Are you ready to stand out in your next interview? Understanding and preparing for Wastewater Treatment Process Control interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Wastewater Treatment Process Control Interview

Q 1. Explain the role of SCADA in wastewater treatment process control.

SCADA, or Supervisory Control and Data Acquisition, is the brain of a modern wastewater treatment plant. It’s a centralized system that monitors and controls various processes across the entire facility. Think of it as a sophisticated dashboard displaying real-time data from all the plant’s sensors and actuators, allowing operators to make informed decisions and intervene if necessary. It allows for remote monitoring and control, automating many tasks and improving efficiency.

SCADA systems collect data from sensors measuring parameters like flow rate, pH, dissolved oxygen, and sludge levels. This data is then processed and displayed on operator interfaces, providing a comprehensive overview of the plant’s performance. Furthermore, SCADA systems can trigger alarms based on pre-defined thresholds, alerting operators to potential problems. For example, if the dissolved oxygen level in an aeration tank drops too low, the SCADA system can automatically increase the aeration rate and notify the operator.

In essence, SCADA enhances operational efficiency, improves data analysis capabilities, reduces human error, and facilitates proactive maintenance, leading to better effluent quality and cost savings.

Q 2. Describe different types of sensors used in wastewater treatment and their applications.

Wastewater treatment relies heavily on a diverse array of sensors to monitor critical parameters. These sensors are the eyes and ears of the plant, providing crucial information for effective process control.

- Flow Meters: Measure the volume of wastewater flowing through different parts of the plant. Examples include magnetic flow meters and ultrasonic flow meters. Accurate flow measurement is essential for dosing chemicals and controlling the treatment process.

- pH Sensors: Measure the acidity or alkalinity of the wastewater. Maintaining the correct pH is crucial for the effectiveness of various treatment processes, such as chemical coagulation and disinfection. Variations from optimal levels can significantly impact the overall process performance.

- Dissolved Oxygen (DO) Sensors: Measure the amount of oxygen dissolved in the wastewater. This is particularly important in activated sludge processes, where sufficient oxygen is essential for the microorganisms responsible for breaking down organic matter. Low DO can lead to poor treatment efficiency.

- Turbidity Sensors: Measure the clarity or cloudiness of the water. This helps monitor the effectiveness of clarification processes and identify potential problems with sedimentation or filtration.

- Level Sensors: Measure the liquid level in tanks and basins. These are crucial for preventing overflows and ensuring proper process operation. Different technologies exist, such as ultrasonic, pressure, and float level sensors.

- ORP (Oxidation-Reduction Potential) Sensors: Measure the ability of a solution to gain or lose electrons, useful for monitoring disinfection processes using chlorine or ozone.

The choice of sensor depends on the specific application and the required accuracy and reliability. Each sensor provides critical data points essential for optimizing treatment processes and ensuring compliance with environmental regulations.

Q 3. How do you troubleshoot a malfunctioning PLC in a wastewater treatment plant?

Troubleshooting a malfunctioning PLC (Programmable Logic Controller) in a wastewater treatment plant requires a systematic approach. PLCs are the heart of the automation system, and their failure can have significant consequences.

- Safety First: Always isolate the PLC from power before attempting any maintenance or troubleshooting. This is paramount for your safety and the integrity of the equipment.

- Check Power and Connections: Verify that the PLC is receiving power and that all connections are secure. Loose connections or power failures are surprisingly common causes of problems.

- Review Alarm Logs and Historical Data: The PLC typically logs alarms and historical data. Examine these logs for clues about the nature of the malfunction. This information can provide critical insights into the timing and conditions leading to the failure.

- Inspect Input/Output Modules: Check the input/output (I/O) modules for any signs of damage or malfunction. This involves verifying that signals from sensors are being received correctly and that actuators are responding as expected.

- Use Diagnostic Tools: Most PLCs have built-in diagnostic tools. Use these tools to identify specific errors or faults within the PLC itself. The diagnostic messages often point directly to the source of the problem.

- Check the PLC Program: If the hardware appears to be functioning correctly, the problem might be within the PLC’s program. This requires access to the PLC programming software and may necessitate reviewing the code for errors or logic problems.

- Call for Expert Assistance: If the problem persists after these steps, it is best to consult with a qualified PLC technician or the manufacturer of the PLC. They have specialized knowledge and tools to diagnose complex issues.

Remember, documentation is crucial. Maintain detailed records of the troubleshooting steps and any modifications made to the system. This is important for future reference and maintenance.

Q 4. What are the key performance indicators (KPIs) you monitor in a wastewater treatment process?

Key Performance Indicators (KPIs) in wastewater treatment are crucial for monitoring efficiency and compliance. They provide a quantitative measure of the plant’s performance and allow for adjustments to optimize the treatment process.

- Influent and Effluent Quality: Parameters like BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), suspended solids, and nitrogen and phosphorus concentrations are tracked to measure the plant’s ability to remove pollutants. These are among the most critical indicators.

- Sludge Production and Dewatering: Monitoring sludge production helps optimize the digestion process. Parameters like sludge volume index (SVI) and dry solids content of the dewatered sludge reflect the effectiveness of sludge handling.

- Energy Consumption: Energy efficiency is critical for sustainability and cost-effectiveness. Monitoring energy consumption per unit of treated wastewater is important.

- Chemical Usage: Tracking chemical consumption (e.g., chlorine, coagulants) helps in optimizing dosing strategies and minimizing costs.

- Process Efficiency: Parameters like F/M ratio (Food-to-Microorganism ratio) in activated sludge processes are indicators of the efficiency of biological treatment.

- Compliance with Permits: Regular monitoring ensures that the treated effluent meets regulatory discharge limits.

By carefully monitoring these KPIs and using data analytics, we can identify trends and anomalies, enabling proactive adjustments to improve the overall efficiency and environmental performance of the plant.

Q 5. Explain the principles of activated sludge process control.

The activated sludge process is a cornerstone of modern wastewater treatment. It relies on a population of microorganisms to break down organic matter in the wastewater. Control of this process is essential for achieving efficient and consistent treatment.

The core principles of control focus on maintaining the right balance within the activated sludge ecosystem. This involves carefully managing several key parameters:

- Dissolved Oxygen (DO): Maintaining sufficient DO is crucial for aerobic microbial activity. Low DO leads to reduced treatment efficiency and the production of unpleasant odors. Control is achieved by adjusting the aeration rate based on DO sensors. Think of it as providing the microorganisms with the air they need to ‘breathe’ and perform their work.

- Mixed Liquor Suspended Solids (MLSS): The concentration of microorganisms in the aeration tank needs to be carefully controlled. Too low an MLSS results in poor treatment efficiency, while excessive MLSS can lead to sludge bulking and operational challenges. Control strategies often involve adjusting the sludge recycle rate.

- Food-to-Microorganism (F/M) Ratio: This ratio represents the amount of organic matter (food) relative to the biomass (microorganisms). Maintaining an optimal F/M ratio is essential for efficient treatment and prevents the depletion or overgrowth of microorganisms.

- Sludge Age: The average time microorganisms spend in the system is another critical factor. Appropriate sludge age helps maintain a healthy microbial community.

- pH: The optimal pH range must be maintained to promote microbial activity and avoid detrimental effects on the biological process.

Control strategies utilize feedback control loops, often implemented within the plant’s SCADA system, to automatically adjust parameters based on real-time sensor readings. This dynamic adjustment ensures optimal process performance, maximizing treatment efficiency and minimizing environmental impact.

Q 6. Describe your experience with different types of control valves used in wastewater treatment.

Control valves are essential components in wastewater treatment, precisely regulating the flow of liquids and gases. Different types are selected based on the specific application and requirements.

- Globe Valves: These are widely used for regulating flow in smaller pipelines due to their simplicity and good control characteristics. They are often used for chemical dosing lines.

- Butterfly Valves: Used in larger pipelines, butterfly valves offer quick on-off control and are suitable for less precise flow regulation. They are frequently used in influent and effluent lines.

- Ball Valves: Provide quick on-off control and are simple to operate, but are less suitable for precise flow regulation. Used where quick isolation is needed.

- Control Valves with Actuators: Most control valves in wastewater treatment are equipped with pneumatic or electric actuators, allowing automated control based on process parameters such as level, flow, or pressure. These systems create precise and automated flow control.

Selecting the appropriate control valve involves careful consideration of factors such as the fluid’s properties (viscosity, corrosiveness), the required flow range, the level of control precision needed, and the overall operating pressure. For example, in a chemical dosing system, a precisely controlled globe valve is preferred for accurate chemical addition, whereas a large butterfly valve might be appropriate for regulating the flow of treated effluent.

Q 7. How do you handle process upsets in a wastewater treatment plant?

Process upsets in wastewater treatment plants are inevitable. They can range from minor fluctuations to major disruptions. Effective handling requires a combination of proactive measures and reactive responses.

Proactive Measures: These aim to prevent or mitigate the severity of upsets:

- Robust Process Monitoring: A comprehensive monitoring system with alarm thresholds is vital to promptly detect deviations from normal operating conditions.

- Regular Maintenance: Preventive maintenance minimizes equipment failures that can trigger process upsets.

- Operator Training: Well-trained operators can more effectively identify and respond to developing problems.

Reactive Responses: These address upsets as they occur:

- Identify the Cause: The first step is to pinpoint the source of the upset. This involves analyzing sensor data and reviewing operational logs.

- Implement Emergency Procedures: Pre-defined emergency procedures outline actions to be taken in various scenarios. For instance, a bypass might be activated to reduce the load on an overloaded unit.

- Adjust Control Setpoints: SCADA systems allow adjusting process parameters to mitigate the effects of the upset. For example, temporarily increasing the aeration rate to compensate for low dissolved oxygen.

- Isolate Affected Units: If a unit is experiencing a severe malfunction, it might be necessary to isolate it to prevent the problem from spreading to other parts of the plant.

- Root Cause Analysis: After the immediate upset is resolved, a thorough root cause analysis should be conducted to prevent similar incidents in the future.

Effective handling of process upsets requires a combination of advanced control systems, well-trained personnel, and a systematic approach to troubleshooting and preventative maintenance. The ultimate aim is to minimize the impact on effluent quality and ensure the plant’s continued operation.

Q 8. What are the common causes of aeration system malfunctions?

Aeration system malfunctions in wastewater treatment plants can stem from various sources. Think of an aeration system as the lungs of the plant – if they fail, the whole process suffers. Common culprits include:

- Mechanical Issues: These are often the most straightforward to diagnose. This could involve problems with the blowers themselves (e.g., bearing failure, motor burnout), plugged or damaged air diffusers (restricting air flow), leaks in the piping system resulting in reduced air delivery, or issues with the air compressor’s functionality, leading to insufficient pressure.

- Electrical Problems: Control system failures, faulty sensors (e.g., pressure sensors, flow meters), or tripped circuit breakers can all significantly impact aeration. For example, a malfunctioning level sensor could cause the blower to run continuously, leading to energy waste and potential damage.

- Biological Fouling: Over time, biofilms can build up on the diffusers, reducing the efficiency of oxygen transfer. This is akin to your lungs becoming clogged with mucus, restricting their ability to function. Regular cleaning and maintenance are crucial here.

- Power Supply Fluctuations: Inconsistent power supply can lead to unpredictable blower operation and affect the oxygen transfer efficiency. A stable power source is vital for reliable performance.

Troubleshooting typically involves a systematic approach: checking power supply, inspecting the blowers and piping for leaks, testing sensors, and physically inspecting diffusers for blockages or damage. Often a combination of these issues could be at play. For instance, a clogged diffuser coupled with a failing pressure sensor might be initially mistaken for a simple blower problem.

Q 9. Explain the importance of dissolved oxygen (DO) control in wastewater treatment.

Dissolved oxygen (DO) control is paramount in wastewater treatment, especially in activated sludge processes. Think of DO as the essential ingredient for the beneficial bacteria that break down organic matter. Adequate DO levels are vital for:

- Efficient Biological Treatment: Aerobic bacteria (those that need oxygen) require sufficient DO to effectively degrade pollutants. Low DO levels lead to incomplete treatment, resulting in poor effluent quality and potential environmental impact. Imagine trying to light a fire with limited oxygen – the process becomes slow and incomplete.

- Nitrification: The conversion of ammonia to nitrates (a crucial step in removing nitrogen from wastewater) requires high DO levels. Insufficient DO will hamper this process, leaving more harmful nitrogenous compounds in the treated water.

- Preventing Sludge Bulking: Maintaining optimal DO levels helps prevent the growth of filamentous bacteria, which can lead to sludge bulking (where the sludge becomes too fluffy and difficult to settle). Bulking can cause operational issues, disrupting the entire treatment process.

- Energy Optimization: Precise DO control avoids over-aeration, which is a major energy consumer in wastewater treatment. Fine-tuning the aeration system minimizes unnecessary energy consumption, while still ensuring effective treatment.

In essence, proper DO control is the key to a well-functioning, efficient, and environmentally responsible wastewater treatment plant. Failure to manage DO levels effectively can lead to costly operational problems, sub-standard effluent quality and potential regulatory violations.

Q 10. How do you calibrate and maintain process instruments in a wastewater treatment plant?

Calibrating and maintaining process instruments in a wastewater treatment plant is crucial for accurate data and efficient operation. It’s like ensuring your car’s speedometer and fuel gauge work correctly; incorrect readings can lead to poor decisions. The process generally involves these steps:

- Regular Inspection: Visual checks for physical damage, corrosion, or leaks are paramount. Regular cleaning to remove dirt and debris can extend the life of instruments and ensure their continued accuracy.

- Calibration: This involves comparing the instrument’s readings against a known standard. For example, a DO probe needs calibration using standardized DO solutions. The frequency of calibration depends on the instrument and its use, but it’s usually part of a planned preventative maintenance schedule. Detailed calibration procedures should be followed strictly to avoid damage.

- Maintenance: This includes replacing worn parts, cleaning sensors, and performing preventative measures to extend the lifespan of equipment. Regular maintenance reduces unexpected breakdowns and ensures data accuracy.

- Documentation: Meticulous record-keeping of calibration dates, procedures, and results is essential for compliance and troubleshooting. Any deviation or irregularities should be noted and addressed promptly. This also aids in identifying trends that may point to bigger issues.

Calibration procedures usually involve using certified reference materials and documenting each step. For instance, when calibrating a pH meter, we’d use buffer solutions of known pH values, following the manufacturer’s instructions. We would then document the calibration points and any adjustments made to the instrument. Similarly for flow meters or level sensors, specific procedures are followed using reference standards to validate their accuracy.

Q 11. Describe your experience with different types of wastewater treatment processes.

My experience encompasses a range of wastewater treatment processes, including:

- Activated Sludge: This is a widely used biological process where microorganisms break down organic matter in wastewater. I’ve worked extensively with both conventional activated sludge and modifications like membrane bioreactors (MBRs), which offer superior effluent quality.

- Sequencing Batch Reactors (SBRs): These are intermittent processes that offer flexibility in operation and better control over the treatment process. I have experience optimizing SBR performance to achieve specific effluent targets.

- Anaerobic Digestion: This process uses anaerobic bacteria (bacteria that thrive without oxygen) to break down organic sludge, producing biogas which can be used for energy generation. I’ve worked on optimizing biogas production and managing digester stability.

- Lagoons: These are simpler, natural systems used for smaller wastewater flows. I’ve helped design and monitor lagoon systems for both aerobic and anaerobic treatment, often integrating them with other treatment processes for more efficient results.

In each case, my focus has been on optimizing process performance, ensuring compliance with environmental regulations, and minimizing operational costs. For example, in an MBR project, I optimized the membrane cleaning cycle to reduce energy consumption while maintaining high effluent quality. In another project involving anaerobic digestion, I identified and addressed issues that were inhibiting biogas production, resulting in a significant increase in energy recovery.

Q 12. Explain the concept of feedback control in the context of wastewater treatment.

Feedback control is a cornerstone of modern wastewater treatment process automation. It’s a closed-loop system where the process output is constantly monitored, compared to a desired setpoint, and adjustments are made to maintain the desired conditions. It’s like a thermostat controlling room temperature:

- Sensor Measurement: A sensor (e.g., DO probe, pH sensor, flow meter) measures the process variable (e.g., dissolved oxygen, pH, flow rate).

- Controller Comparison: A controller compares the measured value with a pre-set target (the setpoint). For example, if the setpoint for DO is 2 mg/L and the sensor reading is 1.5 mg/L, the controller detects a deviation.

- Actuator Adjustment: The controller sends a signal to an actuator (e.g., aeration blower, chemical feed pump) to adjust the process accordingly. In this case, the controller would increase the aeration rate to raise the DO level.

- Continuous Monitoring: The process continues with the controller constantly monitoring and adjusting the actuator output to maintain the setpoint. This creates a continuous feedback loop that ensures stability and optimal performance.

Example: In activated sludge, a feedback control loop might regulate the aeration rate based on DO levels. If the DO drops below the setpoint, the controller automatically increases the aeration rate, ensuring sufficient oxygen for the microorganisms.

Q 13. What are the safety protocols you follow while working with process control systems?

Safety is paramount when working with process control systems in wastewater treatment. My safety protocols include:

- Lockout/Tagout Procedures: Before performing any maintenance or repair work on equipment, I always follow strict lockout/tagout procedures to prevent accidental energization or start-up. This is critical for preventing electrical shocks and other hazards.

- Personal Protective Equipment (PPE): I consistently wear appropriate PPE, including safety glasses, gloves, and protective clothing, depending on the task. This protects me from chemical splashes, physical hazards, and other potential dangers.

- Confined Space Entry Procedures: When working in confined spaces (e.g., inside a clarifier or digester), I adhere to strict entry permits and safety protocols, often involving air quality monitoring and standby personnel.

- Emergency Response Procedures: I’m familiar with the plant’s emergency response plan and know how to respond to various situations, such as chemical spills, equipment malfunctions, or medical emergencies.

- Regular Training: I participate in regular safety training sessions to stay up-to-date on best practices, new regulations, and potential hazards.

Following these protocols ensures a safe working environment for myself and my colleagues, minimizing the risks associated with working with potentially hazardous equipment and chemicals.

Q 14. How do you ensure data integrity and reliability in a SCADA system?

Data integrity and reliability in a SCADA (Supervisory Control and Data Acquisition) system are critical for effective plant operation and regulatory compliance. This requires a multi-pronged approach:

- Regular Data Validation: Regular checks of sensor readings against known values or independent measurements help detect outliers or anomalies. For example, comparing DO readings from multiple probes or comparing SCADA data with laboratory results.

- Redundancy and Backup Systems: Implementing redundant sensors and communication paths ensures that data acquisition continues even if one component fails. This safeguards against data loss due to sensor malfunction or communication issues.

- Data Logging and Archiving: Robust data logging and archiving systems preserve historical data, allowing for trend analysis, troubleshooting, and compliance auditing. Well-designed databases can help track data trends and identify potential problems early on.

- Regular System Audits: Conducting regular audits of the SCADA system, including hardware and software components, identifies potential vulnerabilities and ensures the system is functioning correctly. This also ensures compliance with industry standards and best practices.

- Cybersecurity Measures: Implementing strong cybersecurity measures is vital to prevent unauthorized access and manipulation of data. This includes firewalls, intrusion detection systems, and access control protocols.

By implementing these measures, we minimize the risk of data corruption, ensure the accuracy of information used for process control, and maintain regulatory compliance. For instance, a rigorous data validation process might involve comparing flow meter readings with actual water levels in various tanks. Any significant discrepancies would trigger an investigation, to identify the root cause of the issue.

Q 15. Describe your experience with programming PLCs using ladder logic.

My experience with PLC programming using ladder logic spans over 10 years, encompassing various wastewater treatment plant projects. I’ve extensively used ladder logic to design and implement control systems for processes like aeration, sludge management, and chemical dosing. I’m proficient in Allen-Bradley and Siemens PLC platforms, capable of developing programs from initial design specifications to final commissioning and testing. For example, in one project, I developed a ladder logic program to optimize the aeration process based on dissolved oxygen levels, resulting in a 15% reduction in energy consumption. This involved using timers, counters, and PID control loops to precisely regulate the airflow based on real-time sensor data. Another project required creating a safety shutdown system using ladder logic, ensuring immediate plant shutdown in case of critical parameter failures such as high ammonia levels or low-level alarms in critical tanks.

I’m comfortable working with various PLC communication protocols, including Modbus and Profibus, and integrating PLC systems with SCADA systems for remote monitoring and control. I’m also experienced in troubleshooting and debugging PLC programs, often using simulation software to identify and resolve issues before deploying the code to the actual plant. This preventative approach minimizes downtime and ensures smooth plant operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of advanced process control (APC) in wastewater treatment.

Advanced Process Control (APC) plays a crucial role in optimizing wastewater treatment plant performance. Unlike basic control systems that react to individual process variables, APC uses sophisticated algorithms and modeling techniques to achieve overall plant optimization. This typically involves using model predictive control (MPC) or other advanced strategies to manage multiple interacting variables simultaneously. Imagine juggling multiple balls—basic control handles each ball individually; APC considers all the balls’ interactions and coordinates movements to maintain the overall balance and prevent drops.

In wastewater treatment, APC can optimize processes such as:

- Nutrient removal: Precise control of aeration and chemical dosing for enhanced nitrogen and phosphorus removal.

- Sludge management: Optimized sludge wasting and thickening to minimize energy consumption and maximize treatment efficiency.

- Energy optimization: Reduction of energy consumption through real-time adjustments to aeration, pumping, and other energy-intensive processes.

Q 17. How do you optimize energy consumption in a wastewater treatment plant?

Optimizing energy consumption in a wastewater treatment plant requires a multi-pronged approach combining operational strategies with technological upgrades. First, optimizing aeration is key. This involves using dissolved oxygen (DO) control systems with advanced algorithms and sensors to ensure only the necessary amount of air is used. Using variable frequency drives (VFDs) on pumps to adjust their speed based on actual demand significantly reduces energy consumption.

Secondly, implementing energy-efficient equipment is crucial. This includes using high-efficiency motors and pumps, along with energy recovery systems such as anaerobic digestion to generate biogas that can be used for power generation. Regular maintenance and preventative measures also play a significant role, minimizing equipment failures and reducing energy waste due to inefficiencies.

Finally, employing data analytics can pinpoint energy-intensive processes and areas for improvement. Using historical data, APC systems can identify trends, predict energy demands, and optimize energy usage over time. By combining these approaches, significant reductions in energy consumption, and hence operational costs, can be achieved.

Q 18. What are the environmental regulations relevant to wastewater treatment process control?

Environmental regulations concerning wastewater treatment process control vary widely depending on location, but common themes include effluent quality standards, discharge permits, and reporting requirements. Regulations often specify limits on parameters such as:

- Biochemical Oxygen Demand (BOD): Measures the amount of oxygen consumed by microorganisms during the breakdown of organic matter.

- Chemical Oxygen Demand (COD): Measures the oxygen required to chemically oxidize organic matter.

- Suspended Solids (SS): Represents the total amount of solid particles in the wastewater.

- Nutrients (Nitrogen and Phosphorus): Excessive nutrients can lead to eutrophication in receiving waters.

- pH and Temperature: These parameters must be within specified ranges to protect aquatic life.

Compliance with these regulations requires robust process control systems to continuously monitor effluent quality, ensuring that discharge limits are consistently met. Regular reporting and data logging are crucial to demonstrate compliance to regulatory agencies. Non-compliance can result in penalties and enforcement actions.

Q 19. Describe your experience with different types of flow meters used in wastewater treatment.

My experience encompasses several flow meter types commonly used in wastewater treatment:

- Magnetic flow meters: These are ideal for wastewater due to their non-invasive nature and ability to handle slurries and other solids. They measure flow based on Faraday’s law of induction, requiring conductive fluids.

- Ultrasonic flow meters: These are suitable for both clean and dirty water, measuring flow based on the transit time of ultrasonic pulses. They’re non-invasive and have low maintenance requirements.

- Venturi meters: These meters are based on the principle of Bernoulli’s equation, using pressure differences to measure flow. While relatively inexpensive, they are susceptible to clogging and require regular maintenance.

- Open channel flow meters: Used for measuring flow in open channels, weirs, or flumes. These are often used for measuring influent flows to the plant. Examples include weirs and Parshall flumes.

Q 20. How do you interpret and analyze data from a wastewater treatment process?

Interpreting and analyzing data from a wastewater treatment process involves a multi-step approach. First, data from various sensors (flow meters, DO probes, pH sensors, etc.) is collected and stored using a SCADA system. This raw data is then processed and visualized using various techniques, such as trend charts and statistical analysis. This allows for the identification of patterns and anomalies.

I often use statistical process control (SPC) techniques to identify trends and deviations from expected performance. For instance, using control charts can help detect shifts in effluent quality or identify equipment malfunctions. Advanced data analytics, including machine learning algorithms, can be used to predict future performance, optimize control strategies, and detect early warning signs of potential problems. For instance, predictive models can forecast influent flow variations, allowing for proactive adjustments to maintain optimal treatment.

Finally, interpreting the data requires a deep understanding of the wastewater treatment processes and the interactions between different unit operations. By combining data analysis with process knowledge, we can gain actionable insights to optimize plant operation, improve effluent quality, and minimize operational costs.

Q 21. Explain the importance of regular maintenance of process control systems.

Regular maintenance of process control systems is crucial for ensuring reliable plant operation, preventing costly equipment failures, and maintaining compliance with environmental regulations. A well-maintained system ensures the accurate and timely collection of process data, which is essential for effective process control. Neglecting maintenance can lead to sensor drift, inaccurate measurements, control loop instability, and ultimately, compromised treatment performance.

A preventative maintenance program includes regular calibration of sensors and instruments, inspection of wiring and connections, and periodic testing of control algorithms. This also involves software updates to address bug fixes and incorporate new features. A proactive approach to maintenance, such as predictive maintenance using data analytics, can anticipate potential problems before they occur, preventing costly downtime. A well-defined maintenance schedule, detailed documentation, and skilled technicians are crucial components of a successful maintenance program ensuring the long-term reliability and efficiency of the wastewater treatment plant.

Q 22. How do you manage alarms and notifications in a SCADA system?

Managing alarms and notifications in a SCADA (Supervisory Control and Data Acquisition) system for wastewater treatment is crucial for efficient operation and preventing environmental incidents. A well-designed system uses a layered approach to ensure critical events are addressed promptly while minimizing alarm fatigue.

- Alarm Prioritization: Alarms are categorized by severity (critical, major, minor) and source. Critical alarms, like a pump failure causing overflow, trigger immediate action and potentially automated responses. Less critical alarms, such as a sensor drift, might allow for a delayed response or simply inform operators for future analysis.

- Alarm Filtering and Suppression: The system can be configured to filter out nuisance alarms or suppress repetitive alarms that occur within a defined timeframe. For example, a low-level alarm on a tank might be suppressed if the level is recovering quickly.

- Alarm Acknowledgement and Tracking: Operators must acknowledge alarms, indicating they’ve been reviewed. The system should track who acknowledged the alarm, when it was acknowledged, and what action was taken. This ensures accountability and helps in identifying recurring issues.

- Notification Methods: Multiple notification methods should be available, such as on-screen pop-ups, audible alarms, SMS alerts, and email notifications. The choice depends on the severity of the alarm and the urgency required. For example, critical alarms might trigger immediate SMS alerts to on-call personnel.

- Historical Alarm Data: The system must log all alarm events for trending and analysis. This data is invaluable for identifying patterns, improving maintenance schedules, and optimizing process control strategies. Imagine using historical alarm data to pinpoint a recurring issue in a specific aeration tank – that’s directly improving plant efficiency.

In practice, I’ve found that proactive alarm management, including regular review and adjustment of alarm thresholds and suppression settings, is key to preventing alarm overload and ensuring that crucial alarms are promptly addressed.

Q 23. Describe your experience with troubleshooting process control instrumentation.

Troubleshooting process control instrumentation in wastewater treatment plants requires a systematic approach combining technical expertise, practical experience, and a strong understanding of the treatment process itself. My experience involves a wide range of instrumentation, including flow meters, level sensors, pH probes, dissolved oxygen sensors, and various analytical instruments.

My troubleshooting methodology typically involves:

- Initial Assessment: Start by reviewing the alarm or operational issue. Gather data from the SCADA system, instrumentation readings, and operator logs. This might show erratic sensor readings, which is an immediate clue.

- Sensor Verification: Verify sensor readings against alternative measurements or visual inspection. If a flow meter shows a suspiciously low flow, confirming the pump operation directly is crucial.

- Signal Tracing: Trace the signal path from the sensor to the control system, checking for wiring faults, signal attenuation, or faulty signal processing.

- Calibration and Adjustment: Calibrate sensors and check for proper adjustment according to manufacturer specifications. This is a fundamental part of maintaining accuracy.

- Component Replacement: If necessary, replace faulty components, ensuring proper documentation and testing after replacement.

- Root Cause Analysis: Once the immediate problem is resolved, conduct a thorough root cause analysis to prevent future occurrences. This analysis is key to reducing future downtime and improving plant reliability.

For example, I once resolved a recurring false high-level alarm in a clarifier by identifying a buildup of sludge that was affecting the ultrasonic level sensor. By implementing a regular cleaning schedule, we eliminated the recurring problem and improved process control.

Q 24. What is your experience with different types of control strategies (e.g., PID, cascade control)?

I have extensive experience with various control strategies, focusing on their application within the context of wastewater treatment. The choice of control strategy depends heavily on the specific process and its dynamic characteristics.

- PID Control (Proportional-Integral-Derivative): This is the workhorse of process control and is widely used for regulating flow rates, levels, pH, and dissolved oxygen. The PID controller adjusts the manipulated variable (e.g., valve position) based on the error between the setpoint and the measured value. Tuning the PID controller parameters (Kp, Ki, Kd) is crucial for optimal performance.

- Cascade Control: This strategy is particularly useful when one process variable directly affects another. For example, in aeration control, the dissolved oxygen (DO) level is the primary controlled variable, and the air flow rate is the secondary controlled variable, cascading from the DO controller. This strategy allows for finer control and improved response.

- Feedforward Control: This is used when disturbances in one part of the system significantly affect another. For instance, anticipating increased flow rate into the plant will allow us to adjust the blower operation proactively, preventing significant impact to the DO levels.

- Advanced Control Strategies: Modern wastewater treatment plants often utilize more sophisticated strategies like model predictive control (MPC) to optimize multiple variables simultaneously. MPC uses a mathematical model of the process to predict future behavior and make optimal control decisions.

I’ve implemented cascade control to enhance dissolved oxygen control in activated sludge processes, significantly improving effluent quality. The experience highlighted the importance of accurate sensor measurements and appropriate controller tuning.

Q 25. Explain how you would design a control system for a new wastewater treatment plant.

Designing a control system for a new wastewater treatment plant requires a comprehensive approach, starting with a thorough understanding of the treatment process and the desired control objectives.

- Process Definition: Begin by defining the specific treatment processes and their control requirements. This needs to be thoroughly vetted with process engineers.

- Instrumentation Selection: Select appropriate sensors, actuators, and communication infrastructure based on the treatment process requirements. This includes carefully choosing instrumentation specific to harsh environments found in wastewater plants.

- Control Strategy Development: Develop control strategies for each process unit, selecting appropriate control algorithms (PID, cascade, advanced control) based on process dynamics and control objectives. For example, the activated sludge process requires sophisticated DO control, while primary sedimentation may rely on simple level control.

- SCADA System Design: Design the SCADA system to monitor and control all aspects of the treatment plant, including alarm management, data logging, and reporting. The architecture should be carefully planned to ensure scalability and future growth.

- System Integration: Integrate all components of the control system, ensuring seamless communication and data exchange between the sensors, actuators, controllers, and the SCADA system. This typically involves extensive testing.

- Commissioning and Testing: Thoroughly commission and test the entire control system, including functional testing and performance testing, before plant operation commences.

For a new plant, designing for future expansion and upgrades is essential. This might involve selecting a SCADA system with scalable architecture and modular design to accommodate future expansions.

Q 26. How do you ensure compliance with safety regulations and environmental standards?

Ensuring compliance with safety regulations and environmental standards is paramount in wastewater treatment. This is not merely a regulatory compliance issue, it’s an ethical and operational necessity that underpins public health and environmental protection.

- Safety Systems: Implement robust safety systems, including emergency shutdown systems (ESD), high-level alarms, and interlocks, to prevent accidents and protect personnel. This could include backup power systems critical for certain processes.

- Permitting and Reporting: Work closely with regulatory agencies to ensure compliance with discharge permits and reporting requirements. This involves meticulous record-keeping of effluent quality and plant operations.

- Lockout/Tagout Procedures: Implement and enforce strict lockout/tagout (LOTO) procedures to ensure equipment safety during maintenance and repairs. Training and consistent enforcement are crucial here.

- Operator Training: Provide comprehensive operator training on safe operation procedures, emergency response, and regulatory compliance. This includes regular refresher training and specific training on newly implemented equipment or procedures.

- Environmental Monitoring: Regularly monitor effluent quality parameters and ensure compliance with discharge limits. Continuous online monitoring combined with periodic lab analysis guarantees the necessary accuracy.

- Risk Assessment: Conduct regular risk assessments to identify potential hazards and implement appropriate mitigation measures. This proactive approach is essential for preventing accidents and environmental incidents.

In my experience, proactively engaging with regulatory agencies and building a culture of safety and compliance within the plant’s operation team is crucial. A strong safety culture goes beyond compliance; it leads to a more efficient and reliable plant.

Q 27. Describe your experience with data acquisition and reporting in a wastewater treatment plant.

Data acquisition and reporting in a wastewater treatment plant are essential for monitoring plant performance, identifying areas for improvement, and ensuring regulatory compliance. Effective data management involves the following:

- Data Acquisition Systems: Utilize SCADA systems and other data acquisition tools to collect data from various sensors and instruments across the plant. The data should be timestamped and accurately stored.

- Data Storage and Management: Establish a robust data storage and management system, ensuring data integrity and accessibility. This might include historical databases and secure data servers.

- Data Analysis and Reporting: Use data analysis tools to generate reports on key performance indicators (KPIs), such as effluent quality, energy consumption, and chemical usage. These reports are essential for decision making and process optimization.

- Reporting Requirements: Meet regulatory reporting requirements by generating reports on effluent quality, plant operations, and compliance with environmental standards. Reporting formats and frequencies are carefully tailored to the specific regulatory context.

- Data Visualization: Use dashboards and other data visualization tools to present key performance indicators (KPIs) in a clear and concise manner, enabling operators and management to quickly assess plant performance.

I’ve used data analysis to identify a correlation between aeration tank performance and energy consumption, leading to optimized blower operation and significant cost savings.

Q 28. What are your strategies for continuous improvement in wastewater treatment process control?

Continuous improvement in wastewater treatment process control is an ongoing journey, not a destination. My strategies for continuous improvement are rooted in data-driven decision-making and a commitment to operational excellence.

- Regular Performance Reviews: Conduct regular reviews of plant performance, analyzing KPIs and identifying areas for improvement. This often reveals operational inefficiencies or deviations that need attention.

- Data Analysis and Trending: Use historical data to identify trends and patterns, anticipate potential issues, and optimize process control strategies. This is critical for long-term process improvements.

- Process Optimization: Implement process optimization techniques, such as advanced control strategies and model predictive control (MPC), to enhance efficiency and reduce operational costs. This ensures improved resource utilization and minimizes environmental impact.

- Equipment Upgrades: Invest in upgrades and modernization of process control equipment and instrumentation, particularly when significant technological advancements become available. This maximizes the benefit of updated technology.

- Operator Training and Development: Provide ongoing operator training and development to enhance their skills and knowledge in process control and troubleshooting. Trained operators are crucial for efficient plant operation and prevent errors.

- Benchmarking: Benchmark plant performance against similar facilities to identify best practices and areas for improvement. This facilitates learning and adaptation of optimal methods.

In one plant, we implemented a new DO control strategy based on data analysis, resulting in a 15% reduction in energy consumption. Continuous improvement is an iterative process, involving ongoing evaluation, adaptation, and refinement.

Key Topics to Learn for Wastewater Treatment Process Control Interview

- Process Monitoring and Instrumentation: Understanding SCADA systems, sensors (pH, DO, turbidity, flow), and data acquisition techniques. Practical application: Troubleshooting sensor malfunctions and interpreting data to optimize treatment processes.

- Process Control Strategies: Familiarization with PID control loops, advanced control strategies (e.g., model predictive control), and their application in wastewater treatment. Practical application: Adjusting control parameters to maintain effluent quality within regulatory limits.

- Wastewater Treatment Processes: Deep understanding of biological processes (activated sludge, membrane bioreactors), physical processes (screening, grit removal), and chemical processes (disinfection, coagulation/flocculation). Practical application: Identifying bottlenecks and optimizing individual unit processes to improve overall plant efficiency.

- Data Analysis and Reporting: Interpreting process data to identify trends, diagnose problems, and optimize performance. Practical application: Generating reports to demonstrate compliance with environmental regulations and plant operational efficiency.

- Safety and Regulations: Understanding OSHA regulations, safety procedures related to wastewater treatment, and emergency response protocols. Practical application: Ensuring safe operation of the plant and compliance with all relevant environmental regulations.

- Troubleshooting and Problem Solving: Developing systematic approaches to identify and resolve process upsets and equipment malfunctions. Practical application: Using analytical skills and knowledge of process control principles to quickly address operational issues.

- Automation and Optimization: Understanding the role of automation in improving efficiency and reducing operational costs. Practical application: Identifying opportunities for process automation and optimization using data analysis and process control techniques.

Next Steps

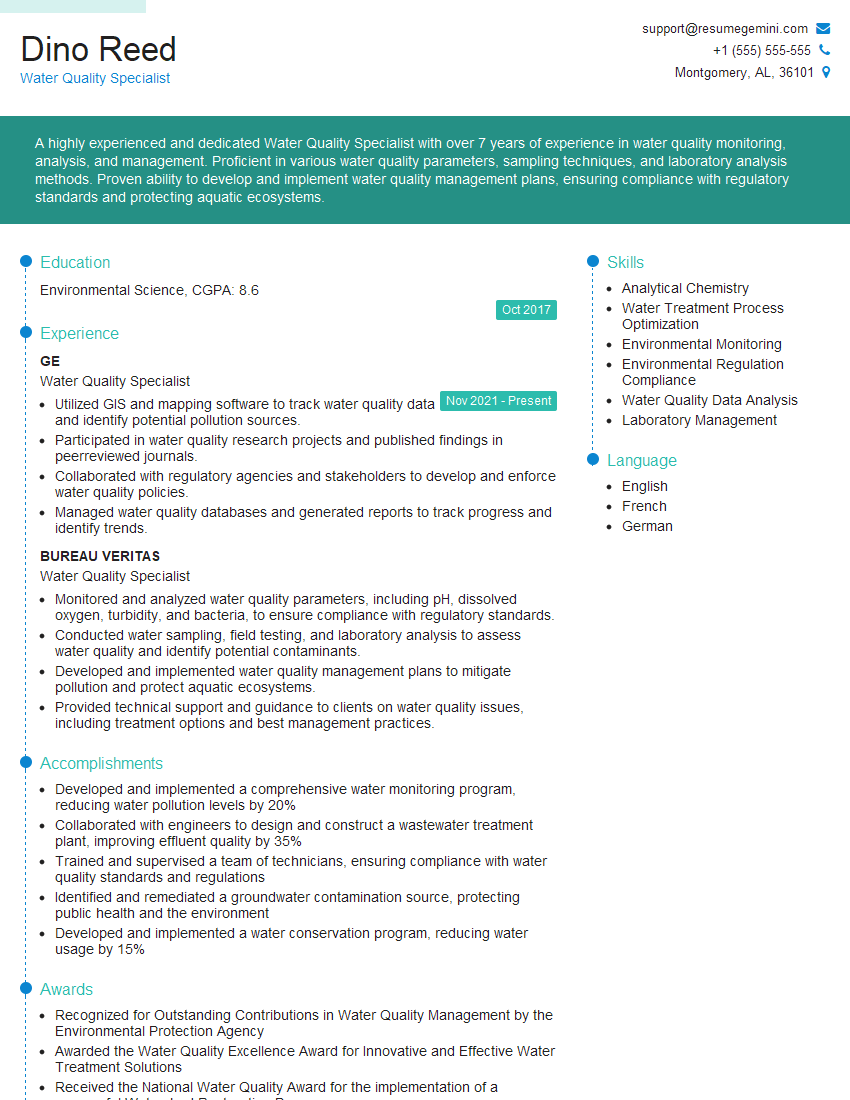

Mastering Wastewater Treatment Process Control is crucial for career advancement in this vital field. It demonstrates a commitment to operational excellence and environmental responsibility, leading to greater opportunities for leadership and specialized roles. To significantly enhance your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. We strongly encourage you to utilize ResumeGemini, a trusted resource, to build a professional resume that showcases your qualifications. ResumeGemini provides examples of resumes tailored to Wastewater Treatment Process Control to guide you in creating a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO