Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Warehouse Equipment Operation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Warehouse Equipment Operation Interview

Q 1. Describe your experience operating a forklift.

I have over seven years of experience operating various forklift models, including sit-down counterbalanced forklifts, reach trucks, and order pickers. My experience spans diverse warehouse environments, from fast-paced distribution centers to smaller, more specialized storage facilities. I’ve consistently demonstrated proficiency in maneuvering forklifts in tight spaces, loading and unloading trucks efficiently, and stacking pallets to optimize warehouse space. For example, in my previous role at Acme Distribution, I was responsible for moving over 1000 pallets daily, consistently meeting or exceeding targets for on-time delivery and minimizing damage to goods. This involved a high degree of precision and the ability to adapt to changing demands throughout the workday.

Q 2. What safety procedures do you follow when operating warehouse equipment?

Safety is paramount in my work. Before operating any equipment, I always perform a thorough pre-operational inspection (detailed below in answer 4). Throughout operation, I adhere strictly to company safety policies, including wearing appropriate personal protective equipment (PPE) such as high-visibility vests, safety glasses, and steel-toe boots. I maintain a safe operating speed, avoiding sudden stops or turns, especially when navigating areas with pedestrian traffic. I’m always mindful of overhead clearances and use audible warnings when necessary. I prioritize awareness of my surroundings – checking blind spots carefully before moving and never operating equipment under the influence of drugs or alcohol. In addition, I’m well-versed in emergency procedures, understanding how to safely shut down the forklift and report any incidents or malfunctions immediately.

Q 3. Explain the different types of forklifts and their applications.

Forklifts come in various types, each suited for different applications.

- Counterbalance Forklifts: These are the most common type, ideal for general material handling, loading/unloading trucks, and stacking pallets. They are versatile but require more space to maneuver.

- Reach Trucks: These are excellent for narrow aisle applications, accessing high racking systems efficiently. They have a longer reach and improved maneuverability in confined areas.

- Order Pickers: Designed for order fulfillment, these forklifts allow operators to pick items at various heights from shelves, improving picking efficiency and reducing walking distances. Some include platforms, others allow for picking items directly from the forks.

- Sit-down Rider Forklifts: Offer improved comfort and visibility for longer shifts. These are common in larger warehouses handling pallets.

- Stand-up Rider Forklifts: Compact and ideal for tight spaces, these are well-suited for maneuverability in smaller warehouses.

The choice of forklift depends on the specific warehouse layout, the type of goods handled, and the overall operational requirements.

Q 4. How do you perform a pre-operational inspection of a forklift?

My pre-operational inspection is a systematic process to ensure the forklift is safe and operational. I follow a checklist, typically including:

- Visual Inspection: Checking for any visible damage to the forks, tires, mast, body, and safety features.

- Fluid Levels: Verifying the levels of hydraulic fluid, engine oil, and coolant.

- Tires: Inspecting tire pressure and condition – looking for wear, tears, or damage.

- Brakes: Testing the functionality of the brakes – ensuring they respond effectively.

- Lights and Horns: Checking that all lights (headlights, brake lights, warning lights) and the horn are working properly.

- Steering and Controls: Testing the steering mechanism and all controls to ensure smooth and responsive operation.

- Safety Devices: Verifying that safety devices like the seat belt, horn, and emergency stop button are in good working order.

If any issues are detected, I immediately report them to my supervisor and do not operate the forklift until the necessary repairs are completed.

Q 5. What are the load capacity limits of the forklifts you’ve operated?

The load capacity limits of the forklifts I’ve operated have ranged from 3,000 pounds to 10,000 pounds, depending on the model and type. I always adhere to the manufacturer’s specified load capacity and never exceed the limit. Overloading a forklift is extremely dangerous and can lead to equipment failure, injuries, or even fatalities. I always carefully check the load capacity plate located on the forklift before lifting any load. Understanding the weight of the goods being handled is essential to prevent overloading.

Q 6. How do you handle different types of warehouse loads (e.g., pallets, boxes)?

Handling various warehouse loads requires adapting my approach. With pallets, I ensure they are stable and properly secured before lifting. I use appropriate forklift attachments, such as forks of suitable width, to avoid damaging the pallet or its contents. For boxes, I consider their weight distribution to prevent tipping. I often use pallet jacks to consolidate individual boxes onto pallets for safer and more efficient handling. For uneven or oddly shaped loads, I take extra precautions to ensure stability and balance using straps or other securing devices. I always prioritize proper load distribution and center of gravity awareness to maintain safe handling and prevent accidents.

Q 7. Describe your experience with order picking and fulfillment.

I have significant experience with order picking and fulfillment, utilizing both manual picking and forklift-assisted order picking. My experience includes working with various Warehouse Management Systems (WMS) to locate, pick, and stage orders efficiently. I’m proficient in utilizing pick sheets and RF scanners for accurate order fulfillment, consistently meeting or exceeding accuracy targets. In a previous role, I was responsible for managing multiple order types, including high-volume and fast-paced orders with tight deadlines. My ability to maintain organization, prioritize tasks, and work efficiently under pressure has enabled me to consistently deliver high-quality order fulfillment services. This often involved precise placement of items to prevent damage and efficiently loading completed orders onto outgoing shipments.

Q 8. How do you maintain warehouse inventory accuracy?

Maintaining warehouse inventory accuracy is crucial for efficient operations and profitability. It involves a multi-pronged approach combining robust systems, meticulous processes, and diligent personnel.

- Cycle Counting: Instead of a full inventory count which disrupts operations, we regularly count a small subset of inventory items. This allows for the identification of discrepancies early on and prevents large errors from accumulating. For example, we might count all items from aisle 3 on Mondays, aisle 5 on Wednesdays, and so on, rotating through the entire warehouse regularly.

- Regular Audits: Periodic, more thorough audits verify the accuracy of cycle counting and identify systemic issues. This could involve physically counting everything in a specific zone or comparing physical inventory to the WMS data.

- WMS Integration: A well-implemented Warehouse Management System (WMS) tracks inventory movements in real-time. Every item received, picked, or put away is logged, minimizing human error. Any discrepancies are flagged for investigation.

- Proper Receiving Procedures: Thorough checks against purchase orders and verification of item quantities and condition upon arrival are fundamental to accuracy. Any discrepancies are immediately reported and rectified.

- Employee Training: Training staff on proper inventory handling, scanning procedures, and reporting discrepancies ensures everyone contributes to accuracy. Regular refresher courses reinforce best practices.

By combining these methods, we create a system of checks and balances, ensuring that our inventory records reliably reflect the actual stock on hand.

Q 9. What is your experience with warehouse management systems (WMS)?

I possess extensive experience with various Warehouse Management Systems (WMS), including [Mention Specific WMS systems you have experience with e.g., Manhattan Associates, Blue Yonder, NetSuite]. My experience spans implementing, configuring, and utilizing WMS functionalities across different warehouse environments.

- Order Management: I’ve worked extensively with WMS to optimize order fulfillment, from receiving purchase orders to generating picking lists, managing shipping labels, and tracking shipments.

- Inventory Control: I’m proficient in using WMS features for tracking inventory levels, managing stock replenishment, identifying slow-moving items, and minimizing stockouts.

- Reporting and Analysis: I utilize WMS reporting capabilities to track key performance indicators (KPIs) such as order accuracy, picking efficiency, and inventory turnover, enabling data-driven decision-making for continuous improvement.

- Integration with other systems: I have experience integrating WMS with Enterprise Resource Planning (ERP) systems, transportation management systems (TMS), and other warehouse technologies to ensure seamless data flow across the supply chain.

For instance, in my previous role, I implemented a new WMS which reduced order fulfillment time by 15% and inventory discrepancies by 10%. This was achieved through optimizing warehouse layout, integrating barcode scanning, and implementing a robust process for receiving and put-away.

Q 10. How do you prioritize tasks in a fast-paced warehouse environment?

Prioritizing tasks in a fast-paced warehouse is about balancing urgency and importance. I use a combination of techniques to effectively manage my workload:

- Understanding Order Urgency: I prioritize orders with tight deadlines or those designated as high priority by clients first. This often involves understanding the order fulfillment process and its timelines.

- Utilizing WMS: The WMS often provides task prioritization features. It will identify the next tasks based on order deadlines, stock location, and other parameters.

- Prioritizing based on Item Value: For similar-deadline tasks, I’d prioritize those involving higher-value or more sensitive items first.

- Batching Similar Tasks: Grouping similar tasks such as picking orders from the same location or preparing shipments with similar destinations saves time and improves efficiency.

- Communication & Collaboration: Open communication with colleagues is key. If a task needs assistance or requires resources that are unavailable, I flag this and re-prioritize accordingly.

Imagine a scenario where we have an urgent rush order, a large backorder, and routine restocking. I’d handle the rush order first, address any critical issues impacting the backorder, and then tackle the restocking.

Q 11. Explain your experience with RF scanners and other warehouse technologies.

I’m proficient in using RF scanners and other warehouse technologies to enhance efficiency and accuracy. This includes:

- RF Scanners: I use RF scanners daily for receiving, put-away, picking, and shipping. This ensures accurate tracking of inventory and minimizes manual data entry errors.

- Warehouse Control System (WCS): I have experience working with WCS software to manage automated guided vehicles (AGVs) and other automated equipment.

- Barcode/RFID Systems: I understand the application of barcode and RFID technology for item identification and tracking.

- Warehouse Management System (WMS) Integration: I’m adept at using scanners that seamlessly integrate with the WMS, reducing errors and improving data integrity.

For example, I once resolved a persistent issue with slow scanner performance by troubleshooting the network connection and updating the scanner firmware, resulting in a significant increase in picking efficiency.

Q 12. Describe your experience using pallet jacks and other material handling equipment.

I have extensive experience operating pallet jacks, forklifts, and other material handling equipment, ensuring safe and efficient movement of goods. My experience includes:

- Pallet Jacks: I’m proficient in using manual and electric pallet jacks for moving pallets within the warehouse, ensuring proper load securing.

- Forklifts: I’m certified to operate various types of forklifts [Mention specific types of forklift licenses you have], adhering to all safety regulations.

- Order Pickers: I’m experienced using order pickers to access and retrieve items from various heights within a warehouse.

- Conveyors: I have some familiarity with operating and maintaining various conveyor systems.

In a recent project, I optimized the pallet stacking procedures in our warehouse using pallet jacks, resulting in increased storage space and reduced travel time for order pickers.

Q 13. How do you ensure the safety of yourself and others while operating warehouse equipment?

Safety is my top priority. I always adhere to all safety regulations and best practices when operating warehouse equipment. This involves:

- Pre-Operational Checks: Before operating any equipment, I conduct a thorough inspection to ensure it’s in safe working condition.

- Proper Training and Certification: I’m certified to operate the equipment I use and have received ongoing safety training.

- Following Safety Procedures: I strictly adhere to all established safety procedures, including wearing appropriate personal protective equipment (PPE).

- Maintaining Awareness of Surroundings: I always maintain a clear line of sight and am aware of my surroundings to avoid collisions or accidents.

- Reporting Hazards: I immediately report any unsafe conditions or equipment malfunctions.

For example, I once noticed a loose floorboard and immediately reported it to management to prevent a potential tripping hazard. Preventing accidents is far more important than meeting arbitrary deadlines.

Q 14. What is your understanding of warehouse safety regulations?

My understanding of warehouse safety regulations is comprehensive. I am familiar with OSHA standards (or relevant regulations in your location) covering:

- Equipment Operation: Safe operation procedures for forklifts, pallet jacks, conveyors, and other material handling equipment.

- Personal Protective Equipment (PPE): Proper use and maintenance of safety gear, including safety shoes, high-visibility vests, hard hats, and hearing protection.

- Load Handling: Safe load securing and weight limits for various equipment.

- Fire Safety: Procedures for fire prevention and response, including locations of fire extinguishers and emergency exits.

- Emergency Procedures: Knowing how to respond to various emergencies, such as accidents, injuries, and equipment malfunctions.

- Housekeeping: Maintaining a clean and organized warehouse to prevent accidents.

Regular refresher training keeps me updated on the latest regulations and best practices, ensuring I maintain a safe and compliant work environment.

Q 15. How do you handle equipment malfunctions or breakdowns?

Equipment malfunctions are an inevitable part of warehouse operations. My approach is systematic and prioritizes safety above all else. First, I immediately cease operation of the malfunctioning equipment and secure the area to prevent accidents. I then follow established safety protocols, which usually involve reporting the issue to my supervisor and filling out the necessary incident reports. Depending on the nature of the malfunction, I might attempt basic troubleshooting – like checking power cords or fluid levels – if I’m trained to do so. However, I will never attempt repairs beyond my skillset; complex repairs are always left to qualified technicians. For example, if a forklift’s hydraulics fail, I wouldn’t try to fix it myself, but instead, clearly mark it as out-of-service and inform the maintenance team. My experience shows that a proactive, safety-first approach minimizes downtime and prevents more significant problems.

Following the initial assessment and reporting, I focus on finding alternative solutions to maintain workflow. This might involve utilizing backup equipment, re-assigning tasks, or temporarily adjusting operational procedures until the malfunctioning equipment is repaired. Throughout this process, clear communication with my team and supervisor is crucial to keep everyone informed and to ensure the smooth continuation of warehouse operations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with loading and unloading trucks?

I have extensive experience in loading and unloading trucks, utilizing various equipment such as forklifts, pallet jacks, and conveyors. My experience spans a range of truck types and sizes, from small delivery vans to large semi-trailers. I am proficient in efficiently loading and unloading pallets and other types of cargo, ensuring that items are properly secured and stacked to optimize space and prevent damage. This involves careful consideration of weight distribution to maintain balance and safety. I am familiar with various loading techniques, including using load-levelers and dock plates to bridge the gap between the truck and the warehouse dock, making the process safer and more efficient.

Safety is paramount in this process. I always check the truck’s condition before starting work, verify securement of the load, and utilize appropriate safety gear, such as high-visibility vests and safety shoes. I’m also experienced with documenting each load, including noting the quantity of items, condition of the packaging, and any potential issues that may need to be addressed. In one instance, I was able to proactively identify damaged packaging during loading which prevented further issues during transport.

Q 17. Describe your experience working with different types of warehouse layouts.

My experience encompasses various warehouse layouts, including traditional, U-shaped, L-shaped, and high-bay configurations. I understand how different layouts impact workflow and equipment selection. For instance, in a traditional warehouse with long aisles, forklifts with a greater reach may be necessary, while a high-bay warehouse necessitates the use of reach trucks or order pickers to access higher levels. I’m adept at adapting my operational strategies to the specifics of each layout. In one case, I helped to optimize the flow of a U-shaped warehouse by suggesting the relocation of certain storage areas and refining the route for order pickers, which reduced travel time and improved efficiency by 15%.

Understanding the layout is critical for efficient inventory management and safe equipment operation. For example, I know to adjust forklift speed in narrow aisles to prevent collisions and maintain awareness of blind spots. My adaptability allows me to quickly become productive in diverse warehouse settings.

Q 18. How do you maintain productivity while adhering to safety regulations?

Maintaining productivity while adhering to safety regulations is a top priority. It’s not a question of choosing one over the other; they are intrinsically linked. Increased safety often leads to increased productivity through reduced downtime and accidents. My strategy involves a combination of proactive measures and careful planning. This starts with receiving proper training and certification on all equipment and safety procedures. I always use Personal Protective Equipment (PPE) such as safety glasses, gloves, and steel-toed boots, and I ensure the equipment I operate is inspected and maintained regularly. I also follow standardized operating procedures meticulously, respecting speed limits and safe operating distances.

Furthermore, I prioritize preventative maintenance by immediately reporting any minor issues or potential hazards, which prevents problems from escalating. Effective communication with co-workers helps to prevent collisions and accidents in busy warehouse environments. For example, I always use visual cues and verbal communication to ensure safe movement of equipment and personnel. By prioritising safety, I’m able to ensure a more efficient and productive work environment overall. In the end, a safe workspace is a productive workspace.

Q 19. What is your experience with inventory control procedures?

My experience with inventory control procedures includes utilizing various systems, both manual and computerized. I’m proficient in receiving, storing, and picking inventory accurately and efficiently. I understand the importance of proper labeling, organization, and location tracking. I have experience with barcode scanning, RFID technology, and WMS (Warehouse Management System) software, and I am comfortable using these tools to maintain accurate inventory records and track items throughout the warehouse. I am also familiar with cycle counting and physical inventory procedures and understand the best practices to minimize discrepancies and maintain accuracy.

For instance, I’ve successfully integrated new RFID technology into an existing system, improving inventory tracking accuracy and speeding up the picking process significantly. I understand that accurate inventory management is essential for optimizing warehouse operations and reducing losses. I’m adept at using various techniques to ensure the efficiency and accuracy of inventory procedures, leading to reduced errors and improved overall operational performance.

Q 20. How do you deal with discrepancies in inventory counts?

Discrepancies in inventory counts are a common challenge, and addressing them effectively requires a methodical approach. My first step involves verifying the discrepancy through a recount, checking for potential data entry errors in the system, and ensuring that the physical inventory matches the digital records. I would investigate all potential causes of the discrepancy, including damaged or misplaced goods, inaccurate labeling, and errors during the receiving or shipping process. I’m also very familiar with using cycle counting, which minimizes disruption compared to a full physical inventory. This approach helps to identify and correct small discrepancies regularly, which prevents larger problems from developing.

If the discrepancy remains after initial investigations, I’d escalate the issue to my supervisor and involve the appropriate personnel – potentially accounting, or the shipping and receiving teams – to conduct a thorough investigation. The process might involve reviewing security footage or engaging in a thorough search to locate misplaced items. Documenting the entire investigation process is essential for future reference and to prevent similar issues from arising again. A detailed record helps identify trends and weaknesses in the current inventory management system, improving processes overall.

Q 21. Describe your problem-solving skills in relation to warehouse equipment operation.

My problem-solving skills are a crucial aspect of my ability to operate warehouse equipment effectively. I approach problems systematically, starting with a clear identification of the issue. This involves analyzing the situation, gathering relevant data, and considering various potential causes. I then develop potential solutions, evaluating each for feasibility, cost, and potential impact on safety and productivity. After choosing a solution, I implement it carefully, monitoring the results and making adjustments as needed. This iterative approach allows me to refine my solutions until the problem is resolved successfully.

For example, when faced with a recurring issue of forklift tire punctures in a specific area of the warehouse, I systematically investigated potential causes. This included examining the warehouse floor for debris or sharp objects, evaluating the tire pressure and maintenance schedule, and analyzing forklift operating patterns. I determined that sharp debris from pallet breakages was the primary cause, so I implemented a solution that involved more rigorous pallet inspections, regular floor sweeping, and the use of protective floor mats in the affected area. This systematic approach led to a significant reduction in tire punctures, improving both safety and equipment uptime.

Q 22. How do you contribute to a positive and efficient team environment in a warehouse?

A positive and efficient team environment in a warehouse is crucial for productivity and safety. My contribution focuses on proactive communication, collaboration, and a commitment to shared goals. I believe in fostering a culture of mutual respect and support, where everyone feels comfortable sharing ideas and concerns.

- Proactive Communication: I consistently keep my team informed about my progress, any potential issues I foresee, and any changes in my workflow. This prevents bottlenecks and ensures everyone is on the same page.

- Collaboration: I actively seek input from my colleagues and offer assistance whenever needed. Teamwork is essential in a fast-paced warehouse environment, and I prioritize collaborative problem-solving.

- Shared Goals: I understand the overall warehouse objectives and align my work accordingly. I’m always looking for ways to improve efficiency and meet targets, working alongside my team to achieve our shared goals. For instance, if we’re facing a backlog, I might suggest implementing a new loading strategy or optimizing our route planning.

- Safety First: I actively participate in safety training and promote safe working practices among my colleagues. I believe that a safe environment leads to a more productive and positive environment.

Q 23. What are your strengths and weaknesses as a warehouse equipment operator?

My strengths as a warehouse equipment operator lie in my proficiency with various types of equipment, my attention to detail, and my ability to work efficiently under pressure. I’m adept at operating forklifts, pallet jacks, and order pickers, and I have a solid understanding of warehouse safety regulations. I’m also highly organized and methodical, ensuring accurate and timely order fulfillment.

One area for improvement is my experience with specific warehouse management systems (WMS). While I am proficient in using common equipment, I am eager to expand my knowledge and skills in this area. I am actively seeking opportunities to learn new WMS platforms and improve my ability to integrate technology into my workflow. I believe that ongoing professional development is crucial in this field, and I am committed to enhancing my skills continuously.

Q 24. What are your salary expectations for this position?

My salary expectations are in line with the industry standard for experienced warehouse equipment operators with my skill set and experience in this region. I’m confident that my contributions would quickly justify the investment. I’m open to discussing a competitive compensation package that reflects my value to your organization.

Q 25. Why are you interested in this specific warehouse equipment operator position?

I’m particularly interested in this position because of [Company Name]’s reputation for its commitment to employee development, its focus on safety, and the opportunity to work with cutting-edge warehouse technology. The chance to contribute to a dynamic team and improve efficiency within a well-respected company is extremely appealing. I’ve also researched [Company Name]’s commitment to sustainable practices and believe that aligns perfectly with my own values.

Q 26. What are your career goals related to warehouse operations?

My career goals involve progressing into a supervisory role within warehouse operations. I am keen to enhance my leadership skills and contribute to the strategic planning and optimization of warehouse processes. I envision myself mentoring junior staff and leading teams to achieve operational excellence. My long-term goal is to become a highly skilled and respected warehouse manager, continuously improving efficiency and safety standards within a thriving organization. I plan to achieve this through continuous learning, actively seeking opportunities for professional development, and demonstrating strong leadership qualities in every role I undertake.

Q 27. What questions do you have for me about this position?

I have a few questions for you regarding this position. First, I’d like to understand more about the specific technologies and WMS used in your warehouse and what opportunities are available for training or professional development. Secondly, could you elaborate on the company’s approach to safety and the specific measures implemented to ensure a safe working environment? Finally, I would like to know more about the team I would be working with and the opportunities for advancement within the company.

Key Topics to Learn for Warehouse Equipment Operation Interview

- Safety Procedures and Regulations: Understanding and applying all relevant safety protocols for operating warehouse equipment, including pre-operation checks, emergency procedures, and hazard identification.

- Equipment Operation and Maintenance: Practical knowledge of operating various warehouse equipment such as forklifts, pallet jacks, order pickers, and conveyors. This includes understanding basic maintenance checks and troubleshooting minor issues.

- Warehouse Layout and Organization: Familiarity with warehouse layouts, inventory management systems, and efficient movement of goods within the facility. Understanding how equipment operation contributes to overall warehouse efficiency.

- Inventory Management Techniques: Knowledge of inventory control processes, including receiving, storing, picking, and shipping goods. Understanding how equipment operation impacts inventory accuracy and efficiency.

- Load Handling and Securing: Proper techniques for loading, unloading, and securing goods to prevent damage and ensure safety. Understanding weight limits and load stability principles.

- Troubleshooting and Problem-Solving: Ability to identify and address minor equipment malfunctions, and to effectively communicate issues to supervisors. Demonstrating problem-solving skills in real-world scenarios.

- Technology Integration: Understanding how warehouse management systems (WMS) and other technologies interact with warehouse equipment and influence operational efficiency. This includes familiarity with RF scanners and other related technologies.

- Productivity and Efficiency: Strategies for optimizing workflow and maximizing productivity while operating warehouse equipment, focusing on safety and minimizing downtime.

Next Steps

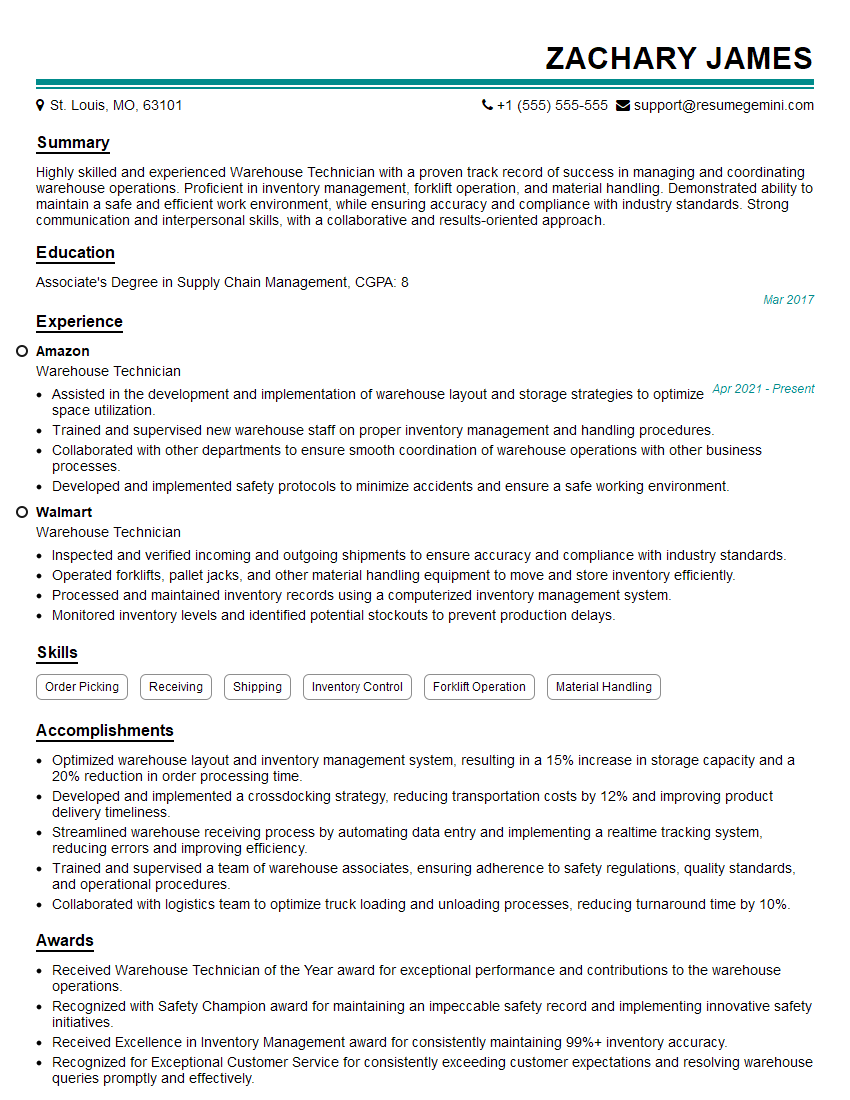

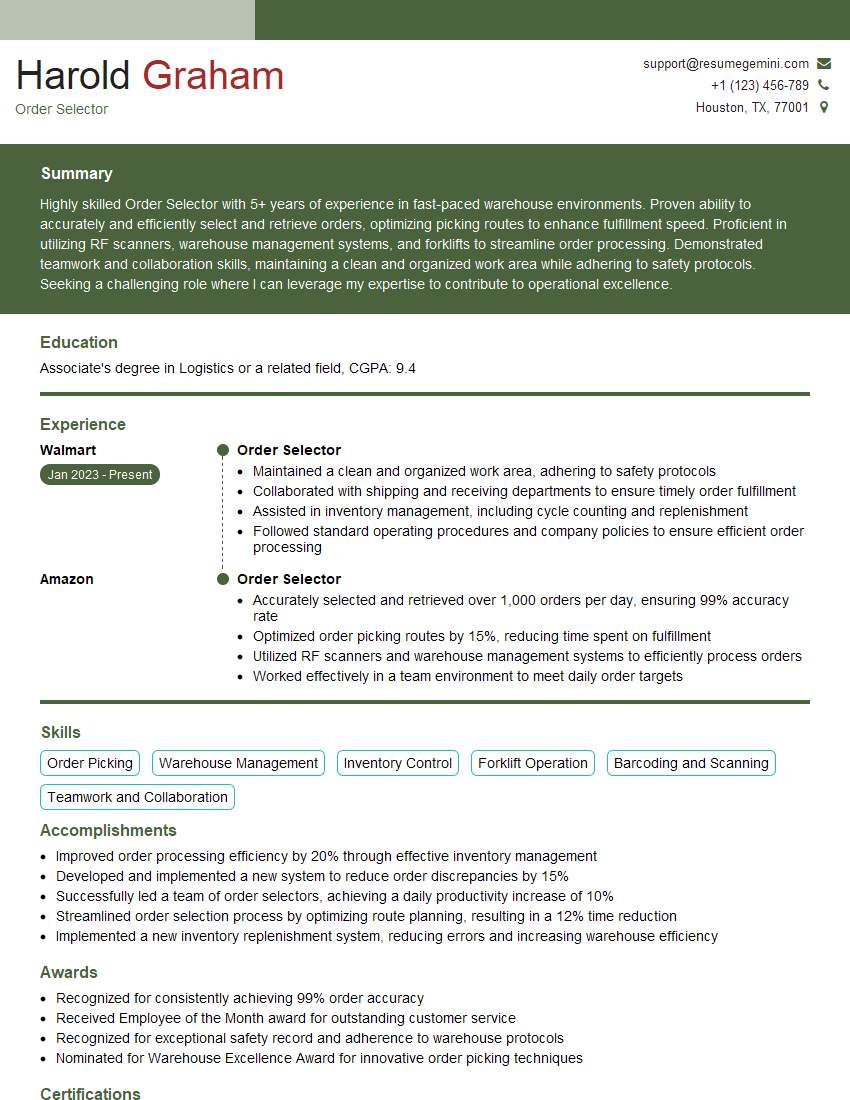

Mastering Warehouse Equipment Operation opens doors to a rewarding career with excellent growth potential. Advancement opportunities often include supervisory roles, specialized equipment operation, and management positions. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Warehouse Equipment Operation are available to guide you, showcasing how to best present your qualifications to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO