn brake pads, I would clearly detail the insufficient pad thickness, referencing the relevant safety standard, and explain how this compromises braking performance, increasing stopping distances and posing a safety risk. I would then specify the need for brake pad replacement and provide information on re-inspection procedures.

Q 23. What measures do you take to ensure the accuracy of your inspections?

Accuracy in vehicle inspections is paramount. To ensure this, I employ a multi-pronged approach. First, I meticulously follow a standardized checklist, ensuring all components are thoroughly examined according to regulations. Second, I use calibrated equipment for measurements like brake testing and headlamp alignment. These tools are regularly checked for accuracy and maintained to high standards. This is crucial for objective and reliable results. Third, I maintain detailed documentation, including photographic evidence for any defects detected. This documentation serves as a verifiable record of the inspection. Finally, continuous professional development keeps my knowledge and skills up-to-date with the latest inspection techniques and regulatory changes. I participate in refresher courses and workshops, which further enhances my accuracy and consistency.

For example, when assessing headlamp alignment, I use a headlamp aimer to ensure precise measurements, documenting the readings and any adjustments made. This ensures accurate compliance with regulations concerning headlight aim and visibility.

Q 24. Explain your experience working under pressure and meeting deadlines.

I thrive in fast-paced environments and am adept at managing multiple tasks under pressure. In previous roles, I’ve consistently met tight deadlines, even during periods of high vehicle volume. I prioritize tasks effectively, focusing on critical inspections first while managing a steady workflow. I also maintain a calm and organized approach even when dealing with multiple vehicles and potentially challenging clients. I find that proactive planning and a systematic approach are vital in these situations.

For instance, during peak seasons, I have successfully managed to inspect and report on more than 20 vehicles daily, ensuring that each report was accurate and timely. My organizational skills and ability to maintain focus under pressure have consistently allowed me to meet and often exceed expectations.

Q 25. Describe your experience with vehicle body damage assessment.

My experience in vehicle body damage assessment is extensive. I can identify and assess various types of damage, ranging from minor scratches and dents to significant structural damage. My assessment includes evaluating the severity of the damage, its location, and its potential impact on vehicle safety and structural integrity. I use standardized scales and reporting methods to document the findings consistently. I am proficient in utilizing different diagnostic tools, including specialized measuring equipment to determine the extent of damage, particularly in cases of collision or accident damage.

For example, in assessing a vehicle with a side impact collision, I’d systematically examine the damaged area, noting the extent of dent, crease, and any buckling of the body panels. I would also check for frame damage using specialized measuring tools and documenting all findings with photographs and detailed descriptions in my report. This allows for accurate cost estimation for repairs and insurance claims.

Q 26. What is your familiarity with various types of vehicle lighting systems?

I’m familiar with a wide array of vehicle lighting systems, including incandescent, halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode) systems. I understand the functional differences between these technologies, such as light output, energy efficiency, and lifespan. I’m also knowledgeable about various lighting components, including headlamps, tail lamps, turn signals, brake lights, and fog lights, and I can effectively test their functionality and alignment according to regulations. My expertise encompasses both the practical aspects of testing and the regulatory requirements for proper lighting operation and maintenance.

For example, I can distinguish between a faulty halogen bulb and a malfunctioning HID ballast, and I can perform tests to verify the correct light intensity and beam pattern for each headlamp type, ensuring they comply with safety standards.

Q 27. How do you stay up-to-date with changes in vehicle inspection regulations?

Staying current with vehicle inspection regulations is an ongoing process requiring continuous effort. I actively participate in professional organizations related to vehicle safety and inspection. This involves attending seminars, conferences, and workshops offered by relevant authorities and industry experts. I also regularly review updated manuals, guidelines, and regulatory changes published by the governing bodies. Subscription to industry-specific publications and online resources helps me remain informed about any modifications or additions to existing regulations. Furthermore, I maintain an open line of communication with colleagues in the field, exchanging knowledge and experiences to stay abreast of emerging trends.

This proactive approach ensures I consistently apply the most up-to-date standards in my inspections, maintaining accuracy and compliance with all applicable laws and regulations.

Q 28. Describe your understanding of different types of vehicle steering systems.

My understanding of vehicle steering systems encompasses various types, including rack and pinion, recirculating ball, and power steering systems. I’m familiar with the components of each system, including steering wheel, steering column, steering gear, tie rods, and linkages. I understand how these systems function, and I can identify potential problems through visual inspection and operational testing. This includes assessing steering play, responsiveness, and alignment. I am also aware of the safety implications of steering system malfunctions and can identify potentially hazardous conditions.

For instance, I can identify excessive play in the steering wheel, indicative of worn components in the steering gear or linkage, and explain the safety risk associated with this condition, emphasizing its potential to compromise control and increase the risk of accidents.

Key Topics to Learn for Vehicle Inspection and Reporting Interview

- Vehicle Systems Knowledge: Understanding the intricacies of various vehicle systems (braking, steering, suspension, electrical, etc.) is crucial. This includes knowing their components, functions, and common failure points.

- Safety Regulations and Standards: Familiarize yourself with relevant safety regulations and industry standards governing vehicle inspections. Be prepared to discuss how these standards are applied in practice.

- Inspection Procedures and Techniques: Master the proper techniques for conducting thorough and efficient vehicle inspections. This involves knowing the correct order of operations and utilizing appropriate tools and equipment.

- Report Writing and Documentation: Practice clear and concise report writing. Accuracy and detail are paramount in documenting inspection findings and recommending necessary repairs.

- Diagnostic Skills and Problem-Solving: Develop your diagnostic skills to identify potential issues based on visual inspection, understanding error codes, or client feedback. Be ready to discuss how you approach troubleshooting and resolving complex problems.

- Legal and Ethical Considerations: Understand your responsibilities and legal obligations related to vehicle inspections, ensuring fair and impartial assessments while maintaining ethical conduct.

- Technology and Software Proficiency: Many inspection processes involve digital tools and software. Demonstrate familiarity with relevant technologies and software used in vehicle inspection and reporting.

- Communication and Interpersonal Skills: Vehicle inspectors frequently interact with clients and colleagues. Practice effective communication skills to clearly explain findings and recommendations.

Next Steps

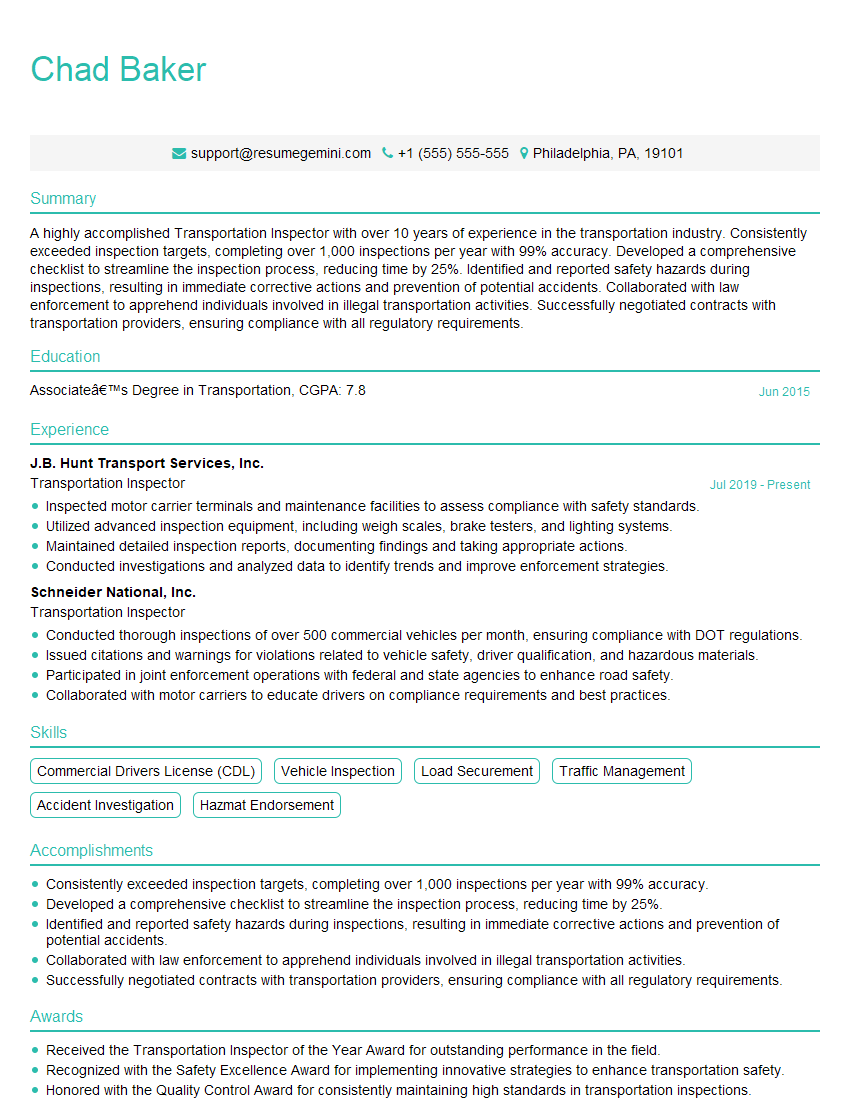

Mastering Vehicle Inspection and Reporting opens doors to a rewarding career with excellent growth potential. A strong foundation in these skills demonstrates professionalism and expertise, leading to increased earning potential and career advancement opportunities. To significantly boost your job prospects, create an ATS-friendly resume that highlights your qualifications effectively. We highly recommend using ResumeGemini to build a professional and impactful resume tailored to the specific requirements of Vehicle Inspection and Reporting roles. ResumeGemini offers examples of resumes specifically designed for this field to help you craft a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO