Cracking a skill-specific interview, like one for Warehousing and Logistics, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Warehousing and Logistics Interview

Q 1. Explain your experience with different Warehouse Management Systems (WMS).

My experience with Warehouse Management Systems (WMS) spans several leading platforms, including Blue Yonder, Manhattan Associates, and NetSuite WMS. I’ve worked with these systems in diverse settings, from small distribution centers to large, multi-national fulfillment operations. My expertise encompasses not just the operational aspects – like order fulfillment, inventory tracking, and putaway strategies – but also the implementation, configuration, and ongoing optimization of these systems. For example, during my time at [Previous Company Name], I was instrumental in the successful implementation of Blue Yonder WMS, which resulted in a 15% reduction in order fulfillment time and a 10% decrease in picking errors. This involved detailed process mapping, user training, and ongoing system monitoring and adjustment. In another role at [Another Previous Company Name], I leveraged NetSuite WMS to integrate our warehouse operations with our existing ERP system, improving data visibility and enabling more accurate forecasting. I’m proficient in customizing WMS settings to align with specific business requirements, integrating with other systems, and developing reporting strategies to monitor key performance indicators.

Q 2. Describe your process for optimizing warehouse layout for efficiency.

Optimizing a warehouse layout is crucial for efficiency. My process involves a systematic approach: First, I carefully analyze the product flow, identifying the most frequently accessed items and those with the highest turnover rates. This often involves using ABC analysis to categorize inventory based on value and volume. Next, I consider the characteristics of the products – size, weight, fragility – to determine appropriate storage locations. Fast-moving items (A-items) are positioned closest to shipping docks and picking stations, using strategies like ‘slotting optimization’ to minimize travel time. Larger, less frequently accessed items (C-items) are often placed in less accessible areas. I use tools like warehouse management software and specialized layout planning software to simulate different configurations and model the impact on throughput. For instance, at [Previous Company Name], I redesigned the warehouse layout using a ‘U-shaped’ flow, reducing travel distance by 20% and increasing overall picking efficiency. This also involved considering safety aspects, ensuring adequate aisle width and implementing clear signage to minimize accidents. Finally, I continuously monitor and adjust the layout based on real-time performance data and changing business needs.

Q 3. How do you handle inventory discrepancies?

Inventory discrepancies are inevitable, but proactively addressing them is key. My approach involves a multi-pronged strategy starting with regular cycle counting. This involves verifying a small portion of the inventory daily rather than a full annual physical count, providing a more frequent snapshot of accuracy. I also utilize barcode scanning and RFID technology to minimize manual data entry errors. When discrepancies arise, I investigate the root cause systematically. This could involve reviewing picking lists, shipping documents, and receiving records. I also examine warehouse processes for areas of potential weakness – for instance, inefficient putaway procedures or damaged labels. Once the cause is identified, I implement corrective actions – which might include staff retraining, improving labeling practices, or refining inventory management processes. Addressing discrepancies promptly helps maintain accuracy and prevents larger problems down the line. For example, at [Previous Company Name], we identified a systematic error in the receiving process, leading to frequent discrepancies. By retraining staff and implementing double-checking procedures, we reduced discrepancies by 50% within three months.

Q 4. What metrics do you use to measure warehouse performance?

I use a range of metrics to measure warehouse performance, broadly categorized into operational efficiency, inventory accuracy, and order fulfillment metrics. These include:

- Order fulfillment rate: Percentage of orders fulfilled on time and in full.

- Inventory accuracy: Percentage of inventory items accurately counted and tracked.

- Picking accuracy: Percentage of orders picked without errors.

- Order cycle time: Time taken to process an order from receipt to shipment.

- Warehouse throughput: Number of units processed per hour or day.

- Inventory turnover rate: Number of times inventory is sold and replenished in a given period.

- Storage space utilization: Percentage of available storage space used effectively.

- Cost per order: Total warehouse costs divided by the number of orders processed.

These metrics, regularly tracked and analyzed, provide a clear picture of warehouse performance, allowing for data-driven improvements. Key Performance Indicators (KPIs) are regularly reviewed to ensure that the warehouse is operating efficiently and effectively. I use dashboards to visualize this data and communicate key findings to stakeholders.

Q 5. Explain your experience with various inventory control methods (FIFO, LIFO, etc.).

My experience encompasses various inventory control methods, including FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and FEFO (First-Expired, First-Out). The choice of method depends heavily on the type of inventory being managed. FIFO is commonly used for perishable goods or products with short shelf lives, ensuring that older items are used first to minimize waste. LIFO is sometimes used for non-perishable goods, particularly when inventory costs are fluctuating, as it can influence the cost of goods sold. FEFO is crucial for products with expiration dates, ensuring that the oldest items are used before they expire. I’ve used all these methods across different projects. For example, in a project involving a food distribution center, the implementation of a strict FEFO system using barcode scanning ensured that no products expired on the shelves. In a project handling non-perishable hardware, we utilized a FIFO system optimized by the WMS to ensure that inventory flow was optimized and that older stock was not left sitting on the shelves unnecessarily, improving turnover. The key is to select the method that best aligns with the product’s characteristics and business objectives, ensuring accurate cost accounting and minimal waste.

Q 6. How do you manage peak seasons and increased order volumes?

Managing peak seasons requires proactive planning and flexible execution. My strategy involves forecasting demand accurately based on historical data and market trends. This allows for sufficient staffing levels, ensuring we have the right number of people to handle increased order volume. We may also temporarily increase warehouse space, either through renting additional facilities or optimizing existing space. Furthermore, I focus on optimizing warehouse processes to maximize efficiency during peak periods. This can include leveraging overtime, cross-training employees to handle multiple tasks, and implementing flexible scheduling. Technology plays a vital role; for example, automation through robotics or conveyor systems can significantly improve throughput. Clear communication and collaboration are also paramount, ensuring that all team members are aware of their roles and responsibilities during this busy period. For example, during the holiday season at [Previous Company Name], we successfully managed a 400% increase in order volume by implementing a combination of these strategies, resulting in minimal delays and high customer satisfaction.

Q 7. Describe your experience with different types of warehouse equipment.

My experience encompasses a wide range of warehouse equipment, including:

- Forklifts (various types: counterbalance, reach truck, order picker): Proficient in safe operation and maintenance.

- Conveyors: Familiar with different types – roller, belt, chain – and their integration into warehouse processes.

- Automated Guided Vehicles (AGVs): Experience in managing and optimizing AGV routes and operations.

- Stackers: Used for high-density storage in narrow aisles.

- Barcode scanners and RFID readers: Essential for accurate inventory tracking and picking.

- Warehouse Management System (WMS) integrated equipment: Experience in configuring and using equipment that interfaces with WMS for optimized control.

I understand the importance of selecting the right equipment for specific tasks, considering factors such as capacity, speed, and safety. I’m also knowledgeable about the maintenance and safety protocols associated with each type of equipment. At [Previous Company Name], we replaced manual pallet jacks with a fleet of automated guided vehicles, resulting in a significant improvement in throughput and reduction in labor costs. This involved careful planning, training, and integration with the existing WMS.

Q 8. How do you ensure warehouse safety and compliance with regulations?

Warehouse safety and regulatory compliance are paramount. My approach is multi-faceted, focusing on proactive prevention and reactive response. It begins with a thorough understanding of all applicable OSHA (Occupational Safety and Health Administration) regulations, local fire codes, and any industry-specific standards.

- Regular Inspections: I implement a robust system of regular safety inspections, documented meticulously, to identify and rectify potential hazards before they cause incidents. This includes checking for proper forklift operation, adequate lighting, clear pathways, and the secure storage of hazardous materials.

- Employee Training: Safety training is not a one-time event; it’s an ongoing process. Employees receive comprehensive training on safe operating procedures, including the use of equipment, handling of materials, and emergency response protocols. This includes regular refresher courses and scenario-based drills.

- Emergency Preparedness: We develop and regularly practice emergency response plans, including fire evacuation procedures, spill containment strategies, and first-aid protocols. This involves clearly marked exits, readily available safety equipment, and designated emergency response teams.

- Documentation and Reporting: Maintaining accurate records of safety inspections, training, and incidents is crucial for demonstrating compliance and identifying areas for improvement. We use a dedicated safety management system (SMS) to track and manage this data effectively. Thorough incident reporting allows us to learn from mistakes and prevent future occurrences.

For example, in a previous role, we implemented a new system for managing hazardous waste, reducing incidents by 30% within six months. This involved comprehensive training on proper handling and disposal procedures and a new color-coded labeling system for easy identification.

Q 9. Explain your experience with transportation management systems (TMS).

My experience with Transportation Management Systems (TMS) spans several years and various platforms. I’ve worked with both cloud-based and on-premise TMS solutions, leveraging them to optimize transportation planning, execution, and analysis.

- Route Optimization: I utilize TMS to plan efficient routes, considering factors like distance, traffic patterns, delivery windows, and driver availability. This leads to reduced transportation costs and improved delivery times. For instance, I’ve used TMS software to analyze historical data and predict potential delivery delays, allowing for proactive adjustments to delivery schedules.

- Carrier Management: TMS facilitates communication and collaboration with carriers, allowing for efficient load tendering, tracking, and payment processing. We utilize features like automated rate calculation and bid management tools to negotiate favorable rates with carriers.

- Shipment Visibility: A key benefit of TMS is real-time shipment tracking and visibility. This enhances transparency and allows for timely intervention if any issues arise during transit. For example, if a shipment is delayed, the TMS system alerts the relevant personnel immediately, allowing for proactive measures to mitigate the impact.

- Reporting and Analytics: TMS provides comprehensive data analysis capabilities, allowing us to track key performance indicators (KPIs) such as on-time delivery rates, fuel efficiency, and transportation costs. This data drives continuous improvement initiatives.

In a previous role, implementing a new TMS resulted in a 15% reduction in transportation costs and a 10% improvement in on-time delivery rates within one year.

Q 10. How do you manage relationships with carriers and logistics providers?

Building and maintaining strong relationships with carriers and logistics providers is essential for efficient and reliable operations. My approach is built on open communication, mutual respect, and a focus on long-term partnerships.

- Collaboration and Communication: I prioritize clear and frequent communication with carriers and providers. This involves regular meetings, proactive updates, and timely feedback on performance. We use a combination of phone calls, emails, and collaborative platforms to maintain consistent communication.

- Performance Evaluation and Feedback: We establish clear performance metrics (KPIs) and regularly evaluate carrier performance based on these metrics. This includes on-time delivery rates, damage rates, and adherence to agreed-upon service levels. Constructive feedback is provided to carriers to help them improve.

- Negotiation and Contract Management: I am skilled in negotiating favorable rates and service agreements with carriers. This involves analyzing market conditions, comparing offers from multiple carriers, and securing contracts that align with our business needs.

- Relationship Building: Building strong personal relationships with key personnel at carrier companies is crucial. This involves attending industry events, participating in networking opportunities, and fostering mutual trust and respect.

For example, by fostering a strong relationship with one key carrier, we secured preferential rates and prioritized capacity during peak seasons, ensuring timely deliveries even during periods of high demand.

Q 11. How do you track and trace shipments?

Shipment tracking and tracing is critical for ensuring timely and accurate delivery. We employ a multi-layered approach combining various technologies and strategies.

- Real-time Tracking Systems: We leverage GPS tracking technology integrated with our TMS and warehouse management system (WMS) to monitor shipments in real-time. This provides visibility into the location and status of each shipment throughout its journey.

- Barcode and RFID Technology: Barcodes and RFID tags are used to track individual packages and pallets throughout the warehouse and during transit. This granular level of tracking allows for precise location identification and inventory management.

- Carrier Tracking Portals: We utilize the tracking portals provided by our carriers to access real-time shipment information and proactively identify potential delays or issues.

- Proactive Communication: We proactively communicate with customers and carriers regarding shipment updates, providing them with real-time tracking information and addressing any inquiries or concerns promptly. This ensures transparency and minimizes disruptions.

Think of it like tracking a package online; we’re constantly monitoring its progress and are prepared to handle any deviations from the expected delivery schedule. For example, if a shipment is experiencing an unforeseen delay, we proactively contact the customer to inform them and find alternative solutions to ensure timely delivery.

Q 12. Describe your experience with customs brokerage and international shipping.

My experience with customs brokerage and international shipping is extensive. I understand the complexities of navigating international regulations and ensuring compliance.

- Customs Documentation: I am proficient in preparing and submitting all necessary customs documentation, including commercial invoices, packing lists, certificates of origin, and other required forms. Accuracy in this documentation is crucial for smooth customs clearance.

- Harmonized System (HS) Codes: I have a thorough understanding of HS codes and their application to various products. Correct classification is critical for accurate duty and tax calculations.

- Regulatory Compliance: I stay updated on all relevant international trade regulations, including import/export restrictions, sanctions, and duty rates. This ensures compliance and minimizes potential delays or penalties.

- Relationship with Brokers: I have established strong working relationships with reputable customs brokers, leveraging their expertise to facilitate efficient customs clearance.

For instance, in a past role, I successfully navigated a complex customs clearance process involving specialized equipment, ensuring timely delivery and avoiding potential penalties by precisely categorizing the goods under the correct HS code.

Q 13. What is your experience with demand forecasting and inventory planning?

Demand forecasting and inventory planning are crucial for optimizing inventory levels and minimizing costs. My approach combines quantitative and qualitative methods.

- Historical Data Analysis: I analyze historical sales data, considering seasonality, trends, and other relevant factors, to develop accurate demand forecasts. Time series analysis techniques are commonly employed.

- Market Research and Trend Analysis: Staying informed about market trends, economic indicators, and competitor activities is crucial for refining demand forecasts. This might involve monitoring industry publications or consulting market research reports.

- Inventory Optimization Techniques: I utilize various inventory management techniques, such as Economic Order Quantity (EOQ) and Just-in-Time (JIT) inventory systems, to determine optimal order quantities and minimize inventory holding costs. The choice of method depends on the specific product and demand characteristics.

- Safety Stock Calculation: Calculating appropriate safety stock levels is critical to mitigate the risk of stockouts, while also avoiding excess inventory. This considers factors such as lead times, demand variability, and service level targets.

In a previous role, by implementing a more sophisticated forecasting model, we reduced inventory holding costs by 10% while simultaneously improving our on-hand inventory levels, resulting in fewer stockouts. This involved a combination of statistical forecasting and qualitative insights gathered from sales and marketing teams.

Q 14. How do you handle damaged or lost goods?

Handling damaged or lost goods requires a systematic approach that prioritizes investigation, documentation, and claim resolution.

- Damage Assessment: Upon discovery of damaged or lost goods, a thorough investigation is conducted to determine the cause of the damage or loss. This includes examining the goods, reviewing shipping documentation, and interviewing relevant personnel.

- Documentation and Reporting: Detailed documentation of the damage or loss, including photographic evidence, is crucial for supporting insurance claims or carrier claims. This information is carefully recorded and submitted to the appropriate parties.

- Carrier Claims: We file claims with the responsible carrier, providing all necessary documentation to support the claim. We actively pursue resolution and work with the carrier to recover losses or arrange for replacements.

- Insurance Claims: If the damage or loss is not covered by the carrier, we file a claim with our insurance provider, providing all necessary documentation.

- Customer Communication: Proactive communication with the customer is paramount. We keep them informed throughout the process, offering solutions such as replacements, refunds, or credits, as appropriate.

For example, we recently resolved a claim for a damaged shipment by collaborating with the carrier and providing comprehensive documentation, leading to a full reimbursement for the damaged goods. This minimized the financial impact on the company and maintained a positive relationship with our customer.

Q 15. Explain your experience with implementing and managing warehouse automation.

My experience with warehouse automation spans several years and includes the implementation and management of various systems, from automated guided vehicles (AGVs) and conveyor systems to Warehouse Management Systems (WMS) and Radio Frequency Identification (RFID) technologies. In one project, we implemented a WMS with integrated RFID tracking in a large distribution center. This significantly improved accuracy of inventory tracking and reduced picking errors by over 20%. Before implementation, we conducted a thorough needs assessment, carefully mapping existing workflows to identify bottlenecks and opportunities for automation. Post-implementation, we focused on continuous improvement, monitoring key performance indicators (KPIs) like order fulfillment rates, picking accuracy, and labor productivity to fine-tune the system. We also prioritized employee training, ensuring staff felt comfortable and proficient with the new technology. Another project involved the strategic deployment of AGVs to optimize the movement of goods across the warehouse floor, reducing transportation time and freeing up human resources for more value-added tasks. The success of these projects hinged on careful planning, strong stakeholder communication, and a commitment to ongoing optimization.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you improve efficiency in receiving, putaway, and picking processes?

Improving efficiency in receiving, putaway, and picking requires a holistic approach focusing on process optimization and technology. In receiving, implementing a streamlined check-in process with barcode scanning and integrated WMS eliminates manual data entry, reducing errors and speeding up the process. For putaway, optimizing storage layouts based on product velocity (frequency of picking) and implementing slotting optimization algorithms ensures that frequently accessed items are easily reachable. This can cut down on travel time and labor costs. In picking, techniques like batch picking, zone picking, and wave picking—where orders are grouped and picked in batches—can significantly boost efficiency. Deploying pick-to-light systems or voice-directed picking systems can further improve accuracy and speed. Regularly reviewing and adjusting these processes based on performance data and employee feedback is crucial for ongoing improvement. Think of it like a well-oiled machine—each part needs to work together smoothly and efficiently.

Q 17. How do you resolve conflicts with warehouse staff?

Resolving conflicts with warehouse staff requires a proactive and empathetic approach. Open communication is key. I always start by listening actively to understand the root cause of the conflict. Is it a workload issue? A lack of clarity on procedures? A personality clash? Once the problem is identified, I work collaboratively to find a solution. This might involve adjusting workflows, providing additional training, clarifying roles and responsibilities, or mediating between conflicting parties. Fairness and consistency are paramount. Applying company policies and procedures impartially builds trust and demonstrates that everyone is treated equitably. In some cases, involving HR might be necessary, but my priority is always to find a resolution within the team first, preserving morale and productivity. I view conflicts as opportunities for improvement, highlighting areas where processes or communication could be strengthened.

Q 18. Describe your experience with lean manufacturing principles in a warehouse setting.

Lean manufacturing principles, focusing on eliminating waste and maximizing value, are highly applicable in warehousing. In one project, we implemented 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize the warehouse floor, creating a cleaner, safer, and more efficient work environment. We also employed Kaizen events—short, focused improvement projects—to identify and eliminate bottlenecks in various processes. For example, we analyzed the picking process, identifying unnecessary movements and streamlining the layout to reduce travel time. Value stream mapping helped visualize the entire workflow, highlighting areas for improvement. By reducing waste (time, motion, inventory), we boosted productivity and reduced operational costs. The key to successful lean implementation is continuous improvement and employee involvement. Empowering employees to identify and solve problems leads to greater buy-in and more effective change.

Q 19. How do you maintain accurate inventory records?

Maintaining accurate inventory records is crucial for efficient warehouse operations. A robust Warehouse Management System (WMS) is essential, providing real-time visibility into inventory levels. This system should be integrated with all other warehouse processes, from receiving to shipping. Cycle counting, a regular process of verifying a sample of inventory against the WMS records, helps identify discrepancies early on. Regular physical inventory counts, although more time-consuming, ensure complete accuracy. Implementing barcode or RFID scanning eliminates manual data entry, reducing errors significantly. Employee training is also vital, ensuring accurate data entry and adherence to established procedures. Regular audits of inventory data, comparing WMS records with physical counts, identify any systematic errors or inaccuracies in the system. Investing in a high-quality WMS and regularly updating it ensures accurate and reliable inventory data.

Q 20. What are your strategies for reducing warehouse operating costs?

Reducing warehouse operating costs requires a multi-pronged approach. Optimizing space utilization, for instance, by implementing efficient storage solutions and maximizing vertical space, reduces the need for costly expansion. Improving the efficiency of processes (as discussed earlier) minimizes labor costs and reduces waste. Negotiating better rates with suppliers and transportation providers can significantly impact overall costs. Implementing energy-efficient equipment and lighting reduces utility expenses. Leveraging technology, such as automated systems and WMS, streamlines operations and minimizes errors, leading to cost savings in the long run. Regularly reviewing and analyzing operational data helps identify areas for improvement and cost reduction. Think of it as continuous cost optimization—a never-ending quest for efficiency and value.

Q 21. How do you ensure timely order fulfillment?

Ensuring timely order fulfillment hinges on several factors. An efficient order processing system, integrating seamlessly with the WMS, ensures orders are processed quickly and accurately. Optimizing picking and packing processes, utilizing techniques mentioned earlier, speeds up order fulfillment. Maintaining accurate inventory records prevents delays caused by stockouts. Effective communication with customers and transportation providers keeps everyone informed and ensures smooth delivery. Monitoring key performance indicators (KPIs) such as order cycle time and on-time delivery rates provides valuable insights into areas needing improvement. Proactive problem-solving, addressing potential bottlenecks before they impact fulfillment, helps maintain timely delivery. A well-trained and motivated workforce is also essential for efficient and timely order fulfillment, because people are the most important part of any successful operation.

Q 22. What is your experience with warehouse space optimization?

Warehouse space optimization is crucial for maximizing efficiency and profitability. It involves strategically arranging storage, equipment, and workflows to minimize wasted space and movement. My approach is multifaceted and begins with a thorough assessment of current operations. This includes analyzing product flow, storage needs (considering dimensions, weight, and turnover rates), and identifying bottlenecks. I then leverage various techniques:

- Slotting Optimization: Assigning products to specific locations based on their frequency of picking, size, and weight to minimize travel time for order fulfillment. For example, fast-moving items are placed in easily accessible locations near shipping docks.

- Vertical Space Utilization: Maximizing height with high-bay racking or mezzanine floors to create more storage capacity within the existing footprint. In one project, implementing a mezzanine floor increased storage by 40%.

- Improved Layout Design: Reorganizing the warehouse layout to improve the flow of goods and reduce congestion. This often involves implementing lean principles and analyzing workflows to eliminate unnecessary steps.

- Technology Integration: Using Warehouse Management Systems (WMS) to provide real-time visibility into inventory levels and optimize storage assignments. WMS can significantly improve space utilization by suggesting optimal locations for incoming goods.

The success of space optimization is measured through key metrics such as cubic utilization, order picking efficiency, and inventory turnover rate. I regularly monitor these KPIs to ensure the implemented strategies are yielding the desired results.

Q 23. How do you handle returns and reverse logistics?

Handling returns and reverse logistics effectively is critical for customer satisfaction and cost control. My approach involves a structured process:

- Efficient Returns Process: Establishing a clear and easy-to-understand returns policy for customers. This often includes online portals or simplified forms to minimize processing time. The process should account for various return reasons (damaged goods, wrong items, etc.).

- Inspection and Sorting: Upon receiving returns, the items are inspected to assess their condition. This determines whether they can be restocked, repaired, or disposed of. Sorting based on condition streamlines the next steps.

- Reverse Logistics Network: Having a robust reverse logistics network in place is essential for efficient returns management. This might involve dedicated return centers, partnerships with carriers specializing in reverse logistics, and clear labeling instructions.

- Data Analysis: Tracking return rates, reasons for returns, and associated costs are vital for identifying areas for improvement and proactively addressing potential issues in the product or supply chain.

- Inventory Management: Careful management of returned inventory is necessary to prevent obsolescence or damage. This requires integrating return data into the overall inventory management system.

I’ve successfully implemented reverse logistics programs that have reduced return processing times by 20% and improved the rate of resellable returns by 15%. This is achieved by leveraging technology, clear processes, and meticulous data analysis.

Q 24. Describe your experience with different warehouse storage methods.

My experience encompasses a wide range of warehouse storage methods, each suited to different product characteristics and operational needs:

- First-In, First-Out (FIFO): Ideal for perishable goods or items with expiration dates, ensuring older stock is used first. This is easily implemented using dedicated storage areas and careful inventory tracking.

- Last-In, First-Out (LIFO): Suitable for non-perishable items where newer inventory is used first. This method is often used for bulk storage, where accessing older stock might be more difficult.

- Random Storage: A flexible method where items are placed in available locations without a predetermined sequence. This requires a robust WMS to track inventory and optimize picking routes. It works well when there’s no specific need for FIFO or LIFO.

- Dedicated Storage: Allocating specific areas for particular product categories or high-demand items to streamline picking and improve efficiency. This is especially beneficial for high-volume items.

The choice of storage method depends greatly on the specific products being handled, the overall warehouse layout, and the order fulfillment strategy. I assess all these factors to recommend and implement the most effective approach for each client.

Q 25. How do you deal with unexpected supply chain disruptions?

Unexpected supply chain disruptions, such as natural disasters, geopolitical events, or supplier issues, require a proactive and adaptable approach. My strategies include:

- Risk Assessment and Mitigation: Regularly identifying potential disruptions and developing contingency plans to minimize their impact. This might involve diversifying suppliers, holding safety stock, or establishing alternative transportation routes.

- Real-time Monitoring: Utilizing real-time data and tracking systems to monitor the supply chain for any signs of disruptions. This allows for early detection and a quicker response.

- Communication and Collaboration: Maintaining open communication with suppliers, carriers, and customers to ensure everyone is aware of the situation and coordinated efforts to mitigate the effects.

- Flexibility and Adaptability: Being able to adjust plans quickly in response to unforeseen circumstances. This might involve shifting to alternative sourcing options or re-routing shipments.

- Inventory Management: Optimizing inventory levels to balance the cost of holding inventory with the risk of stockouts. This requires careful analysis of demand patterns and lead times.

In one instance, a port strike caused a significant delay in raw material shipments. By immediately engaging alternative suppliers and negotiating with carriers, we were able to minimize the production downtime and maintain customer service levels.

Q 26. What is your experience with implementing KPI dashboards for warehouse performance?

Implementing KPI dashboards for warehouse performance is essential for data-driven decision-making and continuous improvement. My approach involves:

- Key Performance Indicators (KPIs): Selecting relevant KPIs that align with overall business objectives. These might include order fulfillment rate, inventory accuracy, picking efficiency, storage utilization, and cost per order.

- Data Collection and Integration: Gathering data from various sources, such as WMS, ERP systems, and operational data, and integrating it into a centralized dashboard.

- Dashboard Design: Creating user-friendly dashboards that visualize KPIs using charts, graphs, and key metrics. The dashboards should be easily understandable and accessible to relevant stakeholders.

- Regular Monitoring and Reporting: Regularly monitoring the dashboard to track progress, identify trends, and pinpoint areas needing attention. This allows for proactive adjustments and continuous improvement.

- Actionable Insights: Using the data to inform decision-making and take corrective actions where necessary. This could involve process improvements, investment in new technologies, or team training.

I’ve successfully implemented dashboards that have improved warehouse efficiency by 15% and reduced operational costs by 10% by highlighting areas needing attention and facilitating data-driven improvements.

Q 27. How do you prioritize tasks and manage your time effectively in a fast-paced environment?

In a fast-paced warehouse environment, effective task prioritization and time management are crucial. My strategies include:

- Prioritization Matrix: Using a prioritization matrix (like Eisenhower Matrix) to categorize tasks based on urgency and importance. This helps focus on high-impact tasks first.

- Time Blocking: Allocating specific time blocks for different tasks or activities to enhance focus and avoid multitasking.

- Delegation: Delegating tasks appropriately to team members based on their skills and availability. This frees up time to focus on higher-priority tasks.

- Regular Planning: Starting each day or shift with a clear plan outlining the tasks to be completed. This prevents reactive problem-solving and ensures efficient work flow.

- Tools and Technology: Utilizing project management tools and software to track progress, manage deadlines, and collaborate effectively with team members.

I often use the Pomodoro Technique to manage my time effectively. The combination of focused work bursts and short breaks enhances concentration and prevents burnout.

Q 28. Explain your familiarity with different types of warehouse racking systems.

My familiarity with various warehouse racking systems is extensive, and the choice of system depends greatly on the specific requirements of the warehouse. These include:

- Selective Pallet Racking: The most common type, offering direct access to all pallets. It’s versatile and suitable for a wide range of products.

- Drive-In/Drive-Thru Racking: Ideal for LIFO storage, where pallets are loaded and retrieved from one side. It’s space-efficient but only suitable for products with similar characteristics.

- Push-Back Racking: A variation of drive-in/drive-thru racking allowing for FIFO storage. It improves access to pallets compared to drive-in systems.

- Double-Deep Racking: Allows for two pallets deep per location, increasing storage density. However, it requires specialized equipment for access.

- Flow Racking: Utilizes gravity to move pallets along inclined lanes. This improves picking efficiency, particularly for FIFO inventory.

- Cantilever Racking: Suitable for long, bulky items that don’t fit on standard pallets. Often used for lumber or pipes.

In choosing a racking system, I consider factors such as storage capacity, product dimensions, turnover rates, accessibility requirements, and budget constraints. A properly designed racking system is crucial for efficient storage and order fulfillment.

Key Topics to Learn for Warehousing and Logistics Interview

- Inventory Management: Understanding inventory control techniques like FIFO, LIFO, and JIT, and their practical implications on warehouse efficiency and cost optimization. Consider how different methods impact order fulfillment and potential waste.

- Warehouse Layout and Design: Analyzing the impact of warehouse design on workflow efficiency. Explore different storage solutions (rack systems, shelving, etc.) and their suitability for various product types and order volumes. Think about how to optimize space utilization and minimize travel time.

- Supply Chain Management: Grasp the overall flow of goods from origin to consumer, identifying key processes and potential bottlenecks. Consider the role of forecasting, transportation, and communication in a successful supply chain.

- Warehouse Operations: Familiarize yourself with receiving, putaway, picking, packing, and shipping processes. Understand the use of warehouse management systems (WMS) and their role in optimizing these operations. Explore common challenges and solutions in these areas.

- Safety and Compliance: Discuss OSHA regulations and best practices for maintaining a safe warehouse environment. Understand the importance of proper handling procedures for different goods and the implications of non-compliance.

- Technology in Warehousing: Explore the use of automation technologies such as automated guided vehicles (AGVs), robotics, and warehouse control systems. Consider how these technologies improve efficiency and accuracy.

- Logistics Optimization: Analyze methods for optimizing transportation routes, delivery schedules, and cost management. Explore different transportation modes and their suitability for different goods and distances.

- Problem-Solving and Decision-Making: Be prepared to discuss how you approach challenges in a warehouse setting. This includes inventory discrepancies, order fulfillment delays, and safety concerns. Highlight your analytical skills and problem-solving methodology.

Next Steps

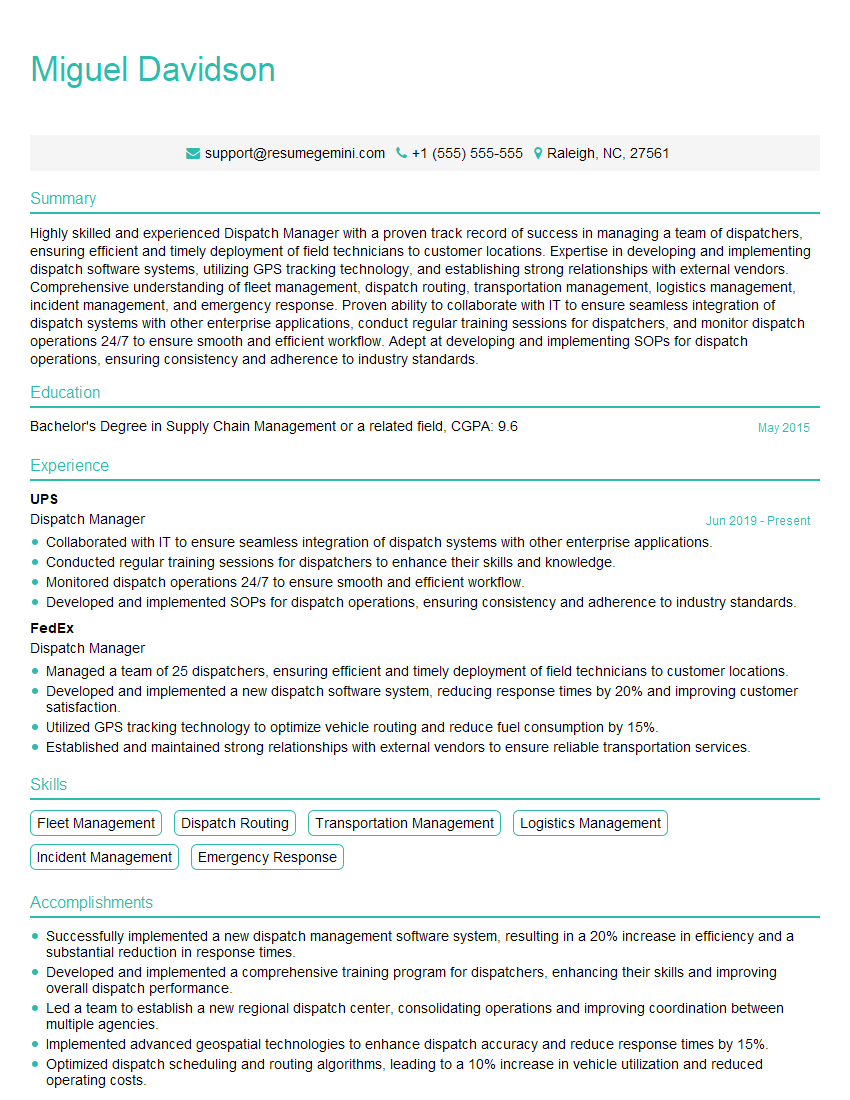

Mastering Warehousing and Logistics opens doors to rewarding careers with excellent growth potential. A strong understanding of these concepts is crucial for securing your dream position. To significantly boost your job prospects, crafting a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. We offer examples of resumes tailored to the Warehousing and Logistics industry to guide you in creating a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO