Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Ventilation System Maintenance interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Ventilation System Maintenance Interview

Q 1. Explain the difference between positive and negative pressure ventilation systems.

Positive and negative pressure ventilation systems differ in how they manage airflow. Imagine a balloon: inflating it creates positive pressure inside, while deflating it creates negative pressure.

A positive pressure system pumps air into a space, slightly increasing the air pressure inside. This prevents outside air from entering, ideal for cleanrooms, operating rooms, or areas needing protection from contaminants. Air is pushed out through gaps and cracks.

A negative pressure system pulls air out of a space, slightly lowering the internal pressure. This creates a vacuum effect, drawing air in from the surrounding environment. This is beneficial in situations where containment of hazardous materials is crucial, such as fume hoods or isolation rooms. This prevents potentially contaminated air from escaping.

The choice between positive and negative pressure depends entirely on the application. The wrong system can be detrimental; a negative pressure system in a cleanroom would allow contaminants to enter, while a positive pressure system in a hazardous materials handling area could spread contamination.

Q 2. Describe the process for troubleshooting a malfunctioning ventilation fan.

Troubleshooting a malfunctioning ventilation fan is a systematic process. First, safety first – always disconnect the power before any hands-on inspection.

The process typically involves:

- Visual Inspection: Check for obvious issues like loose belts, damaged blades, or obstructions in the fan path. Think of it like checking a car engine – you’d look for anything amiss before starting it.

- Power Supply Check: Verify power is reaching the fan motor using a multimeter. A simple lack of power could be the only problem.

- Motor Functionality Test: If power is present, test the motor’s functionality. If it’s not turning, there might be a motor failure requiring professional repair or replacement.

- Control System Check: Examine the fan’s control system (thermostat, timer, etc.) to ensure it’s functioning correctly and sending the appropriate signals to the fan motor. A faulty control might be ‘telling’ the fan to remain off.

- Airflow Check: Once the fan is running, check for proper airflow using an anemometer to measure air velocity and volume. Restricted airflow could point to a clogged filter or ductwork issues.

If these steps don’t resolve the problem, professional assistance is necessary. Attempting complex repairs without proper training can be dangerous.

Q 3. How do you maintain air quality within a ventilation system?

Maintaining air quality in a ventilation system involves a multi-pronged approach, focusing on filtration, cleaning, and proper system operation.

Think of it like keeping your house clean – regular dusting, vacuuming, and replacing air filters are all part of maintaining a healthy environment.

- Regular Filter Changes: This is paramount, removing dust, pollen, and other airborne particles. Following manufacturer’s recommendations is crucial to maximize filter lifespan and efficiency.

- Ductwork Cleaning: Regular cleaning removes dust and debris buildup, improving airflow and preventing the spread of contaminants. This often requires specialized equipment and expertise.

- System Inspection: Regular inspections identify potential problems early, preventing larger, more costly repairs down the line. This involves checking for leaks, cracks, or other damage to the ductwork.

- Proper System Operation: Ensuring the ventilation system operates at the correct speed and capacity is crucial for maintaining effective air exchange and filtering. This includes regular checks on system components such as dampers and sensors.

- Regular Calibration and Testing: Using instruments such as particle counters and air quality monitors allows for verification of desired air quality levels.

Q 4. What safety precautions are crucial when working on ventilation systems?

Safety is paramount when working on ventilation systems. The potential hazards include:

- Electrical Hazards: Always disconnect power before working on any electrical components. Use lockout/tagout procedures to prevent accidental energization.

- Falls: Working at heights requires appropriate fall protection measures, including harnesses and safety lines.

- Confined Space Hazards: Entering ducts or other confined spaces requires proper training, permits, and safety equipment, such as respirators and monitoring equipment for oxygen levels and hazardous gases.

- Moving Parts: Rotating fan blades pose a significant risk. Never work on a fan while it is running, and always use appropriate lock-out/tag-out procedures to prevent unintentional startup.

- Exposure to Hazardous Materials: If dealing with a system handling hazardous materials, appropriate personal protective equipment (PPE) including respirators, gloves, and eye protection is mandatory.

Thorough training and adherence to safety protocols are essential to mitigate these risks. Never compromise safety for efficiency.

Q 5. Explain the importance of regular filter changes in ventilation systems.

Regular filter changes are crucial for maintaining optimal ventilation system performance and indoor air quality. A clogged filter restricts airflow, reducing the system’s efficiency and potentially leading to higher energy bills. More importantly, it compromises air quality by allowing dust, allergens, and other pollutants to bypass the filtration process, affecting the health of building occupants.

Imagine trying to breathe through a clogged straw; that’s essentially what happens to your ventilation system. It struggles to do its job, wasting energy and putting your health at risk. Therefore, following the manufacturer’s recommendations for filter replacement frequency is crucial for keeping your system running efficiently and ensuring clean, healthy air. Over time, dirty filters can even damage the motor components of the ventilation system.

Q 6. How do you identify and address air leaks in a ventilation ductwork system?

Identifying and addressing air leaks in ventilation ductwork requires a systematic approach. Leaks reduce efficiency, waste energy, and can negatively impact indoor air quality.

Methods for detection include:

- Visual Inspection: Checking for obvious gaps, cracks, or loose connections in the ductwork. This is the first and often easiest step.

- Smoke Test: Introducing smoke into the ductwork allows you to visually identify leak locations. It’s a very effective technique, almost like detective work.

- Pressure Testing: Using specialized equipment to measure pressure differences across duct sections helps pinpoint leak locations and quantify the severity of the leak. This provides precise data for repair planning.

- Infrared Thermography: Using an infrared camera can detect temperature differences caused by air leakage, revealing hidden leaks. This is a useful tool for hard-to-reach areas.

Once leaks are identified, repairs involve sealing gaps using appropriate sealant or patching damaged sections. Proper sealing materials are essential for maintaining the integrity of the ductwork and ensuring efficient airflow. For example, mastic sealant is a common choice for sealing gaps in metal ductwork.

Q 7. Describe your experience with different types of ventilation system controls.

My experience encompasses a range of ventilation system controls, from basic on/off switches to sophisticated Building Management Systems (BMS).

I’ve worked with:

- Simple On/Off Controls: These are basic switches that allow for manual control of the fan. Suitable for smaller, less complex systems.

- Timer Controls: These automatically turn the ventilation system on and off at preset times, useful for optimizing energy consumption and ventilation schedules.

- Thermostatic Controls: These activate the ventilation system based on temperature thresholds, maintaining a comfortable environment. A common feature in many HVAC systems.

- Variable Frequency Drives (VFDs): These allow for precise control of fan speed, optimizing airflow and energy efficiency. VFDs are essential for sophisticated systems that require adaptive control strategies.

- Building Management Systems (BMS): These integrated systems provide centralized monitoring and control of various building systems, including ventilation. BMS allows real-time monitoring and automated responses based on building requirements, ensuring optimized efficiency and energy savings.

My experience includes troubleshooting, programming, and maintaining these diverse control systems, ensuring optimal ventilation system performance while prioritizing energy efficiency and safety. I am also comfortable with various protocols used for communication between these systems.

Q 8. What are the common causes of reduced airflow in a ventilation system?

Reduced airflow in a ventilation system is a common issue with several potential causes. Think of your ventilation system like a highway system for air; if there’s a blockage or a narrowing, the flow will be restricted. The most frequent culprits include:

- Filter Clogging: Dirty air filters are the most common cause. They restrict airflow, reducing efficiency and potentially damaging the system’s components. It’s like a traffic jam caused by a pile-up – the air can’t get through.

- Ductwork Obstructions: Debris, pest nests, or even sagging ductwork can partially or completely block airflow. This is like a fallen tree blocking a road – air can’t pass through the affected section.

- Vane or Damper Malfunction: These components control airflow direction and volume. If they are broken, stuck, or improperly adjusted, airflow will be reduced or misdirected. This is like a broken traffic light – the flow is disrupted or uncontrolled.

- Fan Problems: Motor failure, belt slippage, or improper fan speed settings can significantly reduce airflow. This is like a broken-down vehicle on a highway lane – it blocks the normal air flow.

- Leaks in the Ductwork: Leaks in the ductwork lead to air escaping before it reaches its destination. Imagine holes in the highway – some of the traffic (air) gets lost along the way.

- Excessive Static Pressure: This is the resistance to airflow within the ductwork. Excessive pressure usually arises from clogged filters, leaky ductwork or an undersized duct system. This is like trying to drive through a heavily congested area – the higher the resistance, the lower the flow.

Identifying the specific cause requires a thorough inspection and often involves checking air pressure readings across various points in the system.

Q 9. How do you perform preventative maintenance on a ventilation system?

Preventative maintenance is crucial for extending the lifespan of a ventilation system and ensuring optimal performance. It’s akin to regular car servicing; small actions prevent large problems. A comprehensive preventative maintenance program includes:

- Regular Filter Changes: This is the most important step. Change filters according to the manufacturer’s recommendations, often monthly or quarterly depending on usage and environment. In a dusty environment, more frequent changes might be necessary.

- Ductwork Inspection: Visually inspect ductwork for leaks, damage, or obstructions at least annually. Look for signs of corrosion, pests, or sagging.

- Fan Motor Lubrication: Depending on the type of fan motor, lubrication might be required. Consult the manufacturer’s guidelines.

- Belt Tension Checks: For belt-driven fans, check belt tension and replace worn belts as needed. A slipping belt reduces efficiency and can lead to motor damage.

- Damper and Vane Adjustments: Ensure dampers and vanes are operating correctly and airflow is balanced across the system.

- Clean and Inspect Dampers: Clean and ensure smooth and accurate operation of dampers and all actuators. Lubricate where needed.

- Component Cleaning: Regularly clean components like coils, grills and diffusers to prevent dust and debris build-up.

- Air Balancing: Periodically conduct air balancing tests to ensure proper airflow distribution throughout the system.

- Documentation: Keep detailed records of all maintenance activities, including dates, work performed, and any issues found.

By implementing a regular preventative maintenance schedule, you can significantly reduce the risk of major breakdowns and prolong the life of your ventilation system.

Q 10. What are the key components of a ventilation system and their functions?

A ventilation system is composed of several key components working together to deliver clean, conditioned air. Imagine it as a sophisticated circulatory system for your building. The core components include:

- Supply Fans: These are the ‘heart’ of the system, pushing air through the ductwork.

- Ductwork: The ‘arteries and veins’, carrying air throughout the building.

- Air Filters: The ‘kidneys’, removing pollutants from the incoming air.

- Heating/Cooling Coils: The ‘thermostat’, adjusting the air’s temperature.

- Exhaust Fans: The ‘lungs’, removing stale or contaminated air from the building.

- Registers/Diffusers/Grilles: The ‘capillaries’, distributing conditioned air into the spaces.

- Dampers/Vane: These act as valves, regulating airflow in various branches of the system.

- Control Systems: The ‘brain’, managing and monitoring the system’s operation.

Each component has a crucial role, and malfunction in any part can significantly impact the system’s overall performance. For example, a faulty filter can overload the system and reduce efficiency; a leak in the ductwork leads to energy waste. Regular maintenance is essential to prevent such problems.

Q 11. Explain your understanding of different ventilation system designs (e.g., supply/exhaust).

Ventilation system designs vary depending on the building’s needs and the type of air quality required. Two common types are:

- Supply/Exhaust Systems: These systems use separate supply and exhaust fans. The supply fan brings in fresh, conditioned air, while the exhaust fan removes stale air. Imagine it as two separate highways, one bringing fresh air in, and the other taking used air out.

- Balanced Systems: These systems have a balanced airflow rate; the amount of air supplied is equal to the amount exhausted. This ensures a constant air exchange without creating negative or positive pressure within the building. Think of this as a perfectly balanced highway system, with consistent inflow and outflow of traffic.

Other designs include Displacement Ventilation, which delivers air at low velocity near the floor, and Underfloor Air Distribution, which uses the space beneath the floor for air distribution. The choice of design depends on factors like the building’s size, occupancy, and environmental requirements. Each system must be meticulously planned and installed to ensure proper air distribution and efficient operation.

Q 12. Describe your experience with balancing ventilation systems.

Balancing a ventilation system involves adjusting the airflow in each branch of the system to achieve the desired flow rates and pressures. It’s like fine-tuning a complex orchestra – each instrument (duct) needs to play its part perfectly for a harmonious outcome. My experience includes using:

- Pressure Measurement Tools: Using pressure gauges to measure static pressure at various points in the system.

- Airflow Measurement Devices: Using anemometers or thermal anemometers to measure airflow at registers and grilles.

- Damper Adjustments: Adjusting dampers to control airflow in different zones.

- Balancing Valves: Using balancing valves to control airflow in individual branches of the system.

Successful balancing requires a systematic approach. I typically start by measuring airflow and pressure at critical points, then adjust dampers and valves iteratively until the desired airflow rates are achieved. This process requires careful attention to detail and an understanding of the system’s hydraulics. For instance, I once worked on a large office building where improper balancing led to uneven temperatures in different zones. By systematically adjusting dampers and valves, I was able to achieve a uniform temperature throughout the building, significantly improving occupant comfort.

Q 13. How do you interpret and utilize ventilation system schematics and blueprints?

Ventilation system schematics and blueprints are essential for understanding the system’s design, layout, and component locations. These documents are my roadmaps. I use them to:

- Identify Component Locations: Pinpoint the location of fans, ductwork, dampers, and other components.

- Trace Airflow Paths: Follow the path of air from supply to exhaust.

- Understand System Design: Comprehend the overall system design and how different components interact.

- Troubleshoot Problems: Identify the source of problems by tracing airflow and pressure paths.

- Plan Maintenance: Develop a maintenance plan by identifying critical components and areas requiring attention.

I’m proficient in reading both mechanical and electrical schematics, as ventilation systems often involve both aspects. My expertise allows me to quickly interpret complex diagrams, identify potential issues, and develop effective solutions. For example, I once used blueprints to locate a hidden leak in a ductwork section that was difficult to access. This saved time and resources by pinpointing the repair location before undertaking a comprehensive search.

Q 14. What are the common problems associated with ductwork and how are they addressed?

Ductwork is a critical component, but it’s prone to various issues. These problems often impact airflow and efficiency. Common problems include:

- Leaks: Leaks can result in energy waste, reduced airflow, and uneven air distribution. They are often caused by poorly sealed connections or damage to the ductwork itself.

- Sagging: Sagging can restrict airflow and potentially damage the ductwork. It’s often caused by improper installation or insufficient support.

- Corrosion: Corrosion can weaken the ductwork and create leaks. This is particularly common in areas with high humidity or exposure to chemicals.

- Obstructions: Debris, pest nests, or other obstructions can partially or completely block airflow, reducing system efficiency.

- Incorrect Sizing: Improperly sized ductwork can lead to excessive static pressure and reduce airflow. This reduces efficiency and can cause other parts of the system to wear faster.

Addressing these issues requires a variety of techniques. Leaks can be repaired with sealant or by replacing damaged sections. Sagging can be corrected by adding supports. Corrosion might necessitate replacing affected sections. Obstructions are removed through careful cleaning. Incorrect sizing requires re-engineering or modification to the ductwork. Regular inspections and preventative maintenance are key to minimizing these problems and ensuring optimal ductwork performance.

Q 15. How familiar are you with different types of ventilation dampers and their applications?

Ventilation dampers are crucial components controlling airflow within a ventilation system. They regulate the volume and direction of air, ensuring efficient and safe operation. I’m familiar with a wide range of damper types, including:

- Butterfly Dampers: Simple, cost-effective, and commonly used for basic airflow control. Think of them like a valve in a pipe, rotating to partially or fully block airflow. I’ve used these extensively in smaller commercial applications and residential HVAC systems.

- Volume Dampers: These offer more precise control over airflow, often incorporating a more complex linkage mechanism for accurate adjustment. I’ve worked with these in larger systems requiring precise balancing of air distribution across multiple zones.

- Fire Dampers: These are critical for fire safety, automatically closing in case of a fire to prevent the spread of smoke and flames. Regular inspection and testing are essential, and I have a proven track record of ensuring their proper functionality.

- Backdraft Dampers: These prevent backflow of air, common in exhaust systems where reverse airflow could compromise efficiency or safety. I’ve seen these crucial in kitchen ventilation hoods or exhaust systems connected to furnaces.

- Multi-blade Dampers: These provide smoother airflow control than butterfly dampers, particularly in larger ductwork. I’ve found them useful in applications requiring minimal pressure drop.

Selecting the appropriate damper depends heavily on factors like airflow requirements, pressure drop tolerance, and system safety considerations. For instance, a fire damper is non-negotiable in areas with stringent fire codes, while a simple butterfly damper might suffice for a smaller, less critical application.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with various types of ventilation fans and motors.

My experience encompasses a broad range of ventilation fans and motors. I’ve worked with everything from small, centrifugal fans used in bathroom exhausts to large, axial fans found in industrial settings. The choice of fan and motor depends on several factors including air volume, pressure requirements, and power consumption.

- Centrifugal Fans: These are ideal for applications needing higher pressure, such as moving air through long ductwork or against resistance. I’ve frequently used these in HVAC systems for buildings.

- Axial Fans: These are efficient for moving large volumes of air at lower pressures, making them suitable for applications like ventilation shafts or large spaces.

- Motor Types: I’ve worked with various motor types, including AC induction motors (common for their reliability and simplicity), DC motors (often used for speed control), and even specialized motors for energy-efficient applications (e.g., EC motors). Understanding the specific characteristics of each motor type is crucial for proper selection and maintenance.

For example, in one project involving a large industrial ventilation system, we replaced inefficient AC induction motors with high-efficiency EC motors, resulting in a significant reduction in energy consumption and operational costs. This involved careful consideration of motor torque, speed control requirements, and integration with the existing control system.

Q 17. What is your experience with troubleshooting and repairing ventilation system sensors?

Troubleshooting and repairing ventilation system sensors is a critical part of my expertise. These sensors, such as pressure sensors, temperature sensors, and airflow sensors, provide vital data for system control and monitoring. Failures can lead to inefficient operation or even safety hazards.

My troubleshooting approach is systematic. It usually starts with a thorough inspection, often involving visual checks for obvious damage or loose connections. Then, I use diagnostic tools (discussed later) to identify faulty sensors. The repair process varies depending on the sensor type. Sometimes, it’s a simple matter of replacing a faulty sensor, while other times it may involve more complex calibration or testing procedures. For instance, a faulty pressure sensor might be causing improper airflow distribution, which I’d resolve by replacing it and re-balancing the system.

I’m experienced in dealing with various sensor technologies, including analog and digital sensors, and understand how they interact with the system’s control logic. Understanding sensor calibration and accuracy is essential for reliable system operation. A common issue is drift in sensors over time; knowing how to detect and compensate for that is critical.

Q 18. How do you handle emergency repairs on ventilation systems?

Emergency repairs require swift and decisive action. My approach prioritizes safety and minimizing disruption. First, I assess the situation to identify the problem and potential hazards. This might involve isolating the affected area to prevent further problems or potential injuries. Then, I prioritize the repair based on the severity of the issue. A complete system failure requires immediate action, while a minor issue can wait for a scheduled repair.

I always have a readily available toolkit for emergency repairs, containing essential components like spare fuses, belts, and common sensor replacements. I also maintain a network of reliable suppliers for parts that might not be readily available. Communication is critical; keeping building management informed and providing regular updates is essential during an emergency repair.

For instance, I once had to handle a complete fan failure in a hospital operating room during a surgery. The immediate priority was to get the backup system online while contacting a supplier for a replacement fan motor. The quick response prevented any serious complications.

Q 19. Describe your experience with using diagnostic tools for ventilation systems.

I am proficient in using a variety of diagnostic tools for ventilation systems. These tools provide critical data for assessing system performance, troubleshooting malfunctions, and optimizing operation. Some examples of tools I regularly use include:

- Manometers: Used to measure pressure differences across ductwork, helping to identify blockages or imbalances.

- Anemometers: Measure airflow velocity to verify system performance and identify areas needing adjustment.

- Thermal anemometers: Measure airflow while also factoring in temperature, which is crucial in heat transfer analysis.

- Data loggers: Record data over time, helping to identify patterns or trends that might indicate developing problems.

- Multimeters: Essential for checking electrical components, such as motors, sensors, and control circuits.

- Specialized software: Many modern ventilation systems use computer-based control systems and monitoring software which provide invaluable data and diagnostic tools.

The effective use of these tools requires a solid understanding of ventilation system dynamics and the ability to interpret the data generated. I frequently use a combination of these tools to provide a comprehensive diagnosis, ensuring that any problems are identified accurately and efficiently.

Q 20. How do you ensure compliance with safety regulations when working on ventilation systems?

Safety is paramount in ventilation system maintenance. I meticulously follow all relevant safety regulations, including OSHA guidelines and any specific codes applicable to the building or industry. This includes but is not limited to:

- Lockout/Tagout Procedures: Always disconnect power sources before working on electrical components to prevent electrical shock.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as safety glasses, gloves, and respirators, is mandatory, especially when working with potentially hazardous materials or in confined spaces.

- Confined Space Entry Procedures: Following strict procedures for entering confined spaces to ensure adequate ventilation and monitoring for hazardous gases.

- Fall Protection: Using appropriate fall protection equipment when working at heights.

- Respiratory Protection: Using appropriate respirators when working in areas with potential exposure to dust, asbestos, or other harmful substances.

Regular safety training and maintaining updated knowledge of safety regulations are essential. I proactively identify and mitigate potential hazards, ensuring a safe work environment for myself and others. Documentation of all safety measures taken is also a crucial aspect of my work.

Q 21. Explain your knowledge of different types of ventilation system energy-efficiency upgrades.

Energy efficiency is a major focus in modern ventilation system design and maintenance. There are various upgrades that can significantly reduce energy consumption and operational costs. Some common examples include:

- Variable Frequency Drives (VFDs): These allow for precise control of fan speed, reducing energy consumption by matching airflow to actual needs. I’ve often implemented VFDs to optimize energy usage based on occupancy and environmental conditions.

- High-Efficiency Motors: Replacing old, inefficient motors with modern high-efficiency motors (like EC motors) can drastically reduce energy consumption. These motors often come with built-in intelligence to further optimize performance.

- Improved Ductwork Design and Sealing: Properly sealed and insulated ductwork reduces air leakage, preventing energy loss and enhancing system efficiency.

- Heat Recovery Ventilators (HRVs): These systems recover heat from exhaust air and transfer it to incoming fresh air, reducing heating and cooling loads.

- Smart Controls and Sensors: Integrating smart controls and sensors allows for real-time monitoring and optimization of system operation based on occupancy, environmental conditions, and other factors.

The best energy-efficiency upgrades depend on the specific system and its operational profile. A thorough assessment is necessary to identify the most cost-effective and impactful upgrades. For instance, in one project, we implemented a combination of VFDs and improved duct sealing, resulting in a 25% reduction in energy consumption for a large office building.

Q 22. How familiar are you with building codes and regulations related to ventilation?

Building codes and regulations regarding ventilation are crucial for ensuring occupant health and safety. My familiarity extends to ASHRAE standards (like 62.1 for ventilation), local building codes (which vary by jurisdiction – I’m proficient in [mention specific local codes, e.g., California Title 24]), and OSHA guidelines related to workplace air quality. I understand the requirements for minimum ventilation rates, air filtration, and the control of pollutants like carbon dioxide, volatile organic compounds (VOCs), and biological contaminants. For example, I’ve successfully navigated projects requiring compliance with stringent energy efficiency standards, ensuring the ventilation system meets both performance and regulatory requirements without compromising occupant comfort.

I regularly review updates to these codes and regulations to stay current on best practices and to ensure the systems I maintain are compliant. This includes understanding the implications of changes and adapting maintenance schedules accordingly. Ignoring these regulations can lead to hefty fines and, more importantly, jeopardize the health and safety of building occupants.

Q 23. Describe your experience with maintaining different types of ventilation system filters.

My experience encompasses maintaining a wide array of ventilation system filters, from basic fiberglass filters to more advanced HEPA (High-Efficiency Particulate Air) filters and specialized filters designed to remove specific contaminants like activated carbon filters for VOCs. I’m proficient in selecting the appropriate filter type based on the system’s requirements and the specific pollutants being addressed. This includes understanding filter ratings (like MERV – Minimum Efficiency Reporting Value) and their implications for air quality.

Maintaining these filters involves regular inspections for clogging, damage, or excessive wear. I follow established procedures for filter replacement, ensuring proper sealing to avoid bypass leakage. For instance, in a recent project involving a hospital operating room, I implemented a rigorous HEPA filter change-out schedule and meticulous documentation to maintain the sterile environment and prevent the spread of airborne pathogens. Failure to properly maintain filters can significantly reduce the efficiency of the ventilation system, leading to poor indoor air quality and potential health problems.

Q 24. How do you document maintenance activities and generate reports?

I meticulously document all maintenance activities using a combination of digital and physical records. This includes detailed checklists for each task, with specific information on the date, time, performed actions, parts replaced (including serial numbers), any identified issues, and corrective measures taken. Digital records are maintained in a dedicated database or software (more on that in the next answer), with clear, well-organized files. Physical records such as signed-off work orders are kept in a secure location.

Reports generated from this data offer a clear picture of system performance and maintenance history. These reports often include summaries of completed tasks, identified problems and their solutions, and recommendations for preventative maintenance or upgrades. This data is crucial for trend analysis, predictive maintenance, and demonstrating compliance with regulatory requirements. For example, a comprehensive report detailing filter changes over a year helps justify budget requests for filter replacements in the following year.

Q 25. What software or tools do you use for tracking and managing ventilation system maintenance?

I utilize a combination of software and tools to track and manage ventilation system maintenance efficiently. This often includes Computerized Maintenance Management Systems (CMMS) such as [mention specific CMMS software, e.g., Fiix, UpKeep], which allow for scheduling preventative maintenance, tracking work orders, managing inventory, and generating reports. I also utilize mobile apps that integrate with these systems, allowing for real-time updates in the field. In addition to CMMS, I frequently employ specialized testing equipment such as anemometers (for airflow measurement), pressure gauges, and particle counters to measure system performance and identify potential problems. This data is then entered into the CMMS to maintain a comprehensive record.

Q 26. Describe your approach to problem-solving when dealing with complex ventilation system issues.

My approach to problem-solving follows a systematic process. When faced with a complex ventilation system issue, I start by gathering all relevant information: reviewing system documentation, inspecting the system, and talking to building occupants to identify the nature of the problem. This is followed by a thorough diagnosis using appropriate testing equipment and data analysis, to pinpoint the root cause. I then develop several possible solutions, evaluating each for its effectiveness, cost, and feasibility. After selecting the best solution, implementation is carefully planned and executed, with continuous monitoring to confirm the effectiveness of the solution. If the initial solution proves unsuccessful, I re-evaluate the problem and proceed through the process again. For instance, if a system shows low airflow, I might systematically check for ductwork leaks, filter clogging, fan motor issues, or damper malfunctions before identifying the correct course of action.

Q 27. Explain your experience with working in a team environment for maintenance tasks.

I have extensive experience working collaboratively in team environments for ventilation system maintenance. Effective teamwork is paramount in this field, especially when dealing with large or complex systems. My approach involves clear communication, shared responsibility, and a collaborative problem-solving approach. I actively participate in team meetings, share my expertise, and contribute to brainstorming sessions. I’m comfortable delegating tasks to team members based on their skills and experience, and I provide guidance and support when needed. A recent project involved coordinating a team of technicians to replace a large air handling unit in a high-rise building; successful coordination was key to minimizing disruption to building occupants.

Q 28. How do you prioritize maintenance tasks to ensure optimal system performance?

Prioritizing maintenance tasks requires a balanced approach considering the system’s criticality, potential impact of failure, and the cost of maintenance. I employ a risk-based approach, prioritizing tasks that pose the highest risk of system failure or impact on building occupants’ health and safety. This often involves using a combination of preventative maintenance schedules based on manufacturer recommendations and predictive maintenance techniques leveraging data from system monitoring. For instance, a clogged filter in an occupied space is prioritized over a minor issue in a less critical area. I also consider factors like equipment age, past maintenance history, and the potential cost of repairs or replacements when determining the order of maintenance activities. This prioritized approach helps to maximize system uptime, minimize downtime costs, and ensure the long-term efficiency and reliability of the ventilation system.

Key Topics to Learn for Ventilation System Maintenance Interview

- Understanding Ventilation System Types: Explore different ventilation system designs (e.g., exhaust, supply, balanced), their applications, and operational principles. Consider the advantages and disadvantages of each type.

- Air Quality Control: Learn about the importance of maintaining proper air quality, including controlling humidity, temperature, and contaminant levels. Understand the role of filters, sensors, and control systems.

- Preventive Maintenance Procedures: Master the routine tasks involved in preventive maintenance, such as filter changes, belt adjustments, motor inspections, and cleaning. Understand the importance of adhering to scheduled maintenance plans.

- Troubleshooting and Diagnostics: Develop your skills in identifying and resolving common ventilation system issues. This includes understanding fault codes, using diagnostic tools, and applying logical problem-solving techniques.

- Safety Regulations and Procedures: Familiarize yourself with relevant safety regulations and procedures for working with ventilation systems, including lockout/tagout procedures and handling hazardous materials.

- Energy Efficiency and Optimization: Understand methods for improving the energy efficiency of ventilation systems, such as optimizing airflow, adjusting controls, and implementing energy-saving technologies.

- Building Codes and Standards: Become familiar with relevant building codes and standards related to ventilation system design, installation, and maintenance.

- HVAC System Integration: Understand how ventilation systems interact with other HVAC components (heating, cooling) and the overall building management system.

- Record Keeping and Documentation: Learn the importance of accurate and thorough record-keeping for maintenance activities, including documenting repairs, inspections, and preventative maintenance schedules.

Next Steps

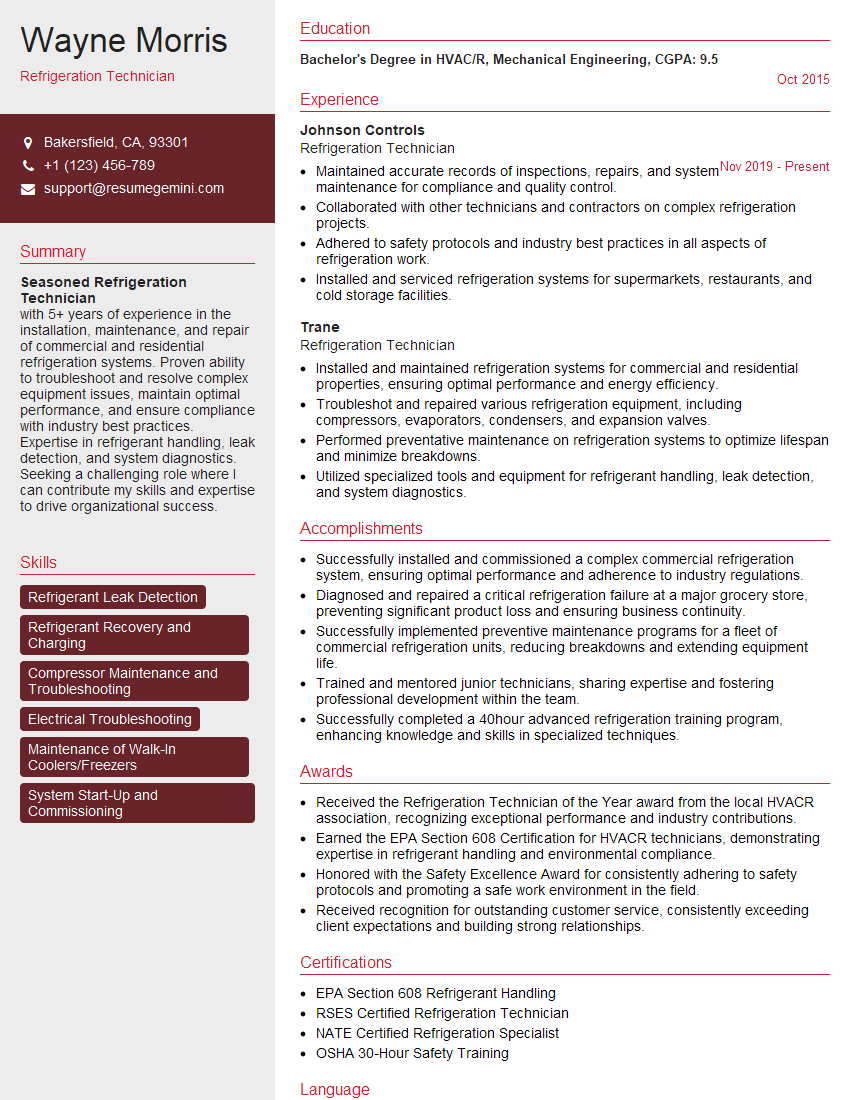

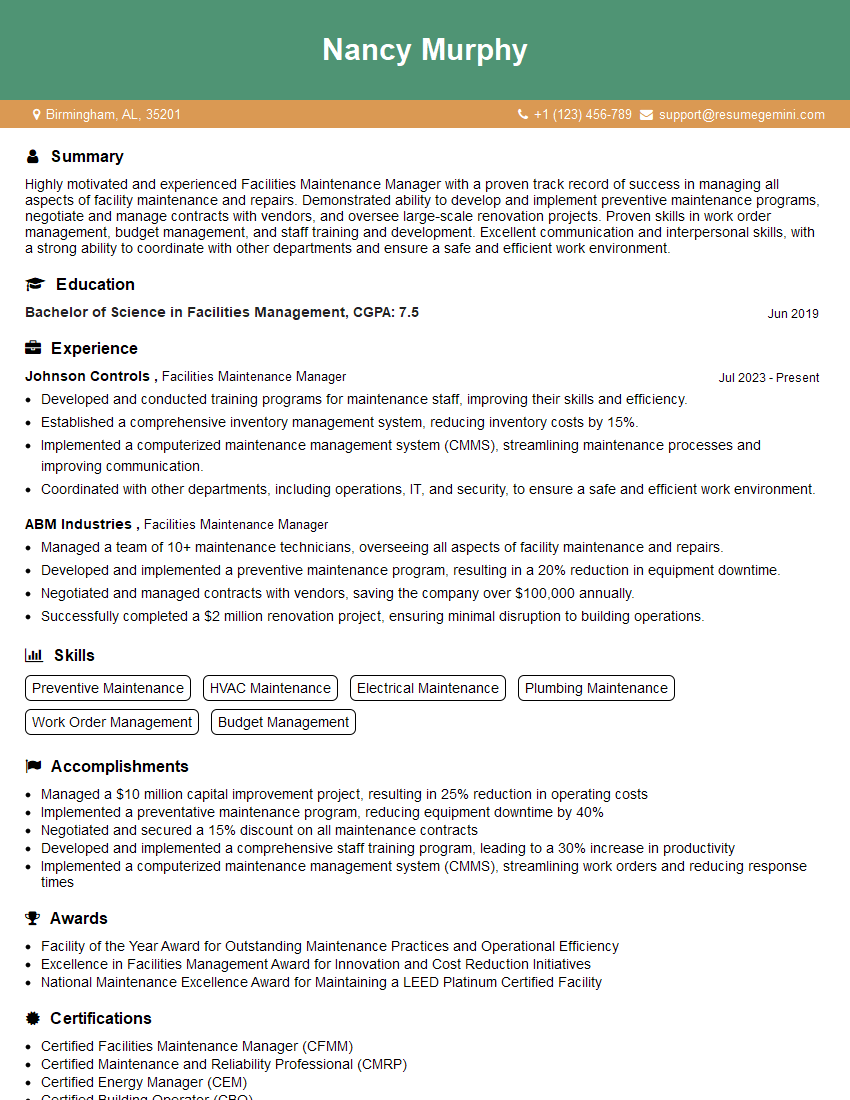

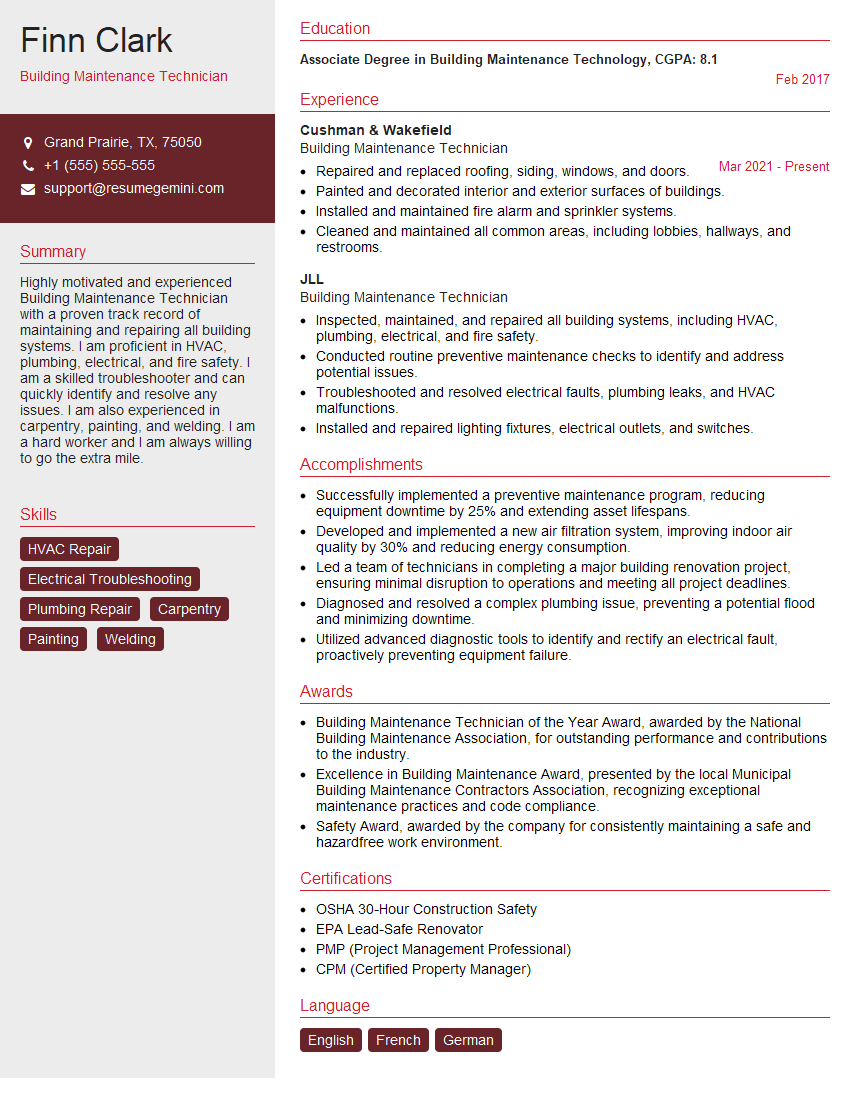

Mastering Ventilation System Maintenance is crucial for career advancement in the HVAC industry, opening doors to higher-paying roles and specialized positions. A strong, ATS-friendly resume is your key to unlocking these opportunities. ResumeGemini can help you create a compelling resume that highlights your skills and experience effectively. Using ResumeGemini, you can build a professional, impactful resume that gets noticed by recruiters. Examples of resumes tailored to Ventilation System Maintenance are available to help guide your process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO