Unlock your full potential by mastering the most common Weld Cutting interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Weld Cutting Interview

Q 1. Explain the different types of weld cutting processes.

Weld cutting encompasses several processes, all aimed at severing materials using heat. The most common are:

- Oxy-fuel cutting (OFC): This uses a mixture of oxygen and fuel gas (acetylene, propane, etc.) to generate a high-temperature flame that melts and oxidizes the metal, allowing it to be blown away. It’s versatile and relatively inexpensive, but limited to ferrous metals that readily oxidize.

- Plasma arc cutting (PAC): A constricted arc of ionized gas (plasma) at incredibly high temperatures melts and vaporizes the metal. PAC is faster than OFC and can cut thicker materials and a wider range of metals, including non-ferrous ones. However, it requires specialized equipment.

- Laser cutting: A highly focused laser beam melts and vaporizes the metal, offering exceptional precision and speed, especially for intricate cuts. It’s suitable for a broad range of materials but is a more expensive process.

- Waterjet cutting: A high-pressure jet of water, often mixed with an abrasive, cuts the material through erosion. It’s exceptionally versatile, capable of cutting almost any material, but can be slower than other methods.

The choice of process depends heavily on factors like material type, thickness, required accuracy, and budget.

Q 2. Describe the safety precautions associated with weld cutting.

Weld cutting presents significant safety hazards. Here are key precautions:

- Eye and face protection: Always wear appropriate safety glasses or a welding helmet with a suitable shade to protect against intense light and flying debris.

- Respiratory protection: Fumes produced during cutting can be toxic. Use appropriate respirators or work in well-ventilated areas.

- Fire prevention: Keep flammable materials away from the cutting area. Have fire extinguishers readily available.

- Clothing: Wear flame-resistant clothing and gloves to protect against burns and sparks.

- Proper handling of cylinders: Oxygen and fuel gas cylinders should be handled and stored properly to prevent damage or explosions. Secure cylinders upright and away from heat sources.

- Confined spaces: Special precautions are necessary when cutting in confined spaces to ensure adequate ventilation and prevent the buildup of toxic gases.

- Proper training and certification: Only trained and certified personnel should operate cutting equipment.

Ignoring these precautions can lead to serious injuries, including burns, eye damage, respiratory problems, and even death.

Q 3. What are the advantages and disadvantages of oxy-fuel cutting?

Oxy-fuel cutting (OFC) offers several advantages:

- Relatively low cost: OFC equipment is less expensive than other methods like plasma arc cutting.

- Portability: OFC torches are relatively portable, allowing cutting in various locations.

- Versatility for ferrous metals: It is highly effective for cutting mild steel and other ferrous materials.

However, OFC also has drawbacks:

- Slower cutting speed: Compared to PAC or laser cutting, OFC is significantly slower.

- Limited to ferrous metals: It’s not effective for cutting many non-ferrous materials.

- Heat-affected zone (HAZ): The heat from the flame can affect the surrounding material, potentially causing warping or weakening.

- Requires preheating for thicker materials: Cutting thicker materials often requires preheating to ensure proper oxidation.

Think of it like this: OFC is a reliable workhorse, but for speed and precision, other methods are often preferred.

Q 4. How do you select the appropriate cutting process for a given material?

Selecting the right cutting process depends on several factors:

- Material type: Ferrous metals are best suited for OFC, while plasma or laser cutting is better for non-ferrous metals and more exotic materials.

- Material thickness: Thinner materials might be efficiently cut with OFC or laser cutting, while thicker materials often necessitate plasma or waterjet cutting.

- Cut quality and precision: Laser cutting provides excellent precision, while OFC might suffice for less critical applications.

- Cost and availability of equipment: OFC is more affordable and widely accessible than laser or plasma cutting.

- Production volume: For high-volume production, automated laser or plasma cutting systems are more efficient.

For example, cutting a thin sheet of mild steel might use OFC due to its simplicity and low cost, while cutting a thick stainless steel plate might require plasma arc cutting for its speed and capability to handle the material thickness.

Q 5. Explain the concept of preheating in weld cutting.

Preheating in weld cutting involves raising the temperature of the material before cutting. It’s crucial for:

- Thicker materials: Preheating reduces the thermal shock on the material, preventing cracking and improving cut quality. The heat allows for a more even and controlled oxidation process.

- High-carbon steel: High-carbon steels are more prone to cracking due to rapid cooling, so preheating minimizes this risk.

- Improved cut quality: By preheating, the material is more readily oxidized and cut, improving the smoothness and accuracy of the cut.

Preheating temperature and methods vary based on the material and its thickness. It’s often accomplished using torches or induction heating. Think of it as preparing the material for a cleaner, less stressful cut.

Q 6. What are the common defects found in weld cutting and how are they prevented?

Common defects in weld cutting include:

- Undercutting: The cut is wider at the bottom than the top, weakening the material.

- Dross: Molten metal residue remains attached to the cut edges, affecting the surface finish.

- Beveling: The cut is angled instead of straight.

- Cracking: Cracks may form in the heat-affected zone due to rapid cooling or improper preheating.

- Rough edges: Uneven cutting surfaces caused by improper technique or equipment issues.

Preventing these defects requires:

- Proper cutting technique: Maintain consistent speed and torch angle.

- Correct gas pressure and mixture: Ensure the proper balance of oxygen and fuel gas for efficient cutting.

- Clean cutting surfaces: Remove any dirt or coating from the material before cutting.

- Proper preheating: Preheating is essential for thicker materials or high-carbon steels to prevent cracking.

- Regular equipment maintenance: Regularly inspect and maintain cutting equipment to ensure optimal performance.

Think of these defects as warning signs of improper technique or equipment issues. Addressing the root cause is crucial for quality cuts.

Q 7. Describe the procedure for setting up an oxy-fuel cutting torch.

Setting up an oxy-fuel cutting torch involves several steps:

- Connect the gas cylinders: Securely connect the oxygen and fuel gas cylinders to the torch using the appropriate regulators and hoses. Ensure the connections are leak-free.

- Adjust the regulators: Set the regulators to the proper pressure according to the material thickness and type of gas being used. Consult the manufacturer’s instructions for appropriate pressure settings.

- Purge the lines: Open the oxygen and fuel gas valves slightly to purge the lines of any air. This prevents dangerous gas mixtures from building up.

- Light the torch: Ignite the fuel gas first, then carefully introduce oxygen to create the cutting flame.

- Adjust the flame: Adjust the oxygen and fuel gas flows to achieve the correct flame type (neutral, oxidizing, or carburizing) required for the specific application.

- Test the cut: Before starting the main cut, perform a test cut on a scrap piece of the same material to check the settings and ensure proper cutting performance.

It’s critical to carefully follow the manufacturer’s instructions and safety guidelines. Improper setup can lead to inefficient cutting, safety hazards, and potential damage to equipment.

Q 8. How do you ensure the safety of yourself and others during weld cutting operations?

Safety is paramount in weld cutting. Think of it like this: a single spark can ignite a fire, and a stray piece of molten metal can cause serious injury. We start by ensuring everyone in the vicinity wears appropriate Personal Protective Equipment (PPE), including safety glasses with side shields, flame-resistant clothing, leather gloves, and sturdy work boots. The area must be well-ventilated to prevent the buildup of harmful gases like carbon monoxide. Before starting any operation, we thoroughly inspect the equipment, checking for gas leaks using a leak detection solution. We also ensure the work area is clear of flammable materials, and fire extinguishers are readily accessible. Finally, a designated fire watch is often maintained, particularly during large-scale operations, ensuring a rapid response in case of an emergency.

For example, before cutting a large steel beam, we’d first clear the area at least 10 meters in every direction, ensuring no combustibles are present. We’d then carefully inspect the torch and regulator for any damage, leaks, or malfunction. Only after these safety checks are complete do we proceed with the cutting operation.

Q 9. Explain the importance of proper gas pressure regulation in weld cutting.

Proper gas pressure regulation is critical for effective and safe weld cutting. Imagine trying to control a water hose with wildly fluctuating pressure – it would be chaotic and potentially dangerous. Similarly, inconsistent gas pressure affects the cutting process significantly. Too much pressure can lead to excessive splatter and potentially damage the workpiece, while too little pressure results in weak cuts, incomplete severing, and inefficient operation. The correct pressure is crucial to maintaining a stable and consistent cutting flame, allowing for accurate and clean cuts.

Each gas (oxygen and fuel gas) has a specified pressure range for optimal performance, typically indicated on the equipment itself and in the manufacturer’s instructions. Regulators control the gas flow, allowing adjustment to the desired pressure. Pressure gauges monitor the cylinder pressure and working pressure, providing visual feedback. Incorrect pressure settings can lead to poor cut quality, increased fuel consumption, and even damage to the cutting equipment.

Q 10. What are the different types of cutting nozzles and their applications?

Cutting nozzles are specialized attachments that focus the gas mixture to create the cutting flame. Different nozzle designs cater to various material thicknesses and cutting requirements. For instance:

- Standard Nozzles: These are general-purpose nozzles suitable for a range of thicknesses. They provide a versatile cutting capability, adequate for many applications.

- High-Velocity Nozzles: Designed for increased cutting speed and deeper penetration, particularly useful when cutting thicker materials or those requiring a faster process.

- Precision Nozzles: These provide a narrower, more concentrated flame, ideal for intricate cutting work where precision is paramount, such as when working with thin materials or creating detailed cuts.

- Long-Reach Nozzles: These allow for cutting in hard-to-reach areas, expanding application possibilities in confined spaces or when dealing with unusually shaped workpieces.

The choice of nozzle depends entirely on the material being cut and the desired cut quality and speed. Incorrect nozzle selection would lead to inefficient cutting, poor surface finish, or even damage to the equipment.

Q 11. How do you identify different types of metals before cutting?

Identifying the metal type is fundamental before cutting. Cutting different metals requires specific settings and techniques. Incorrect identification could lead to unsatisfactory cuts, equipment damage, or even safety hazards. Several methods exist for identification. Visual inspection, often involving checking surface characteristics such as color, texture, and any visible markings, is a starting point. However, a more reliable method involves using a spark test. This involves striking the metal with a grinding wheel and observing the color and pattern of the sparks generated. Different metals produce distinct spark characteristics, enabling their identification. For more complex scenarios or when high accuracy is required, other methods such as chemical analysis or magnetic testing can be employed. Always refer to material safety data sheets (MSDS) for guidance on specific metal properties and cutting considerations.

For instance, if I encounter a workpiece with a relatively smooth surface and a silvery-white color, and a spark test reveals long, branching sparks, I can confidently identify it as mild steel. However, if the sparks are short, yellow, and intense, it might indicate cast iron, and I’d adjust my cutting parameters accordingly.

Q 12. Explain the process of beveling edges before welding.

Beveling, or creating an angled edge on a workpiece before welding, is crucial for creating strong and high-quality welds. Think of it like creating a ramp for the weld material. A beveled edge allows for better penetration and fusion of the weld material into the base metal, resulting in a stronger and more durable joint. This is especially important for thicker materials where direct welding of a square butt joint would create a weld that is too narrow and weak to support the structure.

The bevel angle is chosen based on material thickness and weld type, with common angles ranging from 30° to 60°. Beveling can be achieved using various methods, including grinding, plasma cutting, or even weld cutting itself. The key is to ensure the bevel is clean, even, and free from any defects that could compromise the final weld quality. A properly beveled edge allows for complete penetration and fusion of weld metal, ensuring a mechanically sound and visually appealing weld.

Q 13. What are the factors influencing the cutting speed in different cutting processes?

Cutting speed is a crucial parameter influencing the quality and efficiency of the cutting process. Numerous factors interplay to determine the optimal cutting speed for different processes. These factors include:

- Material Thickness: Thicker materials require slower cutting speeds to ensure complete penetration and avoid overheating.

- Material Type: Different materials have varying melting points and thermal conductivity, impacting the optimal cutting speed. Steel, for example, has different cutting speed requirements than aluminum.

- Gas Pressure: Higher gas pressure generally allows for faster cutting speeds, but must be balanced with the risk of excessive material splatter and possible nozzle damage.

- Nozzle Size and Type: The size and design of the nozzle affect the flame concentration and shape, directly impacting cutting speed. A narrower nozzle might increase precision but reduce speed.

- Preheating: Preheating the material prior to cutting can allow for increased speed and efficiency, particularly in very thick metals or those which are otherwise difficult to cut.

Finding the right balance is critical. Too slow, and the process is inefficient. Too fast, and the quality suffers and risk of damage increases.

Q 14. How do you maintain and clean cutting equipment?

Regular maintenance and cleaning of cutting equipment are crucial for ensuring safe and efficient operation. Think of it like maintaining a car—regular servicing prevents major breakdowns and ensures optimal performance. After each use, we inspect the equipment for any signs of damage or wear and tear. This includes examining the cutting nozzle for debris buildup, cracks, or damage; checking hoses for kinks, leaks, or wear; and inspecting the regulators for proper functionality. Any accumulated debris is cleaned carefully, typically using a soft brush and compressed air to prevent damage to delicate components. For more stubborn debris, appropriate cleaning solutions can be used, but always following the manufacturer’s recommendations.

Regular lubrication of moving parts is important to prevent wear and ensure smooth operation. We also pay close attention to the gas cylinders, checking for damage, ensuring they’re properly secured, and following safe handling procedures. This preventative maintenance not only extends the lifespan of the equipment but significantly reduces the risk of accidents and ensures consistent, high-quality cutting performance. Ignoring this crucial step can lead to premature equipment failure and potential safety hazards.

Q 15. Describe the troubleshooting steps for common weld cutting problems.

Troubleshooting weld cutting problems often involves a systematic approach. Think of it like diagnosing a car problem – you need to check the basics first before moving to more complex issues.

Gas Pressure and Flow: Insufficient gas pressure or improper gas mixture is a frequent culprit. Check your gauges to ensure they’re within the manufacturer’s specified range for your cutting gas (e.g., oxygen and acetylene for oxy-fuel cutting). A clogged nozzle or hose can also restrict flow. Inspect these components carefully and replace as needed.

Tip Condition: A worn or damaged cutting tip will lead to poor cuts, weak preheating, or inefficient oxygen jet. Inspect the tip for cracks, pitting, or excessive wear. Replacing a damaged tip is crucial for a clean cut.

Material Preparation: Improperly prepared material is a major source of issues. Ensure the surface is clean and free of rust, paint, or other contaminants that could interfere with ignition or the cutting process. For thicker materials, consider preheating to improve cutting efficiency.

Cutting Speed: Too slow a speed can lead to excessive heat input and melting, while too fast a speed can result in incomplete cuts or surface defects. The correct cutting speed depends on the thickness and type of metal. Experiment to find the optimal speed for your setup.

Preheating Flame: The preheating flame’s size and characteristics are crucial. An improperly adjusted flame can inhibit the cutting process. Make sure the flame is correctly adjusted according to the manufacturer’s instructions, exhibiting a neutral flame.

Post-Cut Inspection: Always thoroughly inspect your cut after completion. Look for any signs of incompletion, excessive slag, or surface defects. These can highlight specific problems in your procedure or equipment.

For example, I once encountered a situation where the cutting torch wouldn’t ignite. I systematically checked the gas pressure, the tip condition, and finally, discovered a kinked hose causing a blockage. A simple hose replacement solved the problem.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the difference between cutting and gouging.

While both cutting and gouging use a high-temperature arc or flame to remove metal, they differ significantly in their purpose and process.

Cutting: Aims to completely sever a workpiece, creating a clean, narrow kerf (cut). The process uses a high-velocity jet of oxygen to oxidize the molten metal, removing it from the kerf.

Gouging: Is used to remove material from a surface, creating a wider groove. It doesn’t aim for complete separation but for controlled metal removal. Gouging often employs a larger tip or electrode than cutting and involves less oxygen flow.

Think of it this way: cutting is like using scissors to cleanly cut paper, while gouging is like using a chisel to carve away a section.

Q 17. What are the environmental considerations associated with weld cutting?

Weld cutting poses several environmental concerns. Primarily, the process generates fumes and particulate matter that can harm human health and the environment.

Air Pollution: Fumes contain various toxic gases and metal oxides depending on the materials being cut. These gases, such as carbon monoxide and nitrogen oxides, are respiratory irritants and can cause long-term health problems. Particulate matter from the cut contributes to air pollution.

Noise Pollution: The process can create significant noise pollution, especially with mechanized systems. Hearing protection is necessary to prevent hearing damage.

Waste Generation: Weld cutting produces metal slag and spatter, which can contaminate the surrounding area if not properly managed. Proper disposal of this waste is essential to avoid environmental contamination.

Ozone Depletion (for some processes): Certain gases used in some cutting processes, while less common now, could contribute to ozone depletion.

Addressing these concerns involves using proper ventilation, appropriate personal protective equipment (PPE), and responsible waste disposal methods.

Q 18. How do you interpret weld cutting symbols and blueprints?

Interpreting weld cutting symbols and blueprints requires a thorough understanding of welding symbology standards, typically ASME Y14.5M or ISO standards. These symbols convey crucial information about the type of cut, its dimensions, location, and other relevant details.

The symbols usually indicate:

- Type of Cut: Whether it’s a bevel cut, a slot cut, or a contour cut.

- Dimensions: The depth, width, and length of the cut.

- Location: Where the cut should be made on the workpiece, often referenced from a datum.

- Finish: Desired surface finish after the cut.

The blueprints provide the overall context, showing the location of the cuts within the larger assembly. Often, a reference to a detail drawing showing specific cut dimensions and geometry will be included.

For example, a symbol might show a 45-degree bevel cut, 10mm deep, along a specified edge of a plate. The blueprint would show the location of this plate and its relationship to other components in the assembly.

Q 19. What are the different types of cutting gases used in weld cutting?

The choice of cutting gas depends on the material being cut and the desired cutting speed and quality. Common gases include:

Oxygen: Essential for almost all weld cutting processes, as it’s the oxidizing agent that reacts with the molten metal, removing it from the kerf. Often used in combination with other fuel gases.

Acetylene: Commonly used as a fuel gas in oxy-fuel cutting, providing a high-temperature flame for preheating and initiating the cutting process. It offers a good balance of flame temperature and cutting speed for many applications.

Propane: Another fuel gas used in oxy-fuel cutting, often preferred for thicker materials due to its higher burning rate. The flame temperature is lower than acetylene, thus potentially requiring longer preheating.

Natural Gas: A less expensive alternative to propane, also used as a fuel gas in oxy-fuel cutting. It offers slightly lower flame temperature compared to propane.

Plasma Gas: In plasma arc cutting, gases like argon, nitrogen, or compressed air are used to create the plasma arc, which melts and removes the metal.

Each gas has unique properties affecting the cutting process. The choice depends on factors such as material thickness, cutting speed requirements, cost considerations, and environmental regulations.

Q 20. Explain the importance of proper ventilation during weld cutting.

Proper ventilation during weld cutting is paramount for the health and safety of the operator and those nearby. The fumes generated contain harmful gases and particulate matter. Without sufficient ventilation, these contaminants build up, leading to potentially serious health consequences.

Inadequate ventilation can result in:

- Respiratory Problems: Exposure to fumes can cause irritation, coughing, shortness of breath, and in severe cases, chronic lung diseases.

- Carbon Monoxide Poisoning: Carbon monoxide is a colorless, odorless, and highly toxic gas produced during cutting. It can be fatal if inhaled in high concentrations.

- Metal Fume Fever: Inhalation of metal oxide fumes can cause a flu-like illness known as metal fume fever.

Effective ventilation involves using local exhaust ventilation systems, such as fume extractors, or ensuring good general ventilation in the work area. In confined spaces, respiratory protection is crucial, even with ventilation. Think of it like this – you wouldn’t cook without a well-ventilated kitchen; similarly, you shouldn’t perform weld cutting without sufficient ventilation.

Q 21. How do you handle different types of metal thicknesses during cutting?

Handling different metal thicknesses during cutting requires adjustments to the cutting process parameters.

Thinner Metals: Require lower gas pressures and faster cutting speeds to prevent burn-through or excessive melting. Preheating is often unnecessary, but precise control of the cutting speed is vital for clean cuts.

Thicker Metals: Necessitate higher gas pressures and slower cutting speeds. Preheating is often necessary to facilitate the cutting process and reduce the risk of incomplete cuts. The use of a larger cutting tip might also be needed. For extremely thick materials, multiple passes or mechanized cutting techniques might be required.

The choice of cutting tip size is crucial. Larger tips are generally used for thicker materials, while smaller tips are used for thinner materials. The type of cutting equipment also influences the approach. For instance, plasma arc cutting is better suited for thick materials compared to oxy-fuel cutting, while oxy-fuel cutting is more versatile and suitable for smaller parts.

For instance, when cutting a 1/4 inch steel plate, you will need a different setting compared to cutting a 2-inch steel plate, which may require multiple passes or a gouging process depending on the desired outcome.

Q 22. Describe your experience with different types of cutting machines (e.g., plasma, laser).

My experience encompasses a wide range of cutting machines, primarily focusing on plasma and laser cutting. With plasma cutting, I’ve worked extensively with both manual and CNC systems, using various gas mixtures (like oxygen and argon) to cut different thicknesses and types of metals, from mild steel to stainless steel. I’m proficient in adjusting parameters like amperage, gas pressure, and cutting speed to optimize cut quality and efficiency. I’ve also worked extensively with laser cutting machines, utilizing both CO2 and fiber lasers to cut intricate designs in sheet metal. Understanding the differences between the two laser types and their respective applications – for example, fiber lasers excel with thin metal sheets and high precision, while CO2 lasers are better suited for thicker materials – is crucial. I’ve used these technologies in both production and prototyping environments, becoming adept at selecting the best technology for a specific project.

For instance, on a recent project involving stainless steel housings, the intricate designs required the precision of a fiber laser. In contrast, for thicker steel plates used in structural elements, plasma cutting proved more efficient and cost-effective.

Q 23. Explain the process of setting up and operating a CNC cutting machine.

Setting up a CNC cutting machine involves several key steps. First, you need to import the design file – typically a DXF or DWG file – into the machine’s control software. This software allows you to define cutting parameters like speed, power, and gas pressure, depending on the material and desired cut quality. You then need to securely clamp the material to the cutting table, ensuring it’s properly aligned and stable. The next step involves selecting the appropriate cutting tool (plasma torch or laser head), checking gas connections and flow rates, and ensuring the machine’s safety interlocks are functioning correctly. A crucial step is performing a test cut on a scrap piece of the same material to fine-tune the parameters and confirm the machine’s performance before proceeding with the final cut. Once satisfied, the actual cutting process can begin, and you monitor the machine’s operation for any issues.

For example, when cutting a complex part from aluminum sheet metal using a laser cutter, a test cut on a scrap piece allows me to fine-tune laser power, speed, and focus to achieve clean, burr-free edges and avoid issues like excessive heat or material distortion.

Q 24. What are the safety procedures for working with different types of cutting gases?

Safety is paramount when working with cutting gases. With oxygen, the key is to prevent the formation of flammable mixtures and to avoid any ignition sources. This means keeping the area free of oil and grease, using proper grounding techniques, and ensuring all electrical equipment is in good condition. Acetylene requires special attention since it can decompose explosively under pressure. Cylinders must be stored upright and protected from excessive heat. Always use proper regulators and hoses, regularly inspect for leaks using soapy water, and never use open flames near acetylene cylinders. For all gases, proper ventilation is essential to prevent the buildup of potentially harmful or asphyxiating gases.

In my experience, regular safety checks and adherence to a strict safety protocol are mandatory. This includes daily inspection of equipment, appropriate PPE (Personal Protective Equipment) like flame-resistant clothing, safety glasses, and gloves, and a clear understanding of emergency shutdown procedures.

Q 25. How do you ensure the quality of the cut in different cutting processes?

Ensuring cut quality involves optimizing parameters for each process and material. For plasma cutting, this includes adjusting amperage, gas pressure, and cutting speed to achieve the desired kerf width (width of the cut) and edge finish. For laser cutting, factors like power, speed, and focus are critical for minimizing heat-affected zones and creating clean, precise cuts. Regular maintenance of the equipment, such as cleaning the cutting nozzle in plasma cutting and maintaining the laser optics, is also essential. Finally, pre- and post-process inspections are key to evaluating the quality, checking for flaws like dross (molten metal residue) or inconsistencies in cut dimensions, and identifying issues promptly.

For example, using a digital caliper to measure the kerf width and checking for burrs on the cut edges helps to identify and correct any issues in the cutting parameters or machine setup.

Q 26. How do you handle emergency situations during weld cutting operations?

Emergency situations during weld cutting can range from minor equipment malfunctions to serious accidents. My approach involves a systematic response: immediately shutting down the machine using the emergency stop button, assessing the situation to identify the hazard (e.g., gas leak, fire, or injury), and initiating appropriate actions. This may involve activating the fire suppression system, providing first aid, or evacuating the area. In addition, reporting the incident according to company protocols is critical for investigation and corrective action to prevent similar incidents in the future. Effective emergency response requires a thorough understanding of the potential hazards, clear communication procedures, and regular training in emergency response techniques.

For instance, I once experienced a sudden gas leak during plasma cutting. My immediate response was to shut down the system, evacuate the area, and contact emergency personnel. Following the incident, a thorough inspection of the gas lines and regulators was conducted to identify and rectify the root cause of the leak.

Q 27. Describe your experience with quality control procedures in weld cutting.

Quality control in weld cutting is a multi-faceted process. It starts with the selection of appropriate materials and equipment, ensuring they meet the required specifications. During the cutting process, regular monitoring is crucial to maintain consistent cut quality and identify potential defects. This includes checking dimensions, surface finish, and the presence of any defects like dross or warping. Post-process inspections, often involving visual checks, dimensional measurements, and sometimes destructive testing, confirm the final quality. Documentation is key, recording all parameters and observations to ensure traceability and facilitate continuous improvement.

In my previous role, I implemented a system of visual inspection checklists and dimensional measurements which reduced defects by 15% within the first quarter. This data-driven approach improved quality control and streamlined corrective actions.

Q 28. What are your salary expectations for this weld cutting position?

My salary expectations are commensurate with my experience and skills in weld cutting. Considering my extensive experience with various cutting technologies, my proven ability to maintain high quality standards, and my strong safety record, I’m seeking a salary in the range of [Insert Salary Range]. I am open to discussing this further and am confident that my contributions will significantly benefit your company.

Key Topics to Learn for Weld Cutting Interview

- Types of Weld Cutting Processes: Understanding the differences between oxy-fuel cutting, plasma arc cutting, and laser cutting, including their applications and limitations.

- Safety Procedures and Regulations: Demonstrating knowledge of safety protocols, PPE requirements, and relevant industry regulations for safe weld cutting practices.

- Material Selection and Properties: Knowing how different materials react to various cutting methods and selecting the appropriate process based on material characteristics (e.g., thickness, type of steel).

- Equipment Operation and Maintenance: Familiarity with the operation, maintenance, and troubleshooting of common weld cutting equipment (e.g., torches, plasma cutters, lasers).

- Cutting Parameters and Adjustments: Understanding the impact of parameters like gas pressure, amperage, and cutting speed on cut quality and efficiency.

- Weld Cutting Techniques and Procedures: Mastering various cutting techniques for different applications, including straight cuts, bevel cuts, and piercing.

- Quality Control and Inspection: Knowing how to inspect cut edges for defects and ensuring they meet required specifications.

- Troubleshooting Common Issues: Ability to diagnose and solve common problems encountered during weld cutting operations.

- Blueprint Reading and Interpretation: Understanding and interpreting engineering drawings to accurately perform weld cutting tasks.

- Weld Joint Design Considerations: Knowing how the cutting process impacts the overall weld joint design and strength.

Next Steps

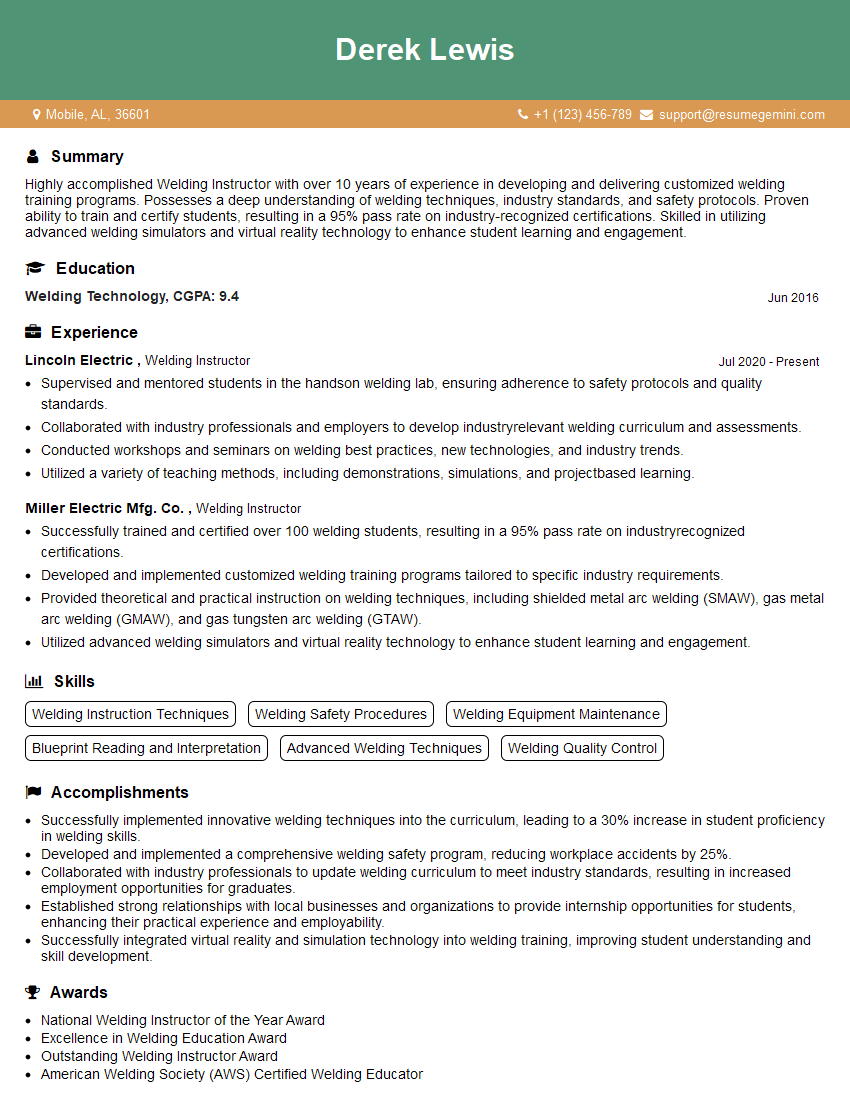

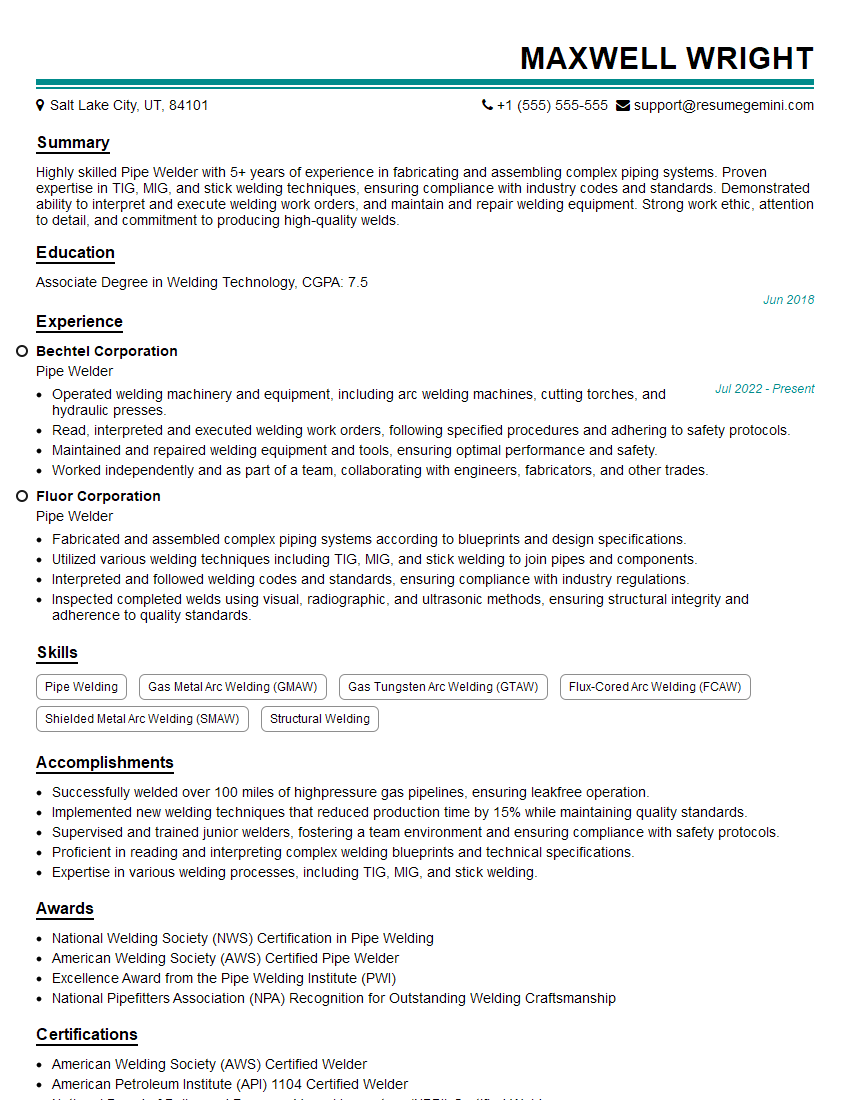

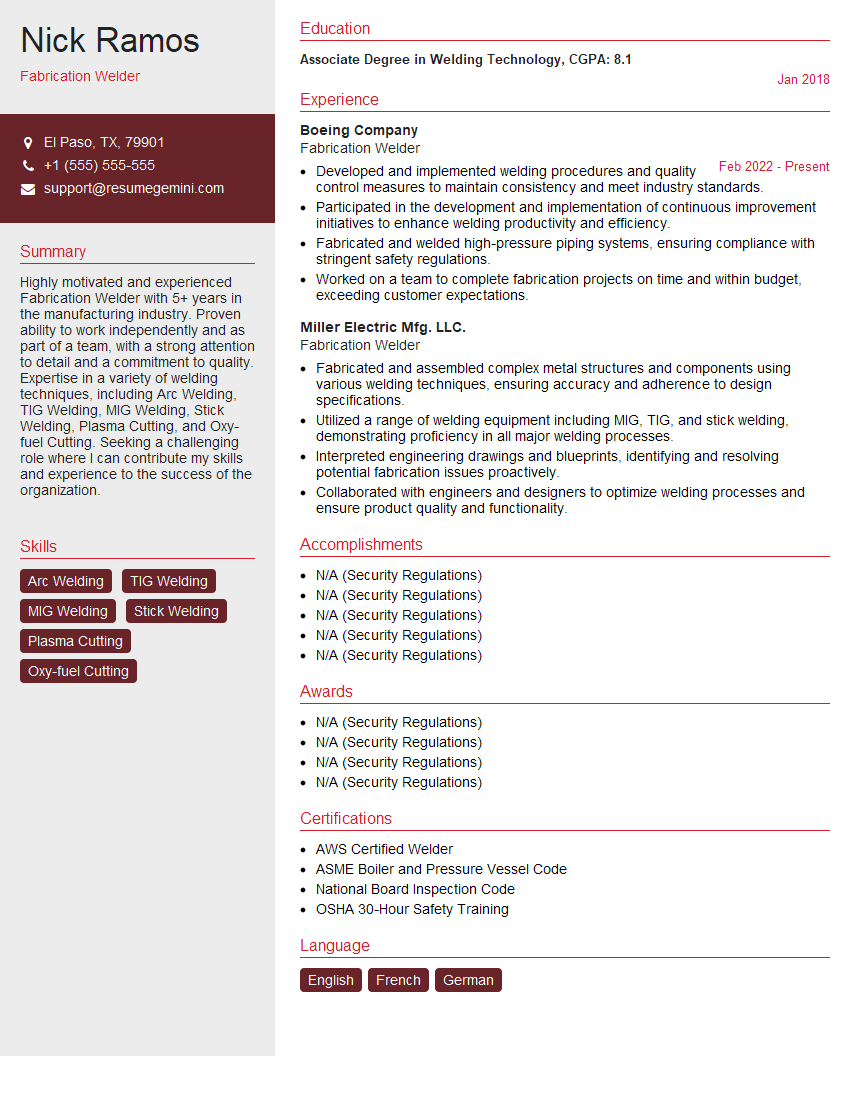

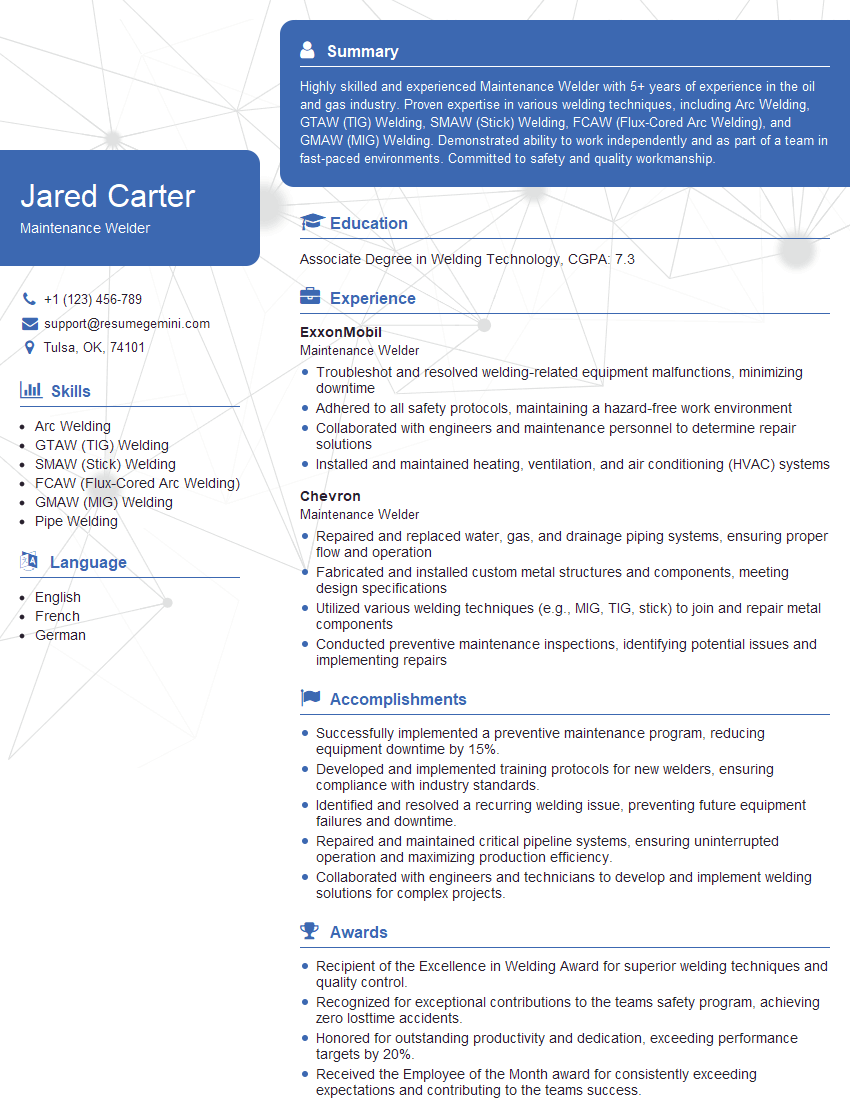

Mastering weld cutting opens doors to a wide range of rewarding and well-paying career opportunities in manufacturing, construction, and various industrial settings. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters. We strongly recommend using ResumeGemini to build a professional and impactful resume that highlights your expertise in weld cutting. ResumeGemini provides helpful tools and resources, and even offers examples of resumes tailored to the weld cutting field to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO