Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top WELDER CONSTRUCTION interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in WELDER CONSTRUCTION Interview

Q 1. What welding processes are you proficient in (e.g., MIG, TIG, Stick)?

Throughout my career, I’ve become proficient in several welding processes, each suited to different materials and applications. My core competencies include:

- MIG (Metal Inert Gas) Welding: This is a versatile process ideal for high-volume production due to its speed and ease of use. I’m experienced with MIG welding various steel types, including mild steel and stainless steel. I’ve used it extensively in projects ranging from simple structural welds to complex automotive parts.

- TIG (Tungsten Inert Gas) Welding: TIG welding allows for precise control and produces exceptionally clean welds. I’m highly skilled in TIG welding aluminum, stainless steel, and various other specialized alloys, often used in applications requiring high-quality, corrosion-resistant joints, such as pipelines or aerospace components.

- Stick (Shielded Metal Arc Welding) Welding: This process is robust and portable, making it suitable for outdoor work or challenging environments. My experience with stick welding covers mild steel and other ferrous metals, particularly useful in situations where power sources are limited.

My proficiency extends beyond just the basic techniques; I understand the nuances of each process, including different wire feeds, gas shielding, and amperage control, enabling me to adapt to diverse project requirements.

Q 2. Describe your experience with different types of welding metals (e.g., steel, aluminum, stainless steel).

My experience with different welding metals is extensive, and understanding the unique properties of each is crucial for successful welding.

- Steel: I’ve worked with various steel grades, from mild steel used in construction to high-strength steel in heavy machinery. The key is understanding the carbon content and its impact on weldability. High-carbon steels, for instance, require preheating to prevent cracking.

- Aluminum: Aluminum’s low melting point and high thermal conductivity necessitate careful control of heat input during welding. I’m skilled in using TIG welding techniques with specific filler materials and techniques to prevent porosity and cracking. I’ve worked on aluminum structures, automotive parts, and aircraft components.

- Stainless Steel: Welding stainless steel requires attention to detail to prevent corrosion. I use specific filler metals and techniques to avoid creating weak points or discoloration. I’ve completed projects involving stainless steel pipelines, food processing equipment, and architectural features.

I regularly consult material data sheets to ensure I’m using the correct welding parameters and filler materials for each specific metal. This avoids defects and ensures the highest weld quality.

Q 3. Explain the importance of pre-weld preparation and cleaning.

Pre-weld preparation and cleaning are absolutely critical for achieving strong, reliable welds. Think of it like building a house—you wouldn’t start constructing walls on a shaky foundation or with dirty bricks.

The preparation process typically involves:

- Surface Cleaning: Removing any dirt, grease, paint, rust, or mill scale from the base metals is essential. Contaminants can weaken the weld and create defects. Techniques include wire brushing, grinding, and chemical cleaning depending on the material and contamination type.

- Joint Preparation: Creating a proper joint design ensures good penetration and avoids weld defects. This might involve beveling, cutting, or fitting the parts precisely according to the blueprint. The joint type (butt, lap, fillet, etc.) is carefully chosen based on the application’s requirements.

- Preheating (when necessary): Some materials, especially thicker sections or high-carbon steel, require preheating to reduce thermal stress and prevent cracking during welding.

Failing to perform adequate pre-weld preparation can lead to porosity, cracking, incomplete fusion, and reduced strength of the weld. The extra time invested in proper preparation is always worth it to ensure the long-term integrity of the weld.

Q 4. How do you ensure weld quality and consistency?

Ensuring weld quality and consistency is a multifaceted process, combining technical skill with a rigorous approach. My strategies include:

- Proper Welding Technique: Maintaining consistent travel speed, amperage, and arc length are fundamental. Each welding process has optimal parameters that I carefully adjust based on the material and joint design.

- Regular Inspection: I routinely inspect my welds during the process to identify and correct any potential defects early on. This includes visual checks for proper penetration, bead shape, and absence of defects.

- Use of Testing Equipment: Where appropriate, I use tools such as a penetration gauge and magnetic particle inspection equipment to further verify weld quality. Destructive testing might be required for critical applications.

- Calibration and Maintenance: I ensure my welding equipment is correctly calibrated and regularly maintained to ensure consistent performance. A poorly maintained welder can produce inconsistent welds.

- Adherence to Welding Procedures: I meticulously follow established welding procedures (WPS) and specifications, using certified filler materials and appropriate safety equipment.

My focus is on producing welds that meet or exceed the required standards of quality and strength for the given application.

Q 5. What safety precautions do you follow while welding?

Safety is my top priority. Welding poses several hazards, and I always adhere to strict safety protocols:

- Personal Protective Equipment (PPE): This includes a welding helmet with the appropriate shade lens, welding gloves, flame-resistant clothing, and safety footwear. I never compromise on PPE.

- Fire Prevention: I ensure a fire-safe work area, removing flammable materials and using fire blankets or extinguishers when needed. The work area is regularly checked for sparks or embers.

- Ventilation: Welding fumes can be toxic, so I work in a well-ventilated area or use appropriate respiratory protection such as a respirator. I am aware of and avoid welding materials containing harmful substances.

- Eye Protection for Others: I ensure that anyone nearby wears appropriate eye protection, even if they are not directly involved in the welding process.

- Safe Handling of Equipment: I always follow safe handling procedures for oxygen and acetylene cylinders and other equipment to prevent accidents.

Regular safety briefings and ongoing training help me stay updated on best practices and ensure my work environment is safe for myself and others.

Q 6. What are the common welding defects and how do you identify them?

Common welding defects can significantly compromise the structural integrity and aesthetic quality of a weld. Recognizing these defects is crucial. Some common ones include:

- Porosity: Small holes or voids in the weld caused by gas entrapment. I identify this through visual inspection.

- Cracking: Fractures in the weld metal, often caused by rapid cooling or stress. Visual inspection and sometimes dye penetrant testing can reveal cracks.

- Incomplete Fusion: The weld metal doesn’t completely fuse with the base metal, creating a weak point. This is often visible during inspection.

- Undercutting: A groove melted into the base metal adjacent to the weld. This is a visual defect indicative of excessive heat input or improper travel speed.

- Spatter: Small metal droplets scattered around the weld, often impacting cosmetic appearance. This is usually addressed with grinding.

My experience allows me to identify these defects using visual inspection, aided by magnification or specialized testing equipment when necessary. Addressing defects early on saves time and resources while ensuring the integrity of the final product.

Q 7. Describe your experience with blueprint reading and interpreting welding symbols.

Blueprint reading and interpreting welding symbols are essential for any welder. I am proficient in reading and understanding engineering drawings and welding symbols to accurately execute weld specifications.

I am familiar with:

- Blueprint Interpretation: I can easily interpret dimensions, tolerances, material specifications, and assembly instructions from blueprints. I understand orthographic projections and sectional views.

- Welding Symbol Interpretation: I can accurately interpret welding symbols, including the reference line, arrow, basic weld symbols, supplementary symbols (e.g., specifying weld size, length, and spacing), and process specifications. For example, a symbol with a triangle on the reference line indicates a fillet weld, while a square symbol indicates a square groove weld. The placement of symbols on the reference line indicates which side of the joint the weld is applied to.

Accuracy in understanding these elements is critical in ensuring that welds are created according to the design specifications, guaranteeing both the integrity and safety of the final structure. I regularly use these skills to execute complex projects successfully.

Q 8. How do you determine the appropriate welding parameters (voltage, amperage, etc.)?

Determining the correct welding parameters is crucial for producing high-quality welds. It’s a balance of several factors, and often involves a bit of trial and error, even for experienced welders. The base parameters are voltage, amperage, and travel speed. These are interdependent; changing one affects the others. Think of it like baking a cake – you need the right temperature, baking time, and ingredients in the correct proportions.

Voltage: Controls the arc’s heat intensity. Higher voltage leads to a hotter, deeper penetration, while lower voltage results in a shallower, less intense weld. For example, welding thicker materials usually requires higher voltage to fully fuse the metals.

Amperage: This determines the amount of current flowing through the arc, impacting weld bead width and penetration. Higher amperage creates wider beads, potentially with deeper penetration, but increases the risk of burn-through. Lower amperage produces thinner beads.

Travel Speed: This influences the heat input per unit length. Slower speeds give more time for heat to transfer, producing wider, deeper welds, while faster speeds create narrow, shallower welds. Too slow, and you risk burn-through; too fast, and the weld might lack penetration.

Other Factors: Beyond these core parameters, the type of metal, its thickness, the type of welding process (MIG, TIG, stick), and the filler metal used all influence the optimal settings. Welders often consult welding procedure specifications (WPS) for specific materials and joint types to ensure optimal weld quality and consistency.

I typically start with parameters suggested by the WPS or based on my experience with similar materials and processes. I then fine-tune these settings during the welding process by visually inspecting the weld bead. A properly fused bead will exhibit smooth surfaces without excessive splatter or porosity.

Q 9. What is your experience with different types of welding joints (e.g., butt, fillet, lap)?

My experience encompasses a broad range of welding joints, each presenting unique challenges and requiring specific welding techniques. I’m proficient in the following:

Butt Joints: These are the simplest, joining two pieces end-to-end. Proper alignment and penetration are critical. I have extensive experience using both square butt and bevelled butt joints, adapting my technique based on material thickness.

Fillet Joints: These connect two members at an angle, creating a triangular weld bead. The leg length and size of the weld bead depend on the load requirements. I’m skilled in making both single- and double-fillet welds.

Lap Joints: This involves overlapping two pieces. The weld penetrates the top layer of the overlapping material. The challenge here is ensuring complete fusion without burning through. I frequently use this joint type in construction, where it often involves multiple weld passes to ensure strength.

Other Joints: I also have experience with corner, T, and edge joints, each demanding its unique approach to achieve maximum strength and durability.

My experience isn’t just about the theoretical understanding; it’s backed by years of hands-on work in diverse projects, ranging from simple metal fabrications to large-scale construction projects.

Q 10. Explain the difference between different weld types (e.g., full penetration, partial penetration).

The difference between full and partial penetration welds lies in how deeply the weld penetrates the base material. Imagine you’re sewing two pieces of fabric together:

Full Penetration Weld: This is like stitching the two pieces completely through, creating a solid, continuous weld throughout the entire thickness of the joined materials. This is essential for applications requiring maximum strength and leak-tightness. Full penetration is usually achieved through multiple passes or specialized welding techniques.

Partial Penetration Weld: This is like only sewing partway through the fabric. The weld doesn’t penetrate the full thickness of the base material. It’s suitable for less demanding applications and often used for thinner materials where full penetration isn’t necessary or feasible. It’s important to note that while providing structural integrity, partial penetration welds may have reduced load-bearing capacity.

The choice between full and partial penetration depends on the design requirements, material thickness, and the application’s load-bearing needs. A structural component will almost always demand a full penetration weld, whereas a less critical connection might suffice with a partial penetration weld. Choosing incorrectly can have serious consequences, leading to structural failure. Therefore, a thorough understanding of design specifications and material properties is paramount.

Q 11. How do you troubleshoot common welding problems (e.g., porosity, cracking)?

Troubleshooting welding defects requires systematic problem-solving. I start by carefully examining the weld visually and then consider the various factors involved.

Porosity: This refers to small holes within the weld. Causes include trapped gas (from moisture or impurities in the filler metal or base material), insufficient shielding gas coverage (in MIG/TIG welding), or excessive welding speed. Solutions involve preheating the base materials, using dry filler metal, ensuring proper shielding gas flow, adjusting welding speed, and potentially adjusting cleaning processes.

Cracking: This can be caused by various issues, including improper welding parameters (too high heat input), poor joint design, contamination, or hydrogen embrittlement (the absorption of hydrogen during welding). I address this by optimizing welding parameters, preheating the work piece, ensuring proper joint fit-up, using appropriate filler materials, and implementing post-weld heat treatments.

Undercutting and Overlap: These are caused by improper welding technique, excessive amperage, or incorrect travel speed. Adjustments to welding parameters and technique directly address these issues.

In addition to these, other problems like lack of fusion, incomplete penetration, and spatter are addressed through similar systematic investigations. Thorough documentation of the welding process, including the parameters used, is critical for efficient troubleshooting.

Q 12. What is your experience with non-destructive testing (NDT) methods for welds?

Non-destructive testing (NDT) is crucial for ensuring weld quality and integrity. My experience includes several common NDT methods:

Visual Inspection (VT): This is the simplest, and often the first, method. It involves visually examining the weld for surface defects like cracks, porosity, or undercutting. This is an important first step which gives a general idea of the quality.

Magnetic Particle Inspection (MPI): Used for ferrous materials, this method detects surface and near-surface cracks by applying a magnetic field and then sprinkling magnetic particles onto the weld. The particles accumulate at any surface discontinuities.

Dye Penetrant Inspection (DPI): Applicable to both ferrous and non-ferrous materials, this technique uses a dye to reveal surface cracks. The dye penetrates the crack, and a developer then draws it to the surface, making cracks visible.

Radiographic Testing (RT): This method uses X-rays or gamma rays to detect internal defects. RT can uncover porosity, cracks, incomplete penetration, and other internal flaws. It is the most widely used NDT for welding quality control.

Understanding and correctly interpreting the results from these methods is critical for identifying potential problems and ensuring the structural integrity of the weld. I have experience not just in performing these tests but also in interpreting the results and recommending appropriate corrective actions.

Q 13. Describe your experience with different types of welding equipment and machinery.

My experience with welding equipment spans a wide range of technologies and machinery:

Shielded Metal Arc Welding (SMAW or Stick Welding): Proficient in using various stick electrodes for different materials and applications.

Gas Metal Arc Welding (GMAW or MIG Welding): Experienced with both pulsed and standard MIG welding, utilizing different shielding gases and wire feed speeds to achieve optimal weld quality for various applications.

Gas Tungsten Arc Welding (GTAW or TIG Welding): Skilled in precision TIG welding, including AC and DC processes, for high-quality welds on various materials, including thin-gauge metals.

Flux-Cored Arc Welding (FCAW): Familiar with self-shielded and gas-shielded FCAW processes, particularly suitable for outdoor applications.

Welding Machinery: I have experience operating various types of welding positioners, mechanized welding systems, and robotic welding systems, ensuring that these systems are appropriately setup for effective welding procedures.

This diverse experience allows me to adapt my skills to various projects and environments, maximizing efficiency and quality in all welding procedures.

Q 14. How do you maintain and care for welding equipment?

Proper maintenance and care of welding equipment are crucial for safety, productivity, and longevity. My routine includes:

Regular Cleaning: After each use, I clean the equipment, removing spatter, slag, and debris from the welding gun, torch, and surrounding areas. This prevents build-up and ensures smooth operation.

Inspection: I regularly inspect cables, hoses, and connectors for any signs of damage or wear. Damaged components are immediately replaced to prevent accidents or equipment failure.

Gas Cylinder Check: I always check gas cylinders for proper pressure and ensure they are properly secured.

Torch and Electrode Maintenance: I maintain the welding torch and electrodes by cleaning and replacing worn or damaged parts. Proper maintenance prevents overheating, excessive wear, and inferior welds.

Scheduled Maintenance: I follow manufacturer recommendations for scheduled maintenance, including lubrication, adjustments, and periodic inspections by qualified technicians.

Preventing problems is far more efficient than dealing with costly repairs. A proactive maintenance approach keeps the equipment in optimal working condition, ensuring safety and reliable performance.

Q 15. What is your experience working with different types of welding filler materials?

My experience encompasses a wide range of welding filler materials, crucial for achieving specific weld properties. I’m proficient with various types, including:

- Mild Steel Electrodes: E6010, E7018 – I’ve extensively used these for general construction, prioritizing strength and durability. For instance, I used E7018 on a recent project constructing a large steel framework, where its low-hydrogen properties were vital for preventing cracking.

- Stainless Steel Electrodes: 308L, 316L – My experience includes working with stainless steel, focusing on corrosion resistance. A project involving the fabrication of food processing equipment required the use of 316L for its superior resistance to various chemicals.

- Aluminum Filler Wires: 4043, 5356 – I’m skilled in Gas Metal Arc Welding (GMAW) of aluminum, understanding the importance of proper shielding gas and wire feed speed. A recent project involved welding aluminum components for a marine application, demanding high-quality welds resistant to saltwater corrosion.

- Flux-Cored Wires: Self-shielded and gas-shielded – I’ve utilized these for increased deposition rates and ease of use in outdoor environments. Construction of a large pipe network benefited from the speed and efficiency of flux-cored welding.

Choosing the right filler material is critical; it’s not a one-size-fits-all situation. Factors such as base material, application, and desired weld properties guide my selection process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with welding in different positions (e.g., flat, vertical, overhead).

Welding in various positions demands different techniques and skills. I’m proficient in all common welding positions:

- Flat Position: This is the easiest position, allowing for maximum control and penetration. It’s a foundational skill for all welders, used in many applications.

- Vertical Position: Requires precise control of the welding parameters and torch angle to prevent sagging or burn-through. I’ve employed this technique in many projects, including welding vertical seams on storage tanks.

- Overhead Position: The most challenging position, requiring advanced skill and experience to prevent weld spatter and maintain consistent weld quality. I’ve successfully completed overhead welding on intricate pipework and structural components, showcasing my expertise.

Adapting my technique based on the position is essential for consistent, high-quality welds. Experience has taught me to adjust travel speed, current, and electrode angle depending on the position.

Q 17. What is your experience with automated welding systems?

My experience with automated welding systems includes working with robotic welding cells and computer numerical control (CNC) welding machines. This involves:

- Programming and setup: I’m familiar with programming welding parameters, including speed, voltage, and wire feed, based on the project requirements and CAD drawings.

- Troubleshooting and maintenance: I’ve been involved in troubleshooting malfunctions, performing routine maintenance, and ensuring the systems’ optimal performance.

- Quality control: Automated systems offer high repeatability and precision. I utilize these systems to guarantee consistent weld quality and meet stringent project specifications.

For example, on a recent project involving large-scale production of steel components, I successfully programmed a robotic welding cell to perform repetitive welds with high precision, reducing production time and enhancing consistency. Understanding both manual and automated techniques is key to efficiency and quality.

Q 18. How do you manage your time and prioritize tasks on a welding project?

Time management and task prioritization are vital in welding projects. My approach involves:

- Project Planning: Carefully reviewing blueprints, specifications, and material availability to create a detailed schedule.

- Task Breakdown: Dividing the project into smaller, manageable tasks, allowing for efficient progress tracking.

- Prioritization: Focusing on critical tasks that impact the overall project timeline. This often involves identifying any potential bottlenecks early on.

- Communication: Maintaining open communication with supervisors and team members to address any issues promptly and stay on schedule.

I use a combination of checklists, daily reports, and project management software to stay organized and maintain project momentum. Think of it like building a house – a solid foundation and well-defined steps ensure timely completion.

Q 19. Describe your experience with working from plans and specifications.

Working from plans and specifications is fundamental to my work. I carefully review all documents before starting any welding project, focusing on:

- Blueprint interpretation: Accurately understanding dimensions, tolerances, and weld symbols.

- Material specifications: Verifying the correct materials are used based on project requirements.

- Weld procedures: Adhering to specified welding processes, parameters, and quality control methods.

My experience includes interpreting complex drawings and specifications for various projects, ensuring the final product aligns precisely with the design intent. Interpreting these documents isn’t just about reading; it’s about visualizing the finished product and translating that vision into reality.

Q 20. How do you handle unexpected problems or challenges during a welding project?

Handling unexpected problems requires a systematic approach:

- Identify the problem: Carefully assess the situation, noting any visible defects or issues.

- Analyze the cause: Determine the root cause of the problem – faulty equipment, incorrect welding parameters, or material defects.

- Develop a solution: Implement a corrective action, whether it involves adjusting welding parameters, replacing materials, or repairing the defect.

- Document and communicate: Record the problem, the solution, and any lessons learned to prevent recurrence.

For instance, if I encounter porosity in a weld, I’d first check for contaminants, adjust gas flow if using GMAW, or replace the electrode if using SMAW. The key is to maintain a calm and methodical approach, ensuring safety and quality throughout.

Q 21. Describe your experience working in a team environment.

I thrive in team environments. My experience shows I’m adept at:

- Collaboration: Working effectively with other welders, fitters, inspectors, and engineers to achieve common goals.

- Communication: Effectively communicating project updates, potential problems, and solutions to team members and supervisors.

- Mentorship: Sharing knowledge and experience with junior welders to enhance their skill set and productivity.

On several projects, I’ve been instrumental in coordinating efforts with other trades, ensuring seamless integration of various aspects of construction. Effective teamwork is the cornerstone of successful project delivery.

Q 22. What are your strengths and weaknesses as a welder?

My greatest strength as a welder lies in my meticulous attention to detail and my proficiency across various welding processes, including GMAW (MIG), SMAW (Stick), and GTAW (TIG). I’m adept at reading blueprints and welding symbols, ensuring accurate and consistent weld quality. I consistently strive for precision, understanding that even minor flaws can compromise structural integrity. A weakness I’m actively working on is my speed on complex, large-scale projects. While my welds always meet the highest quality standards, I am focusing on improving my efficiency through better project planning and improved organization of my workspace. This will allow me to complete projects more quickly without sacrificing quality.

Q 23. Why are you interested in this specific welding position?

This position excites me because it combines my passion for welding with the opportunity to contribute to [Company Name]’s reputation for high-quality construction. I’m particularly drawn to [mention specific project or aspect of the job description, e.g., the use of advanced welding techniques, involvement in a specific type of construction project, company culture]. The chance to work on challenging projects alongside experienced professionals is a significant motivator for me. I believe my skills and dedication align perfectly with your company’s values and project goals.

Q 24. What are your salary expectations?

Based on my experience and the requirements of this position, my salary expectations are in the range of $[lower bound] to $[upper bound] annually. This range reflects my skills, my proven track record, and the current market rates for welders with my qualifications in this region. I’m open to discussing this further and am confident we can reach a mutually agreeable compensation package.

Q 25. What are your long-term career goals?

My long-term career goals involve becoming a certified Welding Inspector and eventually leading a team of welders on major construction projects. I am eager to expand my knowledge of various welding codes and standards, and I intend to pursue relevant certifications to enhance my expertise. I envision myself contributing significantly to the industry, mentoring younger welders, and spearheading innovative approaches to welding techniques and safety protocols.

Q 26. Do you have any questions for me?

Yes, I have a few questions. Firstly, what are the company’s primary safety protocols and training opportunities? Secondly, what type of projects will I be working on in the near future? Finally, what are the opportunities for professional development and advancement within the company?

Q 27. Describe a time you had to overcome a technical challenge while welding.

During a recent project involving the fabrication of a large pressure vessel, I encountered a challenge with weld penetration on a particularly thick section of stainless steel. Initial attempts using my standard MIG settings resulted in insufficient penetration. I systematically addressed this by first carefully analyzing the weld joint design and then adjusting the welding parameters. I increased the amperage, adjusted the wire feed speed, and experimented with different travel speeds to optimize the arc. I also preheated the metal to reduce cooling rate. Through careful observation and iterative adjustments, I achieved the required penetration without compromising the weld’s integrity. Detailed documentation of this process, including the changes made to the parameters, formed part of the project’s final report.

Q 28. Explain your understanding of relevant welding codes and standards (e.g., AWS D1.1).

I have a thorough understanding of relevant welding codes and standards, particularly AWS D1.1 (Structural Welding Code – Steel). This code outlines essential requirements for the design, fabrication, and inspection of structural steel weldments. I understand the significance of weld symbols, including the location, type, size, and other details conveyed through these symbols. I also understand the various weld types (e.g., fillet, groove, butt) and the different weld processes, including the appropriate parameters for each. Furthermore, I’m familiar with the importance of non-destructive testing (NDT) methods, such as visual inspection, magnetic particle testing, and radiographic testing, for ensuring weld quality. My experience ensures I consistently adhere to these standards, prioritizing safety and structural integrity in all my work. For example, I know the specific requirements for preheat and post-weld heat treatment depending on the base material and the type of weld joint.

Key Topics to Learn for Welder Construction Interview

- Welding Processes: Understanding various welding processes like GMAW (MIG), SMAW (Stick), GTAW (TIG), and FCAW (Flux-cored) – their applications, advantages, and limitations in construction.

- Blueprint Reading and Interpretation: Ability to accurately read and interpret welding symbols, dimensions, and specifications found on construction blueprints. Practical application includes identifying weld types, sizes, and locations.

- Welding Codes and Standards: Familiarity with relevant codes (e.g., AWS D1.1) and standards ensuring safe and compliant welding practices in construction projects.

- Material Properties and Selection: Knowledge of different metals (steel, aluminum, stainless steel) commonly used in construction and their impact on weldability. Understanding how to select appropriate materials for specific applications.

- Weld Joint Design and Preparation: Understanding the principles of proper weld joint design and preparation techniques to ensure strong and reliable welds. This includes beveling, edge preparation, and fit-up procedures.

- Safety Procedures and Regulations: Knowledge of OSHA regulations and safety practices related to welding in construction environments, including PPE, fire safety, and hazard mitigation.

- Quality Control and Inspection: Understanding various weld inspection methods (visual, non-destructive testing) to ensure welds meet quality standards and specifications. Problem-solving involves identifying and correcting weld defects.

- Troubleshooting and Repair: Ability to identify and troubleshoot common welding problems, such as porosity, cracking, and undercut. Practical application includes effective repair techniques to rectify defects.

- Welding Equipment and Maintenance: Familiarity with various welding equipment (power sources, torches, safety equipment) and their proper maintenance and operation.

Next Steps

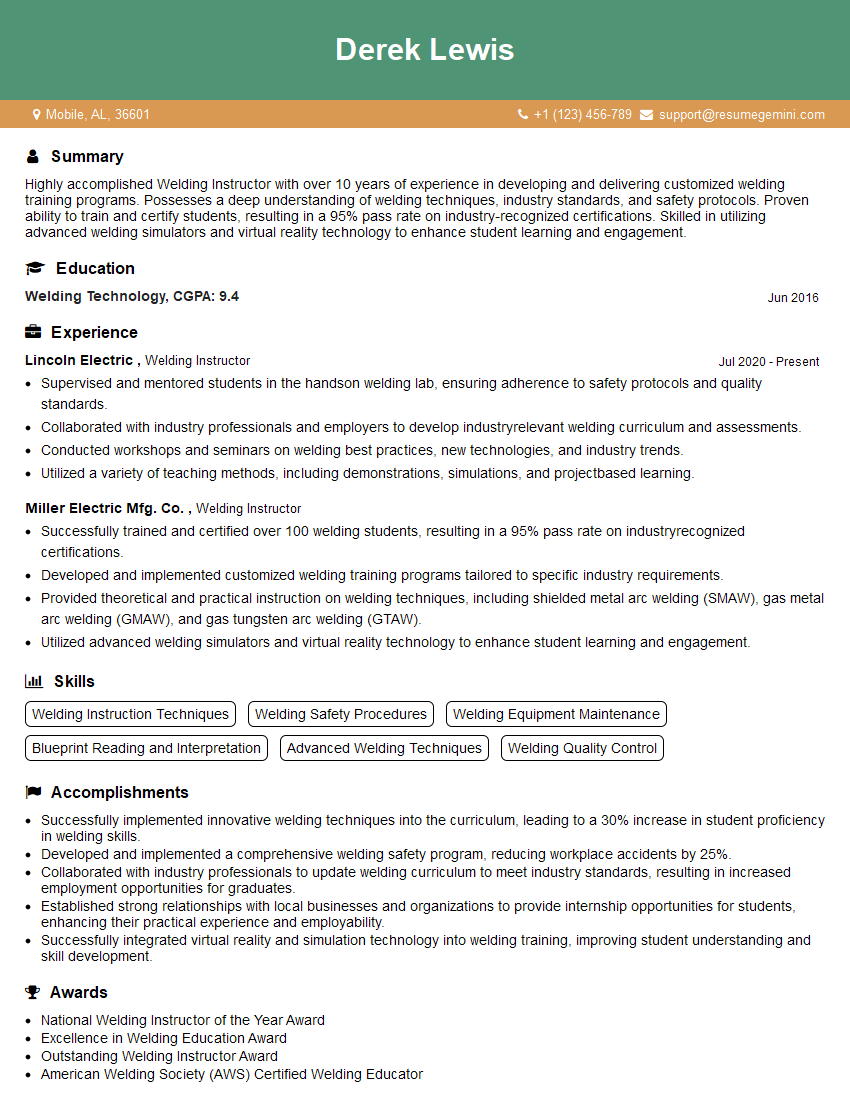

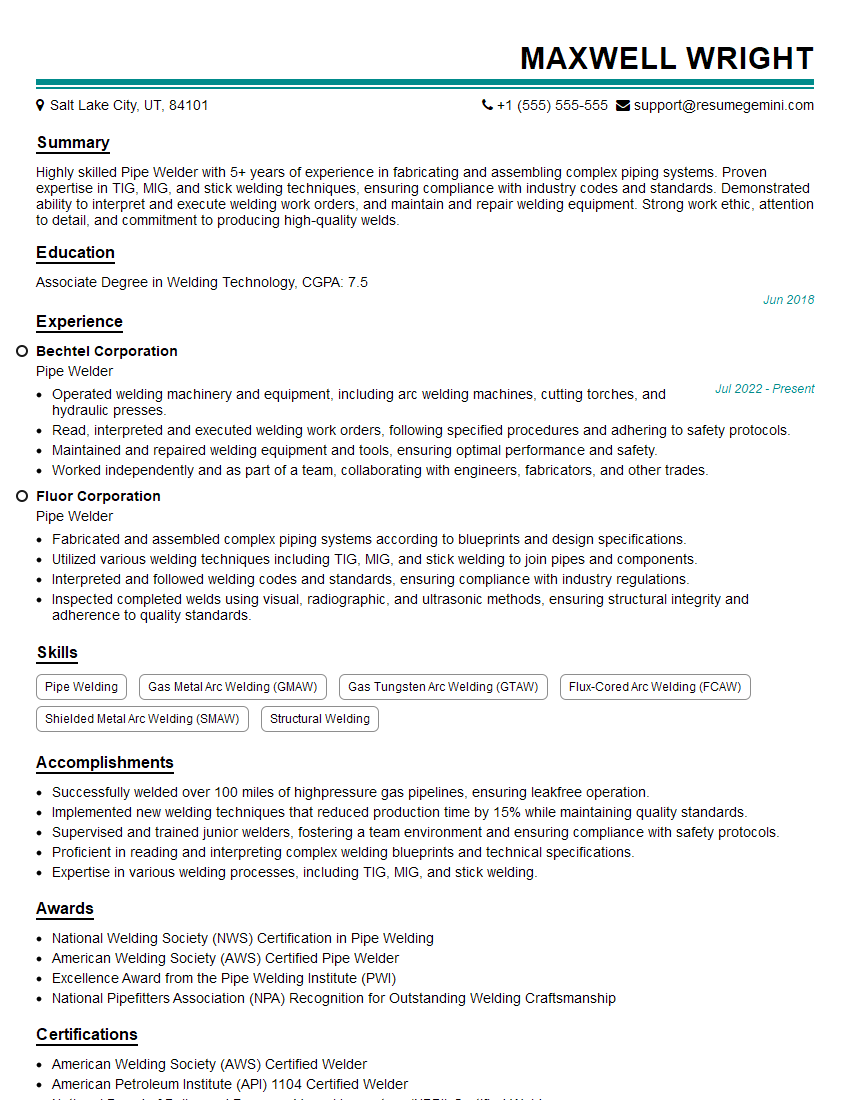

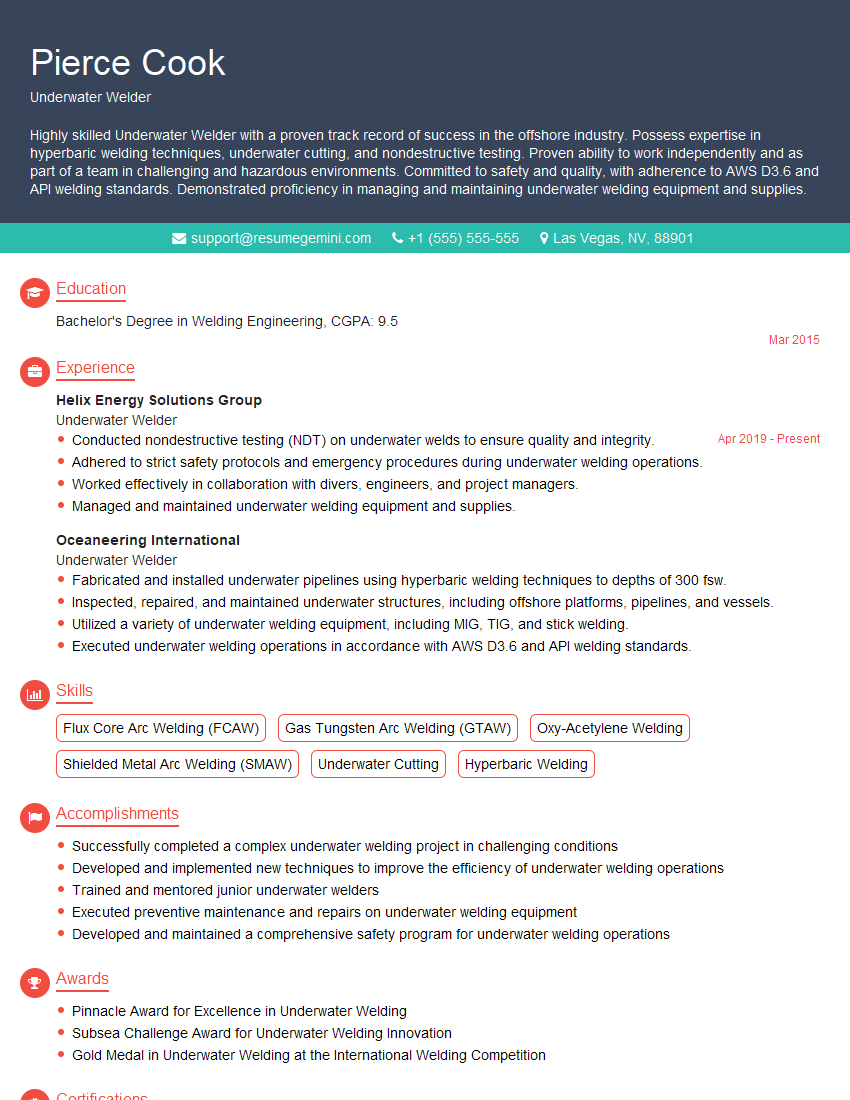

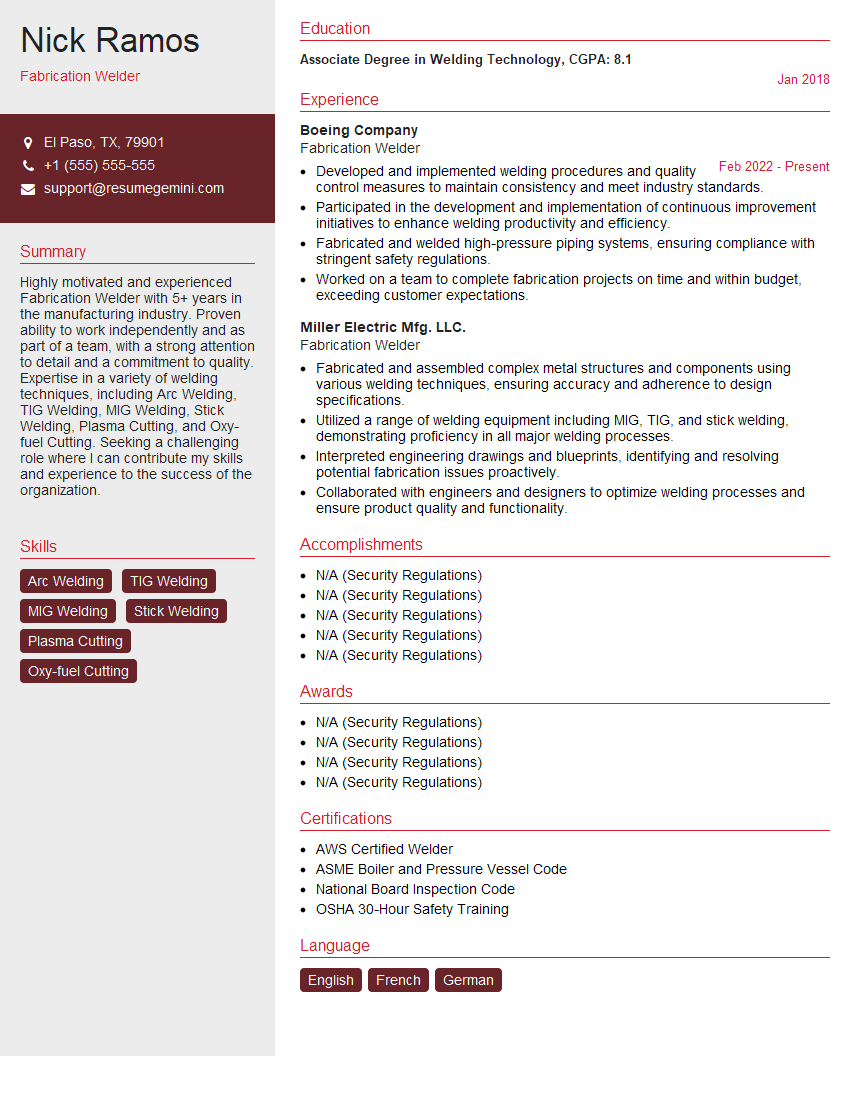

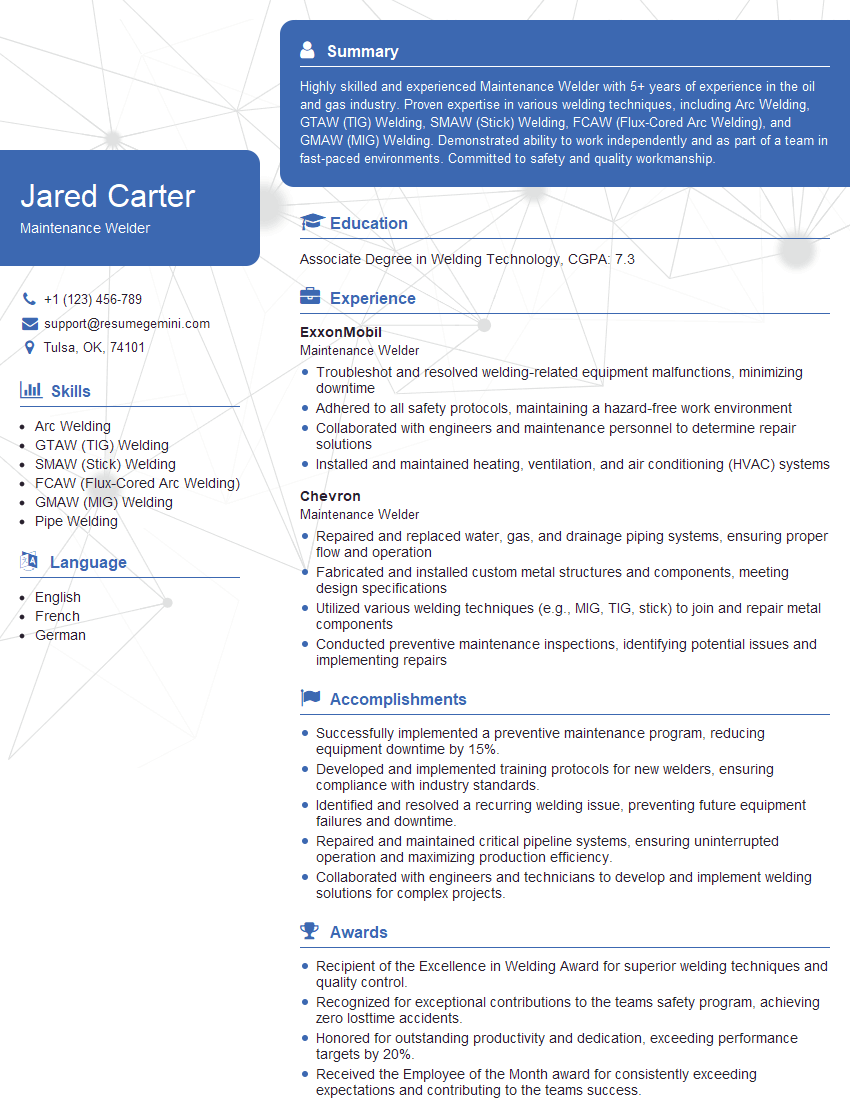

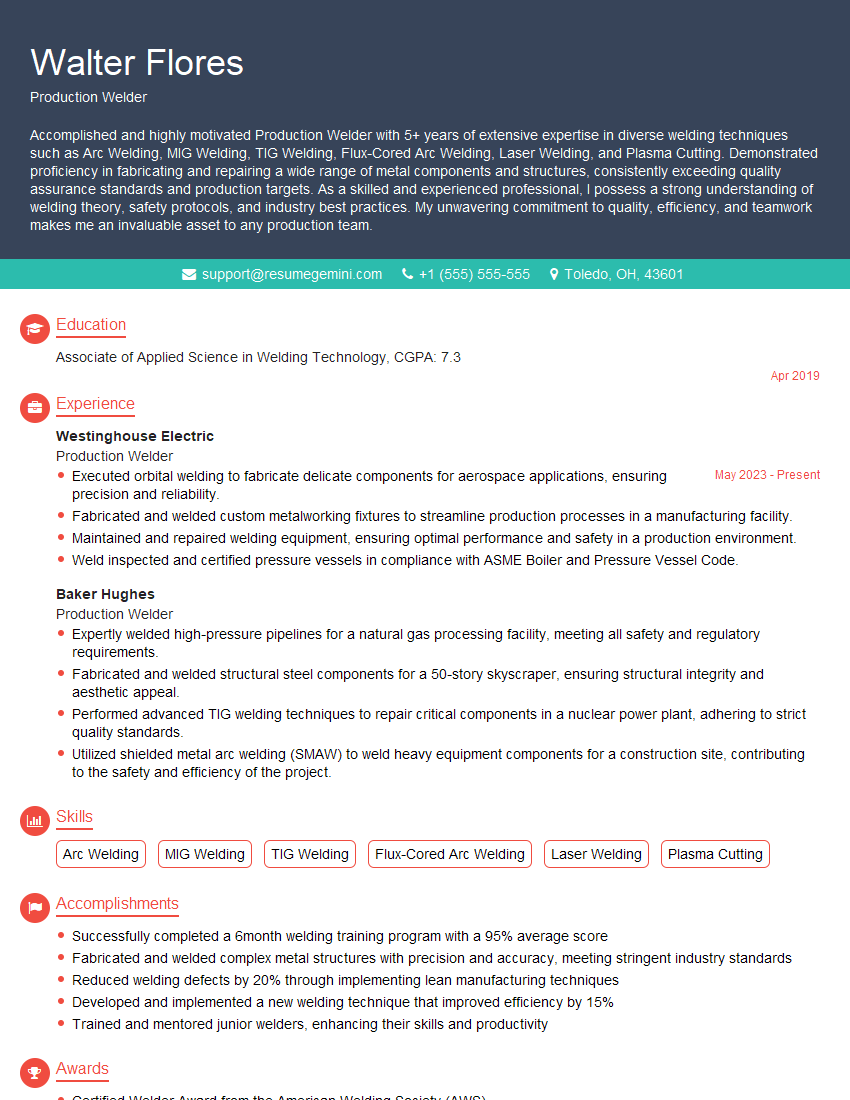

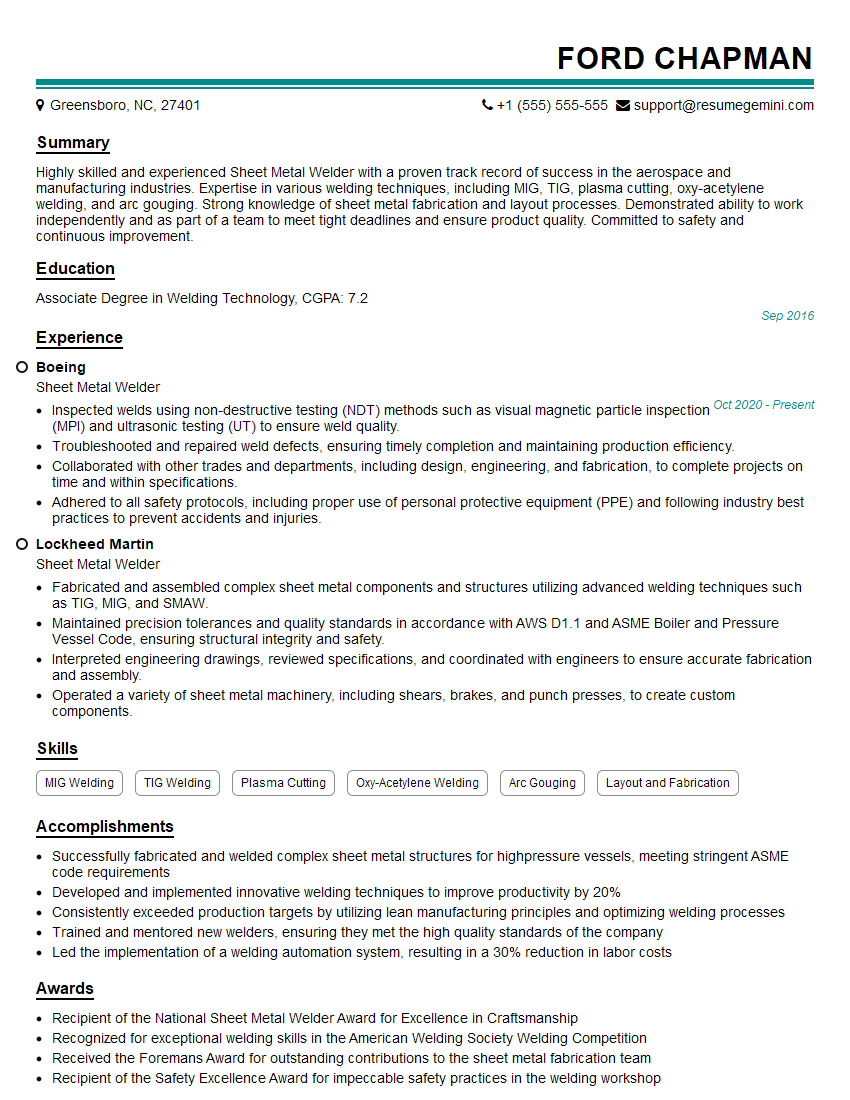

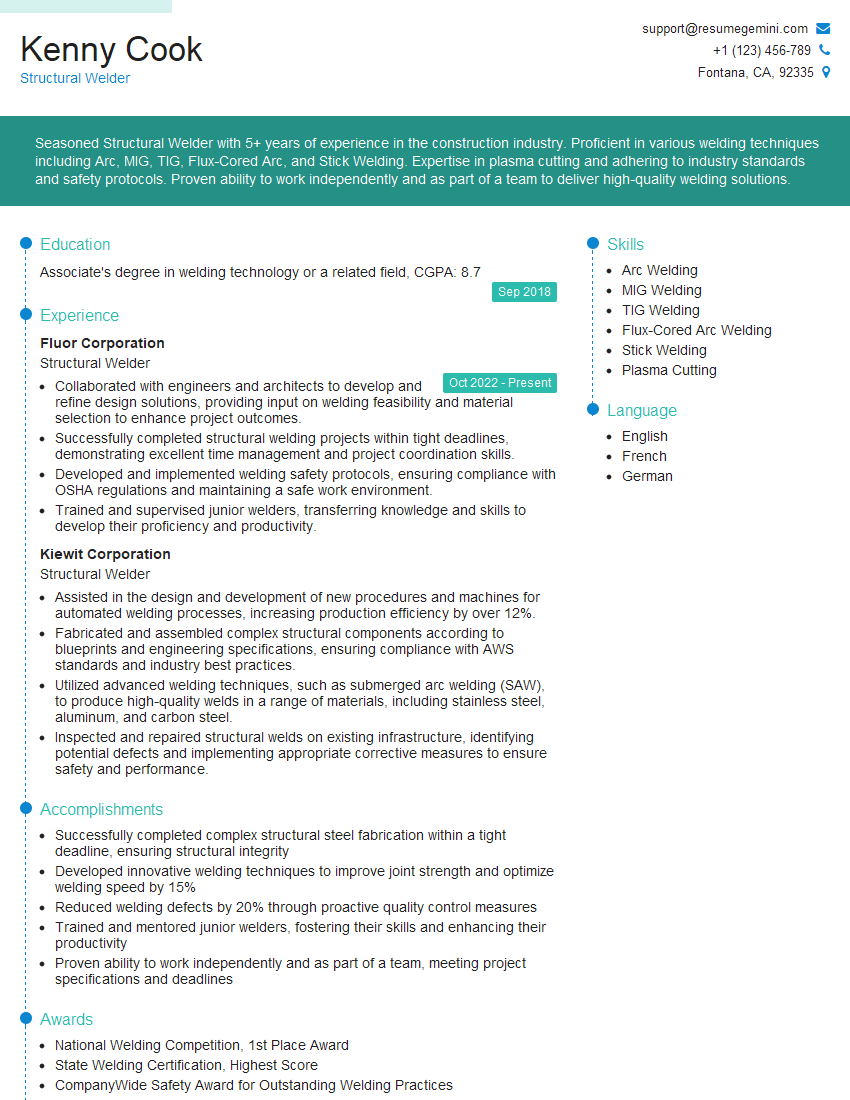

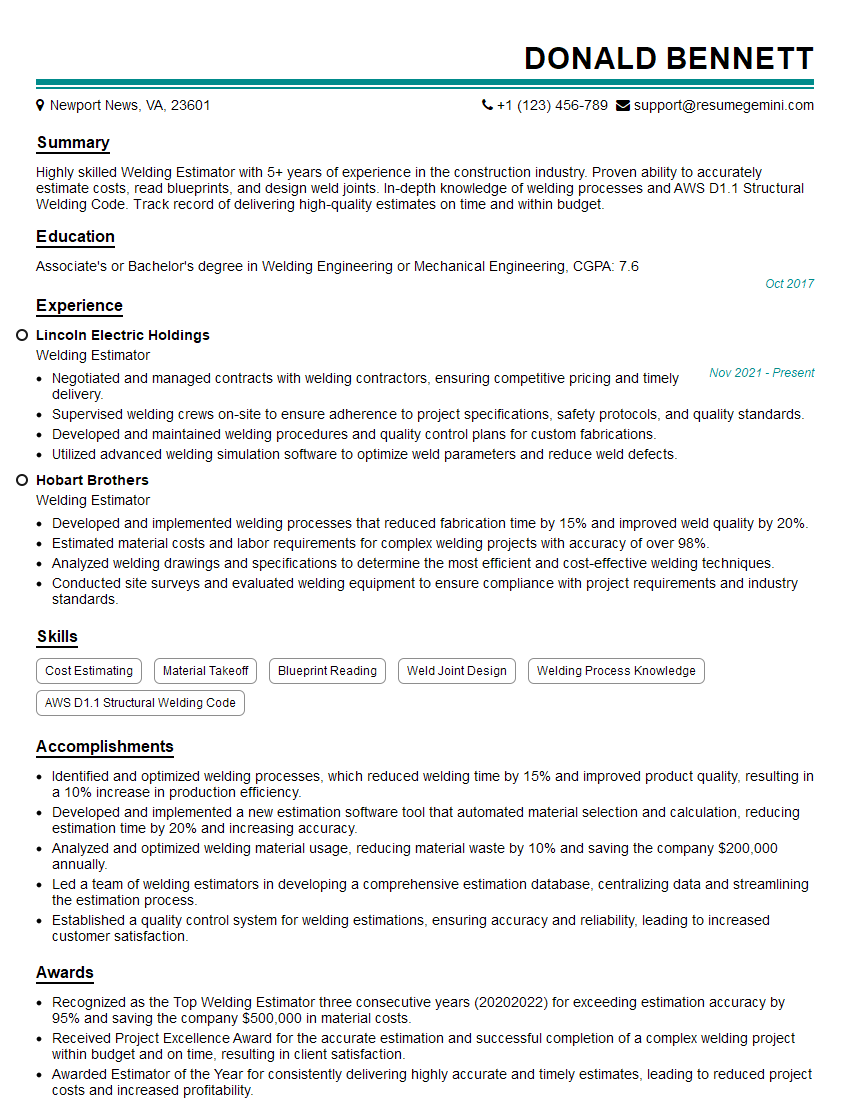

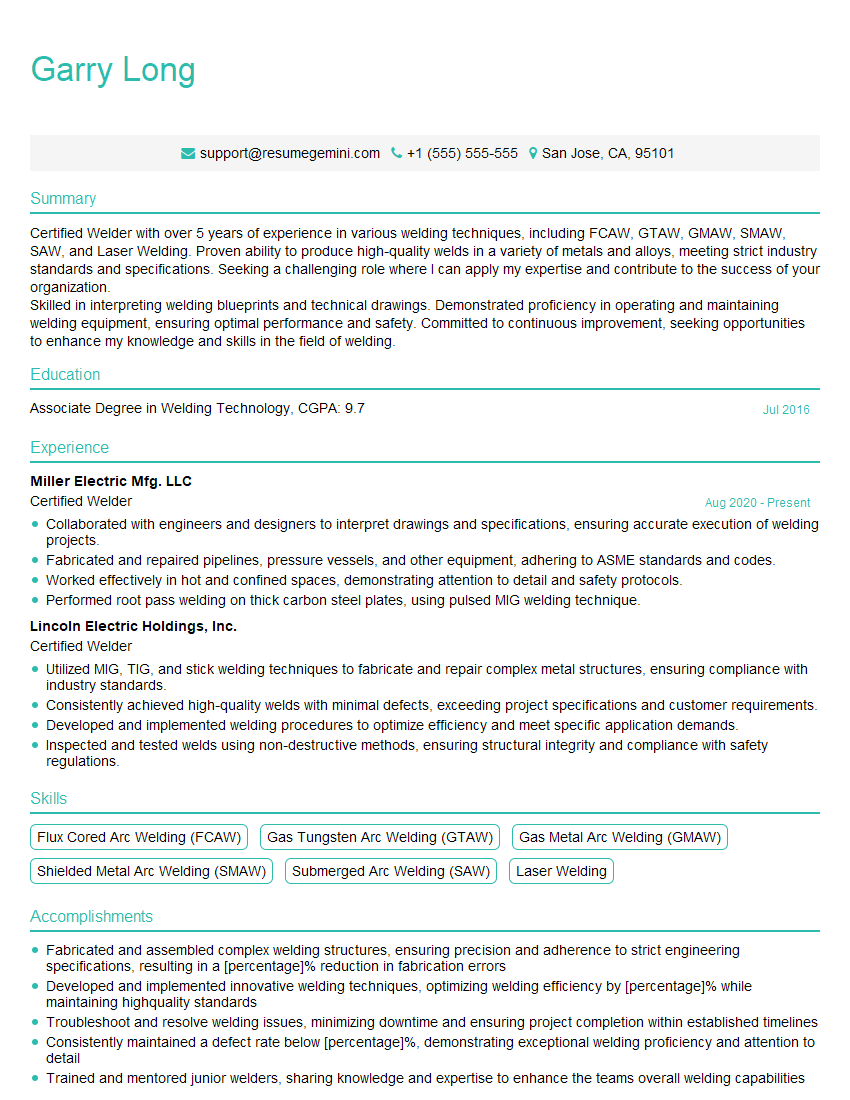

Mastering the skills and knowledge related to Welder Construction is crucial for career advancement in this in-demand field. Opportunities for specialization, higher pay, and project leadership significantly increase with proven expertise. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your qualifications and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Welder Construction positions to help guide you in showcasing your unique skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO